Cracking a skill-specific interview, like one for Photopolymer Plate Processing, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Photopolymer Plate Processing Interview

Q 1. Explain the process of photopolymer plate making from imaging to finishing.

Creating a photopolymer plate involves several key steps, from initial imaging to the final finishing touches. Think of it like baking a cake – each step is crucial for the final product’s quality.

- Imaging: The process begins with creating a digital image of the desired print. This image is then outputted to a filmsetter or directly to a platesetter, which exposes the photopolymer plate. This exposure utilizes UV light to activate the photopolymer. Imagine the UV light as the heat that cooks the cake batter.

- Exposure: The plate is precisely exposed to UV light through a negative or positive film (or directly from a digital platesetter). The intensity and duration of exposure are critical and depend on the plate type and the imaging system. It’s like determining the baking time for your cake – too little, and it’s undercooked; too much, and it’s burnt.

- Processing: After exposure, the plate undergoes processing in a solution designed to wash away the unexposed areas of the photopolymer. This reveals the image, creating a relief image on the plate’s surface. It’s like washing off the excess cake batter to reveal the final baked product.

- Post-Exposure Bake (if needed): Some plates require a post-exposure bake to further harden the exposed areas, ensuring durability and dimensional stability. This is analogous to letting your cake cool to ensure it maintains its structure.

- Finishing: The final steps involve cleaning the plate, potentially using a plate cleaner, and inspecting it for any defects. This guarantees optimal print quality and long-term usability. This is similar to icing and decorating your cake – enhancing its visual appeal and presentation.

The entire process demands precision and control at each stage to yield a high-quality plate ready for printing.

Q 2. Describe different types of photopolymer plates and their applications.

Photopolymer plates come in various types, each suited to specific applications. The choice depends on factors like print resolution, run length, and the printing press being used.

- Thermal Plates: These plates are exposed using heat instead of UV light. They are often used in applications requiring shorter runs or where image detail is less crucial. Think of them as a quicker and simpler baking method.

- UV Plates (conventional and CtP): These are the most common type, using UV light exposure. They offer excellent image resolution and are suitable for longer runs. They are like baking with more precision and time, yielding a finer end product.

- CTP (Computer-to-Plate) Plates: These plates eliminate the need for films, resulting in a faster, more efficient workflow. They are ideal for high-volume printing and where precision and speed are paramount. It’s the most technologically advanced method, representing a more efficient cake-baking process.

- Flexographic Plates: Specifically designed for flexographic printing, these plates are highly flexible and durable, enabling printing on a variety of substrates. These plates can handle the curves and uneven surfaces of flexible packaging.

Selecting the right plate type significantly impacts print quality, efficiency, and cost-effectiveness.

Q 3. How do you ensure proper plate exposure and processing times?

Precise exposure and processing times are vital for producing high-quality photopolymer plates. Incorrect timing can lead to under- or over-exposed areas, impacting the resulting print.

Manufacturers provide guidelines, specifying the exposure time and processing parameters for each plate type. These guidelines often consider factors like the intensity of the light source (UV or thermal), the plate’s sensitivity, and the desired image density. Think of these guidelines as a recipe for baking – following them precisely ensures a successful result.

Exposure is monitored using densitometers to measure the optical density of the exposed plate. Processing times are typically determined by the manufacturer’s recommendations or through testing to achieve the desired image quality. We use specialized timers and automated processing equipment to ensure consistency and accuracy.

Deviation from recommended times should be done cautiously and only after thorough testing, documenting the results to establish new optimal parameters for your specific setup.

Q 4. What are the common causes of plate defects and how do you troubleshoot them?

Several factors can cause defects in photopolymer plates, often related to improper handling, exposure, or processing. These defects can range from minor imperfections to significant print quality issues.

- Under-exposure: Results in weak image areas, leading to low ink density and faded prints. It’s like underbaking a cake.

- Over-exposure: Causes hard-to-wash-away areas, leading to image blocking and poor ink transfer. Think of a burnt cake.

- Dust contamination: Introduces pinholes or spots in the image. It’s like getting a stray crumb in your cake batter.

