Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Perfect Binding Machine Operation interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Perfect Binding Machine Operation Interview

Q 1. Describe the perfect binding process step-by-step.

Perfect binding is a popular bookbinding method ideal for softcover books, magazines, and journals. It involves gluing the edges of folded and gathered pages together to create a spine, then applying a cover. Here’s a step-by-step breakdown:

- Gathering and Folding: Individual sheets of paper are printed, folded (typically using a folding machine), and gathered into sections (signatures).

- Sewing (Optional): Some perfect binding processes involve stitching the signatures together for added strength. This isn’t always necessary, especially for shorter books.

- Roughening: The spine edges of the gathered signatures are often roughened using a sanding machine to improve glue adhesion. Think of it like creating a textured surface for better grip.

- Glue Application: A precise amount of hot melt adhesive is applied to the spine edges using a glue roller within the perfect binding machine.

- Book Block Formation: The glued signatures are pressed together to form a cohesive block, ensuring the glue bonds effectively.

- Cover Attachment: The cover, previously prepared and scored (creased) to allow it to wrap around the book block, is wrapped around the spine and pressed to secure the final product. This is done while the adhesive is still slightly pliable.

- Trimming: A three-knife trimmer (discussed in another question) precisely cuts the book to achieve a neat and professional finish.

Q 2. What are the different types of adhesives used in perfect binding?

Several adhesives are used in perfect binding, each with its own properties and applications. The choice depends on factors like speed of setting, paper type, and budget. Common types include:

- Hot Melt Adhesive: This is the most common type, offering fast drying time and strong bonds. It’s applied hot and sets quickly, making it ideal for high-speed production. Different hot melt formulations cater to specific paper types.

- PUR (Polyurethane Reactive) Adhesive: PUR adhesive provides a stronger bond than hot melt, especially with challenging substrates such as coated or glossy papers. It’s more expensive but offers superior durability and flexibility. Think of it as the high-end option for demanding projects.

- EVA (Ethylene Vinyl Acetate) Adhesive: EVA adhesives offer a good balance between cost and performance, suitable for a wide range of paper stocks.

The selection of the appropriate adhesive is critical for the overall quality and longevity of the bound book.

Q 3. How do you identify and resolve common paper jams in a perfect binding machine?

Paper jams in perfect binding machines are frustrating but usually solvable. Identifying the source requires a systematic approach:

- Safety First: Always turn off the machine and unplug it before attempting any troubleshooting.

- Visual Inspection: Carefully examine the paper path from the input tray to the output tray. Look for any obvious obstructions, like crumpled pages or debris.

- Check Rollers and Sensors: Inspect the rollers for damage or build-up. Clean them if necessary. Also, check any sensors that detect the presence of paper; they might be malfunctioning.

- Trace the Path: Start at the point where the paper last entered the machine and trace it back, checking each stage of the process. Look for pinched or misaligned sheets.

- Clear the Jam: Once you’ve identified the jam, carefully remove the obstruction. Avoid tearing the paper, as this can cause further issues.

- Restart the Machine: After clearing the jam, carefully restart the machine and observe the paper path closely.

If you can’t resolve the jam, consult your machine’s manual or contact a qualified technician. Prevention is key: regular maintenance is crucial to minimize jamming.

Q 4. Explain the role of the three-knife trimmer in perfect binding.

The three-knife trimmer is a crucial component in perfect binding. It’s responsible for precisely cutting the bound book to a uniform size and square edges. It employs three synchronized blades that simultaneously cut the three edges (top, bottom, and fore-edge) of the book block, ensuring accuracy and efficiency.

Its role extends beyond just cutting; it ensures the final product has a professional look and feel. Inaccurate trimming can result in uneven edges, affecting the aesthetic appeal and even the functionality of the book. Consider it the finishing touch, adding that professional polish.

Q 5. How do you adjust the glue application for different paper stocks?

Glue application needs adjustments based on the paper stock. Different papers absorb glue at different rates. Heavier, more absorbent stocks require more glue to ensure proper adhesion, while lighter stocks may need less to avoid excessive glue showing on the spine. This adjustment is usually made using the machine’s glue control settings.

For example, coated papers often need less glue than uncoated papers. You might need to experiment slightly, using test runs to find the optimal glue setting for each paper stock. This ensures a strong bond without excess glue seepage.

Many machines offer adjustable glue rollers, allowing for precise control over glue volume and distribution.

