Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Packaging and Labelling interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Packaging and Labelling Interview

Q 1. Explain the different types of packaging materials and their applications.

Packaging materials selection is crucial for product protection, shelf life, and consumer appeal. The choice depends on factors like product fragility, shelf life requirements, environmental conditions, and cost.

- Paperboard: A versatile material used for cartons, boxes, and folding cartons. It’s relatively inexpensive, recyclable, and readily printable. Think cereal boxes or shoe boxes.

- Corrugated Cardboard: Provides superior cushioning and protection, making it ideal for shipping heavier or fragile goods. Its strength-to-weight ratio is excellent. Examples include appliance packaging or shipping boxes.

- Plastics (e.g., PET, HDPE, PP): Offer excellent barrier properties against moisture, oxygen, and other environmental factors. Used for bottles, films, and pouches. PET is common for beverages, HDPE for milk jugs, and PP for yogurt containers.

- Glass: Offers excellent barrier properties and is inert, making it suitable for food and beverages. However, it’s fragile and heavy. Think wine bottles or jars.

- Metal (e.g., Aluminum, Tin): Provides excellent barrier properties and is durable. Aluminum cans are common for beverages and food, while tin cans are used for various products.

- Wood: Used for crates and pallets, offering robust protection during shipping and handling, especially for heavy or oversized goods.

Choosing the right material involves a careful cost-benefit analysis considering all factors. For instance, while glass offers superior barrier protection, its fragility and weight may increase shipping costs, making plastic a more cost-effective alternative in certain situations.

Q 2. Describe your experience with various packaging design software.

My experience encompasses a range of packaging design software, including Adobe Illustrator, InDesign, and Photoshop for creating and manipulating artwork. I’m also proficient in 3D modeling software such as SolidWorks and AutoCAD to create virtual prototypes and optimize designs for structural integrity and manufacturability. Furthermore, I have experience using specialized packaging design software like PackEdge and ArtiosCAD, allowing me to efficiently create and simulate packaging designs, ensuring they meet required specifications and production constraints. For example, I used ArtiosCAD to design a custom-fit corrugated box for a delicate electronic device, minimizing the risk of damage during shipping.

Q 3. How do you ensure packaging complies with relevant regulations (e.g., FDA, GMP)?

Compliance is paramount. My approach involves a multi-step process starting with a thorough understanding of the relevant regulations, including the FDA’s food contact substance regulations (21 CFR Part 170-189), Good Manufacturing Practices (GMP) guidelines, and other international and regional standards specific to the product and target market. This includes verifying that all materials used are compliant with food safety regulations, ensuring proper labeling with accurate information (ingredients, nutritional facts, warnings, etc.), and maintaining detailed records throughout the entire packaging process. I use a checklist and documentation system to ensure every step meets regulatory demands, preventing potential recalls or legal issues. We regularly conduct internal audits and engage third-party testing labs to verify compliance and maintain a high standard of quality.

Q 4. What are your strategies for optimizing packaging for cost-effectiveness?

Optimizing packaging for cost-effectiveness requires a holistic approach. It’s not simply about finding the cheapest materials; it’s about finding the most efficient combination of materials, design, and production methods. My strategies include:

- Material Selection: Choosing the most cost-effective material that still provides adequate protection and meets regulatory requirements. Sometimes, a slightly more expensive material might reduce waste or increase shelf life, resulting in long-term cost savings.

- Design Optimization: Minimizing material usage through efficient designs and reducing excess packaging. This may involve utilizing nested packaging, optimizing dimensions for efficient pallet loading, and exploring sustainable alternatives.

- Negotiating with Suppliers: Developing strong relationships with suppliers to secure favorable pricing and terms. Bulk purchasing can often lead to significant cost reductions.

- Lean Manufacturing Principles: Implementing lean manufacturing principles to minimize waste throughout the packaging process, from material handling to production, reducing operational expenses.

- Waste Reduction Strategies: Implementing strategies to reduce or eliminate waste, such as using post-consumer recycled materials or designing packaging for easy disassembly and recycling.

For example, I once redesigned a product’s packaging, reducing the material usage by 15% without compromising its protective function, leading to significant annual cost savings.

Q 5. Explain your experience with different printing techniques for labels.

My experience includes various label printing techniques, each with its own advantages and disadvantages. These include:

- Flexographic Printing: A cost-effective method for high-volume printing using flexible plates. It’s ideal for simple designs on flexible materials like films and pouches.

- Offset Lithography: Produces high-quality, detailed images, ideal for labels with intricate designs and sharp color reproduction. It’s better suited for large print runs.

- Digital Printing: Allows for short-run, customized labels, ideal for small batches or personalized products. Offers rapid turnaround times and versioning flexibility.

- Screen Printing: Suitable for thick inks and textured surfaces, commonly used for special effects or bold designs. However, it’s less efficient for complex designs.

The choice of printing technique depends on factors such as print volume, design complexity, budget, and substrate. For instance, I’d choose digital printing for a small batch of customized labels for a promotional campaign, while flexographic printing would be more appropriate for mass production of simple labels for a large grocery chain.

Q 6. How do you manage packaging waste and promote sustainability?