- Improper processing: Can lead to uneven development, poor image resolution, and inconsistent ink laydown. An example would be baking a cake unevenly or forgetting to add a crucial ingredient.

- Plate damage: Physical damage like scratches or dents can impact print quality. This would be like damaging the cake in handling.

Troubleshooting involves systematically investigating each step of the process. Microscopic inspection of the plate can pinpoint the source of the defect, allowing for corrective actions such as adjusting exposure parameters, cleaning equipment, or refining processing techniques.

Q 5. Explain the role of plate thickness and its impact on print quality.

Plate thickness is a critical factor influencing print quality, especially in flexographic printing. Thicker plates offer better durability and resist wear and tear during longer print runs. Think of a thicker cake slice – it’s more resistant to crumbling. However, thicker plates can sometimes lead to less sharp details and a slightly softer image reproduction due to the increased height of the relief. Thinner plates provide sharper details, but they are more prone to damage and are better suited for shorter runs. A thinner cake slice is easier to break but can offer a better mouthfeel and a finer presentation.

The optimal plate thickness is a balance between durability and print quality. It’s selected based on the printing process, the substrate being printed, and the desired print length. Therefore, choosing the appropriate thickness is akin to picking the right size cake slice for each occasion.

Q 6. Describe the different types of plate cleaners and their use.

Plate cleaners are essential for maintaining plate cleanliness and prolonging their lifespan. They remove ink residue, dust, and other debris that can interfere with subsequent prints. Think of it as washing your baking equipment.

- Solvent-based cleaners: These are effective in removing stubborn ink, but require proper ventilation due to the fumes. They are the harsher cleaning solutions and require careful handling.

- Water-based cleaners: Environmentally friendly and easier to handle, but may not be as effective in removing certain types of inks. These are milder, safer options.

- Specialized cleaners: Designed for specific ink types or plate materials, offering optimal cleaning without damaging the plate. These are highly targeted cleaning solutions.

The choice of cleaner depends on the ink system used, the plate material, and environmental considerations. Always follow the manufacturer’s instructions for safe and effective use.

Q 7. How do you maintain and store photopolymer plates to ensure longevity?

Proper storage and maintenance are crucial for extending the lifespan of photopolymer plates. Neglecting these aspects can lead to plate degradation and reduced print quality.

- Storage environment: Plates should be stored in a cool, dry, dark place, away from direct sunlight and extreme temperatures. Think of storing a cake in a cool, dark place, away from humidity.

- Protection from dust and debris: Plates should be covered to prevent dust accumulation. This is analogous to wrapping a cake to keep away pests and dust.

- Proper handling: Avoid scratching or damaging the plate surface. Handle plates with care, avoiding sharp objects that may cause scratches.

- Regular inspection: Periodically inspect plates for any defects or signs of degradation.

By following these guidelines, you can ensure that your photopolymer plates remain in optimal condition for an extended period, minimizing waste and maximizing productivity.

Q 8. What safety precautions are necessary when handling photopolymer plates and chemicals?

Safety is paramount when working with photopolymer plates and chemicals. Photopolymer plates themselves are generally inert, but the processing chemicals can be hazardous. Always wear appropriate personal protective equipment (PPE), including gloves, safety glasses, and a lab coat. Work in a well-ventilated area to minimize exposure to fumes. Many developers and cleaners contain isopropyl alcohol, which is flammable, so keep away from open flames and sparks. Proper handling and disposal of chemicals are crucial; refer to the Safety Data Sheets (SDS) for each chemical used to understand the specific risks and recommended precautions. For example, failure to wear gloves when handling developer can lead to skin irritation, while improper ventilation can result in headaches and dizziness from chemical fumes. Always follow the manufacturer’s instructions meticulously.

- Always wear appropriate PPE.

- Work in a well-ventilated area.

- Consult and follow SDS information.

- Properly dispose of chemicals.

Q 9. Explain the concept of plate resolution and its influence on print detail.