Q 6. What safety precautions must be followed when operating a perfect binding machine?

Safety is paramount when operating a perfect binding machine. Several precautions are essential:

- Lockout/Tagout: Before any maintenance or cleaning, always lock out and tag out the power supply to prevent accidental start-up.

- Personal Protective Equipment (PPE): Use appropriate PPE, including safety glasses to protect against flying debris or glue splatter.

- Proper Training: Ensure operators have received thorough training on the machine’s operation and safety features.

- Clear the Area: Keep the area around the machine clear of obstructions to prevent tripping hazards.

- Caution Near Moving Parts: Be extra cautious around moving parts such as rollers and cutters. Never reach into the machine while it’s running.

- Follow Manufacturer’s Guidelines: Always adhere to the manufacturer’s instructions and safety regulations.

Ignoring safety precautions can lead to serious injury. Prioritizing safety is not just a rule, it’s a responsibility.

Q 7. How do you maintain the cleanliness and optimal function of your machine?

Regular maintenance is crucial for maintaining the cleanliness and optimal function of a perfect binding machine. This proactive approach prevents malfunctions and ensures consistent, high-quality results.

- Daily Cleaning: Remove any paper scraps or glue residue from the paper path and rollers at the end of each workday. This prevents build-up and potential jams.

- Weekly Inspections: Thoroughly inspect the machine for any signs of wear and tear, loose components, or malfunctioning sensors. Addressing small problems early prevents them from becoming major issues.

- Regular Lubrication: Lubricate moving parts as recommended by the manufacturer. This reduces friction and ensures smooth operation.

- Glue Roller Maintenance: Clean and maintain glue rollers regularly to prevent glue build-up. Replacing rollers as needed is crucial for even glue distribution.

- Professional Service: Schedule regular preventative maintenance by qualified technicians. They can perform thorough checks and identify potential problems before they lead to downtime.

Think of maintenance as preventative medicine for your machine. Regular care prolongs its life and ensures consistent high-quality output.

Q 8. Describe the process of setting up a perfect binding job with varying page counts.

Setting up a perfect binding job, regardless of page count, involves a systematic approach. Think of it like baking a cake – you need the right ingredients and the correct order of operations. First, you need to determine the book block thickness. This is crucial for setting the correct glue application and jaw pressure. For a 100-page book, the thickness will be significantly less than a 500-page book, requiring different machine adjustments. We use a caliper to measure the thickness precisely. Then, we adjust the three-knife trimmer to accurately cut the edges of the book block, ensuring clean, even edges. The spine needs to be prepared using the appropriate scoring or milling process, depending on the paper stock and desired aesthetic outcome. The number of pages directly impacts the spine thickness, and thicker spines might require more aggressive scoring. Finally, we program the machine’s settings for glue application, jaw pressure and speed. These settings are crucial, and they are adjusted based on the book block’s thickness and paper type. For example, a thicker book block requires more glue and potentially a slower binding speed to ensure proper adhesion.

We also meticulously calibrate the feeding system to accurately process varying page counts. The conveyor belt speed, the feeder’s pressure rollers, and the overall timing of the machine’s functions are all meticulously adjusted to handle the specific quantity and bulk of the pages. Imagine it’s like adjusting a conveyor belt in a factory to accommodate a variety of item sizes – too fast, and you get jams; too slow, and you reduce throughput.

Q 9. What are the common causes of imperfect binding, such as spine cracking or loose pages?

Imperfect binding, like spine cracking or loose pages, usually stems from a few key issues. Spine cracking often results from insufficient scoring or milling of the spine before gluing, particularly with thicker books. The spine needs to be ‘broken’ to allow for flexibility. Think of it as pre-creasing a piece of paper before folding – you prevent it from tearing. Insufficient glue application is another common culprit. The glue needs to penetrate the scored spine adequately to create a strong bond with the cover. Using the wrong type of glue or improper glue temperature can also lead to weak adhesion. Loose pages often result from uneven glue distribution, leaving some sections unglued. Poorly trimmed book blocks leading to pages not being perfectly aligned, or even a slightly damaged cover can also cause pages to be loose. Insufficient pressure from the binding jaws is yet another potential reason, failing to firmly press the pages and cover together. Lastly, the quality of the paper stock itself plays a role, and we sometimes see issues arising from using low-quality, absorbent stock that doesn’t hold the glue well.

