Preparation is the key to success in any interview. In this post, we’ll explore crucial Plating of Functional Coatings interview questions and equip you with strategies to craft impactful answers. Whether you’re a beginner or a pro, these tips will elevate your preparation.

Questions Asked in Plating of Functional Coatings Interview

Q 1. Explain the difference between electroplating and electroless plating.

Electroplating and electroless plating are both methods used to deposit a thin layer of metal onto a substrate, but they differ significantly in their mechanisms. Electroplating uses an electric current to drive the deposition process, while electroless plating is an autocatalytic chemical process that doesn’t require an external current.

Think of electroplating like painting with electricity: you need a power source (a battery) to move charged metal ions from a solution to the substrate. The substrate acts as a cathode, attracting the positively charged metal ions, while a metal anode provides the replenishment of ions into the solution. Electroless plating, on the other hand, is more like a chemical reaction where the metal ions in the solution are reduced and deposited onto the substrate’s surface through a chemical reducing agent, without the need for an external current. This makes electroless plating useful for complex shapes where uniform electroplating might be difficult.

- Electroplating: Requires an external power source; offers excellent control over thickness and uniformity; suitable for high-volume production.

- Electroless plating: Doesn’t require an external power source; allows for plating of complex shapes; can be less controllable in terms of thickness and uniformity than electroplating.

Q 2. Describe the various types of plating solutions used for functional coatings.

The choice of plating solution depends heavily on the desired properties of the functional coating. Many different metal salts are used, each offering unique characteristics.

- Nickel plating: Widely used for its corrosion resistance, hardness, and wear resistance. Different types of nickel baths (Watts, sulfamate, etc.) offer variations in these properties.

- Chromium plating: Provides exceptional corrosion resistance and a high-luster finish, often used as a decorative and protective topcoat over nickel.

- Zinc plating: Offers good corrosion protection, particularly in outdoor environments. Often used for fasteners and other parts exposed to the elements.

- Gold plating: Used for its excellent conductivity and corrosion resistance in electronics applications. Different karat gold baths can be used to control the cost and conductivity.

- Silver plating: Used where high electrical conductivity and reflectivity are important, such as in electrical contacts and mirrors.

- Copper plating: Often used as an undercoat for other metals, improving adhesion and conductivity.

Beyond the base metal, plating solutions also contain additives to control the properties of the deposited layer, such as brightness agents, stress relievers, and leveling agents.

Q 3. What are the key factors affecting the adhesion of a plated coating?

Excellent adhesion between the plated coating and the substrate is crucial for the longevity and performance of the plated part. Several factors influence this adhesion:

- Surface preparation: A clean, properly prepared substrate is essential. This usually involves cleaning, degreasing, and often etching or other surface treatments to increase surface roughness and create mechanical interlocking.

- Substrate material: The inherent properties of the substrate material affect adhesion. Some materials bond better to certain metals than others. The substrate’s crystalline structure and its susceptibility to oxidation play significant roles.

- Plating bath composition: The type and concentration of ions in the plating solution influence the crystalline structure and the bonding mechanisms between the coating and the substrate.

- Plating parameters: Parameters such as current density, temperature, and pH can affect the growth characteristics of the plated layer and its adhesion to the base material.

- Interdiffusion: At higher temperatures, diffusion can occur between the coating and substrate atoms, leading to the formation of intermetallic compounds which can increase adhesion.

Poor surface preparation is often the root cause of poor adhesion. Imagine trying to stick a sticker to a dusty surface – it won’t adhere properly. Similarly, a contaminated substrate surface will prevent good adhesion of a plated coating.

Q 4. How do you control the thickness and uniformity of a plated layer?

Controlling the thickness and uniformity of a plated layer is critical for ensuring the functional properties of the coating. Several methods are used:

- Current density control: Precise control of the current density applied during electroplating is crucial. Higher current densities typically result in faster deposition but can lead to less uniform coatings and even burning.

- Solution agitation: Stirring or other forms of agitation helps to maintain a uniform concentration of metal ions in the plating solution, promoting even deposition.

- Time control: The longer the plating process continues, the thicker the coating becomes. Accurate timers and monitoring systems are essential.

