The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Packing and shipping products interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Packing and shipping products Interview

Q 1. Explain the importance of proper packaging in preventing damage during transit.

Proper packaging is the cornerstone of successful shipping. It’s the first line of defense against damage, ensuring your product arrives safely and in perfect condition. Think of it like building a protective fortress around your product for its journey. Neglecting this crucial step can lead to costly returns, damaged reputations, and lost revenue.

Effective packaging considers several factors: the product’s fragility, the transportation method, and the environmental conditions it might encounter. For example, fragile items require robust cushioning, such as bubble wrap or foam peanuts, within a sturdy box. Liquids need leak-proof containers and absorbent materials to prevent spills. Electronics demand anti-static packaging to prevent damage from static electricity.

- Shock Absorption: Cushioning materials absorb impacts during transit.

- Protection from Moisture: Waterproof materials prevent water damage.

- Secure Containment: Proper sealing prevents items from shifting and breaking.

- Labeling: Clear and concise labels prevent mishandling and ensure easy identification.

Q 2. Describe your experience with different packaging materials and their suitability for various products.

My experience spans a wide range of packaging materials, each with its own strengths and weaknesses. I’ve worked extensively with corrugated cardboard boxes, various types of cushioning (bubble wrap, foam peanuts, air pillows), protective films, and specialized containers for specific products like temperature-sensitive pharmaceuticals or fragile electronics.

- Corrugated Cardboard: A workhorse of the industry, offering excellent protection for many products at a reasonable cost. The choice of flute (the wavy structure) impacts the box’s strength.

- Bubble Wrap: Excellent for cushioning fragile items, offering effective shock absorption. The number of bubbles per inch influences its protective capacity.

- Foam Peanuts: Affordable and effective for filling void space within a box, preventing items from shifting. However, they are less environmentally friendly than some alternatives.

- Air Pillows: Lightweight and customizable, providing excellent cushioning and reducing waste compared to foam peanuts.

- Rigid Containers: Essential for extremely fragile or valuable items that require robust protection.

Selecting the right material depends heavily on the product’s characteristics and the rigors of the shipping process. For instance, a delicate glass vase would require a rigid container with ample cushioning, while a sturdy book might only need a cardboard box with minimal padding.

Q 3. How do you determine the appropriate shipping method (e.g., ground, air, sea) for a given shipment?

Choosing the appropriate shipping method is crucial for cost-effectiveness and timely delivery. Several factors are considered including speed, cost, distance, product fragility, and regulatory requirements.

- Ground Shipping: Most economical for non-urgent shipments over shorter distances. Suitable for less fragile goods.

- Air Shipping: Fastest but most expensive option. Essential for time-sensitive deliveries and fragile items requiring quick transit.

- Sea Shipping: Least expensive for large volumes over long distances. Appropriate for non-perishable goods where speed is less critical.

For example, a time-sensitive delivery of medical supplies would necessitate air shipping. In contrast, shipping large quantities of furniture across the ocean would make sea shipping more cost-effective. I always weigh the urgency, cost, and risk involved in making this critical decision.

Q 4. What are your strategies for optimizing warehouse space and improving efficiency?

Optimizing warehouse space and improving efficiency are paramount for profitability. My strategies encompass a multi-pronged approach including implementing efficient storage solutions, employing inventory management systems, and streamlining workflows.

- Vertical Space Utilization: Maximize vertical space with high-bay racking systems, allowing for more efficient storage.

- Optimized Layout: Strategically plan warehouse layout for efficient product flow, minimizing unnecessary movement.

- Inventory Management System: Employing a robust inventory management system enables real-time tracking and efficient order fulfillment.

- Cross-Docking: Minimizes storage time by directly transferring goods from incoming to outgoing shipments.

- Lean Principles: Adopting lean principles helps eliminate waste and improve overall efficiency.

For example, implementing a barcoding system combined with a WMS (Warehouse Management System) can drastically reduce picking and packing errors, improving order accuracy and overall efficiency. Regular audits and process improvements are crucial to maintaining the effectiveness of these strategies.

Q 5. How do you handle damaged or lost shipments?

Handling damaged or lost shipments requires a methodical approach, starting with prompt investigation and claim filing. The process involves collaborating with carriers, insurance providers, and customers to resolve the issue fairly.

- Documentation: Thorough documentation is critical, including photographic evidence of damage, tracking information, and communication records.

- Carrier Claims: Filing claims with the carrier promptly, according to their specific procedures.

- Insurance Claims: If applicable, filing claims with the insurance provider to recover losses.

- Customer Communication: Maintaining open and transparent communication with the customer, providing regular updates, and offering appropriate resolutions (replacement, refund).

For example, if a shipment arrives damaged, I would photograph the damage, file a claim with the carrier, and contact the customer to initiate a replacement or refund process. Effective communication and a clear process are key to maintaining customer satisfaction.

Q 6. Describe your experience with inventory management systems.

My experience with inventory management systems includes utilizing both manual and automated systems. I’m proficient in using software like SAP, Oracle, and various cloud-based solutions. These systems are crucial for effective inventory control, order fulfillment, and warehouse management.

- Inventory Tracking: Accurately tracking inventory levels in real-time, minimizing stockouts and overstocking.

