Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Paper Gluing interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Paper Gluing Interview

Q 1. What types of adhesives are commonly used in paper gluing?

The choice of adhesive in paper gluing depends heavily on the application, desired bond strength, open time (how long the glue remains workable), and the type of paper being used. Common adhesives include:

- Polyvinyl Acetate (PVAc) emulsion glues (white glue): These are water-based, relatively inexpensive, and widely used for general paper applications, offering good adhesion and a reasonable open time. They’re ideal for applications where clean-up is easy, like school projects or simple packaging.

- Hot melt adhesives: These are thermoplastic polymers that require heating to liquefy and then cool to solidify, creating a strong bond quickly. They are popular in high-speed industrial applications like box-making due to their fast setting time, but require specialized equipment.

- Dextrin-based adhesives: These are starch-based adhesives that are often used in situations where a non-toxic and biodegradable glue is required. They offer good adhesion but might not be suitable for high-strength applications.

- Animal glues (less common now): Traditionally used, these are derived from animal collagen. They’re strong but sensitive to moisture and are less prevalent due to cost and availability issues.

- Synthetic resins: These offer strong adhesion and water resistance but might be more expensive and require more specialized handling. They’re often used in applications where durability is paramount.

The selection process always involves considering factors like cost, required bond strength, speed of application, and environmental impact.

Q 2. Explain the different methods of paper gluing (e.g., hot melt, cold glue).

Paper gluing methods broadly fall into two categories: hot melt and cold glue applications. Each has its own strengths and weaknesses.

- Hot Melt Gluing: This method utilizes hot melt adhesives which are melted and applied using specialized dispensing equipment. The glue cools and sets quickly, resulting in fast production speeds. Imagine it like a glue gun on a massive scale. It’s commonly used in high-volume applications like corrugated box manufacturing. The speed and strong bond make it ideal for this purpose. However, it requires significant investment in equipment and is less forgiving of inconsistencies in application.

- Cold Glue Gluing: This encompasses methods using water-based adhesives (like PVAc) or other cold-setting adhesives. These adhesives are applied at room temperature, often using rollers, brushes, or spray systems. This method tends to be less expensive in terms of equipment and provides greater flexibility in application. For instance, hand-gluing books or smaller crafts typically use cold glue methods. The downside is slower drying times and less immediate bond strength compared to hot melt.

Other methods, less common but still used, include spray gluing (often for larger surfaces) and roller coating (for even application on continuous webs of paper).

Q 3. Describe your experience with various gluing machines and equipment.

Throughout my career, I’ve worked extensively with a range of gluing machines and equipment, from simple hand-held glue applicators to fully automated high-speed production lines. My experience includes:

- Roller coaters: These apply a consistent layer of adhesive to a continuous web of paper, ideal for large-scale production.

- Spray applicators: Used for applying adhesives evenly to larger, less structured surfaces. Careful calibration is crucial to avoid waste and uneven coating.

- Hot melt glue guns (industrial): These high-capacity guns are used in production lines for fast bonding of cardboard boxes and similar items.

- Automatic case sealers: These machines apply glue and seal cartons efficiently and accurately, significantly increasing production speeds and reducing manual labor.

- Hand-held glue applicators: These range from simple brushes and rollers to more sophisticated devices providing precise glue application for smaller-scale work.

My expertise covers both the operation and maintenance of this equipment, and I’m comfortable troubleshooting malfunctions and ensuring optimal performance.

Q 4. How do you ensure consistent glue application?

Consistent glue application is paramount for ensuring product quality and minimizing waste. Key strategies include:

- Proper machine calibration: Regular checks and adjustments to glue application equipment are essential. This often involves measuring the glue bead width, thickness, and application rate.

- Consistent adhesive viscosity: Maintaining the correct viscosity (thickness) of the glue is critical. This prevents clogging and ensures uniform spreading. Regular monitoring and adjustments are necessary, depending on the type of adhesive and environmental conditions.

- Clean application surfaces: Ensuring that the roller, nozzles, or application surfaces are clean and free of debris helps prevent clogs and uneven glue distribution.

- Proper adhesive storage: Storing adhesives under the correct temperature and humidity conditions helps maintain their consistency and performance. Improper storage can lead to thickening or clumping.

- Operator training: Well-trained operators play a crucial role in achieving consistent glue application. They should understand the machinery, the properties of the adhesives, and how to identify and correct minor discrepancies.

By systematically addressing these factors, we can ensure a predictable and consistent glue application process.

Q 5. What are the key quality control checks for glued products?

