Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Oyster Knife Handling interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Oyster Knife Handling Interview

Q 1. Describe the different types of oyster knives and their uses.

Oyster knives come in various shapes and sizes, each designed for specific tasks and oyster types. The most common types include:

- Standard Oyster Knife: This is a versatile knife with a short, strong blade, typically around 3-4 inches long. Its sturdy build makes it ideal for most oyster varieties.

- Oyster Shucking Knife with a Blunt Tip: This type features a rounded or blunt tip, reducing the risk of injury by minimizing the chance of the blade slipping and puncturing the hand. It is safer for beginners.

- Oyster Knife with a Pointed Tip: These knives feature a sharper point, which can be advantageous for precise opening and access to stubborn oysters with difficult hinges.

- Heavy-Duty Oyster Knife: Designed for commercial use and opening large quantities of oysters, these knives possess thicker, more robust blades capable of withstanding significant pressure.

The choice of knife often depends on personal preference, experience level, and the type of oyster being shucked. A beginner might start with a blunt-tipped knife for safety, while a seasoned professional might prefer a pointed knife for speed and precision.

Q 2. Explain the proper grip and technique for holding an oyster knife.

Proper grip and technique are crucial for both efficiency and safety. Imagine holding a pen – that’s a good starting point. You should hold the oyster knife firmly, but not rigidly.

Grip the handle comfortably, with your index finger resting on top of the blade near the bolster (the junction between the blade and the handle), while your thumb supports the knife from below. This allows for excellent control and precision. Keep your other fingers curled naturally around the handle.

Avoid gripping the knife too tightly, as this can lead to fatigue and accidental slips. The best grip allows for fluid movement and a controlled force during shucking.

Q 3. How do you identify and handle different oyster shell variations?

Oyster shells vary significantly in shape, size, and thickness, requiring adaptable techniques. Some oysters have deep cups, making access to the hinge challenging. Others have very strong, thick shells. Identifying these variations is key to efficient shucking.

Before shucking, I always visually inspect the oyster. I look for any deformities, unusual protrusions, or exceptionally thick areas. A deep cup often requires a different approach than a flatter shell. Sometimes a combination of techniques, including using a knife to pry open an initial gap and then to find the hinge, is necessary.

Experience teaches you to quickly assess an oyster’s shell and adapt your technique accordingly. I’ve learned to identify common shell types from different regions and adjust my pressure and angle to maximize speed and minimize the risk of breakage or damage.

Q 4. What safety precautions do you take when shucking oysters?

Safety is paramount when shucking oysters. Always wear a cut-resistant glove on your non-dominant hand to protect against cuts and slips. This glove should be specifically designed for food service and offer sufficient protection without impeding dexterity.

Ensure you have a stable work surface with adequate lighting. Never rush the process; haste leads to accidents. Work in a clear area, free from clutter or distractions. Keep the knife sharp; a dull knife requires more force, increasing the risk of slips and injuries.

In my experience, respecting the inherent risk and maintaining a calm, controlled environment are crucial for preventing accidents.

Q 5. Describe your method for opening an oyster quickly and efficiently.

My method involves a combination of speed and precision. First, I find the hinge, typically located near the narrower end of the oyster.

I then insert the tip of my oyster knife firmly into the hinge. I work the knife back and forth with short, controlled motions, creating a small gap. Once a small gap is created, I insert the knife further along the hinge, applying pressure to work the oyster open.

The goal is to separate the two halves of the shell cleanly without damaging the oyster meat. With practice, this process becomes remarkably fast and efficient. Experience allows you to instinctively adjust the pressure and angle of the knife depending on the oyster’s shell characteristics.

Q 6. How do you prevent oyster knife injuries?

Preventing oyster knife injuries is a top priority. A sharp knife is far safer than a dull one. A sharp knife requires less force, reducing the likelihood of slips and uncontrolled movements.

Always use a cut-resistant glove. Keep your workspace organized and well-lit to avoid accidents. Use controlled and deliberate movements. Never force the knife; if the oyster is particularly stubborn, use a different technique or let it rest and reattempt later.

Regularly inspect your knife for any damage, and replace it immediately if it becomes damaged. Proper training and practice are vital in developing safe techniques. A well-maintained and correctly used knife is the best preventative measure against accidents.

Q 7. What are the signs of a bad oyster, and how do you handle them?

