Preparation is the key to success in any interview. In this post, we’ll explore crucial Pipeline Operation and Maintenance interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Pipeline Operation and Maintenance Interview

Q 1. Explain the different types of pipeline corrosion and their mitigation strategies.

Pipeline corrosion is a significant concern, leading to leaks, failures, and environmental damage. There are several types, each requiring specific mitigation strategies.

- Internal Corrosion: This occurs on the inside of the pipe, often due to the transported fluid’s chemical properties (e.g., acidity, presence of H2S). Mitigation involves using corrosion inhibitors added to the product stream, selecting corrosion-resistant materials (like stainless steel or coated pipes), and implementing proper pipeline design to minimize stagnant areas.

- External Corrosion: This happens on the outside of the pipe, primarily caused by soil conditions (e.g., acidity, moisture, stray currents). Mitigation strategies include coating the pipe with protective materials (e.g., epoxy, polyethylene), using cathodic protection (applying an electric current to negate corrosion), and proper backfilling to create a well-drained environment around the pipe.

- Microbiologically Influenced Corrosion (MIC): Certain microorganisms in the soil or transported fluid can accelerate corrosion. Mitigation involves using biocides to control microbial growth, optimizing pipeline design to reduce stagnant areas that favor microbial activity, and selecting appropriate materials resistant to MIC.

- Stress Corrosion Cracking (SCC): This type results from a combination of tensile stress and a corrosive environment. Mitigation includes proper stress relief during pipe manufacturing, selecting stress-resistant materials, and controlling the environment to minimize aggressive chemicals.

For example, in a project involving high-pressure CO2 transport, we used internal corrosion inhibitors and selected a high-strength, corrosion-resistant steel to ensure pipeline integrity for decades.

Q 2. Describe the process of pipeline pigging and its purpose.

Pipeline pigging involves sending a specialized device called a ‘pig’ through the pipeline to perform various cleaning, inspection, or measurement tasks. Think of it like a cleaning crew moving through a pipe.

Purpose:

- Cleaning: Removing accumulated deposits like wax, hydrates, or scale that reduce pipeline capacity and efficiency.

- Inspection: Assessing the internal condition of the pipeline, detecting corrosion or defects using intelligent pigs equipped with sensors.

- Dehydration: Removing water or other liquids from the pipeline.

- Batch Separation: Separating different products within the pipeline to prevent mixing.

The process involves launching the pig at a designated point, driving it through the pipeline using the product flow or a dedicated pig launcher, and receiving the pig at another point called a pig receiver. Different pig types are used for various tasks. For instance, a ‘scraper pig’ removes solid deposits, while a ‘smart pig’ employs advanced sensors for internal pipeline assessment.

Q 3. What are the key components of a pipeline integrity management program?

A robust Pipeline Integrity Management (PIM) program is crucial for ensuring safe and reliable pipeline operations. Key components include:

- Risk Assessment: Identifying and prioritizing potential threats to pipeline integrity, considering factors like corrosion, third-party damage, and environmental conditions.

- Data Acquisition and Analysis: Collecting data from various sources (e.g., in-line inspection, pressure monitoring, leak detection systems) and analyzing it to identify potential problems.

- Inspection and Testing: Performing regular inspections (internal and external), non-destructive testing (NDT) methods like ultrasonic testing to detect flaws, and pressure testing to assess pipeline strength.

- Repair and Remediation: Implementing effective repair strategies, including excavation and replacement of damaged sections or in-situ repair techniques.

- Documentation and Reporting: Maintaining detailed records of all inspections, repairs, and risk assessments, and regularly reporting the status of the pipeline’s integrity to stakeholders.

- Emergency Response Plan: Having a clear plan in place for responding to pipeline leaks or other emergencies, including procedures for leak detection, shutdown, and emergency repair.

Implementing a PIM program is an iterative process. In one project, after a risk assessment identified a high-risk section due to soil conditions, we implemented cathodic protection and enhanced monitoring, significantly reducing the risk of corrosion.

Q 4. How do you identify and respond to a pipeline leak?

Pipeline leak identification and response requires a multi-faceted approach.

- Leak Detection: This involves utilizing various methods such as pressure monitoring systems, leak detection sensors, and regular pipeline patrols. Anomalous pressure drops or flow rate changes can indicate a leak.

- Leak Location: Once a leak is suspected, its location needs to be pinpointed using advanced techniques like pressure transient analysis or acoustic leak detection. This helps in focusing the repair efforts.

- Emergency Response: Immediate actions include isolating the affected section of the pipeline to prevent further product release, deploying emergency response teams (trained in hazmat handling if needed), and contacting emergency services and relevant regulatory bodies.

- Repair and Remediation: After securing the area and stopping the leak, the damaged section of the pipeline is repaired or replaced, often requiring excavation.

- Post-Incident Investigation: A thorough investigation is conducted to determine the root cause of the leak, and preventative measures are implemented to prevent similar incidents in the future. This includes updating the PIM program accordingly.

