The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Operational Planning and Management interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Operational Planning and Management Interview

Q 1. Describe your experience with developing and implementing operational plans.

Developing and implementing operational plans involves a systematic approach, starting with a thorough understanding of the organization’s strategic goals. I begin by defining clear objectives, identifying key performance indicators (KPIs), and establishing a timeline. This is followed by resource allocation, process mapping, risk assessment, and contingency planning.

For example, in my previous role at a logistics company, we implemented a new warehouse management system. This involved detailed planning, including staff training, system integration, process optimization, and a phased rollout to minimize disruption. We meticulously documented each step, created detailed workflows, and monitored KPIs like order fulfillment rate and inventory accuracy throughout the implementation. The result was a 20% increase in efficiency and a 15% reduction in errors.

My approach always emphasizes collaboration and clear communication throughout the entire process, ensuring buy-in from all stakeholders. Regular progress reviews and adjustments based on data analysis are crucial for successful implementation.

Q 2. How do you prioritize tasks and projects within a dynamic operational environment?

Prioritization in a dynamic environment requires a flexible and data-driven approach. I utilize a combination of methods, including the Eisenhower Matrix (urgent/important), MoSCoW method (Must have, Should have, Could have, Won’t have), and value-based prioritization. The Eisenhower Matrix helps categorize tasks based on urgency and importance, allowing me to focus on the most critical items first. The MoSCoW method is excellent for prioritizing features or projects based on their business value. Value-based prioritization involves assigning a value score to each task based on factors like impact and alignment with strategic goals.

For instance, if a critical system failure occurs, that immediately becomes the highest priority, overriding pre-planned projects. However, by using these frameworks, I can quickly reassess and readjust priorities, ensuring that long-term strategic goals aren’t completely sidelined by short-term emergencies. Regularly reviewing and updating the priority list is key, especially in volatile environments.

Q 3. Explain your approach to resource allocation and optimization.

Resource allocation and optimization involve strategically distributing available resources (financial, human, technological) to maximize output and efficiency. This requires a deep understanding of resource capabilities, project requirements, and potential constraints. I typically employ techniques like resource leveling, critical path analysis, and what-if scenario planning.

Resource leveling aims to smooth out resource demand over time, preventing bottlenecks. Critical path analysis identifies the sequence of tasks that determine the shortest possible project duration, allowing me to focus resources on critical activities. What-if scenario planning helps anticipate potential resource shortages and develop contingency plans. For example, in a project with limited budget, I might explore different technology options to find the most cost-effective solution without sacrificing quality. Regular monitoring and adjustments are key to maintaining optimal resource utilization.

Q 4. What metrics do you use to track operational performance and efficiency?

Tracking operational performance and efficiency requires a comprehensive set of metrics tailored to the specific operational goals. These metrics should be SMART (Specific, Measurable, Achievable, Relevant, Time-bound). Common metrics include:

- Throughput: The rate at which work is completed.

- Cycle time: The time it takes to complete a process.

- Defect rate: The percentage of flawed outputs.

- Inventory turnover: How quickly inventory is sold or used.

- Customer satisfaction: Measured through surveys or feedback.

- Employee productivity: Outputs per employee.

The specific metrics chosen depend heavily on the context. For a manufacturing plant, defect rate and throughput would be vital. For a customer service team, customer satisfaction and average handling time would be more important. Regular reporting and analysis of these metrics allow for identifying areas for improvement and measuring the effectiveness of implemented changes.

Q 5. How do you identify and address operational bottlenecks or inefficiencies?

Identifying and addressing operational bottlenecks or inefficiencies often involves a systematic approach that includes process mapping, data analysis, and root cause analysis.

Process mapping visually represents the steps involved in a process, allowing for identification of potential bottlenecks. Data analysis, using tools like Six Sigma methodologies or Lean principles, helps pinpoint specific areas causing delays or inefficiencies. Root cause analysis, using techniques like the 5 Whys, delves into the underlying reasons for these problems, enabling the development of effective solutions.

For example, a slow order fulfillment process might be revealed through process mapping and data analysis. Root cause analysis could uncover that the bottleneck stems from inadequate inventory management. The solution might involve implementing a new inventory tracking system or optimizing the warehouse layout.

Q 6. Describe a time you had to make a critical decision under pressure in an operational setting.

During a major system outage at my previous company, we faced a critical situation where a key software application failed, causing a significant disruption to our operations. The pressure was immense as we were losing thousands of dollars per hour.

My immediate action was to assemble a crisis management team, activating our pre-defined disaster recovery plan. We quickly assessed the situation, prioritized the critical tasks, and allocated resources effectively. I made the tough decision to temporarily halt less critical operations to redirect resources towards restoring the primary system. Through decisive action and effective communication, we managed to resolve the issue within six hours, minimizing the overall impact on the business. This experience reinforced the importance of proactive planning, clear communication, and decisive action in crisis management.

