The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Piping and Tubing Installation interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Piping and Tubing Installation Interview

Q 1. Explain the difference between rigid and flexible piping.

The primary difference between rigid and flexible piping lies in their ability to bend and adapt to changes in direction or alignment. Rigid piping, such as steel or cast iron pipes, maintains its shape and requires fittings (elbows, tees, etc.) to change direction. Think of it like building with Lego bricks – each brick is rigid, and you need connectors to change the structure’s course. Flexible piping, on the other hand, such as corrugated stainless steel tubing or certain types of plastic pipes, can be bent to accommodate curves and offsets without the need for as many fittings. This makes installation faster and often simpler, especially in areas with limited space or complex geometries. Imagine using a garden hose—it’s flexible and easily adapts to the shape you need. The choice between rigid and flexible piping depends on the application’s specific requirements, considering factors such as pressure, temperature, and the need for flexibility during installation and operation.

Q 2. Describe the various types of pipe fittings and their applications.

Pipe fittings are essential components that connect, change direction, or modify the flow of fluids within a piping system. They come in various types, each designed for specific applications:

- Elbows: Used to change the direction of the pipe. They come in various angles, such as 45° and 90°.

- Tees: Allow the splitting or joining of pipe lines, forming a ‘T’ junction.

- Reducers/Enlargers: Transition between different pipe diameters.

- Couplings: Connect two pipes of the same diameter end-to-end.

- Unions: Disconnectable couplings that allow for easy pipe separation for maintenance or repair.

- Flanges: Large, flat circular components that use bolts to connect pipe sections. They’re often preferred for high-pressure systems.

- Valves: Control the flow of fluids, including gate valves, globe valves, ball valves, and check valves, each with its unique characteristics.

The choice of fitting depends on factors such as pressure, temperature, fluid type, and the specific configuration of the piping system. For instance, flanges are commonly used in high-pressure steam lines for ease of maintenance, while unions might be preferable in locations where frequent disassembly is anticipated.

Q 3. What are the common pipe materials used in industrial settings and their properties?

Various pipe materials are used in industrial settings, each with unique properties influencing its suitability for specific applications:

- Steel: High strength, durability, and resistance to high pressure and temperature. Commonly used in high-pressure steam and gas lines. However, it’s susceptible to corrosion.

- Stainless Steel: Offers excellent corrosion resistance, making it ideal for applications involving corrosive fluids. Often used in food processing and pharmaceutical industries.

- Cast Iron: Durable and resistant to corrosion, but brittle and heavier than steel. Frequently used in underground drainage systems.

- Copper: Excellent corrosion resistance and thermal conductivity, making it suitable for plumbing and HVAC systems. However, it is relatively expensive.

- PVC (Polyvinyl Chloride): Lightweight, corrosion-resistant, and cost-effective. Commonly used in low-pressure water and drainage systems.

- CPVC (Chlorinated Polyvinyl Chloride): A more robust version of PVC, suitable for higher temperatures.

Material selection is crucial and depends on factors like fluid compatibility, operating pressure and temperature, and environmental conditions. For example, in a chemical plant handling highly corrosive substances, stainless steel would be the preferred choice for its corrosion resistance.

Q 4. How do you determine the appropriate pipe size for a given application?

Determining the appropriate pipe size involves considering several factors:

- Fluid Flow Rate: Higher flow rates require larger pipes to avoid excessive pressure drops.

- Fluid Velocity: Excessive velocity can cause erosion and noise. Pipe size is chosen to maintain an optimal velocity range.

- Pressure Drop: Larger pipes generally result in lower pressure drop over a given distance.

- System Head Loss: The total pressure loss in the system, including friction and fittings, must be considered.

- Future Expansion: Allowing for potential future increase in flow rates is essential.

Engineers often use specialized software or calculation methods based on established standards and equations (like the Darcy-Weisbach equation) to calculate the necessary pipe diameter. The process considers the specific fluid properties, pipe material, and the overall system design.

