The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Phototypesetting Equipment Operation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Phototypesetting Equipment Operation Interview

Q 1. Describe your experience with different types of phototypesetting equipment.

My experience with phototypesetting equipment spans several generations of technology. I’ve worked extensively with both analog and digital systems. Early in my career, I operated machines like the Linotype and Monotype machines, understanding the intricacies of hot metal typesetting, which laid the foundation for my understanding of the entire process. Later, I transitioned to phototypesetters, working with machines from companies like Compugraphic, Mergenthaler Linotype (especially their Linotron series), and Agfa. These digital phototypesetters used different technologies – some utilizing CRT (cathode ray tube) technology to expose film, others employing laser technology for higher resolution and speed. I’m also familiar with the operation and maintenance of various film processors and plate-makers, vital components in the workflow.

The experience with these diverse systems gives me a holistic understanding of the entire process, from typesetting to final output, and allows me to troubleshoot issues across different generations of equipment.

Q 2. Explain the process of creating a film negative from a digital file.

Creating a film negative from a digital file involves several crucial steps. First, the digital file, typically a PostScript or PDF file with high resolution (at least 1200 dpi for good quality), is sent to the phototypesetter. The phototypesetter’s software processes the file, interpreting the text and graphics data. The machine then uses either a laser or CRT to expose the photo-sensitive film. For laser-based systems, the laser scans the film precisely according to the data, creating the negative image. For CRT-based systems, the image is displayed on the CRT, and light shines through to expose the film.

The exposed film then moves to a film processor, which develops the negative, using chemicals to reveal the image. This process needs precise control of temperature and timing for optimal results. Finally, the developed negative is carefully checked for any defects before use in the printing process. Think of it like developing a photograph, but on a much more precise and controlled scale, producing a highly accurate, high-resolution representation of the digital file.

Q 3. How do you ensure accurate color reproduction in phototypesetting?

Accurate color reproduction in phototypesetting relies heavily on color calibration and proper file preparation. We begin by ensuring the digital file uses a standardized color profile, such as CMYK (Cyan, Magenta, Yellow, Key/Black), to match the capabilities of the printing process. The phototypesetter itself often needs color calibration, which involves using color targets to adjust the machine’s output to match a known standard. This is akin to calibrating your computer monitor for accurate colors.

Using a color densitometer – a device that measures the density of ink on a printed sample – is critical for precise color matching. Color correction software and experience in adjusting the various parameters within the phototypesetting software are also crucial for achieving optimal color reproduction. If I’m seeing a colour shift, I can adjust the exposure settings to compensate for any discrepancies.

Q 4. What are the common troubleshooting steps for a malfunctioning phototypesetter?

Troubleshooting a malfunctioning phototypesetter requires a systematic approach. First, check the obvious – is the machine properly powered on? Are there any error messages displayed? The error messages themselves are quite informative and often give clues to the specific problem. Then, I’d visually inspect the machine for any physical obstructions or signs of damage.

Next, I’d check the film supply and the processor chemicals; ensure that they’re fresh and at the correct levels. Low-quality or expired film and chemicals will directly impact the image quality. If the issue is with the image quality itself – poor resolution, banding, or incorrect colors – I would examine the digital input file for errors. Incorrect resolution, color profiles, or data corruption can all affect the output. Finally, if the problem persists, I’d consult the machine’s service manual and possibly contact a service technician.

Q 5. Describe your experience with different types of film and their applications.

My experience encompasses various film types, each with specific applications. Orthochromatic film was commonly used for its sensitivity to certain wavelengths of light, ideal for general text and line art reproduction. Panchromatic film, sensitive to the entire visible light spectrum, offered better tone reproduction for images with varying grayscale. Lithographic film, with high contrast and resolution, is especially suitable for producing sharp, crisp text and line art for printing purposes. Different films also come in varying thicknesses and bases, depending on the requirements of the printing process.

The choice of film depended on the project’s requirements: high-resolution text might need lithographic film, while images might demand panchromatic. This is similar to choosing the correct photographic paper or digital sensor for photography depending on the shot.

Q 6. How do you maintain the quality and precision of phototypesetting equipment?

Maintaining the quality and precision of phototypesetting equipment involves regular preventative maintenance. This includes cleaning the optical components, such as lenses and mirrors, with specialized cleaning materials to prevent dust and debris from affecting the image quality. The film processor also needs regular cleaning and chemical replenishment to ensure consistent results. Regular calibration checks, using test targets, are crucial for ensuring color accuracy and overall system consistency.

