Unlock your full potential by mastering the most common Optical Design and Analysis interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Optical Design and Analysis Interview

Q 1. Explain the concept of paraxial approximation in optical design.

Paraxial approximation is a simplification used in optical design that assumes all rays of light travel at small angles relative to the optical axis. This allows us to use simplified formulas based on small-angle trigonometry, making calculations significantly easier. Imagine throwing a ball – a small angle throw follows a nearly straight path; this is analogous to paraxial rays. In reality, rays may not be perfectly paraxial, but this approximation often provides a good first-order design that can be refined later.

Specifically, it relies on approximations like sin θ ≈ θ and tan θ ≈ θ, where θ is the angle of incidence. This simplifies the lens equation and related formulas dramatically. While not perfectly accurate for large angles, the paraxial approximation provides an excellent starting point for most optical systems, particularly for preliminary designs and analyses. We can then use more rigorous methods to account for non-paraxial effects later.

Q 2. Describe different types of optical aberrations and their correction methods.

Optical aberrations are imperfections in an optical system that prevent perfect image formation. Think of it like a distorted photograph – the image isn’t sharp and clear. There are several types:

- Spherical aberration: Rays from different zones of a lens focus at different points along the optical axis. Correction involves using aspherical surfaces or lens combinations.

- Coma: Off-axis points are imaged as comet-shaped blobs. It’s corrected using optimized lens shapes and combinations.

- Astigmatism: Off-axis points are imaged as two line segments at different focal lengths. Corrective lenses or aspherical surfaces help alleviate this.

- Field curvature: The image plane is curved instead of flat. Correcting this often requires complex lens designs or specialized image sensors.

- Distortion: Straight lines in the object appear curved in the image. This is corrected using lens combinations designed to minimize distortion.

- Chromatic aberration: Different wavelengths of light focus at different points due to the wavelength dependence of refractive index. Achromatic doublets (combining lenses with different dispersive properties) or apochromatic lenses (multiple lenses for better correction) are commonly used.

Correction methods often involve sophisticated lens designs, employing multiple elements of different shapes, materials, and refractive indices. Software tools like Zemax or Code V are used for optimization.

Q 3. How do you design an optical system for a specific wavelength range?

Designing an optical system for a specific wavelength range requires considering the material dispersion and spectral characteristics of the optical components. For instance, designing a system for the near-infrared (NIR) range (e.g., 800-1000 nm) would require different materials and coatings compared to a visible light system (400-700 nm).

The process involves:

- Material Selection: Choosing materials with appropriate refractive indices and low dispersion within the desired wavelength range. Germanium, silicon, and chalcogenide glasses are common choices for the infrared.

- Coating Design: Applying anti-reflection coatings optimized for the specific wavelength range to minimize losses and improve transmission. The coating design will vary depending on the wavelength range and substrate material.

- Aberration Correction: Carefully designing the lens shapes and spacing to minimize aberrations across the entire wavelength range. This often involves using multiple lenses to correct for chromatic aberration and other distortions.

- System Optimization: Using optical design software to optimize the system’s performance (e.g., minimizing spot size, maximizing throughput) over the specified wavelength range. Software like Zemax and Code V allow you to simulate the system’s behavior across the wavelengths.

Ultimately, successful design requires a thorough understanding of material properties, dispersion, and aberration theory.

Q 4. Explain the significance of the point spread function (PSF) and modulation transfer function (MTF).

The Point Spread Function (PSF) and Modulation Transfer Function (MTF) are crucial metrics in evaluating the image quality of an optical system.

Point Spread Function (PSF): The PSF describes how a point source of light is imaged by the optical system. A perfect system would produce a perfect point, but real systems produce a blurry spot. The PSF’s shape and size directly indicate the system’s resolution and sharpness. A narrower PSF implies better resolution.

Modulation Transfer Function (MTF): The MTF is a spatial frequency representation of the PSF. It describes how well the system can transfer different spatial frequencies (details) from the object to the image. A higher MTF value at a given spatial frequency means that the system can better resolve finer details at that frequency. The MTF is often preferred for system characterization because it is easier to interpret and compare across various systems.

In practice, both PSF and MTF are used to assess the image quality and predict performance. Imagine comparing two cameras – one with a narrow PSF and high MTF will produce sharper images.

Q 5. Describe different types of optical lenses and their applications.

Optical lenses come in various types, each designed for specific applications:

- Single lenses (e.g., Plano-convex, Double-convex, Plano-concave): These are simple lenses with one or two curved surfaces. They are used in simple applications like magnifying glasses or focusing light.

- Achromatic doublets: Composed of two lenses cemented together to correct for chromatic aberration. They are commonly found in many optical instruments.

- Aspheric lenses: Have non-spherical surfaces to correct for various aberrations, offering improved image quality compared to spherical lenses. They are used in high-performance cameras and telescopes.

- Diffractive lenses: Utilize diffractive optical elements to manipulate light waves, offering compact design and improved aberration correction. They are useful in specialized applications such as laser scanning and barcode readers.

- Graded-index lenses: The refractive index gradually changes across the lens, enabling better control of light propagation and minimizing aberrations. They are useful for optical fibers and endoscopes.

The choice of lens type depends on the application’s specific requirements, such as resolution, field of view, and the need for chromatic aberration correction.

Q 6. How do you perform optical tolerancing analysis?

Optical tolerancing analysis is crucial in manufacturing to ensure that the final optical system meets performance requirements even with manufacturing variations in lens shapes, surface quality, and spacing. It involves determining the allowable tolerances for each component to meet a desired performance level.

The process generally involves:

- Identify Critical Parameters: Determine which parameters (e.g., lens curvature, thickness, spacing, refractive index) have the most significant impact on the system’s performance.

- Define Performance Requirements: Specify acceptable levels of performance degradation (e.g., maximum allowable wavefront error, MTF degradation).

- Tolerance Analysis: Use optical design software (e.g., Zemax, Code V) to perform a Monte Carlo analysis or other tolerance analysis techniques. This involves simulating the system’s performance with random variations of the component parameters within specified tolerance ranges.

- Optimization: Adjust the tolerances or the system design to ensure that the performance requirements are met, even with manufacturing variations. This often involves a trade-off between cost and performance.

The goal is to define manufacturing tolerances that are achievable and economically feasible while still ensuring the system meets its intended specifications.

Q 7. What are the different types of optical coatings and their purpose?