For instance, designing a water supply line for a building requires careful consideration of peak water demand to prevent low water pressure during peak usage. Insufficient pipe sizing would lead to inadequate water pressure, while excessive sizing results in unnecessary material costs.

Q 5. Explain the process of pipe threading and the tools involved.

Pipe threading is a machining process used to create external (male) or internal (female) threads on a pipe. This allows for the creation of strong, leak-proof connections using fittings such as couplings or elbows. The process typically involves the following steps:

- Cutting the pipe to the desired length.

- Chamfering the pipe end: This removes the sharp edge, facilitating cleaner thread cutting.

- Threading the pipe: This is typically done using a pipe threading machine or, for smaller pipes, hand dies and stocks. The machine uses cutting dies to create the threads.

- Cleaning the threads: Removing any debris from the threads is crucial for a good seal.

The tools involved include pipe cutters, deburring tools, pipe threading machines (for larger diameters), dies and stocks (for hand threading), and thread lubricants (to reduce friction and improve thread quality). Improper threading can lead to leaks or damage to the pipe and fittings. Therefore, accurate threading and the use of proper tools and techniques are crucial for successful piping installation.

Q 6. Describe different welding techniques used in piping systems.

Welding is a common method for joining pipes in high-pressure applications. Several welding techniques are used, depending on the pipe material and the required joint strength:

- Shielded Metal Arc Welding (SMAW): Uses a consumable electrode coated with flux to protect the weld from atmospheric contamination. It’s versatile and relatively inexpensive, but requires skilled welders.

- Gas Metal Arc Welding (GMAW) or MIG welding: Uses a continuously fed consumable wire electrode and a shielding gas to protect the weld. It’s faster and more efficient than SMAW, producing high-quality welds.

- Gas Tungsten Arc Welding (GTAW) or TIG welding: Uses a non-consumable tungsten electrode and an inert shielding gas. It produces very clean, high-quality welds, particularly useful for thin-walled pipes or critical applications. It’s more precise and slower than other techniques.

The selection of the welding method depends on factors like material thickness, the required weld quality, and the available equipment. Proper weld preparation, including cleaning the pipe surfaces and using appropriate filler materials, is crucial for creating strong, leak-free joints. Always ensure adherence to relevant welding codes and standards for safety and quality control.

Q 7. What are the safety precautions to be taken during piping installation?

Safety is paramount during piping installation. The following precautions should always be followed:

- Personal Protective Equipment (PPE): Always wear appropriate PPE, including safety glasses, gloves, hard hats, and safety shoes.

- Confined Space Entry Procedures: If working in confined spaces, strict confined space entry procedures must be followed, including atmospheric monitoring and proper ventilation.

- Lockout/Tagout Procedures: Always follow lockout/tagout procedures when working on energized systems to prevent accidental activation.

- Handling of Hazardous Materials: Follow appropriate safety protocols for handling any hazardous fluids or gases involved.

- Welding Safety: Observe all welding safety precautions, including proper ventilation, fire prevention measures, and eye protection.

- Fall Protection: Use appropriate fall protection equipment when working at heights.

- Proper Lifting Techniques: Utilize proper lifting techniques and equipment to avoid injuries.

- Regular Inspections: Conduct regular inspections of equipment and work areas to identify and rectify potential hazards.

Following these safety measures minimizes risks and ensures a safe working environment, protecting the workers and the integrity of the piping system. Regular training and adherence to safety protocols are essential for a safe and successful piping installation project.

Q 8. How do you interpret piping and instrumentation diagrams (P&IDs)?

Piping and Instrumentation Diagrams (P&IDs) are the blueprints for a piping system. They’re essentially schematic drawings showing the arrangement of piping, valves, instruments, and equipment within a process plant or facility. Interpreting them requires a systematic approach.

First, I look at the overall process flow, tracing the path of fluids (liquids, gases, or slurries) from their source to their destination. I pay close attention to the line numbers and tags associated with each pipe segment, as these uniquely identify them and their specifications. Then, I carefully examine the components along each line: pumps, compressors, heat exchangers, valves (gate, globe, check, ball, etc.), and instruments (pressure gauges, temperature sensors, flow meters). Understanding the symbols and their associated specifications is crucial. For example, a circle might represent a control valve, while a filled circle could indicate a globe valve. The P&ID also shows the size and material of the pipes, operating pressures and temperatures, and the control logic for the system.

