Are you ready to stand out in your next interview? Understanding and preparing for Plowing Fields interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Plowing Fields Interview

Q 1. Describe your experience operating different types of plows.

My experience spans a wide range of plows, from traditional moldboard plows to more modern versions like chisel plows and disk plows. I’m proficient with both pulled and mounted plows, and have worked with various sizes and configurations depending on the field conditions and the type of tractor. For instance, I’ve used a three-bottom moldboard plow for smaller, more manageable fields with heavier clay soils, where deep, clean furrows are crucial for seedbed preparation. In larger fields with lighter soils, I often opt for a larger, five-bottom moldboard plow or even a chisel plow for faster, less intensive tillage. Working with disk plows is ideal for breaking up tough sod or preparing fields with significant residue. Each plow type demands a different approach to operation, requiring adjustments to speed, depth, and tractor settings to achieve optimal results.

For example, moldboard plows require careful attention to maintain a consistent depth and prevent the plow from getting clogged, especially in heavier soils. With disk plows, the key is to adjust the angle and pressure of the disks to ensure proper soil penetration and fragmentation without excessive soil disturbance. The difference in approach highlights the need for adaptability and a deep understanding of soil mechanics and equipment operation.

Q 2. Explain the importance of proper soil preparation before plowing.

Proper soil preparation before plowing is paramount for a successful harvest. It ensures efficient plowing, better seed germination, and healthier plant growth. Neglecting this step can lead to problems like poor seed-to-soil contact, uneven emergence, and reduced yields. Preparation involves several crucial steps, beginning with a thorough assessment of the soil’s condition. This involves checking for compaction, identifying weed infestation, and evaluating the soil’s moisture content.

- Weed Control: Controlling weeds before plowing reduces competition for nutrients and improves overall crop health. Herbicides or other weed management techniques are often implemented before the plow even hits the field.

- Residue Management: Properly managing crop residue is essential. Leaving too much residue can interfere with plowing, while insufficient residue may lead to soil erosion. Techniques like incorporating residue into the soil through tilling or managing it on the surface help to retain moisture and improve soil structure.

- Soil Moisture: The ideal soil moisture content for plowing varies depending on the soil type, but generally, the soil should be moist enough to avoid excessive compaction but not so wet that it becomes sticky and difficult to work with. This is especially critical to avoid creating clods which makes seeding extremely difficult.

By addressing these aspects before plowing, we create a more favorable environment for planting and significantly improve the likelihood of a successful harvest. Think of it like preparing a well-manicured garden bed; you wouldn’t just start planting without first clearing weeds and loosening the soil.

Q 3. What are the different types of plowing techniques and when would you use each?

Various plowing techniques exist, each with its strengths and appropriate applications. The choice depends on factors like soil type, desired tillage intensity, and the presence of crop residue.

- Moldboard Plowing: This traditional method inverts the soil, burying crop residues and creating a clean seedbed. Ideal for heavy clay soils and when deep tillage is required. It’s very effective at burying weed seeds and pest insects.

- Chisel Plowing: This conserves soil moisture and minimizes soil disturbance. Shanks break up compacted layers without fully inverting the soil, suitable for lighter soils and areas with a high amount of crop residue. It is effective when you want to retain crop residue on the surface to combat erosion.

- Disk Plowing: Cuts and mixes the soil without significant inversion. Used for breaking up heavy sod or preparing seedbeds in lighter soils, especially in dry conditions. It leaves a more rough surface, making it ideal for soil with lower organic matter content.

- Contour Plowing: Following the contours of the land to prevent soil erosion, particularly on sloping fields. Crucial for protecting topsoil and reducing water runoff.

For example, I would use moldboard plowing to prepare heavy clay soil before planting corn, while chisel plowing might be more suitable for lighter soils with significant crop residue before planting soybeans. Choosing the right technique optimizes resource use and mitigates potential problems.

Q 4. How do you determine the appropriate plowing depth for various soil types?

Determining the appropriate plowing depth is crucial for optimal soil management and depends heavily on the soil type, crop to be planted, and the presence of subsurface compaction layers. It’s a balancing act; too shallow a depth fails to address compaction issues and may not provide adequate seedbed preparation, while too deep a depth can damage soil structure and lead to excessive soil inversion.

- Soil Type: Lighter sandy soils generally require shallower plowing than heavier clay soils, which may need deeper plowing to break up compacted layers.

- Crop Requirements: Different crops have different root systems and depth requirements. Deep-rooted crops like alfalfa will need a deeper plow depth than shallow-rooted crops.

- Subsurface Compaction: If compaction layers exist, plowing might need to reach below these layers to improve water infiltration and root penetration. This might necessitate the use of subsoilers in addition to standard plowing.

I usually start with a slightly shallower depth than initially planned and observe the soil’s response. If the soil is easily turned and the plow operates smoothly, a slightly deeper depth can be tried. In many cases, I’ll use a soil probe or auger to evaluate the soil profile, and this helps me to determine the depth needed to break through any compaction layers.

Q 5. Explain the process of calibrating a plow for optimal performance.

Calibrating a plow for optimal performance ensures consistent furrow depth, width, and soil inversion. This process involves several steps, starting with a visual inspection of the plow to ensure that all parts are functioning correctly and are properly aligned.

- Depth Adjustment: Adjusting the plow’s depth wheels or hitch ensures consistent plowing depth. This is often done by using a measuring tape or a leveling device to check the depth of the furrows. It’s important that these settings match the desired plowing depth for the soil type and crop.

- Width Adjustment: The width of the furrows is adjusted by changing the spacing between the plow bodies or shares. Consistent width ensures uniform soil coverage. Slight adjustments are often needed to maintain consistent furrow width across varying soil types.

- Draft Adjustment: This involves adjusting the tractor’s drawbar to ensure the plow is pulling at the proper level, which affects depth and width. This ensures the plow pulls correctly to prevent clogging.

