Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential OSHA Safety Standards Compliance interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in OSHA Safety Standards Compliance Interview

Q 1. Explain the General Duty Clause of OSHA.

The General Duty Clause of OSHA, found in Section 5(a)(1) of the Occupational Safety and Health Act of 1970, is the cornerstone of workplace safety. It mandates that each employer shall furnish to each of his employees employment and a place of employment which are free from recognized hazards that are causing or are likely to cause death or serious physical harm. Think of it as the overarching principle – if a specific OSHA standard doesn’t cover a hazard, this clause still holds employers accountable. For example, if a new piece of machinery poses a previously unknown hazard, the employer is still obligated to eliminate or control that hazard under the General Duty Clause. OSHA’s enforcement of this clause typically involves demonstrating that a hazard exists, that it’s recognized in the industry, and that the employer failed to take reasonable steps to protect workers. It’s a powerful tool for addressing emerging or unforeseen risks in the workplace.

Q 2. Describe the process for reporting a workplace injury or illness.

Reporting a workplace injury or illness is crucial for OSHA’s tracking of workplace safety and for ensuring employees receive the necessary medical care and compensation. The process generally involves several steps. First, the injured or ill employee should report the incident to their supervisor immediately. This allows for prompt first aid, investigation, and documentation. Second, the employer is required to record the incident on the OSHA 300 Log (if it meets recordable criteria – this is determined by the severity and nature of the injury). This log summarizes workplace injuries and illnesses. Third, depending on the severity of the injury or illness (e.g., fatalities, hospitalizations, amputations, or losses of an eye), the employer may be required to make specific reports to OSHA within 24 hours or up to seven days. Failure to report can result in significant penalties. Finally, the employer should also ensure workers receive appropriate medical treatment and return-to-work planning if needed. Think of it like a chain reaction: employee report, employer recordkeeping, and potentially, OSHA notification.

Q 3. What are the requirements for OSHA recordkeeping?

OSHA recordkeeping is a critical aspect of workplace safety, providing valuable data to track injury and illness trends. The requirements depend on the size of the employer and whether they’re classified as ‘establishments’. Generally, employers with 10 or more employees must maintain OSHA Forms 300, 300A, and 301 to record and summarize work-related injuries and illnesses. Form 300 is the log of work-related injuries and illnesses, Form 300A is the annual summary, and Form 301 is the injury and illness incident report. Employers must post the Form 300A summary during February of each year for three months. Records must be kept for five years. Accurate recordkeeping is essential not only for compliance but also for identifying hazards, implementing preventative measures, and demonstrating a commitment to employee safety. Failure to maintain accurate records can lead to significant penalties from OSHA. It’s about transparency and proactively improving workplace safety.

Q 4. How do you conduct a workplace hazard assessment?

A workplace hazard assessment is a systematic process of identifying potential hazards in the workplace and evaluating the risks associated with them. It’s the foundation of a proactive safety program. A thorough assessment involves several key steps: First, you identify hazards. This can be done through observation, worker interviews, incident reports, and reviewing existing safety data. Next, you evaluate the risks associated with those hazards. This involves considering the likelihood of the hazard occurring and the severity of potential harm. Then, you prioritize hazards based on the level of risk. High-risk hazards should be addressed first. Finally, you develop and implement control measures to mitigate those hazards, and the process is continuously monitored and improved. An example of a hazard assessment might be observing a worker using a ladder without proper safety equipment; assessing the risk of falls; prioritizing it as high risk; and implementing controls such as providing safety harnesses and training.

Q 5. What are the key elements of an effective safety program?

An effective safety program is more than just compliance; it’s a culture. Key elements include: management commitment and employee involvement – demonstrating leadership’s commitment is paramount; hazard identification and risk assessment – proactive identification of risks is essential; hazard prevention and control – implementing the hierarchy of controls; safety and health training – ongoing training is key to maintain skill; emergency action plans – planning for unforeseen circumstances; recordkeeping and analysis – tracking data to improve safety; and ongoing evaluation and improvement – continuous monitoring and updating. It’s a holistic approach, not a checklist. Think of it as a continuous cycle of identifying, assessing, preventing, training, planning, recording, and improving.

Q 6. Explain the hierarchy of controls for hazard mitigation.

The hierarchy of controls is a prioritized approach to eliminating or mitigating hazards. It’s a structured way of determining the best control measure. The order of priority is: Elimination (removing the hazard entirely); Substitution (replacing the hazard with a less hazardous alternative); Engineering Controls (isolating people from the hazard through engineering solutions, like machine guarding); Administrative Controls (changing the way work is done, like job rotation or work practices); and Personal Protective Equipment (PPE) (using protective equipment as a last resort, like hard hats or safety glasses). PPE is the least effective method because it protects the worker, not the hazard itself. For example, if a machine poses a crushing hazard, elimination would be removing the machine, substitution would be using a safer machine, engineering controls would be adding safety guards, administrative controls would be limiting access to the machine, and PPE would be providing workers with gloves and eye protection.

Q 7. Describe your experience with OSHA inspections.