Managing packaging waste and promoting sustainability is crucial for environmental responsibility and brand image. My approach involves a multi-pronged strategy:

- Sustainable Material Selection: Prioritizing recyclable, compostable, or biodegradable materials whenever possible, such as recycled paperboard or plant-based plastics.

- Lightweighting: Designing packaging to use minimal material without compromising protection, thus reducing overall waste.

- Design for Recyclability: Designing packaging that is easily recyclable and clearly labeled with recycling instructions to encourage proper disposal.

- Collaboration with Suppliers: Working with suppliers to source sustainable materials and explore innovative packaging solutions.

- Waste Audits and Reduction Programs: Implementing waste audits to identify areas for improvement and developing waste reduction programs to minimize environmental impact.

- Life Cycle Assessment (LCA): Conducting Life Cycle Assessments (LCA) to evaluate the environmental impact of different packaging options across their entire life cycle.

For example, I once led a project to redesign a product’s packaging, resulting in a 20% reduction in material usage and a switch to 100% recyclable materials, significantly reducing the company’s environmental footprint.

Q 7. Describe your experience with quality control procedures in packaging.

Quality control in packaging is critical to ensure product integrity and brand reputation. My experience involves implementing a robust quality control system that includes:

- Incoming Material Inspection: Inspecting incoming materials for defects or inconsistencies to prevent flawed packaging from entering the production process.

- In-Process Inspection: Monitoring the packaging process at various stages to identify and correct any errors or deviations from specifications.

- Finished Goods Inspection: Inspecting the finished packages for defects, misprints, or damage before shipment.

- Statistical Process Control (SPC): Using statistical process control methods to monitor and improve the consistency of the packaging process.

- Data Collection and Analysis: Collecting data on quality metrics and analyzing it to identify trends and areas for improvement.

- Root Cause Analysis: Conducting root cause analyses to identify the underlying causes of any quality problems and implement corrective actions.

For example, I once implemented a new statistical process control system that reduced the defect rate in our packaging process by 15%, leading to significant cost savings and improved customer satisfaction.

Q 8. How do you ensure the integrity and safety of packaged goods during transportation?

Ensuring the integrity and safety of packaged goods during transportation is paramount. It involves a multi-faceted approach focusing on both the packaging design and the handling process. Think of it like building a protective fortress for your product during its journey.

- Robust Packaging Design: This includes selecting appropriate materials with sufficient strength and cushioning to withstand shocks, vibrations, and compression. For example, using corrugated cardboard boxes with appropriate flute type for heavier products, incorporating void fill (like air pillows or bubble wrap) to prevent shifting, and employing protective corner boards or edge protectors to safeguard vulnerable areas.

- Proper Packaging and Loading: Careful packaging of individual items, followed by secure loading and bracing within the transport vehicle is crucial. This reduces the risk of damage during transit. Imagine stacking bricks – they need to be stable to avoid collapse.

- Environmental Considerations: Temperature, humidity, and light exposure can affect product stability. Temperature-sensitive items need insulated packaging and potentially refrigerated transport. Light-sensitive products might require opaque packaging. Think of chocolate melting in the sun – that’s a packaging failure!

- Tracking and Monitoring: Utilizing tracking systems allows for real-time monitoring of shipments, enabling swift intervention should any issues arise. This provides peace of mind and facilitates prompt resolution of problems.

By diligently addressing these aspects, we minimize damage, spoilage, and ensure the product reaches its destination in perfect condition.

Q 9. Explain your understanding of barrier properties in packaging materials.

Barrier properties in packaging refer to the material’s ability to prevent the passage of substances like gases, moisture, or aromas into or out of the package. It’s like building a wall to protect the contents. These properties are crucial to maintaining product quality, safety, and shelf life.

- Moisture Barrier: Prevents moisture from entering (causing spoilage) or leaving (leading to dryness). Think of food packaging – crackers need protection from moisture to remain crispy.

- Gas Barrier: Prevents oxygen ingress (which can cause oxidation and rancidity) or prevents volatile compounds from escaping (affecting aroma and flavor). Coffee bags often use a specialized foil to prevent aroma loss.

- Aroma Barrier: Prevents odors from entering or escaping, keeping the product’s scent intact. Perfume bottles need excellent aroma barriers.

- Light Barrier: Protects light-sensitive products from degradation caused by UV light. Many pharmaceuticals and certain foods require protection from sunlight.

The effectiveness of a barrier depends on the material’s composition, thickness, and the manufacturing process. Various materials like polymers, foils, and laminates are used to achieve different barrier levels. Selecting the right barrier properties is a critical design decision.

Q 10. How do you handle packaging design challenges related to product fragility?

Packaging fragile items requires a thoughtful approach to prevent breakage. We’re aiming for protection, not just containment.

- Cushioning and Void Fill: Using materials like bubble wrap, foam peanuts, or air pillows to surround the product and absorb shocks. The amount and type of cushioning depend on the fragility of the product and the expected handling conditions. Imagine a delicate vase – ample cushioning is a must!

- Structural Design: The packaging itself must be strong enough to withstand forces during handling. This might involve using heavier-gauge cardboard, reinforced corners, or custom-designed inserts. Think of a wine bottle carrier – the individual compartments are key to protection.

