The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Pattern creation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Pattern creation Interview

Q 1. Explain the difference between a sloper and a block pattern.

A sloper and a block pattern are both foundational patterns, but they differ significantly in their purpose and level of detail. Think of a sloper as a truly basic, foundational outline—a personalized map of your body shape. It’s a highly customized, close-fitting pattern that captures the individual curves and proportions of a specific body measurement set. It lacks seam allowances and design details. In contrast, a block pattern is a more generalized pattern, often based on standard size charts. While it’s still a fundamental base, it’s less personalized and provides a starting point for a wider range of garments. It usually incorporates basic seam allowances. Essentially, a sloper is a highly personalized block pattern, specific to a person’s body, from which numerous garments can be derived. You can think of a sloper as a ‘blank canvas’ tailored precisely for an individual, while a block is a ‘more generic template’ for a certain size.

Q 2. Describe your experience with various pattern making software (e.g., Optitex, Gerber, Lectra).

I have extensive experience with several industry-leading pattern making software packages, including Optitex, Gerber Accumark, and Lectra Modaris. My proficiency spans from basic pattern creation and manipulation to advanced techniques like grading, marker making, and 3D simulation. With Optitex, I’ve been particularly adept at utilizing its digital draping capabilities to create innovative and complex patterns. Gerber Accumark has been instrumental in streamlining my workflow for production-oriented pattern making, facilitating efficient grading and marker planning. Lectra Modaris, on the other hand, has allowed me to manage intricate pattern details and perform complex alterations across multiple sizes seamlessly. I’m comfortable using each platform’s specific features and functionalities, and I readily adapt my skillset to meet project requirements.

Q 3. How do you create a basic bodice block?

Creating a basic bodice block is a multi-step process, starting with accurate measurements. First, you would construct a basic bodice block using a set of body measurements. This usually starts with a front and back bodice which are created using a simple rectangle, and then the shaping lines are created. Then, you’d add design features like darts (front and back). These darts shape the fabric to fit the body’s curves. The armhole and neckline are then shaped and refined for fit. You’d then make a test garment (a muslin) from this block, and refine the block using the muslin fit. This involves making adjustments to achieve a comfortable and well-fitting garment. This process, from initial measurements to a final, refined block, involves numerous iterations and fittings to achieve the required fit. For example, if the muslin is too tight across the bust, the front bodice dart needs to be widened or adjusted. Each adjustment requires careful consideration of how it affects the overall balance and drape of the garment.

Q 4. How do you adjust a pattern for different body types?

Adjusting a pattern for different body types requires a deep understanding of how body shapes vary. The key is to identify areas where the standard block needs modification. For example, a full-bust adjustment would involve adding width to the bust area while maintaining the balance of the overall bodice. For individuals with broader shoulders, the shoulder line will need adjustments and potentially alterations in the sleeve cap to suit the shape. Similarly, adjustments for a swayback or a high hip would necessitate specific pattern modifications. The strategy is always to maintain the structural integrity of the pattern while making tailored adjustments. Often this would be carried out by altering the shaping lines, such as darts, or by making adjustments to the seam lines. This work often requires multiple iterations and mock-ups to ensure the resulting garment sits well on various body types.

Q 5. Explain the process of grading a pattern.

Grading a pattern involves systematically increasing or decreasing its size to create a range of sizes. This is usually done using specialized software but can be accomplished manually. Each pattern piece is proportionally enlarged or reduced according to set grading rules. These rules may vary depending on the garment type and design features. For example, the length of a sleeve might increase proportionally more than the width. Grading requires precision and a thorough understanding of how different design features scale. Inaccurate grading can result in ill-fitting garments; therefore, thorough checking and testing are essential. Software automation greatly reduces the risk of error and helps with efficiently producing the different sizes.

Q 6. Describe your experience with different pattern making methods (e.g., draping, flat pattern making).

My experience encompasses both flat pattern making and draping. Flat pattern making relies on creating a pattern using measurements and calculations on a flat surface, offering precision and repeatability. Draping, on the other hand, involves manipulating fabric on a dress form to achieve a desired three-dimensional shape, creating a more intuitive and sculptural approach. I find that combining both methods often yields the best results; draping can help visualize the desired shape which can then be translated into a precise flat pattern. For example, I might drape a complex sleeve to visualize the fit before translating that design into a flat pattern for production. Each method has its strengths, and the choice depends on the garment’s complexity and the desired design aesthetic.