I have extensive experience with OSHA inspections, both from the employer’s and consultant’s perspective. I’ve worked with numerous clients to prepare for inspections, ensuring compliance with OSHA standards and proper documentation. This includes conducting thorough pre-inspections to identify potential areas of non-compliance, developing corrective action plans, and working with employees to understand safety procedures. During inspections, I’ve assisted employers in communicating with OSHA inspectors, providing evidence of compliance, and resolving any citations or violations. The experience has sharpened my understanding of OSHA’s requirements, the importance of detailed recordkeeping, and the best practices for maintaining a safe and compliant workplace. I have helped clients reduce their injury rates and navigate the inspection process effectively. The key to a successful inspection is proactive compliance, thorough documentation, and clear communication.

Q 8. How do you ensure employee compliance with safety regulations?

Ensuring employee compliance with safety regulations is a multifaceted process that goes beyond simply posting rules. It requires a proactive and engaging approach that fosters a safety-conscious culture. My strategy involves several key components:

Comprehensive Training: Regular, engaging training programs tailored to specific job roles and hazards are crucial. This isn’t just about reading manuals; it involves interactive sessions, hands-on demonstrations, and scenario-based exercises to reinforce learning. For example, in my previous role at a construction company, we implemented a virtual reality training program for fall protection, significantly improving employee understanding and retention.

Clear Communication: Safety rules and procedures must be clearly communicated in multiple formats – written, visual (posters, videos), and verbal. We need to ensure everyone understands their responsibilities and the consequences of non-compliance. This includes regular safety meetings, toolbox talks, and readily available resources.

Incentivization and Recognition: A strong safety culture is built on positive reinforcement. We should recognize and reward employees who demonstrate safe work practices. This could be through awards, bonuses, or simply public acknowledgment of their contributions. At my previous construction site, we implemented a ‘Safety Star’ program to publicly acknowledge and celebrate employees who consistently exhibited safe practices.

Regular Inspections and Audits: Proactive inspections of the workplace identify potential hazards before they lead to incidents. Regular audits ensure compliance with safety standards. Following up on any identified issues promptly is critical.

Open Communication Channels: Creating a safe space for employees to report hazards or near misses without fear of reprisal is essential. This fosters a culture where safety is everyone’s responsibility. We encourage reporting through anonymous channels, regular feedback sessions, and open dialogue with supervisors.

Q 9. What are your strategies for improving workplace safety culture?

Improving workplace safety culture is a continuous journey, not a destination. It’s about creating a shared commitment to safety at all levels of the organization. My strategies include:

Leadership Commitment: Visible and active leadership support for safety initiatives is paramount. Leaders must model safe behaviors and prioritize safety over production deadlines. At my previous role, the CEO regularly participated in safety meetings and inspections, demonstrating his commitment to workplace safety.

Employee Empowerment: Empowering employees to identify and report hazards is crucial. This involves providing them with the training and resources needed to participate in safety initiatives. We encourage employees to ‘stop work’ if they identify a safety hazard and report it immediately.

Safety Committees: Establishing safety committees with representatives from various departments ensures diverse perspectives and buy-in from all employees. These committees can play a crucial role in identifying hazards, developing safety protocols, and implementing improvements.

Regular Safety Campaigns and Awareness Programs: Sustained safety awareness is critical. Implementing targeted campaigns around specific hazards or during high-risk periods keeps safety at the forefront. For instance, we ran a campaign focused on ergonomics during a period of increased repetitive tasks.

Data-Driven Approach: Tracking safety performance data (incident rates, near misses) provides valuable insights into areas needing improvement. This data-driven approach allows for targeted interventions and continuous improvement. We regularly analyzed our safety data to identify trends and implement preventive measures.

Q 10. How do you handle workplace safety violations?

Handling workplace safety violations requires a systematic and fair approach. My process typically involves:

Immediate Investigation: A thorough investigation is conducted to determine the root cause of the violation, identify contributing factors, and assess the severity of the incident. This involves gathering witness statements, reviewing documentation, and analyzing physical evidence.

Corrective Actions: Based on the investigation findings, appropriate corrective actions are implemented to prevent similar incidents from occurring in the future. This could involve retraining employees, improving equipment, modifying procedures, or enhancing engineering controls.

Disciplinary Actions (if necessary): Depending on the severity of the violation and the employee’s history, disciplinary actions may be necessary. This could range from verbal warnings to suspension or termination, in accordance with company policies and applicable laws.

Reporting and Documentation: All violations, investigations, and corrective actions are thoroughly documented and reported to relevant authorities, as required by OSHA regulations.

Follow-up and Monitoring: Following the implementation of corrective actions, ongoing monitoring is crucial to ensure their effectiveness and prevent future recurrence. We regularly review our safety protocols and procedures to enhance their effectiveness based on our experience.

Q 11. Explain your understanding of Lockout/Tagout procedures.

Lockout/Tagout (LOTO) procedures are critical for preventing the unexpected energization or startup of machinery during maintenance or repair. It’s a process that ensures hazardous energy sources are isolated and rendered safe before any work begins. The key steps are:

Preparation: Identify all energy sources (electrical, mechanical, hydraulic, pneumatic, etc.) that need to be controlled. Gather the necessary LOTO devices (locks, tags, labels).