Recognizing bad oysters is crucial for food safety. Signs of a bad oyster include a foul odor, a cloudy or milky liquid inside the shell, a discoloration of the oyster meat, or an abnormally soft or mushy texture.

If an oyster shows any of these signs, discard it immediately. Never consume an oyster that appears damaged or has an unusual smell or texture. Foodborne illnesses can be severe, and it’s always better to err on the side of caution.

In a professional setting, proper handling includes immediately discarding bad oysters and ensuring all shucking equipment is thoroughly cleaned and sanitized after handling any suspected bad oysters.

Q 8. How do you maintain the sharpness of an oyster knife?

Maintaining a razor-sharp oyster knife is crucial for efficient and safe shucking. Think of it like a surgeon’s scalpel – a dull tool increases risk and effort. I primarily use high-carbon stainless steel knives, known for their edge retention. Sharpening is best done with a honing steel, not a sharpening stone, which can damage the blade’s delicate geometry. I run the blade along the steel, at a consistent angle (about 20 degrees), in a smooth, sweeping motion, away from the edge. I repeat this process 10-15 times on each side, regularly checking the sharpness with my thumb (carefully!). If significant sharpening is needed, I use a very fine grit whetstone, but this is rare with proper honing. Regular honing, after each shucking session, is vital to prolonging the knife’s sharpness.

Q 9. Describe your cleaning and sanitizing procedures for oyster knives.

Hygiene is paramount in oyster shucking. After each oyster, I thoroughly rinse the knife under hot, running water, scrubbing away any shell fragments or oyster residue. Then, I immerse the knife in a sanitizer solution (typically a bleach solution diluted according to the manufacturer’s instructions or a food-grade commercial sanitizer). This ensures the elimination of any harmful bacteria. I allow the knife to soak for at least 30 seconds. After sanitizing, I rinse the knife again with clean water and dry it thoroughly with a clean towel before moving on to the next oyster. This routine prevents cross-contamination and ensures food safety.

Q 10. What is the proper way to discard oyster shells?

Proper disposal of oyster shells is essential for environmental reasons and to maintain a safe workspace. I never simply discard shells into the trash. In restaurants, we typically have designated containers specifically for oyster shells. In my personal work, I collect them in a separate bucket and deposit them at a recycling center or designated location for oyster shell recycling programs. These programs often use the shells for beneficial purposes like creating oyster reefs or other environmentally friendly applications. Never mix shells with other waste.

Q 11. How do you ensure food safety when shucking oysters?

Food safety is my top priority. I always work with clean hands, washing them thoroughly before and after handling oysters. I ensure all my equipment (including the knife, gloves, and shucking board) is impeccably clean and sanitized. Oysters should be shucked quickly to minimize the time they’re exposed to air and bacteria. I avoid touching the oyster meat with my hands and always use clean utensils for serving. I keep shucked oysters chilled at 40°F (4°C) or below and consume them within a short timeframe. Always ensure the oysters are from a reputable source, fresh, and display no signs of spoilage.

Q 12. What are the common mistakes made by oyster shuckers, and how can they be avoided?

Common mistakes include using a dull knife (leading to slips and injuries), improper grip (reducing control and precision), and insufficient sanitization (increasing contamination risk). Inadequate knowledge of oyster anatomy also leads to wasted oysters and injuries. To avoid these mistakes, I recommend practice and proper training. The use of a sharp knife and a firm, controlled grip are essential. A thorough understanding of oyster anatomy helps in precise shucking with minimal waste. Always prioritize safety and hygiene.

Q 13. How many oysters can you shuck per hour?

My shucking speed varies depending on the oyster size and type, but I can comfortably shuck between 150 and 200 oysters per hour. This efficiency comes from years of experience and a well-honed technique. While speed is important, maintaining quality and food safety is always paramount.

Q 14. Describe your experience with different oyster varieties.

I’ve worked extensively with various oyster varieties, each presenting unique challenges and rewards. For example, Kumamoto oysters are small and delicate, requiring a gentle touch. On the other hand, larger oysters like the Pacifics require more force but also offer a larger yield. The Blue Point oyster has a unique flavor profile and requires precise shucking technique. I understand the differences in shell shape, thickness, and the meat’s adherence to the shell to ensure appropriate shucking methods. This knowledge ensures I achieve a perfect shuck every time, with minimal waste and maximum yield.

Q 15. How do you adapt your technique to different oyster sizes and shapes?

