The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Photovoltaic Module Installation interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Photovoltaic Module Installation Interview

Q 1. Explain the different types of photovoltaic modules.

Photovoltaic (PV) modules come in various types, primarily categorized by their cell technology and construction. The most common are:

- Crystalline Silicon Modules: These are the most prevalent type, further subdivided into monocrystalline and polycrystalline. Monocrystalline modules use single-crystal silicon wafers, resulting in a uniform dark color and higher efficiency (typically 18-22%). Polycrystalline modules utilize multiple silicon crystals, appearing blueish and generally having slightly lower efficiency (typically 15-17%).

- Thin-Film Modules: These modules use thin layers of photovoltaic material deposited on a substrate like glass or plastic. They are typically less efficient than crystalline silicon but can be more flexible and cost-effective in certain applications. Common thin-film technologies include amorphous silicon (a-Si), cadmium telluride (CdTe), and copper indium gallium selenide (CIGS).

- Perovskite Modules: This emerging technology offers potential for high efficiency and low manufacturing costs, but it’s still relatively new and less widely available commercially. They are known for their potential to achieve higher efficiencies than conventional silicon cells in the future.

The choice of module type depends on factors like budget, available space, aesthetic preferences, and the desired energy output. For example, a homeowner with limited roof space might opt for high-efficiency monocrystalline modules, while a large-scale solar farm might choose cost-effective polycrystalline or thin-film modules.

Q 2. Describe the process of installing a ground-mounted solar array.

Installing a ground-mounted solar array involves several key steps:

- Site Preparation: This includes surveying the land, clearing vegetation, and ensuring the ground is level. Proper drainage is crucial to avoid water accumulation around the array.

- Foundation Installation: Depending on the soil conditions and array size, this might involve concrete footings, ground screws, or driven piles to support the racking system. The foundation needs to withstand wind loads and other environmental stresses.

- Racking System Assembly: The racking system provides the structure for mounting the PV modules. This involves assembling the base, posts, rails, and other components according to the manufacturer’s instructions. Proper alignment and leveling are essential at this stage.

- Module Mounting: PV modules are carefully placed onto the racking system, ensuring secure fastening and proper spacing for ventilation. The modules are usually clamped or bolted to the rails.

- Wiring and Connections: Individual modules are wired together in series and parallel to form strings, which are then connected to the inverter. Careful attention to wire management and proper connection techniques is crucial to ensure optimal performance and safety.

- Grounding and Bonding: The entire system must be properly grounded to protect against electrical shocks and lightning strikes. This involves connecting the racking system, modules, and other components to an earth ground.

- Inverter Installation and Connection: The inverter converts the DC electricity produced by the modules into AC electricity for use in the building. It needs to be properly connected to the array and the building’s electrical system.

- Commissioning and Testing: Once the system is complete, it undergoes thorough testing to ensure proper functionality and safety. This includes checking voltage, current, and ground fault detection.

Throughout the process, adherence to local building codes and electrical regulations is mandatory.

Q 3. What safety precautions are crucial during PV module installation?

Safety is paramount during PV module installation. Crucial precautions include:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, steel-toed boots, and hard hats. Working at heights may require fall protection equipment like harnesses and safety lines.

- Electrical Safety: Treat all PV modules and wiring as potentially live, even when the system is disconnected. Use insulated tools and follow lockout/tagout procedures to prevent accidental energization.

- Working at Heights: If working on a roof or elevated structure, use appropriate fall protection equipment and follow safe work practices.

- Weather Conditions: Avoid working in extreme weather conditions, such as high winds, rain, snow, or lightning. Postpone installation if conditions are unsafe.

- Fire Safety: Be mindful of fire hazards, especially when working with electrical equipment. Have a fire extinguisher readily available.

- Lifting and Handling: PV modules can be heavy. Use appropriate lifting equipment and techniques to avoid injuries.

- First Aid and Emergency Response: Have a first aid kit readily available and know emergency contact information.

Regular safety briefings and training are essential to ensure all personnel understand and adhere to safety protocols.

Q 4. How do you ensure proper grounding and bonding in a PV system?

Proper grounding and bonding are vital for safety and performance in a PV system. Grounding connects the system to the earth, providing a path for fault currents to flow safely to the ground, preventing electrical shocks and reducing the risk of fire. Bonding connects all metal parts of the system together to ensure equal electrical potential and reduce the risk of voltage surges.

The process typically involves:

- Grounding Electrode: Installing a grounding electrode, such as a ground rod, in direct contact with the earth.

- Grounding Wire: Connecting the grounding electrode to the grounding points on the racking system, inverter, and other metal components using a dedicated grounding wire. This wire should have sufficient gauge and be properly protected.

- Bonding Wire: Connecting all metallic parts of the system, including the racking system, modules frames, and metal conduits, using bonding wires. This creates a continuous low-impedance path for fault currents.

- Ground Fault Circuit Interrupters (GFCIs): GFCIs are essential for safety. They detect ground faults and quickly interrupt the current flow, preventing electrical shocks.

Regular testing with a ground resistance meter is needed to ensure the grounding system’s effectiveness. The resistance should be low enough to provide a safe path for fault currents.