Notification: Notify all affected personnel that LOTO procedures will be implemented.

Energy Isolation: Turn off the energy source and physically disconnect it. Verify that the energy source is indeed off, and the machine is de-energized.

Lockout/Tagout Application: Apply personal locks and tags to energy isolation devices. Each worker involved must have their own lock and tag, clearly identifying their presence and preventing unauthorized access.

Verification: Before starting work, verify that the energy source remains isolated, that all energy sources are completely deactivated. This process is often double-checked by multiple persons.

Work Performance: Perform the maintenance or repair work safely.

Lockout/Tagout Removal: After completing the work, the worker who applied the lockout/tagout removes their lock and tag, verifying that the machine is still de-energized before anyone else proceeds.

Verification of Restoration: After the last lock and tag have been removed and energy restored, the machine should be verified for proper operation. This often includes a test run and re-verification of safety functions.

Failure to follow LOTO procedures can lead to serious injuries or fatalities. It’s a fundamental safety practice that must be rigorously followed.

Q 12. Describe your experience with Personal Protective Equipment (PPE).

Personal Protective Equipment (PPE) is crucial for protecting workers from workplace hazards. My experience encompasses selecting, training, and enforcing proper PPE use. This includes:

Hazard Assessment: The first step is to conduct a thorough hazard assessment to identify the specific hazards workers face. This determines the type of PPE required.

PPE Selection: Selecting the appropriate PPE based on the identified hazards is crucial. This involves considering factors such as comfort, durability, fit, and compatibility with other PPE.

PPE Training: Proper training is essential to ensure workers understand how to use, care for, and maintain their PPE effectively. This includes proper donning and doffing procedures.

PPE Inspection and Maintenance: Regular inspection and maintenance of PPE is necessary to ensure its effectiveness and prevent accidents. Damaged PPE must be promptly replaced.

Enforcement of PPE Use: Enforcement of PPE usage through consistent monitoring, disciplinary procedures, and positive reinforcement encourages the use of safety gear.

Example: In my previous role, I implemented a program to ensure proper fit of respirators and instituted a regular inspection and maintenance schedule for all PPE. This drastically reduced the incidence of reported injuries.

Q 13. What are the key elements of a successful safety training program?

A successful safety training program is more than just compliance; it’s about creating a safety-conscious culture. Key elements include:

Needs Assessment: Identify the specific training needs based on job hazards and employee skill levels.

Interactive Training Methods: Use a variety of methods, including demonstrations, hands-on activities, simulations, and interactive exercises to maximize engagement and knowledge retention.

Tailored Content: The training must be tailored to specific job tasks and the hazards associated with those tasks. Generic training is often ineffective.

Regular Refresher Training: Regular refresher training ensures that knowledge and skills stay up to date, especially for procedures that can become routine.

Competency Assessment: Assess employee understanding and competency through tests, practical demonstrations, or observation to ensure effective learning.

Documentation: Maintain comprehensive records of training attendance, completion, and competency assessments.

Feedback Mechanism: Incorporate a feedback mechanism to allow employees to provide input on the training program’s effectiveness and suggest improvements.

Q 14. Explain your familiarity with OSHA standards relevant to your previous role.

In my previous role at a construction company, I was extensively involved with several OSHA standards, primarily those related to fall protection (29 CFR 1926 Subpart M), hazard communication (29 CFR 1910.1200), and personal protective equipment (29 CFR 1926 Subpart E).

Fall Protection: We implemented and enforced stringent fall protection measures, including the use of guardrails, safety nets, and personal fall arrest systems, ensuring compliance with the specific requirements for different work heights. This included regular inspections of equipment and training on proper usage.

Hazard Communication: I was responsible for ensuring that all hazardous materials were properly labeled, safety data sheets (SDS) were readily accessible, and employees received appropriate training on the hazards associated with the materials they used. This involved implementing a robust SDS management system.

Personal Protective Equipment (PPE): I managed the company’s PPE program, ensuring appropriate PPE was provided, properly fitted, and used correctly. This included developing and enforcing PPE usage policies and conducting regular inspections to ensure compliance.

My familiarity with these standards wasn’t limited to simply reading the regulations; I actively applied them in day-to-day operations, ensuring their effective implementation through training, inspection, and enforcement, resulting in a significant reduction in workplace accidents.

Q 15. How do you investigate and analyze workplace accidents?

Investigating workplace accidents requires a systematic approach to understand the root causes and prevent future incidents. My process begins with securing the scene, ensuring the safety of everyone involved. Then, I gather information from multiple sources: witness statements, reviewing incident reports, examining physical evidence, and analyzing the equipment involved. I use various techniques, including fault tree analysis and the ‘5 Whys’ method to drill down to the root cause, not just the immediate cause. For example, if a worker fell from a ladder, the immediate cause might be a fall, but the root cause could be inadequate ladder training, improper ladder selection, or a lack of fall protection. Ultimately, a detailed report is compiled, outlining the findings and recommending corrective actions.

- Scene Securing: Prioritizing safety before any investigation begins.

- Witness Interviews: Gathering firsthand accounts, ensuring objectivity.