Also, regular preventative maintenance reduces downtime and prevents costly repairs later. It’s like maintaining a car – regular servicing prevents major breakdowns.

Q 7. Explain the process of preparing a file for phototypesetting, including file formats and resolutions.

Preparing a file for phototypesetting involves several critical steps. First, the file needs to be in a format compatible with the phototypesetter. PostScript (PS) and PDF files are most common due to their ability to handle complex layouts and high-resolution images. Resolution is another critical factor. Generally, 1200 dpi or higher is preferred for high-quality text and line art; images might need even higher resolutions. The chosen resolution must balance quality with file size and processing time. Low resolution will lead to poor image quality.

The file should be checked thoroughly for any errors before being sent to the phototypesetter. Issues like incorrect fonts, missing images, or data corruption can cause significant problems in the final output. This is analogous to reviewing a document for spelling errors before printing a final copy. Using a preflight check is a crucial step in this process to ensure everything is in order.

Q 8. What is the role of RIP software in phototypesetting?

RIP software, or Raster Image Processor, is the crucial link between the digital design file and the output device in phototypesetting. Think of it as a translator. It takes the PostScript or PDF file containing your text and images – which are vector-based, meaning made of lines and curves – and converts them into a raster image, a bitmap composed of individual pixels, ready for the platemaker or printer to interpret. This conversion is essential because most output devices, like platesetters, work with raster data.

For example, a complex logo designed in Adobe Illustrator (vector) needs to be rasterized to thousands of tiny dots to be accurately reproduced on a printing plate. The RIP handles this complex process, managing resolution, color spaces, and other crucial aspects to ensure accurate representation on the output device.

Different RIPs offer various features, like color management tools, screening techniques, and image enhancement options, allowing for fine-tuning of the output quality.

Q 9. How do you manage color profiles and ensure consistency across different output devices?

Color consistency across different output devices is paramount in phototypesetting. It’s achieved through careful color profile management. A color profile is essentially a characterization of a specific device’s color capabilities – its gamut (range of reproducible colors), and how it responds to specific color commands. Different devices have different gamuts, so printing a color on a proofer might look different on a platesetter.

My approach involves using a standardized color profile (like ISO Coated v2 (ECI)) as a reference point. I’ll embed this profile within the design file itself. The RIP software then uses this profile to interpret the color data and translate it to the specific profile of the target output device (platesetter, proofing system). This allows for more accurate color matching. Regular calibration of the output devices using colorimeters is crucial to maintain profile accuracy over time.

I also create color-managed proofing workflows, producing soft proofs (on-screen previews) that accurately predict the final output’s colors. This allows me to identify potential discrepancies before actually committing to expensive platemaking.

Q 10. Describe your experience with different types of platemaking processes.

My experience spans several platemaking processes, both analog and digital. I’ve worked extensively with Computer-to-Plate (CTP) systems using various technologies, including thermal plates (where a laser heats the plate to expose it), violet laser plates (using a violet laser for higher resolution), and UV laser plates (offering high sensitivity and resolution). I’m proficient in handling plate processing, including developing, washing, and proofing plates before mounting them on the printing press.

In the past, I also worked with analog methods, using film output and then making plates through traditional photographic processes. While less common today, understanding these methods provides a valuable perspective for troubleshooting and ensures appreciation for the advancements in CTP technology.

Each process presents unique challenges. Thermal plates, for example, are more prone to scratching, while violet and UV laser plates offer greater longevity and finer detail. The choice of plate type depends on various factors such as press type, desired resolution, and budget.

Q 11. How do you identify and resolve issues related to image sharpness and resolution in phototypesetting?

Image sharpness and resolution are critical aspects of phototypesetting. Issues can stem from several sources, such as low-resolution source images, incorrect RIP settings, or problems with the output device itself. Identifying the root cause requires systematic troubleshooting.

- Review Source Files: The first step is to check the resolution of the original images. Low-resolution images will always result in blurry output, regardless of the RIP settings.

- RIP Settings: The RIP’s settings, such as resolution, screening frequency, and halftoning method, significantly influence output quality. Experimenting with these settings, while maintaining consistency, helps to optimize sharpness. For example, increasing the resolution may improve sharpness but may increase file sizes and processing time.

