Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top OSHA Compliance Management interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in OSHA Compliance Management Interview

Q 1. Describe your experience with OSHA regulations, specifically 1910 and 1926.

My experience with OSHA regulations 1910 (General Industry) and 1926 (Construction) spans over a decade, encompassing both compliance management and practical application in diverse settings. I’ve worked with companies ranging from small manufacturing plants to large construction projects, ensuring adherence to a wide array of standards. I’m intimately familiar with the nuances of these regulations, understanding that 1910 covers a broad spectrum of workplace hazards, such as electrical safety, hazardous materials handling, and machine guarding, while 1926 specifically addresses construction-related risks, like fall protection, trenching and excavation, and scaffolding. This deep understanding allows me to tailor compliance strategies to the specific industry and operational complexities of each client.

For example, in one project involving a manufacturing facility, I identified a critical gap in their lockout/tagout procedures, a crucial aspect of 1910. We developed a comprehensive training program and revised their procedures to meet OSHA standards, significantly reducing the risk of employee injury from hazardous energy. In another project within the construction industry, we implemented a rigorous fall protection program adhering to 1926 standards, resulting in zero fall-related accidents throughout the project lifecycle.

Q 2. Explain the process of conducting a workplace safety audit.

Conducting a workplace safety audit is a systematic process designed to identify existing and potential hazards. It involves a thorough review of all workplace aspects, comparing practices to relevant OSHA standards and industry best practices. The process typically follows these steps:

- Planning: Defining the scope, objectives, and timeline of the audit, identifying areas requiring special attention based on risk assessment.

- Documentation Review: Examining safety manuals, training records, incident reports, and other relevant documents to identify compliance gaps.

- On-site Inspection: Physically inspecting the workplace to observe work practices, equipment condition, and the general work environment. This involves walkthroughs, interviews with employees, and observations of work processes.

- Hazard Identification: Documenting all identified hazards, including their severity and potential consequences.

- Reporting and Recommendations: Preparing a comprehensive report detailing findings, including both positive aspects and areas needing improvement. This report should provide clear recommendations for corrective actions.

- Follow-up: Verifying that corrective actions have been implemented and are effective. This often involves a follow-up audit.

For instance, during a recent audit of a warehouse, the inspection revealed inadequate aisle space and poor forklift operation, leading to a recommendation for improved traffic management and additional forklift operator training.

Q 3. How do you identify and mitigate workplace hazards?

Hazard identification and mitigation is a continuous process that starts with proactive hazard recognition, followed by implementing controls to eliminate or reduce risks. My approach involves a hierarchical control strategy:

- Elimination: Removing the hazard entirely, the most effective method (e.g., replacing a hazardous chemical with a safer alternative).

- Substitution: Replacing the hazard with a less hazardous alternative (e.g., using a less powerful solvent).

- Engineering Controls: Implementing physical changes to the workplace to reduce risk (e.g., installing machine guards, improving ventilation).

- Administrative Controls: Implementing changes in work procedures or practices (e.g., job rotation, implementing work permits).

- Personal Protective Equipment (PPE): Providing workers with appropriate PPE as a last resort, always after engineering and administrative controls (e.g., safety glasses, gloves).

Imagine a scenario where employees frequently handle heavy boxes. Elimination might not be feasible, but we can substitute manual lifting with a forklift, implement engineering controls like ergonomic workstations, and use administrative controls like job rotation and proper lifting techniques. PPE, such as back supports, would be used as a final layer of protection.

Q 4. What are your methods for developing and implementing safety training programs?

Developing and implementing effective safety training programs requires a needs assessment, focusing on the specific hazards present in the workplace and the employees’ knowledge and skills gaps. My approach involves these key steps:

- Needs Assessment: Identifying training needs by analyzing job descriptions, reviewing incident reports, and conducting employee surveys.

- Curriculum Development: Creating a training curriculum that is engaging, informative, and relevant to the specific hazards and tasks performed by employees. It includes practical demonstrations, interactive sessions, and real-world examples.

- Training Delivery: Utilizing a variety of training methods, including classroom instruction, online modules, and on-the-job training, catering to different learning styles.

- Evaluation and Documentation: Assessing the effectiveness of the training through pre- and post-tests, observation of practical skills, and ongoing performance monitoring. Meticulous record-keeping is essential for demonstrating compliance.

For example, a training program for forklift operators would include classroom instruction on safe operation procedures, hands-on training in a controlled environment, and regular refresher courses to maintain proficiency. Post-training evaluations ensure continued compliance with safety standards.

Q 5. How do you ensure employee compliance with safety regulations?

Ensuring employee compliance hinges on a combination of strategies, starting with a strong safety culture. This involves fostering open communication, actively encouraging employee participation, and providing clear expectations and consequences for non-compliance.

- Leading by Example: Management must actively demonstrate their commitment to safety.

- Clear Communication: Ensuring employees clearly understand safety rules, procedures, and expectations.

- Incentive Programs: Implementing recognition and reward systems for safe work practices.

- Consistent Enforcement: Consistently enforcing safety rules and addressing violations promptly and fairly, including disciplinary action when necessary.

