Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Operations Management and Support interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Operations Management and Support Interview

Q 1. Describe your experience with process improvement methodologies (Lean, Six Sigma, etc.).

Process improvement methodologies like Lean and Six Sigma are crucial for optimizing operational efficiency. Lean focuses on eliminating waste in all forms – from unnecessary steps in a process to excess inventory – while Six Sigma aims to reduce defects and variability to near-zero levels. My experience encompasses applying both in various settings.

In a previous role, I led a Lean initiative to streamline our order fulfillment process. We used value stream mapping to visualize the entire process, identifying bottlenecks and areas of waste. This resulted in a 20% reduction in lead times and a 15% decrease in operational costs. Specifically, we eliminated redundant steps in data entry and implemented a kanban system for inventory management.

With Six Sigma, I’ve utilized DMAIC (Define, Measure, Analyze, Improve, Control) methodology to improve the accuracy of our customer service call resolution. Through data analysis, we pinpointed the root causes of customer dissatisfaction and implemented targeted training and process changes. This resulted in a 30% improvement in customer satisfaction scores.

Q 2. How would you handle a critical system failure impacting operations?

Handling a critical system failure requires a swift and methodical approach. My first step would be to activate our incident management plan, which involves immediately establishing a communication channel and assembling a crisis response team composed of representatives from IT, operations, and communication.

Simultaneously, we would initiate the following:

- Assessment: Quickly assess the impact of the failure, determining the affected systems and the extent of disruption to operations.

- Mitigation: Implement immediate mitigation strategies, such as activating backup systems or implementing workarounds to minimize downtime.

- Communication: Keep all stakeholders informed through regular updates. Transparency is crucial in managing expectations.

- Root Cause Analysis: Once the immediate crisis is resolved, initiate a thorough investigation to determine the root cause of the failure to prevent future incidents. This usually involves detailed logging and analysis of system events.

- Documentation: Thoroughly document the entire incident, including the timeline, actions taken, and lessons learned.

Imagine a scenario where our CRM system crashes. My team would immediately switch to a backup system, inform clients of temporary disruption, and begin investigating the root cause. This could involve checking server logs, network connectivity, and application code for errors. Post-incident, we would implement preventative measures, like improved monitoring and regular system backups, to avoid similar issues.

Q 3. Explain your approach to managing competing priorities in a fast-paced environment.

Managing competing priorities in a fast-paced environment demands strong organizational and prioritization skills. I employ a prioritized task management system, often using a matrix that considers urgency and importance. This helps me focus on tasks that deliver the greatest impact first.

My approach involves:

- Prioritization Matrix: I categorize tasks based on their urgency and importance (e.g., high urgency/high importance, high urgency/low importance, etc.). This helps me focus on the most critical tasks first.

- Time Blocking: I allocate specific time blocks for focused work on high-priority tasks, minimizing distractions.

- Delegation: Where possible, I delegate tasks to team members, ensuring they have the necessary resources and support.

- Regular Review: I regularly review my task list and adjust priorities as needed, acknowledging that priorities can shift in a dynamic environment.

For instance, if I’m facing a critical deadline for a project while simultaneously needing to address a sudden operational issue, I’ll use the matrix to prioritize. The operational issue might be high urgency/high importance, requiring immediate attention, even if it means temporarily adjusting the project timeline.

Q 4. Describe a time you had to optimize a business process. What were the results?

In a previous role, I optimized our customer onboarding process. Initially, the process was manual, time-consuming, and prone to errors. Customers often experienced delays and frustration.

To optimize this, I implemented a digital onboarding system that automated several steps, including data entry, document verification, and account creation. We also streamlined communication using automated email sequences.

Results: The new system reduced onboarding time by 50%, decreased errors by 75%, and improved customer satisfaction scores by 20%. The quantifiable results showcased the success of the optimization. We measured success through reduced onboarding time, improved customer satisfaction surveys, and a reduction in support tickets related to onboarding issues.

Q 5. What metrics do you consider most important in evaluating operational efficiency?

Evaluating operational efficiency requires a holistic approach, focusing on several key metrics. These can be broadly categorized into:

- Productivity: Metrics like units produced per hour, output per employee, and order fulfillment rate provide insights into workforce efficiency.

- Quality: Metrics such as defect rates, customer satisfaction scores, and error rates reveal the quality of output and processes.

- Cost: Metrics like cost per unit, operational expenses, and return on investment highlight cost effectiveness.

- Time: Metrics such as lead times, cycle times, and turnaround times reflect the speed and efficiency of operations.

- Inventory: Metrics like inventory turnover, days of inventory on hand, and stockout rates are vital for supply chain efficiency.

The specific metrics chosen depend on the nature of the operation, but a balanced scorecard approach considering all these aspects offers a complete picture.

Q 6. How do you identify and mitigate operational risks?

Identifying and mitigating operational risks is an ongoing process that involves proactive risk assessment and mitigation strategies. My approach involves:

- Risk Identification: Conducting regular risk assessments, using techniques like SWOT analysis and brainstorming sessions to identify potential threats. This might involve reviewing past incident reports, industry best practices and considering potential external factors.

- Risk Analysis: Evaluating the likelihood and potential impact of each identified risk. This involves determining the severity and probability of each risk occurring.

- Risk Mitigation: Developing and implementing strategies to reduce the likelihood or impact of identified risks. This could involve implementing control measures, contingency planning, and investing in risk management tools.

- Monitoring and Review: Continuously monitoring and reviewing the effectiveness of risk mitigation strategies, adapting as needed to address emerging risks. This ensures that the mitigation strategies remain relevant and effective.