I also check for critical details like safety devices (relief valves, rupture disks), and emergency shut-off valves. Finally, I cross-reference the P&ID with other documents, such as equipment datasheets and specifications to get a complete picture. Imagine it like reading a map – you need to understand the symbols and follow the lines to see the whole picture. Experience lets you quickly identify potential problems or inconsistencies in the design, preventing issues later on during installation.

Q 9. Explain the importance of proper pipe support and hanger installation.

Proper pipe support and hanger installation is paramount for preventing stress, vibration, and potential leaks. Think of it as providing a strong, stable skeleton for your piping system. Improper support can lead to sagging, misalignment, and even pipe failure, causing significant downtime and safety hazards.

Supports need to be strategically placed to distribute the weight and thermal expansion forces evenly. The spacing depends on pipe size, material, and fluid properties. For instance, longer spans require more supports. There are different types of supports available, including:

- Rigid supports: These provide fixed points and restrict movement.

- Spring supports: These accommodate pipe expansion and contraction due to temperature changes.

- Variable spring supports: These are adjustable to compensate for weight changes.

- Guide supports: These prevent lateral movement and restrict pipe sway.

We use engineering calculations (often software-based) to determine the optimal support locations and types. In addition to calculation, we often consider factors like accessibility for maintenance, vibration dampening, and corrosion resistance. Correctly installed supports prevent fatigue failures and maintain the structural integrity of the piping system over its lifespan. I’ve seen firsthand the disastrous consequences of neglected pipe support – leaks, costly repairs, and even production shutdowns. It’s a critical aspect of the job.

Q 10. Describe different types of pipe insulation and its purpose.

Pipe insulation serves to control temperature, prevent condensation, and reduce energy loss. The choice of insulation depends on the fluid temperature, the ambient conditions, and the required thermal performance. Several types of insulation are common:

- Fiberglass: A cost-effective option suitable for many applications, but not as resistant to moisture as others.

- Mineral wool: Provides excellent thermal performance and is fire-resistant, often used in high-temperature applications.

- Calcium silicate: A durable and high-temperature insulation, resistant to moisture and chemicals, commonly found in boiler applications.

- Polyurethane foam: A lightweight, high-performance insulation with good thermal properties. It can be sprayed on or applied as pre-fabricated sections.

- Polyisocyanurate (polyiso): Similar to polyurethane but offers even better thermal performance and higher resistance to moisture.

Insulation is crucial for maintaining the desired operating temperature of the pipe contents and reducing heat loss (or gain in cryogenic applications). In practical terms, this translates to significant cost savings and a more efficient process. Plus, insulation often prevents condensation, which can lead to corrosion and damage to the pipe and surrounding structures.

Q 11. How do you handle pipe expansion and contraction during installation?

Pipe expansion and contraction due to temperature changes is a significant challenge in piping systems. Ignoring this can lead to stress on the pipe and its connections, potentially causing leaks or failures. Several techniques are used to mitigate these effects:

- Expansion loops: These are U-shaped sections of pipe that allow for expansion and contraction without putting stress on other parts of the system. They’re designed using detailed calculations to accommodate the expected temperature variations.

- Expansion bends: Similar to expansion loops, but in a more compact design.

- Expansion joints: These are mechanical devices that provide flexibility and allow for axial, lateral, or angular movement. There are many types, including bellows, gimbal, and rubber expansion joints. Each type has a specific capacity for movement and must be properly selected.

- Anchors and guides: These are used in combination with expansion devices to control and restrict movement within acceptable limits, preventing excessive stress.

The selection of appropriate methods depends on the system’s design, temperature range, and fluid properties. Accurate calculations and precise installation are critical to ensure the effectiveness of these methods. Imagine a metal ruler – heating it makes it expand, and cooling makes it contract. This is the same principle that must be managed in piping.