Optical coatings are thin layers of material deposited on optical surfaces to modify the reflection, transmission, and absorption of light. They are essential for optimizing the performance of optical systems.

- Anti-reflection (AR) coatings: Reduce reflections from optical surfaces, increasing transmission and improving image contrast. They are commonly used on lenses and windows. These typically employ multiple layers of materials with alternating refractive indices to destructively interfere with reflected light.

- High-reflection (HR) coatings: Increase the reflectivity of optical surfaces, used in mirrors and laser resonators. Multiple layers of dielectric materials are used to constructively interfere with reflected light, resulting in high reflectivity.

- Dichroic coatings: Transmit light within a specific wavelength range while reflecting other wavelengths. These are essential for separating different colors of light in optical instruments (e.g., beam splitters, filters).

- Metal coatings (e.g., silver, gold, aluminum): Provide high reflectivity across a broad spectral range and are used in mirrors and other reflective components. These are simple to apply but can introduce higher absorption losses than dielectric coatings.

The choice of coating depends on the specific application and its spectral requirements. AR coatings minimize stray light, improving image contrast while HR coatings ensure efficient light reflection in lasers.

Q 8. Explain the difference between ray tracing and wave optics simulation.

Ray tracing and wave optics simulation are two fundamental approaches to optical system analysis, differing significantly in their modeling of light. Ray tracing treats light as a collection of rays, following their paths through the optical system based on Snell’s law of refraction and reflection. It’s computationally efficient and well-suited for designing systems where diffraction effects are negligible. Wave optics simulation, on the other hand, models light as a wave, considering its wavelength and interference effects. This approach is crucial when diffraction, interference, and polarization significantly impact system performance, such as in high-resolution imaging or diffractive optical elements.

Think of it like this: ray tracing is like drawing lines to track a ball’s trajectory, while wave optics is like simulating water waves to understand their complex interactions. Ray tracing is faster, perfect for initial design, but wave optics gives a far more accurate picture in scenarios where wave phenomena are dominant. For instance, ray tracing might be sufficient for designing simple eyeglasses, but wave optics is essential when designing high-NA microscope objectives where diffraction limits resolution.

Q 9. How do you optimize an optical system for minimum size, weight, and cost?

Optimizing an optical system for minimum size, weight, and cost requires a multi-faceted approach. It involves careful consideration of lens material selection, element count, and overall system design. Lightweight materials like plastics or specialized glasses can reduce weight, but might come at a cost of reduced optical performance. Similarly, using fewer lens elements simplifies manufacturing, reduces size, and lowers the cost, but may compromise image quality. The key is finding the optimal balance.

One effective strategy is to start with a broad initial design and then iteratively refine the design using optimization algorithms within optical design software. These algorithms allow you to define constraints (e.g., maximum size, weight, cost) and an optimization target (e.g., minimum spot size, maximum transmission). For example, you might start with a lens design using commercially available lenses, then experiment with custom lens shapes and materials while keeping an eye on manufacturability. A thorough tolerance analysis is also vital at each stage to ensure the system’s robustness to manufacturing variations.

Q 10. Describe your experience with optical design software (e.g., Zemax, Code V).

I have extensive experience with both Zemax and Code V, two leading optical design software packages. My proficiency includes using both for a wide array of tasks including lens design, tolerance analysis, illumination design, and non-sequential ray tracing. In Zemax, I’m particularly adept at using its optimization tools, merit functions, and various analysis features like Modulation Transfer Function (MTF) and Spot Diagrams.

In Code V, I’ve utilized its robust capabilities for tolerancing and optimization, particularly appreciated its powerful macro language for automating repetitive tasks and creating custom analysis tools. I’ve successfully used both software packages to design and analyze a range of optical systems, including camera lenses, microscopes, and laser systems. A recent project involved designing a compact telephoto lens in Zemax, optimizing it for both size and image quality and then transferring the design to Code V for thorough tolerance analysis. I’m comfortable working with both software packages independently and can tailor the choice of software to the specifics of the project.

Q 11. How do you evaluate the performance of an optical system?

Evaluating the performance of an optical system involves a comprehensive assessment using various metrics and analysis tools. This goes beyond just looking at the final image. Key metrics include:

- Spot diagrams: Show the distribution of rays at the image plane, indicating the sharpness of the image.

- Modulation Transfer Function (MTF): Measures the ability of the system to resolve different spatial frequencies, crucial for assessing image quality.

- Wavefront error: Quantifies the deviation of the actual wavefront from an ideal wavefront, affecting image quality and pointing accuracy.

- Point Spread Function (PSF): Describes the intensity distribution of the image of a point source, essential for evaluating resolution and sharpness.

- Encircled Energy: Indicates the percentage of light falling within a given radius around the optical axis.

Furthermore, aspects like distortion, chromatic aberration, and transmission should be evaluated. Often, a combination of these metrics is used to make a comprehensive judgment on the system’s performance. For example, a low MTF might indicate issues with resolution, while high wavefront error might suggest manufacturing tolerances or design flaws need attention. I always use a combination of simulations and physical measurements to verify and validate the design’s performance.

Q 12. Explain the concept of diffraction and its impact on optical system performance.

Diffraction is a wave phenomenon where light bends around obstacles or spreads out after passing through an aperture. It’s a fundamental limitation in optics, impacting the resolution and performance of any optical system. The amount of diffraction depends on the wavelength of light and the size of the aperture. The smaller the aperture, the greater the diffraction.

In an optical system, diffraction limits the minimum size of a spot of light that can be formed (the Airy disk), ultimately limiting resolution. This is why high-resolution systems like microscopes require larger aperture lenses to minimize diffraction effects. Diffraction also leads to the formation of diffraction rings or patterns in the image, which can blur fine details and reduce image contrast. Understanding diffraction is key to designing high-resolution systems. For instance, when designing a telescope, we use diffraction calculations to determine the minimum resolvable angular separation between two stars. The design must account for this limit to avoid compromising the telescope’s resolution capability.

Q 13. Describe different types of optical sensors and their applications.

Optical sensors are devices that convert light into electrical signals. Several types exist, each with specific applications:

- Charge-Coupled Devices (CCDs): These are highly sensitive sensors used in astronomy, scientific imaging, and high-end cameras. They excel in low-light conditions and offer high dynamic range.

- Complementary Metal-Oxide-Semiconductor (CMOS) sensors: Widely used in digital cameras, smartphones, and many other imaging applications, offering a good balance of sensitivity, speed, and cost-effectiveness.