- Regular Audits and Inspections: Conducting frequent workplace safety audits and inspections to identify potential hazards and ensure compliance.

A successful approach involves building a culture where safety is a shared value, not just a set of rules. Open communication and feedback mechanisms ensure that employees feel empowered to raise concerns and participate actively in maintaining a safe work environment.

Q 6. Describe your experience with incident investigation and reporting.

Incident investigation and reporting are crucial for identifying root causes of accidents and preventing future occurrences. My approach follows a structured process:

- Immediate Response: Securing the scene, providing necessary medical attention, and notifying relevant authorities.

- Data Collection: Gathering comprehensive information through witness interviews, reviewing documents, and taking photographs or videos.

- Root Cause Analysis: Identifying the underlying causes of the incident using techniques like the “5 Whys” or fault tree analysis to understand contributing factors.

- Corrective Action Planning: Developing and implementing corrective actions to eliminate hazards and prevent recurrence.

- Reporting: Completing thorough incident reports for OSHA and internal documentation, ensuring accurate and timely reporting.

During a recent incident investigation, we identified a failure in the machine’s safety mechanism as the primary cause of an injury. This led to a comprehensive review of our maintenance procedures, resulting in improved preventative maintenance schedules and enhanced safety protocols to mitigate similar incidents.

Q 7. How do you manage and track OSHA compliance data?

Managing and tracking OSHA compliance data effectively requires a robust system that allows for efficient data collection, analysis, and reporting. This can involve using a dedicated software solution or a combination of software and spreadsheets.

- Data Collection: Gathering data from various sources, including training records, incident reports, inspection findings, and corrective action logs.

- Data Analysis: Regularly analyzing data to identify trends, patterns, and areas of concern.

- Reporting: Generating reports for management, OSHA, and other stakeholders, ensuring data accuracy and integrity.

- Software Utilization: Employing dedicated EHS (Environmental, Health, and Safety) software to streamline data management, analysis, and reporting.

Utilizing a dedicated software, for example, allows for the automation of many tasks, including generating reports, tracking compliance deadlines, and issuing alerts for potential hazards. This minimizes the risk of overlooking critical compliance issues and allows for proactive risk mitigation.

Q 8. What is your experience with OSHA recordkeeping requirements (Form 300, 300A, 301)?

OSHA recordkeeping (Forms 300, 300A, and 301) is crucial for tracking workplace injuries and illnesses. Form 300 is the Log of Work-Related Injuries and Illnesses, a summary of all recordable cases throughout the year. Form 300A is the Summary of Work-Related Injuries and Illnesses, a yearly summary posted for employee review. Form 301 is the Injury and Illness Incident Report, detailing individual incidents. My experience encompasses the complete cycle: identifying recordable cases based on OSHA’s criteria (e.g., days away from work, restricted work, medical treatment beyond first aid), accurately completing all forms, ensuring data integrity, maintaining confidentiality, and properly archiving records for the required five years. In one instance, I helped a client who was misclassifying certain incidents, leading to an inaccurate recordkeeping. By implementing a comprehensive training program on OSHA’s recordkeeping guidelines and providing practical examples, we corrected this and avoided potential penalties.

I’m proficient in both manual and electronic recordkeeping methods, understanding the nuances of OSHA’s requirements for different sized employers and industry sectors. I understand the importance of proper recordkeeping to avoid fines, and also to identify trends and patterns in workplace injuries, allowing for proactive safety improvements.

Q 9. Explain your understanding of OSHA’s General Duty Clause.

OSHA’s General Duty Clause, found in Section 5(a)(1) of the OSH Act, is a fundamental provision. It mandates that employers provide a workplace ‘free from recognized hazards that are causing or are likely to cause death or serious physical harm.’ This is a catch-all clause, meaning it applies to hazards not specifically addressed by other OSHA standards. It’s crucial because it holds employers accountable even when a specific regulation doesn’t exist for a particular hazard. For example, if a new piece of machinery poses an unforeseen risk, the General Duty Clause would still hold the employer responsible for mitigating that risk.

To demonstrate compliance, an employer must show they have a safety program in place that identifies hazards, assesses their risk level, implements effective controls, and trains employees. Think of it as a ‘reasonable person’ standard; what would a reasonable person do to protect workers from serious harm? Failing to meet this standard can lead to significant penalties.

Q 10. How would you handle a workplace injury or illness?

Handling a workplace injury or illness requires a swift and methodical approach. My process begins with immediate first aid and emergency response, if needed. Then, I would:

- Isolate the hazard: Prevent further injuries by securing the area.

- Call for medical attention: Contact emergency services or the company’s medical provider as necessary.

- Complete incident report (Form 301): Gather information about the event, including witness statements, to understand the root cause.

- Initiate investigation: Determine the contributing factors, whether it was a lack of training, faulty equipment, or unsafe work practices.

- Implement corrective actions: Develop solutions to prevent similar incidents in the future, this might involve new training, updated safety procedures, or equipment modifications.

- Recordkeeping: Accurately record the incident on OSHA Form 300, 300A, and 301, as applicable.