- Rack design: In rack plating, the design of the rack that holds the parts affects the distribution of current density on the parts, impacting uniformity.

- Rotating barrel plating: For smaller parts, rotating barrel plating ensures uniform coating by continually turning the parts in the plating solution.

- Thickness measurement: Regular measurement of the coating thickness using methods like cross-sectional microscopy, X-ray fluorescence, or magnetic methods is essential for quality control and process optimization.

Think of it like baking a cake: you need to control the baking time and oven temperature for even cooking, and similarly plating needs control of various parameters to attain a uniformly thick and adherent layer.

Q 5. Explain the importance of pre-treatment processes in plating.

Pre-treatment processes are vital steps in the plating process that prepare the substrate for optimal coating adhesion and corrosion protection. These processes aim to remove contaminants, improve surface wettability, and create a suitable surface for nucleation of the plated metal.

- Cleaning: Removes oils, greases, and other organic contaminants from the substrate surface using solvents or alkaline cleaners.

- Degreasing: A more thorough cleaning process to remove stubborn grease and oils, often using ultrasonic cleaning or vapor degreasing.

- Etching: Creates a microscopically roughened surface, improving mechanical interlocking between the substrate and the coating. Acids or alkaline solutions are typically used.

- Pickling: Removes oxides and other surface imperfections from metals like steel, preparing a clean metallic surface.

- Activation: For some materials like aluminum, a process to prepare the surface to accept the plating. This could involve chemical or electrochemical treatments.

Without proper pre-treatment, the plated coating will likely peel or blister, rendering the entire process ineffective. It is the foundation for a successful and long-lasting plating job, like preparing the ground before planting a tree.

Q 6. What are the common defects encountered in plating and their causes?

Several common defects can occur during plating, each with its own causes:

- Pitting: Small holes or voids in the coating, often caused by contaminants on the substrate surface or uneven current distribution.

- Burning: A dark, rough area resulting from excessively high current density, leading to rapid and uncontrolled deposition.

- Nodules: Small bumps or protrusions on the surface of the coating, often caused by impurities in the plating solution or improper agitation.

- Peeling/Blistering: Separation of the coating from the substrate, usually due to poor adhesion caused by inadequate pre-treatment or internal stresses in the coating.

- Roughness: An uneven surface texture, often caused by impurities, improper agitation, or high current density.

- Porosity: Small pores in the coating, reducing its corrosion protection capabilities. Often caused by improper plating parameters or insufficient coating thickness.

Troubleshooting these defects requires careful analysis of the entire process, from pre-treatment to plating parameters. It’s a systematic approach, like solving a detective mystery; you need to identify the clues to find the culprit.

Q 7. Describe the methods used to measure the thickness of a plated coating.

Several methods exist for measuring the thickness of a plated coating, each with its own advantages and limitations:

- Cross-sectional microscopy: A destructive method where the plated part is cut and examined under a microscope. Accurate but requires sample destruction.

- X-ray fluorescence (XRF): A non-destructive method that uses X-rays to determine the elemental composition and thickness of the coating. It’s rapid and accurate for many metals.

- Magnetic methods: These methods measure the magnetic properties of the coating, suitable for ferromagnetic materials. They are fast and relatively inexpensive but might not be suitable for all plating types.

- Electrochemical methods: These methods determine the thickness by measuring the rate at which the coating is dissolved during controlled electrochemical stripping. They are precise but destructive.

- Beta backscatter: This method involves measuring the backscattering of beta particles from the coating. It’s non-destructive and can measure thin coatings on various substrates.

The choice of method depends on factors such as the type of plating, required accuracy, and whether destructive testing is acceptable.

Q 8. How do you ensure the quality and consistency of plated parts?

Ensuring quality and consistency in plated parts is paramount. It involves a multi-faceted approach encompassing meticulous control over every stage of the plating process. Think of it like baking a cake – if you don’t measure ingredients precisely and follow the recipe carefully, you won’t get a consistent result.

Pre-treatment: Careful cleaning and surface preparation are crucial. This includes degreasing, descaling, and possibly etching to ensure proper adhesion of the plating. Inconsistencies here directly impact the final product.