- Order Management: Efficiently processing orders, from receiving to shipping.

- Demand Forecasting: Using historical data to predict future demand and optimize inventory levels.

- Reporting and Analytics: Generating reports on key metrics, such as inventory turnover, order fulfillment rates, and storage costs.

For instance, in a previous role, we implemented a new cloud-based WMS which improved our order fulfillment accuracy by 15% and reduced our storage costs by 10% by optimizing our warehouse layout and inventory levels based on the system’s data analytics.

Q 7. Explain your understanding of shipping regulations and compliance (e.g., HAZMAT, customs).

Understanding and complying with shipping regulations is paramount. This includes adhering to HAZMAT (Hazardous Materials) regulations, customs procedures, and other relevant rules and regulations set by various authorities.

- HAZMAT Regulations: Proper classification, packaging, labeling, and documentation of hazardous materials are critical to ensure safety and compliance.

- Customs Regulations: Accurate declaration of goods, proper documentation, and adherence to import/export regulations prevent delays and penalties.

- International Regulations: Understanding and complying with regulations in different countries for international shipments.

- Shipping Carrier Regulations: Adhering to the specific regulations of the chosen shipping carrier.

Non-compliance can result in significant fines, delays, and even legal repercussions. For example, improperly labeling a hazardous material shipment could lead to serious accidents and substantial penalties. Staying updated on the latest regulations is an ongoing process requiring constant attention to detail.

Q 8. How do you prioritize tasks in a fast-paced shipping and receiving environment?

In a fast-paced shipping and receiving environment, effective prioritization is crucial. I use a combination of methods, prioritizing tasks based on urgency and importance. Think of it like a triage system in a hospital – life-threatening cases (urgent orders with tight deadlines) come first, followed by serious cases (orders with slightly more leeway), and then routine cases (standard orders).

- Urgency: Orders with imminent delivery deadlines, those requiring special handling (e.g., temperature-sensitive goods), or those impacting key clients always take precedence.

- Importance: Consider the overall impact of delays. A large, high-value order will naturally be prioritized over a smaller one, even if their deadlines are similar.

- Workflow Management: I leverage tools like Kanban boards or task management software to visually track progress and identify bottlenecks, allowing for proactive adjustments.

- Communication: Open communication with the team is essential. Keeping everyone informed about priorities minimizes confusion and ensures everyone is working towards the same goals.

For example, if we have an urgent order for a client who is a major contributor to our business and another order that is less urgent, the urgent, high-value order will be fulfilled first, even if the other order was placed earlier. This ensures customer satisfaction and minimizes potential financial losses from missed deadlines.

Q 9. What is your experience with shipping software and related technologies?

I’m proficient in several shipping software systems, including ShipStation, Shopify Shipping, and Amazon Seller Central. My experience extends beyond simply using these platforms; I understand their underlying functionalities and how to optimize them for efficiency. I’m also familiar with Warehouse Management Systems (WMS) and Transportation Management Systems (TMS), allowing for seamless integration across various operational aspects.

For example, I’ve utilized ShipStation to automate label generation, track shipments, and manage multiple carrier accounts, significantly reducing manual processing time and errors. I’ve also used Shopify Shipping’s integration to streamline the order fulfillment process directly within the e-commerce platform, improving order turnaround times. Furthermore, my experience with WMS allows me to optimize inventory management and warehouse operations, ensuring the smooth flow of goods from receiving to shipping.

Q 10. How do you ensure accuracy in order fulfillment?

Accuracy in order fulfillment is paramount. My approach involves multiple checkpoints and verification procedures to minimize errors. This starts with meticulously verifying order details against the inventory system, ensuring correct items, quantities, and customer information are used.

- Double-Checking: A second person verifies picked items against the order before packing, catching potential mistakes early on.

- Barcode Scanning: Utilizing barcode scanners during picking and packing drastically reduces manual entry errors.

- Quality Control Checks: Before shipping, packages are inspected for correct contents, proper packaging, and accurate labeling.

- Inventory Management: Precise inventory tracking using WMS software minimizes stock discrepancies and prevents picking incorrect items.

Imagine if a customer orders a red dress but receives a blue one. That leads to returns, refunds, and damaged customer relationships. My multi-layered approach prevents this by ensuring accuracy at every stage of the process.

Q 11. How do you handle customer inquiries related to shipping and delivery?

Handling customer inquiries requires empathy, efficiency, and accurate information. I approach each inquiry with professionalism, understanding that a frustrated customer can negatively impact our reputation.

- Active Listening: I begin by carefully listening to the customer’s concern to fully understand their situation.

- Tracking Information: I provide real-time tracking information and explain any potential delays proactively.

- Problem-Solving: If there’s an issue, I work systematically to find a resolution, escalating the problem if necessary.

- Clear Communication: I keep customers informed throughout the process, providing updates and managing their expectations.

For example, if a customer reports a delayed package, I first check the tracking information to understand the reason for the delay. Then I communicate this to the customer clearly and honestly, offering alternative solutions if appropriate, such as expedited shipping or a partial refund.

Q 12. Explain your experience with different types of shipping labels and their applications.

My experience encompasses various shipping labels, each suited to specific needs. Understanding their applications is crucial for efficient and compliant shipping.