Q 7. How do you ensure alignment between operational goals and overall business strategy?

Ensuring alignment between operational goals and overall business strategy is paramount for organizational success. This requires a clear understanding of the overarching business objectives and translating them into specific, measurable operational targets.

I achieve this alignment by actively participating in strategic planning sessions, ensuring that operational plans directly contribute to the accomplishment of the business goals. I also establish a system for regular communication and feedback between operational teams and senior management. KPIs are carefully selected to reflect progress towards both operational and strategic goals. For example, if the business strategy focuses on market share expansion, the operational plan might include targets for increasing production capacity or improving customer service to support that objective. Regular review meetings ensure that operational activities stay on track and aligned with the evolving business strategy.

Q 8. What experience do you have with budget management and forecasting in operations?

Budget management and forecasting are crucial for operational success. It involves creating a detailed plan of anticipated income and expenses, then tracking actual performance against that plan. My experience includes developing annual operational budgets, encompassing everything from personnel costs and raw materials to facility maintenance and marketing. I utilize various forecasting techniques, such as trend analysis, regression modeling, and scenario planning, to predict future costs and revenue. For example, in my previous role at Acme Manufacturing, I developed a budget that accurately predicted a 15% increase in production costs due to raw material price fluctuations. This allowed for proactive adjustments to pricing strategies and procurement processes, preventing significant financial losses. I’m proficient with budget management software and excel at presenting financial data clearly to senior management, securing necessary approvals, and adjusting budgets in response to changing market conditions or operational needs.

Q 9. Explain your experience with process improvement methodologies (e.g., Lean, Six Sigma).

I’ve extensively applied Lean and Six Sigma methodologies to streamline operations and enhance efficiency. Lean principles, focusing on eliminating waste (muda) in all forms, have helped me identify and remove bottlenecks in production processes, resulting in improved throughput and reduced lead times. For instance, at Beta Solutions, we implemented a Kaizen event focusing on our order fulfillment process. By analyzing the workflow, identifying redundancies, and implementing small, incremental improvements, we reduced processing time by 20%. Six Sigma, with its emphasis on data-driven decision making and process optimization, has been instrumental in reducing defects and improving product quality. Using DMAIC (Define, Measure, Analyze, Improve, Control) methodology, we tackled a significant issue with faulty components in our flagship product. Through root cause analysis and process adjustments, we reduced defect rates by 95%, significantly improving customer satisfaction and reducing warranty costs.

Q 10. How do you manage stakeholder expectations and communication within operations?

Managing stakeholder expectations and communication is paramount in operations. I employ a proactive and transparent approach. This starts with clearly defining roles, responsibilities, and communication channels at the outset of a project. Regular updates, through various formats (meetings, email reports, dashboards) tailored to different audiences, keep stakeholders informed and engaged. For example, I use weekly progress reports for the executive team, emphasizing high-level results, while providing more detailed technical updates to the operational team. Active listening and addressing concerns promptly are crucial. When challenges arise, I facilitate open dialogue and collaborate with stakeholders to develop solutions, proactively managing expectations. By building trust and open communication, I ensure that stakeholders feel heard and confident in the operational plan’s progress.

Q 11. Describe your experience with risk management in an operational context.

Risk management is an integral part of operational planning. My approach involves a structured process starting with identifying potential risks – ranging from supply chain disruptions to cybersecurity threats – through brainstorming sessions, risk assessments, and analysis of historical data. Next, I analyze the likelihood and potential impact of each risk. This assessment then informs the development of mitigation strategies. These strategies can range from implementing backup suppliers to investing in cybersecurity measures. I regularly monitor and review identified risks, adapting mitigation strategies as needed. For example, during a recent period of geopolitical instability, we proactively secured alternative suppliers for critical raw materials, preventing potential production delays. Regularly updating risk registers and communicating findings to relevant stakeholders ensures proactive risk management.

Q 12. How do you handle unexpected operational challenges or disruptions?

Unexpected challenges are inevitable in operations. My response involves a structured approach: first, rapid assessment of the situation, identifying the root cause and scope of the disruption. Next, I assemble a cross-functional team to tackle the problem. We prioritize immediate actions to minimize the impact, such as implementing contingency plans or rerouting resources. Simultaneously, we investigate the root cause of the disruption to prevent recurrence. For example, a sudden equipment failure once halted production. We immediately activated our backup equipment, minimizing downtime. Concurrently, we launched a root cause analysis to determine the cause of the failure and implement preventative maintenance, preventing future disruptions. This systematic approach minimizes the impact of unforeseen events and focuses on learning from experiences.