Q 10. How do you troubleshoot issues with glue consistency and application?

Troubleshooting glue consistency and application involves a multi-faceted approach. First, we visually inspect the glue for the correct viscosity and temperature. If the glue is too thick, it won’t penetrate the spine properly, leading to weak binding. Too thin, and it will spread unevenly, leading to loose pages. We regularly check the glue temperature using a thermometer to ensure it is within the manufacturer’s specifications. The glue application mechanism itself needs to be inspected regularly. Clogged nozzles, improper glue pump function, and even uneven roller pressure can all affect glue distribution. We might need to clean the nozzles or replace worn parts, depending on the cause. We also run test batches to check glue consistency, making adjustments as needed. This is similar to a chef tasting their sauce before serving a dish – it’s a crucial quality control step.

Q 11. How do you identify and address problems with the cutting mechanism?

Problems with the cutting mechanism, like uneven cuts or jams, require careful diagnosis. We first inspect the blades for sharpness and alignment. Dull blades result in uneven cuts, while misaligned blades can cause skewed cuts or jams. We regularly sharpen or replace blades according to a scheduled maintenance plan. We also check the blade-to-feed alignment. Improper alignment creates inconsistent cutting and even can damage the book block. Sometimes the problem isn’t the blades but the mechanism that feeds the book blocks into the cutter. We check the feeding rollers for proper pressure and even wear. Issues like worn rollers, improper feeding pressure, or obstructions can lead to jams or misaligned blocks. Finally, we regularly lubricate the moving parts of the cutter mechanism to prevent mechanical failures. Regular maintenance is essential to prevent catastrophic failures and ensure consistent, clean cuts.

Q 12. What is the role of the conveyor belt and delivery system?

The conveyor belt and delivery system are the book’s highway to its final destination. The conveyor belt smoothly moves the book blocks through the different stages of the binding process—from the initial feeding to the final delivery. It needs to be calibrated to handle the varying thicknesses of the book blocks and maintain a consistent flow. Think of it as a smoothly operating assembly line. A malfunctioning belt could cause jams or irregular feeding. The delivery system stacks the finished books neatly, ready for packaging. It often includes a stacking mechanism that organizes the books, preventing them from falling over or becoming damaged during handling. These systems’ effectiveness heavily influences productivity and the final product’s quality. A well-maintained conveyor and delivery system guarantees smooth operations and reduces the risk of damage to the finished product. It also ensures a continuous workflow and consistent throughput.

Q 13. How do you ensure the proper alignment of pages before binding?

Proper page alignment before binding is critical for a professional finish. We use various methods to ensure this. First, the initial gathering and collating process plays a significant role. We use specialized equipment to gather the pages in the correct sequence, preventing misalignment from the start. If we’re dealing with significant volumes we may use a gathering machine that utilizes high-speed sensors and error correction mechanisms. Secondly, we may employ pressure rollers in the machine itself, and these rollers gently but firmly press the pages together to create a consistent book block with minimal shifting. Finally, we often conduct visual inspection at crucial points in the process; before and after glue application. Any identified misalignment issues are corrected before proceeding. The goal is to create a book block as flat as possible and to avoid any spine shifting that can lead to uneven glue distribution and loose pages. Think of it like a painter meticulously preparing a canvas before starting their masterpiece. The better the preparation, the higher the quality of the final product.

Q 14. What are the key quality control checks you perform during the perfect binding process?

Quality control checks are integral throughout the perfect binding process, ensuring a high-quality final product. We conduct visual inspections of the finished books, checking for things like spine cracks, loose pages, uneven glue application, and any damage to the cover. We also check the squareness and trim quality of the book block. The spine should be uniformly glued, and the pages should be neatly aligned. Then, we measure the book’s thickness to ensure it conforms to the specifications. We randomly select samples for destructive testing, where we examine the binding’s internal structure to confirm the strength and quality of the glue bond. Beyond visual and manual checks, we analyze the machine’s operational data to identify trends or potential issues. We look at things like glue usage, machine downtime, and error rates. This data helps us to proactively identify and address potential problems and make adjustments for future jobs. Think of it as preventive maintenance and proactive quality control. The goal is to constantly improve the process and prevent defects from happening in the first place.

Q 15. How do you handle different book sizes and thicknesses?