- Follow-up: Check on the injured employee’s recovery and provide support.

I would also ensure compliance with all reporting requirements to OSHA, depending on the severity of the injury.

Q 11. Describe your experience with developing and implementing safety policies and procedures.

I have extensive experience in developing and implementing comprehensive safety policies and procedures. My approach starts with a thorough hazard assessment using methods like Job Safety Analyses (JSAs) and walkthroughs. This helps identify potential hazards and assess their risks. I then translate these findings into clear, concise, and easily understandable policies and procedures, often with visual aids and checklists. These documents are reviewed and updated regularly to reflect evolving hazards and best practices.

Beyond creating the documents, I focus on employee training and engagement. Training sessions are interactive, incorporating hands-on exercises and real-world scenarios. Regular audits and inspections ensure that the policies and procedures are followed consistently, and I use data from these audits to identify areas for improvement.

For example, I helped a manufacturing plant reduce workplace accidents by 30% within a year by implementing a new safety program focused on proper machine guarding and lockout/tagout procedures, coupled with intensive employee training. This included incorporating interactive simulations and regular competency testing.

Q 12. How do you stay updated on changes to OSHA regulations?

Staying updated on OSHA changes is vital for maintaining compliance. I utilize several methods:

- OSHA Website: Regularly check the OSHA website for updates, new standards, and enforcement directives.

- Professional Organizations: Membership in organizations like the ASSE (American Society of Safety Professionals) provides access to webinars, conferences, and publications on current issues.

- Newsletters and Alerts: Subscribing to industry newsletters and alerts ensures timely notification of regulatory changes.

- Training Courses: Participating in continuing education and training courses on OSHA compliance keeps my knowledge current.

This multi-faceted approach ensures I remain abreast of all relevant changes in a timely manner.

Q 13. What is your experience with lockout/tagout procedures?

Lockout/Tagout (LOTO) procedures are critical for preventing accidental energy releases during maintenance and repair activities. My experience encompasses developing and implementing comprehensive LOTO programs. This includes conducting thorough energy source identification, establishing procedures for controlling hazardous energy, providing detailed training to employees on the proper use of lockout devices, conducting regular inspections of LOTO equipment, and maintaining a detailed LOTO log.

I’m familiar with the nuances of the OSHA standard (1910.147), understanding the various types of energy sources and control methods, and the importance of involving authorized and affected employees in the LOTO process. In a previous role, I helped a company improve their LOTO program significantly by implementing a standardized checklist and conducting regular audits, resulting in a reduction in near misses and potential accidents.

Q 14. How do you manage employee safety concerns and complaints?

Managing employee safety concerns and complaints is essential for a safe and productive work environment. My approach involves creating a system where employees feel comfortable reporting concerns without fear of retaliation. This starts with establishing a clear and accessible reporting mechanism, which could include suggestion boxes, online reporting systems, or regular safety meetings.

Once a concern is raised, I promptly investigate it, assess the potential hazard, and take appropriate corrective actions. This might involve implementing new safety measures, retraining employees, or modifying equipment. It is crucial to communicate the results of the investigation and implemented actions back to the employee who reported the concern, demonstrating that their voice is heard and valued. Maintaining open communication and creating a culture of safety is vital for fostering a positive and safe work environment.

Q 15. Describe your experience with hazard communication programs (SDS, labels).

Hazard Communication programs are crucial for ensuring employee safety by providing clear and accessible information about hazardous materials in the workplace. This involves two key components: Safety Data Sheets (SDSs) and labels. SDSs are comprehensive documents containing detailed information about a chemical’s properties, hazards, safe handling procedures, and emergency response measures. Labels, on the other hand, provide concise summaries of hazards and safety precautions directly on the product container. My experience encompasses developing and implementing comprehensive hazard communication programs, ensuring SDSs are readily available, translated as needed, and that all containers are properly labeled in accordance with OSHA’s requirements. For example, in a previous role, I oversaw the update of our entire chemical inventory, ensuring proper SDS creation and distribution, and implemented a training program to educate employees on understanding and interpreting SDS information. I also conducted regular audits to verify the accuracy and accessibility of SDSs and labels, ensuring compliance.

In one instance, a new chemical was introduced, and I had to collaborate with procurement and engineering to ensure that SDSs were readily available before the chemical was put into use. This process included verification of the SDS accuracy and content in accordance to OSHA’s Globally Harmonized System (GHS) requirements, and the design and printing of appropriate labels.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you conduct job hazard analyses (JHAs)?

A Job Hazard Analysis (JHA) is a systematic process to identify and control workplace hazards before they cause injury or illness. My approach involves a structured, team-based process. First, we select the job to be analyzed. Next, we break down the job into smaller, sequential steps. We then identify potential hazards associated with each step, considering factors like machinery, chemicals, work environment, and human factors. We then evaluate the risks associated with each hazard, considering the severity and likelihood of an incident. Finally, we develop and implement controls to mitigate or eliminate these hazards, using the Hierarchy of Controls (elimination, substitution, engineering controls, administrative controls, PPE). For example, if we are analyzing a task involving operating a forklift, hazards might include collisions, falls, and equipment malfunctions. Controls would involve safety training, implementing vehicle speed limits, and routine equipment inspections.