Q 13. What is your experience with data analysis and its application to operational decision-making?

Data analysis is the backbone of effective operational decision-making. I’m proficient in using data analytics tools to monitor key performance indicators (KPIs), identify trends, and uncover areas for improvement. In my previous role, I used data from our CRM and production systems to optimize our marketing campaigns and improve customer satisfaction. For example, by analyzing customer response times, I pinpointed bottlenecks in our customer service process, ultimately leading to a 15% reduction in resolution times. I also leverage data visualization techniques to communicate findings effectively to stakeholders. I believe in utilizing predictive analytics to forecast future performance and proactively adapt operational strategies accordingly. Essentially, data-driven decision making allows for informed, efficient, and proactive management.

Q 14. How do you ensure compliance with regulations and standards within your operational area?

Compliance is critical in any operational setting. My approach starts with a thorough understanding of all applicable regulations and standards, relevant to the industry and operational area. This includes environmental regulations, safety guidelines, and data privacy laws. I develop and implement compliance programs, ensuring that policies and procedures align with these regulations. This includes regular training for employees on compliance matters. We conduct internal audits to identify potential gaps and ensure ongoing compliance. For instance, we conducted regular safety inspections and updated our safety protocols to meet OSHA standards, resulting in a significant improvement in our workplace safety record. Regular reporting and documentation ensure transparency and traceability of compliance efforts. Proactive compliance minimizes risks and ensures a responsible and ethical operational environment.

Q 15. What software or tools are you proficient in for operational planning and management?

Proficiency in operational planning and management software is crucial for efficiency and data-driven decision-making. My expertise spans several key tools. I’m highly proficient in project management software like Microsoft Project and Asana, utilizing their features for task assignment, Gantt chart creation, and progress tracking. For data analysis and reporting, I’m adept at using Microsoft Excel and Power BI to create insightful dashboards visualizing key performance indicators (KPIs) and operational metrics. Furthermore, I have experience with Enterprise Resource Planning (ERP) systems such as SAP and Oracle, enabling me to manage resources effectively across various departments. Finally, I’m familiar with collaborative platforms like Slack and Microsoft Teams to streamline communication and team coordination.

For instance, in my previous role, I used Power BI to create a dashboard showcasing real-time production line efficiency, allowing for immediate identification and resolution of bottlenecks. This proactive approach improved overall output by 15% within the first quarter.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with leading and motivating operational teams.

Leading and motivating operational teams requires a blend of strong leadership, effective communication, and a genuine interest in team members’ growth. My approach centers on fostering a collaborative environment where everyone feels valued and empowered. I believe in leading by example, demonstrating commitment and dedication to achieving shared goals. I utilize various motivational techniques, including regular one-on-one meetings to understand individual challenges and aspirations, providing constructive feedback and recognizing accomplishments both publicly and privately. I also encourage open communication, creating channels for feedback and suggestions, ensuring everyone has a voice in the decision-making process.

In a previous project, my team faced a significant deadline crunch. By fostering open communication, acknowledging their dedication, and collaboratively re-prioritizing tasks, we not only met the deadline but also exceeded expectations, boosting team morale and confidence significantly.

Q 17. How do you delegate tasks effectively and monitor performance within an operational team?

Effective delegation is about assigning tasks to the right people, based on their skills and experience. I assess each team member’s strengths and weaknesses before delegating tasks, ensuring a good fit. This involves clear communication of expectations, including deadlines, deliverables, and performance standards. I provide sufficient resources and support to ensure successful completion. Monitoring performance isn’t solely about checking off boxes; it’s about offering guidance, addressing challenges proactively, and providing timely feedback. I regularly review progress, offer support, and make adjustments as needed. Tools like project management software allow for transparent tracking of tasks and milestones, ensuring accountability and timely intervention if any issues arise.

For example, I once delegated a complex project to a team member who was keen to develop their project management skills. I provided regular check-ins, mentorship, and resources to guide them, which not only helped them succeed but also fostered professional development within the team.

Q 18. What is your approach to conflict resolution within an operational team?

Conflict resolution is a critical aspect of operational management. My approach prioritizes open communication and understanding. I encourage all parties involved to express their perspectives without interruption. I then focus on identifying the root cause of the conflict, separating the issue from the individuals involved. Once the problem is understood, we collaboratively brainstorm solutions, focusing on finding a mutually acceptable outcome that aligns with team goals. Documentation of the agreed-upon solution and follow-up ensures clarity and accountability. My goal is not just to resolve the immediate conflict but also to prevent future occurrences by addressing underlying issues.

In one instance, a conflict arose between two team members regarding project priorities. Through facilitated discussion, we uncovered a misunderstanding about project scope. By clarifying expectations and collaboratively adjusting the project plan, we resolved the conflict and strengthened the team’s collaborative spirit.