In one instance, we quickly identified a leak using a pressure monitoring system, implemented an emergency shutdown, and located the leak using acoustic detection, minimizing environmental impact.

Q 5. Explain the role of SCADA systems in pipeline operations.

Supervisory Control and Data Acquisition (SCADA) systems are the nervous system of modern pipeline operations, providing real-time monitoring and control of the entire pipeline network.

Role:

- Real-time Monitoring: SCADA systems constantly monitor key parameters like pressure, flow rate, temperature, and compressor performance at various points along the pipeline. This gives operators a comprehensive overview of the pipeline’s status.

- Alarm Management: The system triggers alarms if parameters deviate from predefined limits, alerting operators to potential issues like leaks, high pressure, or equipment malfunctions.

- Remote Control: SCADA systems allow operators to remotely control valves, pumps, and compressors, enabling efficient pipeline operation and rapid response to emergencies.

- Data Logging and Reporting: The system logs vast amounts of data, providing valuable information for performance analysis, optimization, and regulatory compliance.

Imagine SCADA as a central control room that monitors a vast network of sensors and actuators, providing operators with real-time insight and the power to take immediate action.

Q 6. What are the safety regulations and procedures you follow in pipeline maintenance?

Pipeline maintenance adheres to strict safety regulations and procedures, prioritizing personnel and environmental protection.

- Lockout/Tagout (LOTO): Before any maintenance activity, LOTO procedures are strictly followed to ensure equipment is de-energized and isolated, preventing accidental start-up.

- Permit-to-Work System: A formal permit system ensures that all necessary safety checks are completed and appropriate precautions taken before commencing work.

- Personal Protective Equipment (PPE): Appropriate PPE, including hard hats, safety glasses, protective clothing, and respiratory equipment, is mandatory for all personnel involved in pipeline maintenance.

- Confined Space Entry Procedures: Strict procedures are followed for entering confined spaces (like pipeline sections) to ensure adequate ventilation, gas detection, and emergency rescue plans are in place.

- Emergency Response Plan: A detailed emergency response plan is developed and regularly practiced to handle various scenarios, including leaks, fires, and injuries.

- Compliance with Regulations: Adherence to all relevant local, national, and international regulations governing pipeline safety and environmental protection.

For example, we always conduct thorough risk assessments before any maintenance work and use a documented permit-to-work system. In a recent project, we utilized advanced gas detection equipment and confined space entry protocols to ensure the safety of our maintenance team.

Q 7. Describe your experience with pipeline hydraulic calculations.

Pipeline hydraulic calculations are essential for designing, operating, and maintaining pipelines efficiently and safely. My experience includes using specialized software and applying fundamental principles of fluid mechanics.

Applications:

- Pressure Drop Calculation: Determining the pressure drop along the pipeline due to friction, elevation changes, and fittings is crucial for selecting appropriate pumps and compressors and ensuring adequate pressure at the destination.

- Flow Rate Calculations: Determining the flow rate given the pipeline’s dimensions, fluid properties, and pressure difference is key for capacity planning and operational optimization.

- Transient Analysis: This involves simulating how the pipeline’s pressure and flow rate respond to changes like pump start-up or valve operation, essential for avoiding water hammer and other transient phenomena.

- Pipeline Sizing: Determining the appropriate diameter of the pipeline based on flow rate, pressure requirements, and cost considerations is a critical part of pipeline design.

I’ve used software like OLGA and PIPEPHASE for complex calculations, incorporating factors such as pipe roughness, fluid viscosity, and temperature. In one project, I performed detailed hydraulic modeling to optimize the pump configuration for a new pipeline extension, resulting in significant energy savings.

Q 8. How do you perform pipeline pressure testing and what are the safety precautions?

Pipeline pressure testing is crucial for ensuring the integrity and safety of the pipeline system. It involves pressurizing the pipeline with a test medium (usually water or air) to a pressure exceeding the maximum operating pressure. This allows us to identify any weaknesses or leaks in the system before it goes into operation or after maintenance.

Safety precautions are paramount and include:

- Pre-test inspection: Thorough visual inspection of the pipeline for any obvious defects before pressurization.

- Isolation of the test section: Completely isolating the test section from the rest of the pipeline using appropriate valves and blind flanges.

- Pressure monitoring: Continuous monitoring of the pressure during the test using calibrated pressure gauges. Any significant pressure drop can indicate a leak.

- Emergency shutdown procedures: Establishing clear emergency shutdown procedures and ensuring all personnel are aware of them. This typically involves rapid depressurization valves and procedures.

- Personal protective equipment (PPE): Ensuring all personnel involved in the testing wear appropriate PPE, including safety glasses, hard hats, and safety boots. High-pressure water tests necessitate additional safety gear.

- Environmental considerations: Taking into account environmental concerns, especially during water testing, to prevent water pollution.

