Are you ready to stand out in your next interview? Understanding and preparing for Phosphating interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Phosphating Interview

Q 1. Explain the purpose of phosphating in metal surface treatment.

Phosphating is a crucial pretreatment process in metal surface treatment that converts a metal surface into a crystalline phosphate coating. This coating isn’t just a pretty finish; it serves several vital purposes. Primarily, it enhances the adhesion of subsequent coatings like paints, primers, or lubricants. Imagine trying to paint a smooth, freshly polished metal surface – the paint would likely peel off easily. The phosphate coating provides a micro-rough surface, creating better mechanical interlocking with the topcoat. Beyond adhesion, it offers excellent corrosion resistance, acting as a barrier against rust and oxidation. This is especially important in harsh environments where bare metal would quickly degrade. Finally, phosphating can improve lubricity, making the surface smoother for metal forming operations and reducing friction.

Q 2. Describe the different types of phosphating processes (e.g., zinc, manganese, iron).

There are three main types of phosphating processes, each offering unique properties and applications:

- Zinc Phosphating: This is the most common type, producing a crystalline coating of zinc phosphate. It offers good corrosion resistance and excellent paint adhesion, making it ideal for automotive parts, appliances, and other applications requiring a durable, paintable finish. The coating is typically gray or light gray.

- Manganese Phosphating: Manganese phosphate coatings are thinner and more uniform than zinc phosphate coatings. They provide excellent lubricity and wear resistance, making them suitable for metal forming operations where a smooth, easily lubricated surface is crucial. They are often used in applications requiring high-temperature resistance.

- Iron Phosphating: Iron phosphate coatings are typically thinner than zinc or manganese phosphate coatings and offer moderate corrosion protection. While their corrosion resistance is lower, their ability to improve paint adhesion is excellent. They are often used as a pretreatment step before powder coating.

The choice of phosphating process depends heavily on the specific application and the desired properties of the final product.

Q 3. What are the key parameters that influence phosphating process quality?

Many parameters influence phosphating process quality. Control over these variables is critical to achieving a consistent and high-quality coating. Key parameters include:

- Temperature: Temperature directly affects the reaction rate and the crystal structure of the phosphate coating. Too low, and the coating will be slow to form; too high, and the coating may be uneven or damaged.

- Time: Sufficient time is needed for the chemical reaction to complete and form a proper coating. Insufficient time will result in an incomplete and less protective coating.

- pH: The acidity (pH) of the phosphating solution is crucial. A precise pH range is required for optimal crystal growth and coating formation. Deviation from the optimal range can lead to defects.

- Concentration of Chemicals: The concentrations of the phosphating solution components (acids, phosphates, accelerators) must be carefully controlled. Inconsistent concentrations lead to inconsistent coating quality.

- Pre-treatment: The quality of the pre-treatment (cleaning and surface preparation) significantly impacts the final coating adhesion and uniformity. Any contaminants remaining on the surface can hinder the phosphating process.

- Agitation: Proper agitation of the phosphating solution ensures uniform coating formation and prevents the settling of solids.

Monitoring and controlling these parameters using automated systems is vital for consistent results in industrial settings.

Q 4. How do you control the thickness of the phosphate coating?

The thickness of the phosphate coating is controlled primarily by adjusting parameters of the phosphating process. These include the concentration of the phosphating solution, the process time, and the temperature. Thinner coatings are generally achieved with lower concentrations, shorter times, and lower temperatures. Conversely, thicker coatings require higher concentrations, longer times, and higher temperatures (within the allowable range to avoid damaging the substrate). The precise control is often achieved through carefully calibrated automated systems monitoring parameters and adjusting them in real time. For example, in-line thickness measuring equipment can provide continuous feedback to the control system, allowing for automatic adjustments to maintain a target thickness.

Q 5. Explain the role of pretreatment steps before phosphating.

Pretreatment steps before phosphating are absolutely essential for ensuring a high-quality, durable, and uniform phosphate coating. These steps remove any contaminants from the metal surface that would interfere with the phosphating process and prevent proper coating adhesion. Common pretreatment steps include:

- Cleaning: This is a crucial step to remove oils, greases, dirt, and other organic contaminants. Methods include solvent cleaning, alkaline cleaning, or emulsion cleaning. The choice of cleaning method depends on the type and amount of contamination.