Q 19. How do you measure the success of operational initiatives?

Measuring the success of operational initiatives requires a defined set of KPIs that align with strategic objectives. These KPIs should be specific, measurable, achievable, relevant, and time-bound (SMART). Common metrics include efficiency gains (e.g., reduced cycle time), cost reductions, improved quality (e.g., defect rate), increased customer satisfaction, and enhanced employee engagement. Data analysis from various sources – including ERP systems, project management tools, and customer feedback surveys – is used to track progress against these KPIs. Regular reporting and analysis help identify areas for improvement and ensure initiatives remain on track.

For example, in a process improvement initiative, we tracked the reduction in processing time for customer orders as a key KPI. By implementing new software and streamlining workflows, we achieved a 20% reduction in processing time, exceeding our target and demonstrating the success of the initiative.

Q 20. Describe your experience with change management within an operational setting.

Change management in operational settings requires a structured approach to minimize disruption and maximize adoption. I typically utilize a phased approach, starting with communication and stakeholder analysis to identify potential impacts and concerns. This is followed by detailed planning, which includes defining clear goals, timelines, and responsibilities. Training and support are crucial to equip the team with the necessary skills and knowledge to adapt to the change. Throughout the implementation phase, I monitor progress closely, address challenges proactively, and provide ongoing support. Finally, post-implementation review evaluates the effectiveness of the change and identifies areas for further improvement.

In one instance, we implemented a new inventory management system. We started with thorough communication, providing regular updates and addressing concerns throughout the process. This proactive approach minimized resistance and ensured a smooth transition, resulting in improved inventory accuracy and reduced costs.

Q 21. How do you ensure the accuracy and reliability of operational data?

Ensuring the accuracy and reliability of operational data is paramount. This involves establishing robust data governance processes, including data validation, regular audits, and error correction mechanisms. Data should be collected from reliable sources, and processes should be put in place to detect and correct inconsistencies. Data integrity checks and validation rules within systems help maintain accuracy. Regular data backups and disaster recovery plans are essential for protecting against data loss. Moreover, training team members on data handling procedures and emphasizing the importance of data accuracy is crucial.

For instance, we implemented a system of regular data reconciliation checks in our supply chain management. This process involved comparing data from different sources and identifying discrepancies. By addressing these inconsistencies promptly, we significantly improved the accuracy of our inventory data, leading to more efficient procurement and reduced stockouts.

Q 22. What is your experience with forecasting and demand planning?

Forecasting and demand planning are crucial for aligning supply with customer demand. My experience encompasses a wide range of forecasting methodologies, from simple moving averages to more sophisticated techniques like exponential smoothing and ARIMA models. I’ve used these methods in various contexts, including predicting seasonal sales fluctuations for a retail company and optimizing production schedules for a manufacturing plant. The key is selecting the appropriate method based on data characteristics, forecast horizon, and desired accuracy. For instance, when dealing with highly volatile demand, robust methods like exponential smoothing with trend and seasonality are preferred, while simpler methods suffice for stable demand patterns. I also have extensive experience in collaborating with sales and marketing teams to gather insights on promotions, new product launches, and market trends, which are vital for refining demand forecasts.

Beyond the quantitative aspects, I understand the importance of qualitative factors. This involves incorporating expert opinions and market intelligence to adjust the quantitative forecasts, resulting in a more comprehensive and accurate picture. This iterative process, involving continuous monitoring and adjustment, is essential for effective demand planning.

Q 23. How do you manage inventory levels effectively?

Effective inventory management is a delicate balancing act between minimizing holding costs and avoiding stockouts. My approach centers around implementing inventory control systems that leverage techniques like Economic Order Quantity (EOQ) and safety stock calculations. EOQ helps determine the optimal order size to minimize total inventory costs, factoring in ordering costs and carrying costs. Safety stock acts as a buffer against unexpected demand fluctuations and lead time variability. The calculation considers service level targets and demand variability. For example, I’ve worked with businesses to implement just-in-time inventory systems, which dramatically reduced storage costs while maintaining adequate stock levels. It requires careful collaboration with suppliers to ensure timely delivery and reliable supply chain relationships.

Beyond these quantitative tools, I emphasize regular inventory audits and cycle counting to ensure accuracy and identify potential discrepancies. Data analytics are also pivotal. Analyzing historical data helps to identify patterns in demand and lead times, which allows for more precise forecasting and inventory optimization. Real-time inventory tracking systems allow for proactive management and prevent stockouts or overstocking.

Q 24. What is your experience with supply chain management and optimization?