Plate resolution refers to the fineness of detail a photopolymer plate can reproduce. It’s measured in lines per inch (lpi) or dots per inch (dpi). Higher resolution plates (e.g., 2400 dpi) can reproduce finer details and smoother gradations, resulting in sharper images and text. Lower resolution plates (e.g., 1200 dpi) might show a more noticeable ‘screen’ pattern or struggle to reproduce fine lines, leading to less detailed prints. Think of it like comparing a high-resolution photograph to a pixelated image – the higher the resolution, the clearer and more detailed the image.

The influence on print detail is significant. A high-resolution plate allows for crisp, clean text, fine lines in illustrations, and smooth transitions in halftones, delivering a superior print quality. Low resolution might result in blurry text, jagged lines, and a visible screen pattern in the printed image, reducing overall print quality.

Q 10. How do you identify and correct issues like dot gain or dot loss?

Dot gain refers to an increase in the size of printed dots compared to the original image, resulting in darker, richer colors and less contrast. Dot loss is the opposite – a reduction in the size of printed dots, leading to lighter colors and a loss of detail. These issues often stem from factors in the printing process, such as incorrect exposure, improper processing, or printing press conditions.

Identifying the problem: Careful inspection of the printed output against a proof is key. Compare dot sizes and densities to identify areas of dot gain or loss. A densitometer can provide precise measurements of dot size and density.

Correcting the problem:

- Exposure adjustments: If dot gain is an issue, reduce the exposure time during plate imaging. If dot loss is the problem, increase the exposure time. This is often the primary adjustment made.

- Processing adjustments: Ensure the developer and other processing chemicals are used at the correct temperature and concentration, and that processing times are accurate. Incorrect processing parameters significantly affect final print quality.

- Press adjustments: Ink viscosity and pressure settings on the printing press also influence dot gain and loss. Consultation with the press operator to make fine-tune adjustments to these is necessary.

- RIP settings: If using a RIP, make sure that the dot gain compensation and other settings are properly calibrated to mitigate the issue.

Systematic testing and adjustments are crucial to fine-tune the process until satisfactory results are achieved.

Q 11. Describe the process of plate mounting and its impact on registration.

Plate mounting is the process of securely attaching the processed photopolymer plate to a mounting cylinder or sleeve on the printing press. This is crucial for accurate registration, which refers to the precise alignment of multiple colors or elements in a printed image. Misregistration results in blurry or misaligned colors, rendering the print unacceptable.

The method involves using a double-sided adhesive tape specifically designed for plate mounting. The tape should be applied evenly to both the plate and the cylinder, ensuring no air bubbles are trapped. The plate needs to be firmly and securely attached to prevent movement during printing. Improper mounting can cause the plate to shift, resulting in registration problems that progressively worsen during printing. Proper alignment is paramount and checked visually before and during press-run.

Impact on registration: Precise plate mounting ensures accurate and consistent color registration throughout the print run. Any inaccuracies in mounting directly translate to registration errors on the final printed product. Therefore, careful and accurate mounting procedures are paramount for achieving high-quality prints.

Q 12. Explain the role of pre-press proofing in photopolymer plate production.

Pre-press proofing plays a vital role in photopolymer plate production by providing a visual representation of the final print before the plates are made and the actual printing takes place. This allows for early detection and correction of potential issues such as color accuracy, sharpness, and registration problems.

Types of proofing include digital proofs (soft proofs) and hard proofs (physical proofs). Digital proofs use software to simulate the final print on screen. Hard proofs use a proofing device to produce a physical representation of the print, often using a similar printing process to the final print to accurately represent any potential defects.

By reviewing the proof, pre-press technicians can identify and correct errors in the design or imaging process before the plates are made, saving time, materials, and costs. This ensures the final printed product accurately reflects the intended design and avoids costly reprints or wasted materials.

Q 13. How do you manage waste generated during plate processing?

Waste management in photopolymer plate processing involves responsible handling and disposal of used chemicals, plates, and other materials. This is crucial for environmental protection and worker safety.