- Testing and Fine-tuning: After initial adjustments, test the plow in a small area and observe the furrows for consistency. Make adjustments to fine-tune the plow until the desired results are achieved. It is not unusual to make small adjustments multiple times while plowing.

Accurate calibration is essential for efficiency and ensures a consistent and effective tillage operation. I always carefully calibrate my plows before starting work and regularly monitor for any needed readjustments during operation. This prevents wasted effort and improves the overall quality of the plow work.

Q 6. How do you identify and address common plowing problems, such as compaction or uneven furrows?

Common plowing problems like compaction and uneven furrows often stem from improper calibration, unsuitable equipment for the soil type, or incorrect operating techniques. Addressing these issues requires a systematic approach.

- Compaction: Compacted soil usually requires a deeper plowing depth to break up the hardpan. Sometimes, additional implements like subsoilers might be necessary to break up severely compacted layers. In other situations, the issue can be addressed by adjusting soil moisture content, or by choosing alternative techniques like chisel plowing that cause less compaction.

- Uneven Furrows: Uneven furrows can indicate a problem with the plow’s alignment, a worn share, or inconsistent ground speed. Checking the plow’s alignment, replacing worn parts, maintaining a consistent tractor speed, and adjusting the tractor’s weight distribution often resolve this problem.

- Clogging: Clogged plows, especially moldboard plows, usually result from high soil moisture content or soil that is too sticky. Addressing this often requires waiting for the soil to dry out or choosing alternative plowing methods or techniques.

For example, if I encounter uneven furrows, I’d first check the plow for any damaged parts and ensure all the plow bodies are properly aligned and functioning. Then, I’d check my ground speed to confirm it’s consistent. If the problem persists, it might require further adjustment of the plow’s depth or width controls.

Q 7. Describe your experience maintaining and repairing plowing equipment.

Maintaining and repairing plowing equipment is crucial for ensuring its longevity and optimal performance. Regular maintenance extends the life of the equipment and prevents unexpected breakdowns during critical periods.

- Regular Inspections: After each use, a thorough visual inspection is essential, checking for wear and tear on shares, points, coulters, and other components. I look for signs of damage, breakage, and excessive wear, replacing parts as needed.

- Lubrication: Regular lubrication of all moving parts is vital to minimize friction and wear. This includes greasing pivot points, bearings, and other critical areas according to the manufacturer’s specifications. A well-lubricated plow operates smoothly, extends its life, and reduces maintenance costs.

- Sharpening and Replacement: Shares and points become dull over time, reducing plowing efficiency. Regular sharpening is crucial for maintaining cutting ability. Worn parts should be replaced promptly to prevent further damage and ensure effective plowing.

- Storage: Proper storage protects the plow from corrosion and damage during periods of non-use. This involves cleaning the plow thoroughly, applying protective coatings where necessary, and storing it in a dry, sheltered area.

I’ve had experiences with everything from simple share replacements to more complex repairs requiring welding or specialized tools. Knowing how to perform basic maintenance and repairs significantly reduces downtime and minimizes operational costs. It’s a combination of preventative maintenance and timely repairs that keeps the equipment running smoothly and effectively.

Q 8. How do you ensure the safety of yourself and others while operating plowing equipment?

Safety is paramount in plowing. Before even starting the tractor, I conduct a thorough pre-operation check, ensuring all fluid levels are correct, lights are functioning, and the plow is securely attached. I then visually inspect the field for any hidden obstacles like rocks, debris, or underground utilities. This prevents damage to equipment and potential injury.

During operation, I maintain a safe speed appropriate for the field conditions and visibility. I avoid distractions and remain alert to my surroundings. I always wear appropriate personal protective equipment (PPE), including safety glasses, hearing protection, and sturdy work boots. When operating near roadways or other areas with potential pedestrian traffic, I utilize warning lights and flags. If working with others, clear communication is vital; we establish hand signals or utilize radios to coordinate movements safely. Finally, regular maintenance on the equipment is crucial to preventing malfunctions that could lead to accidents. I keep a detailed maintenance log to ensure everything is properly functioning. Think of it like driving a car – regular checks and careful operation are crucial for preventing accidents.

Q 9. Explain your understanding of soil conservation practices related to plowing.

Soil conservation is integrated into every aspect of my plowing practices. No-till farming, where we minimize soil disturbance, is a prime example. Instead of completely inverting the soil, we use specialized equipment to plant directly into the previous year’s residue, preserving soil structure, reducing erosion, and improving water infiltration. Contour plowing, where furrows follow the natural contours of the land, also helps reduce erosion by slowing down water runoff. Crop rotation is another key strategy; alternating crops helps maintain soil health and fertility, reducing the need for excessive plowing. Cover crops, planted in the off-season, protect the soil from erosion and improve soil structure. Implementing these practices requires understanding soil type and weather conditions, adjusting techniques as needed. For instance, heavy clay soils might need a different approach than sandy loam soils, and the amount of rainfall will influence choices regarding no-till or reduced-till techniques. It’s about working with nature, not against it. Properly managing the soil is crucial to its long-term productivity, and that is paramount to me.

Q 10. What are the benefits and drawbacks of using GPS-guided plowing systems?

GPS-guided plowing offers significant benefits. Accuracy is greatly improved; overlaps are minimized, saving time and fuel, and ensuring uniform planting. It allows for automated steering, reducing operator fatigue and increasing efficiency, particularly over large areas. You can also program precise plowing depths and patterns, leading to optimized soil conditions. However, there are drawbacks. The initial investment for the GPS system and compatible tractor can be substantial. Signal interference or equipment malfunctions can disrupt operation. Also, a reliance on technology requires regular maintenance and potential troubleshooting skills. I’ve personally found that while the initial cost is high, the long-term savings in fuel and improved yields make it a worthwhile investment for larger farms. However, for smaller operations, the cost-benefit analysis might need more consideration.

