Unlock your full potential by mastering the most common Paper Embossing interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Paper Embossing Interview

Q 1. Explain the difference between blind embossing and registered embossing.

The core difference between blind embossing and registered embossing lies in the presence of ink or foil. Blind embossing creates a raised or recessed design solely through pressure, leaving the paper’s natural color unchanged. Imagine pressing a coin into soft clay – the impression is left behind, but there’s no additional color added. Registered embossing, conversely, combines embossing with printing. The raised or recessed design is precisely aligned with a printed image or pattern, adding a visual layer to the tactile effect. Think of a beautifully embossed logo on a business card, where the logo is not only raised but also printed in a specific color. This precise alignment requires careful registration marks during the setup process.

Q 2. Describe the various types of embossing dies used in the industry.

Embossing dies come in various types, each suited for different applications and desired effects. The most common are:

- Steel Rule Dies: These are robust and durable, ideal for high-volume production. They’re created by cutting shapes into a steel rule, making them highly versatile for complex designs. They are often used for consistent results over a long run.

- Photopolymer Dies: Made from a flexible photopolymer material, these are excellent for intricate details and shorter runs. They offer greater design flexibility compared to steel rule dies but are generally less durable.

- Electroformed Nickel Dies: Known for exceptional detail and longevity, these dies are created through an electroplating process. They are often favored for high-quality, long-lasting embossing and offer superior sharpness and consistency. They’re typically more expensive than other options.

The choice of die depends heavily on the project’s budget, quantity, and the intricacy of the design.

Q 3. How do you troubleshoot common issues with embossing machines?

Troubleshooting embossing machines involves a systematic approach. Common issues include inconsistent embossing depth, paper jams, and uneven pressure.

- Inconsistent Embossing Depth: Check the pressure settings, die condition, and ensure the platen is clean and even. A worn or damaged die will need replacing.

- Paper Jams: Inspect the paper path for obstructions. Ensure the paper is correctly aligned and the machine’s rollers are clean and not damaged. Incorrect paper feed can also cause this.

- Uneven Pressure: This often points to a problem with the machine’s pressure system, such as a faulty cylinder or inconsistent pressure distribution. A qualified technician is often needed to diagnose this.

Keep detailed records of machine settings, materials, and issues encountered for future reference. Preventative maintenance, such as regular cleaning and lubrication, goes a long way in preventing problems.

Q 4. What are the key quality control checks for embossed products?

Quality control for embossed products is crucial. Checks include:

- Embossing Depth and Clarity: Ensure the raised or recessed design is consistent across all pieces and meets the specified depth. A caliper can be used for precise measurements.

- Registration Accuracy (for registered embossing): Verify the perfect alignment of the embossed design with any printed elements. This requires careful visual inspection under magnification if necessary.

- Surface Defects: Inspect for blemishes, scratches, or inconsistencies on the embossed surface. This includes checking for any damage to the paper fibers from excessive pressure.

- Paper Stock Suitability: The paper should be suitable for the chosen embossing method and pressure. Incorrect paper can cause damage to the die and produce unsatisfactory results.

Sampling and regular inspections throughout the production process are vital for catching problems early.

Q 5. Explain the process of setting up an embossing machine for a specific job.

Setting up an embossing machine for a specific job requires precision and attention to detail.

- Die Installation: Carefully mount the embossing die into the machine, ensuring it’s securely fastened and correctly aligned.

- Paper Feed Adjustment: Configure the paper feed system to accommodate the chosen paper stock’s thickness and ensure proper alignment.

- Pressure Adjustment: Set the embossing pressure based on the paper stock’s weight and desired embossing depth. Start with a lower pressure and gradually increase it, testing frequently to avoid damaging the paper or the die.

- Temperature Adjustment (if applicable): Some embossing machines may have temperature controls. These should be adjusted based on the type of paper and the desired results.

- Test Run: Perform a test run using several sheets of paper to check the embossing quality before proceeding with full-scale production. This step is crucial for adjustments and optimization.

Following the manufacturer’s instructions and maintaining detailed records of settings are crucial for consistent results across different jobs.

Q 6. How do you calculate the appropriate embossing pressure for different paper stocks?

Calculating the appropriate embossing pressure requires a balance of experience and experimentation. There’s no single formula. It depends on several factors including the paper stock’s weight (gsm), type (coated, uncoated, etc.), and the desired embossing depth. Generally:

- Heavier paper stocks require higher pressure.

- Coated papers typically require lower pressure than uncoated papers to avoid cracking or tearing.