The process begins with careful segregation of waste materials. Used developer, fixer, and other chemicals should be collected in appropriately labeled containers. Spent plates, if not recyclable, must be disposed of according to local regulations. Many facilities have recycling programs for spent plates. Empty chemical containers must be rinsed thoroughly before disposal.

The aim is to minimize environmental impact through recycling, reuse, and responsible disposal procedures. Always follow local environmental regulations for waste disposal, and consider working with waste management companies specializing in graphic arts waste disposal to ensure responsible and safe handling.

Q 14. Describe different types of plate imaging systems.

Several plate imaging systems exist for creating images on photopolymer plates. The choice depends on factors such as resolution requirements, budget, and production volume.

- Computer-to-plate (CTP): This is the most common method, using lasers or LEDs to expose the plate directly from a digital file. CTP systems are efficient and offer high resolution. Sub-types include thermal CTP, which uses heat to expose the plate, and violet laser CTP, which offers high-resolution imaging.

- Direct-to-plate (DTP): Similar to CTP, but the plate is imaged directly on the press. This minimizes workflow steps but requires specialized press equipment.

- Analog platemaking: This older method uses film as an intermediary step. While less efficient, it may still be used in some specialized applications. This method is becoming obsolete as digital technologies have improved.

Each system has advantages and disadvantages, and the best choice depends on the specific needs of the printing operation. The trend is towards higher resolution and automation, making CTP systems the dominant technology in the market.

Q 15. What is the importance of maintaining consistent temperature and humidity during plate processing?

Maintaining consistent temperature and humidity during photopolymer plate processing is crucial for optimal results and consistent quality. Think of it like baking a cake – you need the right oven temperature and humidity to get the perfect rise and texture. Variations in temperature and humidity affect the chemical reactions within the photopolymer during exposure, development, and post-processing.

- Temperature fluctuations: Can lead to uneven exposure, resulting in variations in plate thickness and image density. Too high a temperature might accelerate the reaction, leading to premature hardening and potential defects. Too low a temperature might slow down the reaction, resulting in under-exposed areas.

- Humidity variations: Affect the absorption and evaporation of processing chemicals. High humidity can lead to slower drying times and potential streaking or blotchiness on the plate. Low humidity can cause the plate to dry too quickly, leading to cracking or other surface imperfections.

Therefore, a controlled environment, often achieved through climate-controlled rooms or specialized processing equipment, is essential for producing high-quality, consistent plates.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you perform a quality check on a processed photopolymer plate?

Quality checking a processed photopolymer plate involves a multi-step process, visually inspecting for defects and then checking the image’s resolution and print capabilities.

- Visual Inspection: Examine the plate for any physical defects such as scratches, pinholes, unevenness in the surface, or any residual unexposed or underdeveloped areas. Look for dust or debris that may have gotten embedded during the processing.

- Dot Gain/Density Measurement: Use a densitometer to measure the dot gain (the increase in dot size during printing) and overall density of different areas of the plate. This ensures proper ink transfer and color reproduction.

- Print Test: Print a test sheet using the processed plate to evaluate the image quality, color accuracy, sharpness, and dot formation. This confirms the plate’s printing capabilities.

- Microscopic Examination: In more advanced quality control, microscopic examination may reveal subtle defects not visible to the naked eye.

A systematic approach to quality checks ensures that only plates meeting stringent quality standards are used for printing, leading to better print consistency and reduced waste.

Q 17. Explain the significance of using appropriate plate processing chemicals.

Using the appropriate plate processing chemicals is paramount for optimal plate performance and longevity. The chemicals are specifically formulated to interact with the photopolymer material in a controlled manner, enabling accurate image reproduction and ensuring the plate’s durability.

- Developer: Dissolves the unexposed areas of the photopolymer, leaving behind a relief image. Using the wrong developer can lead to incomplete development, resulting in poor image quality or unexposed areas remaining on the plate.

- Washout solutions: Remove any residual developer and ensure a clean, clear image. Incorrect washout can lead to a buildup of developer, interfering with the printing process.

- Gumming solutions (optional): Some plates require gumming solution to increase the plate’s ink receptivity and reduce its water sensitivity.