Quality control for glued products involves a multi-step process aimed at identifying defects and ensuring consistent quality:

- Visual inspection: A thorough visual examination to detect uneven glue application, glue spots, gaps, or other visual imperfections.

- Bond strength testing: Testing the strength of the glued joint using specialized equipment. This ensures the bond is strong enough to withstand the intended use.

- Open time testing: Measuring the time the adhesive remains workable before setting. This is important for controlling the production process and preventing premature setting.

- Dimensional accuracy: Checking that the glued product conforms to the specified dimensions. Glue application can sometimes affect the final dimensions of the product.

- Moisture content testing (for certain applications): Measuring the moisture content of the paper and the glue to ensure the optimal environment for bonding and avoid warping or delamination.

These checks, combined with meticulous record-keeping, allow for continuous improvement in the gluing process and the identification of recurring issues.

Q 6. How do you troubleshoot common gluing problems (e.g., uneven glue, sticking)?

Troubleshooting common gluing problems requires a systematic approach. Here’s how I typically tackle some of the most frequent issues:

- Uneven glue application: Check the application equipment for clogs, worn rollers, or incorrect settings. Ensure the adhesive viscosity is correct and that the application surfaces are clean. Sometimes, the issue may also be related to the paper itself – inconsistent paper thickness or moisture content could lead to uneven glue distribution.

- Glue sticking (to application equipment): This is often due to improper adhesive selection, incorrect viscosity, or unclean equipment. Using an appropriate release agent or regularly cleaning the equipment can help prevent sticking.

- Weak bonds: This may be due to incorrect adhesive selection, improper glue application, insufficient drying time, or insufficient pressure during bonding. Checking the bond strength, glue type and application method, and drying conditions helps diagnose the root cause.

- Glue stringing: Excessive glue stringing from the nozzle indicates issues with the nozzle itself, adhesive viscosity, or application pressure. Inspect the nozzle for damage or blockage and adjust the application settings.

A methodical process of elimination, checking the various aspects of the process, is usually effective in identifying the cause and implementing a solution. Detailed records and analysis of problems are essential for continuous improvement.

Q 7. What safety precautions do you take when working with adhesives?

Safety is paramount when working with adhesives. My safety procedures include:

- Personal Protective Equipment (PPE): Always using appropriate PPE, including gloves, eye protection, and respirators, as required by the specific adhesive being used. Different adhesives present different hazards, and using the correct PPE is crucial.

- Proper ventilation: Ensuring adequate ventilation in the work area, especially when working with solvent-based or volatile adhesives. This minimizes inhalation of harmful fumes.

- Safe handling and storage: Storing adhesives correctly according to manufacturer instructions, in designated areas, away from heat and ignition sources. Handling adhesives carefully to prevent spills and contamination.

- Emergency procedures: Being aware of and prepared to respond to spills or other emergencies. Having access to appropriate spill cleanup materials and emergency eye washes is critical.

- Following safety data sheets (SDS): Always consulting and adhering to the safety data sheets provided by the adhesive manufacturers. This document provides essential information about handling, storage, and emergency response.

Safety isn’t just a set of rules; it’s a mindset. I prioritize a safe work environment and proactive risk management to prevent accidents and ensure the wellbeing of myself and my colleagues.

Q 8. How do you handle different paper types and weights in the gluing process?

Handling different paper types and weights in gluing requires a nuanced approach. The key is understanding how various paper characteristics impact adhesive performance. For instance, heavier papers (like cardstock) may need a more robust adhesive and potentially longer drying time compared to lighter papers (like newsprint). Porous papers absorb glue quickly, requiring careful application to avoid uneven distribution and weakening the bond. Non-porous papers like coated stocks may require a different adhesive type to ensure proper adhesion.

- Paper Weight: I adjust the glue application method and potentially the adhesive itself based on the weight. Heavier papers might benefit from a roller or spray application for even coverage, while lighter papers could be handled with a brush or more precise applicator.

- Paper Type: Coated papers often require a different adhesive than uncoated papers. I select adhesives with appropriate tack and open time to account for the surface properties. For instance, a high-tack adhesive might be needed for coated stocks to ensure a strong bond.

- Porosity: For porous papers, I often pre-condition the paper or use a glue with a slower drying time to prevent the paper from absorbing too much glue and becoming brittle or weakened. Sometimes, a primer can improve adhesion on especially absorbent substrates.

