Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Pattern Design and Creation interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Pattern Design and Creation Interview

Q 1. Explain the difference between a sloper and a block pattern.

Both slopers and blocks are foundational pattern pieces, but they serve different purposes. Think of a sloper as a blank canvas and a block as a more refined, style-specific drawing.

A sloper is a basic, foundational pattern representing the body’s shape. It’s a close-fitting, two-dimensional representation of a specific size and body type, typically created from a set of body measurements. It’s incredibly versatile as a starting point for numerous garment designs. It’s like a tailor’s basic pattern, adjusted to fit a specific individual.

A block, on the other hand, is a more developed pattern that incorporates basic design elements like ease (extra fabric for comfort and movement), seam allowances, and sometimes even basic neckline or sleeve shapes. While still fundamental, it’s geared toward a specific garment type (e.g., a bodice block or a sleeve block) and style. A block is more advanced and may account for some style elements.

Essentially, a sloper is the simplest form; you add design elements to create a block. The block is the template for various garment styles.

Q 2. Describe your experience with various pattern-making software (e.g., Gerber, Lectra).

My experience encompasses a wide range of pattern-making software. I’ve worked extensively with both Gerber and Lectra systems, and I’m proficient in using their various modules for pattern design, grading, and marker making. Gerber’s AccuMark is known for its intuitive interface and powerful grading capabilities, particularly useful for managing complex pattern adjustments and large size ranges. I’ve leveraged its features to efficiently create and grade patterns for diverse garments, ranging from simple tops to intricate tailored pieces. Lectra’s Modaris, while having a slightly steeper learning curve, offers superior capabilities in 3D visualization and simulation. This has been invaluable in predicting and resolving potential fit issues before committing to actual sample making, leading to significant time and cost savings.

My expertise includes using these platforms for both 2D and 3D pattern design. I have experience in creating and modifying patterns across a multitude of styles and sizes. I also have a strong understanding of the software’s integration with cutting and production workflows for efficient manufacturing.

Q 3. How do you handle pattern adjustments for different body types and sizes?

Handling pattern adjustments for different body types and sizes is crucial for achieving a proper fit. My approach is multifaceted:

- Understanding Body Types: I start by identifying the key differences between body types and how they affect garment fit (e.g., high bust, full bust, swayback, etc.).

- Base Sloper/Block: I use a well-fitted sloper or block as the foundation. This minimizes adjustments from scratch.

- Grading: Software like Gerber and Lectra streamline grading (size scaling). I carefully review the graded patterns to ensure proportions remain accurate and balanced.

- Individual Adjustments: For significant variations, I utilize additional adjustment techniques, including:

- Pivot points: Moving key points to shape the pattern to fit specific body features

- Ease adjustments: Adjusting ease at strategic points for comfort and fit.

- Dart manipulation: Moving and reshaping darts to accommodate different body proportions.

- Muslin Fitting: I always create and fit muslin prototypes to identify and correct any fit issues before cutting expensive fabrics. This iterative process ensures an accurate final fit for every body type.

For example, adjusting a pattern for a full bust might involve adding width across the bust area and adjusting the darts for a smoother fit. My experience allows me to make these adjustments effectively and efficiently to meet the needs of all body types.

Q 4. What methods do you use to ensure accurate grading of patterns?

Accurate grading is paramount for consistency across sizes. My methods focus on both software-aided and manual techniques to ensure precision:

- Software Grading: I utilize the grading features in Gerber and Lectra to generate scaled patterns automatically. This is a fast and efficient method, but I always carefully review the graded pieces.

- Manual Grading Checks: I manually check key measurements and proportions on the graded patterns to ensure the scaling is accurate and consistent across sizes. This helps to prevent distortions that could occur during the automated grading process.

- Grading Rules: I establish clear grading rules based on industry standards and the specific garment type. This ensures consistent and predictable size progression across the pattern. For example, I might have specific grading rules for sleeve lengths or necklines.

- Test Garments: I always create test garments in various sizes to validate the graded patterns and ensure consistent fit across all sizes.

Using a combination of automated grading and manual verification is crucial. Simply relying on software is risky; manual checking ensures consistent sizing.

Q 5. Explain your process for creating a pattern from a sketch or design.

Creating a pattern from a sketch starts with meticulous planning and a deep understanding of garment construction:

- Sketch Analysis: I thoroughly analyze the design sketch, noting key features like neckline, sleeve style, dart placement, and overall silhouette.

- Measurements & Calculations: Based on the sketch and target size, I calculate key measurements such as garment length, width, and circumference.

- Base Pattern Selection: I choose an appropriate base sloper or block as a foundation, tailoring its selection to the garment style. A simple blouse would start with a bodice block; a coat requires a more complex base.

- Drafting & Manipulation: Using my chosen base pattern, I modify the pattern pieces to reflect the design sketch. I use both manual techniques and CAD software to draft and manipulate the pattern.

- Refinement & Iteration: Through refinement and iteration, including adjusting ease, shaping curves and adding design details, I develop the pattern accurately reflecting the original sketch.

- Test Garment Creation: Before finalizing the pattern, I create a muslin test garment to check for fit issues and make necessary adjustments.