Using manufacturer-recommended chemicals is vital. Substituting or using incompatible chemicals can severely damage the plate and lead to costly rework or even complete plate loss. Always refer to the specific instructions for the plate type you are using.

Q 18. Describe the impact of different exposure intensities on plate quality.

Exposure intensity plays a critical role in determining plate quality. It dictates how deeply the UV light penetrates the photopolymer, affecting the relief image’s depth and overall print quality.

- Under-exposure: Results in weak relief images, leading to poor ink transfer and faded prints. The image may appear thin and lack sharpness.

- Over-exposure: Creates overly deep relief images, increasing the risk of plate damage and potentially leading to undesirable ink buildup on the printing press. It can also cause the plate to become harder and more brittle, reducing its lifespan.

- Optimal exposure: Produces a well-defined relief image with sufficient depth for accurate ink transfer while ensuring the plate’s durability and longevity.

Precise control over exposure intensity is achieved through careful adjustment of the exposure time and light intensity of the imaging system, often calibrated using a densitometer or test strips. This ensures consistent plate quality across all jobs.

Q 19. How do you handle damaged or defective photopolymer plates?

Handling damaged or defective photopolymer plates requires careful consideration to prevent further damage and to mitigate waste.

- Assessment: Carefully examine the damaged plate to determine the extent and cause of the damage (scratches, pinholes, major tears).

- Repair (if possible): Minor scratches or pinholes can sometimes be repaired using specialized plate repair solutions. However, for significant damage, repair is generally not feasible.

- Disposal: Dispose of the defective plates according to local environmental regulations. These plates often contain chemicals and should not be thrown into regular trash.

- Prevention: Implementing robust handling procedures, using protective gloves, and maintaining a clean processing environment can significantly reduce the incidence of damage.

Damaged plates should never be used for printing, as they compromise print quality and may damage the printing press. Prevention is always better than cure in this case.

Q 20. What are the advantages and disadvantages of different photopolymer plate types?

Photopolymer plates come in various types, each with its own advantages and disadvantages. The choice depends on the specific printing application and budget considerations.

- Conventional Plates: Generally more affordable, these plates offer good quality but may have shorter lifespan than other types. Their processing is less forgiving to variations in exposure and development.

- Thermal Plates: These require less processing time and offer higher resolution, but they typically cost more and require specialized equipment for processing. They are very sensitive to heat.

- UV-curable Plates: Offer high durability, resistance to scratches and chemicals, and longer plate life. They often involve a more complex processing procedure and higher initial costs.

Factors like print run length, image complexity, and required print quality will determine which plate type is best. For example, thermal plates are well suited to short-run high-quality jobs, while UV-curable plates are favored for long-run, demanding applications.

Q 21. How do you calibrate your plate imaging system?

Calibrating a plate imaging system is crucial for ensuring consistent exposure and hence, consistent plate quality. Think of it like tuning a musical instrument – you need to ensure all the parts work together harmoniously to produce the desired sound. A miscalibrated system can result in significant variations in image density and may require re-exposure.

- Test Strips: Use calibrated test strips with known densities to test the system’s exposure output. Adjust the exposure settings until the test strip readings match the expected values.

- Densitometer: A densitometer measures the density of the exposed areas of the test strips, providing quantitative data for calibration adjustments.

- Software Calibration: Many plate imagers have built-in software for calibration, allowing for automated adjustments based on the test strip readings.

- Regular Checks: Calibrate the system regularly (e.g., daily or weekly) to ensure consistent performance. Environmental conditions can affect system output, necessitating periodic recalibration.

Proper calibration is an essential step in maintaining the plate imaging system’s accuracy and ensures consistent results in plate production, minimizing waste and maximizing efficiency.

Q 22. Explain the different types of plate mounting systems used in the printing industry.

Plate mounting systems are crucial for securing photopolymer plates to the printing press cylinder, ensuring accurate and consistent image transfer. Different systems cater to various press types and printing needs.