Handling different book sizes and thicknesses on a perfect binding machine involves adjusting several key parameters. Think of it like baking a cake – you wouldn’t use the same recipe for a cupcake and a layer cake. First, you need to adjust the spine preparation unit. This involves changing the clamping pressure to accommodate the thickness of the book block. Thicker books require more pressure to ensure a firm, even spine. Secondly, the glue application system needs to be calibrated. Thicker books need a longer gluing time and potentially a higher glue flow rate to ensure adequate adhesion along the spine. Finally, the cutting and trimming units often require adjustment to accommodate varying book sizes. For instance, the three-knife trimmer needs to be set accurately to ensure precise cuts and prevent waste. Each machine model will have specific adjustments, but the fundamental principles remain the same.

For example, a small paperback might require minimal clamping pressure and a short gluing time, while a large hardback might need significantly more pressure and a longer gluing cycle. Regularly checking the spine thickness and making minute adjustments helps maintain consistent quality throughout the run.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the different types of perfect binding machines?

Perfect binding machines come in a variety of types, primarily categorized by their automation level and production capacity. At the entry-level, we have the manual perfect binders. These require a lot of hands-on operation and are suitable for small-scale print shops or short runs. Next, we have semi-automatic machines, which automate some processes like glue application and book block feeding, but still require operator intervention for tasks like cover feeding. This increases efficiency compared to manual machines. Finally, at the high-end are the fully automatic perfect binding machines. These handle the entire process with minimal human input, making them ideal for high-volume production environments. Within each category, you will find variations in features like the number of stations, gluing systems (hot melt or PUR glue), and finishing options (e.g., three-knife trimmer).

Choosing the right machine type depends heavily on the production volume, budget, and desired level of automation. A small publisher might opt for a semi-automatic machine, while a large commercial printer would likely invest in a fully automatic system.

Q 17. What are the advantages and disadvantages of perfect binding compared to other binding methods?

Perfect binding, while efficient for many applications, has its pros and cons compared to other binding methods like saddle stitch or case binding. Let’s look at the advantages first: It’s highly versatile, handling a wide range of page counts and paper types, and creating a lay-flat spine that’s great for reading. Perfect binding is generally cost-effective for medium to high page count books, and the process is relatively fast. However, there are downsides. The spine isn’t as durable as case binding, making it less suitable for books that will face significant wear and tear. The spine may also show some glue discoloration, and the preparation process (roughing the spine) requires care to achieve a satisfactory result.

Compared to saddle stitch binding, perfect binding allows for much higher page counts (often exceeding 250 pages), but the setup and maintenance of perfect binding are significantly more complex. Saddle stitch is simpler, quicker, and more affordable for short-run, lower page-count publications.

Q 18. How do you calibrate the machine for optimal performance?

Calibrating a perfect binding machine for optimal performance is a crucial step for consistent quality and efficiency. This is a multi-stage process. First, you need to adjust the glue temperature and pressure to ensure proper adhesion without excess glue. Too little glue leads to poor binding, while too much results in messy and uneven spines. This often involves using a test book and making incremental adjustments until the spine exhibits good integrity and shows no excess glue. Next, the jaw pressure in the spine preparation needs to be calibrated. This ensures even roughening across the spine without damaging the pages. Incorrect settings lead to poor adhesion or even damage to the text block. Finally, the cutting and trimming units must be precisely calibrated to ensure uniform and accurate cuts, preventing waste and producing professional-looking books.

Regular calibration is key. I usually perform a calibration check at the start of each production run and make minor adjustments as needed based on the material used. A well-calibrated machine produces consistent, high-quality books and minimizes waste, ultimately reducing costs and improving productivity.

Q 19. Describe your experience with different types of paper and their suitability for perfect binding.

Experience with different paper types is essential for perfect binding. Not all papers are created equal. The paper’s thickness, weight, and texture directly impact the binding process. Heavier papers, for instance, require more clamping pressure during spine preparation and potentially a longer glue drying time. Coated papers often require specific glue types and settings to prevent the glue from damaging the coating. Conversely, uncoated papers, while generally easier to work with, can sometimes absorb too much glue, leading to unevenness. The paper’s absorbency also plays a critical role in glue selection. For example, high-absorbency papers might need a slower-setting glue to allow proper penetration.

I’ve worked extensively with offset papers, digital papers, and even specialty papers like textured stock. Understanding these differences allows me to optimize the machine settings for each paper type, ensuring consistent, high-quality binding results. In the past, I had to troubleshoot a batch where the paper was unexpectedly high in absorbency. After adjusting the glue viscosity and dwell time, the issue was resolved, highlighting how crucial paper understanding is.