Q 12. What are the common causes of pipe leaks and how are they repaired?

Pipe leaks are a common issue with various causes. The most frequent culprits are:

- Corrosion: This is a gradual deterioration of the pipe material, often weakening it and creating pinholes or cracks. It is influenced by the fluid being transported, the pipe material, and the environmental conditions.

- Erosion: This is the wearing away of the pipe material by the flowing fluid, typically occurring in areas of high velocity or turbulence. This is more common with abrasive fluids.

- Improper installation: Poor welding, damaged threads, or incorrect tightening of flanges can all lead to leaks.

- Mechanical damage: External forces, such as impacts or vibrations, can damage the pipe and cause leaks.

- Fatigue: This is the gradual weakening of the pipe material due to repeated stress, leading to cracks and leaks. Often unseen and caused by temperature fluctuations or vibrations.

Repair methods vary depending on the cause and severity of the leak. For small leaks, minor repairs might suffice (e.g., tightening a bolt, applying a sealant). For larger leaks, more extensive repairs might be required, such as replacing a damaged section of pipe or employing specialized welding techniques. Severe corrosion or significant damage often necessitate complete pipe replacement.

Q 13. Explain the process of pressure testing a piping system.

Pressure testing is a crucial step in verifying the integrity of a piping system before it goes into operation. It involves filling the system with a pressurized fluid (usually water or air) and monitoring for leaks. The pressure is maintained for a specified duration, allowing for any weaknesses to become apparent.

The process usually involves these steps:

- System preparation: All valves, fittings, and equipment are inspected and properly secured.

- Isolation: The system is isolated from other parts of the plant to prevent unintended pressure surges or leaks.

- Pressurization: The system is slowly filled with the test fluid and gradually pressurized to the specified test pressure, which typically exceeds the system’s design pressure to ensure a margin of safety.

- Leak detection: The system is carefully inspected for leaks using visual inspection, soap solution, or other leak detection methods.

- Pressure holding test: The pressure is maintained for a specified duration (typically several hours) to ensure the system holds pressure without significant leakage.

- Pressure release: Once the test is complete, the pressure is slowly released.

Pressure testing is essential for ensuring the safety and reliability of the piping system. I’ve seen many instances where pressure tests revealed latent defects that could have caused serious problems later on. It’s a fundamental procedure that prevents costly repairs, production downtime, and potential safety hazards.

Q 14. Describe your experience with different types of pipe joints (e.g., flanged, welded, threaded).

Throughout my career, I’ve worked extensively with various pipe joints. Each type has its advantages and disadvantages, and the choice depends on factors such as pressure, temperature, fluid compatibility, and accessibility.

- Flanged Joints: These are commonly used for larger diameter pipes and high pressures. They consist of flanges bolted together with a gasket to ensure a seal. Flanged joints are relatively easy to assemble and disassemble, allowing for easy maintenance and inspection. However, they can be bulky and require more space than other joint types.

- Welded Joints: These provide a strong and permanent connection, ideal for high-pressure applications. Different welding techniques are employed depending on pipe material and thickness. Welded joints are more complex and require skilled welders adhering to strict codes and standards to ensure proper penetration and leak-free seals. Once welded, they are difficult to repair or replace.

- Threaded Joints: These are commonly used for smaller diameter pipes and lower pressures. They are relatively easy and quick to assemble but might not be suitable for high-pressure or high-temperature applications. Proper thread preparation and sealant application are crucial to avoid leaks. Threading can weaken the pipe if not done correctly.

- Compression Joints: These are often used for smaller pipes where frequent disassembly and reassembly are required. They offer a reliable seal but can be more expensive than other joint types.

My experience includes working with all these joint types across a wide range of projects, enabling me to select the most appropriate joint for a given situation and ensure its proper installation and integrity.

Q 15. What are the regulations and codes you follow during piping installation?