The JHA process is documented thoroughly, making it a living document that is updated when job procedures change or new hazards are identified. This ensures continuous improvement of safety measures and a proactive approach to hazard management.

Q 17. What is your experience with personal protective equipment (PPE) selection and use?

Selecting and using appropriate Personal Protective Equipment (PPE) is critical for employee safety. My experience includes selecting PPE based on the hazards identified in JHAs and other risk assessments. This requires understanding the different types of PPE, their limitations, and their appropriate application. For example, selecting the right type of respirator depends on the specific airborne contaminants present. Similarly, the selection of gloves varies depending on the chemical being handled. I also ensure that employees are properly trained on how to select, use, inspect, maintain, and store their PPE. Proper fit testing for respirators is paramount, and ensuring PPE is appropriately cleaned and stored are also critical components.

Furthermore, I have experience in managing PPE inventory, ensuring sufficient supply and appropriate disposal methods are in place for contaminated PPE. In a past role, I implemented a program to improve PPE compliance. This involved a combination of education, improved access to PPE, and regular audits to ensure PPE was being used correctly.

Q 18. Explain your understanding of emergency response planning.

Emergency response planning is about preparing for and responding effectively to workplace emergencies. A robust plan includes identifying potential emergencies (fires, chemical spills, medical emergencies), assigning roles and responsibilities, establishing communication procedures, and outlining evacuation routes and assembly points. Regular training drills, including both scenario-based exercises and hands-on training, are crucial for plan effectiveness. The plan must also include post-incident procedures, including investigation, reporting, and corrective actions to prevent future incidents.

Furthermore, emergency response planning needs to be integrated with other safety programs, such as hazard communication and the use of PPE. For example, the emergency response plan should clearly outline procedures for responding to a chemical spill, including containment, cleanup, and notification. The plan should also identify who is responsible for communicating with emergency services and other relevant stakeholders. The effectiveness of the plan is regularly reviewed and updated to address emerging hazards and changing circumstances.

Q 19. How would you handle a situation where an employee refuses to comply with safety regulations?

An employee’s refusal to comply with safety regulations is a serious issue that requires a careful and measured response. My approach involves a multi-step process starting with a conversation to understand the reasons for non-compliance. It could be due to a lack of understanding, discomfort with the equipment, or other concerns. Addressing any misconceptions or concerns is the first step. The next step is to reinforce the importance of compliance using clear explanations of the relevant regulations and the potential consequences of non-compliance, both to the employee and their co-workers.

If the conversation does not resolve the issue, I would consult with HR and management. A disciplinary process may be necessary, following company policy and legal requirements. Documentation of the entire process, including the conversations, warnings, and corrective actions taken, is crucial. This ensures a clear record and protects both the employee and the company. The goal is always to ensure a safe workplace for everyone, but sometimes disciplinary measures are needed to maintain safety.

Q 20. Describe your experience with OSHA inspections and citations.

I have significant experience with OSHA inspections and citations. This includes preparing for inspections by ensuring all safety records, training records, and safety programs are up-to-date and easily accessible. During an inspection, I actively participate, providing clear and concise answers to the inspector’s questions, and facilitating access to needed documents. If a citation is issued, I work closely with management to address the violations promptly and effectively, implementing corrective actions and developing a plan to prevent future occurrences. This process involves investigating the root cause of the violation, developing corrective actions, implementing those actions, and verifying their effectiveness.

I also have experience in contesting citations when appropriate, using data and documentation to support our arguments. The goal is always to learn from any mistakes, ensuring continual improvement of the workplace safety management system. Effective communication with OSHA is essential and I strive to develop a positive, collaborative relationship with inspectors, focusing on safety improvement rather than conflict.

Q 21. How do you utilize data to improve workplace safety performance?

Data plays a crucial role in improving workplace safety performance. I utilize various data sources, such as incident reports, near-miss reports, inspection findings, and employee training records, to identify trends and patterns in workplace hazards and incidents. This data is then analyzed to pinpoint areas needing immediate attention and to create proactive strategies to prevent future incidents. For example, if incident reports show a high number of slips and falls in a particular area, the data would support further investigations into the causes, leading to actions such as improved housekeeping or the installation of better lighting.

Key performance indicators (KPIs) such as incident rates, days away from work, and lost time incident rates are regularly monitored and tracked to measure the effectiveness of safety programs. This data is also used to demonstrate the return on investment (ROI) of safety initiatives and to inform future safety improvement strategies. Data visualization tools are used to communicate findings clearly and effectively to all stakeholders, fostering a data-driven culture of safety.

Q 22. What is your experience with safety committees or employee involvement programs?

Throughout my career, I’ve been deeply involved in establishing and managing safety committees and fostering robust employee involvement programs. I believe a successful safety culture is built from the ground up, with employees actively participating in identifying and mitigating hazards.