- Standard Shipping Labels: These are used for most shipments and typically include the recipient and sender addresses, tracking information, and barcode.

- Hazardous Materials Labels: These are required for shipping dangerous goods and must adhere to strict regulations (e.g., IATA or DOT regulations) indicating the type and class of hazardous material.

- International Shipping Labels: These include additional customs information such as HS codes (Harmonized System codes for classifying goods), country of origin, and value of the goods.

- Fragile/Handle with Care Labels: These indicate the need for special handling to prevent damage during transit.

Incorrect labeling can lead to delays, fines, or even the rejection of shipments. Therefore, choosing the right label and ensuring accurate information are essential for smooth shipping.

Q 13. What are your strategies for managing shipping costs?

Managing shipping costs requires a multi-pronged strategy. It’s about finding the right balance between cost and speed of delivery.

- Negotiating with Carriers: Building strong relationships with multiple carriers allows for better rates and potential discounts for volume shipments.

- Optimizing Packaging: Using appropriately sized boxes minimizes wasted space and reduces shipping weight, leading to lower costs.

- Consolidation of Shipments: Combining multiple smaller shipments into larger ones can reduce the overall cost per unit.

- Carrier Selection: Choosing the right carrier for each shipment based on factors like destination, weight, size, and delivery speed helps to optimize costs.

- Shipping Zones: Understanding shipping zones and their associated costs helps in selecting the most cost-effective method.

For example, negotiating a contract with a carrier for a discounted rate on high-volume shipments can significantly impact annual shipping costs. Similarly, using lightweight packaging materials can cumulatively reduce shipping weight and expenses over time.

Q 14. Describe your experience with various freight carriers and their services.

I have extensive experience with a range of freight carriers, including UPS, FedEx, USPS, and LTL (Less Than Truckload) carriers. Understanding each carrier’s strengths and weaknesses allows me to choose the best option for different shipping needs.

- UPS and FedEx: These are excellent for expedited shipping and offer a wide range of services including ground, air, and international shipping.

- USPS: Cost-effective for smaller, lighter packages, particularly for domestic shipments.

- LTL Carriers: These are ideal for larger, heavier shipments, offering a more cost-effective solution than full truckload shipments.

The choice of carrier depends heavily on the shipment’s characteristics. For example, a time-sensitive package might be shipped via FedEx overnight, whereas a larger, less urgent shipment might be sent via an LTL carrier for cost savings.

Q 15. How do you maintain a safe and organized warehouse environment?

Maintaining a safe and organized warehouse is paramount for efficiency and preventing accidents. It’s like running a well-oiled machine – every part needs to be in its place and functioning correctly. My approach involves a multi-pronged strategy focusing on organization, safety protocols, and regular maintenance.

- Clear Aisles and Pathways: We ensure clear and well-marked pathways to prevent tripping hazards and allow for easy forklift navigation. This includes regular sweeping and cleaning to avoid debris accumulation. Think of it like designing a city – you need wide streets for smooth traffic flow.

- Proper Storage and Racking: Products are stored strategically based on frequency of use and size, utilizing racking systems to maximize space and prevent stacking hazards. Heavier items are always placed lower. This is crucial for quick picking and efficient inventory management.

- Safety Training and Equipment: All warehouse staff undergo comprehensive safety training, covering topics such as forklift operation, hazard identification, and emergency procedures. We provide and maintain necessary safety equipment like high-visibility vests, gloves, and safety shoes. Safety is our top priority; it’s not just a policy, it’s a culture.

- Regular Inspections and Maintenance: Routine inspections are conducted to identify and rectify potential hazards – this might include checking for damaged racking, broken lighting, or potential fire risks. We also have a preventative maintenance schedule for all warehouse equipment.

- 5S Methodology: We implement the 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to maintain a consistently clean, organized, and efficient workspace. This is a systematic approach that encourages continuous improvement.

For example, in a previous role, we implemented a color-coded system for inventory – red for high-demand items, yellow for medium, and green for low – which significantly improved our picking efficiency.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you track shipments and ensure timely delivery?

Tracking shipments and ensuring timely delivery requires a robust system integrating technology and effective communication. Think of it as managing a complex network of moving parts, requiring precise coordination.

- Transportation Management System (TMS): We utilize a TMS to track shipments from origin to destination in real-time. This provides visibility into the location and status of each package, alerting us to potential delays.

- Barcode and RFID Technology: We use barcodes and RFID tags to track inventory and packages throughout the entire process, from receiving to shipping. This allows for accurate and quick scanning during various warehouse operations.

- Carrier Integration: Our TMS is often integrated with major shipping carriers, providing automated updates on shipment status and tracking information directly within our system.

- Proactive Communication: We maintain open communication with carriers and customers, providing timely updates and addressing any potential issues proactively. This prevents surprises and keeps everyone informed.

- Delivery Confirmation and Proof of Delivery (POD): We utilize delivery confirmation and POD systems to verify that shipments have been successfully delivered and to resolve any delivery discrepancies.

In one instance, our TMS alerted us to a potential delay due to inclement weather. We immediately contacted the carrier and the customer, proactively suggesting an alternative delivery route and preventing a significant delay.

Q 17. Explain your experience with different types of packaging machinery (e.g., tape machines, shrink wrappers).