Piping installation adheres to a strict set of regulations and codes to ensure safety, functionality, and longevity. These vary depending on the location, the fluid being conveyed (e.g., water, gas, chemicals), and the pressure and temperature involved. Key codes and standards I frequently reference include ASME B31.1 (Power Piping), ASME B31.3 (Process Piping), and ASME B31.4 (Liquid Petroleum Transportation Piping Systems). These codes provide detailed specifications for materials, design, fabrication, assembly, testing, and inspection procedures. For example, ASME B31.3 dictates allowable stresses for different pipe materials at various temperatures, ensuring the system can withstand operating conditions without failure. Local building codes also play a crucial role, dictating requirements for permits, inspections, and specific installation practices within a given jurisdiction. Failure to comply with these regulations can lead to serious consequences, including system failure, environmental damage, and legal repercussions.

- ASME B31.1: Power Piping systems.

- ASME B31.3: Process Piping systems. This is the most commonly used code for industrial applications.

- ASME B31.4: Liquid Petroleum Transportation Piping systems.

- Local Building Codes: These vary by region and jurisdiction.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure the integrity of a piping system?

Ensuring the integrity of a piping system is paramount. It’s a multi-faceted process starting with careful design and material selection. We need to consider the properties of the fluid being transported, the operating pressure and temperature, and potential environmental factors like corrosion. During installation, precise alignment, proper support, and correct welding techniques (including non-destructive testing like radiography or ultrasonic testing) are crucial. Regular inspection and maintenance are also vital, including leak detection, pressure testing, and visual inspections for signs of wear or damage. Think of it like maintaining a human body – regular check-ups and preventative maintenance help prevent major problems. A well-maintained system has fewer leaks, operates more efficiently, and lasts longer. In one project, a meticulous inspection program revealed minor cracks in a weld before they escalated into a major leak, saving the company significant time and resources.

Q 17. What are your skills in using pipe bending tools?

I’m proficient in using a variety of pipe bending tools, from hand-operated benders for smaller diameter pipes to hydraulic benders for larger diameters. My experience includes using both manual and powered tools to create various bends, including standard 90-degree bends, offsets, and saddle bends. I understand the importance of using the right tool for the job, as using an inappropriate tool can lead to deformation, kinking, or even breakage of the pipe. Furthermore, I am well-versed in calculating bend radii according to the pipe material and specifications to ensure the integrity and structural soundness of the finished product. This expertise is critical for creating neat, precise bends that fit smoothly into the system design, enhancing its overall efficiency and aesthetic appeal. I also understand the importance of safety procedures when working with such tools.

Q 18. Describe your experience with different types of valves and their applications.

My experience encompasses a wide range of valves, each with its unique application. I’m familiar with gate valves (for on/off service), globe valves (for throttling and flow regulation), ball valves (for quick on/off action), check valves (for preventing backflow), butterfly valves (for larger diameter lines), and control valves (for precise flow control). The choice of valve depends on factors such as the fluid type, pressure, flow rate, required shut-off speed, and maintenance requirements. For example, a ball valve is ideal for quickly isolating a section of the piping system, while a globe valve would be more appropriate when precise flow control is needed. I’ve worked with valves made from various materials including steel, stainless steel, and PVC, selecting the most appropriate material based on the corrosive nature of the fluid being transported. In one project, I selected corrosion-resistant stainless steel valves for a chemical processing plant to prevent costly leaks and maintain the integrity of the piping system.

Q 19. How do you troubleshoot problems in an existing piping system?

Troubleshooting problems in an existing piping system requires a systematic approach. I begin with a thorough visual inspection, checking for leaks, corrosion, signs of damage, and loose connections. Then, I’d check for pressure drops and flow inconsistencies, and verify valve operation. If a leak is detected, I’d pinpoint its source and consider repair options, which may include replacing a section of pipe, repairing a weld, or replacing a damaged valve or fitting. Pressure testing the system is an important part of this process, ensuring that the repair restores the system’s integrity. I have used various diagnostic tools like ultrasonic leak detectors and pressure gauges to isolate problems. In a past project, a series of pressure drops indicated a partially blocked section of pipe that we identified using a specialized camera inserted into the line. This prevented unnecessary replacement of extensive piping sections, saving time and money.