For example, when gluing a heavy cover to a thinner text block in bookbinding, I’d use a strong, quick-setting adhesive to ensure fast bonding and prevent slippage. On the other hand, for gluing delicate tissue paper, I’d use a weaker, slower-setting adhesive applied very thinly and precisely.

Q 9. Describe your experience with specific types of gluing, such as case making or perfect binding.

My experience spans various gluing applications, with extensive work in both case making and perfect binding.

- Case Making: This involves adhering the cover boards to the book’s text block. I’ve worked with various adhesives, including hot melt, PUR (Polyurethane Reactive), and even traditional animal glues (in restoration work). The choice depends on factors like the desired bond strength, speed of production, and the materials involved. Hot melt is fast and efficient, suitable for high-volume production, but less flexible. PUR offers superior strength and durability but requires specialized equipment. Precision in glue application is crucial to prevent glue squeeze-out and maintain a clean finish.

- Perfect Binding: This method requires precise application of adhesive to the spine of the book block before applying the cover. Here, I focus on achieving consistent glue application to ensure the pages adhere securely without creating a noticeable hump or unevenness on the spine. The viscosity and open time of the adhesive play a significant role. I’ve utilized both hot melt and PUR adhesives in perfect binding, adapting the setup and settings depending on the specific book dimensions and paper type.

One memorable project involved creating custom slipcases using case-making techniques for a limited-edition art book. The client specified a unique paper stock, requiring meticulous adhesive selection and application to ensure proper adhesion without damaging the delicate paper.

Q 10. What is your experience with maintaining gluing equipment?

Maintaining gluing equipment is paramount to ensure consistent performance and prevent costly downtime. My experience includes regular cleaning and lubrication of all moving parts, following manufacturer’s recommendations for each machine. This typically involves daily cleaning to remove dried glue and debris, weekly checks for wear and tear, and regular preventative maintenance, including replacement of worn parts.

- Daily Maintenance: Cleaning glue residue from rollers, applicators, and other components. This prevents build-up that can affect glue distribution and cause malfunction.

- Weekly Maintenance: Checking for loose screws, tightening belts, and inspecting hoses for leaks or damage.

- Preventative Maintenance: Regular lubrication, replacing worn rollers, and scheduled servicing by qualified technicians. This minimizes unexpected breakdowns and extends the equipment’s lifespan.

I keep detailed records of all maintenance activities, including date, type of service, and any parts replaced. This helps track the equipment’s performance and predict potential issues before they occur.

Q 11. How do you manage waste and ensure efficient adhesive use?

Efficient adhesive use and waste management go hand in hand. To minimize waste, I focus on precise application techniques, utilizing the right amount of glue for each job. This includes using appropriately sized applicators, adjusting glue flow rates according to the material and speed, and training staff on best practices.

- Precise Application: Using the appropriate glue applicator (roller, brush, spray nozzle) ensures even distribution, minimizing excess glue.

- Controlled Flow Rate: Adjusting the flow rate on automated systems prevents over-application and waste.

- Glue Recycling: Where possible, I explore opportunities to recycle or reclaim unused adhesive, depending on the adhesive type and company policy.

- Waste Collection and Disposal: Implementing proper waste disposal procedures for used glue and packaging materials, complying with all environmental regulations.

One strategy I’ve implemented successfully is a ‘training and feedback’ program for operators, using visual aids and practice sessions to improve their glue application accuracy. This resulted in a significant reduction in glue waste and improved efficiency.

Q 12. Explain your understanding of different glue viscosity levels and their applications.

Glue viscosity is a critical factor in successful paper gluing. It refers to the thickness or fluidity of the adhesive. Different viscosity levels are appropriate for various applications.

- Low Viscosity: Thin and easily spreadable, ideal for applications requiring fast penetration and covering large areas. Useful for porous papers where quick absorption is desired.

- Medium Viscosity: A balance between flow and adhesion, commonly used in general-purpose gluing applications. Offers good spreadability and sufficient tack for most paper types.

- High Viscosity: Thick and less runny, suitable for applications requiring strong initial tack and precise application. Ideal for heavier papers and applications demanding immediate adhesion.

For example, a low-viscosity adhesive might be suitable for gluing large areas of wallpaper, whereas a high-viscosity adhesive would be preferable for precise bonding in a bookbinding application. I always check the manufacturer’s recommendations for the specific glue and application.

Q 13. How do you determine the correct amount of glue for a given application?

Determining the correct amount of glue depends on several factors: the type of adhesive, the paper types being joined, the desired bond strength, and the application method. There isn’t a single formula; it’s more of a learned skill developed through experience and testing.