Q 11. How do you adapt your plowing techniques to different field conditions (e.g., slopes, obstacles)?

Adapting to different field conditions requires experience and judgment. On slopes, I adjust the plowing technique to follow the contours of the land, minimizing erosion and preventing the tractor from sliding. I might need to work up and down the slope or use specialized equipment designed for hilly terrains. When encountering obstacles like rocks or trees, I carefully maneuver around them, reducing the risk of damage. I might use a different plowshare depending on soil conditions and presence of rocky debris. In situations with wet soil, I might reduce the depth of plowing or postpone the task to prevent compaction. Assessing these situations is crucial for preserving soil structure and protecting the machinery. I often use a combination of visual inspection and sensing the tractor’s behavior; for example, increased engine strain signals the need to adjust the plowing technique or depth.

Q 12. Describe your experience with various types of tractors and their suitability for different plowing tasks.

My experience encompasses a range of tractors, from smaller, more agile models ideal for smaller fields and tight spaces to larger, more powerful machines suited for extensive plowing operations. Smaller tractors, often with less horsepower, excel in maneuverability, making them suitable for maneuvering around obstacles and in irregularly shaped fields. Larger tractors, with greater horsepower and pulling capacity, are efficient for tackling large, flat fields quickly. The choice of tractor depends on factors such as field size, soil type, and the type of plow being used. For example, a heavy-duty tractor with a three-point hitch is necessary for pulling a large moldboard plow in heavy clay soil. In contrast, a smaller tractor might suffice for a light-duty disc plow in a sandy soil. For hilly terrains, a four-wheel drive tractor offering greater stability is preferable.

Q 13. How do you manage fuel efficiency while operating plowing equipment?

Fuel efficiency is a key concern. I optimize fuel consumption by maintaining proper tire pressure, ensuring the tractor is well-maintained, and avoiding unnecessary idling. Selecting the appropriate tractor size for the job is crucial; using a larger tractor than necessary wastes fuel. Proper plowing techniques, such as maintaining a consistent speed and depth, also contribute to fuel savings. I also try to plan routes effectively to minimize unnecessary travel time. Advanced technologies, such as GPS guidance, which minimize overlaps, significantly improve fuel efficiency. Moreover, I utilize regular maintenance checks to ensure there are no fuel leaks or engine inefficiencies. It’s a combination of sensible operational practices and regular maintenance that delivers good fuel economy.

Q 14. What is your experience with different types of plowshares and their applications?

Different plowshares are designed for various soil types and plowing conditions. Moldboard plows, with their curved shares, are effective in turning over heavy soils. Disc plows, with their rotating discs, are better suited for lighter soils or stony areas. Chisel plows, which have shanks that penetrate the soil, are used for minimum tillage or deep ripping to improve drainage. The selection of plowshares is crucial for soil conservation and maximizing efficiency. Using the wrong type of plowshare can lead to soil compaction, reduced yields, and increased wear and tear on equipment. For example, using a moldboard plow in stony soil could damage both the plow and the tractor. Therefore, proper selection based on soil type, intended depth, and the presence of obstacles is crucial for achieving the desired results.

Q 15. How do you handle unexpected equipment malfunctions during plowing?

Unexpected equipment malfunctions are an inevitable part of plowing. My approach prioritizes preventative maintenance to minimize these occurrences, but when they do happen, my response is swift and methodical. First, I assess the situation for safety – ensuring the equipment is safely shut down and the area is secure. Then, I identify the specific problem. Is it a simple fix, like a clogged fuel filter, or something more complex requiring a mechanic? I carry a well-stocked toolbox with common replacement parts for quick repairs. For more significant problems, I have a pre-established network of reliable mechanics I can contact for immediate assistance. I also maintain detailed records of equipment maintenance, which aids in troubleshooting and identifying recurring issues. For instance, if a particular plow component consistently fails, I might explore upgrading to a more durable model. Time is critical during plowing season, so having a backup plan and quick access to resources is paramount.

For example, once I experienced a sudden hydraulic fluid leak mid-operation. By quickly identifying the source of the leak (a cracked hose), I was able to temporarily repair it with a spare hose and clamp, enabling me to finish the day’s work. A full repair was then scheduled for the following day.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your knowledge of various soil types and their impact on plowing.

Soil type profoundly influences plowing strategies. Different soils require different plowing techniques to achieve optimal results and avoid soil compaction or damage. Clay soils, for example, are heavy and sticky when wet, making plowing difficult and potentially leading to clods. They need to be plowed when they’re at the right moisture level to prevent this. Sandy soils, on the other hand, are light and drain quickly, but can be easily eroded if plowed improperly. Loamy soils, a mixture of sand, silt, and clay, are generally considered ideal for plowing, offering a good balance of drainage and structure. I assess the soil type before each plowing operation, using visual inspection, feel, and sometimes even a soil testing kit to determine its characteristics. This informs my decisions about the type of plow to use, the depth of plowing, and the optimal time for the operation.

- Clay: Requires careful timing and possibly the use of a heavier plow to break up large clods.

- Sandy: Requires shallower plowing to avoid erosion and might benefit from techniques to improve soil structure.

- Loamy: Generally easier to plow and allows for greater flexibility in plowing depth and methods.

Q 17. How do you plan and execute a large-scale plowing operation?

Planning a large-scale plowing operation requires meticulous organization and coordination. It begins with a thorough survey of the field to assess its size, topography, soil type, and any obstacles like rocks or ditches. This is followed by a detailed operational plan, including the number of tractors and plows required, the plowing sequence (often in parallel strips to maximize efficiency), and the assignment of tasks to each operator. Effective communication among the team is critical, ensuring everyone understands their role and the overall strategy. Logistics, such as fuel supply, maintenance schedules, and potential weather delays, are also carefully planned. We use GPS-guided technology to optimize plowing routes, minimizing overlaps and maximizing field coverage. Post-plowing tasks, like soil testing or incorporating amendments, are also included in the plan. For example, in one large-scale operation, we divided a 500-acre field into sections, assigning specific teams to each, meticulously tracking progress via GPS and regular communication. This ensured timely and efficient completion without compromising quality.