- Output Device Calibration: A poorly calibrated platesetter or printer will produce blurry or uneven output. Regularly scheduled calibrations using a densitometer and colorimeter are essential.

- Examine the Output: Check for issues like moiré patterns (interference patterns caused by incorrect screening), banding (horizontal or vertical streaks), or graininess. These artifacts indicate problems that need further investigation.

Addressing these issues often involves adjusting the RIP settings, replacing faulty components in the output device, or re-working low-resolution source materials.

Q 12. What are the key differences between analog and digital phototypesetting?

The transition from analog to digital phototypesetting revolutionized the industry. Analog systems, prevalent before the 1980s, relied on photographic film as the intermediary between the typesetter’s input and the printing plate. This involved composing text and images using specialized typesetting machines, exposing film, and then using the film to create printing plates through chemical processes.

Digital phototypesetting, on the other hand, bypasses the film stage entirely. Digital designs are sent directly to a CTP device, which exposes the printing plate using lasers. This results in significant improvements in efficiency, precision, and image quality. Analog systems were limited in resolution and flexibility, while digital methods allow for higher resolutions, color precision, and greater design flexibility.

Think of it like the difference between writing a letter with a typewriter (analog) and using a word processor (digital). The digital method offers significantly more control, flexibility, and efficiency.

Q 13. Describe your experience with quality control procedures in phototypesetting.

Quality control is fundamental in phototypesetting. My approach involves a multi-stage process to ensure consistent output quality. It starts with a thorough review of the design files, checking for resolution, color accuracy, and the correct font settings. Soft proofing is an essential step, verifying the appearance of the output on a calibrated monitor before creating the actual plate.

After platemaking, I inspect the plates for any physical defects, such as scratches or dust particles. I then perform a test print or proof to verify color accuracy, registration (alignment of colors), and overall image quality. This often involves using a densitometer to measure density and a spectrophotometer for colorimetric analysis. Any discrepancies are investigated and rectified before proceeding with the full print run. Detailed records of all quality checks are maintained for traceability.

Finally, post-print inspection may be required, depending on the job’s criticality, to look for any unforeseen issues that might have occurred during the printing process.

Q 14. How do you handle large-format printing tasks using phototypesetting techniques?

Large-format printing using phototypesetting techniques requires careful planning and the use of specialized equipment. The resolution and the size of the print significantly influence the process. While traditional phototypesetting might not be ideal for extremely large formats due to the limitations of some output devices, modern high-resolution CTP devices can handle large-format requirements.

For very large prints, we may need to divide the image into smaller tiles (sections) that are printed separately and then assembled. Accurate registration between tiles is crucial to prevent visible seams. Precise color matching across tiles is equally vital. This process might involve using high-resolution output devices capable of handling large image files and special software to manage the tiling and assembly process. The choice of substrate (material the image is printed on) also becomes a major consideration for larger formats.

Q 15. Explain the concept of halftones and their significance in phototypesetting.

Halftones are an essential technique in phototypesetting used to reproduce continuous-tone images, like photographs, using only dots of varying sizes and densities. Think of it like a pointillist painting – from afar, you see a smooth image, but up close, it’s composed of tiny dots. In phototypesetting, these dots are created using a screen, a grid pattern imposed onto the image. Denser areas of dots represent darker tones, while sparser areas represent lighter tones. The significance lies in the ability to print photographs and other continuous-tone imagery using techniques designed for printing text, which traditionally only worked with solid areas of ink.

For example, a photograph of a sunset would have a dense cluster of dots in the darker areas (e.g., the shadows of trees) and a looser cluster in the lighter areas (e.g., the sky). The screen’s Line Screen Frequency (LSF), measured in lines per inch (lpi), influences the resolution and sharpness of the printed halftone; a higher LSF usually translates to finer detail and a sharper image, but requires a higher-quality printing process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you troubleshoot problems related to registration and alignment in phototypesetting?

Registration and alignment issues in phototypesetting, where different colors or elements don’t perfectly overlap, are frustrating but often solvable. My troubleshooting approach is systematic:

- Visual Inspection: I begin with a careful visual inspection of the output, noting the specific areas of misalignment and the magnitude of the problem. Is it a slight shift, or a significant offset?

- Check the Film: I examine the film negatives or positives to identify if the misalignment originates in the image preparation stage. This involves checking for any irregularities in the film itself, such as scratches, dust, or improper exposure.