Plating Bath Control: Regular monitoring and control of the plating bath’s chemistry (pH, concentration of metal ions, additives) are vital. Automated systems with sensors for real-time monitoring are commonly used. This ensures the bath maintains its optimal properties throughout the plating cycle.

Current Density Control: Maintaining a consistent current density is key. Variations can lead to uneven plating thickness and other defects. This often involves using carefully designed jigging and anode placement to distribute the current evenly over the part’s surface.

Post-Treatment: This includes rinsing, drying, and potentially passivation or other finishing steps. Careful control at each stage prevents contamination and ensures the desired surface properties are achieved.

Quality Control Measures: Regular testing is crucial. This might involve measuring plating thickness using techniques like cross-sectional microscopy or X-ray fluorescence (XRF), examining the surface finish for defects, and performing adhesion tests. Statistical Process Control (SPC) charts help track and identify trends for process improvement.

Q 9. Explain the role of current density in the plating process.

Current density, measured in amps per square decimeter (A/dm²), is the rate of electrical charge flow per unit area of the cathode (the part being plated). It’s a critical parameter because it directly influences the plating process. Imagine it like watering a garden – a low flow rate might not be enough to fully saturate the plants, and too high a flow might wash them away.

Effects of Current Density:

Low Current Density: Results in slow deposition, potentially leading to porous or thin coatings.

Optimum Current Density: Provides a smooth, dense, and adherent coating with the desired thickness. This is determined experimentally for each plating system and part geometry.

High Current Density: Can cause hydrogen embrittlement (weakening of the substrate), burning (rough, uneven deposition), or even treeing (dendritic growth).

Controlling Current Density: This is achieved by adjusting the voltage and current applied to the plating bath, carefully designing the jig to ensure uniform current distribution, and controlling the bath chemistry. The shape of the part and its placement relative to the anode also play significant roles.

Q 10. What are the environmental concerns associated with plating and how are they mitigated?

Plating processes, while crucial for many industries, can have significant environmental impacts. The major concerns revolve around the use and disposal of hazardous chemicals.

Heavy Metal Contamination: Plating baths often contain heavy metals like chromium, nickel, cadmium, and copper, which are toxic if released into the environment. Improper disposal can contaminate soil and water sources.

Cyanide and other toxic chemicals: Some plating baths utilize cyanide, which is highly toxic, requiring special handling and disposal methods. Other chemicals can also pose health and environmental risks.

Wastewater Treatment: The wastewater generated during plating contains various chemicals, requiring effective treatment before discharge to comply with environmental regulations.

Mitigation Strategies:

Waste Minimization: Implementing techniques like drag-out reduction, efficient rinsing procedures, and closed-loop systems to minimize chemical usage and waste generation.

Wastewater Treatment: Utilizing advanced wastewater treatment technologies like chemical precipitation, ion exchange, or electroplating to remove heavy metals and other contaminants.

Recycling and Recovery: Recovering valuable metals from spent plating baths and plating sludges for reuse, reducing both waste and raw material consumption.

Substitute Chemicals: Using less toxic alternatives whenever possible, such as non-cyanide plating baths.

Q 11. Describe the different types of plating baths and their applications.

Plating baths are solutions containing metal salts, conducting salts (to improve conductivity), and additives (to influence plating properties like brightness, leveling, and stress). The choice of bath depends heavily on the desired plating material and properties.

Acid Copper Baths: Used for copper plating, known for high throwing power and good ductility. Commonly used for printed circuit boards and decorative applications.

Cyanide Copper Baths: Offer excellent throwing power and a bright finish. However, due to the toxicity of cyanide, they are increasingly replaced by cyanide-free alternatives.

Nickel Baths: Widely used for protective and decorative coatings, offering good corrosion resistance and hardness. Can be either Watts nickel (sulfate-based) or nickel chloride based, each having different properties.

Chrome Baths: Typically used for decorative chromium plating (bright, shiny finish) or hard chromium plating (high hardness and wear resistance). These baths are highly acidic and require careful handling.

Gold Baths: Used for applications requiring excellent conductivity and corrosion resistance, such as electrical contacts and jewelry. Various types exist, depending on the desired color and other properties.