- Specialized Packaging: For extremely fragile items, specialized containers like custom-fit foam inserts, corrugated fiberboard tubes, or even air-filled inflatable bags may be needed. Consider the transport of electronics – static protection and shock absorption is paramount.

- Orientation and Labeling: Clearly labeling the package with “fragile” handling instructions and proper orientation markings ensures careful handling throughout the supply chain. The simple act of stating “This side up” can make a huge difference.

Careful consideration of these factors, combined with testing, ensures the safe transport of delicate goods. It’s all about mitigating risk at each stage of the process.

Q 11. What are your methods for testing the strength and durability of packaging?

Testing the strength and durability of packaging involves a combination of methods to simulate real-world conditions. The goal is to identify weaknesses and ensure the package performs as expected.

- Drop Tests: Dropping packages from specified heights onto various surfaces to assess their ability to withstand impacts. This simulates accidental drops during handling.

- Compression Tests: Applying pressure to the package to simulate stacking and weight loads during transportation. This helps determine how much weight the package can bear.

- Vibration Tests: Exposing packages to vibrations to mimic the conditions experienced during transit. This reveals weaknesses under constant shaking.

- Climate Testing: Exposing packages to extreme temperatures and humidity levels to assess their ability to maintain integrity under different environmental conditions. This is crucial for products sensitive to temperature fluctuations.

- Burst Tests: Measuring the pressure needed to rupture a package, particularly useful for flexible film packaging.

These tests provide quantitative data to optimize packaging design and material selection, ultimately ensuring product protection. The results guide improvements and prevent costly product damage in the real world.

Q 12. Describe your experience with different types of closures and sealing techniques.

Closures and sealing techniques are crucial for maintaining product integrity and preventing contamination. The choice depends on the product, packaging type, and desired level of protection.

- Screw Caps: Common for bottles and jars, offering a secure and reusable closure. They are easy to use and widely available.

- Press-on Caps: Simple and cost-effective, suitable for less sensitive products. However, they lack the security of screw caps.

- Crimp Seals: Used for cans and tubes, providing a tamper-evident seal. They offer a strong, airtight closure.

- Induction Sealing: Uses heat to seal a foil liner to a container, creating a hermetic seal that prevents contamination. Common in food and pharmaceutical packaging.

- Heat Sealing: Joining two layers of film material using heat, commonly used for flexible packaging like pouches and bags.

- Ultrasonic Sealing: Uses high-frequency sound waves to create a seal without heat, ideal for heat-sensitive materials.

Selecting the right closure and sealing technique is a critical decision that balances usability, cost-effectiveness, and product protection. The choice depends on the specific needs of the product and the intended application.

Q 13. How do you ensure accurate and legible labeling of products?

Accurate and legible labeling is essential for consumer safety, legal compliance, and brand reputation. It must clearly convey all the necessary information.

- Clear and Concise Information: The label must clearly state the product name, ingredients, weight or volume, manufacturer details, and any relevant warnings or instructions. Ambiguity is unacceptable.

- Legible Font and Size: The text must be easily readable, using an appropriate font size and style for the target audience. Smaller text might be acceptable for secondary information but key details need to be prominent.

- Appropriate Language: The label should be in the language(s) understood by the target market. Multilingual labeling is common for global products.

- Accurate Information: All information on the label must be factually correct and up-to-date. Any inaccuracies can have serious legal and ethical consequences.

- High-Quality Printing: The label needs to be printed using durable inks that will not fade or smudge. The overall appearance should be professional and represent the brand well.

- Barcodes and QR Codes: Including barcodes and QR codes improves inventory management and enhances consumer engagement (providing additional product information).

Effective labeling goes beyond simple compliance; it’s a vital part of successful product presentation and customer trust.

Q 14. Explain your understanding of different labeling requirements across various regions.

Labeling requirements vary significantly across different regions due to differing regulations, cultural practices, and consumer expectations. Ignoring these differences can lead to product recalls, fines, and reputational damage.

- Food and Beverage Labeling: Regulations regarding ingredient listing, nutritional information, allergen declarations, and labeling claims differ substantially between countries (e.g., the EU’s stringent allergen regulations versus those in the US).

- Cosmetic and Personal Care Products: Labeling requirements vary concerning ingredient disclosure, safety warnings, and testing methodologies. The EU’s restrictions on certain chemicals are considerably stricter than some other regions.

- Pharmaceutical Products: Strict regulations govern pharmaceutical labeling, requiring detailed information about dosage, warnings, side effects, and storage instructions. Variations exist widely between regulatory bodies.

- Language Requirements: Local language requirements are often mandatory for product labels within a given country or region.

- Unit of Measure: Units of measure (metric vs. imperial) must comply with local standards.

Navigating these diverse requirements necessitates collaboration with international regulatory experts and careful attention to detail to ensure legal compliance and market access.

Q 15. Describe your experience with barcode and RFID technologies in packaging.