Q 18. What are your preferred methods for managing weeds and other unwanted vegetation during plowing?

Weed management is an integral part of plowing. My preferred methods combine preventative measures with targeted control during plowing. Preventative methods include crop rotation and selecting weed-resistant crop varieties. During plowing, I aim to bury weed seeds deep in the soil to prevent germination, incorporating herbicides where appropriate and adhering strictly to label instructions to protect soil health. However, mechanical methods remain my primary focus: deep plowing, followed by harrowing to further break up the soil and expose weed seedlings to sunlight, significantly reduces weed pressure. I avoid excessive tillage which can be counterproductive and increase the weed seedbank. I also monitor the fields closely after plowing for any weed emergence and adjust my strategy as necessary – this may involve spot-treating with herbicides or using a cultivator for specific weed control.

Q 19. How do you monitor soil moisture levels and adjust your plowing strategy accordingly?

Monitoring soil moisture is crucial for successful plowing. Plowing in overly dry soil leads to excessive compaction and poor seedbed preparation, while plowing when the soil is too wet can cause significant damage to the soil structure and equipment. I use a combination of methods to assess soil moisture: visual inspection (checking for color and texture), using a soil moisture meter, and considering recent rainfall. Based on this assessment, I adjust my plowing strategy. If the soil is too dry, I may delay plowing until after sufficient rainfall or irrigation. If it’s too wet, I’ll wait until the soil has dried to a workable consistency. This ensures optimal plowing conditions and protects the soil’s structure. For instance, during a period of prolonged drought, I was able to delay plowing until sufficient rain improved soil moisture, leading to a far more effective plowing operation.

Q 20. What is your experience with no-till farming and its impact on soil health?

No-till farming, a method that minimizes soil disturbance, has a significant impact on soil health. While my primary experience is in conventional tillage, I understand its principles and benefits. No-till farming reduces soil erosion, improves water infiltration, enhances soil organic matter, and promotes biodiversity. It also reduces fuel consumption and labor costs compared to conventional plowing. The reduced soil disturbance protects beneficial soil organisms and reduces the release of carbon dioxide. However, no-till systems require careful management of weeds, pests, and diseases, often relying more on herbicides and crop rotation. Although I’m primarily focused on conventional plowing, I’m aware of the growing interest in no-till practices and believe that understanding its principles is essential for the sustainable management of agricultural lands.

Q 21. Explain the importance of proper field drainage in relation to plowing.

Proper field drainage is essential before and after plowing. Poor drainage leads to waterlogged soils, hindering root growth and making plowing difficult or impossible. Before plowing, I assess the field’s drainage system, looking for areas prone to waterlogging. This often involves examining existing drainage ditches and considering the land’s topography. If necessary, I might suggest improvements to the drainage system before commencing plowing. After plowing, the goal is to maintain a good soil structure that facilitates water infiltration. The plowing process itself can affect drainage, so careful management is needed to avoid creating compacted layers that hinder water movement. Adequate drainage is vital for the health of crops, and the effectiveness of any subsequent agricultural practices.

Q 22. How do you ensure the accurate and efficient use of fertilizers after plowing?

Accurate and efficient fertilizer use post-plowing hinges on understanding soil type and crop needs. We begin with a soil test to determine nutrient deficiencies. This test provides crucial data on the levels of nitrogen, phosphorus, and potassium, among other essential elements. Based on this analysis, we develop a precise fertilizer application plan, using the right type and amount of fertilizer for optimal yield and minimizing environmental impact. For example, if the soil is low in phosphorus, we’d prioritize a phosphorus-rich fertilizer. We utilize methods like variable rate application, using GPS-guided equipment to apply fertilizer precisely according to the soil’s needs, rather than blanket application, saving costs and preventing overuse. Finally, we always incorporate the fertilizer correctly, either through broadcasting followed by incorporation or banding, which ensures optimal nutrient uptake by the crop.

Q 23. Describe your experience with crop rotation and its impact on soil fertility and plowing needs.

Crop rotation is a cornerstone of sustainable agriculture. I’ve extensively employed it over my career, rotating between legumes (like beans or clover), which fix nitrogen in the soil, and heavy feeders (like corn or wheat). This practice minimizes nutrient depletion, reducing the reliance on synthetic fertilizers. Legumes, for instance, enrich the soil with nitrogen, naturally fertilizing subsequent crops. This rotation significantly impacts plowing needs. Fields planted with legumes often require less intensive plowing or minimal tilling as the root systems improve soil structure and prevent compaction. Conversely, heavier crops might need deeper plowing to prepare the soil properly. By monitoring soil health indicators like organic matter content and water infiltration rates, I tailor my plowing techniques accordingly, ensuring minimal disturbance while maximizing soil health. The impact is noticeable: improved soil structure, reduced pest and disease pressure, and higher crop yields.

Q 24. What safety measures do you implement to prevent soil erosion after plowing?

Preventing soil erosion post-plowing is crucial for long-term land health. My approach focuses on a combination of techniques. First, we always plow along the contour lines of the land, following the natural slopes to slow water runoff. This prevents the formation of gullies and channels where topsoil can easily erode. Second, we implement cover cropping. Planting cover crops like rye or alfalfa after harvest but before the next plowing season prevents soil exposure to wind and rain. Their roots bind the soil, preventing erosion. Third, we leave crop residue on the field whenever feasible, using no-till or reduced-till practices. This organic matter acts as a natural shield against erosion. Lastly, in particularly vulnerable areas, we establish windbreaks or utilize terracing to further mitigate the risk of erosion. The goal is to maintain a balance between preparing the soil for planting and preserving its integrity.

Q 25. How do you maintain accurate records of your plowing activities and equipment usage?