- Photomultiplier Tubes (PMTs): Extremely sensitive detectors used for measuring very low light levels, often found in scientific instruments and medical applications.

- Photodiodes: Simple and versatile sensors used in a variety of applications, from light meters to optical communication systems. They are less sensitive than CCDs and CMOS sensors but are cheaper and faster.

- Single-Photon Avalanche Diodes (SPADs): Extremely sensitive detectors capable of detecting individual photons. They have applications in high-precision lidar, 3D imaging and quantum optics.

The choice of sensor depends heavily on the application’s specific requirements, considering factors like sensitivity, speed, dynamic range, noise level, and cost. For instance, a high-speed camera for capturing fast events would use a CMOS sensor, while an astronomical telescope might rely on a CCD for its superior low-light sensitivity.

Q 14. How do you design a system for high-speed optical data transmission?

Designing a system for high-speed optical data transmission involves several key considerations, focusing on minimizing signal loss and distortion, and maximizing bandwidth.

Key aspects include:

- Choosing appropriate optical fibers: Single-mode fibers are preferred for long-distance transmission due to their lower dispersion and attenuation compared to multi-mode fibers.

- Minimizing chromatic dispersion: This is achieved using dispersion-compensating fibers or through advanced modulation formats that minimize the impact of dispersion on signal integrity.

- Employing effective modulation techniques: Techniques like coherent optical modulation allow for higher spectral efficiency and thus higher data rates.

- Using optical amplifiers: To compensate for signal loss over long distances, optical amplifiers are essential in long-haul systems.

- Implementing error correction codes: Forward Error Correction (FEC) codes are used to enhance the reliability of data transmission, accounting for unavoidable noise and errors in the transmission channel.

The design process involves careful selection of components and optimization of parameters to balance cost, performance, and distance requirements. Simulation tools are crucial for accurate prediction of system performance, and in-depth analysis of the system’s response to various noise and environmental conditions.

Q 15. What is the role of optical filters in optical design?

Optical filters are essential components in optical design, acting as selective barriers for light. They control which wavelengths of light pass through while blocking others. Think of them as sophisticated sieves for light. This selective transmission allows for:

- Wavelength Selection: Isolating specific wavelengths for applications like fluorescence microscopy (isolating emitted light) or laser systems (filtering out unwanted emissions).

- Reducing Noise: Removing unwanted background light or stray light that can interfere with the signal of interest, improving image quality and signal-to-noise ratio.

- Protection: Shielding sensitive optical components from harmful wavelengths like UV or IR radiation.

- Color Correction: Modifying the spectral distribution of light to achieve desired color balance or contrast.

For example, in a digital camera, a color filter array (CFA) utilizes filters to capture red, green, and blue components separately to reconstruct a full-color image. Another example is the use of bandpass filters in spectroscopy to isolate specific absorption or emission lines for analysis.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with optical testing and metrology techniques.

My experience encompasses a wide range of optical testing and metrology techniques. I’m proficient in both interferometric and non-interferometric methods. Interferometry, like Fizeau or Twyman-Green, allows for precise measurement of surface figure and wavefront aberrations. I’ve used these techniques extensively to characterize optical components such as lenses, mirrors, and prisms, ensuring they meet the specified tolerances. Non-interferometric methods, such as MTF (Modulation Transfer Function) measurements and spot diagrams, provide information about the image quality and performance of the entire optical system. I have a strong background in using specialized software and equipment for these tests and analyzing the results to identify and address any issues. For instance, I’ve used Shack-Hartmann wavefront sensors for dynamic wavefront measurement in adaptive optics systems.

Beyond that, I’ve worked with techniques like scatterometry, to characterize surface roughness, and ellipsometry, for precise measurement of thin film properties. My experience extends to environmental testing to ensure the robustness of optical systems under varying temperature, humidity, and vibration conditions.

Q 17. How do you handle non-sequential ray tracing in optical design?

Non-sequential ray tracing is crucial for simulating complex optical systems where rays may reflect or scatter multiple times before reaching the detector. Unlike sequential ray tracing, which follows a single ray through the optical system in a predetermined order, non-sequential ray tracing tracks the path of each ray independently, allowing for modeling of various scenarios such as scattering from rough surfaces or diffraction effects. I use specialized software packages like Zemax or LightTools to perform these simulations.

The process typically involves defining the geometry of the optical system, including the shapes and materials of each element, and specifying the light source properties. The software then simulates the propagation of numerous rays through the system, recording their interactions with each component and finally generating results such as irradiance maps, spot diagrams, and stray light analysis. For example, I recently used non-sequential ray tracing to model a high-power laser system to optimize the beam delivery and minimize damage caused by reflections inside the system.

Q 18. Explain the principles of free-space optical communication.

Free-space optical communication (FSO) uses light beams to transmit data wirelessly through the atmosphere. It offers high bandwidth and security, as opposed to radio-frequency communication. The fundamental principle lies in modulating a laser beam (typically infrared) with information signals (e.g. using intensity modulation or polarization modulation), transmitting it through the air to a receiver, which then demodulates the signal to recover the data.

Challenges include atmospheric attenuation caused by absorption and scattering, especially from rain, fog, and dust. Turbulence in the atmosphere also causes beam wander and scintillation (intensity fluctuations), affecting signal quality. To mitigate these issues, advanced techniques such as adaptive optics, which compensate for atmospheric distortions, and error correction codes are employed.

FSO systems are ideal for short to medium-range communication where high data rates are needed and fiber optic cable installation is impractical or cost-prohibitive.

Q 19. How do you design an optical system for a specific application (e.g., microscopy, lidar)?

Designing an optical system for a specific application involves a systematic approach. Let’s take microscopy and lidar as examples:

Microscopy: The goal is to create high-resolution images of small objects. This involves selecting appropriate objectives and eyepieces (or detectors for digital microscopes) to achieve the necessary magnification and numerical aperture. Careful consideration must be given to chromatic aberration correction, field curvature, and other aberrations that can degrade image quality. Illumination strategies, such as Köhler illumination, are also crucial for uniform and optimal sample illumination. In fluorescence microscopy, filters are essential for selecting the excitation and emission wavelengths.

Lidar: Here, the focus is on precisely measuring distance and other properties by analyzing the time-of-flight and intensity of reflected laser pulses. The design must consider the laser source’s wavelength, pulse duration, and divergence; the optical receiver’s sensitivity and field of view; and the atmospheric conditions. Careful alignment and beam shaping are vital for accurate range measurements. Furthermore, the signal processing and data analysis techniques employed are just as important as the optical design itself.