For instance, if the sketch depicts a fitted bodice with a princess seam, my drafting would involve strategically placing the princess seams and shaping the pattern pieces to achieve the desired fit. Each step is crucial for accuracy and achieving the intended look.

Q 6. How do you address fit issues during the pattern making process?

Addressing fit issues is an iterative process that often requires a combination of techniques:

- Muslin Fitting: Muslin fitting is the cornerstone of addressing fit problems. I carefully pin and mark areas needing adjustment directly on the muslin.

- Pattern Adjustments: Based on muslin fitting, I make corresponding adjustments to the pattern pieces. This might involve adding or removing fabric, shifting seams, or altering the shape of the pattern pieces.

- Grading Review: After making adjustments, I review the grading to ensure that the corrections are proportionally applied across all sizes.

- Repeat Fitting: Often, multiple fittings and adjustments are necessary to achieve the optimal fit. This iterative process is crucial to perfecting the pattern.

- Detailed Notes: I meticulously document all pattern adjustments for future reference, making future iterations easier and more efficient.

A common issue might be excess fullness in the bodice. A muslin fitting will reveal this, and I would adjust the pattern by reducing width in the appropriate area, often using darts to redistribute fabric.

Q 7. What are some common challenges you face in pattern making, and how do you overcome them?

Pattern making, while rewarding, presents several challenges:

- Achieving a perfect fit: Every body is unique; achieving consistent fit across varied body types is a continuous challenge. Muslin fitting and careful pattern adjustments are essential.

- Balancing aesthetics and function: Designing a garment that looks great and fits well simultaneously requires experience and artistic skill.

- Time constraints: Tight deadlines often require efficient time management and effective workflow strategies.

- Managing complex patterns: Working with intricate patterns for garments with multiple pieces requires careful organization and attention to detail.

- Software issues: Technical difficulties with pattern-making software can disrupt the workflow. Regular training and proficiency in troubleshooting are vital.

I overcome these challenges using a combination of meticulous planning, efficient workflow management, robust software skills, and a dedicated approach to muslin fitting. I prioritize continuous learning and remain updated on industry best practices.

Q 8. Describe your experience with different fabric types and their impact on pattern design.

Understanding fabric drape, weight, and texture is crucial for successful pattern design. Different fabrics behave differently; a lightweight silk will drape very differently than a heavy wool twill. This impacts how a pattern needs to be constructed to achieve the desired silhouette.

- Lightweight fabrics like silk chiffon or georgette require patterns with minimal seam allowances to avoid bulk and maintain fluidity. They might also require more delicate pattern pieces to prevent distortion during construction.

- Medium-weight fabrics such as cotton poplin or linen are versatile and allow for a wider range of pattern designs. They can handle more complex details without becoming too bulky.

- Heavyweight fabrics such as wool coatings or denim require more robust patterns with generous seam allowances to accommodate the added bulk. These patterns often feature larger, simpler shapes to avoid excessive stress on the seams.

For example, a flowing A-line dress designed for silk chiffon would need very different pattern pieces than one made for a heavy tweed. The silk version would likely have fewer seams and a more delicate finish, whereas the tweed version might incorporate reinforced seams and possibly interfacing to maintain structure.

Q 9. How do you incorporate ease and seam allowances into your patterns?

Ease and seam allowances are fundamental to creating well-fitting and well-constructed garments. Ease is the extra fabric added to a garment pattern to allow for comfort and movement, while seam allowance is the extra fabric added to each piece to allow for the stitching process itself.

Ease is incorporated by adding extra measurements to the body measurements. The amount of ease varies depending on the garment style, fabric type, and desired fit. A snug-fitting garment might have minimal ease, while a loose, flowing garment would have a significant amount. I often use a combination of ease charts and personal fitting experience to determine appropriate ease values for different areas (bust, waist, hip).

Seam allowances are typically a standard measurement (e.g., 5/8 inch or 1.5cm), but can be adjusted based on the fabric’s weight and the type of seam being constructed. Heavier fabrics might require a slightly larger seam allowance for durability. Seam allowances are added directly to the pattern pieces before cutting. I always clearly indicate the seam allowance on the pattern pieces to avoid confusion during construction.

Failure to account for both ease and seam allowance will result in either a garment that’s too tight and uncomfortable or one that is ill-fitting and loose.

Q 10. Explain your understanding of grainlines and their importance in pattern making.

Grainlines refer to the direction of the warp and weft threads in a woven fabric. Understanding grainlines is paramount for proper garment construction and ensuring that the garment hangs and fits correctly. The warp yarns run lengthwise, while the weft yarns run across the width of the fabric.

- Straight grain runs parallel to the selvage (the finished edges of the fabric). Cutting pattern pieces on the straight grain ensures the most stable and least stretchy construction.

- Cross grain runs perpendicular to the selvage. It is often used for smaller pattern pieces where stretch is less critical.

- Bias grain runs diagonally across the fabric. It is highly stretchable and can be used to create soft curves and shaping but requires careful handling to maintain stability.

Ignoring grainlines can lead to a distorted garment that doesn’t hang properly, stretches unevenly, or appears disproportionate. For example, cutting a skirt panel on the bias instead of the straight grain will create a significantly different silhouette due to the increased stretch.