Maintaining accurate records is essential for efficient farm management. We use a combination of digital and physical record-keeping. For field mapping and equipment usage, we employ GPS-enabled machinery, which automatically logs data like plowing depth, speed, and area covered. This information is then uploaded to our farm management software, generating detailed reports. We also maintain a physical logbook where we manually record details like date, field location, soil type, weather conditions, fertilizer application rates, and any maintenance performed on our equipment. This dual approach ensures data integrity and accessibility. Regularly reviewing these records allows us to identify trends, optimize our practices, and make informed decisions for future seasons. For example, tracking fuel consumption helps us assess the efficiency of our plowing equipment and identify areas for improvement.

Q 26. Explain your understanding of the environmental impacts of plowing and strategies for mitigation.

Plowing has significant environmental impacts, primarily through soil erosion, increased carbon emissions from soil disturbance, and changes in soil structure. However, mitigation strategies are key. Reducing tillage intensity through no-till or conservation tillage reduces soil disturbance, preserving soil structure and carbon content. Cover cropping protects the soil from erosion and improves its overall health. Implementing crop rotation helps to minimize nutrient depletion and maintain soil fertility, reducing the need for excessive fertilizer use. Using GPS-guided equipment for precise fertilizer application minimizes waste and reduces environmental pollution. Furthermore, adopting techniques like precision agriculture allows us to optimize resource use, minimizing environmental impact. It’s about balancing the need for soil preparation with the environmental responsibility of maintaining healthy, productive land.

Q 27. How do you determine the optimal time of year for plowing, considering weather conditions and crop needs?

Determining the optimal plowing time depends on several factors. Firstly, the weather conditions are crucial. We need favorable soil moisture; the ground should be neither too wet (leading to compaction) nor too dry (making plowing difficult). Generally, the ideal time is after a period of rain but before heavy rains arrive again. Secondly, the crop’s needs are critical. Different crops have different planting requirements, and the plowing should be timed to allow sufficient time for soil preparation before planting. Early-spring plowing is common in many areas for crops like corn, allowing the soil to warm and the organic matter to decompose. However, for certain crops, fall plowing might be more suitable to allow for better weed control and soil aeration. Weather forecasts and historical data play a significant role in decision-making. I often consult weather services for accurate predictions before making plowing decisions to ensure efficient and timely field preparation.

Q 28. Describe your experience working with a team to complete large plowing projects efficiently and safely.

Large plowing projects require efficient teamwork and meticulous planning. We begin with a detailed assessment of the field, including size, terrain, and soil conditions. We then divide the work into manageable sections, assigning specific tasks and responsibilities to each team member based on their experience and expertise. Clear communication is vital; we use two-way radios to ensure constant coordination during the project. Prior to starting work, we have a safety briefing, emphasizing the importance of proper equipment operation, safe working practices, and emergency procedures. Regular breaks are incorporated into the schedule to prevent fatigue. Post-completion, we conduct a thorough inspection to ensure the work meets the desired standards and to identify areas for improvement in future projects. Effective teamwork, combined with proactive safety measures and clear communication, ensures efficient and safe completion of large-scale plowing operations.

Key Topics to Learn for Plowing Fields Interview

Succeeding in your Plowing Fields interview requires a comprehensive understanding of various aspects. The following outlines key areas to focus your preparation:

- Soil Science Fundamentals: Understanding soil types, composition, and their impact on plowing techniques. This includes knowledge of drainage, fertility, and erosion control.

- Plowing Equipment and Technology: Familiarize yourself with different types of plows, tractors, and other machinery used in plowing. Explore the practical applications of GPS technology and precision agriculture in modern plowing practices.

- Sustainable Plowing Techniques: Learn about conservation tillage methods, no-till farming, and their environmental benefits. Be prepared to discuss the trade-offs between different approaches.

- Crop Management and Yield Optimization: Understand how plowing techniques directly influence crop health and yield. Explore the relationship between soil preparation, planting, and subsequent crop management strategies.

- Safety Regulations and Procedures: Demonstrate awareness of safety protocols associated with operating heavy machinery and working in agricultural environments.

- Problem-Solving and Troubleshooting: Be prepared to discuss how you would approach common challenges encountered during plowing, such as equipment malfunctions or unexpected soil conditions.

- Data Analysis and Interpretation: Understand how data related to soil conditions, yields, and equipment performance can be used to optimize plowing strategies.

Next Steps

Mastering the concepts of Plowing Fields opens doors to exciting career opportunities in agriculture and related fields. To maximize your chances of success, crafting a compelling and ATS-friendly resume is crucial. This ensures your application is effectively screened by Applicant Tracking Systems, increasing your visibility to potential employers.