Supply chain management (SCM) involves the coordination of all activities involved in moving goods and services from the origin to the consumer. My experience covers the entire spectrum, from supplier selection and procurement to logistics and distribution. I’ve worked on projects focused on optimizing supply chain networks using techniques like network optimization models to identify the most efficient distribution channels. This involves analyzing factors such as transportation costs, lead times, and risk mitigation strategies. For example, I successfully implemented a multi-echelon inventory optimization model for a global manufacturing company resulting in a significant reduction in inventory holding costs and improved customer service levels.

My experience also includes working with various SCM software systems, including ERP and WMS platforms. I’m adept at using these systems to monitor key performance indicators (KPIs) such as on-time delivery rates, inventory turnover, and supply chain costs. These KPIs are crucial for assessing supply chain health and identifying areas for improvement. Furthermore, I’ve actively participated in collaborative efforts with supply chain partners to foster stronger relationships, which are essential for efficient and resilient supply chains.

Q 25. Describe your approach to continuous improvement in operational processes.

Continuous improvement is ingrained in my operational philosophy. I advocate for a data-driven approach, using Lean methodologies like Kaizen and Six Sigma to identify and eliminate waste in operational processes. Kaizen emphasizes small, incremental improvements over time, whereas Six Sigma focuses on reducing process variation and improving quality. I’ve successfully implemented both methodologies in various settings. For example, in a previous role, we used Kaizen events to streamline a manufacturing process, resulting in a 15% increase in productivity.

My approach includes regular performance reviews, process mapping, and the use of tools such as value stream mapping to visualize the flow of materials and information within the process. This allows us to identify bottlenecks and areas where improvements can be made. I also encourage a culture of employee involvement and feedback, as frontline employees often possess valuable insights into process inefficiencies. The use of root cause analysis techniques like the 5 Whys helps to get to the core reasons for problems and design lasting solutions. Regular monitoring and review of KPIs are essential to track progress and ensure continuous improvement.

Q 26. How do you utilize technology to enhance operational efficiency?

Technology plays a vital role in enhancing operational efficiency. I’m proficient in using various software applications, including ERP systems (Enterprise Resource Planning), WMS (Warehouse Management Systems), and SCM software to manage and optimize operations. These systems provide real-time visibility into inventory levels, production schedules, and supply chain performance. For example, implementing a real-time tracking system allowed us to monitor shipment progress, leading to significant improvements in on-time delivery.

Beyond these established systems, I’m also experienced in leveraging data analytics tools and business intelligence dashboards to gain actionable insights from operational data. This data-driven decision-making approach allows for better forecasting, inventory management, and proactive identification of potential problems. Automation is another key technology. Automating repetitive tasks, such as data entry and order processing, frees up human resources for more strategic activities, thereby improving efficiency and reducing error rates.

Q 27. Describe a situation where you had to improve operational efficiency. What were the results?

In a previous role at a logistics company, we faced significant delays in order fulfillment, resulting in customer dissatisfaction and increased costs. After analyzing the process, I identified several bottlenecks, including inefficient warehouse layout and a lack of real-time visibility into inventory levels. To address these issues, we implemented a new warehouse management system (WMS) that integrated with our existing ERP system. This allowed for real-time tracking of inventory and automated order fulfillment processes. We also redesigned the warehouse layout to optimize workflow and minimize travel time for picking and packing orders.

The results were significant. We saw a 20% reduction in order fulfillment time, a 10% decrease in shipping costs, and a marked improvement in customer satisfaction, measured through reduced complaints and improved customer retention rates. The project also highlighted the importance of clear communication and collaboration across different departments, including warehouse operations, logistics, and customer service.

Q 28. How would you approach streamlining a complex operational process?

Streamlining a complex operational process requires a systematic and structured approach. I would begin by mapping the current process using tools like value stream mapping to visually represent all the steps involved, including time and resource consumption. This provides a clear understanding of the process flow and helps identify bottlenecks and areas of inefficiency. Next, I’d employ process analysis techniques like root cause analysis to identify the root causes of inefficiencies, not just the symptoms. The 5 Whys technique is a helpful tool here. For example, instead of merely addressing late deliveries, we would delve into the reasons for the delays: Was it due to supplier issues, internal processing delays, or transportation problems?

Based on this analysis, I would develop a revised process design, incorporating best practices and technologies where appropriate. This might involve automating tasks, reorganizing workflows, or implementing new technologies to improve efficiency. Crucially, the revised process would need to be tested and refined iteratively. The implementation would involve training staff and ensuring adequate support to facilitate a smooth transition. Finally, regular monitoring of KPIs and ongoing feedback mechanisms would be crucial to ensure that the improvements are sustained and to identify opportunities for further optimization. The whole process emphasizes collaboration with stakeholders across departments and potentially even with external suppliers to ensure a holistic approach.