- Rinsing: Thorough rinsing after cleaning is critical to remove all cleaning agents, preventing interference with the phosphating process. Multiple rinsing stages are often employed to ensure complete removal.

- Surface Activation (optional): In some cases, surface activation treatments such as pickling (acid treatment) are used to remove surface oxides or scales and improve the reactivity of the surface, thereby promoting better phosphate crystal growth.

Think of pretreatment like preparing a wall before painting – you wouldn’t paint directly onto a dirty, dusty wall, right? The same principle applies to phosphating. Proper pretreatment ensures that the phosphate coating adheres effectively and provides the desired protection and performance.

Q 6. What are the common defects found in phosphating and their causes?

Several defects can occur during phosphating, often indicating problems with the process parameters or pretreatment. Some common defects include:

- Uneven coating: This often indicates problems with the solution agitation, temperature uniformity, or pretreatment inconsistencies. Parts with uneven surface finish can also cause this.

- Poor adhesion: This points to inadequate pretreatment, residual contamination on the surface, or improper phosphating parameters (temperature, pH).

- Sludging: An excessive buildup of phosphate crystals, often due to an imbalance in the chemical composition of the solution or excessive process time.

- Black staining or discoloration: Usually caused by inadequate rinsing or the presence of iron contaminants.

- Pitting or blistering: May indicate improper pretreatment, leaving behind contaminants trapped underneath the coating, or aggressive cleaning leading to surface damage.

Identifying the cause requires careful analysis of the process parameters and a thorough examination of the surface defects. Microscopy and chemical analysis of the coating can be invaluable in troubleshooting.

Q 7. How do you troubleshoot problems with phosphate coating uniformity?

Troubleshooting phosphate coating uniformity issues requires a systematic approach. Here’s a step-by-step strategy:

- Visual Inspection: Begin with a thorough visual inspection of the coated parts. Identify the areas with non-uniform coating and note the pattern of the defects.

- Process Parameter Review: Check the process parameters (temperature, time, pH, concentration, agitation) and compare them to the established specifications. Look for any deviations.

- Pretreatment Evaluation: Assess the effectiveness of the pretreatment steps. Inspect the parts before phosphating to ensure they are properly cleaned and free from contaminants. Consider repeating or improving the pre-treatment stages.

- Solution Analysis: Analyze the phosphating solution for proper concentration and pH. Outdated or contaminated solution may be contributing to the problem. Consider replenishing or replacing it.

- Equipment Inspection: Inspect the phosphating equipment for any malfunctions that could contribute to uneven coating distribution. This may include tank agitation, spray nozzles, or immersion systems.

- Test Runs: After identifying and addressing potential causes, perform small-scale test runs with adjusted parameters to determine their effectiveness in improving uniformity.

Remember, consistent quality control procedures and regular monitoring of process parameters are crucial for preventing uniformity issues in the first place.

Q 8. Describe the quality control measures used in phosphating.

Quality control in phosphating is crucial for ensuring a consistent, high-quality coating. It involves several key steps, starting even before the process begins.

- Pre-treatment Inspection: The cleanliness of the substrate (the metal part to be phosphated) is paramount. We meticulously inspect for any oil, grease, or other contaminants that could interfere with the phosphating process. Visual inspection is often combined with solvent cleaning tests to verify cleanliness.

- Process Monitoring: Throughout the phosphating process, we monitor key parameters such as temperature, chemical concentrations (using titration or other analytical methods), and immersion time. Deviations from the established parameters are immediately addressed to prevent defects. For example, if the temperature drops too low, the crystal structure of the phosphate coating might be compromised, resulting in a weaker coating.

- Coating Weight Measurement: After phosphating, we measure the weight of the phosphate coating to ensure it meets the specified requirements. This is a crucial indicator of coating thickness and uniformity, both of which directly impact corrosion resistance. We use techniques like the weight-gain method or specialized coating thickness gauges.

- Visual Inspection: A thorough visual inspection of the coated parts is carried out to check for defects such as uneven coating, blisters, or staining. This ensures aesthetic quality and identifies any potential areas of weakness.