Q 11. Describe your experience with muslin fitting and pattern adjustments.

Muslin fitting is an essential step in pattern making. It involves creating a test garment (muslin) from the pattern before cutting into the final fabric. This allows for adjustments to be made to ensure a perfect fit before committing to the expensive or precious final fabric.

The process typically involves:

- Creating a muslin using inexpensive fabric.

- Trying on the muslin and marking areas needing adjustment (tightness, looseness, length, etc.).

- Removing the muslin and making necessary pattern alterations. These are usually marked directly onto the muslin and then transferred back to the original pattern.

- Repeating steps 1-3 until a satisfactory fit is achieved.

Pattern adjustments can include:

- Adding or removing fullness at the bust, waist, or hips.

- Adjusting length at the hem, sleeves, or neckline.

- Altering shoulder seams or armholes.

- Adjusting darts for better shaping.

I always meticulously document the adjustments I make to my patterns so I can easily replicate them for future projects and/or for making variations for different sizes or body types.

Q 12. How do you work with a design team to translate design concepts into patterns?

Collaborating effectively with a design team is vital for translating design concepts into wearable garments. This process begins with a clear understanding of the designer’s vision. This includes style inspiration, technical specifications, target market, fabric selection and overall aesthetic. My role as a pattern maker is to translate this vision into a functional and well-fitting pattern.

I work closely with designers and other team members during the design and sampling process using a combination of digital tools like CAD software and physical prototyping.

Typical collaboration steps include:

- Initial Design Review: Reviewing sketches, mood boards, and fabric swatches to discuss the technical feasibility of the design.

- Pattern Development: Creating a base pattern, often using slopers or body measurements.

- Sampling: Making samples (often in muslin), fitting the samples, and making any necessary adjustments.

- Pattern Grading: Adapting the pattern to various sizes.

- Technical Specifications: Creating detailed technical specifications for production, including seam allowances, finishing techniques, and fabric requirements.

Open communication and regular feedback are essential throughout this collaborative process. I believe in a constructive environment that values shared knowledge and creative problem-solving to achieve the most exceptional outcome.

Q 13. What are your preferred methods for documenting pattern adjustments and changes?

Accurate documentation is paramount in pattern making. It ensures consistency, reproducibility, and ease of communication across teams and projects.

My preferred documentation methods include:

- Detailed Pattern Sketches: I annotate my patterns with all measurements, markings, and changes. I use color-coded notations to differentiate different types of adjustments.

- Digital Pattern Software: I use digital pattern design software (e.g., Optitex, Gerber) to create, edit and store patterns and changes. The software’s version control and annotation features create a clear audit trail of changes.

- Spreadsheets and Databases: I use spreadsheets or databases to track measurements, grading information, and other critical data. This is particularly helpful for managing multiple sizes and styles simultaneously.

- Photographic Documentation: I take detailed photos of muslin fittings, highlighting areas of fit problems and corrections.

Using a combination of these methods ensures a comprehensive record of every adjustment, modification, and revision, making it easier to reproduce the pattern or make further adjustments.

Q 14. Describe your experience with industrial sewing machines and tools.

Extensive experience with industrial sewing machines and tools is essential for efficient and high-quality pattern making. I am proficient in operating a variety of machines, including but not limited to:

- Industrial Straight Stitch Machines: For constructing seams, hemming, and other basic sewing operations. I understand the different stitch types and their applications, such as lockstitch, chainstitch, etc.

- Overlock/Serger Machines: For finishing seam edges and preventing fraying.

- Coverstitch Machines: For creating professional-looking hems and finishes.

- Buttonhole Machines: For creating consistently sized buttonholes.

Beyond machines, I am also adept at using a range of tools: industrial shears, pattern weights, marking tools (tracing wheels, pencils, tailor’s chalk), seam rippers, pressing equipment, measuring tapes, rulers. I understand the importance of proper machine maintenance and safety procedures, and I am confident in troubleshooting minor mechanical issues.

Proficiency with industrial machinery and tools allows me to construct prototypes and sample garments quickly and efficiently, enabling faster turnaround times and efficient pattern development.

Q 15. How do you manage multiple projects simultaneously with differing deadlines?

Managing multiple pattern design projects with varying deadlines requires a strategic approach. I employ a project management methodology that combines meticulous planning with flexible adaptation. Think of it like conducting an orchestra – each instrument (project) has its own part and tempo, but the conductor (me) ensures harmony and timely completion.

- Prioritization: I begin by prioritizing projects based on urgency and impact. This involves careful analysis of deadlines and client needs, using tools like Gantt charts or Kanban boards to visualize timelines and dependencies.

- Time Blocking: I allocate specific time blocks for each project, ensuring focused work sessions. This prevents context switching and maintains productivity. For example, I might dedicate Monday mornings to sketching for a bridal gown collection, and Tuesday afternoons to finalizing technical drawings for a menswear line.

- Communication: Clear and consistent communication with clients is crucial. Regular updates, including potential roadblocks and solutions, keep everyone informed and allows for timely adjustments to prevent delays.

- Flexibility: Unexpected issues arise – that’s the nature of creative projects. I build in buffer time and remain adaptable, adjusting my schedule as needed while maintaining transparency with clients.