My experience with packaging machinery encompasses a variety of equipment used to improve efficiency and package quality. This includes both automated and manual equipment.

- Tape Machines: I’m proficient in operating various tape machines, including automated high-speed tape dispensers and manual tape guns. We use these for sealing cartons efficiently and securely. Selecting the right tape (e.g., water-activated tape, pressure-sensitive tape) is critical for the type of product and shipping conditions.

- Shrink Wrappers: I have experience with both L-bar and tunnel shrink wrappers. These machines provide excellent protection and a professional finish for products. The selection of film (e.g., PVC, POF) depends on the product and environmental conditions.

- Case Sealers: I am familiar with automatic and semi-automatic case sealers, which efficiently and consistently seal cardboard boxes, ensuring the contents remain secure during transit.

- Pallet Wrapping Machines: I’ve used various pallet wrapping machines to secure palletized goods, reducing damage during transport. The right stretch film is critical here to ensure adequate load stability.

For example, by upgrading to a high-speed automated tape dispenser, we reduced our packaging time by 20%, which had a significant impact on overall warehouse productivity.

Q 18. How do you resolve discrepancies between inventory records and physical inventory?

Resolving discrepancies between inventory records and physical inventory is a critical aspect of warehouse management. It’s like balancing a financial statement – accuracy is essential. A discrepancy could indicate various issues, from simple human error to more significant problems.

- Cycle Counting: We conduct regular cycle counting, which involves physically counting a small portion of the inventory at various times instead of doing a full count at once. This minimizes disruption and helps identify discrepancies early on.

- Inventory Management Software: We utilize inventory management software to maintain accurate records. The system is regularly updated with each transaction. This is the heart of the system, allowing us to maintain real-time inventory data.

- Root Cause Analysis: When discrepancies are found, we investigate the root cause – was there an error in data entry, a misplaced item, damage, theft, or something else? Understanding the root cause is critical to preventing future issues.

- Physical Verification: A physical verification of the items involved in the discrepancy is necessary. This often requires a thorough search of the warehouse and potentially checking for damages or losses.

- Reconciliation: After identifying and addressing the root cause, the inventory records are reconciled to reflect the actual physical count. This often involves adjusting quantities in the inventory management software.

In one case, we discovered a significant discrepancy that was traced back to a faulty barcode scanner. Replacing the scanner and implementing a more rigorous quality control process for scanning eliminated the problem.

Q 19. How do you handle returns and exchanges?

Handling returns and exchanges efficiently is vital for customer satisfaction and minimizing losses. It’s like providing excellent customer service after the sale.

- Clear Return Policy: We have a clear and easily accessible return policy that outlines the process for customers. This should be easily accessible on our website and packaging.

- Dedicated Returns Area: We designate a specific area in the warehouse for processing returns. This helps keep returns separate from active inventory, making the process more organized.

- Inspection and Verification: Returned items are inspected to verify their condition. This determines whether they can be restocked or if they need to be disposed of.

- Refund or Exchange Processing: We process refunds or exchanges quickly and efficiently according to our return policy. This can often involve integrating with payment gateways or CRM systems.

- Data Tracking: We track return data to identify trends and potential issues with products or the return process itself. This data is invaluable for improving our products and customer service.

We once analyzed return data and discovered a high rate of returns for a particular product due to packaging issues. By addressing the packaging problem, we significantly reduced the number of returns for that product.

Q 20. Describe your experience with international shipping.

International shipping presents unique challenges compared to domestic shipping, requiring a greater understanding of customs regulations, documentation, and logistics. It’s like navigating a complex global network.

- Customs Regulations: I’m familiar with navigating the complexities of customs regulations, including HS codes, tariffs, and documentation requirements for various countries. This involves understanding trade agreements and export/import restrictions.

- Incoterms: I understand Incoterms (International Commercial Terms) and their implications for responsibility and cost allocation between buyer and seller. This is crucial for avoiding misunderstandings and disputes.

- Documentation: I’m proficient in preparing necessary documentation, including commercial invoices, packing lists, certificates of origin, and other required forms. Accuracy is essential in preventing delays or rejection of shipments.

- International Carriers: I have experience working with various international carriers and selecting the most appropriate and cost-effective shipping options based on the destination, product, and required delivery time.

- Freight Forwarders: I’ve worked with freight forwarders to manage complex international shipments, leveraging their expertise in customs clearance and international logistics.

In a past role, we successfully navigated complex export regulations to ship a large order to Japan, requiring meticulous preparation of documentation and coordination with a freight forwarder. The shipment arrived on time and without any customs issues.

Q 21. What is your experience with palletizing and securing loads for transport?

Palletizing and securing loads for transport is crucial for preventing damage during transit and ensuring efficient handling. It’s like building a strong, stable structure for the journey.

- Proper Palletizing Techniques: I’m skilled in applying proper palletizing techniques, ensuring even weight distribution and minimizing the risk of collapse. This includes understanding different pallet types and their load-bearing capacities.

- Load Securing Methods: I’m experienced in various load securing methods, including stretch wrapping, shrink wrapping, banding, and corner boards. The choice of method depends on the type of product, its weight, and the distance being shipped.