- Examine the Plates: If the issue is with the printing plates, I check for proper alignment during plate mounting on the press. Improper mounting can lead to significant registration problems. I would check for any wear on the press components.

- Adjust Press Settings: Press settings like the gripper margins and side guides often need fine-tuning for optimal registration. Minor adjustments are sometimes all that’s needed. This requires familiarity with the specific printing press.

- Test Prints: I always run test prints after making any adjustments to confirm the correction.

For instance, if there’s a consistent color shift, it might indicate a problem with the printing press itself, such as worn rollers. If the misalignment is sporadic, it could point to a problem with the plate or film.

Q 17. What safety precautions do you follow when operating phototypesetting equipment?

Safety is paramount when operating phototypesetting equipment. My safety routine includes:

- Eye Protection: Always wearing safety glasses to protect against stray light and potential debris.

- Proper Ventilation: Ensuring adequate ventilation to avoid inhaling any chemicals used in processing film or plates.

- Chemical Handling: Following strict safety protocols when handling chemicals, including wearing appropriate gloves and using designated disposal containers. Many chemicals used in the darkroom environment are hazardous.

- Electrical Safety: Checking for damaged cords, avoiding water near equipment, and following all manufacturer instructions concerning electricity.

- Fire Safety: Being aware of the location of fire extinguishers and emergency exits.

- Machine Guarding: Using any provided safety guards on the machines themselves and following all manufacturer-provided instructions.

I always approach equipment operation with a cautious and meticulous mindset, understanding that even seemingly minor mistakes could have significant consequences.

Q 18. Describe your experience with different types of fonts and their application in phototypesetting.

My experience spans various font types, each with unique applications in phototypesetting. Serif fonts (like Times New Roman) are excellent for body text due to their readability, while sans-serif fonts (like Arial) are often used for headlines and display text as they are cleaner and more modern. Script fonts, like Edwardian Script ITC, provide a more elegant and artistic feel, best suited for invitations or certificates.

Beyond these basic categories, I’ve worked with numerous specialized fonts, including monospaced fonts for programming or technical documents (like Courier), and decorative fonts for creative projects, choosing them carefully based on the overall project aesthetic and intended audience. A high-end fashion magazine will require a different font selection than a technical manual.

Q 19. How do you handle special effects and design elements in phototypesetting?

Handling special effects and design elements involves utilizing the capabilities of the phototypesetting equipment and software. This could include:

- Reverse Type: Creating text that is white on a dark background.

- Drop Shadows: Adding a shadow effect behind the text for a three-dimensional appearance.

- Kerning and Tracking: Adjusting the spacing between individual letters (kerning) and the spacing between words (tracking) to improve readability and visual appeal.

- Color Separation: Preparing artwork for multicolor printing by separating the artwork into individual color plates (Cyan, Magenta, Yellow, Black).

- Image Manipulation: Adjusting contrast, brightness, and color balance of images to ensure they reproduce well in the final printed piece.

For example, I once used drop shadows and reverse type to create a dramatic headline for a poster, successfully emphasizing the message. Careful attention to detail is crucial to avoid overwhelming the design.

Q 20. Describe your experience with different types of paper and their suitability for phototypesetting.

Paper selection significantly impacts the quality of phototypesetting output. The choice depends on the desired final product and printing method. High-quality coated papers are excellent for sharp, vivid images and rich colors, making them ideal for high-end publications and brochures. Uncoated papers provide a more natural feel and are suitable for letterheads or documents where texture is desired.

Different paper weights and thicknesses (gsm – grams per square meter) influence the final product’s durability and feel. Heavier papers are more durable but can affect the printing press’s capability. I have experience working with a variety of paper types, from high-gloss coated stock to matte-finish card stock, always selecting the paper type based on factors such as project requirements, printing technique, and budget.

Q 21. How do you ensure the accurate scaling and positioning of text and images?

Accurate scaling and positioning are achieved through a combination of precise measurements and the use of specialized software. Before any printing, I carefully plan layouts using design software, ensuring accurate scaling of text and images based on the desired dimensions. This often involves using rulers, grids, and other visual aids to guarantee accurate placement.

Once the layout is confirmed, I utilize the phototypesetting software’s features for precise control over positioning. Many programs allow for inputting exact measurements in points or millimeters to ensure that text and images align perfectly according to the pre-determined design. Test prints are essential for final verification before committing to large print runs.

Q 22. How do you manage deadlines and prioritize tasks effectively in a fast-paced prepress environment?