- Permitting and regulatory compliance: Adhering to all relevant permits and regulatory requirements for pressure testing.

For example, during a hydrostatic test, we’d carefully monitor the pressure build-up and observe for any sustained pressure drops, which would pinpoint a leak location needing immediate attention.

Q 9. What are the different types of pipeline materials and their applications?

Pipelines utilize various materials, each suited for specific applications. The choice depends on factors such as the transported fluid, pressure, temperature, soil conditions, and environmental regulations.

- Steel: The most common material due to its strength, durability, and weldability. Carbon steel is used widely, while higher-strength steel alloys are used for high-pressure applications or harsh environments.

- High-Density Polyethylene (HDPE): A popular choice for lower-pressure applications, particularly for gas distribution and water transmission. It offers excellent corrosion resistance and flexibility, making it suitable for challenging terrain.

- Fiber Reinforced Polymer (FRP): Used in specific applications where corrosion resistance is crucial, and lighter weight is advantageous. It’s often seen in corrosive environments and for smaller-diameter pipelines.

- Ductile Iron: Provides good strength and corrosion resistance, often used in municipal water systems and smaller pipelines.

- Concrete: Primarily for large-diameter pipelines carrying water under low pressure. Concrete pipelines are usually reinforced with steel.

For instance, a long-distance crude oil pipeline would typically use high-strength steel due to the high pressure and potential for corrosion, while a residential natural gas distribution line might opt for HDPE due to its lower operating pressures and ease of installation.

Q 10. Explain the process of pipeline hydrostatic testing.

Hydrostatic testing is a critical procedure for verifying pipeline integrity before commissioning or after repairs. It involves filling the pipeline with water and pressurizing it to a specified test pressure. The pressure is maintained for a period to check for leaks.

The process typically follows these steps:

- Pipeline preparation: Thorough cleaning and inspection of the pipeline section to be tested.

- Isolation: Isolating the test section using valves and blind flanges.

- Filling: Slowly filling the pipeline with water until the desired test pressure is reached.

- Pressure holding: Maintaining the test pressure for a specific duration, as defined by relevant codes and standards. This allows for sufficient time to detect slow leaks.

- Pressure monitoring: Continuously monitoring the pressure using calibrated gauges. Any significant drop indicates a leak.

- Leak detection: Identifying the location and cause of any leaks found during the test.

- Repair (if necessary): Repairing any leaks or defects before resuming the test or returning the pipeline to service.

- Documentation: Complete and accurate documentation of the entire process, including test pressures, duration, and any findings.

Think of it like a rigorous health check for the pipeline. We’re stressing the system to find any weaknesses before they can cause serious problems.

Q 11. How do you interpret pipeline inspection data (e.g., ILI data)?

Interpreting pipeline inspection data, such as In-Line Inspection (ILI) data, requires specialized knowledge and software. ILI data provides detailed information about the pipeline’s internal condition.

The interpretation process usually involves:

- Data acquisition: Gathering data from various ILI tools, such as magnetic flux leakage (MFL), ultrasonic testing (UT), or geometry tools.

- Data cleaning and preprocessing: Removing noise and inconsistencies from the raw data.

- Data analysis: Using specialized software to analyze the data and identify potential defects, such as corrosion, dents, or cracks.

- Defect classification: Classifying the identified defects based on their severity and type.

- Reporting: Generating comprehensive reports summarizing the inspection findings and recommendations for repairs or mitigation strategies.

For example, an MFL tool might identify a long region of significant metal loss, indicating significant corrosion. This would necessitate further investigation and possibly repair. The analysis uses thresholds and algorithms to differentiate between minor anomalies and critical defects. This requires deep understanding of the ILI tool’s capabilities and limitations.

Q 12. Describe your experience with pipeline cathodic protection systems.

Cathodic protection (CP) is crucial for preventing corrosion in pipelines, particularly steel pipelines. It involves applying a negative electrical potential to the pipeline, making it the cathode in an electrochemical cell. This prevents the pipeline from becoming an anode and corroding.

My experience includes:

- Design and implementation: Participating in the design, installation, and commissioning of CP systems. This includes specifying anode materials and placement, designing rectifier systems and monitoring systems.

- Testing and maintenance: Conducting regular tests to ensure the CP system is functioning effectively. This often involves measuring potential differences and current flow.

- Troubleshooting and repair: Diagnosing and fixing problems with existing CP systems. This could involve replacing anodes, repairing rectifier units, and addressing issues with grounding.

- Data analysis and reporting: Analyzing CP system performance data to identify trends and potential problems. This involves creating reports and making recommendations for improvements or maintenance.

For example, I’ve worked on projects where we had to address stray current interference affecting the CP system’s effectiveness. We investigated the source of the interference (usually nearby electrical systems), and implemented mitigation strategies to restore effective corrosion protection. Proper CP is vital, as corrosion can lead to catastrophic pipeline failure.

Q 13. What are the common causes of pipeline failures?