In both cases, extensive simulations and modeling using optical design software are integral parts of the design process, followed by prototyping and testing.

Q 20. What are the challenges in designing high-power laser systems?

Designing high-power laser systems presents unique challenges beyond those encountered in low-power systems. Key concerns include:

- Thermal Management: High power lasers generate significant heat, which can lead to thermal lensing (changes in refractive index due to temperature gradients), distortion, and ultimately damage to optical components. Effective cooling strategies are crucial, often involving liquid cooling systems or other advanced techniques.

- Damage Thresholds: Optical components have damage thresholds that limit the maximum power they can handle. Choosing appropriate materials and coatings with high damage thresholds is critical. Careful design to minimize intensity peaks and reflections is equally important.

- Beam Quality: Maintaining a high beam quality (low divergence, smooth wavefront) is essential for efficient beam delivery and focusing. Aberrations in the optical system can degrade beam quality and reduce efficiency.

- Safety: High-power lasers pose significant safety risks. The system must be designed and implemented with appropriate safety measures, including beam enclosures, interlocks, and warning systems.

For instance, designing a high-power laser cutting system needs a sophisticated understanding of beam delivery and focusing optics and attention to the safety protocols to protect the user from the intense radiation.

Q 21. Explain your understanding of polarization in optical systems.

Polarization refers to the orientation of the electric field vector of an electromagnetic wave like light. In optical systems, polarization can significantly impact performance. Light can be linearly polarized (electric field oscillating along a single plane), circularly polarized (electric field vector rotating), or elliptically polarized (a combination of linear and circular).

Understanding polarization is crucial because different optical components interact differently with light depending on its polarization state. For example, polarizing filters only transmit light with a specific polarization orientation. Birefringent materials (like calcite) split a beam into two orthogonally polarized beams. Reflections from surfaces also alter polarization. In optical design, we consider polarization effects to:

- Control light propagation: Using polarizers and waveplates to manipulate polarization state for specific applications.

- Reduce reflections and glare: Employing polarizing filters in cameras and displays.

- Improve image quality: Minimizing polarization-dependent aberrations.

- Enable specific applications: Polarization is critical in areas such as polarimetry, ellipsometry, and optical sensing.

For example, in a liquid crystal display (LCD), polarization is crucial to control the transmission of light, resulting in the image we see. Ignoring polarization can lead to unexpected behavior and reduced system performance.

Q 22. How do you handle thermal effects in optical design?

Thermal effects are a critical consideration in optical design because temperature changes can significantly impact the performance of an optical system. These effects manifest as changes in refractive index, material dimensions, and even lens mounting stresses. To handle these, we employ several strategies.

- Material Selection: Choosing materials with low thermal expansion coefficients (like Zerodur or ULE) minimizes dimensional changes with temperature fluctuations. For instance, in a space-based telescope, where temperature swings are extreme, these materials are crucial.

- Finite Element Analysis (FEA): FEA simulations model the thermal stresses within the system, helping predict how components will deform and impact optical performance. This allows us to optimize the design for thermal stability. We use software like ANSYS to conduct these analyses.

- Compensating Designs: We can incorporate design features that compensate for thermal effects. For example, using bimetallic elements in mounts can counteract expansion, or designing the system with inherent thermal symmetry to minimize distortions.

- Thermal Control Strategies: This could involve active cooling (e.g., thermoelectric coolers) or passive methods (e.g., insulation, thermal shielding) to maintain a stable operating temperature. A common example is using heaters and thermal insulation to maintain the temperature of a sensitive interferometer.

In one project, I designed a laser scanner for outdoor use, where temperature variations were significant. By combining low-expansion materials and FEA modeling, we minimized performance degradation over a wide temperature range, ensuring accurate scanning results across different seasons.

Q 23. Explain your experience with optical material selection.

Optical material selection is crucial for achieving the desired optical performance while considering factors such as cost, availability, and environmental conditions. My experience encompasses a broad range of materials, including glasses (e.g., BK7, fused silica), crystals (e.g., calcium fluoride, zinc selenide), and polymers (e.g., PMMA, polycarbonate).

- Refractive Index: The refractive index is a primary factor determining how light bends when passing through the material. We select materials with appropriate refractive indices to achieve the desired focal length, aberration correction, and overall system performance.

- Dispersion: Dispersion describes how the refractive index varies with wavelength. Managing dispersion is crucial for chromatic aberration correction; selecting materials with low dispersion or combining materials with different dispersions is a key design aspect.

- Transmission Range: The wavelength range over which the material transmits light effectively is a key consideration, particularly for systems operating in specific spectral regions (e.g., UV, visible, IR). Materials like fused silica are highly transmissive in the UV and visible, while zinc selenide excels in the infrared.

- Mechanical Properties: Factors like hardness, strength, and thermal expansion coefficient are vital for ensuring structural integrity and stability. This is especially important in environments with high shock or vibration.

- Cost and Availability: These are often limiting factors. While certain materials may offer superior optical properties, their cost or limited availability might necessitate using alternatives.

For instance, in a project designing an infrared imaging system, choosing zinc selenide was essential because of its high transmittance in the infrared, while its mechanical properties ensured robustness in rugged field conditions. Conversely, in a cost-sensitive application like a simple magnifying glass, using PMMA was a practical choice due to its low cost and ease of manufacturing.

Q 24. Describe different types of optical mounts and their importance.

Optical mounts are critical components that hold optical elements in precise positions, ensuring the system maintains its designed performance. Several types exist, each with specific advantages and disadvantages.

- Kinematic Mounts: These mounts use three points of contact to define the position and orientation of an element, minimizing stress and ensuring stability. They are excellent for applications requiring high precision.

- Flexure Mounts: These use flexible elements to support and position optical elements, offering excellent stability and minimal vibration transfer. They are commonly used in high-precision applications like interferometry.

- Retaining Rings and Cells: These are simpler and less expensive mounts, suitable for less demanding applications where high precision is not paramount. They can be robust but may introduce more stress on the optical element.

- Active Mounts: These incorporate actuators (e.g., piezoelectric transducers) to adjust the position and orientation of optical elements in real-time, compensating for environmental factors or allowing dynamic focusing. These are used in advanced systems requiring precise adjustments.