Q 5. Explain the importance of module orientation and tilt angle.

Module orientation and tilt angle significantly impact a PV system’s energy production. Optimizing these factors maximizes the amount of sunlight the modules receive throughout the day and year.

Orientation: Ideally, modules should be oriented towards the south in the Northern Hemisphere and towards the north in the Southern Hemisphere. This ensures they receive the most direct sunlight throughout the day. East-west orientation is also possible, but generally results in slightly lower energy production.

Tilt Angle: The optimal tilt angle depends on the latitude of the location and the time of year. Generally, setting the tilt angle equal to the latitude maximizes annual energy production. However, tracking systems can further enhance energy generation by automatically adjusting the module’s angle and orientation throughout the day to follow the sun’s path.

For example, a system installed at 34° latitude would ideally have a tilt angle of around 34°. However, compromises may be necessary due to site constraints or other factors. Careful analysis using solar modeling software can help determine the best orientation and tilt angle for a given location.

Q 6. Describe your experience with different racking systems.

I have extensive experience with various racking systems, including:

- Ground-Mount Systems: These include systems using concrete footings, ground screws, and driven piles. The choice depends on the soil conditions and the size of the array.

- Roof-Mount Systems: I’ve worked with various roof-mount systems, including rail systems, ballast systems, and integrated systems that are directly attached to the roof. The choice depends on the type of roof (tile, metal, flat) and its structural integrity.

- Pole-Mount Systems: These are suitable for areas where ground-mounting is not feasible and involve mounting the modules on poles. They often include adjustable tilt mechanisms for optimal solar energy harvesting.

My experience includes working with different manufacturers and designs, allowing me to select the most appropriate system for each project considering factors such as cost, durability, ease of installation, and aesthetics. Each system has unique installation procedures and safety requirements that I meticulously follow.

For example, in a recent project involving a metal roof, we used a rail-less roof mount system to minimize roof penetration and ensure a clean, aesthetically pleasing installation. In another project with a large, open field, we used a ground screw system for its cost-effectiveness and ease of installation in the specific soil conditions.

Q 7. How do you troubleshoot a faulty PV module?

Troubleshooting a faulty PV module involves a systematic approach:

- Visual Inspection: Start by visually inspecting the module for any obvious signs of damage, such as cracks, hotspots, or discoloration. Check for shading or debris affecting the module.

- Electrical Testing: Use a multimeter to measure the voltage and current output of the module. Compare the readings to the module’s specifications. Low voltage or current can indicate a problem.

- Infrared Thermography: Use an infrared camera to detect hotspots on the module’s surface. Hotspots can indicate cell damage or faulty connections.

- Bypass Diodes: Check the bypass diodes to ensure they are functioning correctly. If a cell is damaged, the bypass diode should shunt the current around the faulty cell to prevent the entire module from failing.

- Connection Checks: Ensure all connections within the module and the wiring to the inverter are secure and corrosion-free.

- Data Logging: Review data logger information to identify any patterns or anomalies in the module’s performance over time.

If a fault is identified, the appropriate action might be repair, replacement, or further investigation. Accurate diagnosis requires a solid understanding of PV module functionality and electrical systems.

For instance, a module showing significant lower output than others in the string and exhibiting a hotspot on infrared inspection would likely require replacement. A module with damaged wiring might be repaired if the damage is minor and safe to fix.

Q 8. What are the common causes of shading losses in a PV array?

Shading losses in a PV array occur when one or more modules are partially or completely obstructed from sunlight. Even a small shadow can significantly reduce the power output of the entire string, as modules operate at the level of the most shaded module in a series connection. This is due to the series nature of the connection, where the current is limited by the weakest link.

- Trees: Overhanging branches are a common culprit, especially during certain times of the day or year.

- Buildings: Adjacent structures can cast shadows, particularly in the morning or evening.

- Chimneys and other structures: Even smaller obstructions can create noticeable shading effects.

- Clouds: While not permanent, passing clouds can cause intermittent shading losses.

- Soil buildup or snow accumulation: This can partially obscure the panels.

Imagine a series of water pipes, each representing a PV module. If one pipe is partially blocked, the flow of water (electricity) through the entire system is reduced, not just in the blocked pipe. To mitigate shading, careful site analysis is crucial, ensuring optimal panel placement and orientation to minimize shadows throughout the day and year.

Q 9. Explain the process of connecting PV modules in series and parallel.

Connecting PV modules involves two main configurations: series and parallel. These configurations impact the voltage and current of the system.

Series Connection: Modules are connected end-to-end, adding their voltages together while maintaining the same current. Think of it like adding batteries in a flashlight – the voltage increases for brighter light, but the current stays the same.

Module 1 (+) --- Module 2 (+) --- Module 3 (+) --- ... --- Inverter (+)

Module 1 (-) --- Module 2 (-) --- Module 3 (-) --- ... --- Inverter (-)

Parallel Connection: Modules are connected with positive terminals to positive and negative to negative. This adds the currents while maintaining the same voltage. This is analogous to adding multiple water pipes side-by-side; the total flow increases but the pressure remains the same.