In the fast-paced prepress world, effective deadline management is crucial. I approach this using a combination of techniques. Firstly, I meticulously review all incoming jobs, assessing their complexity, required turnaround time, and resource needs. This allows me to create a realistic schedule, breaking down large projects into smaller, manageable tasks. I leverage project management tools to visualize the workflow and track progress. Secondly, prioritization is key. I use a combination of urgency and importance to determine which tasks need immediate attention. The Eisenhower Matrix (urgent/important) helps categorize tasks, ensuring high-priority jobs get the necessary resources and attention. Finally, I proactively communicate potential delays or challenges to the team and clients, ensuring transparency and enabling collaborative problem-solving. For example, if a particularly complex job requiring specialized fonts arises, I will immediately communicate the need for additional time to avoid impacting other deadlines. This proactive communication prevents bottlenecks and maintains a smooth workflow.

Q 23. Describe your experience working with different types of prepress software.

My experience with prepress software is extensive. I’m proficient in Adobe Creative Suite (InDesign, Illustrator, Photoshop), which are essential for preparing files for phototypesetting. I’ve also worked extensively with RIP software (Raster Image Processor) like Harlequin and Creo. These are vital for translating digital files into instructions for the phototypesetter. Furthermore, I possess experience with preflighting software, which helps to identify and correct potential problems in files *before* they reach the phototypesetter, saving time and reducing waste. For example, using preflighting, I can catch issues like incorrect color spaces, missing fonts, or low-resolution images, ensuring that the output meets the highest quality standards. My experience also includes working with color management software, ensuring consistent color reproduction across different devices and outputs.

Q 24. How do you manage and maintain the inventory of consumables used in phototypesetting?

Maintaining a well-organized inventory of consumables is paramount for efficient phototypesetting. I use a combination of physical and digital inventory tracking systems. Physically, I maintain clearly labeled storage areas for different consumables like film, developer, fixer, and cleaning solutions, ensuring proper storage conditions are maintained to prevent degradation. Digitally, I use a spreadsheet or dedicated inventory management software to track stock levels, order dates, and expiry dates. This allows for proactive reordering of low-stock items, preventing production delays. I also implement a regular stocktaking process, comparing physical inventory with digital records, identifying any discrepancies and adjusting records accordingly. For instance, I establish minimum stock levels for each consumable and set up automatic alerts when those levels are reached. This helps optimize inventory levels, minimizing storage costs and preventing stockouts.

Q 25. Explain your understanding of color separation techniques in phototypesetting.

Color separation is a critical step in phototypesetting, especially for four-color (CMYK) printing. The process involves separating a full-color image into its four constituent colors: Cyan, Magenta, Yellow, and Black. Each color is then outputted onto a separate film. These films are then used to create printing plates, with each plate representing one of the CMYK colors. This is achieved using specialized software that analyzes the color information of the image and creates separate channels for each color. The precision of this separation is crucial for accurate color reproduction in the final print. Historically, this was done using sophisticated cameras and filters, but now digital methods using software are predominantly used. For instance, in a multi-color logo, the software meticulously separates the logo’s different color elements, ensuring each color’s precise representation on its film. This ensures that when the plates are printed together, the colors blend perfectly, creating the original image faithfully.

Q 26. How do you communicate effectively with designers, printers, and other team members?

Effective communication is fundamental in a prepress environment. I prioritize clear, concise communication with designers, printers, and team members. I use a variety of methods depending on the situation. For quick updates, I use instant messaging or email. For more complex discussions or problem-solving, I prefer face-to-face meetings or video conferencing. I focus on active listening, ensuring I understand the requirements and concerns of others. I also provide regular updates on project progress, highlighting any potential issues early on. For example, if a designer has submitted a file with formatting issues, I would immediately communicate those issues clearly and collaboratively discuss solutions to ensure the project proceeds smoothly. Clear and timely communication prevents misunderstandings and ensures everyone is aligned on the project goals.

Q 27. What are your strengths and weaknesses related to phototypesetting operations?

My strengths lie in my meticulous attention to detail, my problem-solving abilities, and my proficiency in various phototypesetting software and hardware. My ability to manage multiple projects simultaneously and meet tight deadlines is also a significant strength. However, my weakness is sometimes getting overly focused on detail, which can occasionally slow down the workflow slightly. To address this, I’ve adopted time-management techniques and prioritize tasks effectively to balance attention to detail with overall efficiency. I continuously strive to improve my workflow and time management skills through training and self-learning.