The choice of mount depends on several factors: the required precision, environmental conditions, cost constraints, and the size and weight of the optical element. For example, a high-precision telescope would likely employ kinematic or flexure mounts, while a simple camera lens might use a less sophisticated retaining ring mount.

Q 25. How do you design an optical system for a specific environmental condition?

Designing an optical system for a specific environmental condition necessitates considering a wide range of factors that can impact performance. These include temperature, pressure, humidity, shock, and vibration.

- Environmental Testing: Rigorous environmental testing is crucial to validate the system’s performance under the intended conditions. We perform tests that simulate expected operating conditions, such as temperature cycling and vibration testing. This often involves using environmental chambers to reproduce these conditions.

- Material Selection: Choosing materials suitable for the operating environment is critical. Materials must withstand anticipated temperature ranges, pressure levels, and other environmental stresses. For example, using a material with high UV resistance in a system exposed to sunlight is essential.

- Sealing and Encapsulation: In harsh conditions, protecting optical elements from moisture, dust, or other contaminants might require hermetic sealing or encapsulation. This could involve using epoxy potting or vacuum sealing.

- Robust Mechanical Design: The mechanical design must ensure the system’s integrity and stability under stress. This involves proper component selection and integration, with consideration of shock and vibration mitigation strategies.

- Compensation Mechanisms: We may incorporate active or passive mechanisms to compensate for environmental variations, such as temperature-compensated lens mounts or active vibration isolation systems.

For a project involving underwater imaging, we designed a pressure-resistant housing and selected materials with high refractive index and water resistance. We also employed precise alignment techniques to account for pressure-induced changes in refractive indices.

Q 26. Explain your experience with optical system assembly and integration.

Optical system assembly and integration require meticulous attention to detail to ensure proper alignment, minimizing stray light, and maximizing performance. My experience involves various techniques and procedures.

- Precision Alignment: Precise alignment of optical elements is crucial to achieve the desired optical performance. This typically involves using precision alignment fixtures and tools such as interferometers and autocollimators.

- Stray Light Control: Minimizing stray light is essential, particularly in high-sensitivity applications. We employ strategies like baffling, light traps, and anti-reflection coatings to reduce stray light.

- Cleanroom Environment: Assembly often takes place in a cleanroom environment to minimize dust and other contaminants that could degrade performance. This is particularly important for high-precision optical systems.

- Testing and Verification: Thorough testing and verification are essential to ensure that the assembled system meets its performance specifications. This might involve measuring focal length, resolving power, and other key performance metrics.

- Integration with Other Systems: Optical systems are often integrated with other subsystems, such as detectors, sensors, and control electronics. Effective integration requires careful planning and coordination.

In a recent project involving a high-resolution imaging spectrometer, I led the assembly and integration of the entire system, ensuring precise alignment of the gratings, lenses, and detectors. This resulted in a system that met all its performance specifications.

Q 27. How do you utilize optimization algorithms in optical design?

Optimization algorithms are indispensable tools in optical design, enabling us to explore a vast design space efficiently and find optimal solutions that satisfy multiple performance requirements simultaneously. Several algorithms are commonly used.

- Damped Least Squares (DLS): A widely used merit function optimizer that balances speed and robustness. It’s effective for minimizing aberrations in optical systems.

- Parametric Optimization: This involves optimizing design parameters, such as radii of curvature, thicknesses, and refractive indices, to achieve desired performance metrics.

- Global Optimization Algorithms: Techniques like genetic algorithms and simulated annealing can explore the design space more thoroughly, potentially finding solutions that are not easily accessible through local optimization methods. These are particularly useful for complex optimization problems.

- Multi-objective Optimization: Algorithms such as NSGA-II (Non-dominated Sorting Genetic Algorithm II) can handle multiple conflicting objectives, such as minimizing aberrations while simultaneously reducing cost or weight. This is critical when balancing multiple design goals.

I frequently utilize Zemax’s optimization capabilities, employing different algorithms based on the specific design problem and constraints. For example, in the design of a compact telephoto lens, I used a combination of DLS and global optimization to minimize aberrations while maintaining a small overall size and weight.

Q 28. Describe your experience with optical manufacturing processes.

Familiarity with optical manufacturing processes is essential for a successful optical designer. This knowledge enables informed design choices, realistic performance predictions, and effective collaboration with manufacturers. My experience includes understanding the capabilities and limitations of various manufacturing techniques.

- Lens Grinding and Polishing: Traditional methods for creating precise lens surfaces, which involves grinding and polishing to achieve the required surface accuracy and shape. This process influences the tolerances I specify in my designs.

- Molding: Cost-effective for mass production of simpler lenses, especially in plastics. This process impacts the precision achievable and the choice of materials.

- Diamond Turning: A precision machining technique used for producing aspheric and freeform surfaces. Its capability to make complex shapes affects design choices.

- Thin Film Coating: Essential for controlling reflectivity and transmission at various wavelengths. Understanding coating processes allows for specifying appropriate coatings to enhance performance.

- Assembly and Testing: Optical component assembly and testing methodologies directly impact the successful realization of a design. Experience with these ensures designs are manufacturable.

For a project involving a large-aperture telescope mirror, I collaborated closely with the manufacturer to select the appropriate polishing techniques and tolerances, ensuring that the final mirror met the stringent surface accuracy requirements. Understanding the manufacturing process allowed me to make design tradeoffs that were both achievable and efficient.

Key Topics to Learn for Optical Design and Analysis Interview

- Geometric Optics: Understanding ray tracing, paraxial approximation, and the fundamental principles of image formation. Practical application: Designing simple lens systems and analyzing their performance.

- Physical Optics: Grasping diffraction, interference, polarization, and their impact on optical system performance. Practical application: Analyzing the limitations of optical systems and improving image quality.

- Optical Aberrations: Familiarize yourself with different types of aberrations (spherical, chromatic, coma, astigmatism, etc.), their causes, and correction techniques. Practical application: Optimizing lens designs to minimize aberrations.

- Optical Design Software: Demonstrate proficiency with industry-standard software like Zemax, Code V, or similar. Practical application: Modeling and simulating optical systems, optimizing designs, and performing tolerance analysis.

- Optical Materials: Understand the properties of various optical materials (glass, polymers, crystals) and their selection criteria for specific applications. Practical application: Choosing appropriate materials for different optical components to optimize performance.

- Optical Tolerancing and Manufacturing: Knowledge of manufacturing processes and their impact on optical system performance. Practical application: Defining realistic tolerances for optical components and assemblies.