For example, in a manufacturing setting, a risk assessment might reveal the risk of equipment failure. Mitigation strategies could include regular maintenance, redundancy of critical equipment, and insurance to cover potential losses.

Q 7. Explain your understanding of supply chain management.

Supply chain management encompasses the entire flow of goods and services, from the origin of raw materials to the delivery of the final product to the end customer. It’s a complex network involving multiple stakeholders, including suppliers, manufacturers, distributors, and retailers.

My understanding of supply chain management extends to key areas such as:

- Sourcing and Procurement: Selecting reliable suppliers, negotiating favorable contracts, and managing the procurement process efficiently.

- Inventory Management: Optimizing inventory levels to meet demand while minimizing storage costs and preventing stockouts.

- Logistics and Transportation: Efficiently planning and executing the transportation of goods from origin to destination.

- Demand Planning and Forecasting: Accurately forecasting future demand to optimize production and inventory levels.

- Supply Chain Visibility: Using technology and data analytics to track and monitor the flow of goods throughout the supply chain.

- Risk Management: Identifying and mitigating potential risks throughout the supply chain.

Effective supply chain management is crucial for delivering high-quality products on time and at a competitive cost. Poor supply chain management can lead to delays, stockouts, increased costs, and damaged reputation.

Q 8. Describe your experience with inventory management and control.

Inventory management is the process of overseeing the flow of goods, from procurement to sale. Effective control ensures optimal stock levels, minimizing storage costs and preventing stockouts or overstocking. My experience encompasses implementing and optimizing inventory management systems across various industries.

In a previous role at a manufacturing company, we transitioned from a manual inventory system to an automated one using a robust Enterprise Resource Planning (ERP) system. This involved meticulously mapping our existing inventory, implementing barcode scanning, and training staff on the new system. We saw a significant improvement in accuracy (reducing discrepancies by 40%) and efficiency (reducing cycle counting time by 60%). Prior to that, while working for a logistics company, I utilized ABC analysis to prioritize inventory based on value and demand, focusing management efforts on the most critical items (A-class). This targeted approach freed up resources and improved overall inventory turnover.

I’m proficient in various inventory control techniques, including Just-In-Time (JIT) inventory, Economic Order Quantity (EOQ) calculations, and safety stock management. I also have experience with forecasting demand using time series analysis and statistical modeling to accurately predict future needs and prevent stockouts.

Q 9. How do you ensure compliance with relevant regulations and standards in your operations?

Compliance is paramount in operations. It ensures legal adherence, protects the organization from penalties, and builds trust with stakeholders. My approach focuses on proactive measures rather than reactive fixes.

- Identifying Applicable Regulations: I begin by thoroughly researching and identifying all relevant regulations and standards, including industry-specific laws, safety standards (like OSHA), environmental regulations, and data privacy laws (like GDPR or CCPA).

- Implementing Compliance Procedures: This involves developing and implementing comprehensive procedures to ensure consistent adherence to the identified regulations. This includes creating checklists, training materials, and internal audits to monitor our compliance.

- Regular Audits and Monitoring: Consistent monitoring through regular internal audits helps identify any compliance gaps early. External audits are also crucial for independent verification and maintaining certification where applicable.

- Documentation and Record-Keeping: Meticulous documentation of all compliance-related activities ensures traceability and strengthens the organization’s ability to demonstrate compliance to auditors.

For instance, in a previous role involving the handling of hazardous materials, I implemented a comprehensive safety program that included detailed training for staff, the implementation of strict safety protocols, and regular inspections to guarantee compliance with OSHA regulations. This resulted in a significant reduction in workplace accidents and improved overall safety.

Q 10. Explain your experience with project management methodologies within an operations context.

My project management experience within operations heavily relies on Agile and Lean methodologies. Agile’s iterative approach allows for flexibility and adaptation to changing requirements, common in operational settings. Lean focuses on eliminating waste and improving efficiency.

In one project, I led the implementation of a new warehouse management system (WMS) using an Agile approach. We worked in short sprints, regularly reviewing progress and adapting our plans based on feedback and changing needs. This iterative process ensured that the final system effectively met our requirements and incorporated valuable learnings from each iteration. We utilized tools like Kanban boards to visualize workflow and track progress effectively.

Applying Lean principles, I also led a process improvement project focused on reducing lead times in our order fulfillment process. By identifying and eliminating bottlenecks using techniques like value stream mapping, we were able to significantly reduce processing time and improve customer satisfaction. The success of both projects highlights my adaptability and proficiency in integrating diverse project management methodologies within operational contexts.

Q 11. Describe your experience with budgeting and resource allocation for operational projects.

Budgeting and resource allocation are critical for effective project management in operations. My experience involves developing accurate budgets, securing necessary funding, and allocating resources efficiently to maximize project success while staying within budgetary constraints.

When developing a budget, I start by defining project scope, objectives, and deliverables. Then, I estimate the cost of resources needed (personnel, materials, software, etc.). I utilize various budgeting techniques such as zero-based budgeting (starting from scratch) or incremental budgeting (adjusting from previous budgets). I then present a detailed budget proposal, justifying all costs and potential risks.

Resource allocation involves carefully assigning personnel, equipment, and materials to project tasks. I utilize techniques like critical path analysis to prioritize tasks and allocate resources to the most critical activities first. This ensures that projects stay on schedule and within budget. For example, during a large-scale facility upgrade, I successfully managed a $2 million budget by carefully allocating resources and negotiating favorable contracts with vendors. This led to the project being completed on time and under budget.

Q 12. How do you handle conflict resolution within your operational team?