- Testing: I often conduct small-scale tests with varying glue amounts before applying the adhesive to the entire project. This allows me to fine-tune the application method and ensure optimal results. I might create several test samples using different glue quantities and assess the bond strength, drying time, and overall appearance.

- Experience: My years of experience have taught me to visually assess the required glue amount based on the paper type and application method. I use my judgment to ensure appropriate coverage without excess.

- Manufacturer Guidelines: I always consult the manufacturer’s instructions for the specific adhesive being used. These guidelines often provide recommendations for various applications and substrate types.

One example: when perfect binding a book, I start with a small amount of glue, and then adjust the applicator setting to find the ideal balance for a secure bond that doesn’t ooze out from the spine.

Q 14. What are the implications of using incorrect glue or improper application?

Using incorrect glue or applying it improperly can have significant consequences.

- Weak Bonds: Using an adhesive that isn’t suited for the specific paper types can lead to weak bonds, resulting in pages falling out of a book, or a cover separating from its core. This can be disastrous for a product’s durability and user experience.

- Glue Squeeze-out: Over-application can result in excess glue, creating unsightly messes and potentially damaging the paper or other materials.

- Poor Aesthetics: Uneven application creates an unprofessional and visually unappealing finish.

- Delayed Drying Time: Using an adhesive with an inappropriately long open time can cause delays in production and potentially cause the paper to wrinkle or distort before the glue sets.

- Material Damage: Some adhesives can react negatively with certain paper types, causing discoloration, warping, or even dissolving the paper.

In one instance, using the wrong glue on a high-volume project resulted in significant production delays and rework. The chosen adhesive wasn’t compatible with the coated paper used, leading to weak bonds and requiring us to re-glue entire batches. This highlighted the importance of careful adhesive selection and rigorous testing.

Q 15. How do you ensure the structural integrity of a glued product?

Ensuring the structural integrity of a glued product hinges on several key factors: the correct adhesive selection, proper surface preparation, and optimized application techniques. Think of it like building a house – a weak foundation (poor surface prep) or the wrong type of mortar (adhesive) will lead to a structurally unsound building.

- Adhesive Selection: The adhesive must be compatible with both substrates (the materials being glued). For instance, a water-based adhesive might be unsuitable for materials sensitive to moisture. The strength requirements of the final product will also dictate the adhesive’s tensile strength and bonding properties.

- Surface Preparation: Cleanliness is paramount. Dust, oil, or other contaminants on the paper surfaces will prevent proper adhesion. This often involves cleaning and potentially pre-treating the surfaces to enhance their receptivity to the glue.

- Application Technique: The amount of adhesive applied is crucial. Too little, and the bond will be weak; too much, and it might cause bleed-through or warping. Precise application, often controlled by automated systems, ensures consistent bond strength across the entire product.

- Curing Conditions: Allowing sufficient time for the adhesive to cure under appropriate temperature and humidity is essential for achieving maximum bond strength. Incorrect curing can lead to weakened bonds and product failure.

For example, in a bookbinding application, using a weak adhesive or not properly preparing the paper edges will result in pages falling out. A strong adhesive and meticulous application are essential for creating a durable and long-lasting product.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with automated gluing systems.

I have extensive experience with various automated gluing systems, ranging from simple roller coaters to sophisticated robotic systems. My experience includes working with both hot-melt and cold-glue applications in high-volume production environments.

- Roller Coaters: These are excellent for uniform glue application on large sheets of paper. I’ve used these in applications involving the production of corrugated boxes and large format posters. The precise control over glue thickness is a significant advantage.

- Jetting Systems: These offer precise placement of glue, which is especially beneficial in applications requiring intricate designs or complex gluing patterns. I’ve employed these in bookbinding and the creation of custom packaging solutions. The speed and precision are vital for efficiency.

- Robotic Systems: These are highly versatile and can handle various gluing tasks with high accuracy. They are beneficial when dealing with complex geometries or high-precision work. I’ve overseen the integration of robotic systems in the manufacturing of specialized paper-based products, improving both speed and consistency.

My expertise extends to troubleshooting and maintaining these systems, ensuring optimal performance and minimizing downtime. Understanding the intricacies of each system, from calibration to maintenance schedules, is crucial for efficient production.

Q 17. How do you adapt to different gluing techniques and processes?

Adaptability is crucial in the paper gluing industry, as diverse products necessitate different approaches. My experience encompasses a wide range of techniques, including:

- Hot-Melt Gluing: Used for strong bonds that require quick setting times. This is often used in packaging applications.