- Vacuum Systems: These are widely used and rely on suction to hold the plate firmly against the cylinder. They are relatively simple, cost-effective, and easy to operate. Think of it like a giant suction cup holding the plate in place. Proper plate flatness is crucial for optimal vacuum sealing.

- Mechanical Clamping Systems: These systems use clamps or other mechanical devices to secure the plate. They offer greater holding force than vacuum systems, making them suitable for high-speed printing or applications with demanding plate materials. They’re like robust clamps tightening onto the plate.

- Combination Systems: Some advanced systems combine both vacuum and mechanical clamping for superior holding power and stability, providing the best of both worlds. This combines the ease of use of vacuum systems with increased security for high-speed or challenging print jobs.

The choice of mounting system depends on factors like press type, printing speed, plate material, and budget. For instance, a high-speed web press might necessitate a robust mechanical clamping system, while a smaller sheetfed press might suffice with a vacuum system.

Q 23. Describe how different substrates affect photopolymer plate performance.

The substrate, or base material, upon which the photopolymer is coated significantly impacts plate performance. Different substrates offer varying levels of flexibility, dimensional stability, and chemical resistance. This directly influences print quality, longevity, and overall efficiency.

- Aluminum: This is the most common substrate due to its excellent dimensional stability, lightweight nature, and relatively low cost. However, its susceptibility to oxidation must be considered.

- Steel: Offers exceptional durability and dimensional stability, particularly advantageous in high-volume, long-run printing. However, it’s heavier and more expensive than aluminum.

- Plastic: Polymer-based substrates offer flexibility and lighter weight, but may not offer the same dimensional stability as metal substrates. They are frequently used in applications where flexibility is needed, such as flexible packaging printing.

For example, an aluminum substrate might be ideal for a standard commercial printing application, while a steel substrate might be preferred for high-volume packaging printing where wear and tear is more significant. The choice also needs to consider the plate processing chemicals’ compatibility with the substrate.

Q 24. What are the environmental considerations of photopolymer plate processing?

Environmental considerations are paramount in photopolymer plate processing, concerning both the production process and the disposal of used materials.

- Wastewater: Processing chemicals, particularly developers and cleaners, can contain hazardous substances requiring careful treatment before discharge. Proper wastewater treatment facilities are necessary to comply with environmental regulations.

- Air Emissions: Some processing steps may generate volatile organic compounds (VOCs). Proper ventilation and emission control systems are necessary to minimize their impact on air quality and worker safety.

- Waste Disposal: Used plates and processing materials must be disposed of responsibly, following local and national environmental regulations. Recycling programs are often available for certain materials.

- Energy Consumption: The processing equipment itself has an environmental impact through its energy consumption. Employing energy-efficient equipment and optimizing processing parameters can reduce the environmental footprint.

Adopting eco-friendly processing techniques, such as using water-based chemistries or investing in closed-loop systems for chemical recovery, is crucial for minimizing the environmental impact of photopolymer plate processing.

Q 25. How do you troubleshoot problems related to plate adhesion?

Plate adhesion problems, where the image area doesn’t adhere properly to the substrate, are a significant concern. Troubleshooting involves systematically checking various factors.

- Plate Preparation: Ensure the plate is properly cleaned and free from any residues before processing. Improper cleaning can leave behind contaminants that hinder adhesion.

- Exposure Parameters: Incorrect exposure time or intensity can result in poor image development and adhesion issues. Follow the manufacturer’s recommendations precisely and consistently.

- Processing Chemicals: Using outdated or contaminated processing chemicals can dramatically affect adhesion. Regularly check the condition and expiry dates of the chemicals.

- Substrate Condition: Damaged or improperly prepared substrates may also cause adhesion problems. Ensure that the substrate’s surface is clean, smooth and free from defects.

- Environmental Conditions: Temperature and humidity can influence the processing and adhesion process. Maintaining a controlled environment is critical for consistency and quality.

For example, if you notice patchy adhesion, first suspect exposure issues; if there’s widespread poor adhesion, the processing chemicals are more likely at fault. Always systematically check each factor to pinpoint the cause.