Start with a low pressure and gradually increase it, checking the results on test sheets. Too little pressure will produce a shallow emboss, while too much can lead to paper damage or die breakage. Experience and a thorough understanding of different paper types is key to mastering this.

Manufacturers often provide guidance, but practical experimentation is often the most reliable method.

Q 7. What are the safety precautions when operating embossing equipment?

Safety is paramount when operating embossing equipment. Key precautions include:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses to protect against flying debris and gloves to prevent injuries from sharp edges and potentially harmful materials.

- Machine Guards: Ensure all safety guards are in place and functioning correctly before operating the machine. Never attempt to bypass safety features.

- Proper Training: Only trained and authorized personnel should operate the embossing machine. Understanding the machine’s controls and potential hazards is essential.

- Machine Maintenance: Regular maintenance and inspections are critical to prevent malfunctions that could lead to accidents.

- Emergency Procedures: Be familiar with the emergency stop procedures and know the location of emergency shut-off switches.

Remember, a safe working environment reduces the risk of injury and ensures consistent, high-quality output.

Q 8. How do you maintain and clean embossing dies and machinery?

Maintaining embossing dies and machinery is crucial for consistent, high-quality results and the longevity of your equipment. Think of it like regularly servicing your car – preventative maintenance prevents major problems.

Die Maintenance: After each use, gently brush away any paper scraps or debris from the dies using a soft brush. For more stubborn residue, a lint-free cloth dampened with isopropyl alcohol can be effective. Always avoid abrasive cleaners that could scratch the die surface. Store dies in a clean, dry place to prevent rust or damage. Periodically inspect dies for any wear and tear. Significant damage might require professional resurfacing or replacement.

Machine Maintenance: Regular cleaning of the embossing machine is essential. This usually involves removing any paper jams, cleaning the rollers with a suitable cleaning solution (check your machine’s manual for recommendations), and lubricating moving parts as recommended by the manufacturer. Keep the machine free from dust and debris. A schedule of preventative maintenance, including checking pressure settings and belt tension, will extend the life of your machinery and ensure optimal performance. Remember to always disconnect the power before performing any cleaning or maintenance tasks.

Q 9. What are the different types of paper best suited for embossing?

The ideal paper for embossing depends on the desired effect and the embossing machine used. Thicker papers generally produce a more dramatic emboss, while thinner papers might be more suitable for delicate designs. Here are some popular choices:

- Cover weight papers: These offer a good balance of thickness and embossability, producing a crisp, clean impression.

- Cardstock: A sturdy choice ideal for creating a strong, defined emboss. Different weights offer varying levels of embossing depth.

- Specialty papers: Papers with textures or finishes (like linen or cotton) can add unique visual interest to the embossed design. However, be mindful that their texture can sometimes impact the clarity of the emboss.

- Vellum: A translucent paper that creates a more subtle emboss, ideal for a soft, elegant look.

It’s always best to test a sample of your chosen paper before embarking on a large project to ensure it yields the desired results on your specific machine.

Q 10. Describe your experience with various embossing techniques (e.g., foil stamping).

My experience encompasses a range of embossing techniques, including traditional blind embossing (creating a raised or indented impression without color) and foil stamping (adding metallic or colored foil to the embossed design). Blind embossing is a great technique for adding texture and dimension, while foil stamping adds an element of luxury and visual impact.

Foil Stamping: This involves using a heated die to press metallic or pigmented foil onto the paper, creating a shiny, colored embossed effect. It’s a more complex process, requiring precise temperature and pressure control. I’ve worked with various foil types, including gold, silver, and specialty colors, experimenting with different finishes to achieve the desired look. The challenge lies in achieving consistent foil adhesion and avoiding imperfections like wrinkles or uneven color transfer. Mastering this technique requires practice and a good understanding of the interplay between pressure, temperature, and foil type.

Other techniques: I also have experience with debossing (creating a recessed impression), which offers a contrasting visual effect to embossing. I understand the importance of selecting appropriate dies and adjusting machine settings to achieve the desired depth and clarity for each technique.

Q 11. How do you handle a jam in the embossing machine?

A jam in the embossing machine is a common issue, often caused by paper misfeeds or excessive build-up of debris. Always follow the manufacturer’s instructions for your specific model, but here’s a general approach:

- Turn off and unplug the machine: Safety first! Never attempt to clear a jam while the machine is powered on.

- Inspect the paper path: Carefully examine the rollers and paper feed area to locate the jam. Use tweezers or a soft brush to carefully remove any trapped paper or debris.