- Optical Testing and Measurement: Familiarize yourself with common optical testing methods and instrumentation. Practical application: Evaluating the performance of optical systems and identifying sources of error.

- Non-imaging Optics: Understanding the principles and applications of non-imaging optics, such as concentrators and light pipes. Practical application: Designing efficient illumination systems.

Next Steps

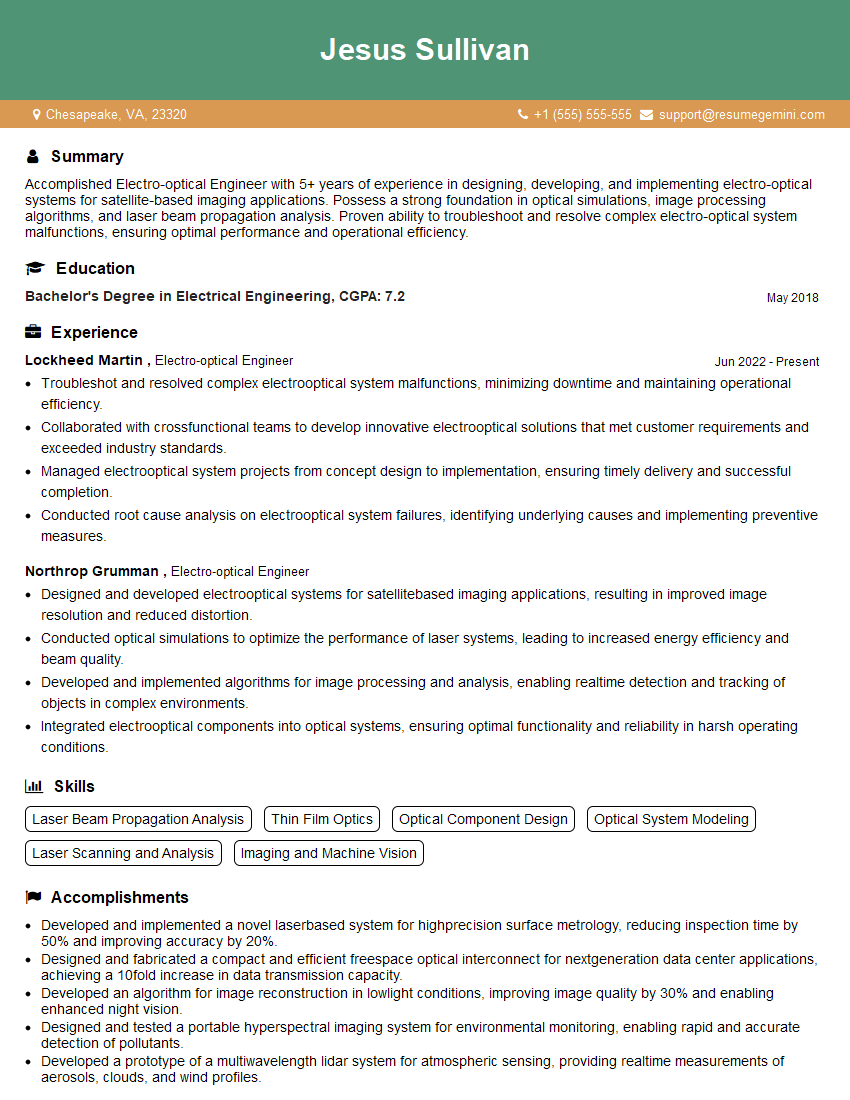

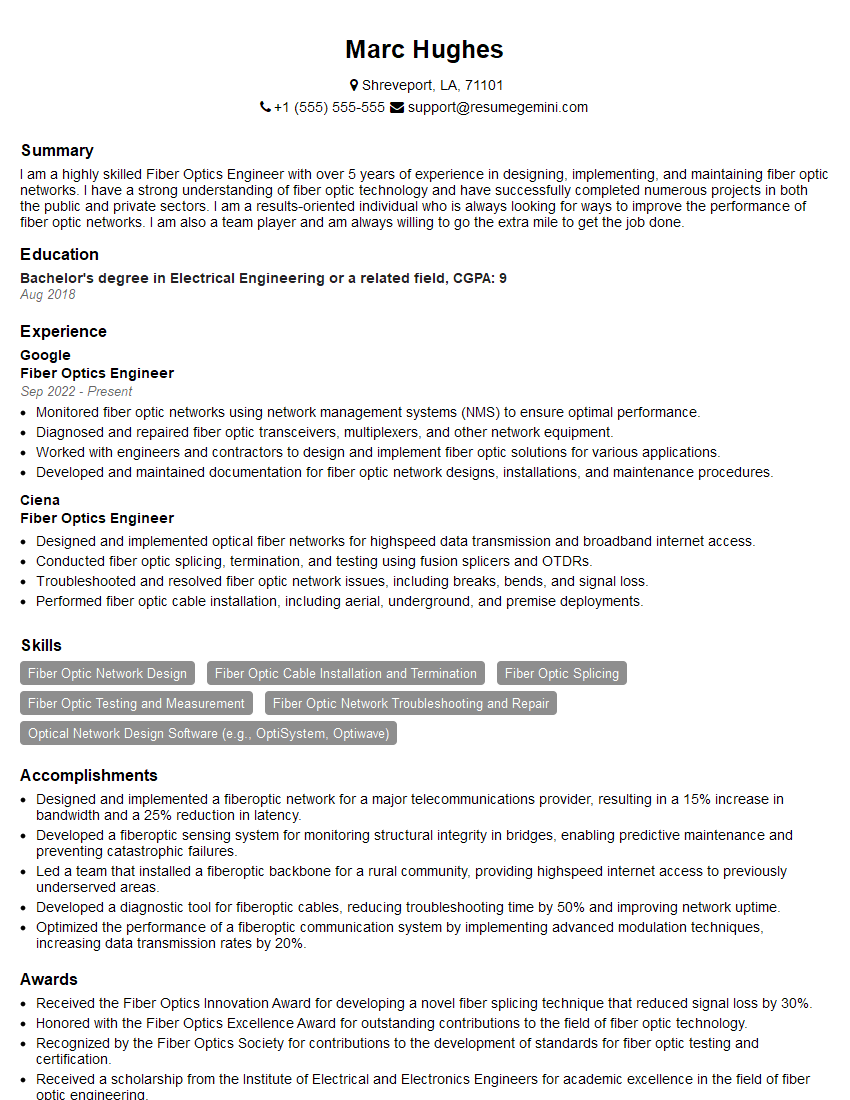

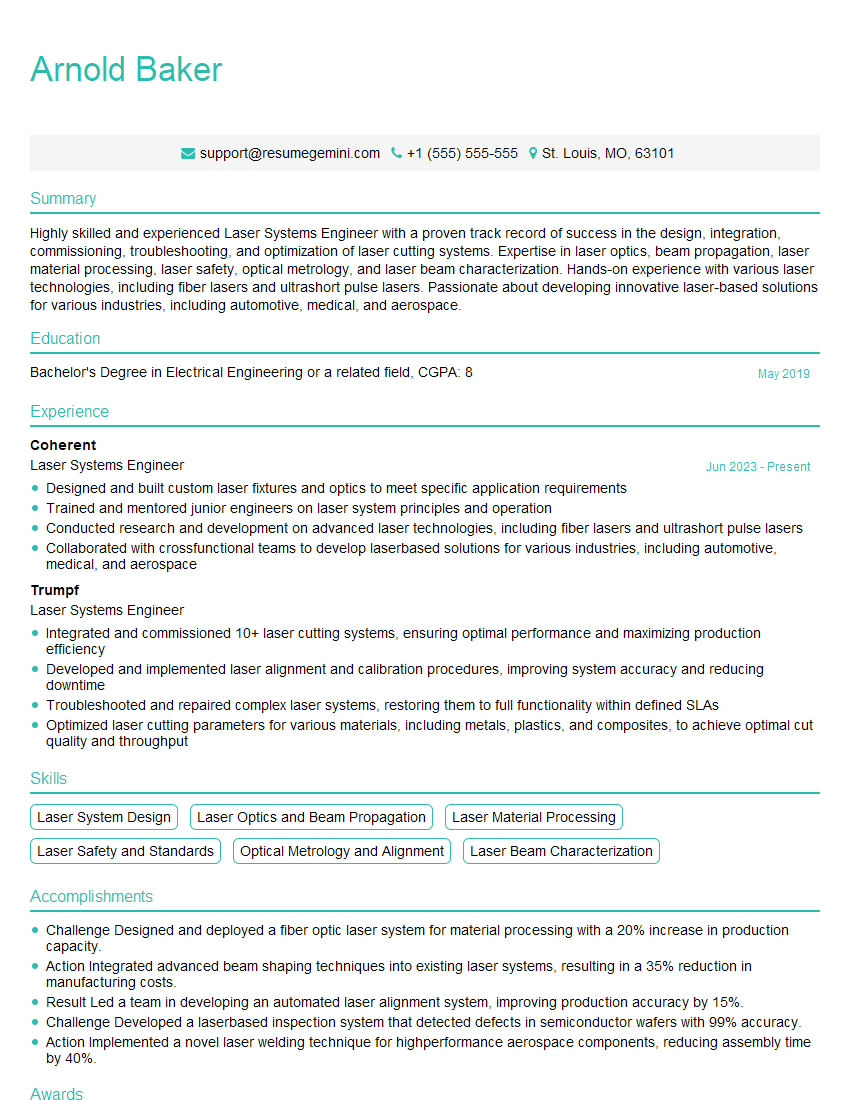

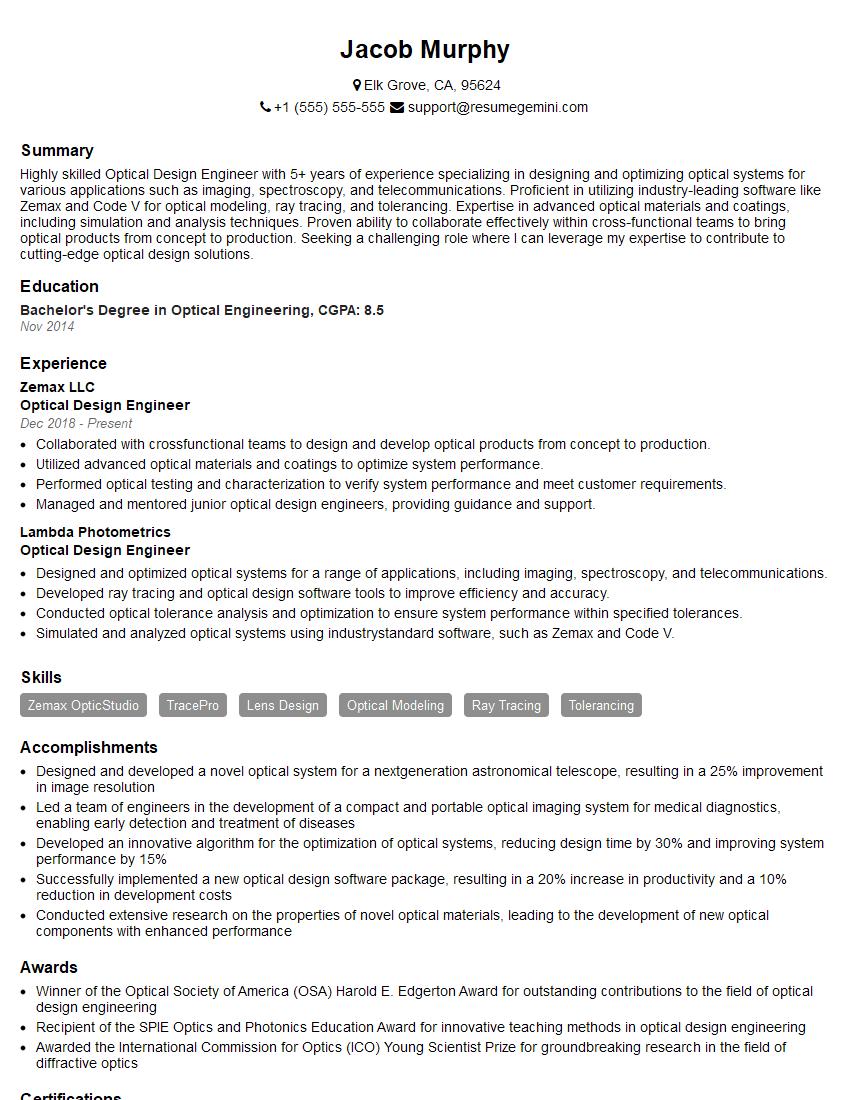

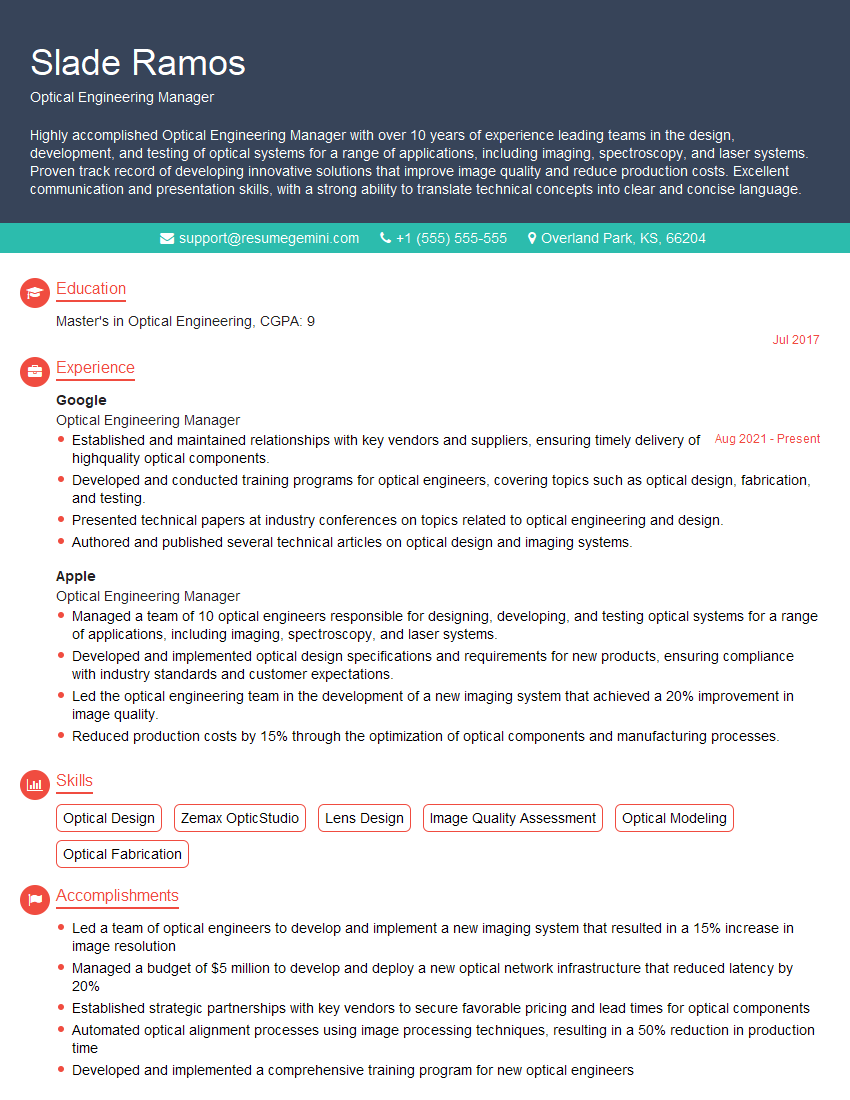

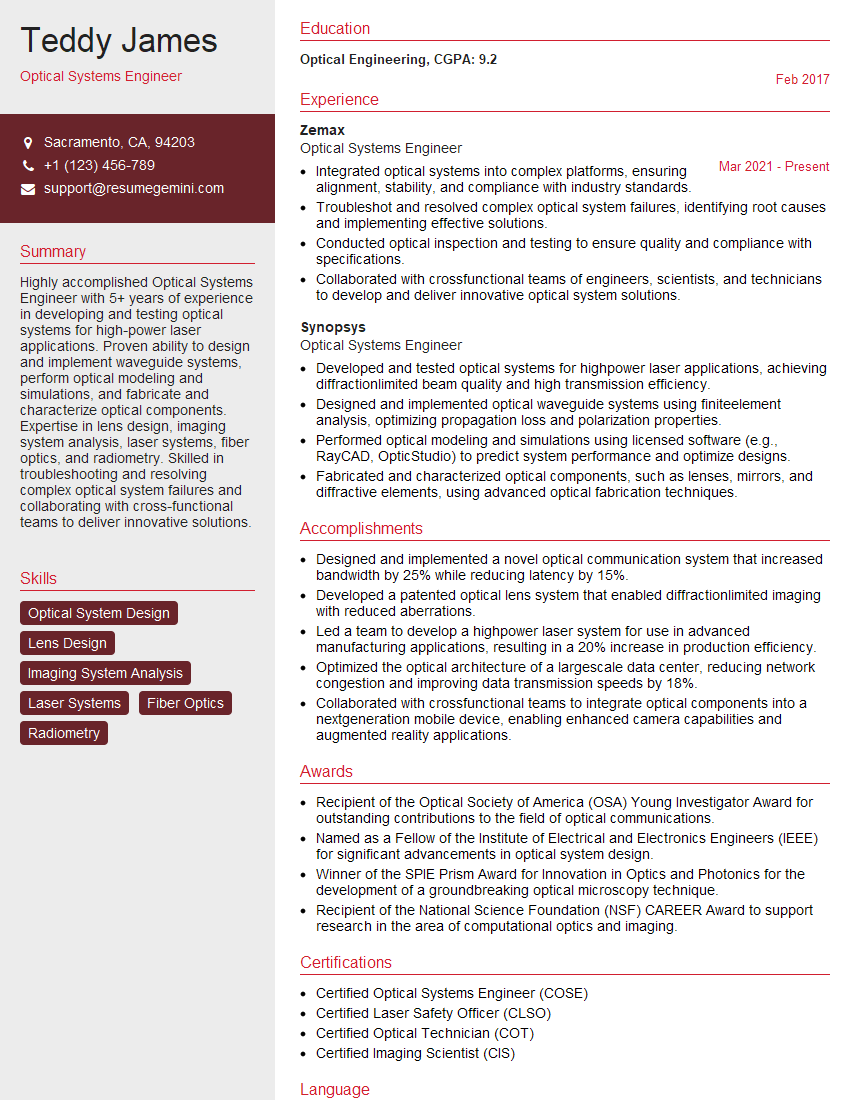

Mastering Optical Design and Analysis opens doors to exciting and rewarding careers in diverse fields, from medical imaging to telecommunications. A strong foundation in these areas is crucial for career advancement and securing your dream role. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of Optical Design and Analysis roles. Examples of resumes specifically designed for this field are available to guide you. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good