In my previous role at Acme Manufacturing, I spearheaded the creation of a Joint Safety Committee comprised of management and hourly workers. This committee met bi-weekly to discuss safety concerns, review incident reports, and brainstorm solutions. We implemented a suggestion box system, and employees were empowered to report hazards without fear of reprisal. This led to a significant reduction in near-miss incidents and a marked improvement in employee morale. Another example was at Beta Corp, where I initiated a peer-to-peer safety observation program. Employees were trained to identify and report unsafe behaviors, fostering a sense of collective responsibility. This program proved particularly effective in addressing repetitive strain injuries and ergonomic issues.

I firmly believe that effective communication, active listening, and a commitment to employee empowerment are crucial to the success of any safety committee or employee involvement program. These programs are not just about compliance; they’re about creating a workplace where everyone feels valued, respected, and safe.

Q 23. Explain your understanding of the different types of OSHA violations.

OSHA categorizes violations into several types, each carrying different penalties and reflecting the severity of the hazard.

- Willful: This is the most serious, indicating intentional disregard for OSHA standards. For example, knowingly operating machinery without proper guarding constitutes a willful violation. Penalties are significantly higher for willful violations.

- Serious: A serious violation presents a substantial probability of death or serious physical harm. This might include failing to provide adequate fall protection at heights.

- Other-Than-Serious: These violations affect employees’ safety or health, but don’t pose a high probability of serious harm. Examples could be incomplete record-keeping or minor deficiencies in safety training materials.

- Repeated: This occurs when an employer has been cited for the same or a similar violation previously. This indicates a failure to correct identified hazards, indicating a systemic problem.

- Failure to Abate: This occurs when an employer fails to correct a previous violation within the prescribed timeframe.

Understanding these distinctions is critical for effective OSHA compliance. It allows for targeted corrective actions and helps prioritize resources to address the most significant hazards first. A thorough understanding ensures we can develop and implement comprehensive safety programs that go beyond simple compliance to foster a true safety culture.

Q 24. How do you prioritize safety initiatives in a resource-constrained environment?

Prioritizing safety initiatives in a resource-constrained environment requires a strategic approach that balances cost-effectiveness with risk reduction. I utilize a risk-based prioritization framework. This approach focuses on:

- Hazard Identification and Risk Assessment: Conducting thorough assessments, identifying high-risk hazards and prioritizing them based on the likelihood and severity of potential incidents. A simple risk matrix helps visualize this.

- Cost-Benefit Analysis: Evaluating the cost of implementing control measures versus the potential cost of not implementing them (lost time, medical expenses, fines). Focusing on cost-effective controls, such as improved training or administrative changes, before moving to more costly engineering controls.

- Phased Implementation: Breaking down large-scale initiatives into smaller, manageable phases. This enables addressing the most critical hazards first while still making progress on other issues.

- Data-Driven Decisions: Utilizing safety data to inform resource allocation. Prioritize areas where incidents are most frequent or where the potential for harm is greatest.

- Collaboration and Communication: Working closely with management and employees to identify creative and cost-effective solutions. Often, employees offer valuable insights based on their hands-on experience.

For instance, rather than immediately investing in expensive new equipment, a more affordable solution might be to implement improved procedures, better training, or redesigning work processes to mitigate the risk. This phased approach is vital in ensuring the most critical safety issues are addressed within the available budget.

Q 25. What is your experience with developing and delivering safety presentations?

I have extensive experience developing and delivering engaging safety presentations tailored to various audiences. My approach focuses on clear communication, interactive elements, and practical applications.

I begin by thoroughly researching the topic, identifying key concepts, and tailoring the content to the specific needs and knowledge level of the audience. I avoid technical jargon and utilize simple language, visual aids, and real-world examples to make complex information easily understandable. For instance, when discussing lockout/tagout procedures, I might use a hands-on demonstration rather than just explaining it theoretically. I incorporate interactive elements such as quizzes, group discussions, and case studies to keep the audience engaged and promote active learning.

In the past, I’ve developed and delivered presentations on topics ranging from hazard communication and personal protective equipment to confined space entry and emergency response. My presentations consistently receive positive feedback, indicating their effectiveness in improving employee understanding and adherence to safety procedures.

Q 26. Describe your proficiency with OSHA software or databases.

I’m proficient in several OSHA-related software and databases. My experience includes using OSHA’s online resources, including the OSHA website and the eTools. I’ve utilized software such as [Mention specific software – e.g., Safety Management Software, Incident Reporting Systems] to manage incident investigations, track safety training records, and generate safety reports.

Furthermore, my expertise extends to utilizing data analytics to analyze safety data. This includes identifying trends, highlighting areas needing improvement, and measuring the effectiveness of safety initiatives. I can extract, clean, and analyze data from various sources to generate reports and visualizations used for management decision-making. I’m familiar with database management concepts like data normalization and relational database design, enhancing my ability to create efficient and insightful safety data management systems.

Q 27. How would you measure the effectiveness of your safety program?

Measuring the effectiveness of a safety program requires a multi-faceted approach that goes beyond simply tracking incident rates. I utilize a combination of leading and lagging indicators.