- Load Stability: I focus on creating a stable load that can withstand the stresses of transportation, preventing shifting or damage. This often involves interleaving layers of product or using dunnage to fill voids.

- Safety Considerations: Safety is paramount, and we adhere to all safety regulations regarding load securing. This ensures the safety of warehouse staff and prevents accidents during handling and transport.

- Compliance with Regulations: We comply with all relevant regulations regarding load securing, which vary depending on the mode of transport (truck, rail, sea).

For example, we once optimized our palletizing process, leading to a 15% reduction in damaged goods during transit and improving overall shipping efficiency.

Q 22. How do you ensure the correct quantity of items is included in each order?

Ensuring the correct quantity of items in each order is paramount for customer satisfaction and operational efficiency. We employ a multi-layered approach, starting with meticulous order processing. This involves double-checking the order against the system, verifying item numbers and quantities against the packing list, and using barcode or RFID scanners to track items as they move through the fulfillment process.

During picking, we use a system of checks and balances. Pickers often use handheld devices that guide them through the process, automatically marking items as picked. A second individual may perform a spot-check of the picked items against the list. Finally, before sealing the package, a final quantity check is performed to confirm accuracy. This often involves a visual inspection, as well as weighing the package, especially for items with known weights.

We also regularly conduct internal audits to pinpoint areas for improvement. This may reveal recurring discrepancies, which could indicate issues with our picking process, inventory management, or even system errors. Addressing these issues proactively ensures continued accuracy and efficiency.

Q 23. Explain your understanding of different shipping terms (e.g., FOB, CIF).

Shipping terms define responsibilities and costs between the buyer and seller. Two common terms are FOB (Free On Board) and CIF (Cost, Insurance, and Freight). FOB designates the point at which ownership and responsibility for the goods transfer from the seller to the buyer. For example, FOB origin means the seller is responsible for getting the goods to the origin point (e.g., their warehouse), after which the buyer assumes responsibility for shipping costs and risks. FOB destination means the seller retains responsibility until the goods arrive at the buyer’s location.

CIF, on the other hand, indicates that the seller is responsible for the cost of the goods, insurance to cover potential loss or damage during shipment, and the freight charges to the named port of destination. The buyer assumes responsibility upon arrival at the designated port. Understanding these terms is crucial for accurate cost allocation and risk management in international trade. Incorrect interpretation can lead to unexpected expenses and disputes.

Other terms include DDP (Delivered Duty Paid), where the seller handles all costs and risks until delivery to the buyer’s location, and EXW (Ex Works), where the buyer takes responsibility from the seller’s premises.

Q 24. How do you maintain accurate records of shipping and receiving transactions?

Maintaining accurate records is vital for tracking shipments, managing inventory, and complying with regulations. We use a combination of software and physical documentation. Our system typically includes a warehouse management system (WMS) that automatically tracks inventory levels, order fulfillment, and shipping updates. This provides real-time visibility into the entire process.

Each transaction is recorded with detailed information including the order number, items shipped, quantities, shipping carrier, tracking number, and delivery confirmation. All documentation—packing slips, bills of lading, and proof of delivery—is meticulously maintained, either digitally within our WMS or in physical archives. Regular reconciliation between the physical inventory and system records is conducted to identify and rectify any discrepancies promptly.

We also ensure data integrity through regular backups and data validation processes. Access to the system is controlled and audit trails are maintained to track all user activity. This comprehensive approach minimizes errors and ensures accurate accounting for all shipping and receiving transactions.

Q 25. What are your experience with different types of carriers (LTL, FTL)?

My experience encompasses various carrier types, including Less-than-Truckload (LTL) and Full-Truckload (FTL) shipments. LTL is cost-effective for smaller shipments that don’t require a whole truck, sharing space with other consignments. I’ve worked with LTL carriers like FedEx Freight and YRC Freight, optimizing shipments to minimize costs while ensuring timely delivery. This involves careful palletization, proper labeling, and choosing the right carrier based on destination and transit time requirements.

For larger shipments, FTL offers greater control and efficiency. I’ve managed FTL shipments with carriers such as Schneider and Swift Transportation, ensuring the truck is fully utilized and properly loaded to prevent damage. This necessitates efficient load planning and communication with the carrier to coordinate pickups and deliveries. Selection of the right carrier involves factors such as their reputation, reliability, and their ability to handle specific types of cargo.

Beyond LTL and FTL, I have also experience with small package carriers (UPS, USPS) and specialized carriers for oversized or hazardous materials.

Q 26. Describe your experience working under pressure and meeting deadlines.

Working under pressure and meeting deadlines is an integral part of this role. I thrive in fast-paced environments, prioritizing tasks effectively to ensure timely order fulfillment. For instance, during peak seasons like the holidays, I’ve successfully managed a surge in order volume while maintaining accuracy and meeting all deadlines. This involved implementing efficient workflows, delegating tasks effectively, and actively communicating with the team to address any bottlenecks.

My approach involves breaking down large tasks into smaller, manageable steps, setting realistic deadlines for each step, and proactively identifying potential delays. I use project management techniques like Kanban or Scrum to track progress and adapt to changing circumstances. Open communication with all stakeholders keeps everyone informed and allows for quick adjustments as needed. A calm and organized demeanor, even under pressure, is critical to maintaining productivity and morale.