Shucking oysters of varying sizes and shapes requires adaptability. Think of it like tailoring a suit – you need to adjust your approach to fit the unique form of each oyster. Smaller oysters require a more delicate touch and precise placement of the knife to avoid shattering the shell. Larger oysters, however, might need a more forceful initial cut to gain access to the hinge. The shape also matters; deep-cupped oysters require a different approach than flatter ones. For instance, with a deep-cupped oyster, I might start by inserting the knife near the hinge, working my way around the circumference to open it cleanly. With a flatter oyster, a more direct approach to the hinge is often more effective.

- Smaller Oysters: Gentle insertion, precise movements.

- Larger Oysters: More forceful initial cut, controlled leverage.

- Deep-cupped Oysters: Circumferential cutting starting near the hinge.

- Flatter Oysters: Direct approach to the hinge.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the importance of proper knife angle when shucking oysters.

The knife angle is paramount. Imagine the oyster shell as a fragile eggshell. A wrong angle can lead to a broken shell and wasted oyster. The ideal angle is generally between 15 and 30 degrees, aiming for the hinge. This allows the knife to slip between the shell halves with minimal force, preventing cracks and ensuring a clean separation. Holding the knife at too shallow an angle risks slipping and injuring yourself, while too steep an angle can cause the shell to crack. I often adjust the angle slightly based on the oyster’s shape and the position of the hinge. Consistency and precision in this are key to becoming a proficient shucker.

Q 17. How do you handle a broken oyster knife during service?

A broken oyster knife during service is a serious issue, demanding immediate action. Safety is paramount. First, I’d immediately discard the broken knife and inform my supervisor or manager. We have a strict protocol for handling broken tools to prevent injury. Then, I would switch to a new, sharp knife, and proceed with my work, prioritizing efficiency and safety for both myself and my team. While this is frustrating, a smooth and professional response is essential to maintain service standards. Having a readily-available backup knife is crucial to prevent any significant delays.

Q 18. What is your preferred method for removing oyster liquor?

My preferred method for removing oyster liquor is gentle and controlled. I avoid excessive shaking or jarring movements which might damage the oyster meat. Instead, I use a small, clean spoon or a dedicated oyster shell to carefully scoop out the liquor, ensuring none is wasted. The liquor adds immense flavor and is an essential part of the experience. Sometimes a gentle tilt of the shell is all that’s needed to allow the liquor to flow out. The key is to be delicate and respectful of this precious liquid.

Q 19. How do you preserve the quality of the oyster during the shucking process?

Preserving oyster quality during shucking demands speed, precision, and hygiene. I prioritize swift shucking to minimize the time the oyster is exposed to air, which can affect freshness. I also keep the oysters cool, often working on a bed of ice. Using a clean and sanitized knife prevents contamination. Maintaining a cool, clean workspace is crucial in preserving quality. I handle the oysters as minimally as possible to avoid damaging the delicate meat. In essence, it’s a balance of efficiency and meticulous care.

Q 20. What are the different methods of presenting shucked oysters?

Shucked oysters can be presented in several ways, each offering a distinct visual appeal and dining experience. A simple, elegant presentation might involve arranging the oysters on a bed of ice, garnished with lemon wedges. More elaborate presentations might include different sauces, mignonette, or even creative plating styles. Some restaurants serve them on the half-shell, while others might present them on a plate or platter. Ultimately, the presentation style depends on the restaurant’s concept and the desired ambiance.

- Classic Presentation: On the half-shell with lemon.

- Garnished Presentation: With sauces, mignonette, and herbs.

- Plated Presentation: Arranged artistically on a plate.

Q 21. Describe your experience working under pressure in a high-volume environment.

I thrive under pressure in a high-volume environment. During busy lunch or dinner rushes, my experience allows me to maintain composure and efficiency. I remember one particularly hectic Friday night where we had an unexpected surge of customers. By working methodically, prioritizing speed and precision, and communicating effectively with the kitchen staff, we managed to meet the demands without compromising quality or service. Maintaining a calm and focused demeanor, even during chaos, is a skill I’ve honed over years of experience. Effective teamwork and efficient workflow are indispensable in these situations.

Q 22. How do you handle customer complaints related to oyster quality?