- Cold-Glue Gluing: Employs water-based or solvent-based adhesives, ideal for situations where heat sensitivity is a concern. Bookbinding frequently uses this method.

- Spray Gluing: Offers even coverage for large areas, though control over adhesive amount is crucial to avoid excess. Useful in wallpaper application.

- Roller Coating: Ideal for large-scale, consistent glue application on flat surfaces. Commonly used in box manufacturing.

I adapt by analyzing the specific needs of the product, considering factors such as material compatibility, required bond strength, and production speed. This systematic approach, combined with my practical experience, allows me to quickly integrate new processes and techniques. For example, I successfully transitioned a production line from a slower, less efficient spray gluing system to a more precise jetting system, resulting in a 20% increase in production output.

Q 18. How familiar are you with different types of paper and their glueability?

My understanding of paper types and their glueability is extensive. Different paper types exhibit varying porosity, surface coatings, and fiber structures, all of which impact adhesive performance.

- Porous Papers (e.g., newsprint, recycled paper): These readily absorb adhesives, potentially leading to weak surface bonds and increased drying times. A more viscous adhesive might be necessary.

- Non-porous Papers (e.g., coated papers, photographic paper): These often require specialized adhesives designed to adhere to smooth surfaces. Pre-treatment might be needed to improve adhesion.

- Coated Papers: The type of coating (e.g., gloss, matte) significantly influences adhesive selection. Some coatings might repel certain adhesives.

I use this knowledge to select the most appropriate adhesive for the specific paper type, ensuring strong, reliable bonds. For instance, when gluing photographs, I’d use a photo-safe adhesive to avoid damaging the image. Working with recycled paper requires careful adhesive selection to compensate for inconsistencies in the paper structure.

Q 19. What are the challenges of gluing porous versus non-porous materials?

Gluing porous versus non-porous materials presents distinct challenges. Porous materials absorb the adhesive, potentially leading to insufficient surface adhesion and slower drying times. Non-porous materials, on the other hand, may require surface treatment to enhance their wettability and ensure proper adhesion.

- Porous Materials: The key is to choose an adhesive with good penetration and sufficient tack to create a strong bond despite the absorption. Sometimes, a primer or sizing agent might be necessary to improve adhesion.

- Non-Porous Materials: Adhesives designed for smooth, non-porous surfaces are essential. Surface treatments like corona treatment or plasma treatment can improve the surface energy of these materials, enabling better adhesion.

For example, gluing porous cardboard to a non-porous plastic film requires a specialized adhesive with good adhesion to both types of materials. If the wrong adhesive is selected, the bond might fail, especially under stress.

Q 20. Explain your understanding of adhesive curing times and conditions.

Understanding adhesive curing times and conditions is critical for achieving optimal bond strength and product quality. Curing involves the chemical process where the adhesive transitions from a liquid or semi-liquid state to a solid state, forming a strong bond.

- Temperature: Higher temperatures generally accelerate curing, but excessive heat can damage the materials or cause the adhesive to degrade. The optimal temperature depends on the adhesive type and the materials being bonded.

- Humidity: Humidity can affect the drying time of water-based adhesives, potentially leading to slower curing or weaker bonds. Controlled humidity environments are sometimes necessary.

- Pressure: Applying pressure during curing can improve the bond strength by ensuring intimate contact between the surfaces.

- Open Time: This is the time allowed for the adhesive to be repositioned before it sets. This is critical for precise placement.

Knowing the specific curing requirements for each adhesive is crucial. Incorrect curing conditions can lead to weak bonds, delamination, or other defects. I always consult the manufacturer’s specifications for optimal curing parameters and consistently monitor and control these parameters in my work.

Q 21. How do you maintain cleanliness and hygiene around the gluing area?

Maintaining cleanliness and hygiene in the gluing area is vital for preventing contamination, ensuring consistent product quality, and maintaining a safe work environment. This involves several key practices:

- Regular Cleaning: Spills and adhesive residue must be cleaned promptly to avoid contamination of materials and equipment. Appropriate cleaning agents should be used without damaging the surfaces.

- Equipment Maintenance: Regular maintenance of gluing equipment ensures accurate and consistent adhesive application and prevents clogs or malfunctions. This might include cleaning rollers, nozzles, and other components.

- Personal Protective Equipment (PPE): Employees should always use appropriate PPE, such as gloves and eye protection, to prevent exposure to adhesives and other chemicals. This is paramount to health and safety.