Module 1 (+) ---(+)--- Module 2 (+) ---(+)---...---Inverter (+)

Module 1 (-) ---(-)--- Module 2 (-) ---(-)---...---Inverter (-)

The optimal combination of series and parallel connections depends on the system voltage requirements of the inverter and the characteristics of the PV modules. Proper calculation ensures the system operates within its safe operating limits.

Q 10. How do you interpret PV module datasheets?

PV module datasheets are crucial for system design and troubleshooting. They contain critical parameters that dictate how the module will perform. Key parameters to look for include:

- Maximum Power (Pmax): The peak power output of the module under standard test conditions (STC).

- Open Circuit Voltage (Voc): The voltage when no current flows.

- Short Circuit Current (Isc): The current when the voltage is zero.

- Voltage at Maximum Power (Vmp): The voltage at which the module produces its maximum power.

- Current at Maximum Power (Imp): The current at which the module produces its maximum power.

- Temperature Coefficients: How much power, voltage, and current change with temperature variations.

- Tolerance: The acceptable deviation of Pmax from the stated value.

Understanding these parameters allows you to accurately estimate the system’s energy production, determine appropriate string sizing, and choose compatible inverters. It’s important to compare datasheets from different manufacturers to make informed purchasing decisions. I always verify that the datasheet matches the physical module markings.

Q 11. What are the NEC codes relevant to PV module installation?

The National Electrical Code (NEC) contains several articles relevant to PV module installation, focusing primarily on safety and proper system design. Key articles include:

- Article 690: This article covers the requirements for solar photovoltaic (PV) systems. It includes detailed specifications for grounding, wiring, overcurrent protection, and system interconnection.

- Article 705: This article outlines the requirements for the installation of utility interactive photovoltaic power systems.

- Article 110: Covers general safety requirements for electrical installations, including aspects relevant to solar PV work, such as working spaces and personal protective equipment.

Staying updated with the latest NEC revisions is critical for ensuring compliance and maintaining safety standards. I always consult the most recent NEC code versions before and during every installation to ensure compliance.

Q 12. Describe your experience with microinverters and string inverters.

I have extensive experience with both microinverters and string inverters, each with its own advantages and disadvantages.

Microinverters: These are small inverters connected to individual modules. They optimize the performance of each module independently, minimizing the impact of shading and maximizing energy production even with partially shaded arrays. However, the overall system cost is usually higher compared to string inverters due to the higher number of inverters.

String Inverters: These inverters convert the DC power from a string of modules into AC power. They’re generally more cost-effective but less efficient in partially shaded conditions. A single fault in a module string can impact the whole string.

The choice between microinverters and string inverters depends on factors such as budget, site conditions (shading), and system design goals. For example, in projects with significant shading, microinverters are preferred due to their module-level optimization capabilities, while larger systems with minimal shading often utilize string inverters for cost-effectiveness.

Q 13. How do you ensure proper wire management and cable routing?

Proper wire management and cable routing are crucial for safety, system performance, and aesthetics. It ensures that wiring does not pose tripping hazards, is protected from damage, and can easily be inspected.

My approach involves:

- Using proper conduits and raceways: This protects cables from physical damage and environmental factors.

- Employing cable ties and straps: For neat organization and to minimize slack.

- Labeling wires clearly: This aids in troubleshooting and future maintenance.

- Maintaining sufficient spacing between cables: To reduce the risk of overheating.

- Following manufacturer’s instructions: Regarding wire sizes, routing, and connection methods.

I always consider the long-term aspects of wire management – a well-organized system is easier to inspect, maintain, and expand in the future. A poorly managed cable system can increase the risk of electrical issues and future maintenance costs.

Q 14. What are the best practices for working at heights?

Working at heights during PV module installation is inherently risky. Safety is paramount. My approach to working at heights includes:

- Proper training and certification: I am certified in fall protection techniques and have up-to-date training.

- Using appropriate fall protection equipment: Including harnesses, anchor points, lanyards, and safety nets, always inspected before each use.

- Implementing a comprehensive fall protection plan: This plan specifies equipment, procedures, and emergency response protocols.

- Regular inspections of equipment and work areas: To identify and mitigate potential hazards.

- Following all relevant OSHA regulations: Including those specific to fall protection in the construction industry.

- Utilizing scaffolding or lifts when feasible: To minimize the need for prolonged work at heights.

I never compromise on safety. A fall from even a small height can be catastrophic. Prioritizing safety measures prevents injuries and ensures a successful project completion.

Q 15. Describe your experience with different types of PV module connectors.

PV module connectors are crucial for ensuring safe and efficient energy transfer within a photovoltaic system. Over my career, I’ve worked extensively with various types, each with its strengths and weaknesses. The most common are MC4 connectors, known for their robust design, ease of use, and weather resistance. These are often the industry standard due to their reliable locking mechanism and IP67 rating, meaning they’re protected from dust and water immersion. However, I’ve also used other types, including the less common, but equally important, Amphenol connectors, which are often favored in higher-power systems or specialized applications where higher current carrying capacity is required. Then there are the older style, less reliable connectors, that while sometimes encountered in older systems, we actively avoid in new installations due to their increased likelihood of corrosion and failure. Choosing the right connector is critical; it depends on factors like system voltage, current requirements, environmental conditions, and cost considerations. For example, in a high-altitude installation prone to UV degradation, selecting a connector with enhanced UV resistance is paramount. In coastal areas, corrosion-resistant connectors are essential. My experience allows me to select and troubleshoot these components effectively.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle damaged or defective PV modules?