Q 7. How do you handle pattern alterations during the fitting process?

Handling pattern alterations during fitting is an iterative process. After a muslin fitting, I carefully note any areas needing adjustment—tightness, looseness, pulling, or any other inconsistencies. I then translate these observations into precise pattern adjustments. This often involves making small adjustments to the seam lines, darts, or other design features. The process is methodical; I might begin by making a small alteration, creating a new muslin, and repeating the fitting process until the garment hangs and fits flawlessly. For instance, if the back neckline is pulling, I’ll ease the curve of the neckline slightly in the pattern. Each adjustment is documented for future reference and consistency across sizes or production runs. This iterative process requires patience, attention to detail, and a deep understanding of garment construction.

Q 8. Explain the importance of accurate measurements in pattern making.

Accurate measurements are the cornerstone of successful pattern making. Think of it like building a house – if your foundation (measurements) is off, the entire structure (garment) will be flawed. Inaccurate measurements lead to ill-fitting garments, wasted fabric, and ultimately, dissatisfied clients. Every measurement, from bust and waist circumference to sleeve length and shoulder width, must be precise to ensure the final garment fits the intended wearer perfectly.

For example, a 1/2 inch error in the bust measurement can result in a garment that’s too tight or too loose, significantly impacting its comfort and appearance. Professional pattern makers use a variety of tools to ensure accuracy, including measuring tapes, rulers, and sometimes even digital measuring devices.

Q 9. How do you ensure the accuracy of your patterns?

Ensuring pattern accuracy is a multi-step process. I begin by taking meticulous measurements, always double-checking for consistency. I use high-quality tools and techniques. Next, I meticulously draft the pattern pieces using precise calculations and templates. I then create a muslin (a test garment made from inexpensive fabric) to check the fit and make any necessary adjustments. This muslin fitting stage is crucial, allowing me to identify and correct any errors before cutting into the final fabric. Finally, I always check the finished pattern pieces against the original measurements to confirm accuracy. This iterative approach minimizes errors and ensures a perfect fit.

Q 10. Describe your experience with creating patterns for different fabrics.

My experience spans a wide range of fabrics, from lightweight silks and delicate laces to heavy wools and sturdy denim. Each fabric has unique draping properties and requires a tailored approach to pattern making. For instance, a pattern for a flowing silk dress will need more ease (extra fabric for drape) than a pattern for a structured denim jacket. The choice of pattern paper itself can even vary – I might use a lightweight tissue paper for silk patterns to avoid adding unnecessary bulk. Understanding fabric behavior is key. I’ve worked extensively with knits, learning how their stretch impacts the need for negative ease, unlike woven fabrics.

I remember one project where I was creating a dress from a very delicate silk chiffon. The pattern had to be exceptionally precise to avoid any distortion or puckering. Using a lightweight tracing paper was crucial to avoid adding unnecessary weight and causing any problems with the final garment.

Q 11. How do you choose the appropriate seam allowance for a garment?

Seam allowance is the extra fabric added to the pattern pieces before sewing to create the seam. The appropriate seam allowance depends on several factors: the fabric type, garment style, and the sewing machine being used. A typical seam allowance is 5/8 inch (1.5 cm), but this can vary. Heavier fabrics, such as denim, may require a larger seam allowance (3/4 inch or more) for durability, while delicate fabrics might use a smaller allowance (1/4 inch or less) to minimize bulk. Specific garment styles also dictate the seam allowance, for instance, French seams require smaller seam allowances than standard seams. The chosen allowance should be clearly marked on the pattern pieces to maintain consistency.

Q 12. Explain your process for creating a pattern from a sketch or design.

Creating a pattern from a sketch begins with interpreting the design’s shape and proportions. I start by sketching the design on paper, adding detailed notes and measurements. Then, I create a basic block pattern (a foundation pattern for the specific body type). This block is then manipulated to match the design’s specifications. I add or remove darts, adjust seam lines, and modify the shape of the pattern pieces to achieve the desired silhouette. This may involve several iterations of drafting, muslin fitting, and adjustments. I always incorporate my knowledge of garment construction techniques to ensure the pattern is both aesthetically pleasing and structurally sound.

Q 13. How do you troubleshoot common pattern making problems?