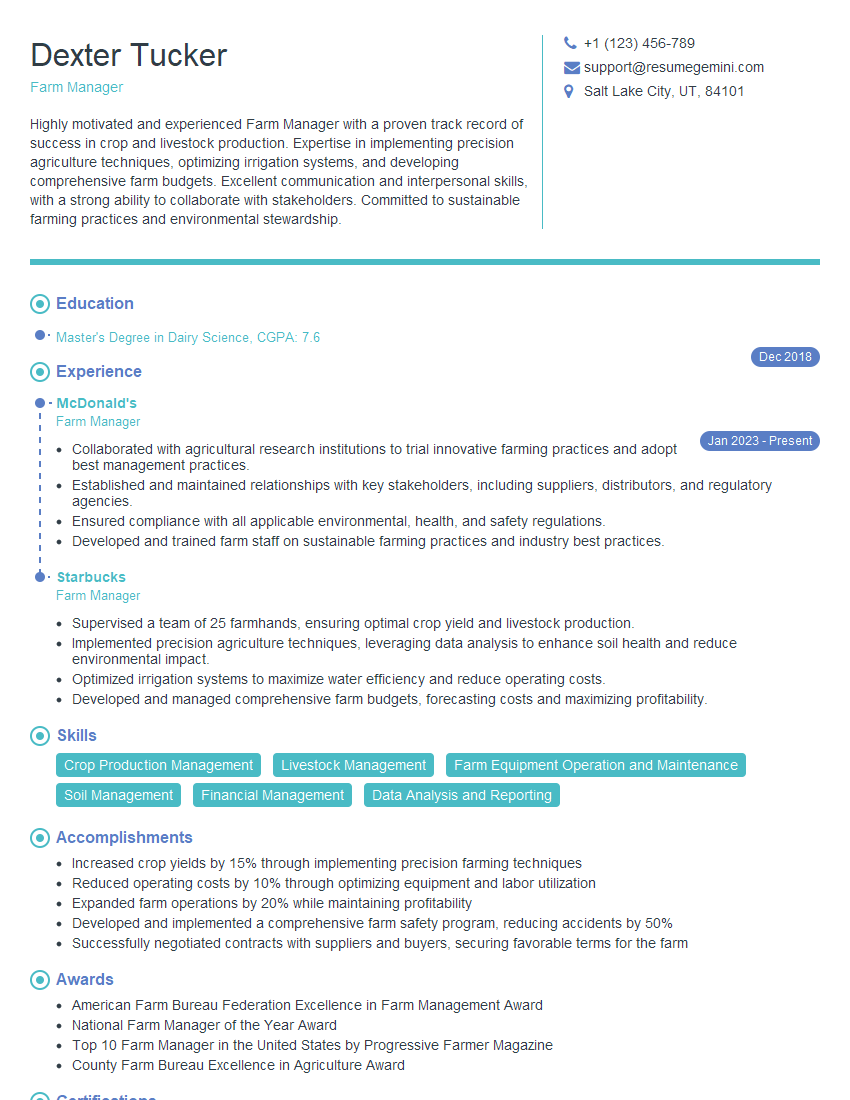

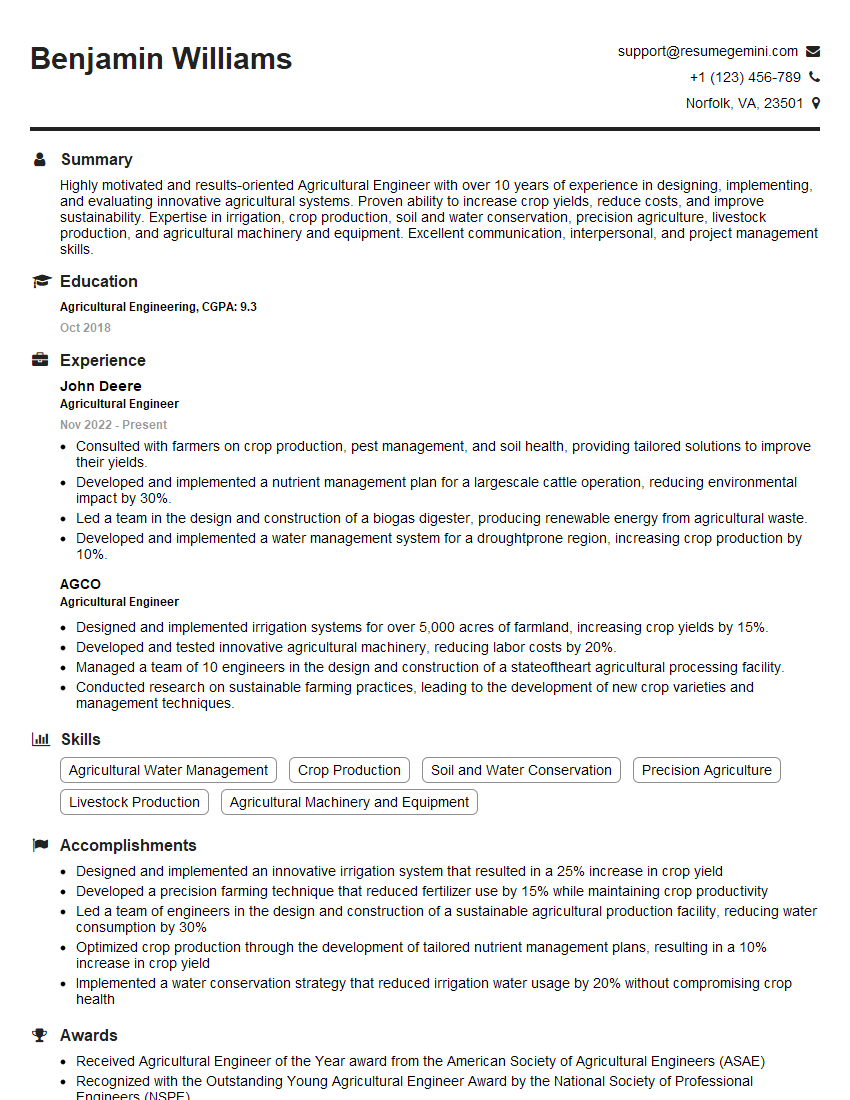

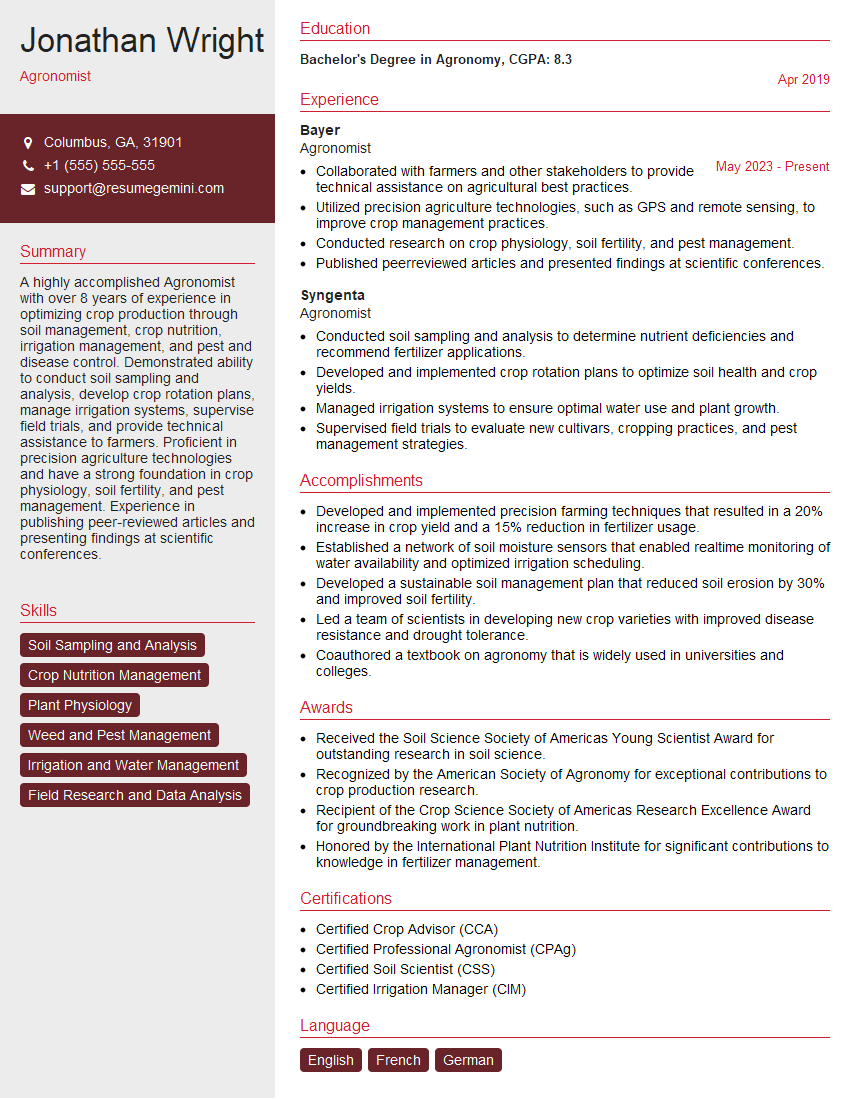

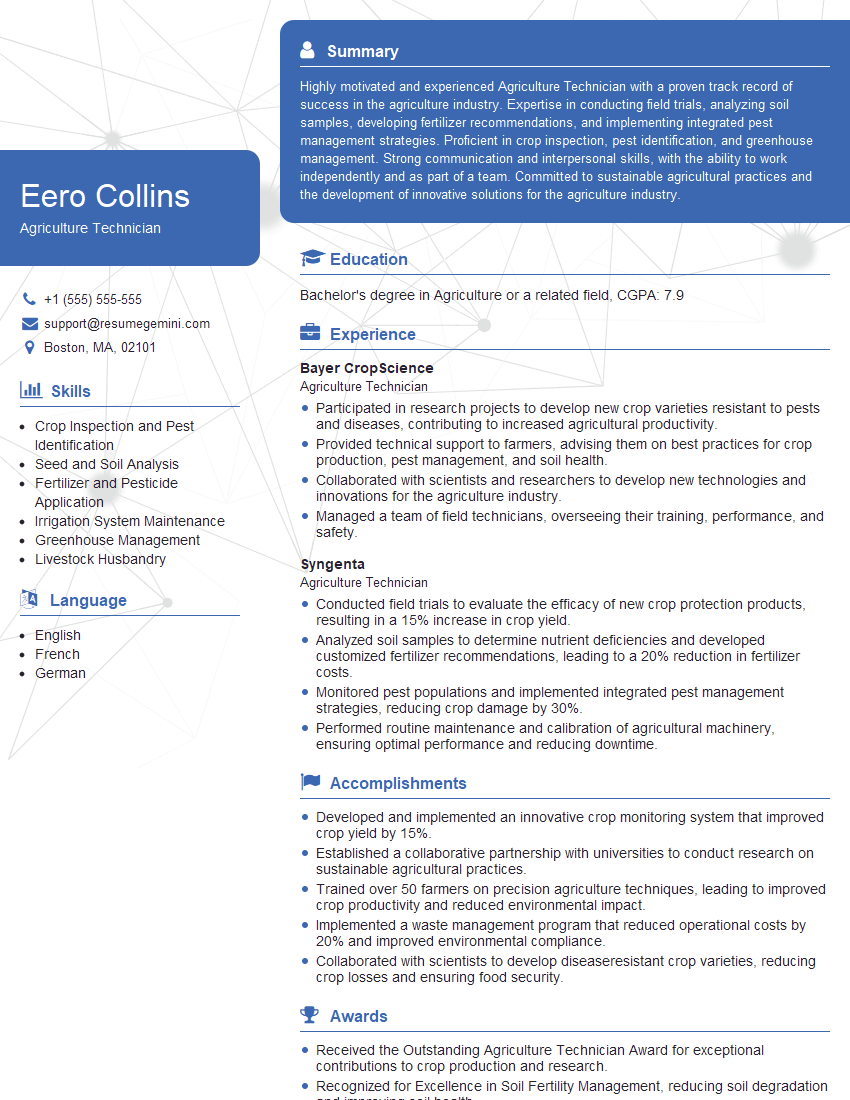

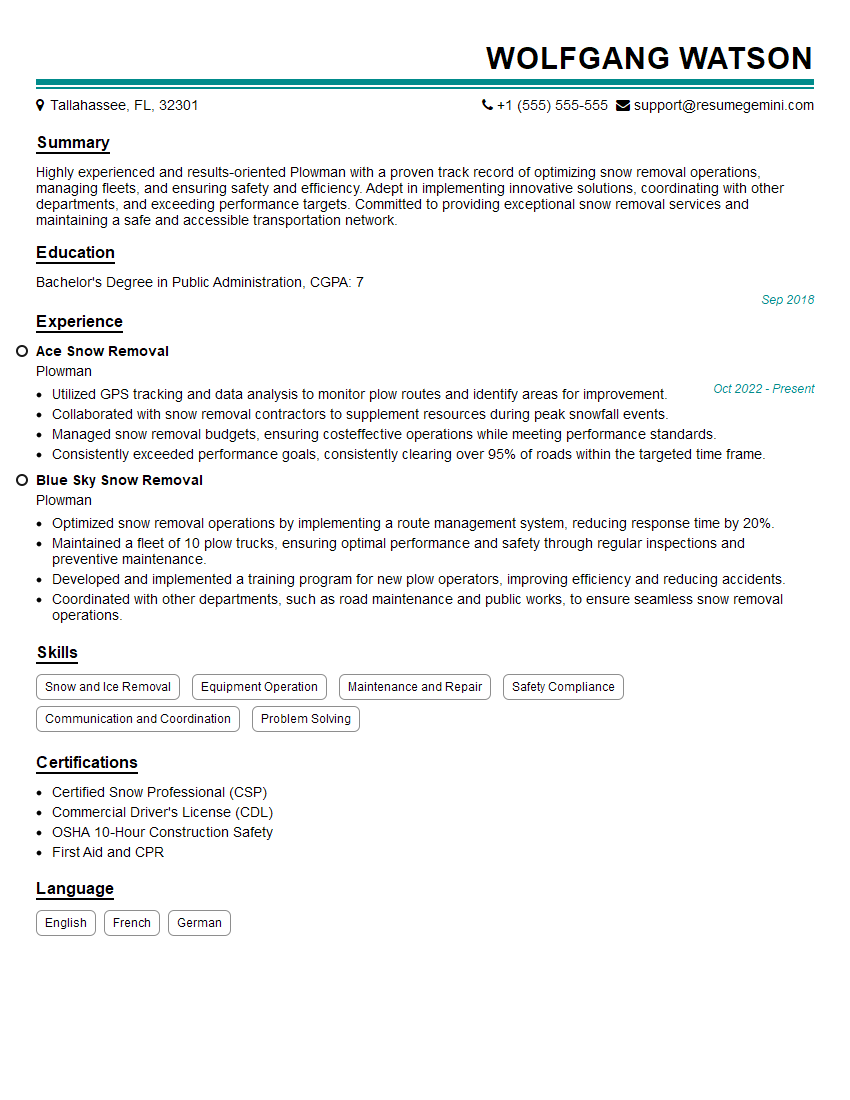

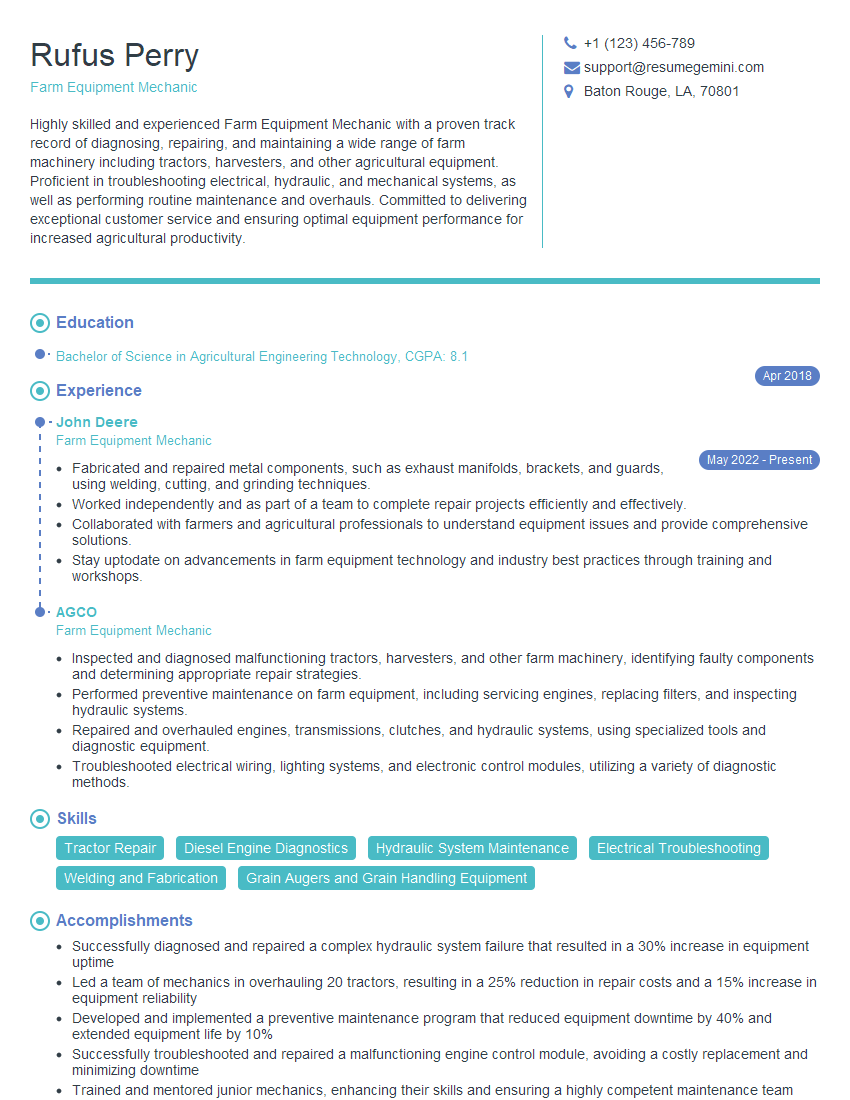

We strongly recommend leveraging ResumeGemini to build a professional and impactful resume tailored to the Plowing Fields industry. ResumeGemini provides an intuitive platform and offers examples of resumes optimized for this specific field, helping you present your skills and experience in the best possible light. Take advantage of this resource to significantly enhance your job application process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good