Handling customer complaints about oyster quality begins with empathetic listening. I would first apologize for their dissatisfaction, ensuring they feel heard and valued. Then, I would ask clarifying questions to understand the specific issue: Was the oyster dead? Did it have an off-flavor? Was it undercooked? This helps pinpoint the problem’s source. If the complaint is legitimate, for example, a genuinely bad oyster (signs of spoilage such as a strong ammonia smell or discoloration), I would offer a replacement or refund immediately. I would then discreetly investigate the source of the problem, checking our oyster supplier’s quality control and our own storage procedures. This ensures future incidents are minimized. Finally, I would follow up with the customer to ensure they are satisfied with the resolution. I believe proactive communication and a commitment to customer satisfaction are paramount.

For example, if a customer complained about a gritty oyster, I would first check if there was a shell fragment, which is an easily resolvable issue. If not, the problem could relate to the oyster’s environment or how it was harvested. This points to a need for improved supplier communication and more stringent selection criteria.

Q 23. What is your knowledge of oyster-borne illnesses and prevention?

Oyster-borne illnesses, primarily caused by Vibrio bacteria (such as Vibrio vulnificus and Vibrio parahaemolyticus), are a serious concern. These bacteria thrive in warm, salty water and can accumulate in oysters. Prevention is crucial. It involves strict adherence to safe handling practices throughout the entire supply chain, from harvesting to consumption. This includes proper refrigeration at consistently cold temperatures (ideally between 33°F and 40°F or 0.5°C and 4°C), avoiding cross-contamination with other foods, and thorough cooking of oysters for those susceptible to illness. Thoroughly washing hands before and after handling oysters is essential. I regularly review the latest guidelines from the FDA and local health authorities to ensure our practices are up-to-date. Regular staff training is implemented to maintain a high level of awareness among the kitchen team on proper handling techniques and illness prevention.

Q 24. Describe your experience with oyster storage and handling.

My experience with oyster storage and handling is extensive. I’m trained in the principles of FIFO (First In, First Out) inventory management. Oysters should be stored in their original containers, on ice, in a refrigerated area away from other food items to prevent cross-contamination. It’s imperative to maintain consistent, low temperatures throughout the entire storage period. Regularly checking the oysters’ condition – looking for signs of spoilage such as open shells, unusual smells, or slimy textures – is a daily procedure. Oysters should never be stored at room temperature for extended periods. If any deterioration is observed, immediate removal and discarding of affected oysters are essential. I meticulously document temperature logs and oyster inventory to maintain complete traceability. Proper rotation, careful handling to avoid damage, and constant monitoring of temperature are essential to preserving their quality and safety.

Q 25. How do you assess the freshness of oysters?

Assessing oyster freshness involves a multi-sensory approach. First, I check the shell: A tightly closed shell is a good initial indicator. If it’s slightly open, I gently tap it; a live oyster will quickly close its shell. Next, I check for a strong, salty, briny aroma. An ammonia-like odor indicates spoilage. I then look at the oyster itself: A plump, moist oyster with a bright, glistening appearance is a sign of freshness. A dull, dry, or discolored oyster is likely not fresh. Finally, the texture should be firm and not slimy. Any sign of unusual discoloration or excessive slime points to spoilage. This process ensures only high-quality, safe oysters make it to our customers.

Q 26. What are the different types of oyster presentation for different culinary applications?

Oyster presentation varies greatly depending on the culinary application. For a simple appetizer, oysters on the half shell with mignonette sauce are classic. For a more sophisticated presentation, oysters can be incorporated into elaborate dishes like oyster stew, oyster Rockefeller, or pan-fried oysters. The preparation method influences the presentation as well: Grilled oysters will have a char that’s visually appealing; raw oysters will highlight their natural beauty. The size and type of oyster can also influence the presentation; larger oysters might be better suited for grilling or frying, while smaller ones may be ideal for dishes requiring numerous oysters. Each presentation aims to complement the dish’s taste and overall dining experience. A beautiful, well-thought-out presentation enhances the dining experience significantly.

Q 27. How do you comply with local health and safety regulations related to oyster handling?

Compliance with local health and safety regulations is paramount. I’m thoroughly familiar with the food safety codes in our area. This includes maintaining proper refrigeration temperatures, recording temperature logs, practicing safe food handling techniques, adhering to strict hygiene standards (hand washing, sanitation of equipment), and promptly disposing of spoiled oysters. I understand the regulations around shellfish tags and traceability, ensuring we only use oysters from approved sources and maintain accurate records. We undergo regular inspections and actively participate in any required training sessions or certification programs to ensure continued compliance. Maintaining a clean and organized workspace is also part of our commitment to these standards. Our team’s compliance with these regulations is regularly monitored and reinforced.