For instance, I once managed a children’s clothing line alongside a high-end evening wear collection. By prioritizing the urgent deadlines for the evening wear samples and strategically scheduling the children’s line’s less time-sensitive tasks, I successfully delivered both collections on time and to client satisfaction.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with 3D pattern design software.

I’m proficient in several 3D pattern design software packages, including CLO3D and Marvelous Designer. My experience spans from basic pattern creation to advanced techniques like 3D draping, grading, and simulation of fabric behavior. These programs are invaluable for visualizing the final garment before production, allowing for early detection and correction of potential issues.

In CLO3D, for example, I’m adept at utilizing the advanced avatar customization features to create realistic 3D models tailored to specific body types. This ensures a precise fit and allows me to test different design variations virtually. Marvelous Designer, on the other hand, excels at simulating the drape and fall of fabrics, providing a realistic preview of how the garment will hang on a body.

Beyond the technical aspects, I understand the workflow optimization these programs offer. I can efficiently utilize features such as pattern grading tools, automating tedious tasks and minimizing errors, which ultimately reduces production time and costs.

Q 17. What is your experience with digital pattern making techniques?

My experience with digital pattern making techniques is extensive. I’m comfortable working with both 2D and 3D software, leveraging the strengths of each to optimize the design process. Digital pattern making offers significant advantages over traditional methods in terms of efficiency, accuracy, and scalability.

- Software Proficiency: I use industry-standard software like Adobe Illustrator and Photoshop for creating digital prints and manipulating pattern pieces. I’m also proficient in using specialized pattern making software like Optitex and Lectra.

- Workflow Optimization: I’ve developed streamlined workflows that integrate digital techniques seamlessly into the entire design process, from initial sketching to final production. This includes using digital grading and marker making software to optimize fabric utilization and reduce waste.

- Innovation: I actively explore new digital tools and techniques to enhance creativity and efficiency. For instance, I’ve experimented with using 3D scanning to create custom avatars for better fit accuracy and exploring AI-powered design tools for generating pattern variations.

A recent project involved designing a complex, asymmetrical dress. Using digital pattern making, I quickly created and iterated on several variations, testing different seam lines and draping effects before settling on the final design. This significantly reduced the time and material costs compared to traditional methods.

Q 18. How do you ensure the accuracy and consistency of your patterns?

Ensuring accuracy and consistency in patterns is paramount. My approach is multifaceted, combining rigorous quality control measures with a keen eye for detail. Think of it like building a house – a strong foundation ensures a stable structure.

- Precise Measurements: I always start with accurate measurements and consistently use the same measurement system throughout the process. This includes using precision tools and double-checking all dimensions.

- Pattern Checks: I meticulously check each pattern piece for symmetry, proportions, and grainlines before proceeding to the next step. This often involves creating test garments to identify and correct any errors early on.

- Digital Verification: For digital patterns, I utilize software’s built-in tools for checking for inconsistencies and errors. This helps catch subtle mistakes that might be missed during manual checking.

- Grading Standards: When grading patterns for different sizes, I adhere to industry standards and use specialized software to ensure accurate scaling and consistent proportions across sizes.

For example, when creating patterns for a structured jacket, I’d use precise measurements for the shoulder slope, armhole depth, and sleeve cap height, and then meticulously check the symmetry and balance of the front and back panels. Any inconsistencies are addressed before creating the final pattern.

Q 19. How familiar are you with different types of pattern drafting methods?

My familiarity with various pattern drafting methods is extensive. I’m proficient in both flat pattern drafting and draping techniques, understanding their strengths and limitations in different contexts. Think of it as having multiple tools in your toolbox – each serves a specific purpose.

- Flat Pattern Drafting: I’m well-versed in various flat pattern drafting methods, including the basic sloper method, French curve method, and other advanced techniques. This involves creating patterns from two-dimensional measurements and calculations.

- Draping: I’m experienced in draping techniques, both on a dress form and directly on a model. This is particularly useful for creating more complex, three-dimensional shapes and for understanding how fabric drapes and behaves.

- Combination Methods: Often, I combine flat pattern drafting and draping to achieve optimal results. For example, I might draft a basic bodice block using the flat pattern method and then drape the sleeves or neckline to refine the fit and drape.

- Understanding Fabric Behavior: The chosen method greatly depends on the type of fabric. For example, stiff fabrics lend themselves well to flat pattern drafting, while drapey fabrics often require draping to achieve the desired shape.

For a tailored shirt, I would typically use flat pattern drafting for the body, creating a precise base. However, for a flowing evening gown, draping on a mannequin would be more suitable to achieve the desired fluidity and drape of the fabric.

Q 20. How do you handle revisions and feedback on patterns?

Handling revisions and feedback is an integral part of the design process. I embrace feedback as an opportunity for improvement and refinement. Open communication and a collaborative approach are key.

- Clear Communication: I ensure a clear understanding of the revision requests, asking clarifying questions if needed to avoid misunderstandings. This might involve visual aids such as annotated sketches or marked-up pattern pieces.

- Organized Tracking: I maintain a meticulous record of all revisions, tracking changes and feedback in a centralized system. This could be a digital document or a physical file, but maintaining a consistent and organised system is key.