Key Topics to Learn for Operational Planning and Management Interview

- Strategic Planning & Goal Setting: Understanding how operational plans align with overall business strategy, including the development of SMART goals and key performance indicators (KPIs).

- Process Optimization & Improvement: Familiarize yourself with Lean methodologies, Six Sigma principles, and other process improvement techniques. Be prepared to discuss practical applications and case studies of process optimization within an organization.

- Resource Allocation & Management: Mastering the principles of allocating resources (budget, personnel, equipment) efficiently and effectively to achieve operational goals. Consider scenarios involving resource constraints and prioritization.

- Risk Management & Mitigation: Demonstrate an understanding of identifying, assessing, and mitigating operational risks. Practice outlining risk mitigation strategies and contingency planning.

- Performance Monitoring & Evaluation: Discuss methods for tracking KPIs, analyzing performance data, and identifying areas for improvement. Be ready to explain how to use data-driven insights to inform operational decisions.

- Change Management & Implementation: Understand the principles of effective change management and how to implement new processes or technologies smoothly and efficiently, minimizing disruption.

- Project Management Fundamentals: While not exclusively operational planning, understanding project management principles like scheduling, budgeting, and execution is highly relevant.

- Technology & Operational Systems: Demonstrate familiarity with relevant software and technologies used in operational planning and management (e.g., ERP systems, project management software).

- Communication & Collaboration: Highlight your ability to effectively communicate plans, progress updates, and challenges to various stakeholders within an organization.