- Waste Management: Proper disposal of waste adhesive and cleaning materials is essential to protect the environment. We strictly follow regulations concerning hazardous waste disposal.

Implementing and consistently following these procedures ensure a clean and efficient work environment, minimizing the risk of defects and maintaining high standards of product quality and worker safety.

Q 22. What are the environmental considerations related to adhesive use?

Environmental considerations in adhesive use are crucial for sustainability and worker safety. We must consider the volatile organic compounds (VOCs) released by many adhesives, which can contribute to air pollution and have health implications. The disposal of used adhesives and their containers also presents an environmental challenge, requiring proper handling and potentially specialized waste disposal methods.

For example, water-based adhesives are generally preferred over solvent-based ones because they have lower VOC emissions. We also prioritize adhesives with recycled content and biodegradable options whenever feasible. Proper ventilation during application and careful adherence to manufacturer’s safety data sheets (SDS) are vital for mitigating environmental and health risks.

- VOC emissions: Choosing low-VOC or VOC-free adhesives significantly reduces air pollution.

- Waste management: Implementing a system for collecting and properly disposing of adhesive waste reduces environmental impact.

- Sustainable sourcing: Opting for adhesives made with recycled materials or from renewable resources promotes sustainability.

Q 23. How do you handle different adhesive drying times?

Handling varying adhesive drying times requires careful planning and execution. Fast-drying adhesives demand speed and precision, necessitating well-coordinated workflows to prevent sticking or misalignment. Slower-drying adhesives allow for more correction and adjustment, but require longer processing times and potentially more storage space. We tailor our process to the specific adhesive.

For instance, when using a fast-drying adhesive in a high-volume production line, we might employ automated systems with precise dispensing and quick clamping mechanisms. With a slower-drying adhesive, we might use a staged approach, allowing time for the adhesive to set before proceeding to the next step, perhaps implementing a conveyor system with timed intervals.

Q 24. What is your experience with troubleshooting jammed or malfunctioning machinery?

Troubleshooting jammed or malfunctioning machinery requires a systematic approach. My experience involves identifying the problem, isolating the cause, and implementing a solution, often involving a combination of mechanical, electrical, and pneumatic expertise.

For example, a recent jam in our high-speed folder-gluer was initially suspected to be a paper-feed issue. However, upon closer examination, we discovered a minor misalignment in the gluing rollers, causing friction and a jam. We adjusted the rollers, cleaned any adhesive build-up, and the issue was resolved. A detailed log of maintenance and troubleshooting is crucial for predicting and preventing future problems.

Q 25. Describe a time you had to solve a complex gluing problem.

One challenging gluing problem involved a complex, three-dimensional cardboard display with intricate cutouts and folds. The adhesive consistently failed to bond certain sections reliably, resulting in structural weaknesses. Initially, we considered using a stronger adhesive, but that risked damaging the delicate paperboard.

Our solution involved modifying the gluing pattern. By using a combination of spot gluing in high-stress areas and a thin application of adhesive along the primary seams, we achieved a stronger, more consistent bond without compromising the structural integrity. This involved careful analysis of the structural weaknesses of the piece and precise adjustments to the gluing machine settings. The successful resolution highlighted the importance of understanding structural design and adaptive problem-solving.

Q 26. How do you ensure the accuracy of glue placement on complex shapes?

Ensuring accurate glue placement on complex shapes requires a combination of precise dispensing methods and meticulous planning. For intricate shapes, robotic or automated gluing systems can provide exceptional accuracy. We often employ specialized tooling—for example, custom-designed nozzles or application heads—to achieve the necessary precision.

For instance, when gluing components with intricate designs, we may use computer-aided design (CAD) models to program robotic arms to dispense glue along precisely defined paths, accounting for the shape’s curves and angles. Manual application requires skilled technicians and specialized tools such as precision applicators, brushes or syringes, and templates or jigs for accurate placement.

Q 27. What are the different types of glue pots and their maintenance?

Glue pots come in various types, each with unique maintenance requirements. There are gravity-fed pots, pressure-fed pots, and circulation pots.

- Gravity-fed pots: Simple and cost-effective, but require consistent monitoring of glue levels and regular cleaning to prevent clogging.

- Pressure-fed pots: Provide more consistent glue flow, but require regular maintenance of the pressure system and careful monitoring of the pressure gauge.

- Circulation pots: Maintain a consistent glue temperature and viscosity, reducing clogging but necessitating cleaning of the circulation system to remove debris.