Handling damaged or defective PV modules requires a systematic approach prioritizing safety and adherence to relevant regulations. First, a thorough visual inspection is crucial to identify the extent of damage, be it cracks, hotspots, delamination, or physical damage. Safety is paramount, so the module must be isolated from the rest of the system to prevent electrical hazards. This usually involves disconnecting the module from the string using the appropriate tools and safety precautions, like wearing insulated gloves. Following established safety procedures, we document the damage using photographs and a detailed description. Then, depending on the type and extent of damage, several options are available. Minor issues, like superficial scratches, might not significantly affect performance. However, if the damage compromises the structural integrity or electrical functionality, the module should be replaced. We always prioritize using modules from the same manufacturer and batch to ensure consistent performance across the array. Finally, proper disposal of damaged modules is crucial, complying with local recycling regulations and minimizing environmental impact.

Q 17. Explain the process of commissioning a PV system.

Commissioning a PV system is a critical process ensuring its safety and optimal performance. It involves a series of checks and tests following installation. First, a visual inspection of the entire system – from modules to inverters and cabling – verifies its physical integrity and adherence to design specifications. This helps identify any obvious faults or installation errors. Then, we perform electrical testing using specialized equipment to measure voltage, current, and power output at various points in the system. This involves checking for ground faults, insulation resistance, and proper functioning of the protection devices. We also verify the proper configuration of the inverter and its communication with the monitoring system. Data loggers are used to collect performance data over a period to ensure the system is meeting the expected output. Documentation is a crucial part of the process, meticulously recording all measurements, findings, and any corrective actions taken. A final inspection confirms the system operates efficiently, safely, and meets the design requirements. The commissioning report, including all test results and certifications, is then submitted to the client. This ensures everyone involved is informed about the system’s status and performance guarantee.

Q 18. What are the signs of a faulty inverter?

A faulty inverter can significantly impact a PV system’s performance. Several signs can indicate a problem. One common sign is a noticeable reduction in energy production, even under optimal sunlight conditions. This can often be detected by comparing the system’s output against its expected capacity. Another indicator is the presence of unusual noises, like buzzing, clicking, or humming from the inverter. Overheating of the inverter can also be a warning sign, often accompanied by a noticeable increase in the unit’s surface temperature. Error codes displayed on the inverter’s screen can pinpoint the nature of the malfunction, although understanding these codes requires specialized knowledge. Furthermore, the inverter might fail to start up, or experience frequent shutdowns. Sometimes, the inverter’s communication with the monitoring system may be interrupted, hindering data acquisition. Any of these signs warrants an immediate inspection and possible repair or replacement of the faulty inverter. Ignoring these warning signs can lead to further damage, system downtime, and potentially safety hazards.

Q 19. How do you perform a visual inspection of a PV array?

A visual inspection of a PV array is a crucial step in ensuring the system’s health and identifying potential issues. It should be performed systematically, covering all aspects of the array. I start by checking the physical condition of the modules, looking for any signs of damage, such as cracks, discoloration, delamination, or hotspots. Then I inspect the wiring and connections, ensuring that all cables are securely fastened and free of damage. The mounting system is also thoroughly checked for stability, ensuring there is no sign of movement, corrosion, or loosening. Any debris or shading on the modules is carefully noted as it can significantly affect performance. Additionally, I pay attention to the condition of the grounding system and look for any signs of corrosion or damage. The inspection also includes checking the condition of the junction boxes and other components. Detailed photos and written records document each observation. This visual inspection is the first line of defense against many potential issues, allowing for early detection and preventive maintenance before they become costly problems.

Q 20. What are your experience with different types of mounting hardware?

My experience encompasses a variety of mounting hardware, each suited for different roof types and ground conditions. I’ve worked with ground-mounted systems using various types of racking systems, from simple post-mount structures to complex trackers that optimize solar panel orientation throughout the day. For rooftop installations, I’ve utilized various types of roof mounts, including rail systems for tile roofs, flashing mounts for metal roofs, and integrated solutions for flat roofs. The choice of mounting hardware is determined by several factors including the roof type, the structural integrity of the building, local building codes, and the specific requirements of the PV modules. For example, a robust ground mount system is necessary for exposed areas prone to strong winds, while a lightweight roof mount is suitable for lighter-weight PV panels on residential buildings. Careful consideration must be given to corrosion resistance, particularly in coastal areas or environments with high humidity. Over the years, I’ve seen various levels of quality in different manufacturers’ mounting components, reinforcing the importance of choosing reputable suppliers that provide high-quality, long-lasting hardware.

Q 21. How do you calculate the energy output of a PV array?