Barcode and RFID technologies are crucial for efficient track-and-trace systems in packaging. Barcodes, like UPCs and EANs, provide a simple, cost-effective way to identify individual products. They are read optically using scanners and contain encoded information such as product identification and batch numbers. I’ve extensively used barcodes in projects ranging from designing labels for consumer goods to implementing inventory management systems for large warehouses. RFID, or Radio-Frequency Identification, offers a more advanced solution. RFID tags, unlike barcodes, don’t require line-of-sight for reading. They use radio waves to transmit data, allowing for automated identification and tracking of products throughout the supply chain, even within pallets or containers. For instance, I worked on a project implementing RFID tags in pharmaceutical packaging, enabling real-time monitoring of drug distribution and preventing counterfeiting. My experience encompasses selecting the appropriate technology based on factors like cost, required data density, and the environment the packaging will face. Choosing between barcode and RFID is always a trade-off, balancing cost and functionality.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you incorporate consumer needs and preferences into packaging design?

Understanding consumer needs and preferences is paramount in packaging design. This starts with thorough market research, analyzing demographics, purchasing habits, and lifestyle trends. For example, if I’m designing packaging for a new line of organic baby food, I’d research parents’ priorities, focusing on safety, eco-friendliness, ease of use, and nutritional information. I’d use focus groups and surveys to gather feedback on design elements – color schemes, materials, and the overall aesthetic. We’d consider factors like shelf appeal – does the package stand out among competitors? – and usability – is it easy to open, reseal, and store? The design process is iterative; we test prototypes and incorporate feedback to ensure the packaging effectively caters to the target audience and reflects the product’s brand identity and values. In one project involving a sustainable snack brand, we opted for compostable packaging and a minimalist, earthy color scheme to resonate with environmentally conscious consumers.

Q 17. How do you evaluate the performance and effectiveness of packaging designs?

Evaluating packaging design effectiveness involves a multi-faceted approach. We assess performance across several key areas: Physical Protection: Does the packaging effectively protect the product during transportation and storage from damage (shock, vibration, moisture)? Barrier Properties: Does the packaging maintain product quality and extend shelf life by protecting against oxygen, moisture, light, or other environmental factors? Usability: Is the packaging easy to open, handle, and close, minimizing consumer frustration? Sustainability: Are the materials environmentally friendly, recyclable, or compostable? We use various methods like drop tests to assess physical protection, measuring oxygen transmission rate to evaluate barrier properties, and conducting usability studies to assess consumer ease of use. We also consider cost-effectiveness, calculating the overall packaging cost against the product value and potential losses due to damage. Data analysis helps quantify the outcomes of these tests, allowing us to make data-driven decisions for improvement.

Q 18. Explain your experience with packaging automation and robotics.

My experience with packaging automation and robotics spans various technologies including robotic palletizing, automated case packing, and high-speed filling machines. I’ve been involved in selecting and integrating equipment for several projects, focusing on increasing efficiency and reducing labor costs. One significant project involved implementing a robotic arm to automatically place products into boxes, replacing a manual process that was prone to errors and slow. This involved collaborating with robotics engineers, programming the robots, and ensuring seamless integration with the existing packaging line. The challenge lies in optimizing the speed and accuracy of the robots while minimizing downtime. This often requires careful planning and integration with other automated systems like conveyors and labeling machines. The benefits of automation are significant – increased throughput, improved consistency, reduced labor costs, and reduced product damage. Understanding the specific needs of the packaging line is critical for successful integration of robotic systems.

Q 19. What is your experience with supplier relationship management in packaging?

Supplier relationship management (SRM) is crucial in the packaging industry. I manage relationships with multiple suppliers, including material providers (e.g., paperboard, plastic, inks), packaging converters (manufacturers of boxes, labels, and other packaging components), and logistics providers. Strong relationships are key to securing high-quality materials at competitive prices, and ensuring timely delivery. I employ strategies such as regular communication, performance reviews, and collaborative problem-solving. I prioritize establishing clear expectations and contractual agreements with suppliers. For instance, I’ve successfully negotiated contracts that guarantee sustainable sourcing practices and reduced lead times. When challenges arise, such as material shortages or quality issues, effective communication and collaboration are crucial to finding mutually beneficial solutions. It is crucial to use a balance of both long-term strategic relationships and contingency suppliers to ensure stability and adaptability in the face of market fluctuations.

Q 20. Describe your approach to troubleshooting packaging-related issues.

Troubleshooting packaging issues requires a systematic approach. It often begins with clearly defining the problem – is it a quality issue, a performance issue, or a cost issue? I typically follow a structured approach: 1. Data Collection: Gather data on the problem’s frequency, severity, and impact. This might involve examining damaged products, reviewing production records, and collecting feedback from customers or production staff. 2. Root Cause Analysis: Use tools such as the 5 Whys or fishbone diagrams to identify the underlying cause. For example, if packages are arriving damaged, we might determine the root cause to be inadequate cushioning material or improper handling during transportation. 3. Solution Development: Based on the root cause analysis, develop potential solutions and assess their feasibility and cost-effectiveness. 4. Implementation & Verification: Implement the chosen solution, monitor its effectiveness, and make adjustments as needed. 5. Documentation: Document the problem, the root cause, and the solution implemented. This knowledge base helps prevent similar problems in the future.

Q 21. How do you manage projects related to packaging design and development?