Q 20. How do you handle different types of cover materials?

Handling different cover materials requires careful consideration and adjustments to the machine’s settings. The thickness and stiffness of the cover are key factors. A thicker cover, like a board-covered book, might need more clamping force during the covering process to ensure proper adherence. The material’s texture also plays a significant role. A highly textured cover might require a slower feeding mechanism to prevent jams or wrinkling. Furthermore, the cover material’s susceptibility to glue and heat needs to be considered. Some materials might be damaged by excessively high temperatures or certain types of adhesives. The use of PUR (Polyurethane Reactive) glue is often preferable for challenging cover materials.

For example, when working with a delicate linen cover, a gentler feeding speed and careful monitoring of the glue temperature are crucial to avoid damaging the material. Adaptability to different materials is essential for a perfect binding operator.

Q 21. What are the common maintenance tasks for a perfect binding machine?

Regular maintenance is paramount for the longevity and optimal performance of a perfect binding machine. This involves a combination of daily, weekly, and monthly tasks. Daily tasks include cleaning the glue system (removing any excess glue) and checking the three-knife trimmer for debris. Weekly checks include inspecting the rollers and belts for wear and tear, lubricating moving parts, and verifying the correct pressure settings. Monthly maintenance might involve a more thorough inspection of the machine’s components, replacing worn-out parts like rollers or belts, and a deeper cleaning of the glue system. Additionally, regular servicing by a qualified technician is recommended to identify and address potential problems before they become major issues.

Ignoring maintenance can lead to machine breakdowns, reduced production efficiency, and compromised book quality. A proactive maintenance schedule minimizes downtime and ensures consistent, high-quality output.

Q 22. Describe your experience with troubleshooting electrical or mechanical issues.

Troubleshooting electrical or mechanical issues in a perfect binding machine requires a systematic approach. I start by identifying the symptom – is the machine completely down, or is there a specific function malfunctioning? Then, I systematically check the most likely causes. For electrical issues, I’ll use a multimeter to check voltage, amperage, and continuity in circuits, looking for blown fuses, faulty wiring, or problems with the control panel. I’m familiar with various safety precautions, including lockout/tagout procedures. Mechanical issues often involve checking for worn parts, misalignment, or jammed components. This might involve inspecting the roller system for wear, checking the jaw alignment for proper book closure, or investigating the glue system for clogs or leaks. I’ve found that keeping a detailed maintenance log is crucial for tracking down recurring problems and predicting potential failures. For example, one time a recurring paper jam was traced back to a slightly misaligned feeder tray, an issue easily solved with minor adjustment but crucial to overall machine efficiency.

I’m also proficient in interpreting error codes displayed on the machine’s control panel, which significantly speeds up diagnosis. Essentially, I use a combination of methodical testing, technical knowledge, and preventative maintenance to resolve these issues quickly and effectively, minimizing downtime.

Q 23. How do you calculate the production time for a given job?

Calculating production time involves more than just the machine’s speed; it requires a holistic approach. First, I assess the job specifications: the number of books, their size, the type of cover stock, and the number of pages. Then, I consider the machine’s capabilities – its maximum binding speed, the setup time (preparing the machine for the specific job), and the potential for downtime. I also account for the number of operators and their efficiency. A crucial element is the ‘make-ready’ time – the time required to adjust the machine settings for the job. Thicker books take longer to bind, and higher page counts increase production time accordingly.

For example, if a job requires binding 1000 books, each with 200 pages, and the machine can bind 50 books per hour with a 30-minute setup time, the calculation would be roughly like this: (1000 books / 50 books/hour) + 0.5 hours (setup) = 20.5 hours. However, this is just an estimate. I always add a contingency factor to account for potential unforeseen delays, like paper jams or minor mechanical issues. Experience helps refine these estimates for higher accuracy.

Q 24. What is your experience with different adhesive application methods?

I have experience with various adhesive application methods, including hot melt, cold glue, and PUR (Polyurethane Reactive) systems. Hot melt is the most common for its speed and efficiency, particularly suitable for high-volume jobs. However, it requires careful temperature control to avoid scorching the pages. Cold glue offers better flexibility and is less likely to damage sensitive papers, but it has a slower drying time which impacts production speed. PUR is a high-strength adhesive, perfect for demanding applications needing durability and lay-flat capabilities, but also requires specialized equipment and training.