Choosing the appropriate bath requires careful consideration of factors such as required properties of the coating (hardness, corrosion resistance, conductivity), the substrate material, and environmental regulations.

Q 12. Explain the concept of throwing power in electroplating.

Throwing power refers to the ability of an electroplating bath to produce a relatively uniform coating thickness on a complex-shaped part, especially in recesses or areas that are not directly facing the anode. Think of it as the ability of the plating solution to ‘reach’ all parts of the workpiece equally.

Factors Affecting Throwing Power:

Bath Conductivity: Higher conductivity generally leads to better throwing power.

Current Density Distribution: Uniform current distribution enhances throwing power. Jig design and anode placement are crucial.

Bath Additives: Certain additives can improve throwing power by influencing the current distribution and the plating process.

Geometry of the Part: Complex shapes inherently have more difficult-to-plate areas.

Importance of Throwing Power: Good throwing power is essential when plating parts with intricate designs or deep recesses, ensuring uniform protection and functionality across the entire component. Poor throwing power can lead to uneven coating thickness, potentially compromising performance and appearance.

Q 13. How do you troubleshoot problems related to pitting, burning, or poor adhesion in plating?

Troubleshooting plating defects requires systematic investigation. Let’s consider the mentioned problems:

Pitting: Small holes or depressions in the coating. This could stem from:

- Contamination in the plating bath.

- Insufficient cleaning of the substrate.

- Presence of inclusions in the plating solution.

- Localized high current density.

Troubleshooting Steps: Analyze the bath chemistry, improve substrate cleaning, filter the bath, and adjust jigging to ensure uniform current distribution.

Burning: Rough, uneven, and sometimes nodular deposition often caused by:

- Excessive current density.

- Insufficient agitation.

- Impurities in the bath.

Troubleshooting Steps: Reduce current density, improve agitation (e.g., air agitation or solution pumping), and filter the bath.

Poor Adhesion: The plating readily peels or flakes off. This can be due to:

- Inadequate substrate preparation (poor cleaning, insufficient etching).

- Contamination of the substrate surface.

- Improper pre-treatment.

- Incompatibility between the substrate and the plating material.

Troubleshooting Steps: Re-evaluate the cleaning and pre-treatment steps, ensuring proper surface preparation and compatibility of materials.

In general, troubleshooting involves careful observation of the defects, analysis of the plating parameters, and systematic adjustment of the process to address the root cause.

Q 14. What are the safety precautions to be followed while working with plating solutions?

Working with plating solutions demands strict adherence to safety precautions due to the hazardous nature of many chemicals involved. Consider safety paramount.

Personal Protective Equipment (PPE): Always wear appropriate PPE, including gloves (nitrile or neoprene), eye protection (safety goggles or face shields), lab coats, and respiratory protection (if necessary) to minimize exposure to toxic fumes or splashes.

Ventilation: Ensure adequate ventilation to minimize exposure to hazardous fumes. Plating tanks should ideally be housed in a well-ventilated area or equipped with fume hoods.

Chemical Handling: Handle chemicals carefully, following the manufacturer’s safety data sheets (SDS). Avoid direct contact with skin or eyes. Use appropriate dispensing equipment.

Emergency Procedures: Be familiar with emergency procedures in case of spills or accidents, including appropriate first aid measures and procedures for contacting emergency services. Ensure spill kits are readily available.

Waste Disposal: Dispose of all plating waste properly, following all relevant environmental regulations and guidelines. Never pour waste down the drain without appropriate treatment.

Training: Receive proper training on handling and using plating solutions, including safety procedures and emergency response.

Remember, a safe working environment is not just a policy; it’s a commitment to protecting your health and the environment.

Q 15. Explain the role of additives in plating solutions.

Additives in plating solutions are crucial for controlling the plating process and achieving desired coating properties. They’re like the secret ingredients in a recipe, each playing a specific role to enhance the final product.

- Brighteners: These additives produce a bright, shiny finish, preventing dull or matte surfaces. Think of them as the ‘shine enhancer’ in a plating solution. For example, certain organic compounds are used as brighteners in nickel plating.