- Clear the jam: Gently pull the jammed paper from the machine. Avoid pulling forcefully, as this could damage the machine or the dies. If the paper is heavily creased or stuck, try loosening it carefully with tweezers.

- Check for obstructions: Once the jam is cleared, check the paper path for any other obstructions that might cause further jams. Regular cleaning can prevent this.

- Test the machine: Once you’re sure the jam is cleared and there are no obstructions, reconnect the power and run a test sheet to ensure the machine is functioning correctly.

If you are unable to clear the jam or if the machine continues to malfunction, contact a qualified technician for assistance.

Q 12. What are the common causes of inconsistent embossing results?

Inconsistent embossing results can be frustrating, but usually stem from a few common causes:

- Inconsistent pressure: Uneven pressure across the die can lead to variations in the depth and clarity of the emboss.

- Incorrect die temperature (for foil stamping): Improper temperature can cause poor foil adhesion, wrinkles, or uneven color transfer.

- Poor paper quality: Variations in paper thickness or texture can impact the consistency of the emboss.

- Damaged or worn dies: Damaged or worn dies will produce uneven or unclear impressions.

- Incorrect machine settings: Improper settings such as speed, pressure, or temperature can all contribute to inconsistencies.

- Dirty rollers or machine components: Accumulated debris can interfere with the embossing process.

Troubleshooting involves systematically checking each of these factors. A methodical approach, combined with testing different settings and paper types, is usually sufficient to identify the root cause.

Q 13. How do you ensure accurate registration in embossing?

Accurate registration in embossing is critical for aligning the embossed image precisely with the printed design, especially when combining embossing with other printing techniques. Imagine trying to perfectly align a stamp onto a postcard – that’s essentially what registration ensures.

Techniques for accurate registration: This is achieved through careful alignment of the die and the paper. Many machines have registration marks or guides that aid in precise placement. Using high-quality dies with accurately positioned design elements is also crucial. In complex projects involving multiple embossing or printing steps, the use of specialized registration systems or jigs is often necessary to ensure precise alignment throughout the entire process. This could include registration marks printed on the sheet which then act as guides during the embossing process.

Importance of accurate registration: Without precise registration, the embossed image might appear misaligned, offset, or skewed, ruining the overall aesthetic appeal and potentially impacting the readability of text within the design.

Q 14. Explain your understanding of different embossing patterns and designs.

Embossing patterns and designs are incredibly diverse, ranging from simple textures to intricate, detailed artwork. The possibilities are virtually limitless.

- Geometric patterns: These include lines, dots, grids, and other repeating geometric shapes. They offer a clean, modern look and are commonly used in business stationery or packaging.

- Floral patterns: Delicate floral designs add a touch of elegance and sophistication, often used in invitations, cards, or high-end packaging.

- Textured patterns: These mimic the look and feel of different materials, such as linen, leather, or wood, adding depth and visual interest.

- Custom designs: Many companies offer custom die-cutting and embossing services, allowing for the creation of truly unique designs.

- Logo embossing: A common application is embossing company logos onto products or packaging to enhance branding and create a sense of quality.

The choice of pattern or design is often dictated by the project requirements, the target audience, and the overall aesthetic goal. Careful consideration of the design’s complexity and the capabilities of the embossing equipment is crucial for successful execution.

Q 15. How do you select the correct die for a specific embossing project?

Choosing the right embossing die is crucial for achieving the desired effect. It’s like selecting the right brush for a painting – the wrong tool yields poor results. The selection process depends on several factors:

- Design Complexity: Simple designs might use a single-level die, while intricate designs require multi-level dies for depth and detail. For example, a simple logo might need a single-level die, whereas a detailed floral pattern would require a multi-level die to create depth and texture.

- Paper Stock: The thickness and texture of the paper significantly influence die selection. Thicker papers require sturdier dies capable of withstanding the pressure. A delicate paper might be damaged by a die designed for thicker card stock.

- Desired Embossing Height: The height of the embossed image is determined by the die’s construction. A shallower emboss might be sufficient for a subtle effect, whereas a deeper emboss is needed for a more dramatic result. For instance, a subtle raised logo might only need a shallow emboss, while a textured invitation might need a much deeper emboss.

- Embossing Style: The style—whether it’s debossing (pressed inwards), embossing (raised), or a combination—dictates the type of die needed. The dies themselves are designed for specific styles and will not work interchangeably.

Ultimately, close consultation with the die manufacturer or supplier is recommended to ensure the perfect die is selected for the project.