Understanding the properties of each adhesive is critical for selecting the right one for a given job. Factors like paper type, cover stock, binding requirements (lay-flat vs. standard), and budget all influence the choice. For instance, if the client needs a book that lays perfectly flat, PUR is the ideal choice. If speed and cost are paramount and the paper type is robust, hot melt works efficiently.

Q 25. How do you ensure the consistent quality of the finished product?

Consistent quality is paramount in perfect binding. I use a multi-pronged approach: First, rigorous quality checks at each stage of the process, starting with paper inspection to ensure that there are no defects or irregularities. Next, regular maintenance and calibration of the machine are vital for maintaining consistent glue application and accurate book trimming. I also constantly monitor the machine’s performance, checking the alignment of components and the condition of the rollers. Moreover, regular checks of the finished product ensure that the spine is consistently glued, the covers are securely attached, and the edges are neatly trimmed.

Visual inspection is essential but using precision measuring tools helps ensure that the bound books meet the specified dimensions. Statistical Process Control (SPC) techniques can also be implemented to track key metrics and identify any deviations from established quality standards. If a problem arises, I perform root-cause analysis to address it, making adjustments as needed to maintain consistent output. For instance, if the spine glue is inconsistent, I’ll check the glue temperature and flow rate. I use checklists and quality control documents to ensure a standardized process.

Q 26. Describe your experience working with different types of finishing equipment.

Beyond perfect binding machines, I’m familiar with various finishing equipment, including three-knife trimmers, cutters, and folding machines. Understanding how these different pieces of equipment interact is crucial for a smooth workflow. For example, the output from a three-knife trimmer needs to be precisely sized to fit the perfect binding machine’s specifications. This requires careful coordination and understanding of tolerances. I also have experience with gathering machines used to collate pages before binding, and with casemaking machines for the creation of slipcases or protective covers.

The proficiency with multiple finishing machines allows for optimizing the entire book production process, improving efficiency and minimizing bottlenecks. Moreover, cross-training in these different areas allows me to identify and resolve problems across the entire finishing workflow, significantly improving troubleshooting capabilities and overall project success.

Q 27. How do you prioritize tasks and manage your workload efficiently?

Prioritizing tasks and managing my workload effectively requires a structured approach. I typically use a combination of planning tools and established workflows. I begin by analyzing all incoming jobs, assessing their urgency, deadlines, and complexity. I then prioritize them based on these factors, often using a Kanban board or similar visual management system to track progress. This allows for easy identification of bottlenecks and potential delays. I break down complex tasks into smaller, manageable steps, assigning realistic timelines to each step. Regularly reviewing the schedule helps me stay on track and adjust plans as needed.

Effective communication with colleagues and supervisors is essential for coordinating tasks and avoiding conflicts. I ensure regular updates on progress, highlighting any potential roadblocks early on. My experience has taught me that proactive planning and flexible adjustment are vital for managing a fluctuating workload and delivering quality results consistently.

Q 28. Describe a time you had to troubleshoot a complex problem with the perfect binding machine.

One time, we experienced intermittent malfunctions with the perfect binding machine’s gluing mechanism – the glue would apply inconsistently, leading to poorly bound books. Initially, we suspected a problem with the glue itself, but after thorough inspection, the glue was within specification. We then systematically checked every component related to glue application: the pump, the heating element, the metering valve, and the application rollers. After several hours of troubleshooting, we discovered a tiny piece of debris lodged in the metering valve, causing intermittent blockage. Removing the debris resolved the problem completely.

This experience highlighted the importance of meticulous inspection, even in seemingly minor components. It also reinforced the value of teamwork. We worked collaboratively, each person focusing on a specific aspect of the machine, allowing for quick and efficient identification of the root cause. Thorough documentation of this troubleshooting process also helped prevent similar issues in the future.

Key Topics to Learn for Perfect Binding Machine Operation Interview

- Machine Setup and Pre-Press Preparation: Understanding the pre-flight checks, paper handling, and correct alignment procedures for optimal binding.

- Perfect Binding Process: Detailed knowledge of each stage – gathering, gluing, trimming, and covering – including troubleshooting common issues at each step.

- Material Handling and Quality Control: Identifying appropriate materials for perfect binding, performing quality checks throughout the process, and addressing issues like misalignment or insufficient glue.