Regular maintenance includes daily cleaning to remove dried glue and debris, periodic checks of seals and gaskets, and routine inspections for wear and tear. The frequency of maintenance depends on the type of glue pot and the frequency of use. Proper maintenance prevents clogging, ensures consistent glue application, and prolongs the life of the equipment.

Q 28. Describe your experience with pre-press and post-press processes related to gluing.

My experience with pre-press and post-press processes related to gluing is extensive. Pre-press involves preparing the materials for optimal gluing. This includes verifying the accuracy of the die-cuts, ensuring consistent substrate quality and selecting the correct adhesive for the job and the materials being glued. Post-press operations often involve quality control checks to ensure that the glued product meets the required specifications such as proper alignment, sufficient adhesion and structural integrity.

A critical pre-press task is verifying die-cut accuracy. Slight inconsistencies in cutting can lead to alignment problems during gluing. Post-press quality control involves visually inspecting the glued products for any imperfections such as misalignment, glue bleed-through, or insufficient bonding. This can lead to adjustments in the pre-press process such as die-cutting parameters or adhesive selection and application techniques.

Key Topics to Learn for Paper Gluing Interview

- Types of Adhesives: Understanding different glue types (e.g., PVA, hot melt, starch-based) and their properties (e.g., drying time, viscosity, strength) is crucial. Consider the advantages and disadvantages of each in various applications.

- Paper Properties and Their Impact on Gluing: Explore how paper weight, texture, and porosity affect adhesion. Learn to identify potential challenges and solutions related to different paper types.

- Gluing Techniques and Equipment: Familiarize yourself with various gluing methods (e.g., manual, automated) and the machinery involved. Understand the principles of even glue distribution and optimal pressure application.

- Quality Control and Troubleshooting: Learn about common gluing defects (e.g., wrinkles, bubbles, weak bonds) and their causes. Develop problem-solving skills to address these issues efficiently.

- Health and Safety Regulations: Understand relevant safety procedures and regulations concerning adhesive handling, including personal protective equipment (PPE) and waste disposal.

- Production Efficiency and Optimization: Explore strategies for maximizing gluing speed and minimizing waste while maintaining high-quality results. This includes understanding workflow optimization and process improvement techniques.

- Industry Best Practices: Research and understand current industry standards and best practices for paper gluing in your specific area of interest (e.g., bookbinding, packaging, etc.).