Q 20. What software are you proficient in for piping design or analysis?

I’m proficient in several software packages commonly used in piping design and analysis. My expertise includes AutoCAD for 2D and 3D modeling of piping systems, allowing me to visualize the system and design efficient layouts. I am also skilled in using specialized piping design software like AutoPIPE, which allows for stress analysis and ensures the system meets required safety standards. Furthermore, I’m experienced with software that calculates fluid dynamics, allowing for optimized system performance and reduction of energy waste. These programs enable me to accurately model complex piping configurations, analyze stress loads, and identify potential issues before installation, leading to more efficient and safer systems. I can use this data to create detailed isometric drawings and material take-offs for the construction team.

Q 21. Describe your experience with different types of pumps and their integration into piping systems.

My experience with pumps spans various types, including centrifugal pumps (common for general applications), positive displacement pumps (for high viscosity fluids or precise flow rates), and submersible pumps (for applications where the pump is immersed in the fluid). I understand the principles of pump selection and integration into piping systems, considering factors like flow rate, pressure head, fluid characteristics, and efficiency. Proper pump selection is critical for ensuring efficient operation and avoiding issues such as cavitation (formation of vapor bubbles within the fluid, potentially damaging the pump). I also consider the need for suction and discharge piping, including proper sizing and valving to prevent issues. For example, a poorly designed suction line could lead to insufficient flow to the pump, impacting its performance. I’ve worked with different pump manufacturers and understand the importance of adhering to their specific installation guidelines to ensure optimal performance and longevity.

Q 22. Explain your understanding of hydraulics and its relevance to piping systems.

Hydraulics is the study of fluid in motion and its applications. In piping systems, understanding hydraulics is crucial because it dictates the flow of liquids or gases through the pipes. Factors like pressure, flow rate, friction losses (head loss due to friction within the pipes), and pipe diameter directly impact the system’s performance. Imagine trying to fill a bathtub with a tiny straw versus a large hose – the hose delivers water much faster due to a larger diameter and less friction.

For example, a poorly designed piping system with inadequate diameter might lead to insufficient flow rate, hindering the operation of equipment reliant on that fluid. Conversely, understanding hydraulic principles allows for efficient system design, minimizing energy consumption and maximizing the effectiveness of the fluid transport. We use calculations based on Bernoulli’s equation and Darcy-Weisbach equation to predict pressure drop and determine appropriate pipe sizing, pump selection, and valve placement.

Q 23. How do you manage a piping installation project?

Managing a piping installation project involves meticulous planning and execution. It’s like orchestrating a complex symphony. First, thorough review of the blueprints and specifications is crucial, followed by detailed material procurement planning to ensure timely availability of pipes, fittings, valves, and supports. Next, I coordinate the workforce, ensuring everyone has the right tools, safety equipment, and clear instructions. We establish a robust quality control process – frequent inspections, material verification, and adherence to codes and standards (like ASME B31). Effective communication is paramount – regular meetings with contractors, clients, and inspectors are vital for resolving potential issues promptly and keeping the project on track and within budget. Finally, thorough testing and documentation are crucial for project closure.

For instance, on a recent project involving high-pressure steam lines, I implemented a staggered scheduling approach to minimize disruptions. This involved phasing the work based on critical path activities, reducing the chances of delays.

Q 24. What are your skills in reading and interpreting blueprints?

Reading and interpreting blueprints is fundamental to my role. I’m proficient in understanding isometric drawings, orthographic projections, and piping and instrumentation diagrams (P&IDs). My skills extend to interpreting symbols, dimensions, specifications, and material designations, which all help in accurate planning and execution. I can easily identify pipe sizes, materials, valve types, and locations of supports from blueprints, and I’m adept at using these plans to create accurate shop drawings and installation sequences.

For example, I once discovered a clash between a newly designed pipe route and an existing structural beam purely from reviewing the blueprints. This averted a costly rework later during the installation phase. I understand the importance of different views (plan, elevation, section) and the relevance of each symbol to ensure accurate measurements and installations.