Career Expert Tips:

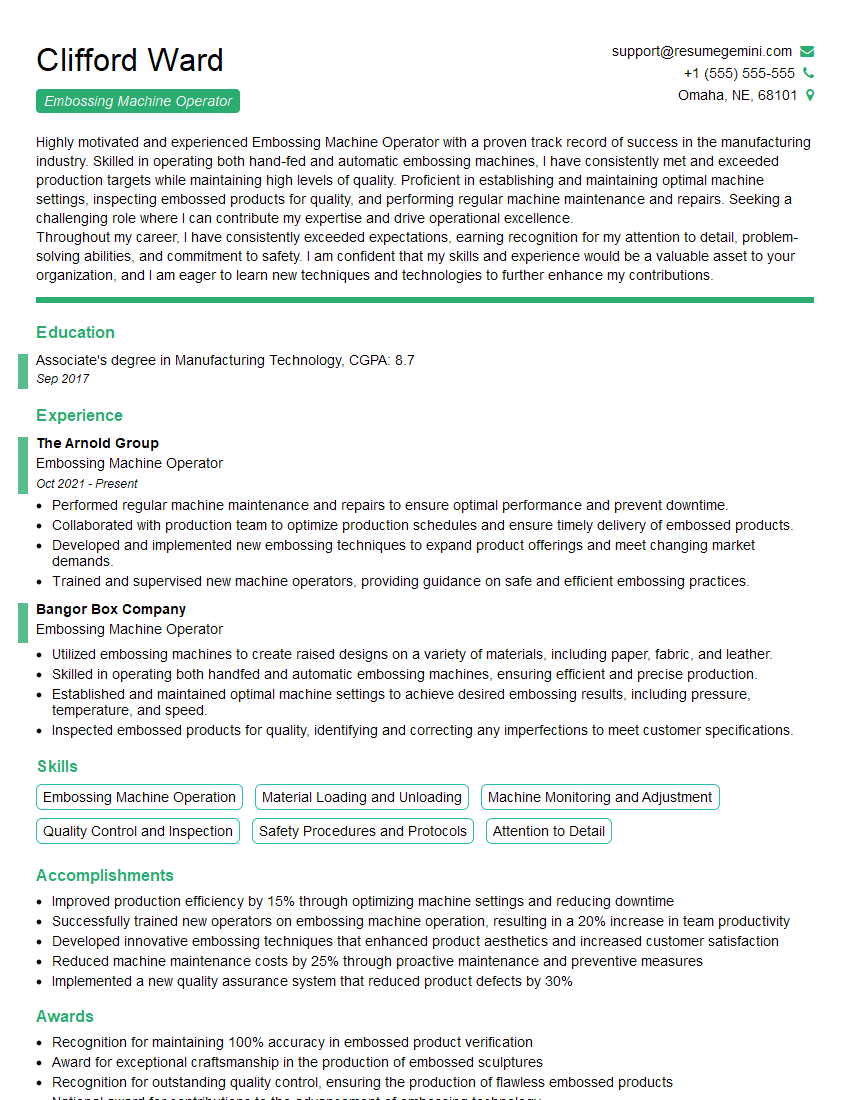

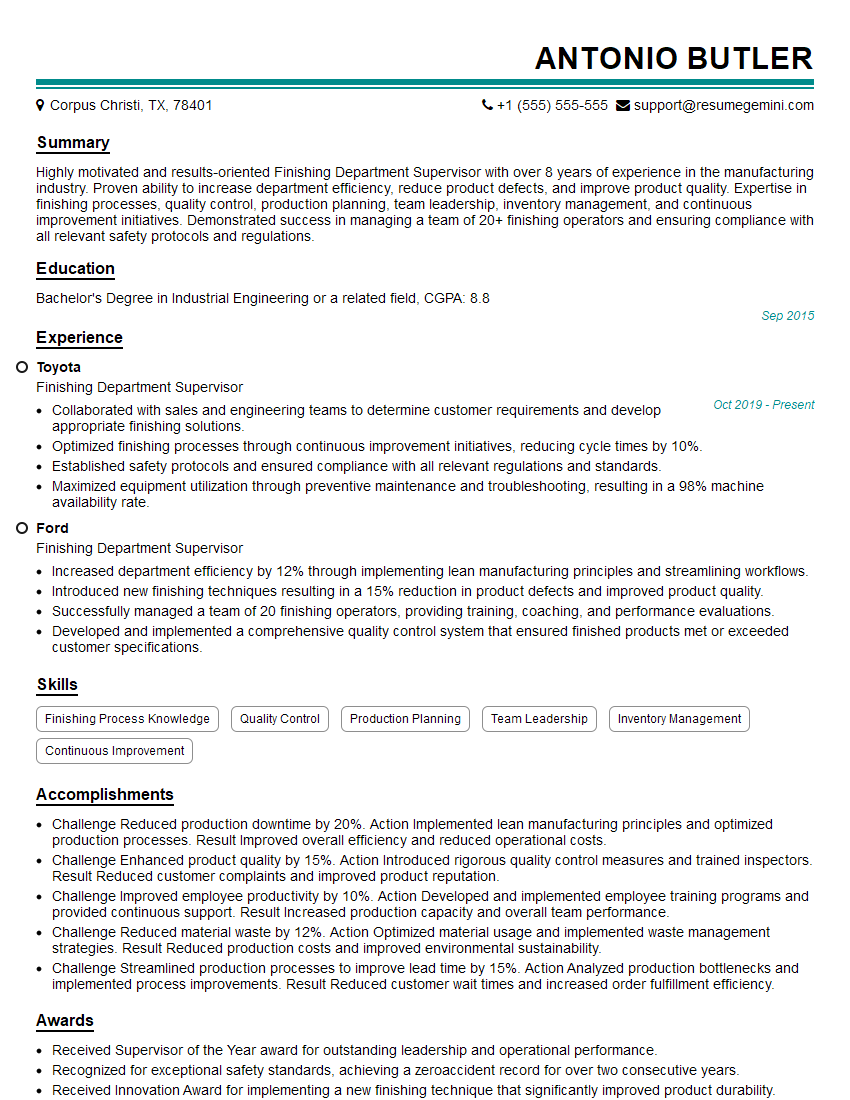