- Iterative Process: I approach revisions iteratively, making adjustments based on feedback, then presenting the updated pattern for further review. This cyclical process ensures that the final product meets the client’s expectations.

- Constructive Dialogue: I foster open communication with clients, discussing the rationale behind design choices and incorporating their feedback effectively.

In a recent project, a client requested adjustments to the sleeve length and shoulder width of a coat. I carefully noted their feedback, made the necessary changes to the pattern, and then provided detailed illustrations showing the alterations. This iterative process ensured that the final design perfectly matched their vision.

Q 21. Explain your understanding of different types of seams and their application.

Understanding different seam types and their applications is crucial for creating well-constructed garments. Each seam type offers different aesthetic and functional qualities.

- Seam Allowance: First, it’s essential to understand seam allowance (the extra fabric left outside the stitching line). This is crucial for accurate construction and consistent garment dimensions. Standard allowances vary depending on fabric and garment type.

- French Seam: This seam is enclosed, creating a clean, high-end finish, particularly suited for fine fabrics. The raw edges are entirely concealed.

- Flat Felled Seam: Known for its durability, this seam is commonly used in workwear or outerwear. One seam allowance is folded over and stitched down, creating a strong, flat finish.

- Hong Kong Seam: This high-end finish involves binding the seam allowance with bias tape, creating a luxurious and clean look. It’s ideal for luxurious garments.

- Overlocked Seam: This seam is finished with an overlocker machine, creating a neat and secure edge which prevents fraying. This is efficient and suitable for mass production.

- Seam Selection based on Fabric and Style: The choice of seam is influenced by the fabric weight, drape, and the overall aesthetic of the garment. Delicate fabrics require a clean finish like a French seam, while durable fabrics may be suitable for a felled seam.

For a delicate silk blouse, I might choose a French seam for its clean finish. However, for a pair of sturdy jeans, a durable flat-felled seam would be more appropriate.

Q 22. How do you create patterns for different garment styles (e.g., dresses, pants, jackets)?

Creating patterns for different garments hinges on understanding the garment’s unique construction and desired silhouette. While the fundamental principles remain the same – taking accurate measurements, drafting basic blocks, and adding design details – the application varies significantly.

Dresses: Pattern creation for dresses often involves manipulating a basic bodice and skirt block. Consideration is given to neckline styles (e.g., V-neck, sweetheart), sleeve types (e.g., sleeveless, short sleeves, long sleeves), waistlines (e.g., empire waist, natural waist), and skirt shapes (e.g., A-line, flared, pencil). I might start with a sloper (a basic bodice and skirt pattern) and then adjust the pattern pieces to achieve the desired design.

Pants: Pants patterns demand precision in the crotch curve and leg shaping. Different pant styles – from skinny jeans to wide-leg trousers – require adjustments to the basic pant block. Factors like rise (high-waisted, low-waisted), leg width, and inseam length all influence the final pattern pieces. I might use a combination of drafting and draping techniques to perfect the fit.

Jackets: Jacket patterns are complex, involving numerous pattern pieces and intricate construction details. The pattern needs to account for different collar styles (e.g., notched collar, shawl collar), closures (e.g., buttons, zipper), and lining. Creating a well-fitting jacket pattern requires careful consideration of shoulder shaping, armhole depth, and sleeve cap ease.

For each garment type, I always prioritize accurate measurements and meticulous fitting, creating multiple muslin toiles (test garments) to refine the fit before finalizing the pattern.

Q 23. What experience do you have with creating patterns for different sleeve styles?

My experience with sleeve patterns is extensive. I’m proficient in creating patterns for a wide array of sleeve styles, from simple set-in sleeves to more complex styles like raglan, dolman, kimono, and puff sleeves. Each sleeve type presents unique challenges. For instance:

Set-in sleeves require careful attention to the cap height and ease to ensure a smooth, comfortable fit into the armhole. I utilize techniques like easing and careful grading to achieve this.

Raglan sleeves are constructed differently, extending seamlessly into the neckline, which simplifies the construction but requires precise grading to maintain the intended shape.

Puff sleeves often involve gathering or shirring techniques, and the pattern needs to incorporate the appropriate allowance for these design features.

I use both traditional drafting and computer-aided design (CAD) software to create and modify these sleeve patterns. I have created many different sleeve variations by manipulating the basic sleeve block. I understand how changes to the sleeve cap, ease, and length affect the overall look and fit.

Q 24. Describe your experience with pattern manipulation techniques (e.g., dart manipulation, ease adjustments).

Pattern manipulation is a core skill for any pattern maker. I’m experienced in a variety of techniques including dart manipulation and ease adjustments, enabling me to transform basic blocks into unique garment designs.

Dart Manipulation: Darts are used to shape fabric and create curves. I can move, redistribute, or remove darts to achieve different silhouettes. For example, I might convert a bust dart into a shoulder dart for a more seamless look, or I might pivot a dart to create a more fitted bodice. The process often involves redrawing curves and carefully adjusting the seam allowances.

Ease Adjustments: Ease refers to the extra fabric added to a pattern to allow for comfort and movement. I can adjust the amount of ease in different areas of the garment (e.g., more ease in the chest, less ease at the waist) to fine-tune the fit. Understanding ease is critical for achieving a proper fit and drape.