Calculating the energy output of a PV array involves considering several key factors. The most fundamental is the rated power of individual PV modules. This is typically expressed in Watts (W) and is usually found on the module’s label. The total power of the array is simply the sum of the rated power of all modules in the array. However, this only gives the maximum possible output under ideal conditions. We must then account for several derating factors. These include the temperature coefficient of the modules, which affects their performance in higher temperatures, shading effects, and losses due to wiring, inverters, and other system components. These derating factors are usually expressed as percentages, and the overall array output is then adjusted accordingly. Furthermore, we use solar irradiance data specific to the location to determine the expected sunlight hours per day. This data, combined with the array’s rated power and derating factors, allows us to calculate the daily, monthly, and annual energy output. Software tools and online calculators are often used to aid in these complex calculations and provide a reliable estimate of the energy generated by the array. Accurate estimations are crucial in determining system sizing and evaluating the overall financial viability of a PV project.

Q 22. Describe your experience with troubleshooting electrical issues in PV systems.

Troubleshooting electrical issues in PV systems requires a systematic approach. I start by visually inspecting the entire system, looking for obvious problems like loose connections, damaged wiring, or shading issues. Then, I use diagnostic tools like multimeters and clamp meters to measure voltage, current, and resistance at various points in the system. This allows me to pinpoint the location of the fault. For example, if I find low voltage at the output of a specific string of panels, I know the problem lies within that string. I’ll then carefully examine each panel in that string, checking for shorts, open circuits, or bypass diodes that might be malfunctioning. I also look at the wiring connecting the panels and the combiner box for any damage. If the problem involves the inverter, I’ll examine its error codes and consult the manufacturer’s documentation to diagnose the issue. Once the problem is identified, I implement the necessary repairs or replacements, always ensuring safety procedures are followed, including proper lockout/tagout procedures.

A recent example involved a system with significantly reduced output. Initial visual inspection revealed nothing. Using a clamp meter, I identified a significant current drop at a specific combiner box. Further investigation revealed a corroded connection within the box, causing high resistance and power loss. After cleaning and tightening the connection, the system’s output returned to normal.

Q 23. How do you ensure compliance with building codes and permits?

Compliance with building codes and permits is paramount. Before starting any installation, I thoroughly review all relevant local, state, and national codes, including the National Electrical Code (NEC) and any specific requirements for renewable energy systems. I obtain all necessary permits from the appropriate authorities, submitting detailed plans and specifications that adhere to these codes. This includes providing detailed system design drawings, calculations demonstrating the system’s safety and compliance with building codes, and documentation of all equipment used. Throughout the installation process, I maintain meticulous records, including inspections and testing documentation, to ensure that the final installation conforms to all regulations. I also ensure the system meets all safety requirements, such as proper grounding and overcurrent protection. This meticulous attention to detail is crucial to guarantee the system operates safely and legally.

Q 24. Explain the process of cleaning and maintaining PV modules.

Cleaning and maintaining PV modules is crucial for optimal performance. Regular cleaning removes dust, dirt, bird droppings, and other debris that can significantly reduce energy output. I typically recommend cleaning the modules at least twice a year, more frequently in dusty or polluted environments. The cleaning process involves using soft water and a non-abrasive detergent, carefully applying the solution to the panels using a soft sponge or brush. It is important to avoid using harsh chemicals or abrasive materials that could damage the panels’ delicate surface. After cleaning, I rinse the panels thoroughly with clean water and allow them to air dry. Power should be switched off before cleaning for safety reasons. I also advise regular visual inspections for any signs of damage or degradation, such as cracks, discoloration, or hotspots. Early detection of these issues can help prevent larger problems.

Q 25. What are the environmental considerations for PV module installation?

Environmental considerations are a crucial aspect of PV module installation. Minimizing the environmental impact throughout the project lifecycle is vital. This includes careful site selection to avoid sensitive ecosystems or habitats. During installation, we strive to minimize land disturbance and protect existing vegetation. We use environmentally friendly materials and practices whenever possible and ensure proper disposal of waste generated during the installation. We also consider the long-term environmental benefits of the system, such as reduced carbon emissions from fossil fuel-based electricity generation. We often incorporate biodiversity considerations into the design, such as using pollinator-friendly vegetation around the array. Furthermore, we select modules with high efficiency to minimize the land area required for a given power output.

Q 26. Describe your experience working with different types of solar panels (monocrystalline, polycrystalline, thin-film).

I have extensive experience working with various solar panel technologies, including monocrystalline, polycrystalline, and thin-film. Monocrystalline panels are known for their high efficiency and aesthetic appeal, but they are generally more expensive. Polycrystalline panels offer a balance between efficiency and cost-effectiveness. Thin-film panels are typically less efficient but are flexible and can be integrated into building materials more easily. The choice of panel type depends on the project requirements, budget constraints, and available space. My experience includes installing large-scale systems using monocrystalline panels for maximum energy output and smaller residential systems using polycrystalline panels due to cost considerations. I am equally comfortable working with any technology, and I can adapt my installation techniques to suit the specific needs of each project.

Q 27. How familiar are you with using diagnostic tools for PV systems?