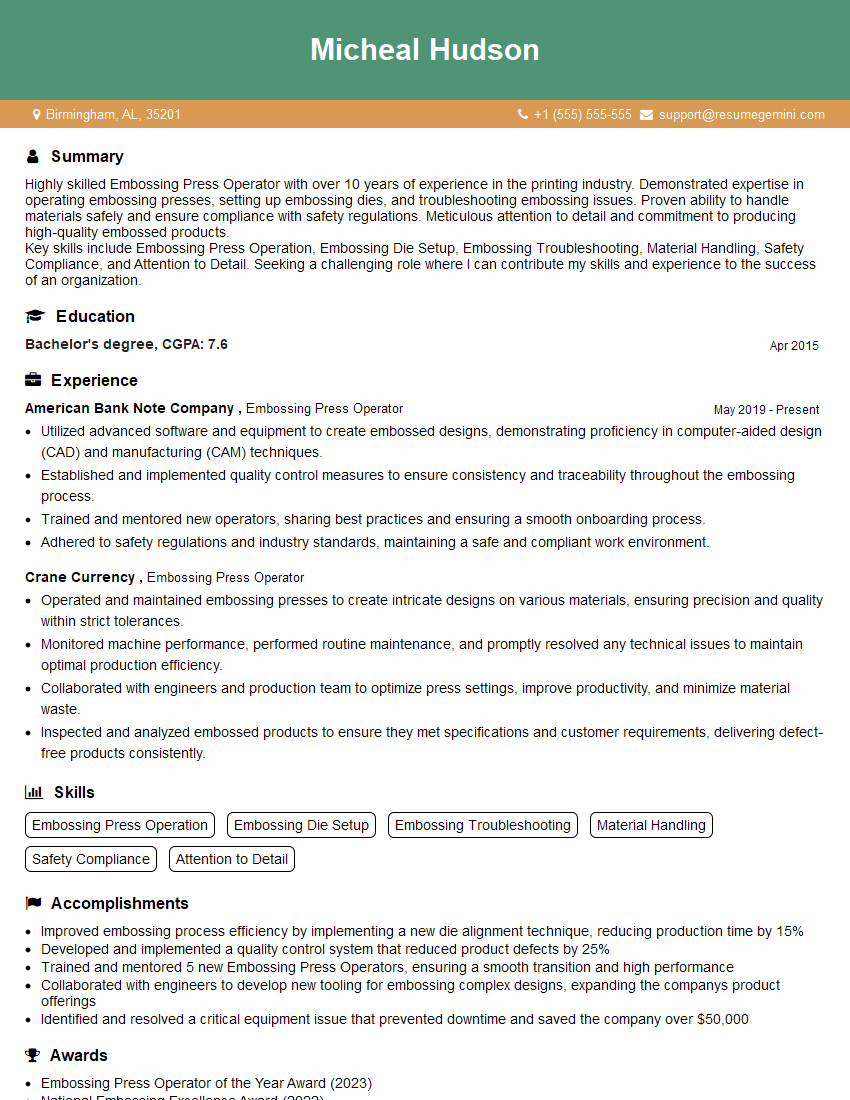

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different embossing machines.