Next Steps

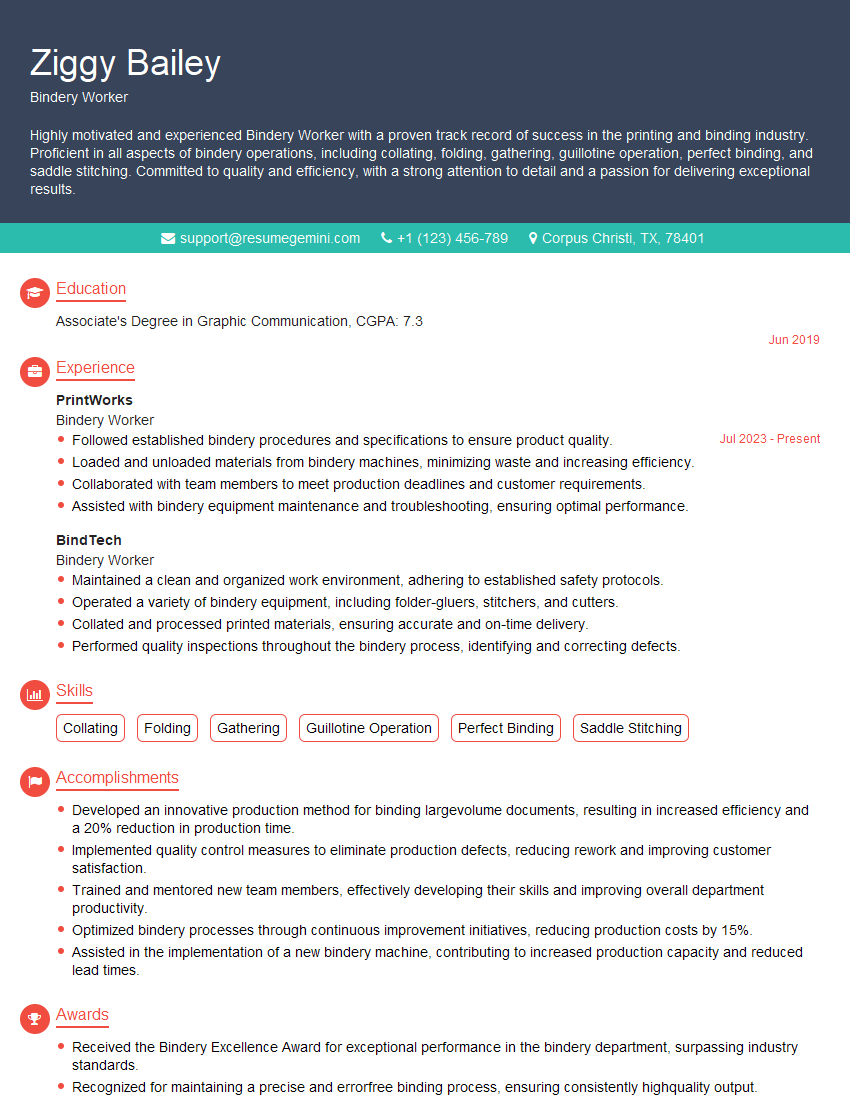

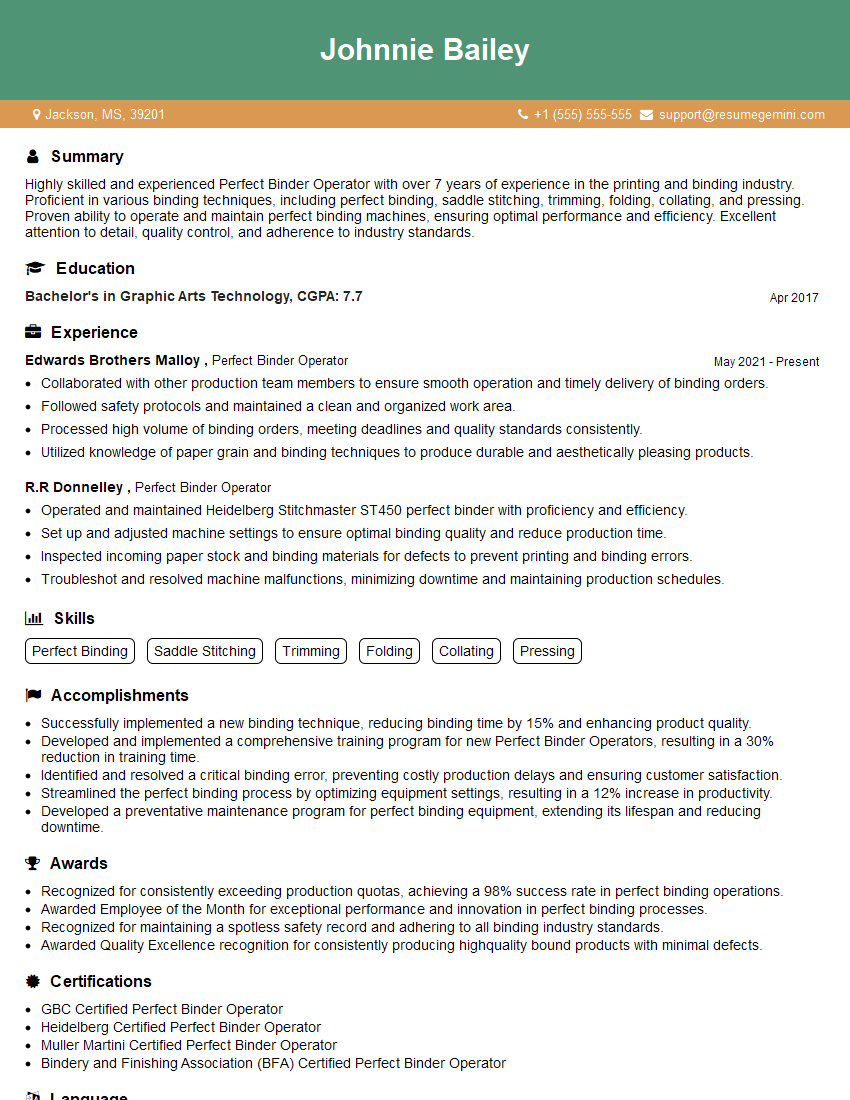

Mastering paper gluing opens doors to diverse and rewarding career opportunities within various industries. A strong understanding of this skillset demonstrates meticulousness, attention to detail, and problem-solving abilities – highly valued qualities in many workplaces. To maximize your job prospects, creating an ATS-friendly resume is vital. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume, highlighting your skills and experience effectively. Examples of resumes tailored to Paper Gluing are available to guide you through the process. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good