Conflict resolution is an essential skill in operations management. My approach emphasizes open communication, collaboration, and finding mutually beneficial solutions.

- Active Listening: I begin by actively listening to all involved parties to understand their perspectives and concerns. This is crucial to identifying the root cause of the conflict.

- Facilitation and Mediation: I facilitate open communication, encouraging collaborative problem-solving. I guide the discussion toward finding common ground and resolving differences.

- Objective Assessment: I strive to objectively assess the situation and identify the core issues without taking sides. This helps to prevent the conflict from escalating.

- Collaborative Solution: I work with the team to develop a mutually acceptable solution that addresses the concerns of all parties involved.

- Follow-up: I follow up to ensure that the agreed-upon solution is implemented and that the conflict doesn’t resurface.

For example, I once mediated a disagreement between two team members regarding project priorities. By actively listening to both sides and facilitating a collaborative discussion, we were able to develop a compromise that satisfied both parties and ensured project timelines remained intact.

Q 13. What is your experience with data analysis and its use in improving operational efficiency?

Data analysis plays a crucial role in improving operational efficiency. My experience involves leveraging data to identify areas for improvement, optimize processes, and make data-driven decisions.

I’m proficient in various analytical techniques, including descriptive statistics (mean, median, mode), regression analysis (to identify correlations between variables), and time series analysis (for forecasting). I utilize tools like Excel, SQL, and data visualization software (like Tableau or Power BI) to analyze operational data.

In a previous role, we used data analysis to identify bottlenecks in our supply chain. By analyzing delivery times, inventory levels, and transportation costs, we pinpointed specific areas where inefficiencies were occurring. This led to process improvements, resulting in a 15% reduction in lead times and a 10% decrease in transportation costs.

I also regularly use Key Performance Indicators (KPIs) to track performance and identify areas needing improvement. This data-driven approach allows us to proactively address issues and continually enhance operational efficiency.

Q 14. How would you implement a new operational system or technology?

Implementing a new operational system or technology requires a structured approach to ensure successful adoption and avoid disruption. My strategy encompasses several key phases:

- Needs Assessment and Planning: Begin by thoroughly assessing the current operational challenges and identifying how the new system/technology addresses these. Define clear objectives and project scope.

- Vendor Selection and Procurement: Carefully research and select a vendor that meets your specific needs and budget. Negotiate contracts and ensure clear service level agreements (SLAs).

- System Design and Customization: Work with the vendor to design the system to your specific requirements. This may involve customizing existing modules or developing new ones. Ensure system integration with existing systems.

- Testing and Training: Conduct thorough testing to ensure functionality and identify any bugs. Develop and implement comprehensive training programs for all users to ensure smooth adoption.

- Deployment and Go-Live: Deploy the new system in a phased approach (if possible) to minimize disruption. Monitor the system closely during the initial go-live period and address any issues promptly.

- Post-Implementation Review and Optimization: Conduct a post-implementation review to assess the effectiveness of the new system. Identify areas for optimization and make necessary adjustments.

For example, when implementing a new Customer Relationship Management (CRM) system, we followed a phased rollout, starting with a pilot group to test the system before a full deployment. This minimized disruption and allowed us to address any issues before impacting the entire organization. Post-implementation review helped us identify areas for optimization, resulting in increased user adoption and improved efficiency.

Q 15. Explain your experience with performance monitoring and reporting.

Performance monitoring and reporting is crucial for understanding the health and efficiency of operational processes. It involves collecting data, analyzing trends, and presenting insights to stakeholders. My experience spans various methodologies, from using basic spreadsheet tools for smaller projects to implementing sophisticated monitoring systems like Nagios and Zabbix for larger-scale infrastructure management.

For example, in my previous role, we used Nagios to monitor server uptime, response times, and resource utilization. Any deviations from pre-defined thresholds triggered alerts, allowing us to proactively address potential issues before they impacted users. We then used this data to create weekly and monthly reports, highlighting key performance indicators (KPIs) such as average response time, error rates, and overall system availability. These reports helped inform decisions around resource allocation, system upgrades, and process improvements.

In another project, I developed custom dashboards using Grafana, which visualized data from various sources, offering a holistic view of system performance. This allowed for quicker identification of bottlenecks and facilitated better decision-making in a fast-paced environment. The ability to customize dashboards meant we could tailor reporting to the specific needs of different stakeholders, from technical teams to executive management.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you measure the success of operational initiatives?

Measuring the success of operational initiatives requires a multi-faceted approach, going beyond simple completion. We need to define clear, measurable, achievable, relevant, and time-bound (SMART) goals upfront. These goals should align with overall business objectives. Success is then gauged by comparing actual results against these predefined targets.

For example, if the initiative aims to reduce customer support response time, success would be measured by tracking the average response time before and after the implementation. Other metrics might include customer satisfaction scores (CSAT), resolution rates, and the number of escalated issues. It’s important to consider both quantitative and qualitative data. Quantitative data provides objective metrics, while qualitative data, such as feedback from customer surveys or employee interviews, offers valuable context and insights.

A crucial aspect is identifying leading indicators, which predict future success, and lagging indicators, which reflect past performance. For instance, improved employee training (leading indicator) may lead to a reduction in error rates (lagging indicator). By tracking both, we gain a complete picture of the initiative’s impact.

Q 17. Describe your approach to managing a diverse team in an operational setting.

Managing diverse teams requires fostering a culture of inclusivity, collaboration, and open communication. I believe in empowering team members by delegating tasks based on their strengths and providing opportunities for professional development. Regular feedback, both positive and constructive, is vital for individual growth and team cohesion. Clear communication channels and well-defined roles and responsibilities ensure that everyone understands their contributions and how they fit into the bigger picture.