- Levelers: Levelers promote uniform coating thickness, especially on parts with complex geometries. They help fill in imperfections and ensure a consistent finish. Imagine them as the ‘smoothing agents’ that reduce surface roughness.

- Stress reducers: These minimize internal stresses within the plated layer, preventing cracking or warping. Think of these as the ‘relaxants’ for the metal coating, ensuring its stability.

- Carriers: These help distribute the metal ions evenly throughout the solution, improving efficiency and consistency. These are the ‘delivery drivers’ for the metal ions to the workpiece.

- Buffers: Buffers help maintain the pH of the solution, ensuring stable plating conditions. They are the ‘pH regulators,’ preventing drastic changes that could affect the plating quality.

Without the right combination of additives, the plating might be dull, uneven, brittle, or prone to defects. The careful selection and control of additives are critical for producing high-quality functional coatings.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe the process of stripping a plated coating.

Stripping a plated coating involves removing the deposited metal layer from the substrate. This is often necessary for rework, reclaiming valuable metals, or correcting plating defects. The stripping process depends heavily on the type of coating and the substrate material. It’s a bit like carefully peeling away a layer of paint to reveal the original surface.

Common stripping methods include:

- Chemical Stripping: This involves immersing the plated part in a chemical solution that dissolves the coating. The choice of solution depends on the plated metal. For example, nitric acid is commonly used to strip silver, while chromic acid is used for stripping zinc.

- Electrochemical Stripping: This technique uses an electrolytic cell to reverse the plating process. The plated metal acts as the anode, and it dissolves into the solution as current is applied. This method offers greater control over the stripping process.

- Mechanical Stripping: This involves using physical methods, such as grinding, sanding, or blasting, to remove the coating. This is often used for very thick coatings or when other methods are unsuitable but may damage the base material.

Safety precautions are paramount during stripping, as many stripping solutions are corrosive and hazardous. Proper ventilation and personal protective equipment (PPE) are essential.

Q 17. What are the different types of plating racks and their applications?

Plating racks are essential for holding parts during the plating process, ensuring uniform coating distribution. They are tailored to the shape and size of the parts being plated, much like a tailor-made garment. The choice of rack depends heavily on the application.

- Rack Plating: Uses individual racks designed to hold parts firmly, providing good electrical contact and allowing for precise control over the plating process. This method is ideal for high-quality plating on complex parts.

- Barrel Plating: Employs rotating barrels containing the parts. This method is highly efficient for plating small, similar parts, like screws or fasteners, but doesn’t allow for the same level of control over individual parts as rack plating.

- Hook Plating: Utilizes simple hooks to suspend parts in the plating bath. Suitable for simple shapes and small batches but is less efficient than rack or barrel plating.

- Jigs and Fixtures: These custom-designed holders are used for specific complex shapes or when precise coating thickness is crucial for particular areas.

The material of the rack is also important, as it must be electrically conductive and resistant to corrosion in the plating bath. Common materials include copper, stainless steel, and titanium.

Q 18. How do you determine the appropriate plating parameters for a specific application?

Determining appropriate plating parameters involves understanding the desired coating properties and the substrate material. It’s like finding the perfect recipe ingredients and cooking time for a delicious meal. The process requires careful consideration of several factors:

- Current Density: The amount of current applied per unit area affects coating thickness, grain size, and stress. Too high of current can lead to ‘burning’ or uneven deposition.

- Voltage: The potential difference across the electrodes affects the rate of metal deposition and efficiency of the process.

- Temperature: Affects the reaction rate, influencing coating thickness and uniformity.

- Solution Composition and Concentration: The type and concentration of metal salts and additives directly impact coating properties.

- Plating Time: The duration of the process determines the final thickness of the coating.

- Agitation: Mixing the solution ensures even distribution of metal ions and additives.

These parameters are often optimized through experimentation and experience. Electroplating baths require close monitoring of various parameters, and data logging is essential to maintaining process quality and consistency. Computer-controlled plating systems are frequently used to automate these processes.

Q 19. What are the advantages and disadvantages of different plating processes (e.g., barrel plating, rack plating)?

Barrel and rack plating are two common methods with distinct advantages and disadvantages.