Pipeline failures can stem from various factors, often a combination of causes. These include:

- Corrosion: External corrosion from soil conditions and internal corrosion from the transported fluid. This is often the leading cause of pipeline failure.

- Stress: High operating pressures, thermal stresses, or external forces from soil movement or third-party damage.

- Material defects: Manufacturing defects, flaws in welds, or degradation of material properties over time.

- Third-party damage: Damage caused by excavation activities, construction, or other external forces.

- Natural disasters: Earthquakes, floods, landslides, and other natural events can damage pipelines.

- Scour and erosion: Erosion of soil around the pipeline, undermining its support and leading to stress and failure.

- Improper installation: Errors during the initial pipeline construction can create weak points leading to failure later.

A classic example is a pipeline failure due to external corrosion exacerbated by soil conditions. Acidic soils can accelerate corrosion, leading to thinning of the pipe wall, ultimately resulting in a leak or rupture. Understanding the various failure mechanisms allows for better preventative measures.

Q 14. How do you manage pipeline right-of-way issues?

Pipeline right-of-way (ROW) management involves addressing land use issues along the pipeline’s path. This is critical for maintaining pipeline integrity, ensuring public safety, and complying with regulations. Effective management involves:

- ROW acquisition and maintenance: Securing the necessary land rights for the pipeline and maintaining clear access for inspections and maintenance.

- Third-party coordination: Working with landowners, utility companies, and other entities operating within the ROW to prevent conflicts and damage.

- Public awareness and outreach: Educating landowners and the public about the pipeline and safety procedures.

- Enforcement of ROW regulations: Taking action to address unauthorized activities or encroachments within the ROW.

- Environmental protection: Minimizing the environmental impact of pipeline operations within the ROW.

- Emergency response planning: Developing and implementing plans to handle emergencies within the ROW.

For example, we might work with farmers to schedule pipeline inspections during periods of low agricultural activity to minimize disruption. We also regularly monitor the ROW to identify and address encroachment issues, protecting both the pipeline and the environment.

Q 15. Explain the process of pipeline emergency shutdown.

A pipeline emergency shutdown is a critical procedure designed to rapidly halt the flow of product through a pipeline in response to a threat such as a leak, fire, or equipment malfunction. It’s a safety-first measure intended to prevent environmental damage, injury, and property loss. The process is typically initiated through a series of automated and manual actions.

The process usually follows these steps:

- Detection: A leak detection system (LDS) such as pressure or flow sensors, or even a manual observation, triggers an alert.

- Alarm: Automated systems sound alarms at the control center and potentially at field locations.

- Verification: Operators verify the alarm by checking multiple data points and potentially conducting visual inspections if safe to do so.

- Isolation: Automated shutdown valves (ASVs) begin to close, isolating the affected section of the pipeline. These valves are often remotely controlled from a central control room, providing a quick response even in hazardous areas.

- Manual Confirmation: Operators confirm that the pipeline segment is successfully isolated. This might include checking pressure readings and conducting further investigation.

- Emergency Response: The emergency response team is activated, following pre-determined procedures, to deal with the incident, including securing the area, assessing the damage, and initiating repair procedures.

- Post-Incident Analysis: A thorough investigation follows the incident to identify the root cause, implement corrective actions to prevent recurrence, and review the effectiveness of the emergency shutdown system.

For example, imagine a significant pressure drop detected in a crude oil pipeline. The LDS triggers an immediate alarm. The control room operator verifies the drop isn’t due to normal operational fluctuations. ASVs isolate the section, and the emergency response team arrives to investigate and address the leak.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key performance indicators (KPIs) for pipeline operations?

Key Performance Indicators (KPIs) for pipeline operations are crucial for monitoring efficiency, safety, and regulatory compliance. They help identify areas for improvement and ensure the pipeline system operates optimally. KPIs can be grouped into several categories:

- Safety: Incident rates (e.g., leaks, fires, spills), number of safety violations, employee safety training completion rates, and emergency response times.

- Operational Efficiency: Throughput (volume of product transported), operating costs per barrel/unit, equipment uptime, and on-time delivery rates.

- Maintenance Efficiency: Maintenance cost per unit length, mean time between failures (MTBF), mean time to repair (MTTR), and planned vs. unplanned maintenance ratio.

- Environmental Compliance: Spill volume, frequency of environmental incidents, emissions levels, and compliance audit results.

- Regulatory Compliance: Number of regulatory violations, successful completion of inspections and audits.

For instance, tracking the MTBF of a specific pump helps determine when predictive maintenance is needed, preventing costly unscheduled downtime. Similarly, monitoring the spill volume demonstrates environmental responsibility and reduces regulatory risks.

Q 17. How do you ensure compliance with environmental regulations in pipeline operations?

Ensuring compliance with environmental regulations in pipeline operations demands a proactive and multi-faceted approach. It requires meticulous planning, robust procedures, and ongoing monitoring. Key aspects include:

- Spill Prevention, Control, and Countermeasure (SPCC) Plans: These plans outline procedures to prevent spills, contain them if they occur, and clean them up effectively. Regular drills and training maintain preparedness.