In my experience, addressing individual needs and preferences is key. Some team members thrive in independent roles, while others prefer collaborative settings. Understanding these nuances allows for optimized task allocation and team structure. Conflict resolution is an important skill, and I utilize a collaborative approach, focusing on finding mutually beneficial solutions rather than assigning blame. Regular team-building activities can help improve camaraderie and trust within the team, ultimately increasing overall effectiveness.

For example, I once managed a team with members from diverse cultural backgrounds and technical expertise. To facilitate effective communication, we adopted clear communication protocols, using a project management tool to track progress and ensure everyone was on the same page. We also organized regular team meetings, both formal and informal, to encourage knowledge sharing and collaboration.

Q 18. How do you stay updated on best practices in operations management?

Staying updated on best practices in operations management requires a proactive and multi-pronged approach. I regularly attend industry conferences and webinars, participate in professional organizations like APICS (Association for Operations Management), and actively engage in online communities and forums. Reading industry publications, such as Harvard Business Review and journals focused on operations management, keeps me abreast of the latest trends and research.

I also leverage online learning platforms like Coursera and edX to expand my knowledge in specific areas. Moreover, I seek out opportunities to network with other professionals in the field, exchanging ideas and learning from their experiences. This combination of formal learning and informal networking ensures that I’m constantly evolving my skillset and staying at the forefront of operational excellence.

For instance, recently I completed a course on Lean Six Sigma methodologies, which has significantly improved my ability to identify and eliminate waste in operational processes. Continuous learning is not merely a professional necessity but a personal commitment to improvement.

Q 19. What are your strengths and weaknesses in relation to operations management?

My strengths lie in my analytical skills, problem-solving abilities, and my ability to lead and motivate teams. I’m adept at identifying inefficiencies and implementing process improvements. I’m also highly organized and detail-oriented, ensuring projects are completed effectively and on time. My experience with various monitoring tools and reporting techniques allows me to provide data-driven insights to support decision-making.

One area for improvement is delegation. While I’m comfortable delegating tasks, I sometimes struggle to fully relinquish control, a tendency I’m actively working to overcome. I’m addressing this by consciously practicing more effective delegation techniques and trusting my team’s abilities. I believe in continuous self-improvement and actively seek feedback to identify and address any weaknesses.

Q 20. Describe your experience with vendor management within operational contexts.

Vendor management is crucial for ensuring the smooth operation of various aspects of a business. My experience encompasses selecting, negotiating contracts with, and overseeing performance of vendors providing services ranging from IT infrastructure to logistics. This involves establishing clear service level agreements (SLAs), regularly monitoring vendor performance against those agreements, and addressing any shortcomings promptly and effectively.

A key aspect is building strong relationships with vendors. Open communication and collaborative problem-solving are essential to ensure mutual understanding and achieve optimal results. Regular performance reviews, incorporating both quantitative and qualitative data, help track vendor performance and identify areas for improvement. These reviews are used to make informed decisions about contract renewals and future collaborations.

For example, in a previous role, I managed a vendor responsible for our cloud infrastructure. We established SLAs defining uptime, response time, and security protocols. By using monitoring tools and regular check-ins, we ensured the vendor consistently met the agreed-upon standards. When issues arose, we worked collaboratively with the vendor to find quick and effective solutions, minimizing disruption to our operations.

Q 21. How do you prioritize tasks and projects within a dynamic operational environment?

Prioritizing tasks and projects in a dynamic environment requires a structured approach. I typically use a combination of techniques, including prioritization matrices (like Eisenhower Matrix), project management methodologies (such as Agile or Scrum), and risk assessment. The Eisenhower Matrix helps categorize tasks based on urgency and importance, allowing me to focus on high-impact, high-urgency items first.

Agile methodologies allow for flexibility and adaptation to changing priorities. Regular sprint planning and daily stand-up meetings facilitate ongoing assessment and adjustment of project plans. Risk assessment helps identify potential roadblocks and allows for proactive mitigation strategies. This combination ensures that resources are allocated efficiently and critical tasks are completed in a timely manner.

For instance, if a critical system failure occurs, this would immediately become the highest priority, overriding other tasks temporarily. However, we’d simultaneously leverage the Agile framework to assess the impact and adjust the sprint backlog to address the issue quickly, minimizing downtime and business disruption. The risk assessment would then help inform decisions about preventative measures to avoid similar issues in the future.

Q 22. How do you ensure effective communication across different operational teams?

Effective communication across operational teams is the bedrock of any successful operation. It’s not just about sending information; it’s about ensuring everyone understands, agrees on, and acts on that information. I achieve this through a multi-pronged approach.

Establishing Clear Communication Channels: This involves identifying the best communication tools for each team and purpose. For instance, instant messaging might be suitable for quick updates, while email is better for formal documentation or longer messages. Regular team meetings, both formal and informal, are crucial for fostering collaboration and addressing concerns.

Defining Roles and Responsibilities: Each team member needs a clear understanding of their role and how it contributes to the overall operational goals. This prevents duplication of effort and ensures accountability. A well-defined communication matrix specifying who communicates with whom and on what issues is incredibly helpful.

Utilizing Collaborative Platforms: Tools like project management software (e.g., Asana, Jira) or shared document repositories (e.g., Google Workspace, Microsoft Teams) enable teams to access information simultaneously, track progress, and provide feedback efficiently.

Promoting Open and Transparent Communication: A culture of open communication, where team members feel comfortable raising concerns or seeking clarification, is essential. Regular feedback sessions and open-door policies can encourage this.