Troubleshooting is an integral part of pattern making. Common issues include ill-fitting garments, distorted pattern pieces, and incorrect seam lines. I approach these problems systematically. First, I meticulously review the initial measurements and pattern drafting process. Incorrect measurements are often the root cause, highlighting the importance of accurate data collection. If the problem lies in the pattern construction, I carefully examine each pattern piece for any distortions or miscalculations. If the issue is with the fit, I perform a muslin fitting, pinpointing areas that need adjustments. This might involve taking new measurements or making changes to the pattern pieces based on the muslin fit. This step-by-step approach helps isolate the error and find effective solutions.

Q 14. Describe your experience working with different types of pattern paper.

I’ve worked with a variety of pattern papers, each with its own advantages and disadvantages. Lightweight tissue paper is great for creating initial drafts and making quick adjustments because it’s easy to trace and manipulate. However, it’s not durable enough for long-term storage. On the other hand, heavier-weight pattern paper is sturdy and long-lasting, suitable for creating master patterns, but can be more challenging to manipulate. I also use transparent pattern plastic for precise pattern manipulation and storage because of its durability. The choice of paper depends on the project; for a one-off garment, tissue paper might suffice, but for a production run, durable paper is essential to ensure long-term pattern usage.

Q 15. How familiar are you with industrial sewing techniques?

My familiarity with industrial sewing techniques is extensive. I’ve worked with a wide range of industrial sewing machines, from single-needle to multi-needle machines, and understand their capabilities and limitations. This includes experience with different stitch types, seam finishes, and the importance of proper machine maintenance for efficient and high-quality production. I understand the nuances of working with different fabrics and how machine settings need to be adjusted accordingly. For example, I know that delicate fabrics like silk require a smaller stitch length and lower tension than heavier fabrics like denim. This knowledge is crucial in ensuring the patterns I create are not only aesthetically pleasing but also practical for industrial production, considering factors like speed, durability, and cost-effectiveness.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage your time effectively when working on multiple patterns simultaneously?

Managing multiple patterns simultaneously requires a structured approach. I utilize project management techniques, prioritizing tasks based on deadlines and complexity. I break down each pattern into smaller, manageable steps: drafting, adjustments, grading, and testing. I create a detailed schedule, allocating specific time blocks for each pattern and task. This allows me to switch between projects without losing track or causing delays. Tools like digital calendars and to-do lists are indispensable. For instance, I might allocate Mondays and Wednesdays to drafting new patterns, Tuesdays and Thursdays for adjustments and grading, and Fridays for pattern testing and revisions. This approach, combined with excellent time management skills, ensures efficient workflow and prevents feeling overwhelmed.

Q 17. How do you maintain organization within your pattern-making process?

Organization is paramount in pattern making. I maintain a meticulous system for storing both physical and digital patterns. Physical patterns are stored using clear, labeled folders, categorized by garment type and size. Each pattern piece is clearly marked with its name, size, and any relevant notes. Digitally, I use a dedicated file management system, employing a consistent naming convention. For example, ‘DressA_Size10_V1.pdf’ clearly identifies the pattern, size, and version. This allows easy retrieval and version control. I regularly archive completed patterns to prevent data loss. Additionally, I utilize digital tools for pattern grading and adjustments, ensuring consistency and accuracy across different sizes. This organized system prevents confusion and reduces errors, saving valuable time and resources.

Q 18. What are your preferred methods for documenting pattern adjustments?

I document pattern adjustments using a combination of methods to ensure clarity and traceability. I annotate directly onto the physical pattern pieces using a non-permanent marker or adhesive notes, detailing the exact measurements and locations of adjustments. I also maintain a detailed digital record, often using a spreadsheet or specialized pattern-making software. This digital record includes a description of the change, the reason for the change, and measurements before and after the adjustment. This method creates a clear history of modifications, making it easier to reproduce the pattern or make future adjustments. For example, if I adjust the shoulder width by 0.5 inches, I document the initial width, the new width, and the reason (e.g., better fit for a wider shoulder). Visual aids, like photographs, can be beneficial in capturing complex adjustments.

Q 19. How do you incorporate design details into a pattern?