Q 28. Describe a time you had to solve a complex technical problem related to phototypesetting.

During a high-profile project, we encountered a critical issue with a phototypesetter’s output – the colors were consistently off. After ruling out issues with consumables and software settings, I suspected a problem with the phototypesetter’s calibration. My troubleshooting involved systematically checking each aspect of the calibration process, including the color density of the lasers and the accuracy of the color profiles. I found that the laser responsible for generating cyan was slightly underperforming. Through careful adjustment and recalibration, I successfully restored accurate color reproduction. This involved understanding the phototypesetter’s internal mechanisms and using diagnostic tools to identify and resolve the specific hardware malfunction. This experience underscored the importance of understanding the technology and having the ability to troubleshoot effectively under pressure.

Key Topics to Learn for Phototypesetting Equipment Operation Interview

- Understanding Phototypesetting Principles: Grasp the fundamental concepts behind phototypesetting, including image creation, digital fonts, and the role of light and film in the process. Be prepared to discuss the evolution of phototypesetting technologies.

- Equipment Operation and Maintenance: Demonstrate your practical experience with various phototypesetting machines. This includes detailed knowledge of their functionalities, maintenance procedures, troubleshooting common issues, and safety protocols.

- Pre-press Workflow and Procedures: Explain your understanding of the complete workflow, from receiving digital files to generating film negatives or plates ready for printing. Be ready to discuss file preparation, color correction, and quality control checks.

- Film Processing and Handling: Showcase your familiarity with darkroom techniques (if applicable), film processing chemicals, and proper handling procedures to ensure image quality and minimize waste.

- Troubleshooting and Problem-Solving: Highlight your ability to diagnose and resolve technical issues effectively. Prepare examples of problems you’ve encountered and how you successfully addressed them.

- Quality Control and Assurance: Discuss your experience with implementing quality control measures to ensure the consistent output of high-quality images and text. This includes understanding industry standards and best practices.

- Digital Asset Management: Discuss your understanding of organizing and managing digital files related to phototypesetting projects, ensuring efficient workflows and easy retrieval.