- Rack Plating:

- Advantages: Excellent control over individual part plating, higher quality finish possible, suitable for complex shapes.

- Disadvantages: Lower throughput, higher labor costs, unsuitable for small parts or mass production.

- Barrel Plating:

- Advantages: High throughput, low labor costs, ideal for small, similar parts, mass production friendly.

- Disadvantages: Less control over individual part plating, potential for part-to-part scratching, finishing quality may be lower compared to rack plating.

The choice between barrel and rack plating depends on factors such as part geometry, batch size, desired coating quality, and production volume. Mass production often favors barrel plating, while high-quality finishing necessitates rack plating.

Q 20. Explain the concept of passivation in plating.

Passivation is a post-plating treatment that enhances the corrosion resistance of the coating. It’s like adding a protective shield to the plated surface. This is done by forming a thin, stable oxide layer on the surface of the plated metal.

For example, passivation of stainless steel involves creating a chromium oxide layer that protects the underlying metal from corrosion. Similarly, many plated coatings, such as zinc, are passivated to improve their corrosion resistance and durability. This often involves immersion in a chemical solution that promotes the formation of this protective layer. The specific passivation process depends on the plated metal.

Passivation can significantly extend the lifespan of plated components, especially those exposed to harsh environments.

Q 21. How do you maintain and troubleshoot plating equipment?

Maintaining and troubleshooting plating equipment requires regular inspection and preventative maintenance. Think of it as regular check-ups for a car to ensure smooth operation. This involves:

- Regular Cleaning: Cleaning the plating tank, filters, and other equipment removes contaminants that can affect the plating process.

- Solution Analysis: Regular analysis of the plating solution ensures the correct concentration of metal ions and additives.

- Anode Inspection: Checking the anodes for wear and tear ensures efficient metal dissolution.

- Equipment Calibration: Calibrating instruments like power supplies and temperature controllers ensures accurate process control.

- Troubleshooting: Addressing issues such as pitting, burning, or poor adhesion requires understanding the root cause and taking corrective actions. This might involve adjusting plating parameters, changing the solution, or replacing worn-out components.

- Safety Procedures: Adhering to strict safety procedures is critical, as plating solutions and equipment can be hazardous.

Detailed records and logs should be maintained for each plating run. These records help track performance, identify trends, and facilitate troubleshooting. Effective preventative maintenance significantly reduces downtime and improves plating quality.

Q 22. Describe your experience with different types of plating metals (e.g., gold, silver, nickel, chromium).

My experience encompasses a wide range of plating metals, each with its unique properties and applications. For instance, gold plating is prized for its excellent conductivity and corrosion resistance, making it ideal for electronics and connectors. I’ve worked extensively with gold plating processes, including those using cyanide and non-cyanide baths, optimizing for thickness uniformity and adhesion. Silver plating, known for its high reflectivity and conductivity, is frequently used in mirrors and electrical contacts. My work with silver has involved troubleshooting issues related to tarnish and ensuring consistent plating thickness across complex geometries. Nickel plating serves as a foundation for many other coatings, offering corrosion protection and a base for subsequent finishes like chrome. I’ve managed nickel plating lines, focusing on optimizing bath composition and controlling internal stresses to prevent cracking. Finally, chromium plating provides exceptional hardness and wear resistance, crucial for tools and decorative applications. My experience includes optimizing chromium plating processes for different applications, ranging from hard chrome for tooling to decorative chrome for automotive parts. Each metal presents specific challenges – from managing bath chemistry to controlling plating parameters to achieve the desired properties.

Q 23. Explain your understanding of plating specifications and standards.

Plating specifications and standards are crucial for ensuring the quality and reliability of the final product. These specifications dictate the thickness of the plating, its uniformity, its adhesion to the substrate, its corrosion resistance, and its overall appearance. Common standards I’ve worked with include ASTM (American Society for Testing and Materials) and ISO (International Organization for Standardization) standards. For example, ASTM B117 (Salt Spray Test) is used to assess the corrosion resistance of plated parts, while ASTM B568 provides guidelines for determining the thickness of metallic coatings. Understanding these standards is critical for meeting client requirements and ensuring the plated components perform as intended. A specific example might involve a client requiring a gold plating of 5 microns +/- 0.5 microns with a minimum adhesion strength of X N/cm². I would ensure our process adheres to these parameters using precise measurements and quality control procedures, meticulously documented and tracked.