Managing packaging design and development projects involves a structured approach using project management methodologies like Agile or Waterfall. I start with a thorough understanding of project objectives, budget, and timeline. I establish clear roles and responsibilities within the project team, including designers, engineers, and suppliers. Throughout the project, I maintain open communication and hold regular meetings to track progress, address challenges, and make informed decisions. I utilize project management software to track tasks, milestones, and budgets. Risk management is a critical aspect of the process. I identify potential risks (e.g., material shortages, design flaws, regulatory changes) and develop mitigation plans. For instance, in one project involving a complex multi-material package, I created a detailed risk assessment and implemented rigorous quality control measures to minimize potential issues. The successful completion of a project relies heavily on effective communication, meticulous planning, and adaptable problem-solving.

Q 22. Explain your understanding of shelf-life extension and its impact on packaging.

Shelf-life extension is the process of increasing the time a product remains safe, palatable, and of acceptable quality before spoilage. This is crucial for minimizing waste and maximizing profitability. Packaging plays a vital role; it’s the first line of defense against external factors that degrade product quality.

For example, consider the impact of oxygen on food products. Oxygen exposure can lead to oxidation, rancidity, and the growth of aerobic microorganisms. Packaging solutions such as modified atmosphere packaging (MAP), where the air inside the package is replaced with a mixture of gases like nitrogen and carbon dioxide, significantly extend shelf life by inhibiting these processes. Vacuum packaging removes oxygen altogether, offering another excellent example.

Other packaging strategies for shelf-life extension include using materials that provide a barrier against moisture, light, and temperature fluctuations. Barrier films are specifically designed to control gas permeability, water vapor transmission, and light transmission, all factors impacting food quality and safety.

In my experience, effective shelf-life extension requires a holistic approach. It involves careful consideration of the product’s characteristics, its sensitivity to various environmental factors, and the selection of an appropriate packaging material and design to create a protective microclimate for the product.

Q 23. How do you ensure traceability of products through packaging and labeling?

Product traceability, the ability to track a product’s journey from origin to consumer, is paramount for quality control, safety, and recall management. Packaging and labeling are essential tools for achieving this.

- Unique Identification Codes: Each package should contain a unique identifier, such as a barcode (UPC, EAN), RFID tag, or a lot number. These codes link the product to its manufacturing batch, production date, and other relevant information within a database.

- Lot Numbering and Tracking: Detailed records of lot numbers, manufacturing dates, and locations need to be meticulously maintained throughout the supply chain. This allows for rapid identification and isolation of contaminated or defective batches.

- Labeling Information: Labels must clearly indicate the product’s origin, ingredients, and best-by or expiration dates. This ensures customers have access to critical information about the product’s quality and safety.

- Supply Chain Management Software: Integrating packaging information with supply chain management software enables real-time tracking and monitoring of product movement, providing complete visibility and enhanced traceability capabilities.

For example, in the pharmaceutical industry, each drug package contains a unique serial number linked to detailed manufacturing data. This allows for effective counterfeit detection and allows authorities to quickly identify and recall contaminated batches if necessary. Similarly, food manufacturers use lot numbers to trace the origin of ingredients and ensure that products meet stringent safety standards.

Q 24. What are your experience with different types of packaging machinery?

My experience encompasses a wide range of packaging machinery, including form-fill-seal machines, cartoners, case packers, palletizers, and labeling equipment.

- Form-Fill-Seal (FFS): I’ve worked extensively with FFS machines for flexible packaging, such as pouches and bags. This includes troubleshooting mechanical issues, optimizing production speeds, and ensuring consistent package quality.

- Cartoners and Case Packers: I have experience in setting up and maintaining automatic cartoning and case packing lines, focusing on improving efficiency and minimizing downtime. This often includes programming and adjusting machinery settings to handle different product sizes and packaging configurations.

- Labeling Machines: My expertise covers various labeling technologies, including pressure-sensitive labeling, wrap-around labeling, and shrink-sleeve labeling. I’ve been involved in selecting appropriate labeling machines, integrating them into existing production lines, and ensuring accurate and consistent label application.

- Palletizers: I’m familiar with robotic and conventional palletizers, focusing on optimizing palletizing patterns and improving the overall efficiency of the packaging process. This includes selecting the appropriate palletizing configuration to minimize waste and maximize shipping efficiency.

My experience extends to troubleshooting malfunctions, conducting preventative maintenance, and implementing improvements to enhance the overall performance and reliability of packaging machinery.

Q 25. Describe your understanding of packaging material sourcing and procurement.

Sourcing and procurement of packaging materials is a critical aspect of packaging management, impacting both cost and sustainability. It requires a strategic approach balancing cost, quality, and environmental considerations.

- Supplier Selection: Thorough due diligence is vital. I evaluate potential suppliers based on factors such as their manufacturing capabilities, quality control systems, reliability, and ethical sourcing practices. This may involve conducting site visits and audits.

- Material Specification: Precise material specifications are crucial. This includes defining required properties like barrier performance, strength, printability, and recyclability. The specifications are often based on product requirements and regulatory compliance needs.

- Negotiation and Contract Management: Effective negotiation with suppliers is crucial for securing favorable pricing and terms. This includes managing contracts to ensure compliance with agreed-upon quality, delivery schedules, and environmental standards.