Q 27. How do you adapt to changes in shipping procedures or regulations?

Adaptability is key in the shipping industry, which is constantly evolving with new regulations and technological advancements. I actively monitor industry news, regulatory updates, and best practices to stay informed about changes. This often involves attending industry webinars, participating in professional development courses, and networking with peers and experts.

When faced with changes in shipping procedures or regulations, I adopt a structured approach. First, I carefully review the changes to fully understand their implications. Then, I identify any necessary modifications to our processes, policies, and systems. I collaborate with my team to implement these changes effectively, providing training and support as needed. Finally, I monitor the impact of the changes and make adjustments as necessary to ensure continuous improvement. For example, when new customs regulations were introduced, I led the effort to update our documentation and processes to comply.

Q 28. How do you contribute to a positive team environment in a warehouse setting?

Contributing to a positive team environment is crucial for overall efficiency and morale. I believe in fostering open communication, mutual respect, and collaboration. I actively participate in team meetings, sharing my expertise and providing support to colleagues. I also encourage a culture of continuous improvement, offering constructive feedback and celebrating successes together.

I believe in leading by example, maintaining a positive attitude, and being willing to assist colleagues when needed. This might involve helping with a difficult task, sharing knowledge, or simply offering words of encouragement. I also believe in recognizing and rewarding good work, acknowledging individual contributions to team achievements. In short, I strive to create a collaborative and supportive environment where everyone feels valued and empowered to contribute their best.

Key Topics to Learn for Packing and Shipping Products Interview

- Order Fulfillment Processes: Understanding the entire order lifecycle, from receiving an order to its final shipment. This includes picking, packing, and staging for dispatch.

- Packaging Materials and Selection: Knowing different types of packaging materials (e.g., boxes, fillers, tape) and how to select the appropriate materials for various products to ensure safe and efficient delivery. Practical application: Choosing the right box size and type to prevent damage during transit.

- Inventory Management: Understanding how inventory is tracked and managed within a warehouse setting, including stock rotation and cycle counting. This plays a crucial role in efficient order fulfillment.

- Shipping Methods and Carriers: Familiarity with different shipping carriers (e.g., UPS, FedEx, USPS) and their services, including understanding shipping costs, delivery times, and tracking options. Practical application: Choosing the most cost-effective and reliable shipping method for a specific order.

- Shipping Regulations and Compliance: Knowledge of relevant regulations, including hazardous materials handling and international shipping requirements. Understanding the implications of non-compliance.

- Warehouse Safety Procedures: Demonstrating awareness of safety protocols, including proper lifting techniques, equipment operation, and maintaining a clean and organized workspace.

- Problem-Solving and Efficiency: Being able to identify and resolve issues efficiently, such as damaged goods, incorrect orders, or delays in shipping. Practical application: Developing strategies for optimizing warehouse operations and streamlining the shipping process.

- Technology and Software: Familiarity with warehouse management systems (WMS) and other relevant software used for tracking inventory and managing shipments.