Incorporating design details into a pattern requires a deep understanding of both design and construction. Design details are integrated into the pattern drafting process, not added as an afterthought. For example, adding darts for shaping, pleats for volume, or princess seams for a fitted silhouette are all accomplished by manipulating the pattern pieces. The specific techniques depend on the detail—a sleeve ruffle might require adding a separate pattern piece, while a curved hemline involves adjusting the bottom edge of the pattern. It’s crucial to consider the interaction between different design elements and how they influence the garment’s overall fit and drape. Creating a toile (a test garment) is a critical step in this process, allowing me to assess the effects of these design details before proceeding to final production.

Q 20. What are some common mistakes to avoid in pattern making?

Several common mistakes can hinder the pattern-making process. One significant error is neglecting to take accurate measurements. Incorrect measurements lead to ill-fitting garments. Another frequent mistake is failing to account for ease (extra fabric for comfort and movement). Insufficient ease results in tight-fitting clothes, while excessive ease can create a sloppy look. Furthermore, improper grading (scaling patterns to different sizes) can lead to inconsistencies and sizing issues. Ignoring grainlines, which are essential for fabric drape and stability, is another common mistake that impacts the garment’s appearance and functionality. Finally, neglecting to test patterns through toiling (making a sample garment) before full production can result in costly errors and time-consuming revisions.

Q 21. Describe your experience with creating patterns for different garment styles (e.g., dresses, pants, jackets).

I have extensive experience creating patterns for diverse garment styles, including dresses, pants, jackets, and more. My experience spans various levels of complexity, from simple A-line dresses to intricate tailored jackets with structured shoulders and complex lining. For dresses, I’m proficient in designing various necklines, sleeves, and skirt styles. For pants, I’m adept at creating different fits, from relaxed to slim, accommodating various waistbands and pockets. With jackets, I understand the nuances of constructing different collar types, lapels, and closures. I’m familiar with pattern drafting methods like the sloper (basic bodice block) and the use of pattern-making software for efficient and precise pattern creation. My experience encompasses both menswear and womenswear, considering the specific body shapes and stylistic differences between genders.

Q 22. Explain your understanding of ease and fit in pattern making.

Ease and fit are crucial concepts in pattern making, determining how a garment will drape and feel on the body. Ease refers to the extra fabric added to a garment’s basic measurements to allow for comfort and movement. It’s like adding extra space to a tailored suit so you can comfortably sit and move your arms. Different areas need different amounts of ease – for instance, a sleeve needs more ease than a fitted bodice. Fit, on the other hand, describes how closely the garment conforms to the body’s shape. A snug fit has minimal ease, while a loose fit has substantial ease. Understanding the interplay between ease and fit is key to creating well-fitting garments. For example, a dress designed for a relaxed fit might have 2 inches of ease across the bust, whereas a tailored shirt might only have ½ inch.

The amount of ease required depends on the garment style, fabric type, and personal preference. A stretchy knit fabric would require less ease than a crisp cotton. A design specifying a ‘close-fitting’ style will have less ease than a ‘loose-fitting’ one. Mastering ease and fit involves careful consideration of body measurements, design aesthetics, and fabric characteristics.

Q 23. How do you work collaboratively with other team members in a pattern-making environment?

Collaboration is paramount in pattern making. I thrive in team environments. My approach involves open communication, active listening, and a willingness to share my expertise while learning from others. I’ve worked in teams where we use a combination of methods. We might use shared digital pattern design platforms, enabling real-time collaboration and feedback on designs. During the design process, we would frequently hold design reviews where we would discuss different design options and feedback on the design would be given by the team to the lead designer, and changes were made accordingly. For example, I worked with a team on a complex bridal gown. The designer created the initial sketch, I developed the base pattern, the seamstress provided feedback on sewability, and the drafter ensured grading to various sizes. Each member’s input was critical to the final product’s success. Clear communication and respect for diverse perspectives are key to effective teamwork.

Q 24. How do you stay current with industry trends and technology in pattern making?

Staying current in pattern making requires continuous learning. I regularly attend industry conferences and workshops, subscribe to professional publications such as ‘Threads’ magazine and online resources, and actively engage in online communities dedicated to pattern making. I also explore new technologies like CAD (Computer-Aided Design) software. CAD software allows for faster pattern creation, precise grading, and efficient collaboration. Software like Gerber Accumark or Optitex is widely used in the industry, offering advanced functionalities like 3D draping and pattern simulation. Continuous exploration of these advancements is crucial for maintaining a competitive edge and improving efficiency and accuracy in my work. I believe in embracing new technologies to stay at the forefront of the industry.