- Inventory Management: Efficient inventory management is essential to avoid stockouts and minimize waste. This may involve implementing Just-in-Time (JIT) delivery systems or employing sophisticated inventory tracking and forecasting methods.

- Sustainability Considerations: Increasingly, sustainable packaging is a priority. I evaluate suppliers’ environmental performance and seek out eco-friendly materials, such as recycled content or biodegradable options, aligning with the company’s sustainability goals.

For instance, I successfully negotiated a long-term contract with a supplier offering recycled PET for our product packaging, resulting in significant cost savings and a reduction in our environmental impact.

Q 26. Explain your experience with packaging line optimization and improvement.

Packaging line optimization is a continuous process aiming to improve efficiency, reduce waste, and enhance product quality. My experience in this area involves a structured approach, often using Lean Manufacturing principles.

- Value Stream Mapping: This technique visually maps the entire packaging process, identifying bottlenecks and areas for improvement. It helps in visualizing the flow of materials and information and pinpointing waste generation points.

- Process Improvement Techniques: I apply various techniques like Kaizen (continuous improvement), Six Sigma, and 5S methodology to systematically address identified bottlenecks and reduce downtime.

- Automation and Technology Integration: Implementing automation technologies such as robotic palletizers, automated guided vehicles (AGVs), and advanced sensor systems can significantly improve efficiency and reduce labor costs.

- Data Analysis: Regular data analysis of production metrics—such as output rate, downtime, and defect rates—provides insights for continuous improvement. I utilize this data to track the effectiveness of implemented changes and identify further optimization opportunities.

- Training and Personnel Development: Investing in training for operators to improve their skills and understanding of the packaging processes can significantly enhance the line’s efficiency and product quality.

In a recent project, I implemented a new line balancing strategy, reducing the cycle time by 15% and increasing overall throughput by 20% without significant capital investment.

Q 27. How do you ensure compliance with brand guidelines in packaging design?

Adhering to brand guidelines is crucial for maintaining brand consistency and recognition. Packaging design must accurately reflect the brand’s identity, values, and target market.

- Understanding Brand Guidelines: Thorough understanding of the brand’s style guide, including logo usage, color palettes, typography, and imagery, is the first step. This involves working closely with the marketing and design teams.

- Design Review and Approval Process: A structured review and approval process ensures all packaging designs align with brand guidelines. This process often involves multiple stakeholders, including marketing, design, legal, and production teams.

- Digital Asset Management: Using a digital asset management system to store and share approved brand assets ensures consistent access and usage throughout the design process.

- Quality Control: Rigorous quality control checks are necessary at various stages of production to ensure that printed materials accurately reflect the approved designs. This includes reviewing pre-press proofs and inspecting the final printed packaging.

- Global Brand Consistency: For multinational companies, maintaining brand consistency across different regions and markets requires careful consideration of cultural nuances and local regulations.

For example, I’ve worked on projects where we had to adapt packaging designs for different markets while ensuring alignment with global brand guidelines. This required careful coordination with local teams and adapting designs to meet local regulatory requirements.

Q 28. Describe your experience with conducting cost-benefit analysis for packaging options.

Conducting a cost-benefit analysis for packaging options is crucial for making informed decisions that balance cost-effectiveness with quality and sustainability. It’s a systematic approach to comparing various packaging solutions.

- Defining Objectives and Scope: Clearly define the project goals, such as cost reduction, improved shelf life, or enhanced sustainability. Identify specific criteria for evaluating different packaging options.

- Identifying Potential Packaging Options: Explore various packaging materials, designs, and formats to satisfy the product’s requirements and marketing objectives.

- Cost Estimation: Accurately estimate the total costs of each option. This includes material costs, manufacturing costs, transportation costs, and potential waste disposal costs.

- Benefit Assessment: Quantify the benefits of each packaging option. This could include reduced product damage, extended shelf life leading to reduced waste, improved consumer appeal, and positive environmental impact.

- Comparative Analysis: Compare the total cost and benefits of each option, often using techniques such as net present value (NPV) or return on investment (ROI) calculations. This allows for a clear understanding of the financial implications of each decision.

- Risk Assessment: Identify potential risks associated with each option, such as supply chain disruptions, material availability issues, and potential environmental liabilities.

For example, in a recent project, we compared the cost and benefits of switching from glass jars to plastic containers. The cost-benefit analysis showed that switching to plastic offered significant cost savings while maintaining acceptable product protection, ultimately leading to a more financially viable and environmentally responsible choice.

Key Topics to Learn for Packaging and Labelling Interview

- Packaging Materials Science: Understanding the properties of various materials (e.g., paperboard, plastics, metals) and their suitability for different products and applications. Consider factors like barrier properties, printability, and recyclability.

- Packaging Design & Engineering: Explore concepts like structural design, ergonomics, and functionality. Be prepared to discuss how packaging protects the product during transport and storage, and enhances its shelf life.

- Labeling Regulations & Compliance: Familiarize yourself with relevant legal requirements (e.g., FDA regulations, ingredient labeling, hazard warnings) and best practices for accurate and compliant labeling.

- Sustainable Packaging Practices: Discuss environmentally friendly packaging options, reducing waste, and the circular economy principles in packaging design and management.