Q 28. Describe your experience working with a team in a fast-paced kitchen environment.

In a fast-paced kitchen, teamwork is essential. My experience includes working in high-volume settings where efficient and collaborative teamwork was crucial to meet customer demands. I am adept at anticipating needs, communicating clearly and effectively with colleagues, and contributing to a smooth workflow. I have collaborated with chefs, line cooks, and prep cooks, helping to maintain a positive and productive team environment even under pressure. Clear communication during peak hours prevents errors and ensures timely service. I believe in mutual respect and a shared commitment to delivering the highest standards in food quality and customer satisfaction. My ability to work effectively and efficiently under stress benefits the entire team, ensuring a smooth and successful service.

Key Topics to Learn for Oyster Knife Handling Interview

- Knife Selection and Maintenance: Understanding different types of oyster knives (e.g., blunt, pointed), their appropriate uses, and proper cleaning and sharpening techniques.

- Shucking Techniques: Mastering various shucking methods for different oyster shapes and sizes, emphasizing speed, efficiency, and safety.

- Safety Procedures: Prioritizing safe handling practices to minimize injury risk, including proper grip, knife control, and awareness of surroundings.

- Oyster Anatomy and Identification: Recognizing different oyster varieties and understanding their unique characteristics impacting shucking techniques.

- Quality Control and Waste Reduction: Identifying and handling damaged or undesirable oysters, minimizing waste, and maximizing yield.

- Troubleshooting and Problem-Solving: Addressing common challenges encountered during shucking (e.g., broken shells, difficult openings), and implementing effective solutions.

- Hygiene and Sanitation: Adhering to strict hygiene standards to maintain food safety and prevent contamination.

- Speed and Efficiency: Developing the skill and technique to shuck oysters quickly and consistently without compromising quality or safety.