Q 25. Describe a time you had to solve a complex pattern-making problem. What was your solution?

I once faced a challenging problem when creating a pattern for a complex asymmetrical draped bodice. The design involved multiple layers of fabric with irregular folds and curves. The initial pattern resulted in uneven draping and poor fit. My solution was a multi-step process. First, I created a muslin prototype to test the design’s drape. This allowed me to observe the fabric’s behavior and make necessary adjustments to the pattern pieces. Then, I utilized draping techniques on a dress form to refine the shape and create the desired asymmetry. Finally, I digitized the refined muslin pattern, allowing me to accurately grade the pattern for different sizes. This iterative process, combining traditional draping with digital pattern making, ensured the final pattern produced a well-fitting and aesthetically pleasing garment. Learning from the initial setback and combining different methods proved instrumental in solving this complex challenge.

Q 26. What are the key considerations for creating patterns for different sizes?

Creating patterns for different sizes requires a deep understanding of body proportions and sizing standards. Key considerations include:

- Grading: This involves systematically increasing or decreasing the pattern pieces’ dimensions to accommodate different body sizes. This process requires precise calculations and an understanding of how body measurements change across size ranges. Incorrect grading can result in ill-fitting garments.

- Body measurements: Accurate body measurements are the foundation of pattern grading. Different size charts are used depending on the target market and brand specifications.

- Design adjustments: Some design elements might require adjustments as sizes change. For example, a neckline might need to be altered to remain proportionate across size ranges.

- Ease adjustments: Ease is important across different sizes and often requires adjustments to maintain consistent fit and comfort across the size range.

Q 27. How do you ensure the sustainability of your pattern making process?

Sustainability in pattern making focuses on minimizing waste and optimizing resource utilization. I prioritize digital pattern making as much as possible, reducing the need for multiple paper prototypes. I utilize efficient cutting layouts to maximize fabric yield and minimize waste. The selection of sustainable fabrics is also crucial, including those made from recycled materials or produced with eco-friendly methods. Furthermore, I focus on creating patterns that are versatile, easily adaptable to different sizes and styles, thereby reducing the need to create numerous patterns for similar garments. Implementing these practices minimizes environmental impact while maximizing resource efficiency.

Q 28. Explain your understanding of different types of pattern notches and markings.

Pattern notches and markings are essential for accurate garment construction. Notches indicate matching points on different pattern pieces, ensuring proper alignment during sewing. They are usually small, triangular cuts in the pattern piece. Markings, on the other hand, provide further information, such as:

- Placement markings: Indicate locations for pockets, buttons, buttonholes, darts, or other design details.

- Grainlines: Indicate the direction of the fabric’s warp and weft threads, crucial for ensuring proper drape and garment stability.

- Seam allowances: Markings sometimes include seam allowances for easy reference.

- Center front/back markings: Identify the center of the pattern piece for symmetry and accuracy.

Key Topics to Learn for Pattern Creation Interview

- Fundamental Pattern Types: Understanding and differentiating various pattern types (e.g., repeating, generative, fractal) and their respective applications.

- Algorithmic Thinking: Applying logical reasoning and problem-solving skills to design efficient and scalable pattern generation algorithms.

- Data Structures & Algorithms: Selecting appropriate data structures (e.g., arrays, linked lists, trees) and algorithms (e.g., recursion, iteration) for optimal pattern creation.

- Pattern Implementation: Practical experience implementing patterns using various programming languages (e.g., Python, JavaScript, C++). Focus on code efficiency and readability.

- Optimization Techniques: Identifying and implementing strategies to improve the performance and resource utilization of pattern generation processes.

- Testing and Debugging: Developing robust testing methodologies to ensure the accuracy and reliability of generated patterns and identifying and resolving errors efficiently.

- Design Principles: Applying design principles like modularity, reusability, and maintainability to create scalable and adaptable pattern solutions.

- Pattern Libraries & Frameworks: Familiarity with existing pattern libraries and frameworks, and understanding their strengths and limitations.

- Case Studies & Examples: Analyzing real-world applications of pattern creation and understanding how different patterns are used to solve specific problems.