I am highly proficient in using a variety of diagnostic tools for PV systems. This includes multimeters for measuring voltage and current, clamp meters for measuring current without breaking the circuit, IR cameras for detecting hotspots, and specialized solar panel testers that can identify faulty cells or modules. I am also familiar with using software and data loggers to monitor system performance and identify any trends or anomalies. My experience includes using these tools to troubleshoot problems, verify system performance, and optimize energy output. The use of these instruments allows me to quickly and accurately identify problems, saving both time and money.

Q 28. What are your strengths and weaknesses in this field?

My strengths lie in my methodical approach to troubleshooting, my strong understanding of building codes and safety regulations, and my ability to work effectively both independently and as part of a team. I am also adept at communicating technical information to non-technical clients. One area where I am continually working to improve is my knowledge of the newest advancements in PV technology and smart grid integration. I actively participate in professional development activities and stay updated on industry best practices to address this.

Key Topics to Learn for Photovoltaic Module Installation Interview

- Understanding PV System Design: Learn the basics of system design, including array sizing, orientation, and tilt angle calculations. Understand the impact of these choices on system performance.

- Module Handling and Installation Techniques: Master safe handling procedures for photovoltaic modules. Practice installing modules on various roof types and ground mounts, including proper grounding and cable management.

- Electrical Connections and Wiring: Gain a thorough understanding of DC wiring techniques, including safe practices, proper connectors, and troubleshooting common wiring issues. Familiarize yourself with different types of combiner boxes and their functions.

- Racking Systems and Mounting Structures: Become proficient in identifying and installing various racking systems, considering factors like roof type, load capacity, and wind conditions. Understand the importance of structural integrity.

- Safety Regulations and Best Practices: Thoroughly review relevant safety regulations and best practices for working at heights, handling electrical systems, and adhering to OSHA standards. This is crucial for demonstrating your commitment to safety.

- Troubleshooting and Maintenance: Learn to identify and address common problems in PV module installations, such as faulty connections, shading issues, and module malfunctions. Understand preventative maintenance procedures.

- Inverters and System Integration: Develop a working knowledge of inverters, their functions, and their integration into the overall PV system. Understand the importance of proper inverter configuration and monitoring.

- Permitting and Codes Compliance: Familiarize yourself with local building codes and permitting requirements for PV installations. Understanding this demonstrates professionalism and legal compliance.