- Leak Detection Systems (LDS): Real-time monitoring systems constantly check pipeline integrity and rapidly alert operators to potential leaks, enabling swift responses. Regular calibration and testing are vital.

- Emergency Response Planning: Well-defined plans, including contact lists, emergency response teams, and procedures, are critical for effective handling of any spills or environmental incidents.

- Regular Inspections and Maintenance: Routine inspections and preventive maintenance minimize the risk of leaks and equipment failures. This includes internal and external pipeline assessments, and regular testing of safety equipment.

- Environmental Monitoring: Regular sampling of soil and water around the pipeline helps monitor for any signs of contamination and ensures compliance with emission limits.

- Regulatory Reporting: Accurate and timely reporting of any incidents, spills, or emissions is mandatory to comply with regulatory requirements.

For example, a company might implement a sophisticated LDS complemented by regular aerial patrols for visual inspections to detect and address even the smallest leaks promptly.

Q 18. Describe your experience with pipeline risk assessment and management.

Pipeline risk assessment and management is a systematic process to identify, analyze, and mitigate potential hazards. It involves a combination of qualitative and quantitative techniques to prioritize risks and develop control measures.

My experience includes using various methodologies, such as:

- Hazard and Operability (HAZOP) studies: Systematic examination of the pipeline system to identify potential hazards and operational issues.

- Failure Mode and Effects Analysis (FMEA): A structured approach to identify potential failures, their effects, and the severity of those effects.

- What-if analysis: Brainstorming potential scenarios and evaluating their consequences.

- Quantitative Risk Assessment: Using probabilistic models to estimate the likelihood and consequences of various incidents.

Risk mitigation involves implementing control measures, ranging from engineering controls (e.g., improved materials, enhanced leak detection systems) to administrative controls (e.g., improved operating procedures, enhanced training programs) and personal protective equipment (PPE).

For instance, during a HAZOP study on a newly constructed pipeline, we identified a potential risk of ground subsidence. By implementing a comprehensive ground monitoring system, and adjusting the pipeline’s route to avoid the high-risk area, we successfully mitigated this risk before operation.

Q 19. How do you handle pipeline maintenance scheduling and planning?

Pipeline maintenance scheduling and planning is crucial for ensuring safety, reliability, and cost-effectiveness. It involves a combination of preventive, predictive, and corrective maintenance strategies.

My approach generally includes:

- Developing a comprehensive maintenance plan: This considers the pipeline’s age, operating conditions, material specifications, and regulatory requirements.

- Implementing a Computerized Maintenance Management System (CMMS): This software allows for tracking maintenance activities, managing work orders, and scheduling tasks based on equipment condition and operational needs.

- Utilizing predictive maintenance techniques: This involves employing condition monitoring technologies, such as vibration analysis and ultrasonic testing, to identify potential equipment failures before they occur.

- Optimizing maintenance schedules: Balancing the cost of maintenance with the risk of equipment failure to determine the optimal frequency of inspections and repairs.

- Managing resources effectively: This includes coordinating maintenance crews, procuring necessary parts and materials, and ensuring efficient execution of the maintenance plan.

For example, using a CMMS, we scheduled regular inspections of critical pipeline sections based on their age and historical failure rates. This allowed us to allocate resources effectively and minimize disruptions to operations.

Q 20. What are your experiences with different pipeline repair techniques?

Pipeline repair techniques vary depending on the type of damage, the pipeline’s material, and the operating conditions. My experience encompasses several methods:

- Clamp repairs: Used for relatively small cracks or corrosion pits. Clamps mechanically reinforce the weakened section.

- Weld repairs: More extensive repairs for significant damage, requiring skilled welders and strict quality control procedures.

- Pipe replacement: The most comprehensive method involving replacing a damaged section of pipe. This demands careful excavation, welding, and testing.

- Sleeving: A non-destructive technique where a sleeve is installed around the damaged section to restore integrity.

- In-line inspection (ILI): Used to assess the condition of the pipeline without excavation, identifying areas needing repair.

The choice of repair technique depends on a risk assessment that weighs the cost, the safety implications, and the required downtime against the severity of the damage. For example, a small corrosion pit might be repaired with a clamp, while a large crack would necessitate pipe replacement.

Q 21. Describe your experience with pipeline data acquisition and analysis.

Pipeline data acquisition and analysis is crucial for optimizing operations, ensuring safety, and complying with regulations. It involves gathering data from various sources and using it to improve decision-making.

My experience includes working with:

- SCADA (Supervisory Control and Data Acquisition) systems: These systems monitor and control the pipeline’s operation, collecting data on pressure, flow, temperature, and other parameters.

- Leak detection systems (LDS): These systems provide real-time data on pipeline integrity and help identify potential leaks.