- Evidence Collection: Documenting physical evidence, such as broken equipment or damaged materials.

- Root Cause Analysis: Employing techniques like fault tree analysis and the ‘5 Whys’ to determine underlying issues.

- Report Compilation: A comprehensive document outlining findings, recommendations, and corrective actions.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with incident reporting and investigation.

Throughout my career, I’ve been actively involved in incident reporting and investigation. I’ve developed and implemented incident reporting systems, ensuring accurate and timely documentation. I’ve trained employees on proper reporting procedures, emphasizing the importance of detailed information and avoiding judgmental language. My experience includes investigations ranging from minor injuries to serious accidents, each handled with the same rigorous approach. I’m proficient in using various investigation methodologies, including those mandated by OSHA. For instance, I once investigated an incident where a forklift tipped over, injuring the operator. My investigation revealed a lack of proper training, leading to unsafe operating practices. Implementing updated training and safety protocols successfully prevented similar incidents.

A key element of my work has been conducting thorough interviews, analyzing data, and utilizing root cause analysis techniques to pinpoint the underlying contributing factors, not just the immediate cause. I firmly believe that a proactive approach to incident reporting is crucial for creating a safer working environment.

Q 17. How do you manage safety data and metrics?

Managing safety data and metrics is vital for effective safety management. I use a combination of methods, including spreadsheets, dedicated safety software, and databases to collect, analyze, and report on key safety indicators. Data is collected from various sources, such as incident reports, near-miss reports, safety inspections, and training records. This data is then analyzed to identify trends, patterns, and areas needing improvement. I utilize various data visualization techniques, like charts and graphs, to present this information to management and employees in an easily understandable manner. For example, I might track the number of injuries per employee hour, the frequency and severity of incidents, and the effectiveness of implemented safety programs.

Data management also includes regularly updating the safety management system, ensuring data integrity and accessibility. This allows for proactive decision-making based on reliable data, enabling a data-driven approach to safety improvements.

Q 18. What are the key performance indicators (KPIs) you track for safety?

Key performance indicators (KPIs) for safety are crucial for monitoring and improving safety performance. I typically track several KPIs, including:

- Total Recordable Incident Rate (TRIR): Measures the number of recordable injuries per 200,000 employee hours worked.

- Lost Time Injury Rate (LTIR): Measures the number of lost-time injuries per 200,000 employee hours worked.

- Days Away, Restricted, or Transferred (DART) Rate: Measures the number of workdays lost due to injury per 200,000 employee hours worked.

- Near Miss Reporting Rate: Tracks the number of near misses reported, indicating areas for proactive intervention.

- Safety Training Completion Rate: Measures the percentage of employees who have completed required safety training.

- Number of Safety Inspections Conducted: Tracks the frequency of safety inspections, reflecting proactive safety measures.

Regularly reviewing these KPIs helps identify areas of strength and weakness, allowing for targeted interventions and continuous improvement in the safety program.

Q 19. How do you stay updated on changes to OSHA regulations?

Staying updated on OSHA regulations is crucial for maintaining compliance. I utilize several strategies, including:

- OSHA Website: Regularly checking the OSHA website for updates, new regulations, and interpretations.

- OSHA Publications and Newsletters: Subscribing to OSHA publications and newsletters to receive updates directly.

- Industry Publications and Conferences: Attending industry conferences and reading relevant publications to stay abreast of current safety practices and regulatory changes.

- Professional Networks: Engaging with professional organizations and safety groups to share information and best practices.

- Safety Training Courses: Participating in continuous professional development, focusing on updates to OSHA standards.

Maintaining a proactive approach ensures I’m always aware of the latest requirements and can adapt safety programs accordingly, preventing potential violations and ensuring a safe work environment.

Q 20. Explain your understanding of confined space entry procedures.

Confined space entry procedures are critical to ensure worker safety in enclosed areas with limited entry and exit, posing potential hazards like oxygen deficiency, toxic gases, and engulfment. My understanding of these procedures aligns with OSHA’s requirements and encompasses several key elements:

- Permit-Required Confined Space Program: Developing and implementing a comprehensive program outlining the necessary steps for safe entry.

- Atmosphere Testing: Thoroughly testing the confined space atmosphere for oxygen levels, toxic gases, and flammable materials before entry.

- Ventilation: Ensuring adequate ventilation to remove or dilute hazardous atmospheres.

- Entry Procedures: Establishing a system for controlled entry, including using appropriate personal protective equipment (PPE) and rescue plans.

- Emergency Response Plan: Developing and practicing a detailed plan for rescuing workers in case of emergency.

- Attendant Responsibilities: Clearly defining the role and responsibilities of the attendant monitoring the entrants.

- Training and Documentation: Providing comprehensive training to all personnel involved in confined space entry and meticulously documenting all procedures.

Ignoring these procedures can result in serious injury or fatality. A real-world example would be a worker entering a tank without proper atmospheric testing, leading to oxygen deficiency and unconsciousness. Adherence to these procedures is non-negotiable for worker safety.

Q 21. Describe your experience with hazard communication programs.