- Corrosion Testing: We perform corrosion tests like salt spray testing to assess the corrosion resistance of the phosphate coating. This test simulates real-world conditions and helps determine the longevity of the protective layer. The duration of exposure and the type of salt spray solution are selected to meet specific industry standards or customer requirements.

Think of it like baking a cake: you need the right ingredients (chemicals), the right temperature, and the right timing to get a perfect result. Similarly, precise control over phosphating parameters ensures the desired coating quality.

Q 9. How do you ensure the proper disposal of phosphating chemicals?

Responsible disposal of phosphating chemicals is vital for environmental protection and worker safety. This involves a multi-faceted approach.

- Hazardous Waste Classification: We correctly identify phosphating solutions as hazardous waste according to local and national regulations. This classification dictates the appropriate handling and disposal methods. Often, phosphating solutions contain heavy metals and acids which require special treatment.

- Wastewater Treatment: Spent phosphating solutions are typically treated to neutralize the acidity and reduce heavy metal content before discharge. This might involve chemical precipitation, filtration, or other advanced treatment methods depending on the specific chemicals and local regulations. The treated wastewater should meet discharge limits before release into the environment.

- Sludge Management: The solid sludge generated during wastewater treatment must be managed appropriately. This might involve solidification, stabilization, and disposal in a licensed hazardous waste landfill.

- Proper Containerization and Labeling: All phosphating chemicals and waste must be stored and transported in clearly labeled containers that meet safety standards. This prevents accidental spills and ensures safe handling.

- Working with Licensed Professionals: We regularly collaborate with licensed waste management companies specializing in hazardous waste disposal. They have the expertise and facilities to ensure the environmentally sound disposal of phosphating waste.

Ignoring proper disposal not only carries significant environmental risks but also exposes the company to potential legal repercussions and hefty fines.

Q 10. What are the safety precautions involved in phosphating?

Phosphating involves handling strong chemicals and requires stringent safety precautions. This includes:

- Personal Protective Equipment (PPE): Workers must wear appropriate PPE, including gloves, eye protection, respirators, and protective clothing to prevent skin and respiratory irritation or exposure to hazardous chemicals. The specific PPE will depend on the chemicals used and the stage of the phosphating process.

- Ventilation: Adequate ventilation is essential to remove chemical fumes and maintain a safe working environment. Local exhaust ventilation systems are often used near phosphating tanks to capture and remove fumes at their source.

- Emergency Showers and Eyewash Stations: These facilities must be readily available in case of accidental spills or splashes. Training on their proper use is crucial.

- Spill Response Plan: A well-defined spill response plan should be in place to address accidental spills of phosphating chemicals, including procedures for containment, cleanup, and disposal. This plan should also address emergency response procedures.

- Training and Education: All personnel involved in phosphating must receive thorough training on safe handling procedures, emergency response protocols, and the potential health hazards associated with the chemicals used.

- Regular Monitoring: Regular monitoring of air quality and worker exposure levels should be implemented to ensure compliance with occupational safety regulations.

Safety in phosphating is not just a checklist; it’s a continuous process that requires attention to detail and a culture of safety awareness.

Q 11. Explain the difference between zinc phosphating and manganese phosphating.

Zinc phosphating and manganese phosphating are both common types of phosphating, but they differ in their chemical composition and resulting properties.

- Zinc Phosphating: This process uses zinc salts to produce a crystalline zinc phosphate coating. Zinc phosphate coatings are typically gray or light-brown in color and offer excellent corrosion resistance and paint adhesion. They are frequently used in the automotive industry, for example, on engine parts, as their corrosion resistance is a critical factor in their longevity.

- Manganese Phosphating: This process employs manganese salts to create a thin, black or dark-gray coating. Manganese phosphate coatings are known for their excellent lubricity and wear resistance, making them suitable for applications where friction and wear are major concerns. A common application is on the internal surfaces of firearm barrels, where the lubricating effect reduces friction and wear.

The key difference lies in their application. Zinc phosphating prioritizes corrosion protection while manganese phosphating focuses on lubrication and wear resistance. The choice depends entirely on the specific application and required properties of the final coated part.

Q 12. What are the advantages and disadvantages of using different types of phosphating chemicals?

Different phosphating chemicals offer varying advantages and disadvantages, impacting cost, coating properties, and environmental impact.