Next Steps

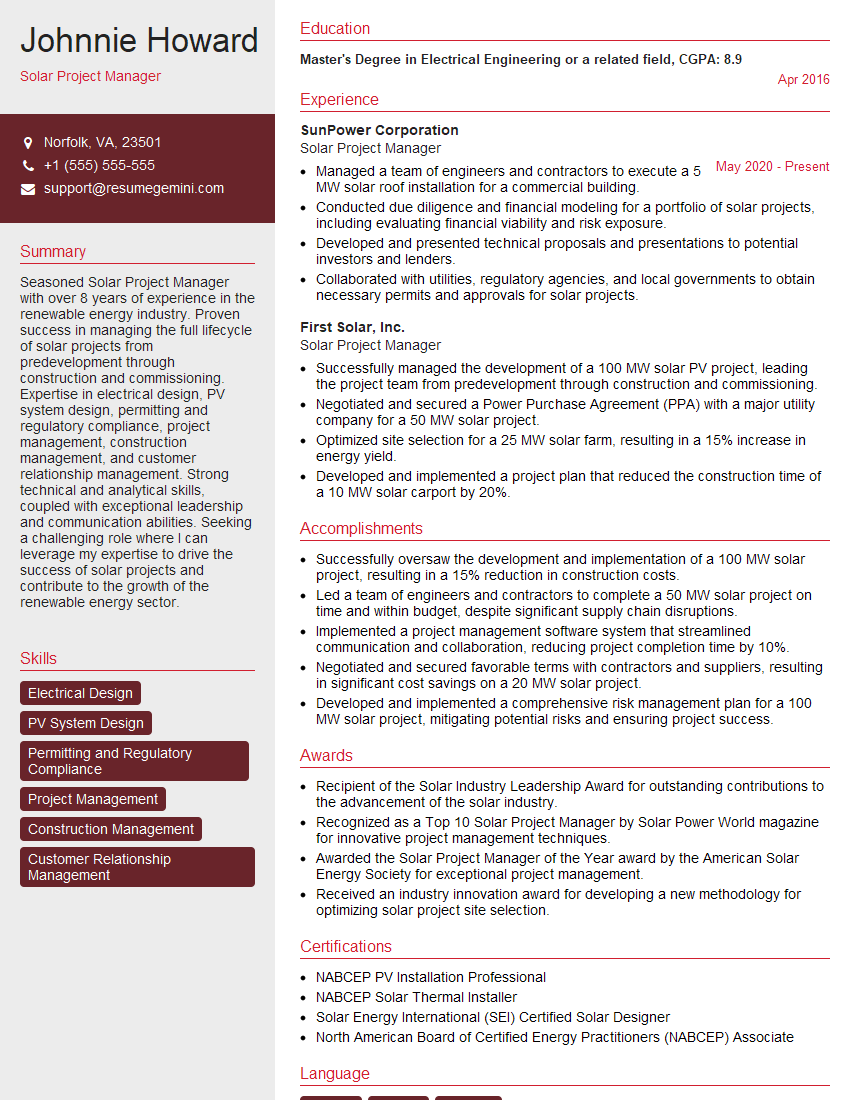

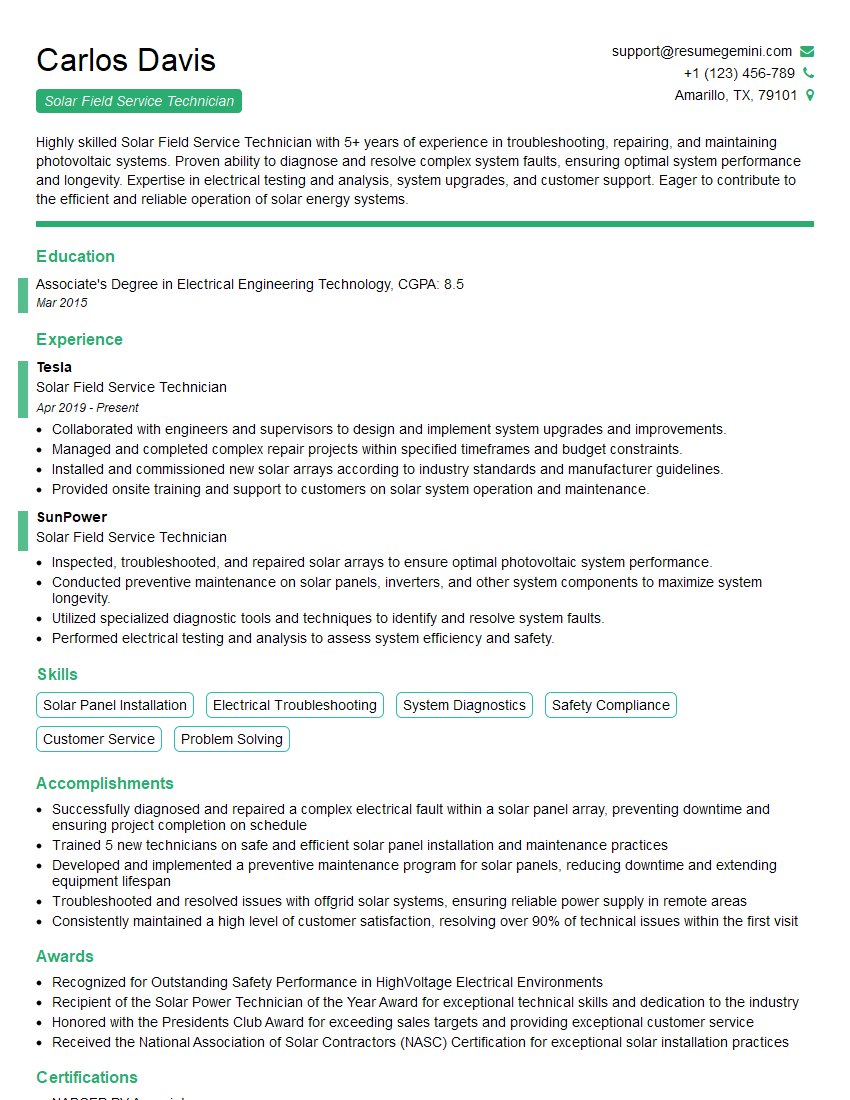

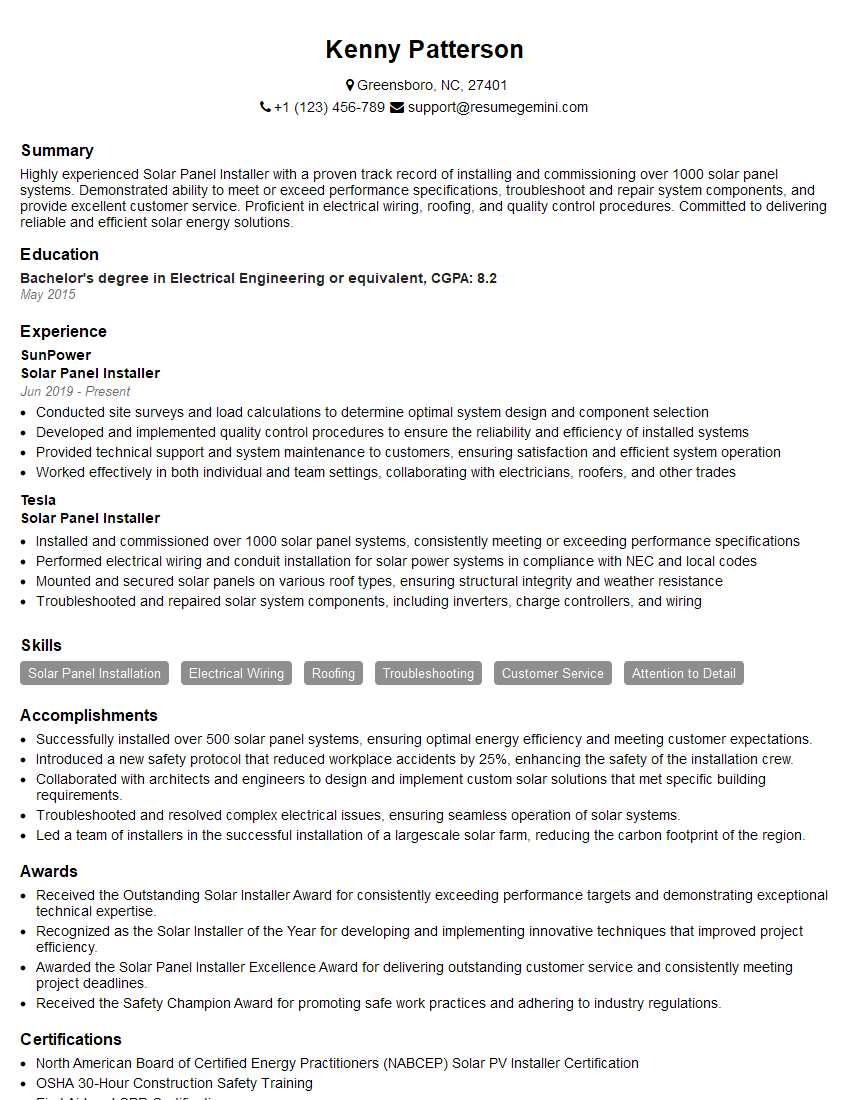

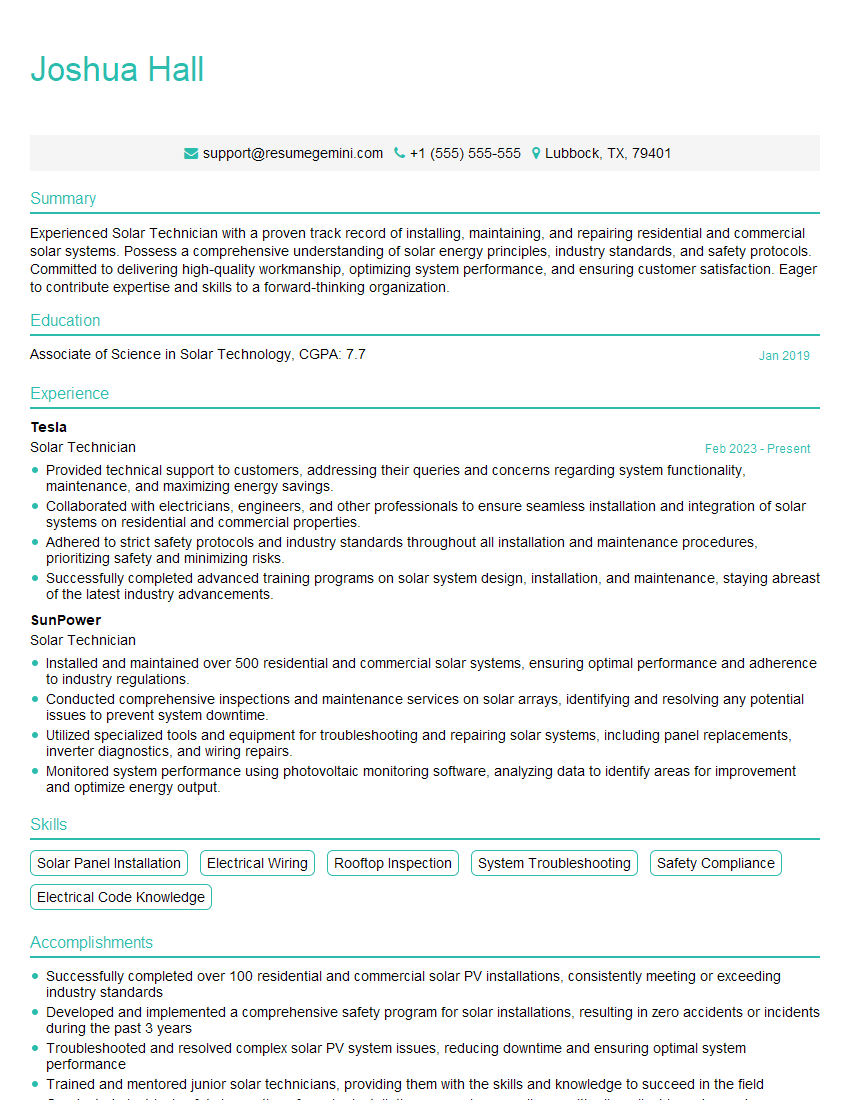

Mastering Photovoltaic Module Installation opens doors to a rewarding career in a rapidly growing green technology sector. Demand for skilled professionals is high, and your expertise will be invaluable in building a sustainable energy future. To significantly increase your chances of landing your dream job, a well-crafted, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume, highlighting your skills and experience in the best possible light. Examples of resumes tailored to Photovoltaic Module Installation are available, giving you a head-start in presenting yourself as the ideal candidate.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good