Q 25. Explain your experience with different types of pipe hangers and supports.

I’ve extensive experience with various pipe hangers and supports, including rigid hangers, spring hangers, constant support hangers, variable spring hangers, and snubbers. The choice of support depends heavily on the pipe’s size, material, operating temperature, pressure, and the overall system’s dynamic characteristics. Rigid hangers provide fixed support, while spring hangers accommodate thermal expansion and vibration. Constant support hangers maintain a constant load, regardless of pipe movement, and variable spring hangers adjust to changing loads. Snubbers are used to limit movement during seismic activity or other sudden events.

For instance, in a project involving long, high-temperature steam lines, we used constant support hangers to manage the weight and thermal expansion. For more sensitive applications with vibrations, we would deploy spring hangers and snubbers to mitigate movement and stress on the piping.

Q 26. How do you ensure the cleanliness and purity of a piping system?

Ensuring cleanliness and purity in a piping system is crucial, especially in applications handling sensitive fluids like pharmaceuticals or high-purity chemicals. This involves several steps: Pre-installation cleaning of pipes and fittings to remove debris and contaminants using specialized cleaning solutions and methods. The use of appropriate flushing techniques during and after installation is critical. For example, we may use a solvent flush followed by a water flush to ensure removal of any residual materials. This process is documented and verified to confirm adherence to cleanliness standards. Finally, the selection of appropriate pipe materials (stainless steel or other corrosion-resistant materials for instance) is important to prevent contamination and ensure system longevity. Following stringent procedures is critical to ensure the desired purity levels are achieved.

Q 27. Describe your experience with hydrotesting and pneumatic testing procedures.

Hydrotesting and pneumatic testing are crucial for verifying the integrity of a piping system. Hydrotesting involves filling the system with water under pressure to detect leaks. Pneumatic testing uses compressed air, generally preferred for higher-pressure systems as it involves less weight and risk compared to water. Both tests involve carefully planned procedures, including pressure holding time observations and documentation of any leaks or pressure drops. I’m experienced in conducting these tests safely and effectively, adhering to all relevant safety regulations and documenting the results meticulously. I understand that the test pressure and duration are calculated according to the system’s design pressure and materials.

For example, in a recent project, we encountered a small leak during hydrotesting which was efficiently repaired and retested before proceeding.

Q 28. How do you handle unexpected issues or changes during a piping installation project?

Handling unexpected issues is where experience truly matters. It requires a calm, systematic approach. First, we thoroughly assess the issue, documenting observations and measurements. We then develop a range of solutions – this may involve consultation with engineering staff, review of industry best practices, and consideration of the impact on project timelines and budget. After selecting the best solution, we implement it, ensuring all necessary safety precautions are followed. Thorough documentation of the issue, solution, and impact is crucial for learning and improvement. Effective communication with all stakeholders keeps everyone informed of progress and potential repercussions.

In one instance, we discovered a significant discrepancy between the as-built drawings and the actual pipe route. After thorough investigation, we quickly collaborated with engineering to revise the design and execute the change order effectively and without major delays.

Key Topics to Learn for Piping and Tubing Installation Interview

- Pipe and Tube Materials: Understanding the properties and applications of various materials like steel, copper, PVC, and HDPE. This includes knowing their strengths, weaknesses, and suitability for different applications and pressure ratings.

- Pipe Fitting and Joining Techniques: Mastering different joining methods such as welding (various types), threading, flanging, and using compression fittings. Be prepared to discuss the advantages and limitations of each method.

- Blueprint Reading and Interpretation: Demonstrate your ability to accurately read and interpret piping and instrumentation diagrams (P&IDs) and isometric drawings. Practice identifying pipe sizes, materials, fittings, and flow directions.

- Safety Regulations and Practices: Showcase your knowledge of relevant safety standards, including lockout/tagout procedures, confined space entry, and hazard identification related to piping systems. This is crucial for any successful installation.

- Pressure Testing and Leak Detection: Explain the process of pressure testing piping systems and methods for detecting and addressing leaks. Knowing different types of testing and the tools involved is vital.