- In-line inspection (ILI) data: Provides detailed information on the internal condition of the pipeline.

- Geographic Information Systems (GIS): Used to visualize pipeline location and integrate various data sources, aiding in spatial analysis.

Data analysis involves using statistical methods, data visualization techniques, and predictive modeling to extract meaningful insights. For example, we used SCADA data to identify recurring pressure fluctuations in a specific pipeline segment. Further analysis revealed a valve malfunction, allowing for timely preventive maintenance, avoiding potential future issues.

Q 22. How do you ensure the accuracy and reliability of pipeline data?

Ensuring accurate and reliable pipeline data is paramount for safe and efficient operations. We achieve this through a multi-layered approach combining robust data acquisition, rigorous validation, and continuous monitoring.

Data Acquisition: We utilize a variety of sensors and instrumentation, including flow meters, pressure gauges, temperature sensors, and leak detection systems. These are strategically placed along the pipeline to capture comprehensive data. Regular calibration and maintenance of these instruments are crucial. For example, we might use smart pigging technology to inspect the pipeline’s internal condition, providing real-time data on corrosion, defects, and geometry.

Data Validation: Raw data undergoes rigorous validation checks. This involves cross-referencing data from multiple sources, detecting and correcting anomalies, and applying statistical methods to identify outliers. For instance, we’d compare flow rates from multiple meters along a section of pipeline to identify discrepancies that might indicate a leak or malfunction.

Data Monitoring and Analysis: Sophisticated Supervisory Control and Data Acquisition (SCADA) systems are employed to continuously monitor pipeline parameters and identify any deviations from expected performance. This allows for proactive intervention and prevents potential problems from escalating. We might use advanced analytics, such as machine learning, to identify patterns and predict potential issues before they occur.

Through this integrated system, we ensure that the pipeline data is not only accurate but also provides valuable insights for operational efficiency and safety. Any inconsistencies are investigated thoroughly to identify root causes and prevent future occurrences.

Q 23. Explain your understanding of pipeline regulatory compliance.

Pipeline regulatory compliance is an absolute necessity and involves adhering to a complex web of local, state, and federal regulations. My understanding encompasses various aspects, including safety regulations, environmental protection, and operational standards.

Safety Regulations: These are paramount and cover aspects like pipeline design, construction, operation, and maintenance, all aimed at minimizing the risk of incidents such as leaks, explosions, and fires. This involves complying with regulations set by organizations such as PHMSA (Pipeline and Hazardous Materials Safety Administration) in the US or equivalent bodies in other regions.

Environmental Protection: Stringent regulations are in place to prevent environmental damage from pipeline spills or leaks. This necessitates emergency response plans, spill prevention control and countermeasures (SPCC) plans, and environmental impact assessments. We must adhere to regulations regarding the handling and disposal of hazardous materials.

Operational Standards: These dictate how pipelines should be operated and maintained, including inspection and testing protocols. This covers aspects like pressure limits, flow rates, and integrity management programs. Regular audits and inspections are conducted to ensure compliance.

Staying abreast of changes in regulations requires constant monitoring and continuous improvement. We actively participate in industry training programs, attend conferences, and consult with regulatory bodies to ensure our pipeline operations maintain the highest level of compliance.

Q 24. Describe your experience with pipeline design and construction.

My experience with pipeline design and construction spans various phases, from initial feasibility studies to final commissioning. I’ve been involved in projects ranging from small-diameter gathering lines to large-diameter trunk lines.

Feasibility Studies: This involves assessing the technical and economic viability of a pipeline project, considering factors such as terrain, soil conditions, environmental impact, and regulatory requirements. Route selection, material selection, and preliminary cost estimates are key elements.

Detailed Engineering: This phase includes developing detailed design specifications, creating construction drawings, and procuring materials. I have experience with hydraulic modeling and stress analysis to ensure pipeline integrity under various operating conditions. Software like AutoPIPE or similar tools are routinely employed.

Construction Oversight: This involves supervising the construction process, ensuring adherence to design specifications, and conducting quality control checks. This includes overseeing welding, coating, and testing procedures to ensure the pipeline’s structural integrity and leak-tightness.

Commissioning and Start-up: This phase involves testing and commissioning the pipeline to ensure it operates as designed. This includes pressure testing, flow testing, and operational training of personnel.

I have worked on projects using various materials, including steel, polyethylene, and fiberglass reinforced plastic, and have experience with different construction techniques, including trenching, directional drilling, and river crossings. My understanding of best practices ensures that projects are completed safely, efficiently, and to the highest standards.

Q 25. What is your experience with pipeline automation and control systems?

My experience with pipeline automation and control systems is extensive. I’ve worked with various SCADA (Supervisory Control and Data Acquisition) systems and other advanced technologies to optimize pipeline operations and enhance safety.