Next Steps

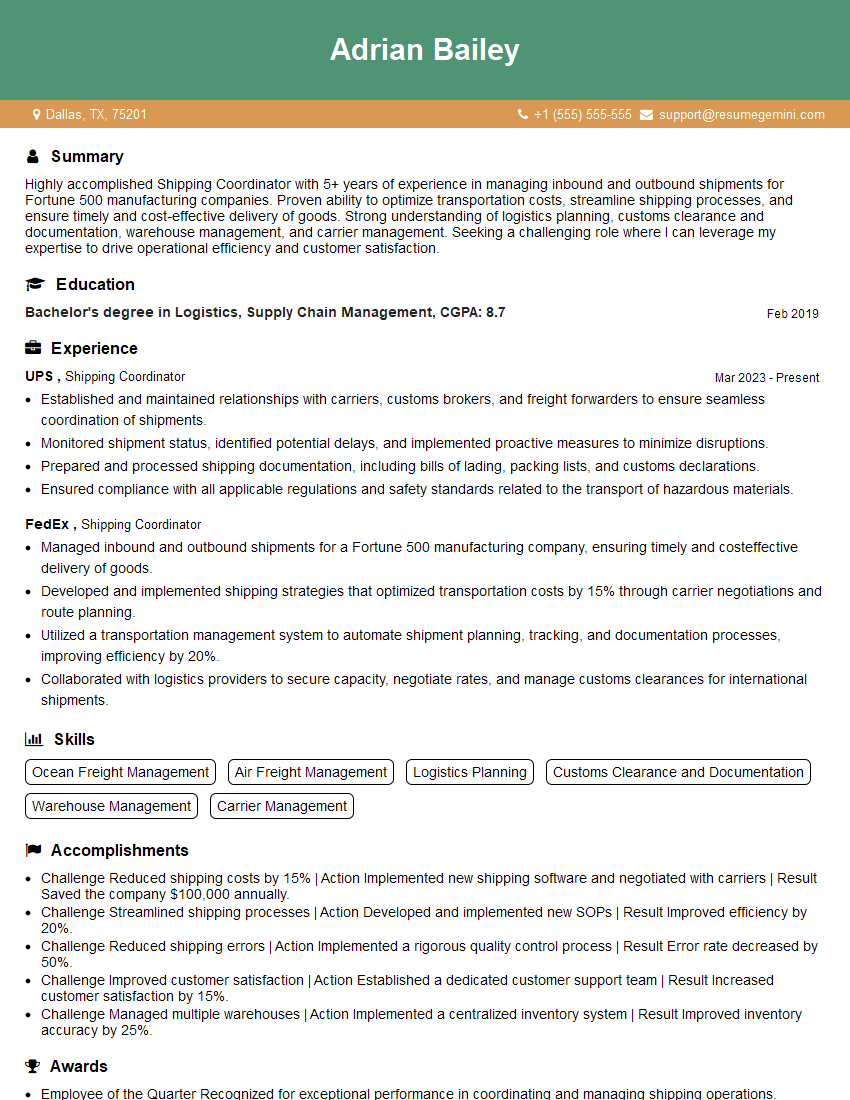

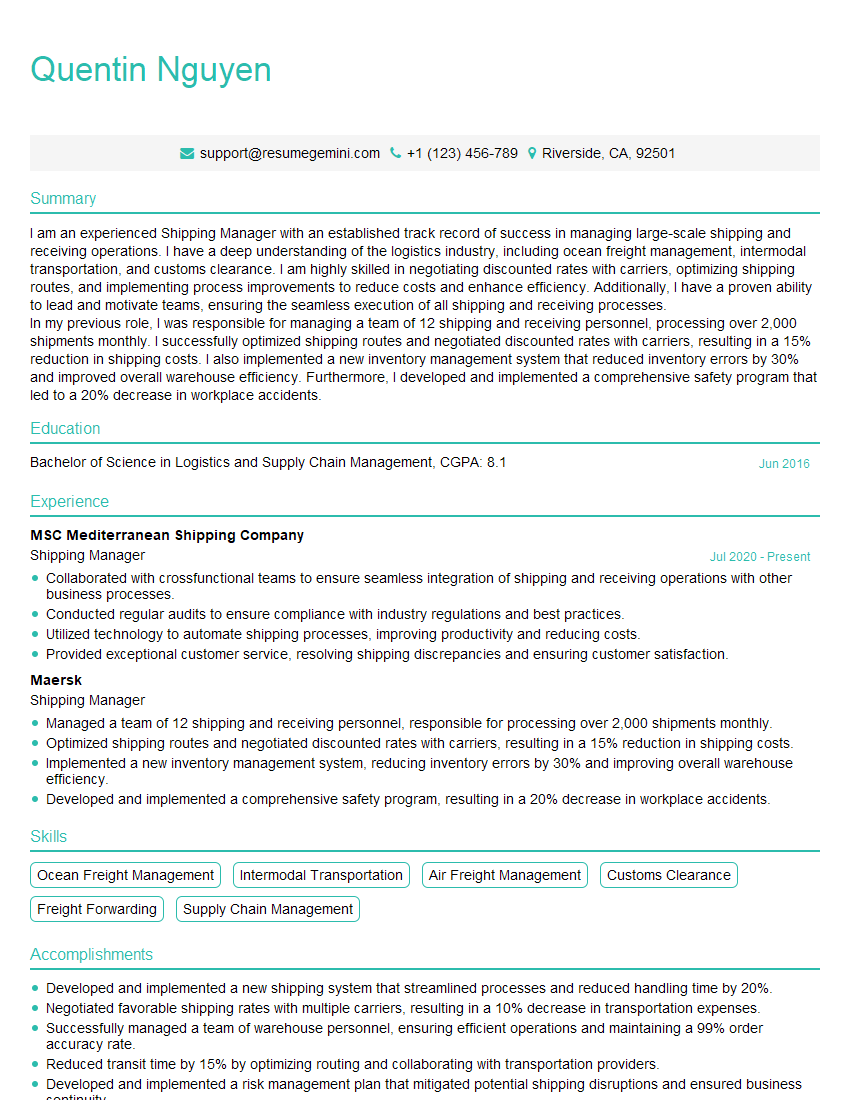

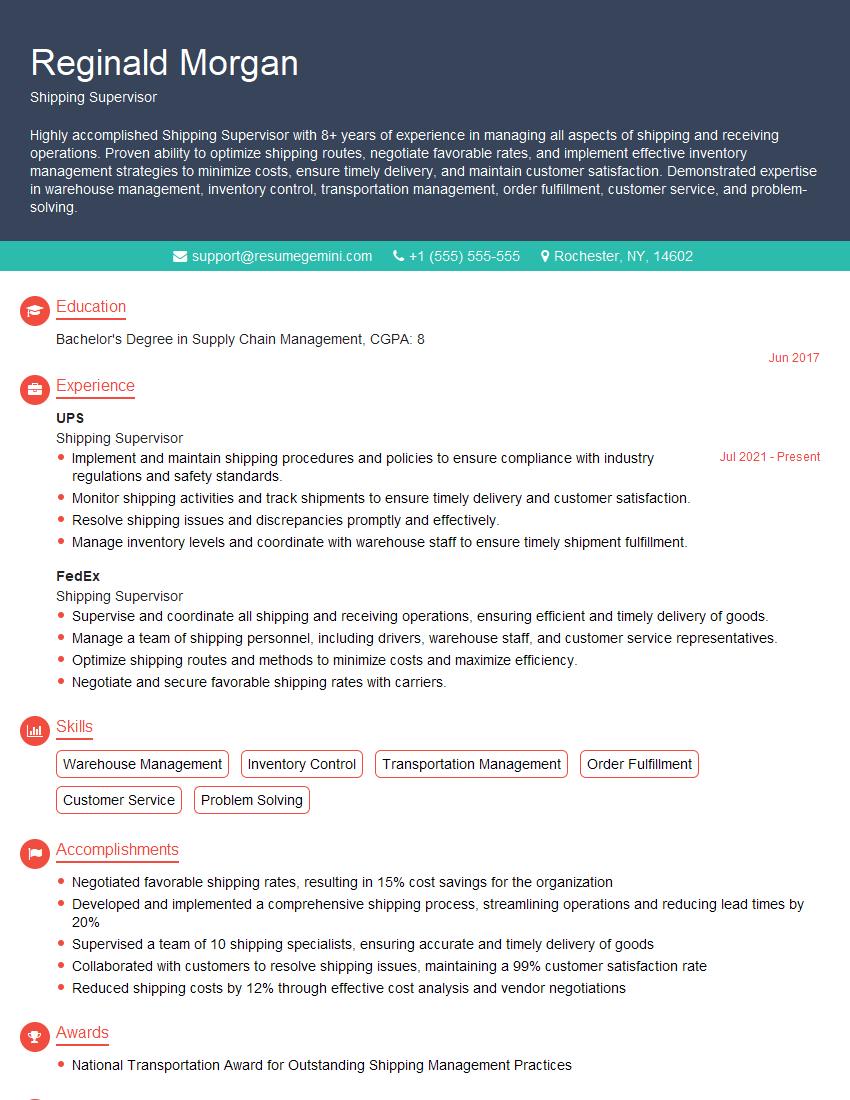

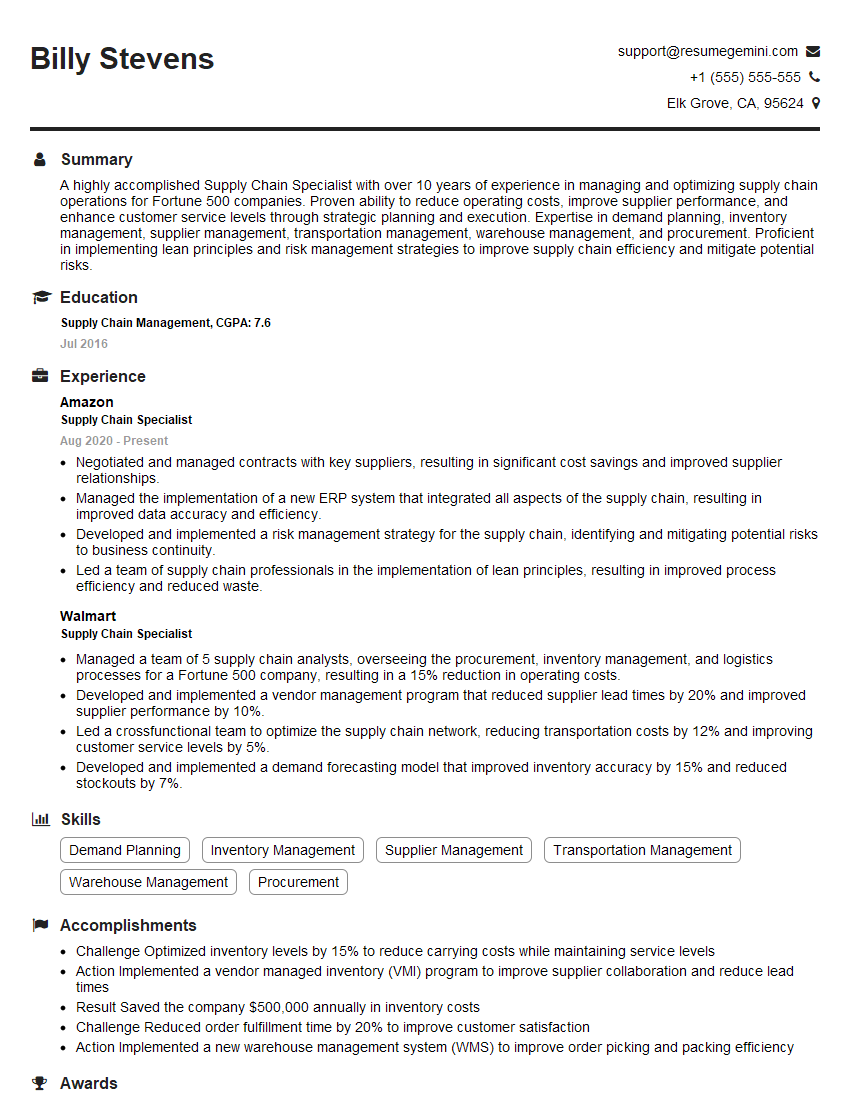

Mastering packing and shipping procedures is essential for career advancement in logistics and supply chain management. It demonstrates practical skills highly sought after by employers. To increase your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored to packing and shipping products are available to guide you. Invest time in crafting a strong resume – it’s your first impression to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good