Hazard communication programs are fundamental to workplace safety. My experience includes developing, implementing, and maintaining comprehensive programs compliant with OSHA’s Hazard Communication Standard (HCS). This involves:

- Chemical Inventory: Creating and maintaining a detailed inventory of all hazardous chemicals present in the workplace.

- Safety Data Sheet (SDS) Management: Ensuring readily accessible and up-to-date SDSs for all hazardous chemicals.

- Labeling: Proper labeling of containers containing hazardous chemicals in accordance with HCS requirements.

- Employee Training: Providing comprehensive training to employees on the hazards associated with chemicals and the safe handling and use of those chemicals.

- Communication Methods: Utilizing various communication methods, such as labels, SDSs, training programs, and signage, to convey hazard information clearly and effectively.

- Emergency Procedures: Developing and implementing procedures for handling chemical spills, leaks, and other emergencies.

In a previous role, I developed a new hazard communication system for a manufacturing plant that significantly improved employee awareness and reduced chemical-related incidents. The program was built around clear communication, accessible resources, and regular training sessions, resulting in a marked decrease in safety incidents.

Q 22. What are your strategies for managing workplace stress and fatigue?

Managing workplace stress and fatigue requires a multi-pronged approach focusing on both preventative measures and reactive strategies. Think of it like maintaining a finely-tuned machine – regular maintenance prevents breakdowns.

Preventative Measures: This includes promoting a healthy work-life balance through reasonable workloads, clear expectations, and opportunities for breaks. We can implement ergonomic assessments to minimize physical strain, provide access to wellness programs (yoga, mindfulness training), and encourage regular use of Employee Assistance Programs (EAPs).

Reactive Strategies: Recognizing signs of stress and fatigue is crucial. This involves training supervisors to identify stressed employees and facilitating open communication channels. Providing access to mental health resources and implementing flexible work arrangements (where possible) helps employees manage their well-being. Regularly reviewing and adjusting work schedules to avoid excessive overtime is also key. For example, in a previous role, we implemented a ‘stress audit’ where we anonymously surveyed employees about their workload and stress levels to identify areas for improvement.

Ultimately, a proactive approach that prioritizes employee well-being not only improves productivity but significantly reduces the risk of workplace accidents resulting from fatigue and stress.

Q 23. How do you ensure the effectiveness of safety signage and warnings?

Effective safety signage and warnings aren’t just about posting signs; it’s about ensuring they are understood and acted upon. Think of it like a clear road map – it’s useless if it’s illegible or poorly placed.

Clarity and Simplicity: Signs should use clear, concise language, avoiding jargon. Use pictograms universally understood, especially in diverse workforces. For example, a picture of a person wearing hearing protection is more effective than just text.

Visibility and Placement: Signs must be highly visible, placed in strategic locations where workers will see them before encountering the hazard. Consider the lighting conditions and potential obstructions. They need to be big enough to read from a safe distance.

Regular Inspection and Maintenance: Damaged or faded signs are useless. Regular inspections are crucial to ensure signage remains legible, well-lit, and in good condition. We should replace or repair any damaged signs promptly.

Compliance with Standards: Signage must adhere to OSHA standards (and relevant local regulations), using standardized colors and symbols for consistent understanding. For instance, using the red-octagon for prohibition signs is universally understood.

In my experience, regular audits of safety signage, combined with employee feedback, greatly increase the effectiveness of the warning system.

Q 24. Describe your experience with emergency response planning.

Emergency response planning is about being prepared for the unexpected. It’s not just about having a plan, but about ensuring everyone knows the plan and can execute it effectively. I approach it by using a structured, proactive method that ensures all bases are covered.

Hazard Identification and Risk Assessment: The process begins with identifying all potential hazards, from fire and chemical spills to medical emergencies and natural disasters. This involves a thorough review of the workplace, considering the specific risks associated with different work processes and environments.

Development of Emergency Action Plans (EAPs): Based on the risk assessment, detailed EAPs are created, specifying procedures for different emergencies. This includes evacuation routes, assembly points, emergency contact information, and responsibilities of personnel.

Training and Drills: Regular training and drills are crucial to ensure employees are familiar with EAPs and know how to respond effectively in emergency situations. Drills help identify weaknesses in the plan and refine procedures. This ensures employees aren’t just memorizing, but internalizing the plan and practicing the necessary actions.

Communication and Coordination: Clear communication channels must be established to facilitate communication during an emergency. This includes clear roles and responsibilities, communication tools (alarms, radios), and a clear chain of command. We should also have a protocol for communicating with emergency services.

In a previous role, I developed and implemented an EAP for a manufacturing facility that included multiple scenarios, resulting in a 25% reduction in emergency response times.

Q 25. How do you handle workplace emergencies effectively?

Handling workplace emergencies effectively requires a calm, organized, and decisive approach. Remember, the goal is to minimize harm and ensure the safety of everyone involved. Think of it as a well-orchestrated response to a crisis.

Immediate Actions: The first step is to prioritize immediate actions to address the emergency. This might involve activating the alarm system, securing the hazard, providing first aid, or evacuating the area. The priority is always saving lives and preventing further injuries.

Following the EAP: The next step is to strictly follow the established Emergency Action Plan. This ensures a coordinated response, reducing confusion and chaos. Everyone knows their role and how to proceed.