- Zinc Phosphating (Advantages): Excellent corrosion resistance, good paint adhesion, relatively inexpensive.

- Zinc Phosphating (Disadvantages): Can be more susceptible to damage compared to manganese phosphate coatings.

- Manganese Phosphating (Advantages): Excellent lubricity and wear resistance, relatively uniform coating.

- Manganese Phosphating (Disadvantages): Lower corrosion resistance than zinc phosphating, may be slightly more expensive.

- Iron Phosphating (Advantages): Used as a base for paint, offering improved adhesion.

- Iron Phosphating (Disadvantages): Not as effective in corrosion resistance as zinc or manganese phosphating.

The selection of phosphating chemicals depends on the specific needs of the application. For instance, a component requiring high corrosion resistance would benefit from zinc phosphating, while a component that experiences significant friction, such as a piston, would be better served by manganese phosphating. Cost analysis and environmental considerations must also factor into the decision-making process.

Q 13. How does temperature affect the phosphating process?

Temperature plays a critical role in the phosphating process, significantly influencing coating quality and speed.

Effect of Temperature: Higher temperatures generally lead to faster reaction rates, resulting in a quicker phosphating process. However, excessively high temperatures can cause the coating to be too thin, non-uniform, or even result in coating defects like blisters. Conversely, temperatures that are too low result in slow reaction rates, leading to an uneven or incomplete coating. The optimal temperature is specific to the type of phosphating chemicals and the desired coating characteristics. Typically, operating temperatures range between 90-180°F (32-82°C), but precise values are determined through careful experimentation and process optimization.

Practical Example: In a zinc phosphating process, a lower-than-optimal temperature may lead to a dull, uneven coating with poor corrosion resistance. It may even fail to form a proper coating. Conversely, excessive temperature can lead to thin, weakly adhering coatings that readily flake off.

Q 14. How does the concentration of phosphating chemicals affect the coating quality?

The concentration of phosphating chemicals directly impacts the quality of the phosphate coating. Precise control is crucial for optimal results.

Effect of Concentration: An insufficient concentration of phosphating chemicals might lead to a thin, weak, or incomplete coating, compromising its protective properties. Conversely, excessively high concentrations can result in a very thick, non-uniform coating or even cause undesirable chemical reactions that damage the substrate. It’s crucial to use accurate measuring instruments and follow precise chemical formulations recommended by the chemical manufacturer.

Practical Example: In a real-world scenario, if the concentration of acid is too low, the reaction may not proceed effectively, resulting in an insufficient amount of phosphate crystals forming on the substrate. This weakens the corrosion resistance. Too high of an acid concentration may cause etching or pitting of the substrate surface, weakening the base metal and degrading the bond with the phosphate coating.

Regular monitoring of chemical concentrations using titration or other analytical methods is paramount for maintaining consistent coating quality and preventing defects.

Q 15. What is the role of accelerators in the phosphating process?

Accelerators in phosphating are crucial for speeding up the otherwise slow chemical reaction that forms the phosphate crystal layer on the metal surface. Think of it like adding a catalyst to a chemical reaction in a chemistry experiment – it makes things happen faster and more efficiently. They typically consist of compounds like nitrates or nitrites. These compounds act by oxidizing the metal surface, creating nucleation sites where the phosphate crystals can readily form. Without accelerators, the phosphating process would be significantly slower, making it less practical for industrial applications.

For example, in a zinc phosphating bath, the accelerator helps to control the rate of zinc phosphate precipitation, ensuring a uniform and consistent coating. Different accelerators can be used to fine-tune the coating’s properties, such as its weight and crystal size.