Regular Training and Updates: Keeping teams informed about new procedures, technologies, or changes in operational strategy through training and updates is crucial for maintaining consistent communication and avoiding confusion.

For example, in a previous role, we implemented a daily stand-up meeting using a project management tool, which significantly improved transparency and responsiveness. Issues were quickly identified and resolved, preventing them from escalating into major problems.

Q 23. Explain your experience with capacity planning and resource optimization.

Capacity planning and resource optimization are critical for ensuring operational efficiency and profitability. My experience involves forecasting demand, analyzing resource availability, and optimizing resource allocation to meet business objectives.

Demand Forecasting: I’ve utilized various forecasting techniques, including statistical modeling and trend analysis, to predict future demand accurately. This involves considering historical data, seasonal variations, and market trends.

Resource Analysis: This includes evaluating the availability of resources such as personnel, equipment, and materials. I use tools to analyze resource utilization and identify bottlenecks. For example, I used simulation software to model different resource allocation scenarios to optimize staffing levels in a contact center.

Resource Optimization: Once demand and resource availability are understood, I develop strategies for optimizing resource allocation. This might involve cross-training employees, investing in new equipment, or outsourcing certain tasks. Prioritization matrices and resource leveling techniques are often employed.

Performance Monitoring: Continuous monitoring of resource utilization and operational efficiency is crucial. This involves tracking key performance indicators (KPIs) and adjusting resource allocation as needed. Regular reporting and analysis are key to staying proactive.

In one project, I implemented a new capacity planning model that reduced operational costs by 15% while simultaneously improving customer service levels. This involved a combination of improved forecasting, optimized staffing schedules, and efficient resource allocation across different teams.

Q 24. How do you deal with unexpected operational challenges or disruptions?

Unexpected operational challenges are inevitable. My approach focuses on preparedness, quick response, and effective problem-solving.

Proactive Risk Management: I identify potential disruptions through risk assessment and develop contingency plans. This could involve having backup systems, alternative suppliers, or emergency procedures in place.

Rapid Response Team: Having a dedicated team responsible for handling unexpected events is crucial. This team should be well-trained and equipped to address a wide range of issues quickly and efficiently.

Communication and Collaboration: Open and transparent communication is paramount. Keeping all stakeholders informed about the situation and the actions being taken helps maintain confidence and prevents misinformation.

Problem Solving and Root Cause Analysis: Once the immediate crisis is under control, I conduct a thorough root cause analysis to understand why the disruption occurred and implement preventative measures to avoid recurrence.

Post-Incident Review: After the event, a formal review is conducted to evaluate the effectiveness of the response, identify areas for improvement, and update contingency plans.

For example, during a major software outage, we immediately activated our disaster recovery plan, communicated effectively with clients, and quickly restored service. Post-incident analysis revealed a weakness in our backup system, which was promptly addressed.

Q 25. Describe your experience with root cause analysis and problem-solving in an operational setting.

Root cause analysis (RCA) is a systematic approach to identifying the underlying causes of problems. It’s not just about fixing the immediate symptom but uncovering the root issues to prevent recurrence. I commonly use the 5 Whys technique and Fishbone diagrams.

5 Whys Technique: This involves repeatedly asking “why” to drill down to the root cause. For instance, if a machine malfunctioned, we might ask: Why did the machine malfunction? (worn part). Why was the part worn? (lack of maintenance). Why was there a lack of maintenance? (inadequate scheduling). Why was the scheduling inadequate? (poor planning). Why was the planning poor? (lack of training).

Fishbone Diagram (Ishikawa Diagram): This visual tool helps organize potential causes by category (e.g., manpower, machinery, materials, methods, environment, measurement). Brainstorming sessions are used to identify potential causes within each category.

Data Analysis: RCA often involves analyzing data to identify trends or patterns that might contribute to the problem. This could include operational data, customer feedback, or maintenance logs.

In a past role, using the 5 Whys and data analysis, we uncovered a systemic issue with supplier quality leading to frequent equipment failures. Addressing this supplier issue dramatically reduced downtime and maintenance costs. This involved not only finding a new supplier but also improving our supplier selection process.

Q 26. How do you ensure quality control throughout the operational process?

Quality control is an ongoing process, not a one-time event. It involves establishing quality standards, implementing processes to meet those standards, and continuously monitoring and improving performance.

Defining Quality Standards: Clear, measurable quality standards must be established for all aspects of the operational process. This might involve defining acceptable error rates, response times, or customer satisfaction levels.

Process Control: Implementing processes to ensure that quality standards are met is critical. This could involve using checklists, standardized procedures, or quality control checkpoints at various stages of the process.

Continuous Monitoring: Regularly monitoring performance against established quality standards is essential. This involves tracking key performance indicators (KPIs) and identifying areas for improvement. Data analysis helps reveal trends and patterns.

Corrective and Preventative Actions: When quality issues are identified, corrective actions are taken to address the immediate problem. Preventative actions are then implemented to prevent similar issues from occurring in the future. Root cause analysis plays a vital role here.

Feedback Loops: Establishing feedback loops with customers and employees is crucial for identifying areas where quality can be improved. Regular surveys and feedback sessions provide valuable insights.

For instance, in a manufacturing setting, I implemented a Six Sigma project that significantly reduced the defect rate by improving process control and training employees on proper procedures. This involved statistical process control (SPC) techniques and regular quality audits.

Q 27. What experience do you have with developing and implementing operational strategies?

Developing and implementing operational strategies requires a comprehensive understanding of the business goals, operational processes, and the competitive landscape. My approach is data-driven and focuses on continuous improvement.