Q 26. Explain the concept of screening and its relationship to photopolymer plate processing.

Screening is the process of breaking down a continuous-tone image into a pattern of dots to allow for reproduction on a printing press. This dot pattern significantly impacts the quality of the final print. In photopolymer plate processing, the screening is embedded within the plate during the exposure process.

The size and shape of the dots, often referred to as the screen ruling (measured in lines per inch, lpi), influence the image’s resolution and tonal range. Higher lpi values create finer details and smoother gradations but require higher resolution image data and more precise platemaking.

The type of screening used (amplitude-modulated, frequency-modulated, or hybrid) affects the appearance of the printed image, impacting sharpness, moiré patterns, and overall visual quality.

Choosing the correct screen ruling, angle, and screening technology is crucial to achieving the desired print quality. A mismatched screen ruling or inappropriate technology can lead to undesirable artifacts in the final print, such as moiré patterns or a lack of fine detail.

Q 27. How do you ensure proper ink transfer from the photopolymer plate to the substrate?

Ensuring proper ink transfer is vital for achieving high-quality prints. This depends on several aspects of the photopolymer plate processing and printing setup:

- Plate Surface Properties: The plate surface must be hydrophilic (water-loving) in the non-image areas and oleophilic (ink-loving) in the image areas. Correct processing ensures proper balance between these properties.

- Ink Properties: The ink’s viscosity and tack need to be optimized for the plate and the printing substrate. Incorrect ink viscosity will lead to inconsistent ink transfer or poor image definition.

- Anilox Roller: If using flexographic printing, the anilox roller (which meters the ink onto the plate) requires proper cleaning and cell structure selection to ensure consistent and controlled ink transfer.

- Printing Pressure: The correct amount of pressure between the plate and the substrate is necessary for optimal ink transfer. Insufficient pressure can lead to light prints, while excessive pressure can cause smudging or poor image registration.

- Plate Cleaning: Regular cleaning and maintenance of the plate to remove ink and debris are essential for consistent ink transfer throughout the printing run.

Think of it as a handshake between the plate and the ink; if the conditions aren’t right, the handshake is weak, and the ink transfer is compromised.

Q 28. Describe the impact of plate wear on print quality and productivity.

Plate wear significantly affects both print quality and productivity. As a plate is used, the image areas gradually deteriorate, leading to several problems.

- Decreased Image Sharpness: Wear causes a gradual loss of detail, leading to blurry or less defined images, particularly noticeable in fine details and small text.

- Inconsistent Ink Transfer: Uneven wear can result in inconsistent ink coverage, leading to variations in print density and tonal range across the printed surface.

- Increased Waste: As the plate wears, more waste is generated due to increased print defects. This reduces printing efficiency.

- Dot Gain: Wear can cause increased dot gain (where dots enlarge), potentially leading to richer, darker, and less sharp images.

- Reduced Plate Life: Plate wear eventually requires replacement, leading to downtime and increased costs.

Regular inspection of the plate for signs of wear, employing appropriate plate cleaning procedures, and optimizing printing parameters all contribute to extending plate life and maintaining print quality. Ignoring plate wear quickly decreases productivity and increases waste.

Key Topics to Learn for Photopolymer Plate Processing Interview

- Plate Preparation and Imaging: Understanding the process of preparing photopolymer plates, including cleaning, pre-treatment, and exposure techniques. This includes familiarity with different plate types and their characteristics.

- Exposure and Development: Knowing the principles of UV exposure, the role of light intensity and exposure time, and mastering the development process to achieve optimal image quality. Practical experience with different developing solutions and techniques is crucial.

- Post-Exposure Processing: Understanding the importance of post-exposure processes like washing, baking, and finishing. This includes troubleshooting issues related to plate defects and optimizing these steps for consistent results.

- Quality Control and Troubleshooting: Familiarize yourself with quality control measures and common issues encountered in photopolymer plate processing. This includes identifying and resolving defects such as pinholes, scumming, and mottling.

- Safety and Environmental Considerations: Understanding the safety procedures and environmental regulations associated with handling chemicals and operating equipment. This is essential for a safe and responsible workflow.