Q 24. How do you ensure compliance with environmental regulations in plating operations?

Environmental compliance is paramount in plating operations. We employ rigorous measures to minimize the environmental impact of our processes. This includes careful management of wastewater, using closed-loop systems whenever possible to reduce water consumption and minimize waste discharge. We treat our wastewater according to all relevant regulations, employing techniques like chemical precipitation, filtration, and ion exchange to remove heavy metals and other contaminants. Regular monitoring and analysis of wastewater are performed to ensure compliance. Furthermore, we utilize environmentally friendly plating chemistries, such as non-cyanide alternatives for gold and silver plating, whenever feasible. We also prioritize proper handling and disposal of hazardous materials, complying with all relevant local, state, and federal regulations. Maintaining accurate records and reporting is also crucial for demonstrating compliance to regulatory authorities. Our commitment to environmental responsibility includes regular training for our staff on safe handling procedures and environmental regulations.

Q 25. Describe your experience with statistical process control (SPC) in plating.

Statistical Process Control (SPC) is integral to maintaining consistent plating quality. We use SPC tools like control charts (e.g., X-bar and R charts) to monitor key process parameters such as plating thickness, current density, and bath temperature. By regularly collecting data and plotting it on control charts, we can identify trends and variations in the process and promptly address any issues before they impact the quality of the plating. For example, if the plating thickness consistently falls outside the control limits, we would investigate the root cause, which could range from variations in bath chemistry to issues with the plating equipment. Implementing SPC enables proactive problem-solving, reducing waste and improving overall process efficiency. This data-driven approach ensures that our plating consistently meets the required specifications.

Q 26. Explain your experience with root cause analysis in troubleshooting plating problems.

Troubleshooting plating problems often involves a systematic approach using root cause analysis. When faced with a plating defect, such as pitting or poor adhesion, we employ techniques like the ‘5 Whys’ or fishbone diagrams to identify the underlying causes. For example, if we encounter poor adhesion, we might ask: Why is the adhesion poor? (Answer: The surface wasn’t properly cleaned). Why wasn’t the surface properly cleaned? (Answer: The cleaning solution was depleted). This iterative questioning helps to uncover the root cause, rather than just addressing the symptoms. Once the root cause is identified, we implement corrective actions, retest the process, and document the findings to prevent similar issues from recurring. Data analysis, visual inspection, and consultation with experts are often part of this process. A documented root cause analysis helps to improve our overall process understanding and prevent future occurrences.

Q 27. Describe your experience with process optimization in plating.

Process optimization in plating involves continuously improving efficiency, quality, and cost-effectiveness. This involves optimizing plating parameters such as current density, bath temperature, and plating time. We employ Design of Experiments (DOE) methodologies to systematically investigate the effects of these parameters on the final plating quality. We might experiment with different cleaning procedures, bath compositions, or pre-treatment methods to find the optimal conditions that yield consistent, high-quality plating with minimal defects. We also focus on improving the efficiency of our plating processes, reducing cycle times, and minimizing waste. For instance, we may implement automation to reduce manual labor and increase throughput, ensuring faster turnaround times while maintaining quality standards. Regular review of process parameters and the implementation of findings from root cause analysis help drive continuous improvement and optimization.

Key Topics to Learn for Plating of Functional Coatings Interview

- Electroplating Fundamentals: Understanding Faraday’s laws, electrode kinetics, and the influence of current density and plating bath composition.

- Types of Functional Coatings: Familiarize yourself with various coating types like nickel, chrome, zinc, gold, and their respective applications (e.g., corrosion resistance, wear resistance, conductivity).

- Surface Preparation Techniques: Mastering pre-treatment methods such as cleaning, degreasing, and etching for optimal adhesion and coating quality.

- Plating Bath Chemistry: Grasp the role of different additives (brighteners, levelers, stress reducers) in achieving desired coating properties.