- Supply Chain & Logistics: Understand the flow of packaging materials, from sourcing to manufacturing to distribution. Be ready to discuss the impact of packaging on efficiency and cost.

- Production Processes: Gain knowledge of common packaging and labeling production techniques (e.g., printing, filling, sealing) and their associated challenges and solutions.

- Quality Control & Assurance: Understand the importance of quality control throughout the packaging process, including inspection methods and statistical process control techniques.

- Cost Optimization & Analysis: Be able to discuss strategies for minimizing packaging costs without compromising quality or functionality. Consider material selection, design efficiency, and waste reduction.

Next Steps

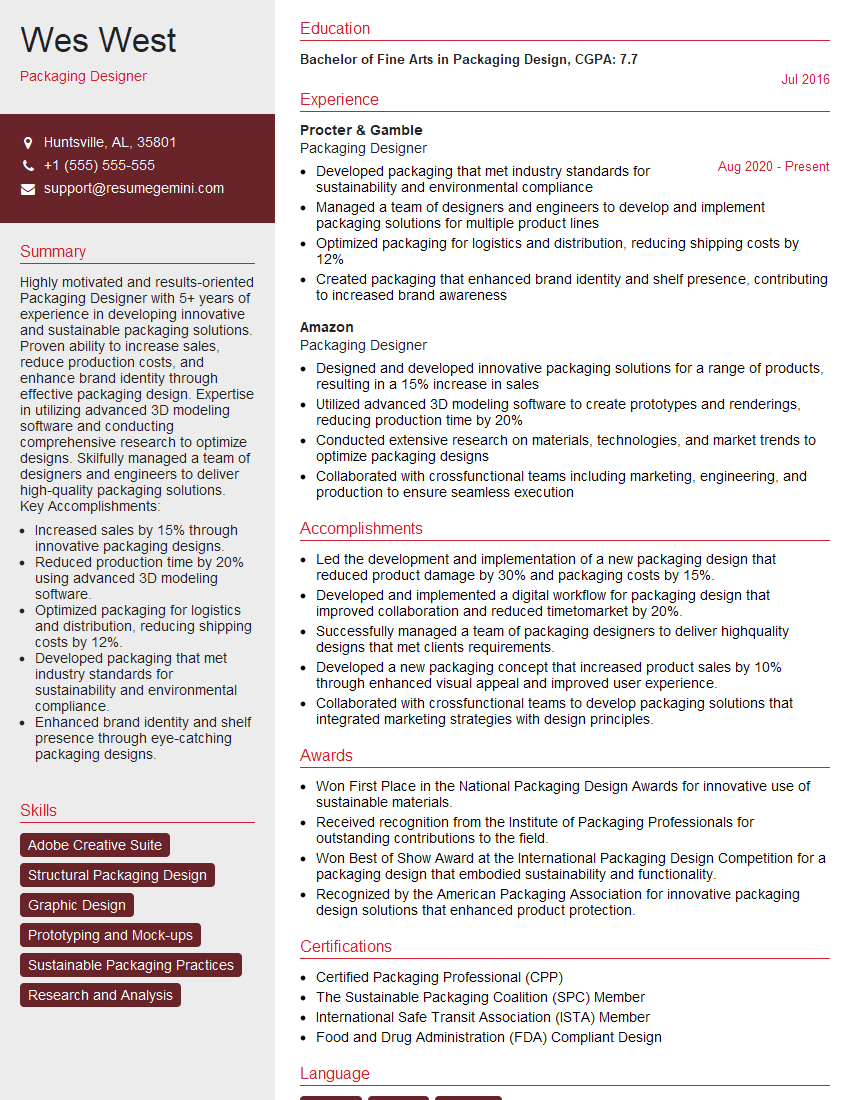

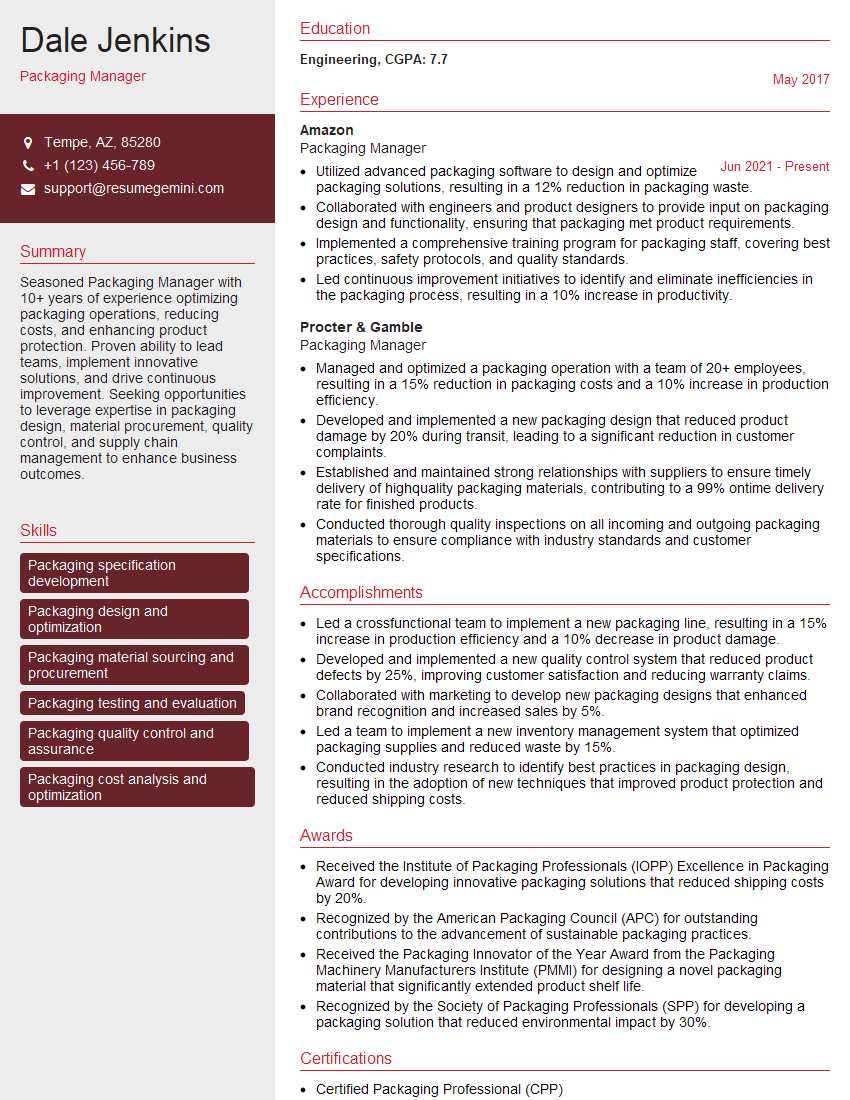

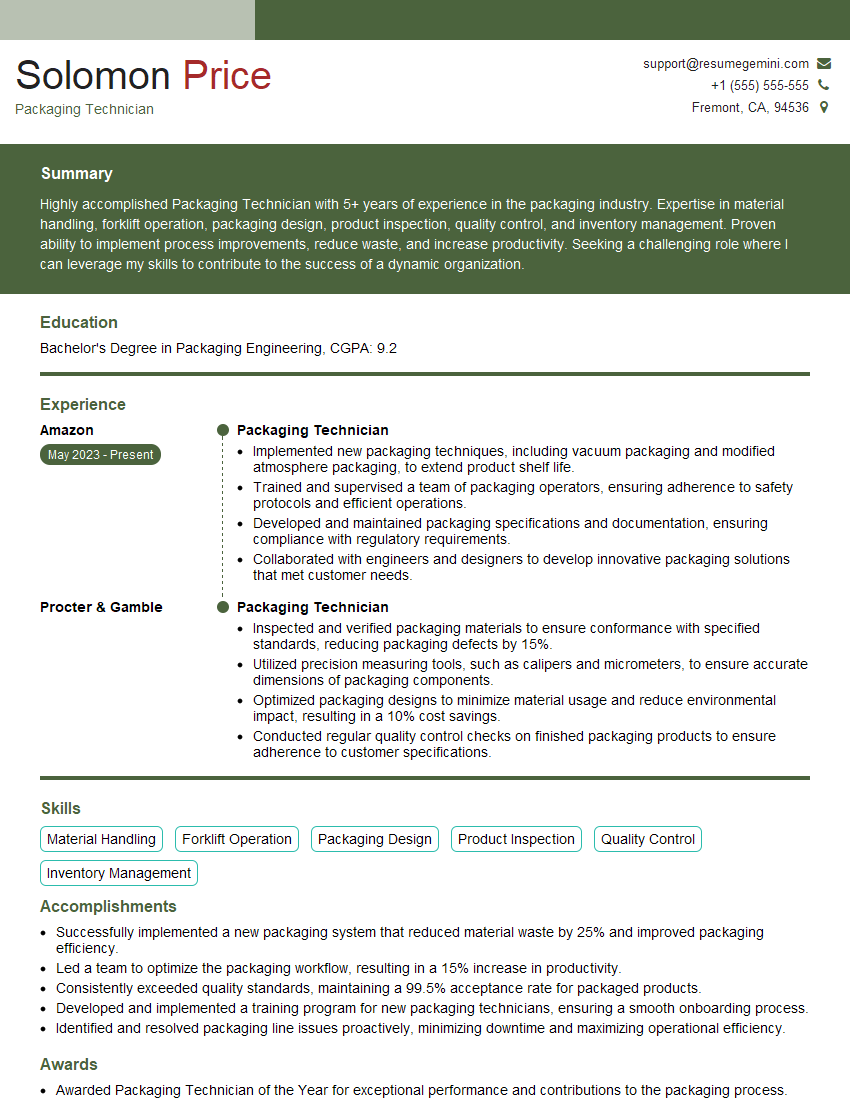

Mastering Packaging and Labelling opens doors to exciting career opportunities in a dynamic and ever-evolving industry. A strong understanding of these key areas will significantly enhance your interview performance and increase your chances of landing your dream job. To further strengthen your application, focus on crafting an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the Packaging and Labelling industry. Examples of resumes specifically designed for this field are available through ResumeGemini, allowing you to showcase your qualifications effectively.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good