Next Steps

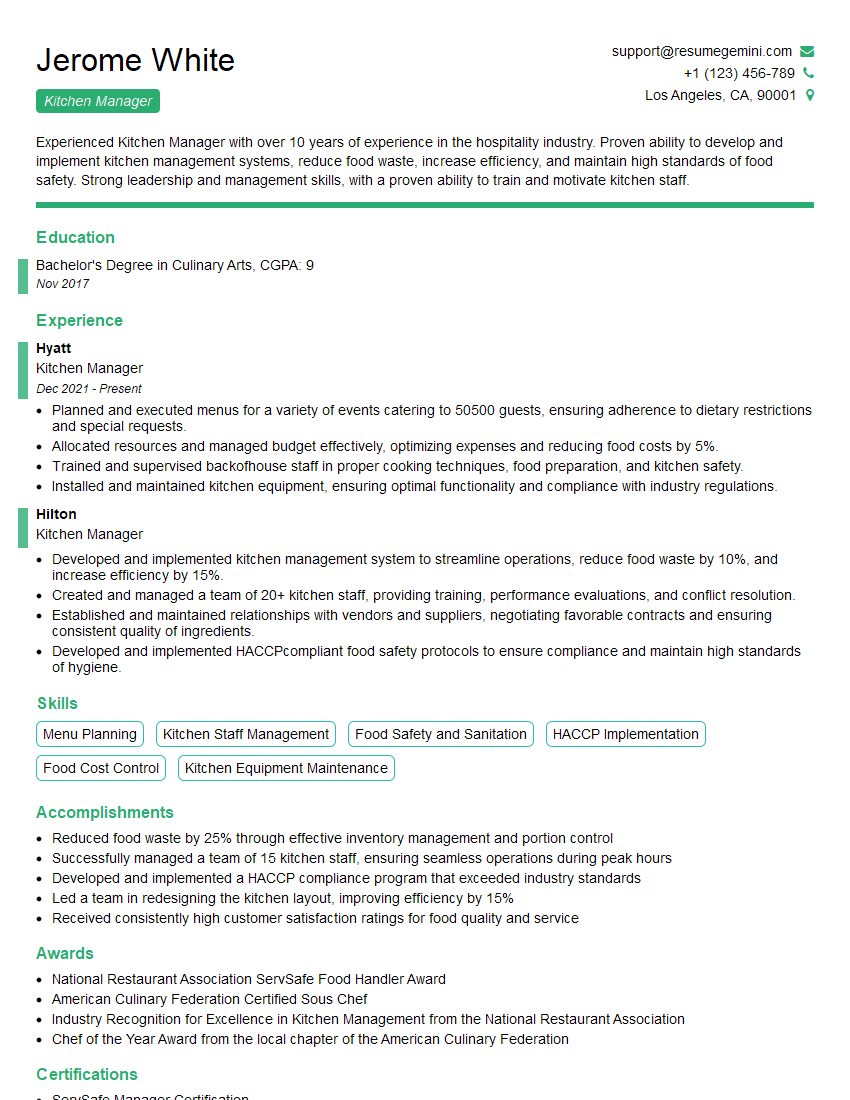

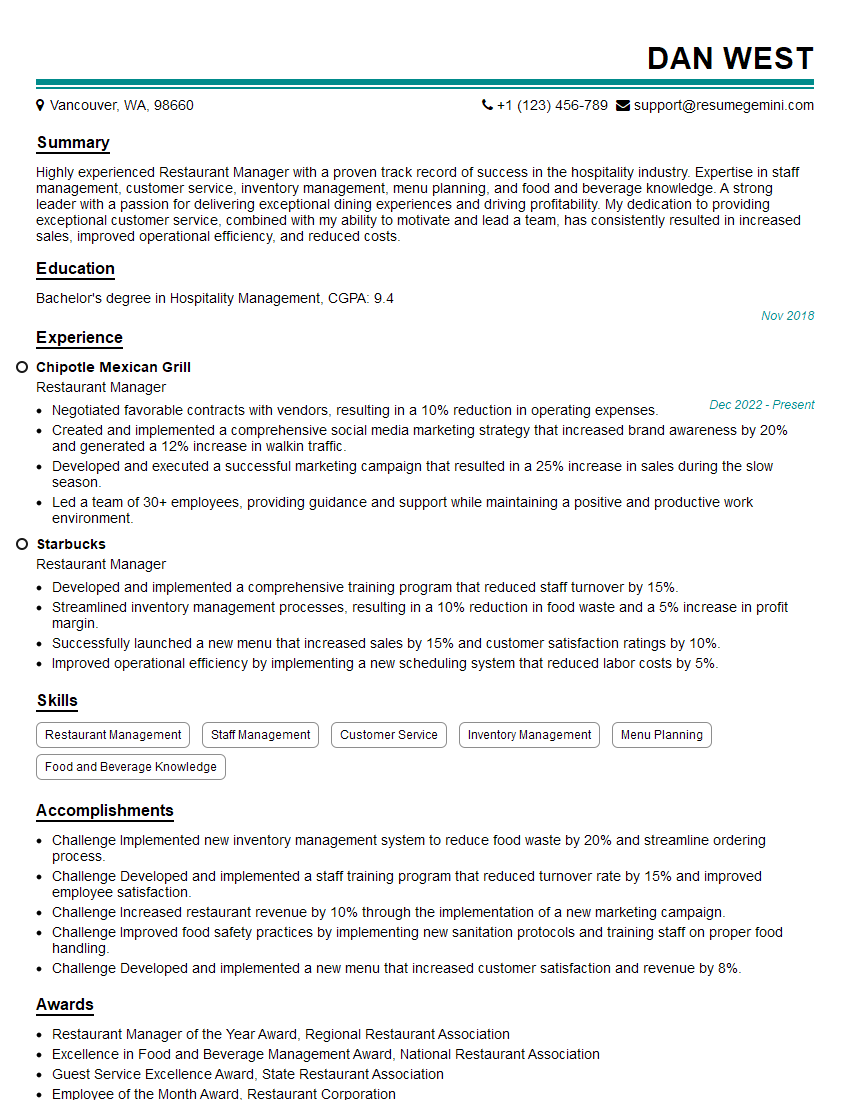

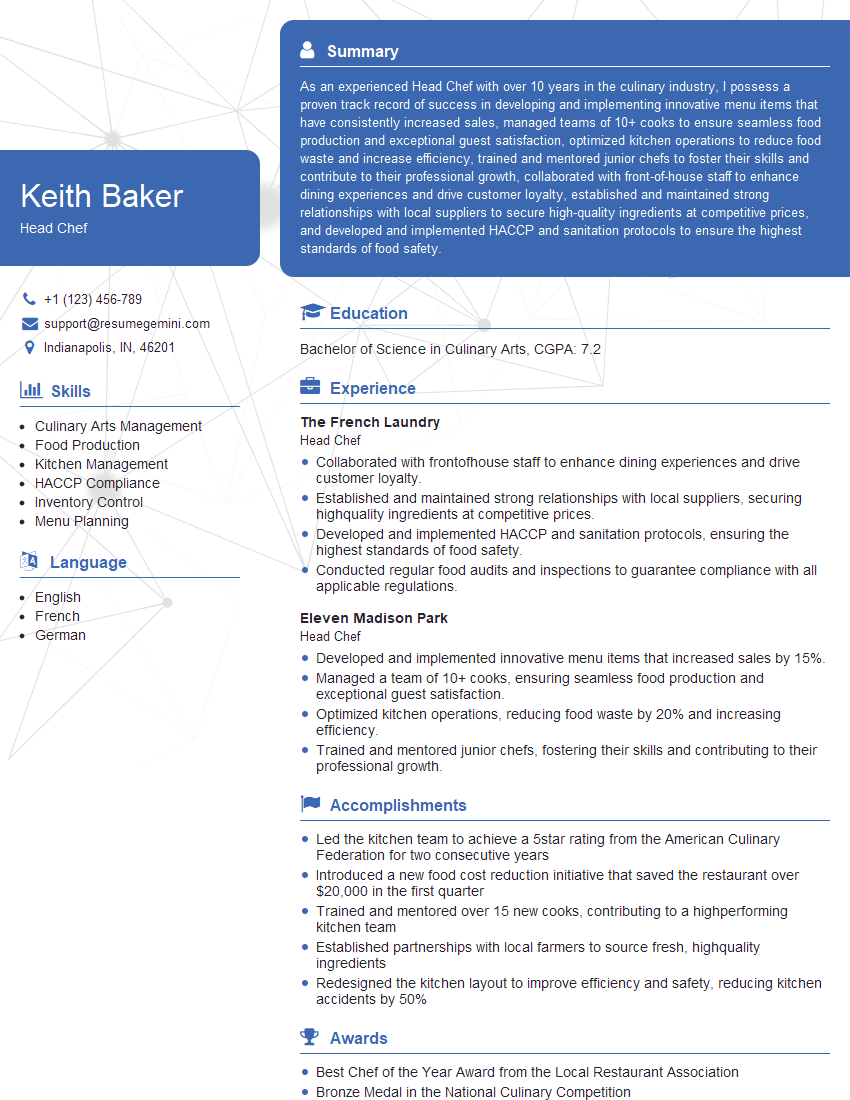

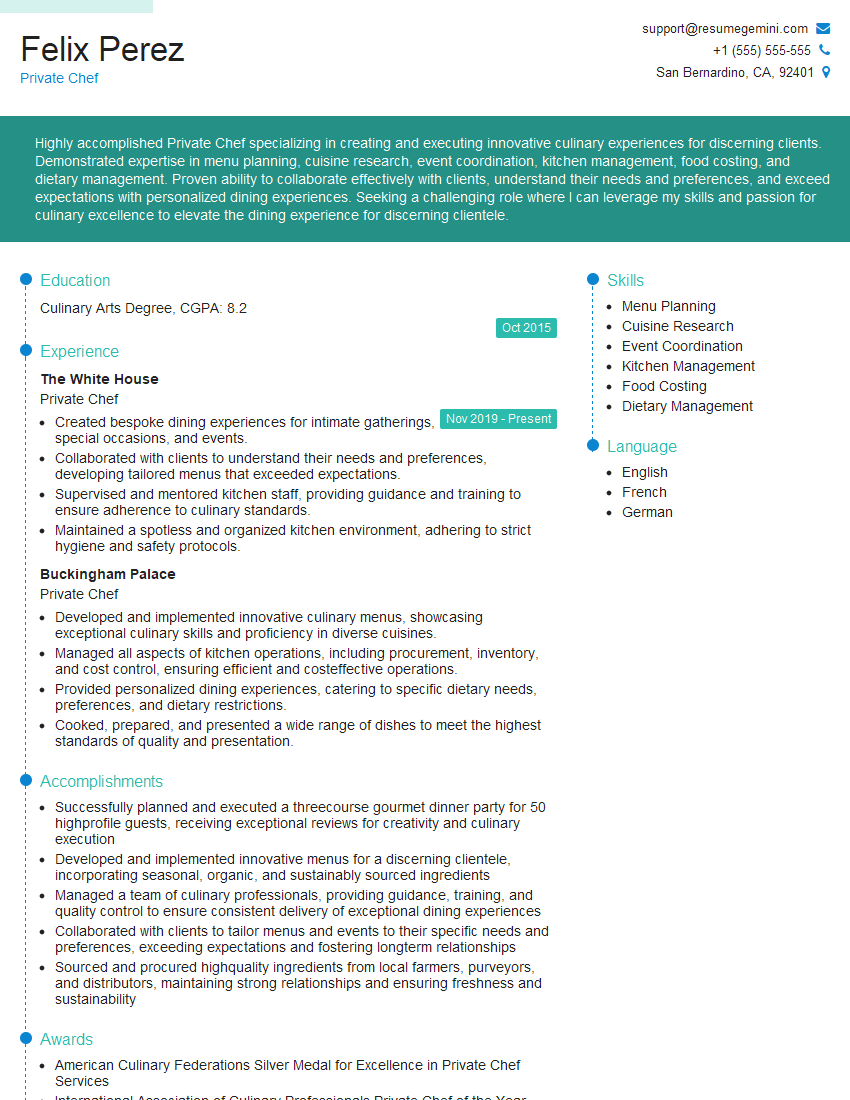

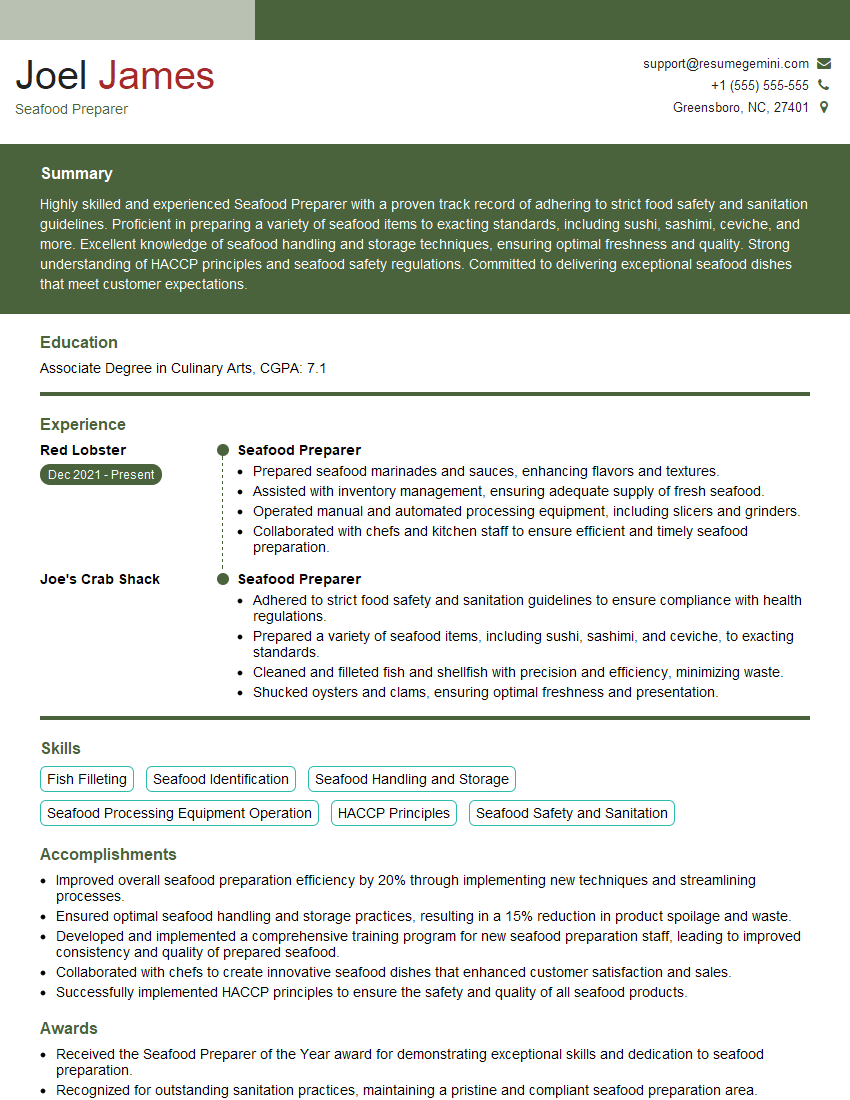

Mastering oyster knife handling is crucial for career advancement in the culinary and hospitality industries. Proficiency in this skill demonstrates precision, dexterity, and a commitment to food safety – highly valued attributes by employers. To maximize your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience. Examples of resumes tailored to Oyster Knife Handling are available to further assist your preparation.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good