Career Expert Tips:

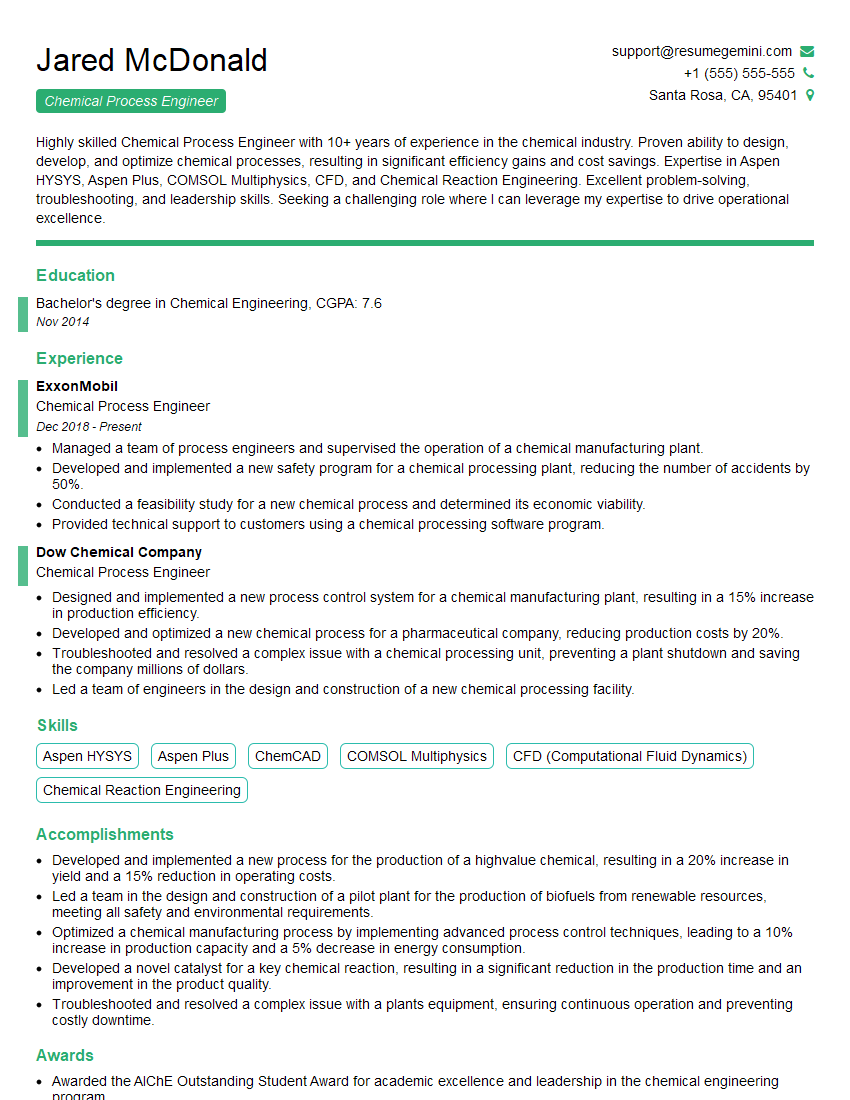

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the process of analyzing a phosphate coating’s weight and thickness.

Analyzing the weight and thickness of a phosphate coating involves a combination of techniques. Weight determination is relatively straightforward. We typically clean and weigh a sample of the phosphated metal, then strip the coating using a suitable chemical solution (often an acid), clean again, and weigh it again. The difference in weight represents the weight of the phosphate coating. This is often expressed as grams per square meter (g/m²).

Measuring thickness is more complex and usually requires specialized equipment. Common methods include:

- Microscopy: Cross-sectional microscopy, where the coated sample is embedded in resin, sliced, and viewed under a microscope, allows for direct visual measurement of coating thickness.

- Electrochemical methods: These involve measuring the current flow during the dissolution of the phosphate coating in a controlled electrochemical environment. The amount of charge passed is directly related to the coating’s thickness.

- Magnetic methods: These are used for measuring non-magnetic coatings on ferromagnetic substrates. A magnetic probe measures the change in magnetic flux caused by the coating.

The choice of method depends on factors like coating type, thickness, and the available equipment. For example, a very thin coating might require cross-sectional microscopy, while a thicker coating could be easily measured using a magnetic gauge.

Q 17. How do you determine the corrosion resistance of a phosphated surface?

Corrosion resistance of a phosphated surface is assessed using various accelerated corrosion tests. These tests simulate real-world conditions in an accelerated manner to evaluate the coating’s protective ability. Common methods include:

- Salt spray testing (ASTM B117): This involves exposing the phosphated sample to a salt mist (typically 5% NaCl solution) for a specified period. The extent of corrosion is visually assessed and rated.