Strategic Planning: I begin by aligning operational strategies with overall business objectives. This involves defining clear goals, identifying key performance indicators (KPIs), and developing a roadmap for achieving those goals.

Process Improvement: I analyze existing operational processes to identify areas for improvement. This might involve streamlining workflows, automating tasks, or eliminating bottlenecks. Lean principles and Six Sigma methodologies are often valuable here.

Technology Implementation: I evaluate and implement new technologies to improve operational efficiency and effectiveness. This could involve adopting new software, automation systems, or data analytics tools. Thorough testing and training are vital.

Change Management: Introducing new strategies or technologies requires careful change management to minimize disruption and ensure employee buy-in. Effective communication and training are crucial components.

Performance Monitoring and Evaluation: After implementation, I monitor performance against established KPIs and make adjustments as needed. Regular reviews and evaluations ensure that the strategies are achieving the desired outcomes. This includes analyzing data, gathering feedback, and adapting strategies based on actual results.

In one project, I led the implementation of a new inventory management system that reduced inventory holding costs by 20% while simultaneously improving order fulfillment times. This involved a detailed analysis of current processes, the selection of appropriate software, and comprehensive training for the warehouse team.

Q 28. Describe a situation where you had to make a difficult decision impacting operational efficiency.

In a previous role, we faced a critical situation where a major supplier experienced an unexpected production halt, threatening to disrupt our entire production schedule. This meant a significant delay in fulfilling customer orders and potential reputational damage.

The decision I had to make involved choosing between two difficult options: 1) Accepting the delay and informing customers of the potential disruption, or 2) sourcing alternative suppliers at a significantly higher cost, potentially impacting profitability.

After careful consideration of the potential risks and benefits of each option, along with the financial implications and potential customer backlash, I opted for the second option – finding alternative suppliers. While more expensive, it mitigated the reputational damage and minimized the disruption to our customers. We were transparent with our customers, explaining the unforeseen circumstances and our proactive efforts to find a solution.

This decision highlighted the importance of supplier diversification and having contingency plans in place. Though it was a challenging and costly choice, it ultimately protected our company’s reputation and long-term relationships with our customers.

Key Topics to Learn for Operations Management and Support Interview

- Process Improvement Methodologies: Understanding Lean, Six Sigma, and Kaizen principles and their practical application in streamlining operations and enhancing efficiency. Consider examples of successful implementations and potential challenges.

- Supply Chain Management: Knowledge of inventory management, logistics, procurement, and supplier relationship management. Be prepared to discuss strategies for optimizing the supply chain and mitigating risks.

- Project Management Fundamentals: Familiarity with project planning, execution, monitoring, and closure. Discuss your experience with project methodologies like Agile or Waterfall and how you’ve applied them to solve operational challenges.

- Resource Allocation and Optimization: Discuss strategies for effectively allocating resources (human, financial, material) to maximize productivity and minimize costs. Consider scenarios involving competing priorities.

- Data Analysis and Reporting: Demonstrate your ability to interpret operational data, identify trends, and create reports to inform decision-making. Highlight your experience with relevant tools and software.

- Risk Management and Contingency Planning: Discuss your approach to identifying, assessing, and mitigating operational risks. Prepare examples of contingency plans you’ve developed and implemented.

- Team Leadership and Communication: Highlight your experience in leading and motivating teams, fostering collaboration, and communicating effectively with stakeholders at all levels.

- Technology and Automation: Understanding the role of technology in operations management and your experience with relevant software and systems (e.g., ERP, CRM).

- Problem-Solving and Decision-Making: Prepare examples showcasing your ability to analyze problems systematically, identify root causes, and develop effective solutions under pressure.

- Change Management: Discuss your experience managing organizational change, including strategies for communicating change effectively and mitigating resistance.