Next Steps

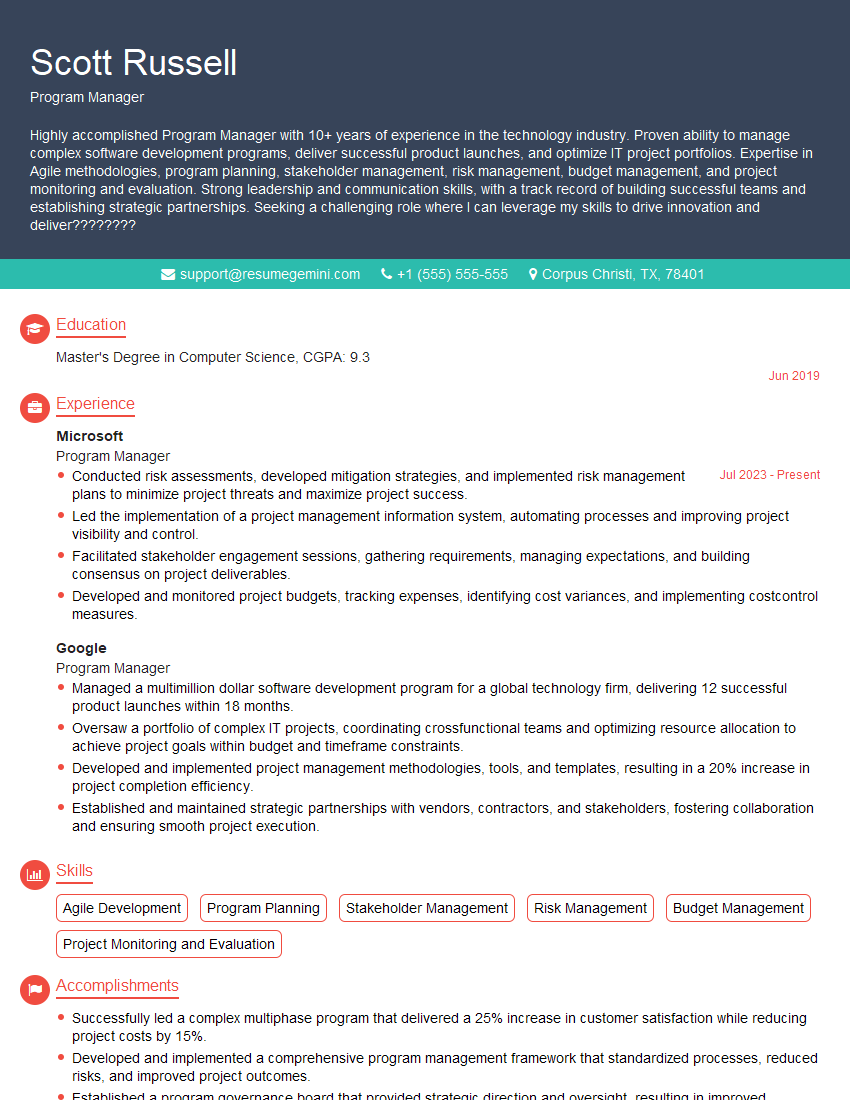

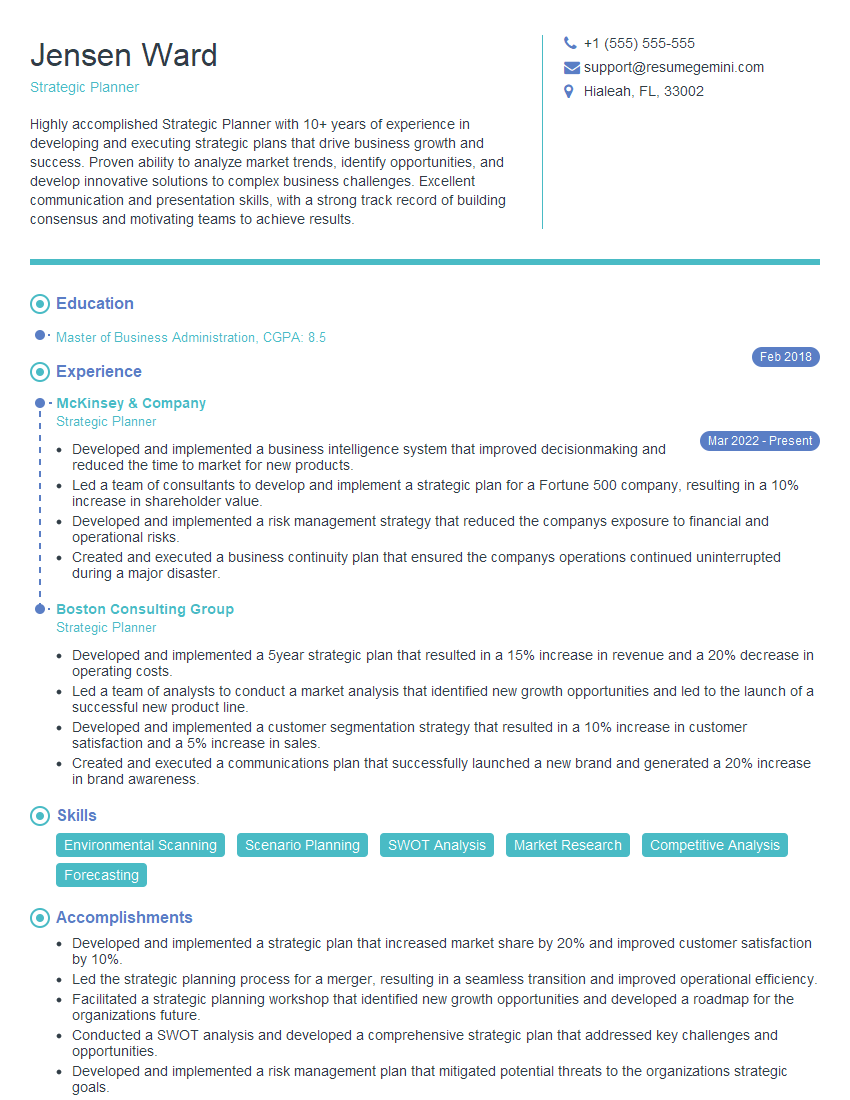

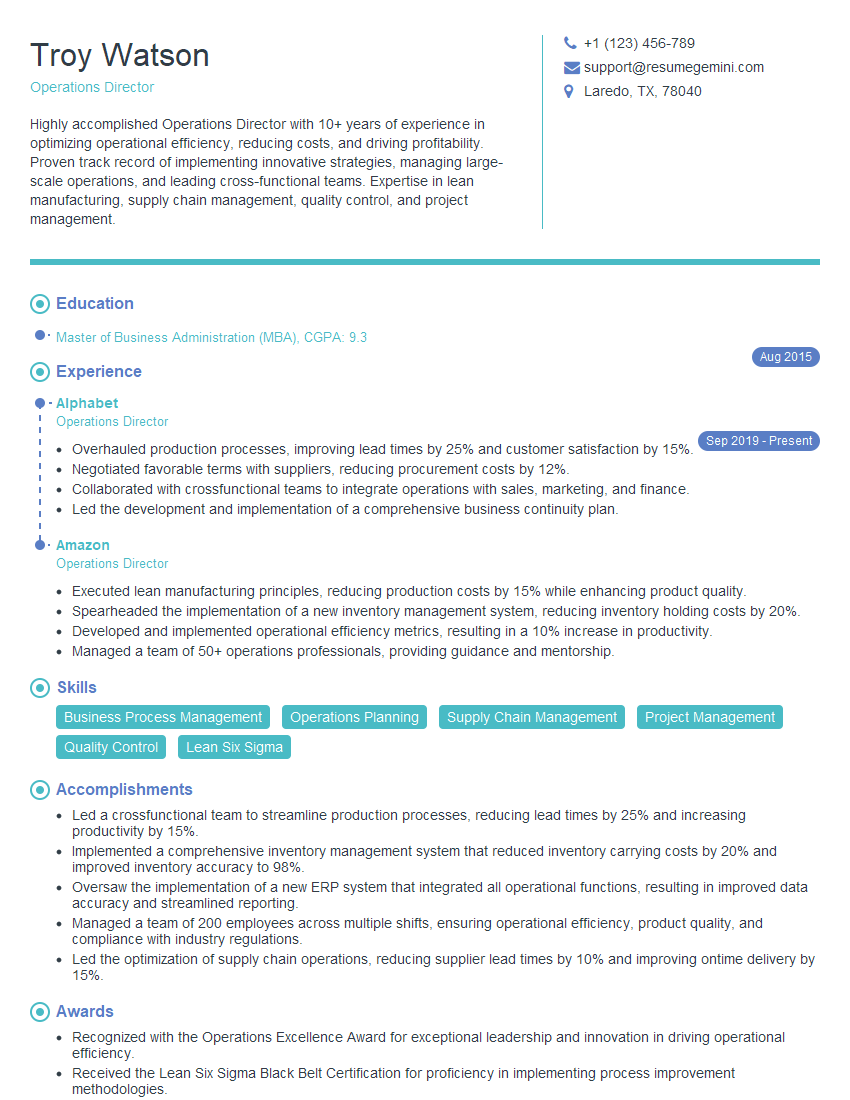

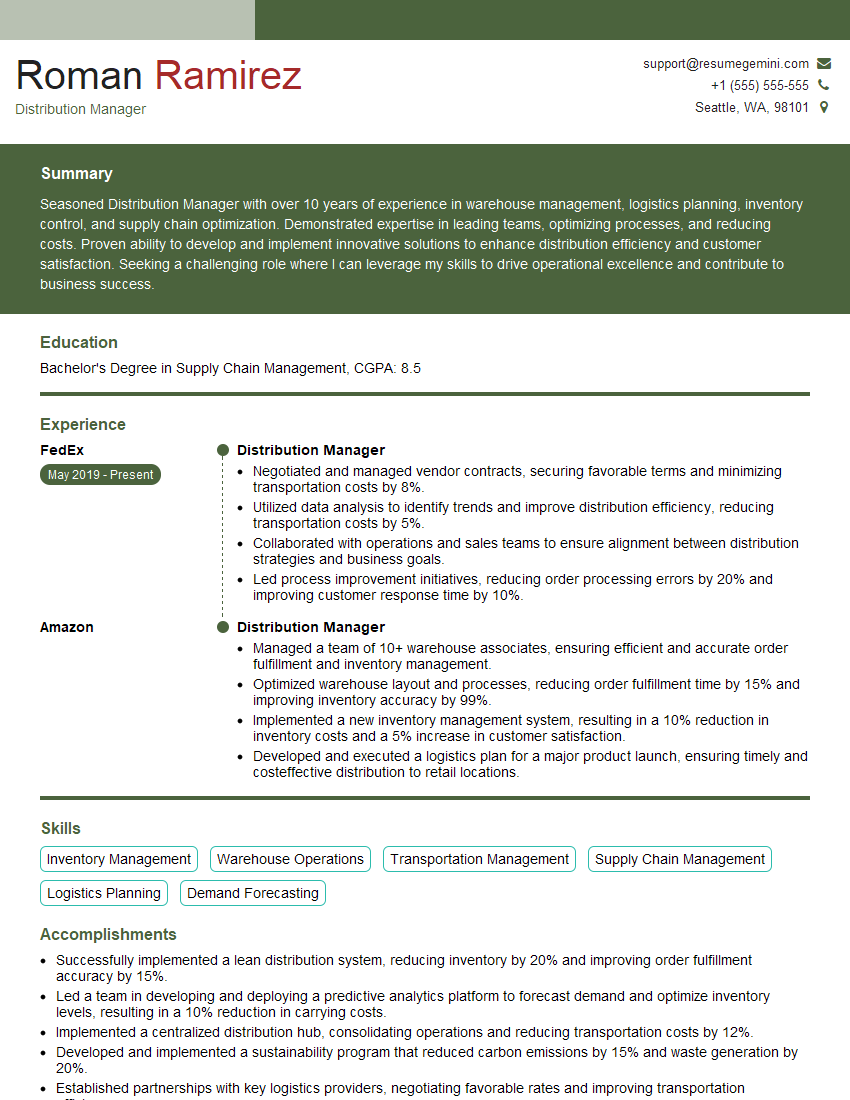

Mastering Operational Planning and Management is crucial for career advancement, opening doors to leadership roles and significantly impacting organizational success. To maximize your job prospects, it’s essential to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We offer examples of resumes tailored to Operational Planning and Management roles to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good