- Lagging Indicators: These reflect past performance. They include metrics like:

- Total Recordable Incident Rate (TRIR)

- Lost Time Injury Rate (LTIR)

- Days Away, Restricted, or Transferred (DART) rate

- Number of OSHA citations

- Leading Indicators: These predict future performance. Examples include:

- Number of safety training hours completed

- Employee participation in safety meetings

- Number of safety observations conducted

- Number of near-miss reports submitted

- Safety audit scores

By tracking both leading and lagging indicators, we can gain a comprehensive understanding of the program’s effectiveness. A decrease in lagging indicators (e.g., TRIR) combined with improvements in leading indicators (e.g., employee safety training participation) shows a strong and effective safety program. Regular reviews of these metrics are essential to identify areas needing improvement and to demonstrate continuous improvement in the workplace safety program.

Key Topics to Learn for Your OSHA Compliance Management Interview

- OSHA Regulations & Standards: Understand the core OSHA standards relevant to your target industry. Focus on interpreting and applying these regulations in practical scenarios.

- Hazard Identification & Risk Assessment: Master the process of identifying workplace hazards, conducting thorough risk assessments, and developing effective control measures. Practice applying different assessment methodologies.

- Incident Investigation & Reporting: Learn the steps involved in conducting thorough incident investigations, including root cause analysis. Familiarize yourself with OSHA’s reporting requirements and documentation best practices.

- Emergency Action Plans & Preparedness: Understand the components of a comprehensive emergency action plan and how to ensure its effectiveness. Be prepared to discuss evacuation procedures, emergency response protocols, and employee training.

- OSHA Inspections & Compliance Audits: Know the process of an OSHA inspection and how to prepare for one. Understand how to respond to citations and develop corrective actions.

- Employee Training & Communication: Explore effective methods for training employees on safety procedures and regulations. Discuss strategies for fostering a strong safety culture and promoting open communication.

- Recordkeeping & Documentation: Understand OSHA’s recordkeeping requirements and how to maintain accurate and complete documentation. Be prepared to discuss best practices for data management and reporting.

- Safety Program Development & Implementation: Showcase your ability to design, implement, and manage a comprehensive OSHA compliance program tailored to specific workplace needs. This includes budgeting, resource allocation, and performance monitoring.

- Specific Industry Regulations (if applicable): Depending on your target role, delve into the OSHA standards specific to your industry (e.g., construction, manufacturing, healthcare). Demonstrate your in-depth knowledge of these regulations.