- Installation Techniques and Best Practices: Discuss proper installation techniques, including pipe support, alignment, and preventing stress on the system. Highlighting best practices for efficiency and longevity is important.

- Troubleshooting and Problem Solving: Be prepared to discuss common problems encountered during installation and how you would approach troubleshooting and resolving them. This demonstrates practical experience and analytical skills.

- Code Compliance: Familiarity with relevant building codes and industry standards related to piping and tubing installation. Knowing how these standards impact installation is essential.

Next Steps

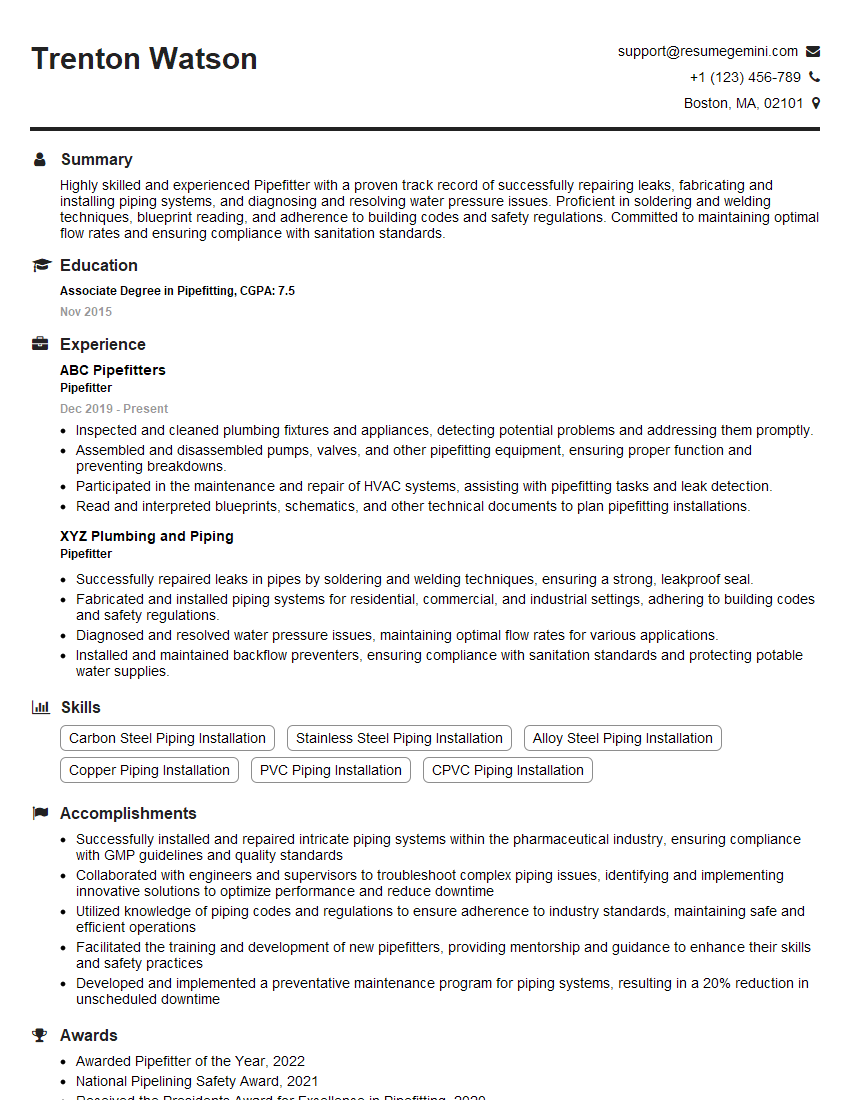

Mastering Piping and Tubing Installation opens doors to rewarding careers in various industries, offering excellent opportunities for advancement and specialization. To maximize your job prospects, crafting a strong, ATS-friendly resume is paramount. ResumeGemini is a trusted resource to help you build a professional and impactful resume that showcases your skills and experience effectively. Examples of resumes tailored to Piping and Tubing Installation are available to help you get started. Invest time in creating a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good