My experience encompasses a wide range of embossing machines, from small, manual tabletop presses to large, automated industrial machines. I’ve worked with both hot-foil embossers and cold-foil embossers, each having its own set of capabilities and limitations.

- Manual Presses: These are ideal for smaller projects and allow for precise control over pressure and placement. They’re excellent for experimentation and prototyping, but are less efficient for large-scale production.

- Automatic Presses: These are high-speed machines designed for mass production. They offer consistent results and higher throughput but require more significant initial investment and specialized maintenance. These are often used in large print shops.

- Hot-Foil Embossers: These machines use heat and pressure to apply foil in addition to embossing. This allows for adding metallic accents or color to the embossed design. They are frequently used in packaging and luxury goods.

- Cold-Foil Embossers: These presses use pressure alone to create the emboss without heat, reducing production cost and environmental impact. They are gaining popularity for their eco-friendliness.

My experience extends to machine setup, operation, maintenance, and troubleshooting. I am comfortable working with a variety of machines and adapting my techniques based on the machine’s specific features and capabilities.

Q 17. What software or design tools are you familiar with for embossing design?

Embossing design requires specialized software and tools. My proficiency includes:

- Adobe Illustrator: This is my primary tool for creating vector-based artwork, which is essential for clean and precise embossing dies. I use it to create outlines, manage layers, and export files in the correct format for die-making.

- Adobe Photoshop: Useful for incorporating raster images or adding textures and details to the design before vectorization. This allows for creative design elements that can be translated into the embossing process.

- CorelDRAW: Another vector-based program with similar functionality to Illustrator, providing an alternative depending on project needs and client preferences.

- CAD Software: For more complex 3D designs and die creation, I’m familiar with CAD programs that allow for precise modeling and rendering of the embossing dies before manufacturing.

I understand the limitations of each software and can optimize designs for successful embossing. For instance, I know that overly fine details can be lost during the embossing process, so I adapt designs accordingly.

Q 18. Explain the role of pre-press preparation in the embossing process.

Pre-press preparation is vital for a successful embossing job. Think of it as preparing the canvas before painting a masterpiece. It involves several key steps:

- Design Review and Optimization: Ensuring the design is suitable for embossing, including appropriate line weights and detail. This is where I flag potential issues that might occur during the process.

- Die Creation or Selection: This is where the appropriate die is chosen based on design complexity, paper stock, and the desired effect as discussed previously.

- Proofing and Approvals: Creating digital and/or physical proofs for client approval before proceeding to production. This helps prevent costly mistakes later on.

- Material Preparation: Ensuring the paper stock is correctly sized, aligned, and free of imperfections. This impacts the uniformity of the embossing process.

Proper pre-press preparation minimizes errors, saves time, and ensures consistent, high-quality results. Skipping this stage often leads to significant issues during the actual embossing process.

Q 19. How do you handle customer requests for custom embossing?

Handling custom embossing requests involves a collaborative approach. I begin by understanding the client’s vision, discussing the feasibility of their design, and offering potential solutions based on my expertise.

- Initial Consultation: I discuss the project’s goals, budget, and timeline. This includes reviewing design concepts, material choices, and any specific requirements.

- Design Development: I assist clients in refining their design, ensuring it’s suitable for embossing, and considering factors like paper weight, die costs, and production capabilities.

- Die Creation and Testing: I work with die makers to create custom dies based on the approved design. I oversee the testing process and make adjustments to the design or die as needed until a satisfactory result is achieved.

- Production and Delivery: I manage the production process, ensuring quality control throughout, and deliver the finished product on time and within budget.

A successful custom embossing project requires clear communication, creative problem-solving, and a deep understanding of both design and production processes.

Q 20. Describe your experience with troubleshooting embossing machine malfunctions.

Troubleshooting embossing machine malfunctions requires a systematic approach. I start with a thorough assessment of the problem and then systematically check various components.

- Visual Inspection: Checking for obvious issues such as loose connections, damaged parts, or material jams.

- Pressure Adjustment: Verifying the machine’s pressure settings are correct for the paper stock and die being used.

- Temperature Control: (For hot-foil embossing) Ensuring the temperature is appropriate for the foil and material. Incorrect temperature can cause the foil to stick to the die or not adhere properly.