- Humidity testing (ASTM D2247): The sample is exposed to a controlled environment of high temperature and humidity. This promotes corrosion by creating condensation on the surface.

- Cyclic corrosion testing: This test involves exposing the sample to cycles of different environments (e.g., salt spray, humidity, drying) to simulate real-world conditions more accurately.

The results of these tests, typically expressed as the time to failure or the corrosion rating, give an indication of the corrosion resistance provided by the phosphate coating. A higher resistance to corrosion translates to a longer lifespan of the coated component. For instance, a component intended for outdoor use would require a much higher corrosion resistance than one used indoors.

Q 18. What are the environmental regulations related to phosphating?

Environmental regulations related to phosphating are stringent and vary depending on location. They primarily focus on reducing or eliminating the discharge of hazardous chemicals, especially heavy metals like zinc, manganese, and phosphates. These regulations often involve:

- Wastewater treatment: Treatment plants must effectively remove phosphates and heavy metals from the wastewater generated during phosphating. This may involve chemical precipitation, filtration, or other advanced treatments.

- Air emissions control: Control measures are necessary to reduce emissions of volatile organic compounds (VOCs) and acidic fumes produced during the phosphating process. This often involves scrubbers and filtration systems.

- Hazardous waste disposal: Spent phosphating solutions and other waste materials must be disposed of according to relevant regulations, often requiring specialized hazardous waste disposal facilities.

- Chemical usage restrictions: Regulations may restrict the types and amounts of chemicals used in phosphating, promoting the use of more environmentally friendly alternatives.

Compliance with these regulations is essential for any phosphating operation to avoid penalties and maintain its operational license. Staying informed about evolving regulations is crucial for operators.

Q 19. Explain the concept of phosphating line optimization.

Phosphating line optimization aims to improve the efficiency and quality of the phosphating process while minimizing costs and environmental impact. This involves a holistic approach that considers various aspects of the process, including:

- Process chemistry optimization: Fine-tuning the composition and parameters of the phosphating bath (temperature, concentration, pH) to achieve optimal coating properties (weight, thickness, uniformity, and corrosion resistance).

- Pre-treatment optimization: Ensuring the metal surface is properly cleaned and prepared for phosphating, leading to better adhesion and coating quality.

- Equipment maintenance and efficiency: Regular maintenance of phosphating equipment (tanks, pumps, sprayers) to prevent failures and ensure optimal performance. This also extends to optimizing the layout of the line to minimize material handling and improve throughput.

- Wastewater management optimization: Implementing strategies to reduce wastewater volume, optimize treatment, and recycle/reuse process chemicals where possible.

- Data-driven monitoring and control: Implementing sensors and automated control systems to monitor process parameters and make real-time adjustments, ensuring consistency and reducing waste.

Optimization is an iterative process involving continuous monitoring, analysis, and adjustment. For example, real-time monitoring of coating weight can prompt adjustments to the phosphating bath parameters to maintain consistency.

Q 20. How do you handle variations in metal substrate composition during phosphating?

Variations in metal substrate composition can significantly affect the phosphating process. Different metals react differently with the phosphating solution, leading to variations in coating quality and uniformity. For example, high carbon steels can be more challenging to phosphate compared to low-carbon steels. Here’s how to handle these variations:

- Pre-treatment adjustments: Adjusting the cleaning and pre-treatment steps to better prepare the surface for phosphating. This may involve altering the cleaning solutions or using different surface activation techniques.

- Multi-stage phosphating: Utilizing multi-stage phosphating processes with different baths optimized for different substrate compositions. This ensures good coatings even with mixed batches of metal components.

A thorough understanding of the chemistry involved and the specific properties of each metal substrate is essential for successful phosphating in such instances. Often, detailed material specifications from the supplier and internal testing are critical for successful processing.

Q 21. What are the common phosphating equipment failures and how to address them?

Common phosphating equipment failures include issues with pumps, heaters, filters, spray nozzles, and tanks. Addressing these failures requires a proactive and systematic approach.

- Pumps: Failure can be due to corrosion, wear, or clogging. Regular maintenance, including lubrication and cleaning, can prevent issues. Replacement of worn-out parts may be necessary.

- Heaters: Heaters can malfunction due to scaling, corrosion, or electrical faults. Regular descaling and inspection are crucial. Replacement of damaged heating elements may be required.