SCADA Systems: I am proficient in using SCADA systems for monitoring pipeline parameters such as pressure, flow, temperature, and compressor performance. These systems provide real-time data and allow for remote control of pipeline facilities. I’ve worked with various vendors’ SCADA systems and understand the intricacies of system configuration, data analysis, and alarm management.

Pipeline Simulation Software: I utilize pipeline simulation software to model pipeline behavior under various operating conditions. This helps in optimizing pipeline operations and predicting the impact of changes in operating parameters. This is critical for preventing issues like overpressurization or under-pressurization.

Advanced Control Systems: My experience includes working with advanced control systems, including those based on Programmable Logic Controllers (PLCs), distributed control systems (DCS), and advanced process control (APC) strategies. These systems allow for more sophisticated control strategies, enhancing the efficiency and safety of pipeline operations. For example, APC can help optimize flow rates and minimize energy consumption.

I understand the importance of cybersecurity in pipeline automation and control systems. I am aware of the risks associated with cyberattacks and have implemented measures to mitigate these risks. This includes implementing robust security protocols and conducting regular cybersecurity audits.

Q 26. How do you troubleshoot pipeline operational issues?

Troubleshooting pipeline operational issues requires a systematic approach. My experience involves employing a combination of analytical skills, practical knowledge, and the use of diagnostic tools.

Data Analysis: The first step involves analyzing data from SCADA systems, sensors, and other sources to identify the root cause of the problem. This includes identifying trends, patterns, and anomalies that might indicate a problem. For example, a sudden drop in pressure could indicate a leak, while a gradual decrease could signal a valve malfunction.

On-Site Inspection: If necessary, on-site inspections are conducted to visually inspect the pipeline and its components. This might involve using specialized equipment such as leak detection tools, ultrasonic testing devices, or remotely operated vehicles (ROVs).

Diagnostic Tools: Various diagnostic tools are used to pinpoint the location and cause of the problem. This could involve pressure testing, flow testing, or using specialized software to analyze pipeline performance.

Corrective Actions: Once the problem is identified, appropriate corrective actions are taken. This might involve repairing a leak, replacing a faulty component, or adjusting operational parameters.

My experience includes troubleshooting a variety of issues, from minor equipment malfunctions to major pipeline incidents. A methodical approach, coupled with a strong understanding of pipeline systems, is crucial for effective troubleshooting and minimizing downtime.

Q 27. What is your understanding of pipeline integrity assessment techniques?

Pipeline integrity assessment techniques are crucial for ensuring the long-term safety and reliability of pipelines. These techniques involve various non-destructive testing (NDT) methods and data analysis to identify potential flaws or weaknesses in the pipeline.

In-Line Inspection (ILI): ILI involves using intelligent pigging technology to inspect the internal condition of the pipeline. This technology can detect various defects, including corrosion, cracks, dents, and other anomalies. The data collected is then analyzed to assess the pipeline’s integrity.

External Corrosion Direct Assessment (ECDA): ECDA involves using non-destructive techniques, such as electromagnetic testing and ultrasonic testing, to assess the extent of external corrosion on the pipeline. This is crucial for identifying areas that may require remediation.

Pressure Testing: Pressure testing involves pressurizing the pipeline to a specified level to check for leaks or other pressure-related issues. This is a common technique used for verifying the integrity of pipelines.

Data Analysis and Risk Assessment: Data obtained from various integrity assessment techniques is analyzed to determine the risk of failure for different pipeline sections. Risk-based assessments prioritize repairs or remediation efforts based on the severity and probability of failure.

The choice of integrity assessment techniques depends on factors such as pipeline material, age, operating conditions, and regulatory requirements. A comprehensive integrity management program incorporates a combination of techniques to ensure the pipeline remains safe and reliable throughout its lifespan.

Q 28. Describe your experience with pipeline maintenance reporting and documentation.

Accurate and comprehensive maintenance reporting and documentation are essential for tracking pipeline performance, complying with regulations, and ensuring efficient maintenance planning. My experience involves using various software and systems to maintain detailed records.

Computerized Maintenance Management Systems (CMMS): I am proficient in using CMMS software to track maintenance activities, schedule inspections, and manage spare parts inventories. This helps in optimizing maintenance schedules and minimizing downtime.

Inspection Reports: Detailed inspection reports are generated for each maintenance activity. These reports include information such as the date, time, location, type of work performed, and any findings or recommendations. Photographs and videos may be included for detailed documentation.

Data Analysis and Trend Identification: Maintenance data is analyzed to identify trends and patterns that might indicate potential problems. This allows for proactive maintenance to be performed before failures occur, improving pipeline reliability.

Regulatory Compliance: All maintenance records are kept in compliance with relevant regulations. This ensures that the information is readily available for audits and inspections by regulatory bodies.

Effective maintenance reporting and documentation are not just about compliance; they’re about proactively managing assets, improving efficiency, and ensuring the long-term safety and reliability of the pipeline. I believe in maintaining clear, concise, and readily accessible records, crucial for informed decision-making and improved operational performance.