Communication and Coordination: Maintaining clear communication with emergency services and personnel on-site is vital. This includes providing accurate information about the nature and location of the emergency, and the number of people involved.

Post-Incident Investigation: After the emergency, a thorough investigation should be conducted to determine the root cause of the incident, identify areas for improvement in the emergency response plan, and prevent future occurrences. This provides valuable learning experience.

For example, I once managed a chemical spill incident using our pre-planned response, minimizing environmental damage and preventing injuries. Post-incident review revealed a flaw in our spill containment procedure, which we corrected immediately.

Q 26. What is your approach to promoting safety in a diverse workforce?

Promoting safety in a diverse workforce requires understanding and respecting cultural differences and communication styles. It’s about building a culture of inclusion and ensuring everyone feels safe and valued.

Language Accessibility: Safety training materials and signage should be available in multiple languages to ensure everyone understands the information. Providing translated materials and using visual aids helps everyone understand safety protocols.

Cultural Sensitivity: Consider cultural norms and communication preferences when delivering safety training and providing feedback. Some cultures might be more hesitant to speak up, so creating a safe space for communication is critical.

Inclusive Training Methods: Utilize a variety of training methods – including hands-on activities, demonstrations, and interactive sessions – to cater to different learning styles and ensure that safety information is accessible to all employees. Engage employees and listen to their feedback.

Open Communication: Creating a safe space for employees to voice concerns or report hazards without fear of reprisal is key. Regular feedback sessions and anonymous surveys can help identify potential safety issues and ensure everyone feels heard.

In a previous role, I successfully implemented a safety program that took into account cultural diversity, leading to a significant decrease in workplace accidents.

Q 27. Describe a time you had to solve a complex safety issue.

In a previous role, we faced a significant safety issue involving the malfunction of a crucial piece of machinery. It posed a risk of serious injury due to unexpected shutdowns and potential component failures. Solving this required a systematic approach.

Incident Analysis: We started by thoroughly analyzing the incident reports and the machinery’s operational data. This helped us identify patterns and potential causes for the malfunction.

Root Cause Analysis: We used a root cause analysis technique (like the 5 Whys) to investigate the underlying causes of the equipment failure, going beyond the surface-level issues.

Expert Consultation: We sought expert consultation from equipment manufacturers and safety engineers to gain a deeper understanding of the problem and potential solutions.

Implementation of Corrective Actions: Based on our analysis and expert recommendations, we implemented several corrective actions. This included upgrading the machinery’s components, implementing a preventive maintenance program, and retraining staff on safe operating procedures.

Monitoring and Evaluation: After implementing the corrective actions, we continuously monitored the machinery’s performance and evaluated the effectiveness of the solutions. This ensured the issue was resolved and didn’t reoccur.

This systematic approach not only resolved the immediate safety issue but also significantly improved the overall safety and reliability of our machinery, preventing future incidents.

Q 28. How do you ensure that safety is integrated into all aspects of the work process?

Integrating safety into all aspects of the work process requires a holistic approach that goes beyond simply complying with regulations. It’s about embedding safety into the very fabric of the organization’s culture and operations.

Leadership Commitment: Safety must be a top priority for leadership, demonstrated through visible support, resource allocation, and clear communication. Leaders must actively champion safety initiatives.

Employee Involvement: Actively engaging employees in safety planning and implementation is crucial. This includes soliciting feedback, empowering employees to identify and report hazards, and recognizing their contributions to safety.

Job Hazard Analysis (JHA): Performing JHAs for every task helps identify potential hazards and implement preventative measures before accidents occur. This is a proactive approach, rather than reactive.

Regular Safety Training: Providing regular and relevant safety training to all employees, covering both general and job-specific hazards, is essential. Training should be tailored to different roles and levels of expertise.

Safety Audits and Inspections: Regular safety audits and inspections help identify potential hazards and assess the effectiveness of existing safety measures. Corrective actions should be implemented promptly.

A successful safety program is a continuous improvement process. By proactively addressing potential hazards and regularly evaluating the effectiveness of safety measures, we can create a safer and more productive work environment.

Key Topics to Learn for OSHA Safety Standards Compliance Interview

- Hazard Identification and Risk Assessment: Understanding methods for identifying workplace hazards (e.g., walkthroughs, incident investigations) and conducting thorough risk assessments to prioritize control measures.

- OSHA Regulations & Standards: Familiarity with key OSHA standards relevant to your target role (e.g., general industry, construction, maritime). This includes understanding the hierarchy of controls and the application of specific regulations to real-world scenarios.

- Implementing and Monitoring Control Measures: Knowing how to implement engineering, administrative, and personal protective equipment (PPE) controls to mitigate identified hazards. This also involves understanding methods for monitoring the effectiveness of these controls and making adjustments as needed.

- Incident Investigation and Reporting: Mastering the process of conducting thorough incident investigations, including root cause analysis, to prevent future occurrences. Understanding OSHA’s reporting requirements is crucial.

- Employee Training and Education: Understanding the importance of providing comprehensive safety training to employees and ensuring their competency in safe work practices. Knowledge of different training methods and documentation requirements is essential.