- Die Alignment: Checking the alignment of the die to ensure it’s properly seated and in line with the embossing plate.

- Maintenance Procedures: Regular cleaning and lubrication of the machine to prevent issues and extend the lifespan of the components. This includes cleaning debris from the embossing plates and the die itself.

If the problem persists after these checks, I would consult the machine’s manual or contact a qualified technician for assistance. The goal is to restore the machine’s functionality quickly and minimize production downtime.

Q 21. How do you ensure the longevity of embossing dies?

Embossing dies are expensive and represent a significant investment. Proper care and maintenance are essential to ensure longevity.

- Cleanliness: Always clean the die thoroughly after each use to remove paper fibers, ink, and other debris that can dull the surface and affect the embossing quality. Specialized cleaning solvents should be used cautiously and according to the manufacturer’s instructions.

- Storage: Store dies in a clean, dry environment, preferably in a protective case or container. This prevents damage from moisture, dust, or accidental scratches.

- Proper Use: Avoid overloading the machine and using inappropriate pressure, which can damage the die. Always follow the manufacturer’s instructions and guidelines for operating the machine and using specific die types.

- Regular Inspection: Periodically inspect dies for signs of wear and tear, such as cracks, chips, or dull edges. Addressing minor issues promptly can prevent more significant damage in the future.

- Professional Sharpening/Repair: When needed, contact a specialist for sharpening, repair, or re-engraving the die. It’s usually more cost-effective to repair or re-sharpen than to replace the die. This will significantly extend the lifespan.

By following these practices, you can significantly extend the life of your embossing dies, ensuring consistent high-quality results and reducing the need for frequent replacements.

Q 22. What are the environmental considerations in the embossing process?

Environmental considerations in embossing are significant and primarily revolve around responsible material sourcing and waste reduction. The process uses energy for heating and machine operation, contributing to a carbon footprint. Therefore, selecting sustainable paper sources, such as recycled or Forest Stewardship Council (FSC)-certified papers, is crucial. Furthermore, minimizing waste through efficient die design and precise production planning reduces material and energy consumption. Water usage is another factor; cleaning processes should be optimized for minimal water use and proper waste management of cleaning solutions. Finally, responsible disposal of used dies and other materials is essential, considering the potential presence of metals or other non-biodegradable components.

For example, in a recent project, we switched to a supplier offering recycled paper with a comparable embossing performance, reducing our carbon footprint by 15%. We also implemented a new cutting and stacking process, resulting in a 10% decrease in paper waste.

Q 23. Explain your understanding of the different types of foil used in embossing.

Foil embossing uses metallic or pigmented foils to enhance the embossed image, adding visual appeal and texture. There are several types, each with unique properties:

- Hot Stamping Foil: This is the most common type. It’s a thin film coated with a metallic or pigmented layer, transferred onto the paper using heat and pressure. Different finishes include high-gloss, matte, and textured options, offering a wide range of aesthetic possibilities. For instance, a high-gloss gold foil provides a luxurious look, while a matte silver foil creates a subtler, more modern feel.

- Cold Foil: Applied without heat, cold foil offers advantages in terms of energy efficiency. It’s typically applied using a separate unit integrated into the printing press. The foil is transferred using pressure, and the embossing is usually done in a separate step. This method is beneficial for heat-sensitive substrates.

- Specialty Foils: These include foils with holographic effects, textured surfaces, or pearlescent finishes, adding unique visual interest. For example, a holographic foil could create a dynamic, eye-catching effect on a product packaging.

Q 24. How do you measure the depth and sharpness of an embossed image?

Measuring the depth and sharpness of an embossed image is crucial for quality control. We use a combination of methods:

- Optical Measurement: A precision measuring device, like a profilometer, scans the embossed surface to create a 3D profile, accurately measuring depth and assessing the sharpness of the edges. The data obtained helps quantitatively assess the embossing parameters.

- Visual Inspection: Experienced personnel perform a visual inspection using a magnifying glass or microscope. This checks for imperfections like inconsistent depth, uneven embossing, or damage to the foil (if applicable). This method helps detect subtle flaws that might be missed by automated measurements.

- Tactile Assessment: Simply running fingers over the embossed image provides a tactile assessment of the depth and sharpness. This subjective assessment is used in conjunction with objective measurements to get a full picture of the embossing quality.

We maintain detailed records of these measurements for each job, allowing us to track and improve the embossing process over time.

Q 25. What is your experience with different types of paper finishes and their impact on embossing?