- Quality Control and Testing: Understand common quality control methods such as thickness measurement, adhesion testing, and porosity testing.

- Troubleshooting Common Plating Issues: Develop problem-solving skills to address issues like pitting, burning, and poor adhesion during the plating process.

- Health and Safety Regulations: Be aware of relevant safety protocols and environmental regulations concerning handling chemicals and waste disposal in plating operations.

- Practical Applications across Industries: Explore the use of functional coatings in diverse sectors like automotive, aerospace, electronics, and biomedical engineering.

- Advanced Plating Techniques: Research emerging technologies such as electroless plating, pulse plating, and high-speed plating.

Next Steps

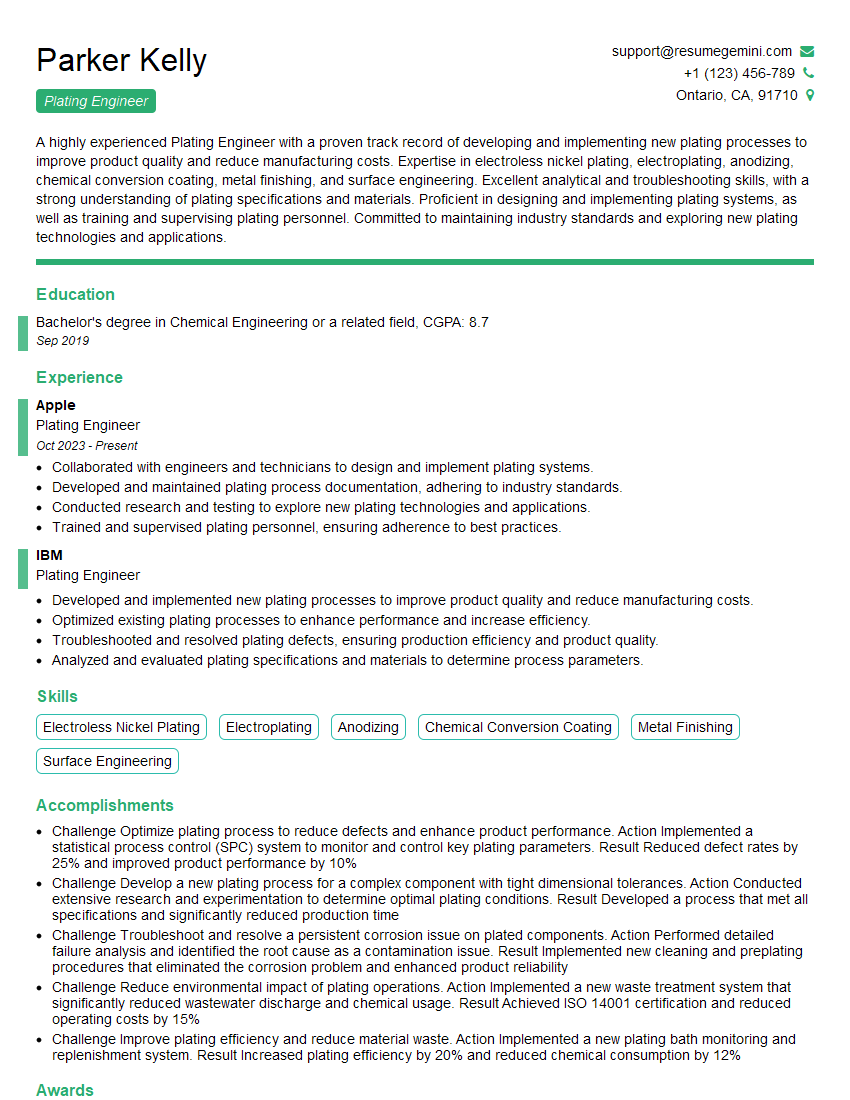

Mastering the principles and applications of Plating of Functional Coatings opens doors to exciting career opportunities in materials science, manufacturing, and engineering. A strong understanding of this field significantly enhances your employability and paves the way for career advancement. To stand out in the job market, it’s crucial to present your skills and experience effectively. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your expertise in Plating of Functional Coatings. Examples of resumes tailored to this specialization are available to guide you. Invest time in crafting a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good