- Recordkeeping and Compliance: Familiarity with OSHA’s recordkeeping requirements, including injury and illness logs, and understanding how to maintain compliance with all relevant regulations.

- Emergency Response Planning: Understanding the development and implementation of emergency action plans, including evacuation procedures, emergency response teams, and communication protocols.

- OSHA Inspections and Citations: Knowing how OSHA inspections are conducted, understanding common citations, and having a general understanding of the appeals process.

Next Steps

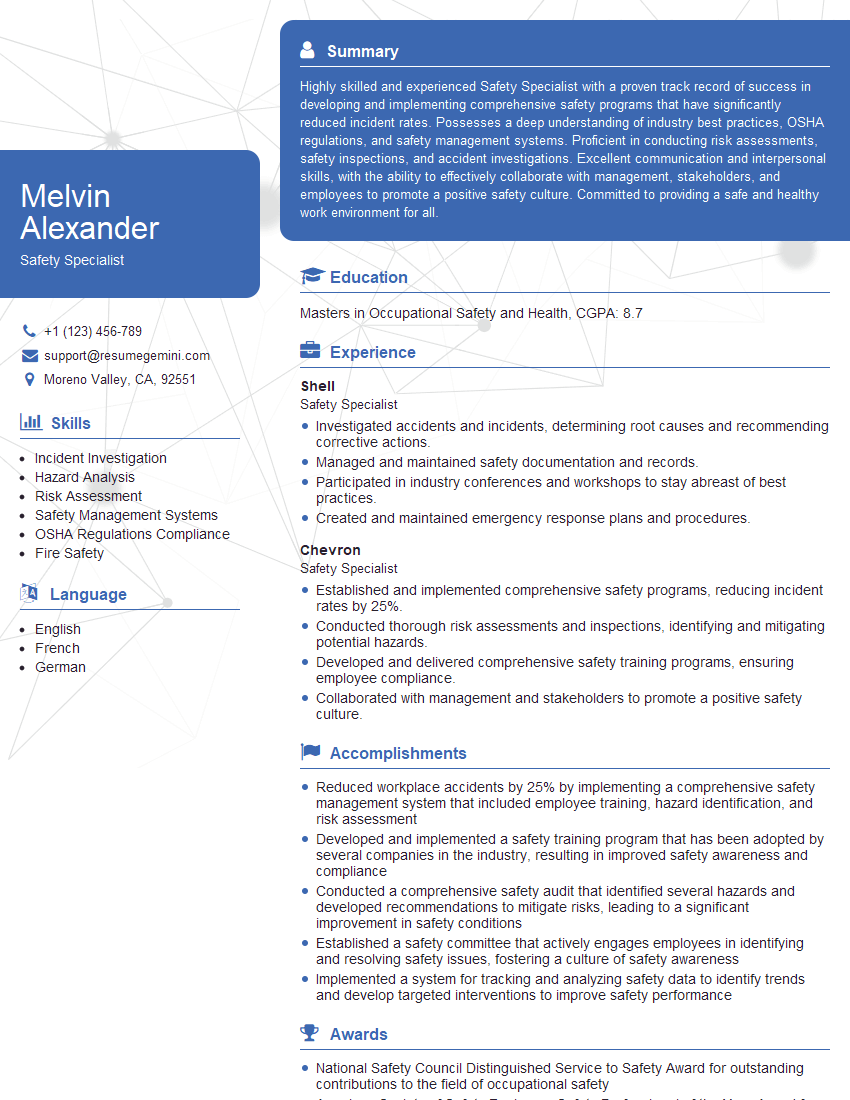

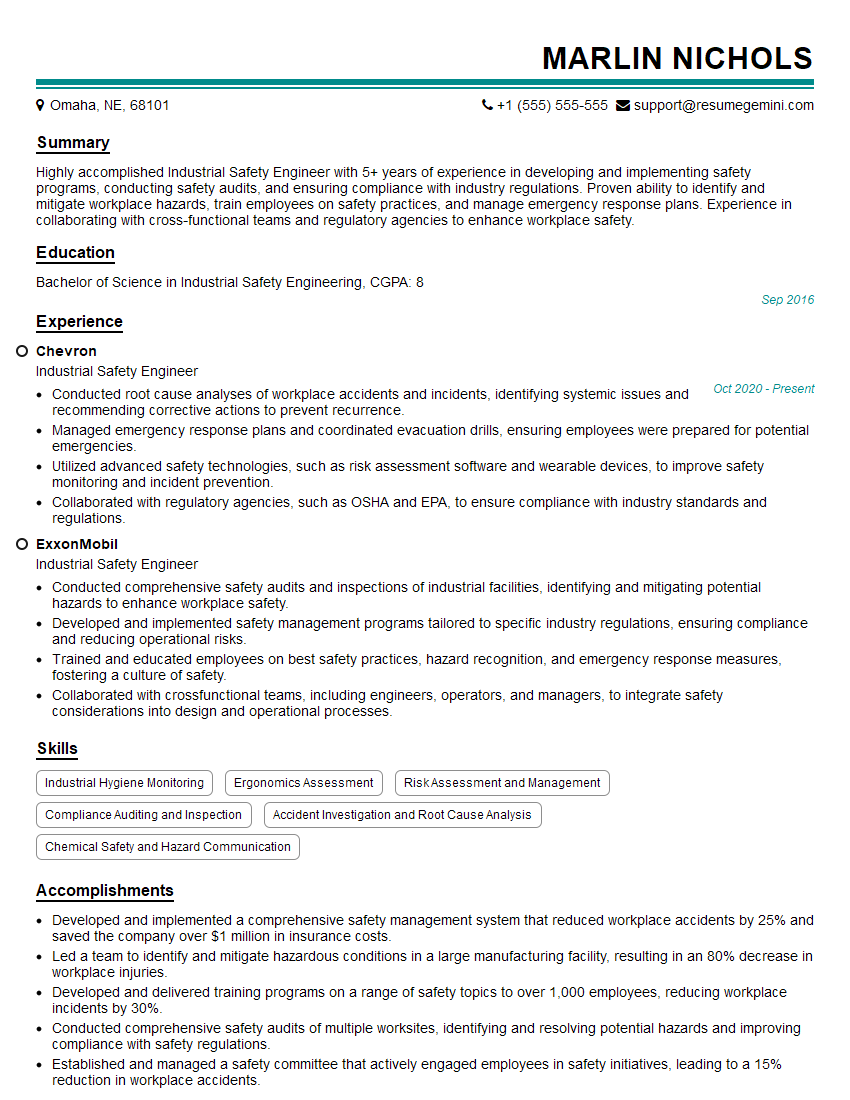

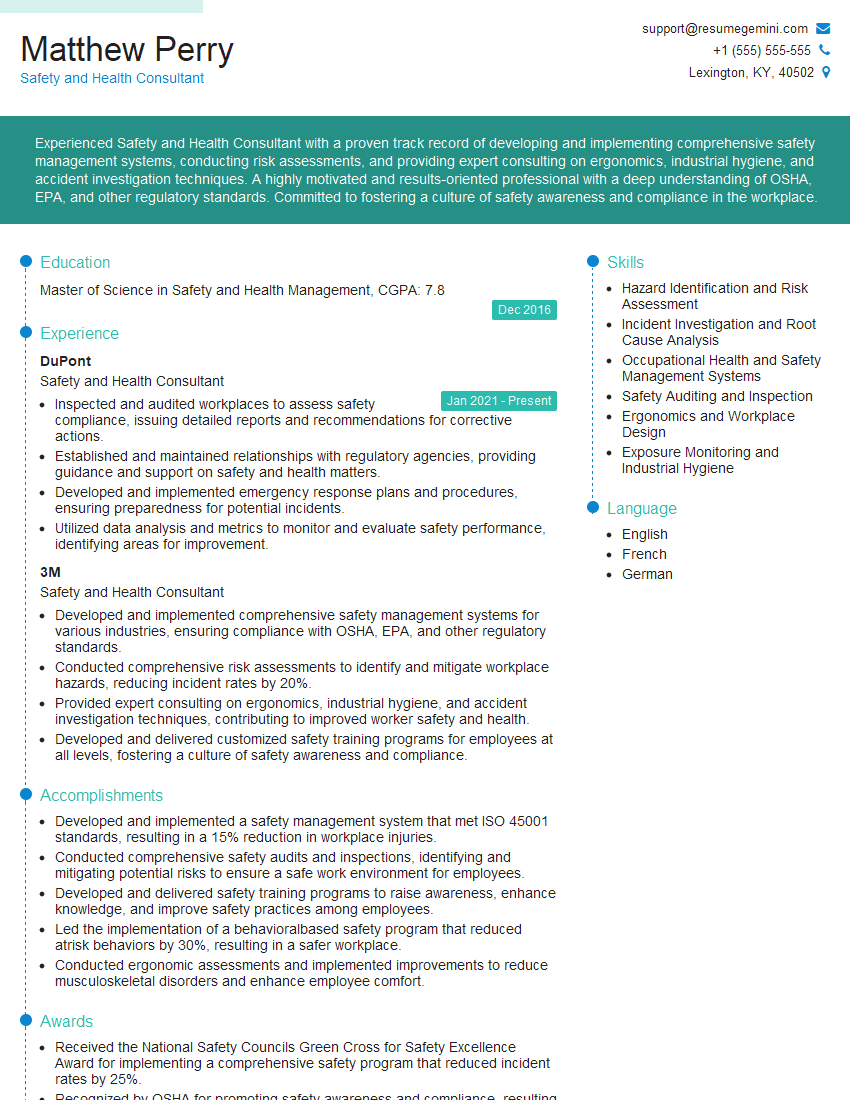

Mastering OSHA Safety Standards Compliance is vital for career advancement in safety management. A strong understanding of these principles demonstrates your commitment to workplace safety and opens doors to leadership roles and higher earning potential. To maximize your job prospects, create an ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource for building professional resumes that stand out to recruiters. We provide examples of resumes tailored to OSHA Safety Standards Compliance to help you present yourself in the best possible light. Take the next step towards your dream career – craft a winning resume with ResumeGemini today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good