Next Steps

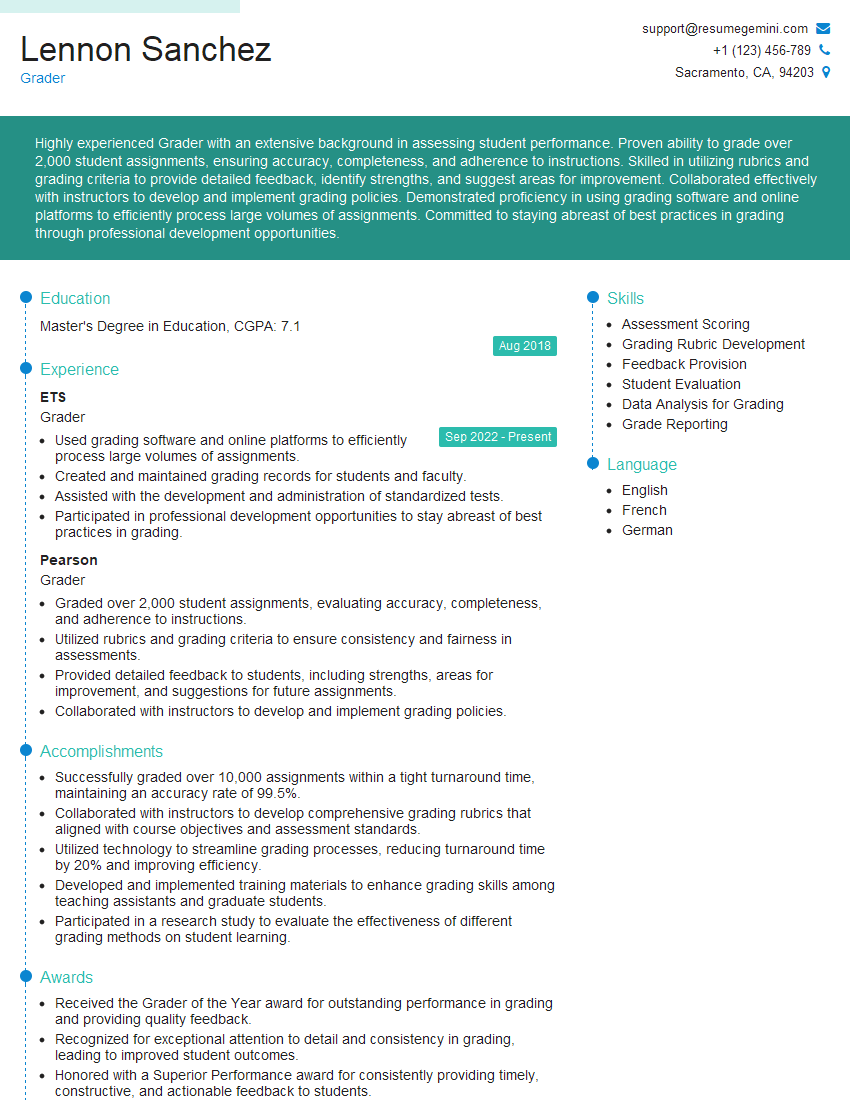

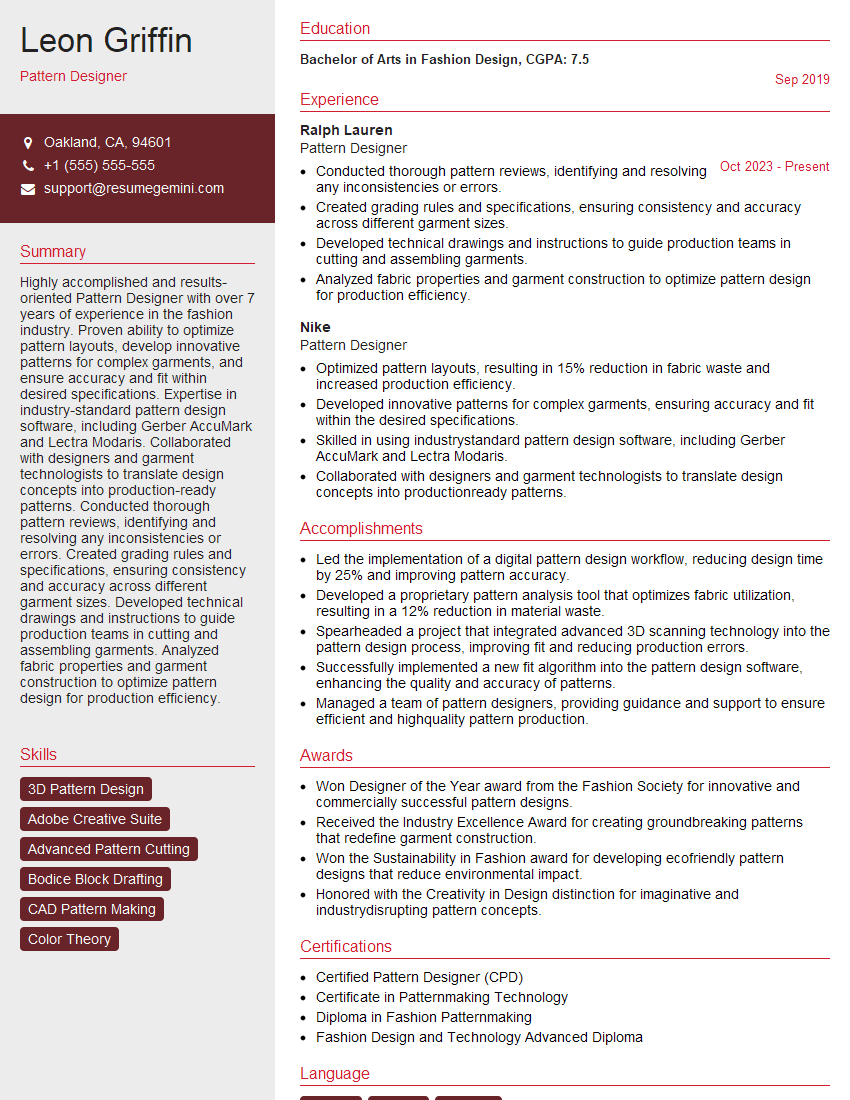

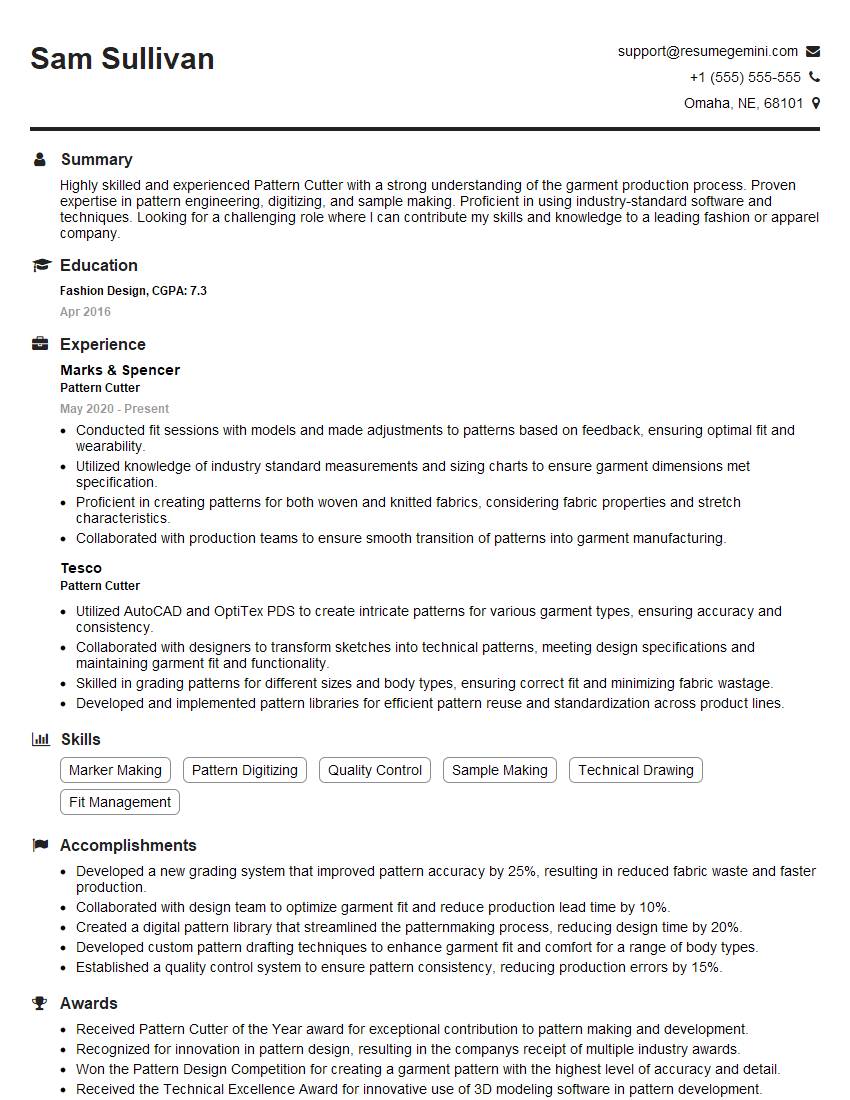

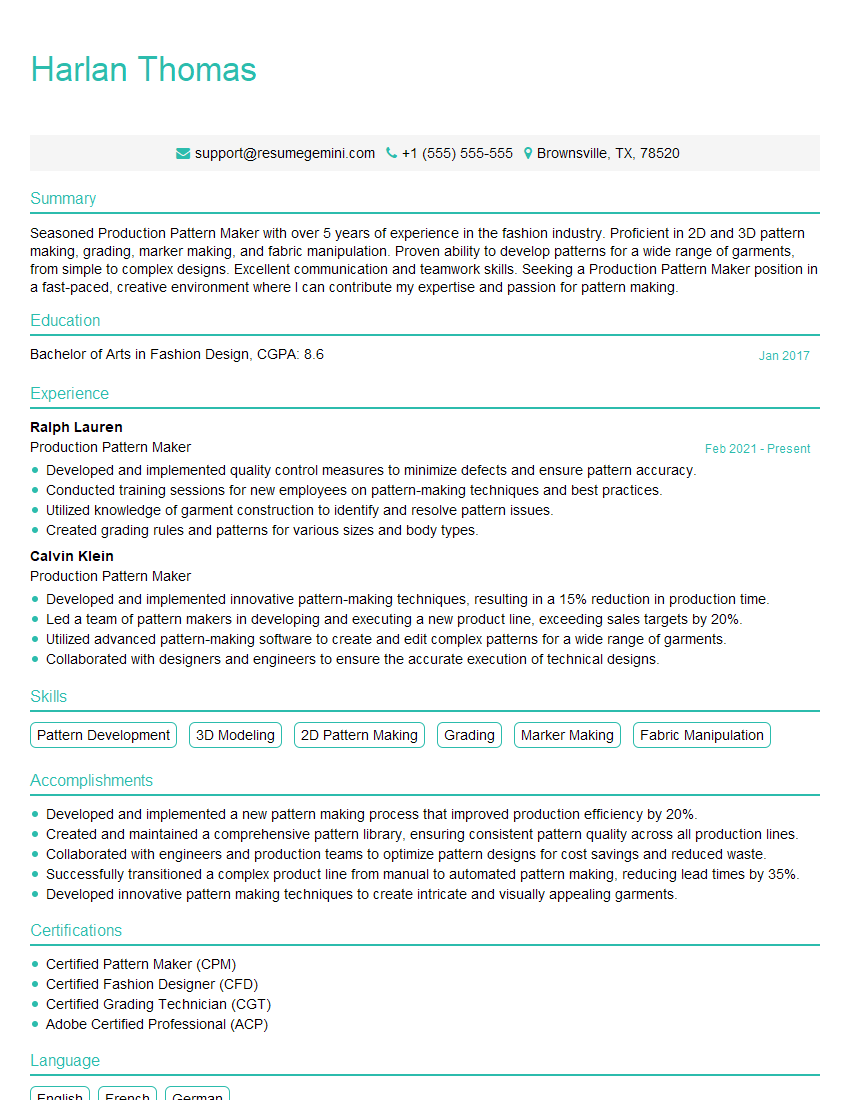

Mastering pattern creation is a highly valuable skill, opening doors to exciting opportunities in diverse fields like software development, game design, and data visualization. A strong understanding of pattern generation significantly enhances your problem-solving abilities and allows you to create elegant and efficient solutions. To maximize your job prospects, invest time in crafting a compelling and ATS-friendly resume that showcases your skills and experience. ResumeGemini is a trusted resource that can help you build a professional resume that highlights your abilities effectively. Examples of resumes tailored to pattern creation are available to guide your efforts.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good