These techniques are crucial for creating well-fitting garments that flatter the body. For example, I recently used dart manipulation to transform a simple sheath dress pattern into a more form-fitting, figure-hugging design. I strategically moved and reshaped the existing darts to create the desired curves.

Q 25. Explain your process for creating a pattern for a complex garment.

Creating a pattern for a complex garment, like a tailored coat or a structured gown, is a multi-step process that demands meticulous attention to detail. Here is my typical workflow:

Research and Design: I begin by thoroughly researching the garment’s design, considering details such as style, fit, construction, and fabrics.

Measurements and Block Creation: Accurate measurements are essential. I create a sloper or a base block appropriate to the garment type – and if needed, I adjust the block to fit the model or design specifications.

Drafting or Draping: I draft or drape the pattern pieces, adding design elements like collars, pockets, and other details. This process often involves several iterations to refine the design.

Muslin Toile: I make multiple muslin toiles to test the fit, making any necessary adjustments before cutting the final fabric.

Grading: Once the pattern fits perfectly, I grade the pattern to different sizes. This is essential for mass production.

Technical Drawings: I create technical drawings that are used for production. These drawings should accurately show the pattern pieces, including the seam allowances and markings for construction.

Throughout the process, I utilize both manual drafting techniques and CAD software, selecting the most appropriate methods based on the complexity of the design. For example, for a complex, intricately-shaped garment, I might start with draping on a dress form to establish the basic shape before transferring the draped form to paper to create the pattern pieces.

Q 26. How do you ensure your patterns are suitable for mass production?

To ensure patterns are suitable for mass production, several key considerations are vital:

Grading: The pattern must be accurately graded across a range of sizes. This involves systematically scaling the pattern pieces to accommodate different body measurements, ensuring consistency and a consistent fit across all sizes.

Efficiency: The pattern should be designed for efficient cutting and construction. This means minimizing fabric waste and simplifying the construction process to reduce labor costs.

Clear Markings: Clear and consistent markings on the pattern pieces are essential for accurate cutting and construction, preventing errors during mass production. These markings should be consistent and easily understood by the manufacturing team.

Production-Ready Format: The final pattern should be presented in a format readily used by the production team. This often involves the use of specialized software and formats that are compatible with the factory’s cutting equipment.

I meticulously review all my patterns for potential challenges in manufacturing and work closely with production teams to fine-tune patterns and make them suitable for large-scale production. Efficiency is key for minimizing costs in the manufacturing process.

Q 27. Describe a time you had to troubleshoot a pattern-making problem. What was your approach?

I once encountered a significant challenge while creating a pattern for a structured blazer with a complex princess seam. The initial muslin toile revealed unwanted puckering at the princess seam and a poor fit around the bust. My approach to troubleshooting involved:

Analyze the Problem: I carefully examined the muslin, paying close attention to the areas where the puckering and poor fit were most pronounced. I took detailed measurements to identify inconsistencies.

Identify Potential Causes: I considered various factors that could contribute to the problem: inaccurate measurements, insufficient ease, incorrect grading, or a flawed design.

Test Solutions: Based on my analysis, I experimented with several solutions. I adjusted the dart placement, added or removed ease in specific areas, and regraded sections of the pattern. For each modification, I made a new toile to test the effect.

Iterative Process: The process was iterative; I continuously refined the pattern based on the results of each toile. This involved careful adjustments and meticulous attention to detail.

Through this process, I ultimately resolved the problem by slightly adjusting the curve of the princess seam and redistributing the ease around the bust. This highlight the importance of systematically troubleshooting, testing solutions, and iterating until the desired results are achieved.

Q 28. How do you stay updated on the latest trends and technologies in pattern design?

Staying updated in the dynamic world of pattern design requires a multifaceted approach. I utilize several strategies to remain current with trends and technologies:

Industry Publications and Websites: I regularly read industry publications and visit websites dedicated to fashion design and pattern making, such as online magazines and blogs.

Trade Shows and Conferences: Attending trade shows and conferences allows me to network with other professionals and see the latest innovations in software and techniques firsthand.

Continuing Education: I actively seek out professional development opportunities, including workshops, seminars, and online courses. This ensures I stay ahead of advancements in the field.

Software Updates: I regularly update my CAD software and familiarize myself with new features and functionality. This empowers me to work efficiently and explore new design possibilities.

These efforts are essential for adapting to evolving trends and using the most efficient and effective methods in my work.

Key Topics to Learn for Pattern Design and Creation Interview

- Drafting Techniques: Understanding various drafting methods (e.g., sloper creation, flat pattern making, draping) and their applications for different garment types and body shapes.

- Pattern Alterations & Grading: Mastering techniques for adjusting patterns to fit different sizes and body types, including grading for production.

- Software Proficiency: Demonstrating expertise in industry-standard CAD software (e.g., Optitex, Gerber) and their application in pattern design and creation.

- Fabric Selection & Manipulation: Understanding how fabric properties (drape, stretch, weight) influence pattern design and construction. Discuss practical approaches to handling different fabrics.

- Pattern Making for Specific Garments: Showcase your knowledge of creating patterns for various garments (e.g., blouses, trousers, dresses) with attention to detail and construction considerations.