Key Topics to Learn for Pipeline Operation and Maintenance Interview

- Pipeline Hydraulics and Flow Dynamics: Understanding pressure, flow rate, and friction loss calculations; analyzing pipeline performance using simulation software.

- Pipeline Integrity Management: Implementing inspection and maintenance programs (e.g., in-line inspection, hydrostatic testing); risk assessment and mitigation strategies for pipeline failures.

- Pipeline Control Systems and SCADA: Operating and troubleshooting SCADA systems; understanding pipeline automation and remote monitoring techniques.

- Pipeline Safety Regulations and Compliance: Familiarity with relevant safety standards (e.g., OSHA, PHMSA); emergency response procedures and protocols.

- Pipeline Materials and Corrosion Control: Understanding different pipeline materials and their properties; corrosion mechanisms and prevention techniques (e.g., cathodic protection).

- Pipeline Construction and Repair: Knowledge of welding techniques, pipeline installation methods, and repair procedures for various pipeline components.

- Data Analysis and Reporting: Analyzing pipeline performance data to identify trends and anomalies; generating reports on pipeline operations and maintenance activities.

- Problem-Solving and Troubleshooting: Applying analytical skills to diagnose and resolve pipeline operational issues; utilizing root cause analysis techniques.

- Emergency Response and Crisis Management: Understanding emergency procedures and protocols; participating in drills and simulations to prepare for real-world scenarios.

Next Steps

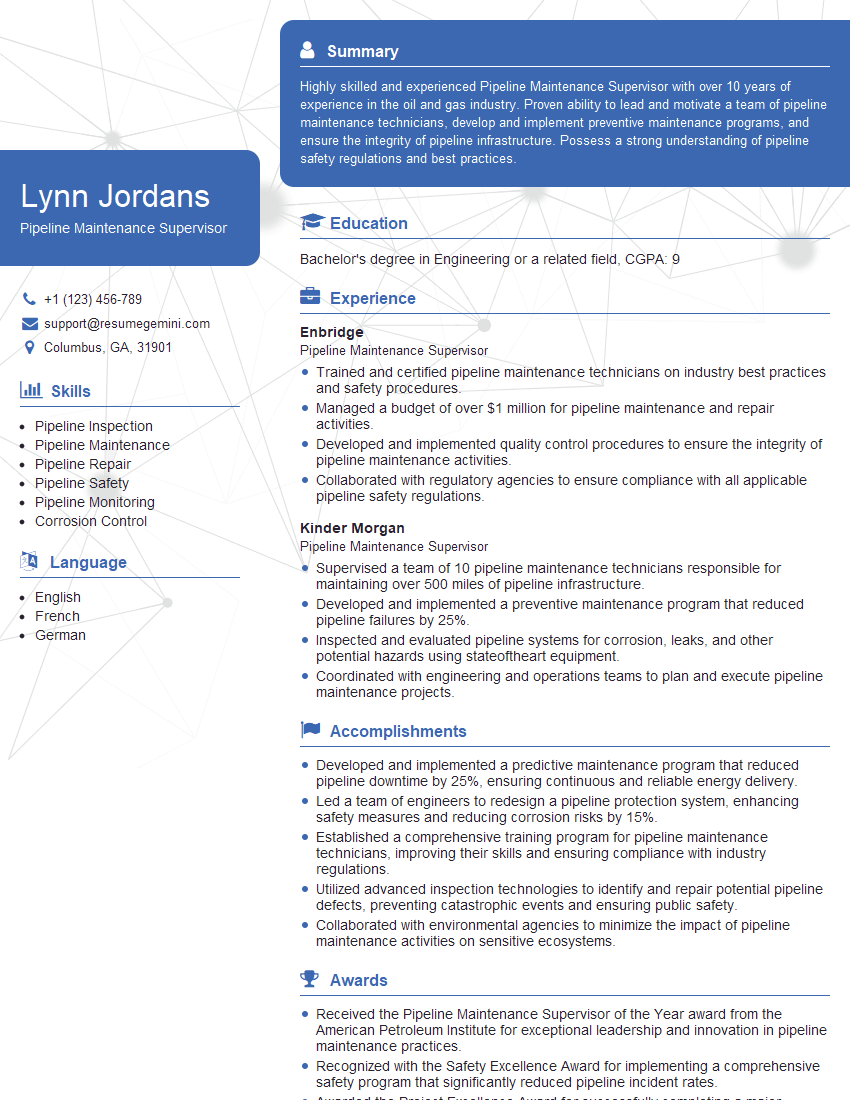

Mastering Pipeline Operation and Maintenance opens doors to a rewarding and stable career with significant growth potential. Advancement opportunities often involve increased responsibility, specialized training, and higher earning potential. To secure your ideal role, a strong resume is crucial. Creating an ATS-friendly resume significantly increases your chances of getting your application noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Pipeline Operation and Maintenance are available to help guide you. Take the next step in your career journey today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good