- Filters: Clogging by sludge and other solids can reduce efficiency. Regular cleaning or replacement of filters is essential. Using appropriate filter media is also important.

- Spray nozzles: Clogging or wear can lead to inconsistent coating application. Regular cleaning and replacement are necessary. Using appropriate nozzle sizes and pressures is crucial for achieving optimal coating thickness and uniformity.

- Tanks: Corrosion, leaks, and build-up of sludge are common issues. Regular inspection, cleaning, and repair are essential. Proper material selection for tanks is crucial for longevity.

A preventative maintenance program with scheduled inspections and cleaning is key to avoiding equipment failures and minimizing downtime. Keeping detailed maintenance logs and records can be invaluable for troubleshooting and proactive problem solving.

Q 22. How does phosphating compare to other surface treatment methods (e.g., powder coating, anodizing)?

Phosphating, powder coating, and anodizing are all surface treatment methods aimed at enhancing the properties of metal parts, but they differ significantly in their mechanisms and applications. Phosphating forms a thin, crystalline phosphate coating that provides corrosion resistance, paint adhesion, and lubrication. It’s relatively inexpensive and environmentally friendly compared to other options. Powder coating, on the other hand, applies a thick, polymeric layer offering excellent protection against corrosion and wear, and a wide range of aesthetic options. It’s highly durable but requires more complex application equipment and higher temperatures. Anodizing is an electrochemical process specifically for aluminum and titanium, growing a thicker, oxide layer that is exceptionally hard and corrosion-resistant. It’s visually appealing and provides good wear resistance but it’s more expensive than phosphating. The best choice depends on the specific application requirements; for example, phosphating is ideal for parts needing good paint adhesion and corrosion protection in a cost-effective manner, while anodizing is preferred for high-wear applications on aluminum components needing superior corrosion resistance and aesthetic appeal. Powder coating is often chosen where impact resistance and a wide variety of colors and textures are prioritized.

Q 23. Describe your experience with different types of phosphating equipment.

My experience encompasses various phosphating equipment, including automated spray systems, immersion lines, and smaller batch units. I’ve worked with both continuous flow and batch processing systems. Automated spray systems offer excellent efficiency for high-volume production, providing consistent coating thickness and reducing labor costs. They often incorporate automated pre-treatment stages like cleaning and rinsing. Immersion lines are simpler and suitable for smaller parts or lower production volumes, but offer less control over coating uniformity. Smaller, batch-processing units are ideal for prototyping, testing new formulations, or handling specialized parts. I’m familiar with the operation and maintenance of each type, understanding their strengths and limitations, including factors like tank design, spray nozzle configuration, and automated control systems. For example, working with a problematic spray system, I identified the cause of uneven coating thickness as faulty spray nozzle alignment, leading to a complete system recalibration and improvement in coating consistency.

Q 24. Explain your understanding of phosphating process control using statistical process control (SPC).

Process control in phosphating is crucial to ensure consistent quality. Statistical Process Control (SPC) is a powerful tool for this, allowing us to monitor and manage variations throughout the process. We employ control charts – such as X-bar and R charts for coating weight and X-bar and S charts for coating thickness, to track key parameters like coating weight, thickness, and crystal size. These charts graphically display the data, highlighting any trends or shifts that indicate potential problems. By setting control limits based on historical data, we can identify when the process is out of control and take corrective actions promptly. For example, a sudden increase in coating weight could signal a change in solution concentration, prompting a recalibration of the chemical feed system. We also use capability analysis to assess the process’s ability to meet specifications and identify areas for improvement. By implementing SPC, we minimize defects and maintain product quality within defined tolerances.

Q 25. How do you ensure the consistent quality of phosphated parts across different batches?

Consistent phosphating across batches is achieved through a multi-pronged approach. Firstly, rigorous control of the phosphating solution is paramount. This involves regular chemical analysis to ensure the correct concentrations of all components are maintained. Automated replenishment systems help in this regard. Secondly, precise control of process parameters like temperature, immersion time, and agitation is essential. Automated systems with programmable logic controllers (PLCs) help maintain these parameters consistently. Thirdly, meticulous cleaning and preparation of the parts before phosphating are crucial to ensure a consistent surface for the coating to adhere to. This involves degreasing, cleaning, and activation steps. Finally, regular calibration and maintenance of the phosphating equipment is vital to prevent variation caused by malfunctioning components. We use standardized operating procedures (SOPs) and documented quality checks at every stage of the process to ensure batch-to-batch consistency and traceability.