Next Steps

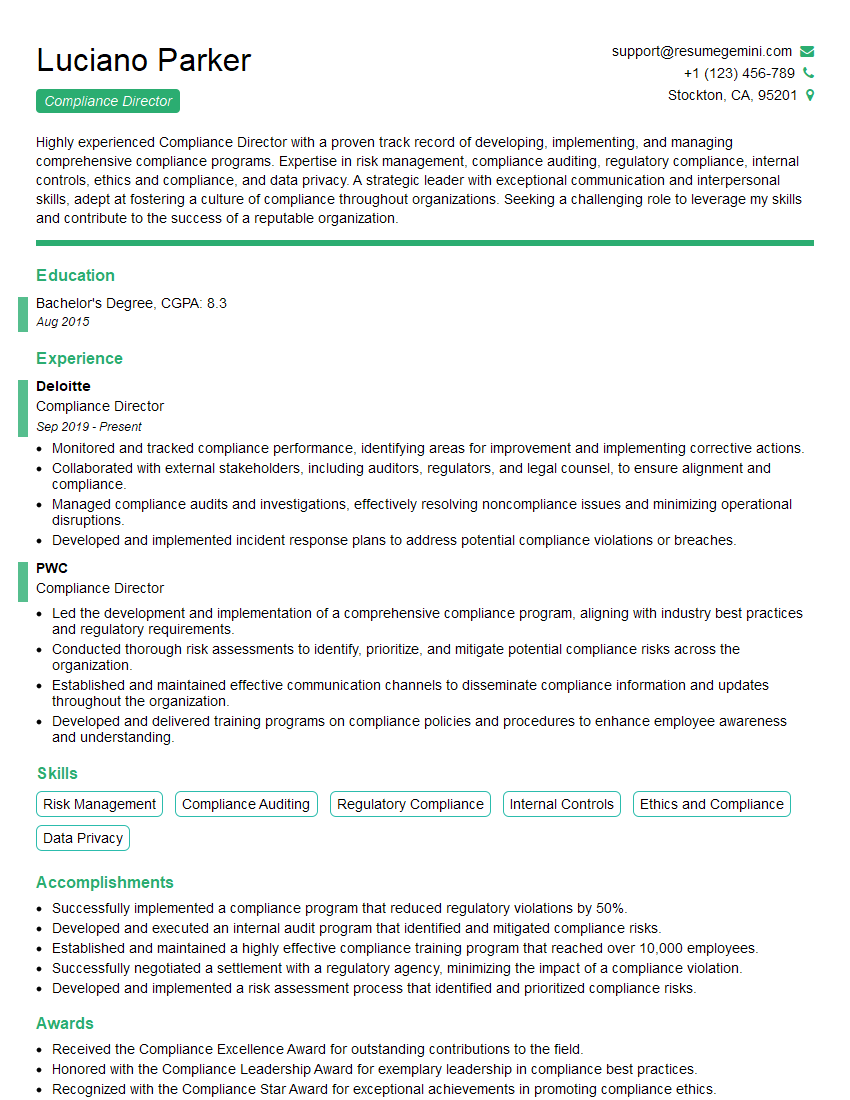

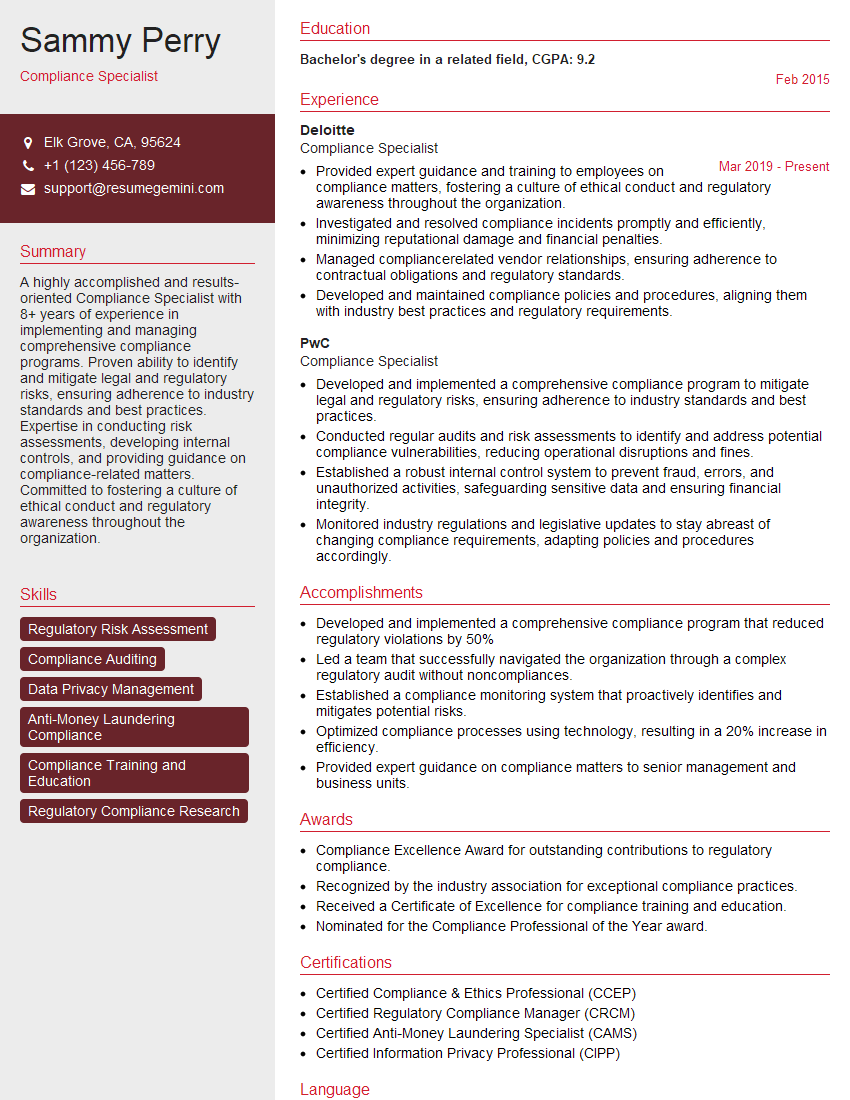

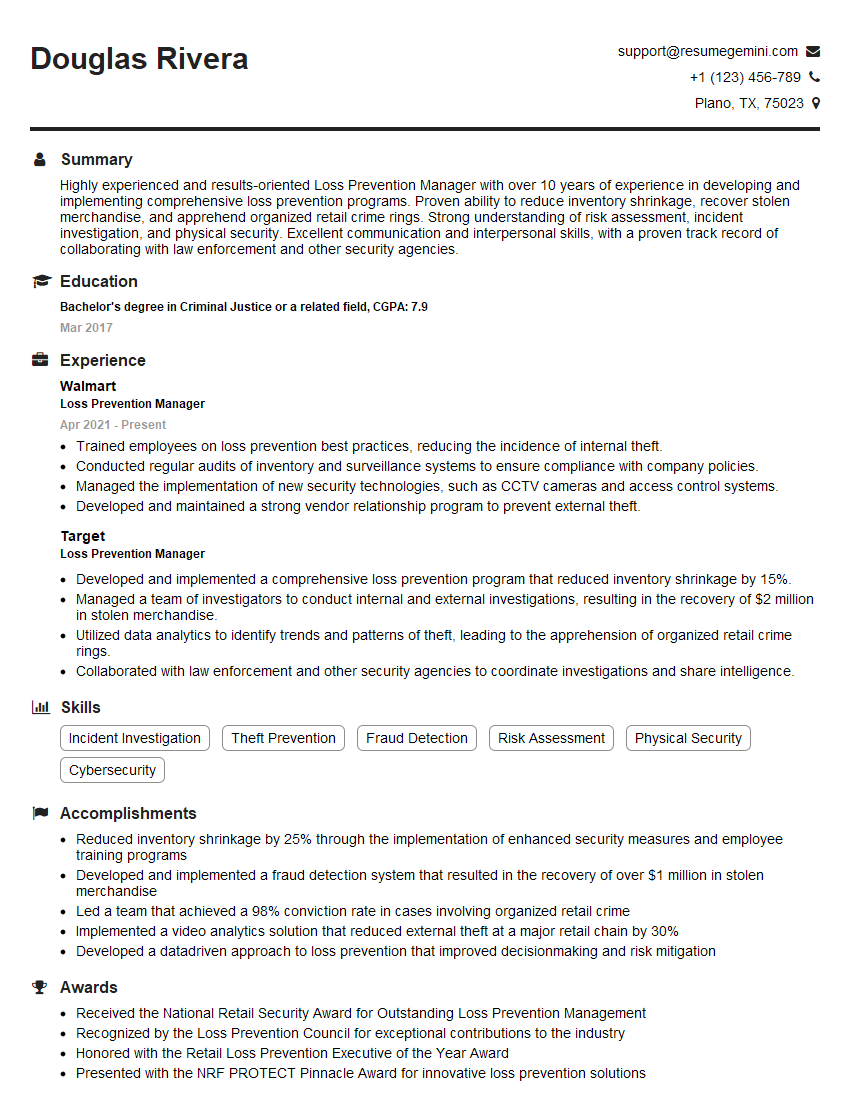

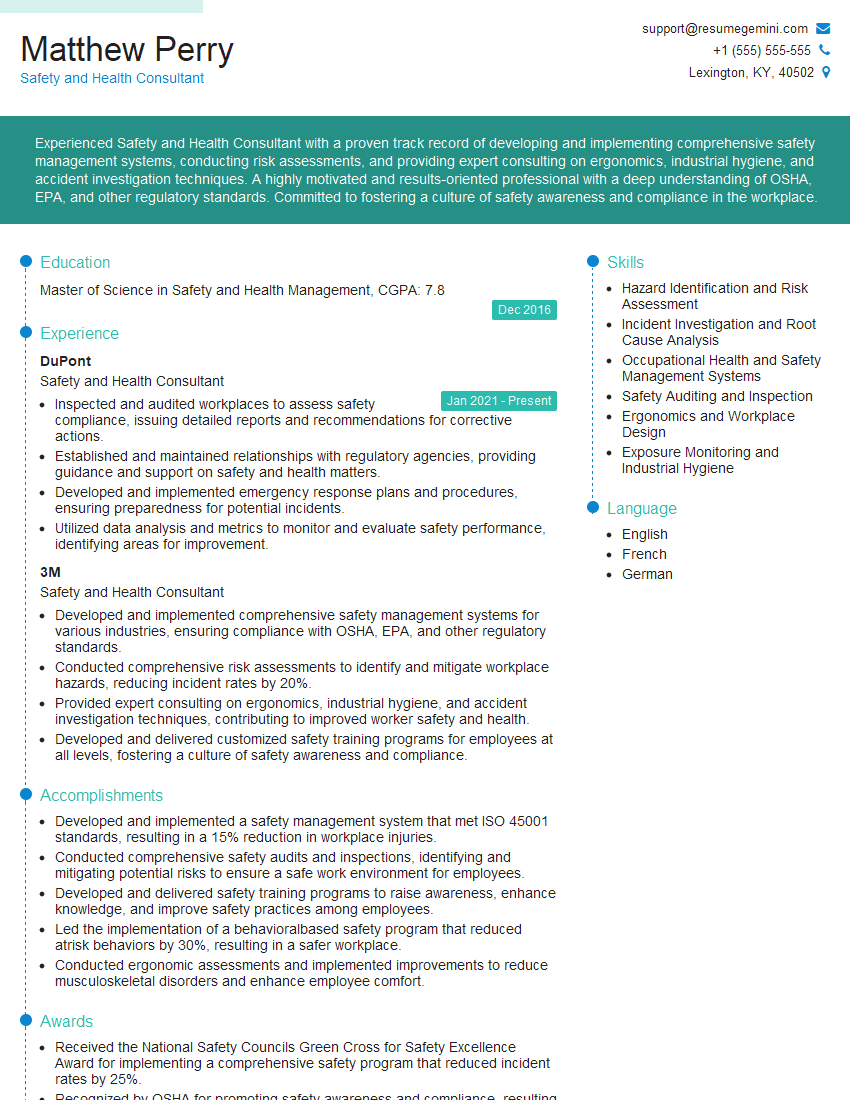

Mastering OSHA Compliance Management opens doors to rewarding careers with significant impact. Demonstrating your expertise through a strong resume is crucial. An ATS-friendly resume increases your chances of getting noticed by recruiters. To build a compelling and effective resume, consider using ResumeGemini – a trusted resource that helps you craft professional and impactful resumes. ResumeGemini provides examples of resumes tailored to OSHA Compliance Management, giving you a head start in presenting yourself as a top candidate. Invest in your future – your career growth depends on it.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good