Next Steps

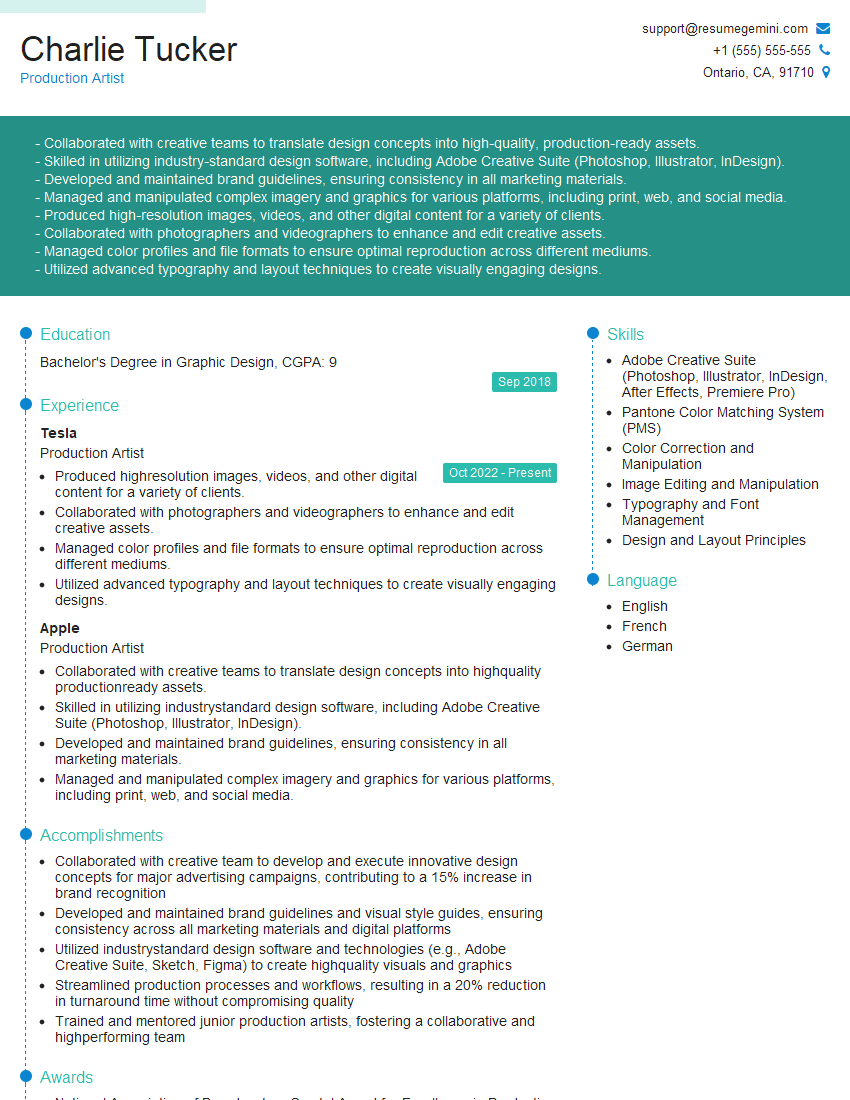

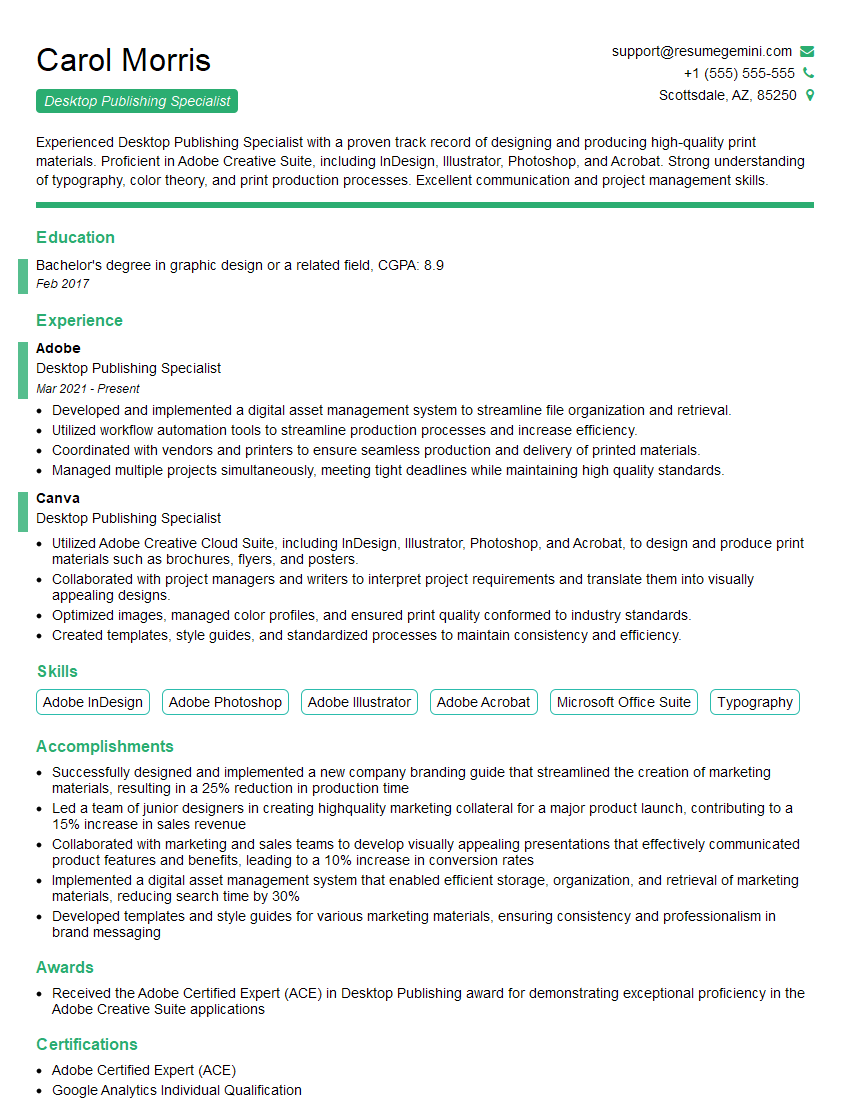

Mastering Phototypesetting Equipment Operation opens doors to exciting career opportunities in printing, publishing, and related fields. A strong understanding of these technologies is highly valued, making you a competitive candidate in a specialized market. To maximize your job prospects, create a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific requirements of the Phototypesetting Equipment Operation field. Examples of resumes tailored to this profession are available within ResumeGemini to provide further guidance.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good