- Understanding Construction Methods: Explain your understanding of different garment construction techniques and how pattern design impacts the final product’s fit and finish.

- Problem-Solving in Pattern Design: Describe your approach to troubleshooting pattern fitting issues, and highlight your ability to adapt and refine patterns based on fit tests.

- Sustainable Pattern Design: Demonstrate awareness of sustainable practices in pattern making, including minimizing fabric waste and considering eco-friendly materials.

- Design Principles and Aesthetics: Discuss how design principles (e.g., balance, proportion, emphasis) inform your pattern design choices and contribute to the overall aesthetic of a garment.

Next Steps

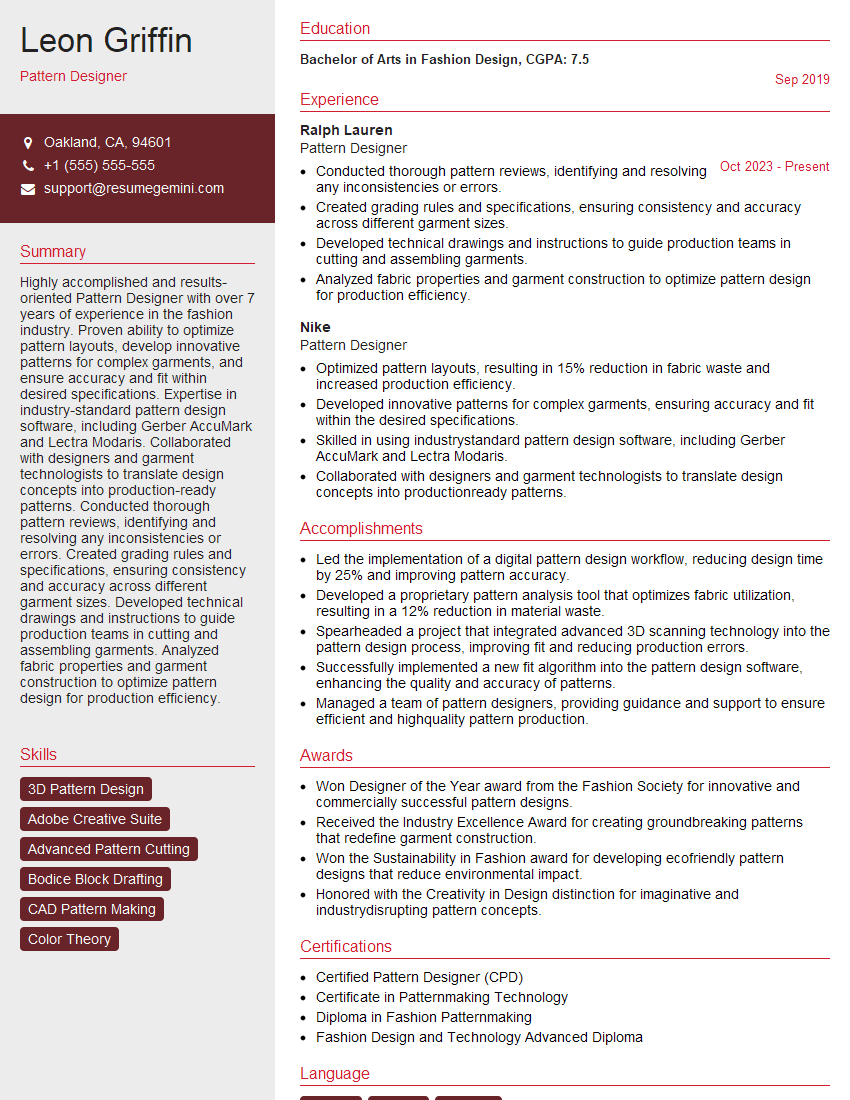

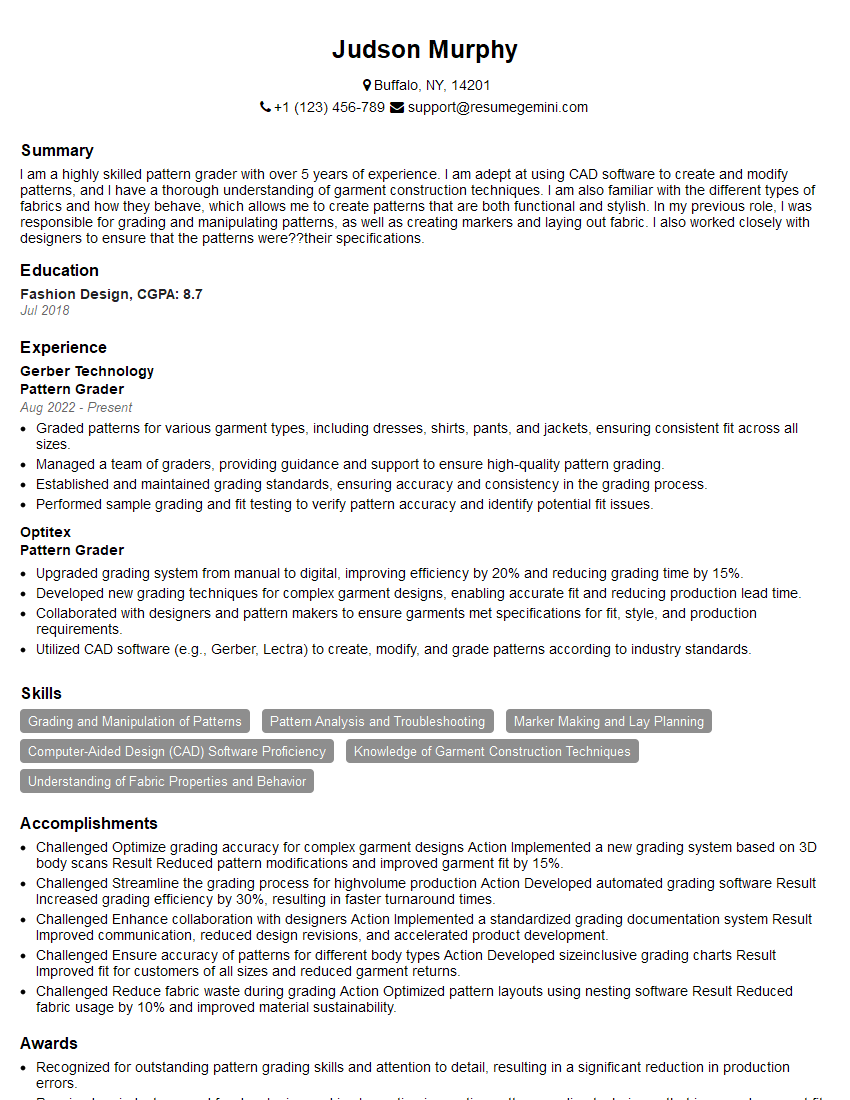

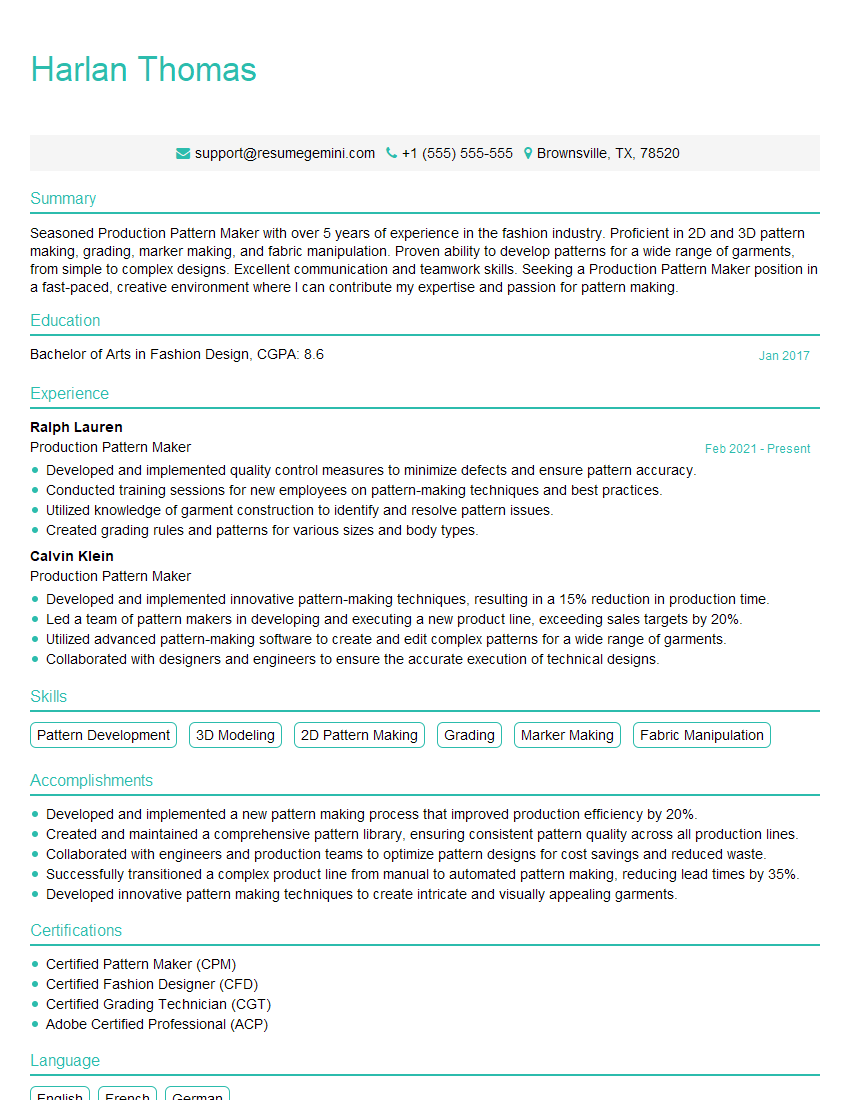

Mastering Pattern Design and Creation is crucial for a successful and rewarding career in the fashion industry, opening doors to diverse roles and exciting opportunities for growth. To maximize your job prospects, focus on building a strong, ATS-friendly resume that effectively highlights your skills and experience. ResumeGemini is a trusted resource to help you craft a professional and impactful resume. We provide examples of resumes tailored to Pattern Design and Creation to help guide you in showcasing your unique abilities. Let ResumeGemini help you make a lasting impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good