Paper finishes significantly impact the embossing process. Different finishes affect the outcome in terms of depth, sharpness, and the overall appearance of the embossed image:

- Coated Paper: Usually provides a smoother surface and yields crisp, well-defined embossing. However, extremely smooth coatings can sometimes result in shallower embossing.

- Uncoated Paper: Offers a more textured surface which might create a softer, less defined embossed image. The texture can influence the overall appearance, potentially resulting in a more rustic or vintage look.

- Textured Paper: Embossing on textured paper can be challenging. The existing texture might interact with the embossing, creating an uneven or unpredictable result. The type of texture—e.g., linen, laid—influences the final outcome.

For example, a luxurious invitation printed on heavy-weight, smooth coated paper will require different embossing parameters compared to a rustic thank you note printed on uncoated, textured paper. Understanding the interplay between paper finish and embossing is vital for achieving the desired aesthetic.

Q 26. How do you manage production deadlines in an embossing environment?

Managing production deadlines in embossing requires meticulous planning and effective communication. We utilize a project management system to track every stage of the process, from initial design and die creation to production and delivery. This system provides a clear overview of the timeline and allows us to identify potential bottlenecks early on. A critical path analysis helps determine the most time-sensitive tasks, allowing us to allocate resources effectively. Regular meetings with the production team ensure that any delays are addressed promptly and solutions are implemented quickly. Maintaining open communication with clients is also vital to manage expectations and ensure a smooth workflow. For urgent projects, we may utilize overtime or optimize the production workflow by prioritizing critical tasks.

Q 27. Describe your experience with quality control processes in embossing.

Quality control is paramount in embossing. Our processes involve multiple checks at each stage:

- Die Inspection: Dies are meticulously inspected for any flaws before use to prevent errors in the embossing process.

- Material Inspection: Paper and foil (if used) are checked for defects like tears, inconsistencies, or color variations.

- In-Process Monitoring: We continuously monitor the embossing process to ensure consistent pressure, temperature, and speed. Sampling and inspection at various points during the run are carried out.

- Final Inspection: Once the embossing is complete, a rigorous final inspection involves checking for any defects like uneven embossing, inconsistent depth, or damage to the paper or foil.

Any defects identified are documented, and corrective actions are implemented. Our quality control system conforms to industry standards, ensuring high-quality output.

Q 28. How do you stay updated on new technologies and trends in paper embossing?

Staying updated on the latest technologies and trends in paper embossing is crucial for maintaining a competitive edge. We utilize several methods:

- Industry Publications and Trade Shows: We regularly review industry publications and attend trade shows to learn about new equipment, materials, and techniques.

- Online Resources and Webinars: We actively participate in online communities and forums dedicated to printing and embossing technologies. Webinars and online courses provide valuable insights into advancements in the field.

- Collaboration and Networking: We maintain relationships with suppliers, industry peers, and technology providers. Sharing knowledge and experiences provides opportunities to discover and implement new methods.

- Research and Development: We dedicate time and resources to testing new materials and processes, ensuring that our embossing operations remain at the forefront of technological advancements.

This continuous learning approach allows us to adopt innovative techniques to enhance our quality, efficiency, and environmental responsibility.

Key Topics to Learn for Your Paper Embossing Interview

- Paper Types and Their Suitability: Understanding the characteristics of different paper types (weight, texture, fiber content) and how they affect the embossing process. Consider the impact of paper choice on the final embossed product.

- Embossing Techniques: Become familiar with various embossing methods, including blind embossing, registered embossing, and foil embossing. Understand the advantages and limitations of each technique.

- Die Design and Construction: Explore the principles of die creation, including materials, design considerations, and the role of die depth and pressure in achieving the desired embossing effect. Be prepared to discuss different die types.

- Press Operation and Maintenance: Gain a practical understanding of how embossing presses function, including setup, operation, and troubleshooting common issues. Knowledge of preventative maintenance is crucial.

- Quality Control and Troubleshooting: Learn to identify and resolve common embossing defects, such as inconsistent impressions, cracking, or tearing. Discuss quality control measures throughout the embossing process.

- Design and Production Workflow: Understand the entire workflow, from initial design and die creation to final product inspection. This shows a holistic understanding of the industry.

- Safety Procedures and Regulations: Demonstrate awareness of safety protocols and industry regulations related to operating embossing machinery and handling materials.

Next Steps

Mastering paper embossing opens doors to exciting career opportunities in packaging, print finishing, and creative design. A strong understanding of this craft is highly valued by employers. To maximize your job prospects, create an ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a professional and impactful resume. We provide examples of resumes tailored specifically to the paper embossing industry to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good