- Different Printing Processes and Plate Selection: Understanding how different photopolymer plates are suited to specific printing techniques (e.g., offset, flexographic) and the factors influencing plate selection.

- Equipment Operation and Maintenance: Demonstrate understanding of the machinery involved in the process, including its operation, maintenance, and troubleshooting procedures.

Next Steps

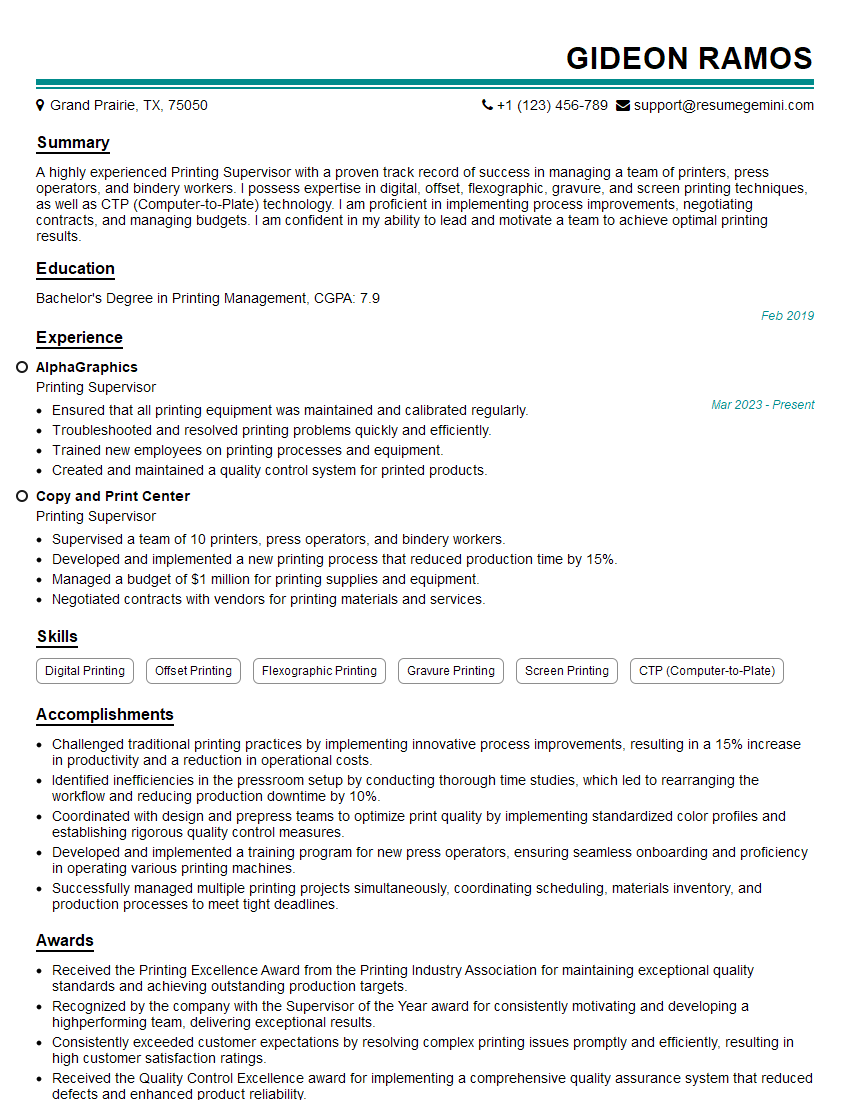

Mastering Photopolymer Plate Processing opens doors to exciting career opportunities in the printing and packaging industries. A strong understanding of this process is highly valued and demonstrates a commitment to precision and quality. To maximize your job prospects, creating an ATS-friendly resume is paramount. This ensures your application is effectively screened by applicant tracking systems. We highly recommend using ResumeGemini to build a professional and impactful resume. ResumeGemini provides tools and resources to craft a compelling narrative, highlighting your skills and experience. Examples of resumes tailored to Photopolymer Plate Processing are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good