- Maintenance and Troubleshooting: Familiarity with routine maintenance tasks, identifying common malfunctions, and performing basic repairs or knowing when to escalate issues.

- Safety Procedures and Regulations: Understanding and adhering to all safety protocols related to operating heavy machinery and working in a production environment.

- Production Efficiency and Optimization: Strategies for maximizing output while maintaining high quality, including understanding factors affecting speed and efficiency.

- Understanding Different Binding Types: Comparing and contrasting perfect binding with other binding methods to highlight its strengths and limitations.

- Advanced Techniques and Problem Solving: Demonstrating the ability to analyze problems, identify root causes, and implement effective solutions to production challenges.

Next Steps

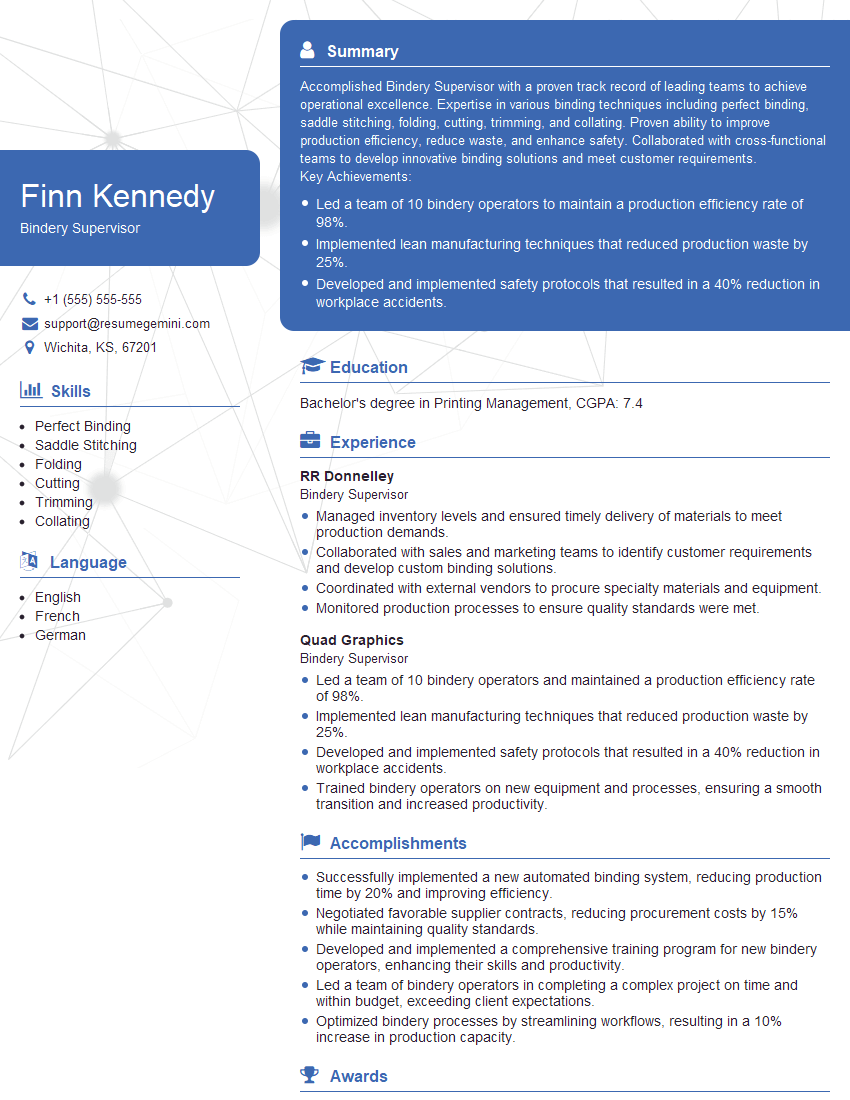

Mastering Perfect Binding Machine Operation opens doors to rewarding careers in print finishing and production. Your expertise in this specialized area makes you a valuable asset to any print shop or bindery. To significantly boost your job prospects, create a resume that’s both ATS-friendly (Applicant Tracking System-friendly) and showcases your skills effectively. ResumeGemini is a trusted resource that can help you craft a professional resume tailored to the print industry. We provide examples of resumes specifically tailored to Perfect Binding Machine Operation to guide you in creating a winning application. Invest the time in building a strong resume – it’s your key to unlocking exciting career opportunities.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good