Q 26. What is your experience with different types of phosphating solutions (e.g., spray, immersion)?

My experience includes both spray and immersion phosphating solutions. Spray phosphating offers better control over coating thickness and distribution, particularly for complex-shaped parts. It’s also faster and more efficient for high-volume production. However, it requires more sophisticated equipment and careful control of spray parameters like pressure and nozzle configuration. Immersion phosphating, on the other hand, is simpler and less expensive, suitable for smaller parts and lower production volumes. It offers uniform coating thickness for simple geometries but can lead to uneven coating on parts with intricate shapes. The choice between the two methods depends on factors like part geometry, production volume, and desired coating characteristics. For instance, I’ve found spray phosphating particularly effective for automotive parts with intricate details, achieving a highly uniform coating, while immersion phosphating was sufficient for simpler parts like fasteners in a smaller batch manufacturing process.

Q 27. Describe a challenging phosphating problem you solved and how you approached it.

One challenging problem I encountered involved inconsistent coating weight on a specific part, resulting in frequent rejections. Initial investigations focused on equipment malfunction and chemical analysis, but yielded no clear solution. We systematically investigated each process step, focusing on pre-treatment. We discovered that variations in the degreasing process were leaving inconsistent residues on the parts. By implementing a stricter control procedure for the degreasing stage, including more frequent monitoring of the degreasing solution and a more thorough rinsing process, we resolved the coating weight inconsistencies. The improvement was significant – a reduction in rejections from 20% to less than 2%. This experience highlighted the importance of systematic troubleshooting and attention to seemingly minor details in the overall phosphating process. We also implemented further improvements including better quality control checks to avoid a recurrence.

Q 28. What are your future goals in the field of phosphating?

My future goals involve deepening my expertise in environmentally friendly phosphating technologies, particularly exploring and implementing nanotechnology-enhanced phosphating solutions for improved corrosion resistance and reduced chemical consumption. I also aim to contribute to the development and optimization of advanced process control strategies, leveraging machine learning and predictive modeling to enhance process efficiency and consistency. I am eager to contribute to research and development efforts focused on creating more sustainable and efficient phosphating processes that minimize environmental impact while delivering superior performance.

Key Topics to Learn for Phosphating Interview

- Chemistry of Phosphating: Understand the chemical reactions involved in the phosphating process, including the role of acids, metal ions, and accelerators. Explore different types of phosphating solutions (zinc, manganese, iron).

- Process Parameters and Control: Learn how factors like temperature, time, and solution concentration affect the quality of the phosphate coating. Discuss methods for monitoring and controlling these parameters for consistent results.

- Surface Preparation: Master the importance of proper surface preparation before phosphating, including cleaning, degreasing, and pre-treatments. Understand how surface imperfections impact the final coating.

- Coating Properties and Applications: Explore the properties of phosphate coatings, such as corrosion resistance, paint adhesion, and lubricity. Discuss the various applications of phosphating across different industries (automotive, aerospace, etc.).

- Troubleshooting and Quality Control: Learn to identify and troubleshoot common problems encountered during the phosphating process, such as poor coating adhesion, uneven coating thickness, and contamination. Familiarize yourself with quality control methods used to ensure consistent coating quality.

- Environmental Considerations: Understand the environmental impact of phosphating and the regulations surrounding its use. Explore eco-friendly alternatives and sustainable practices within the phosphating process.

- Equipment and Processes: Gain familiarity with different types of phosphating equipment (spray, immersion, etc.) and their operational principles. Understand the different stages involved in a complete phosphating line.

Next Steps

Mastering phosphating opens doors to exciting career opportunities in manufacturing, automotive, and various other industries. A strong understanding of this process is highly valued by employers seeking skilled professionals. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, optimized for Applicant Tracking Systems. Examples of resumes tailored to the Phosphating industry are available to help guide you. Invest the time to build a strong resume—it’s your key to unlocking your career potential.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good