Next Steps

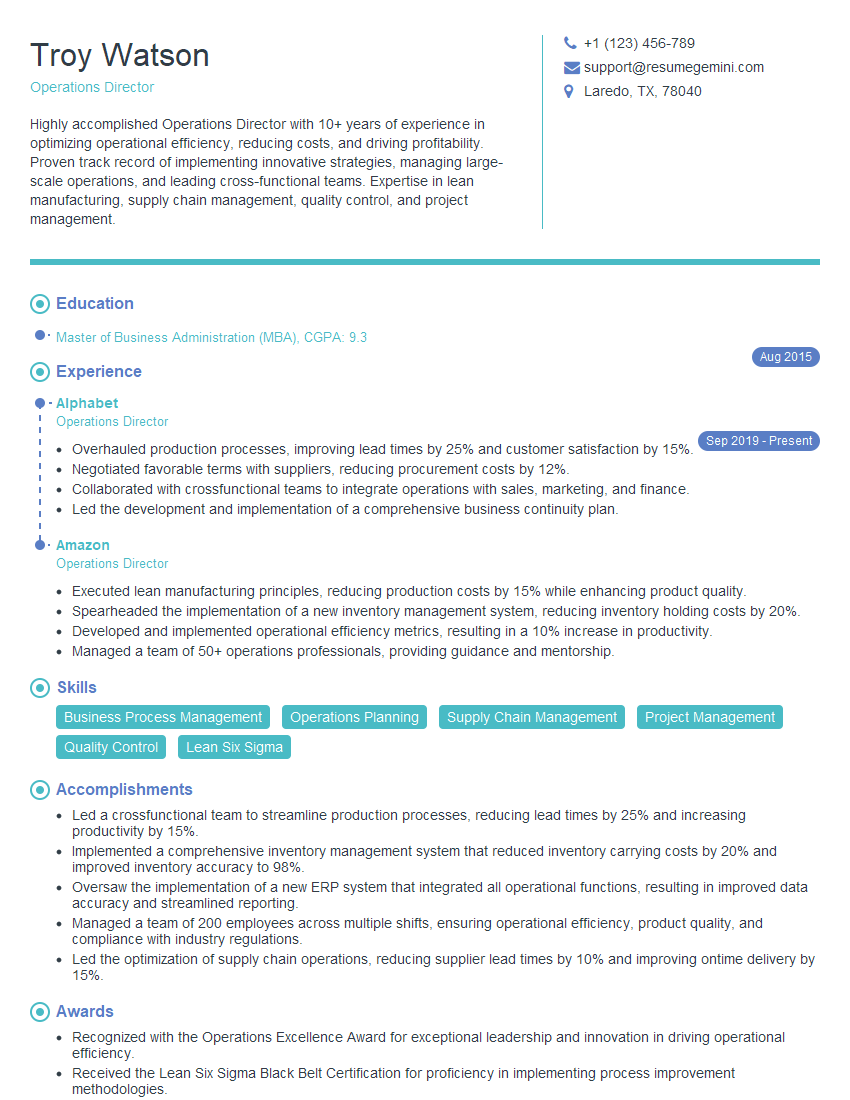

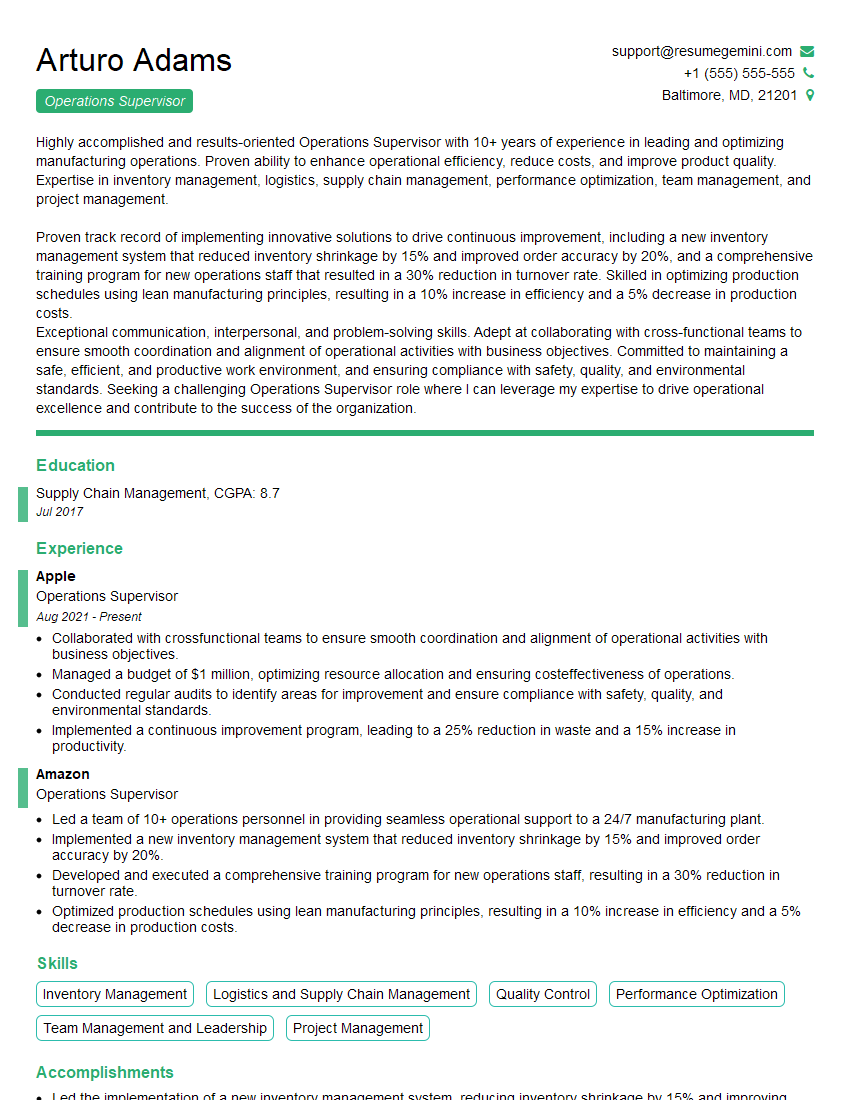

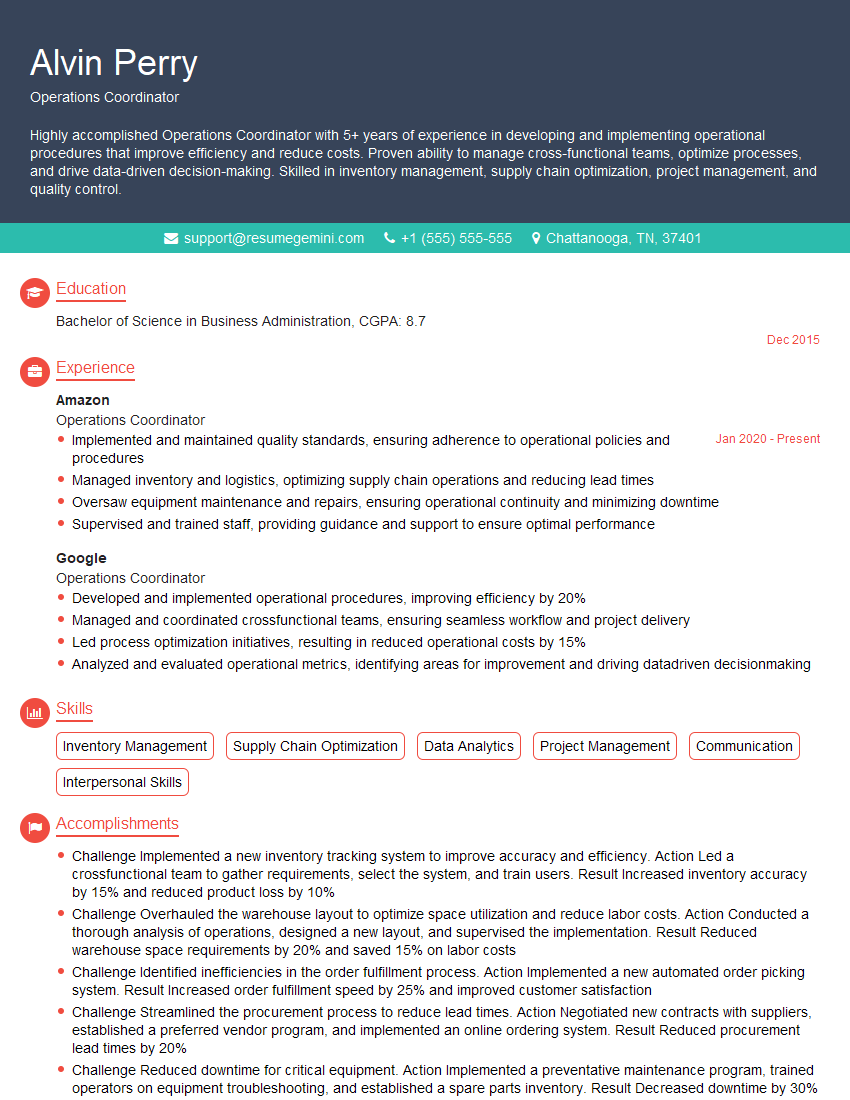

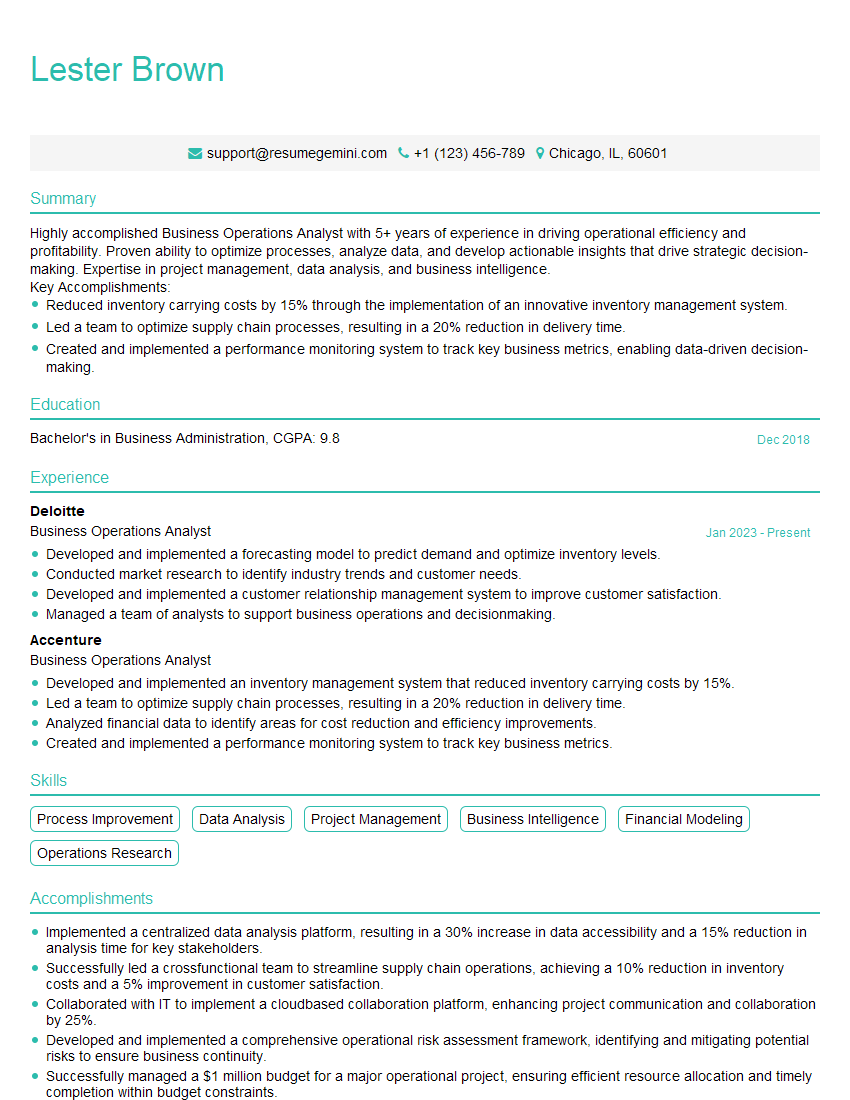

Mastering Operations Management and Support opens doors to exciting career advancements and leadership opportunities. A strong understanding of these concepts will significantly enhance your interview performance and increase your chances of securing your dream role. To further strengthen your application, creating an ATS-friendly resume is crucial. This ensures your qualifications are effectively highlighted to recruiters and helps your application stand out. We recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides valuable tools and resources, including examples of resumes tailored to Operations Management and Support, to help you craft a compelling application that showcases your skills and experience.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good