Are you ready to stand out in your next interview? Understanding and preparing for Plumbing Drawings interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Plumbing Drawings Interview

Q 1. Explain the difference between isometric and orthographic plumbing drawings.

Isometric and orthographic drawings are two different ways of representing a three-dimensional object on a two-dimensional plane. Think of it like looking at a building: orthographic drawings are like having separate, precise views from the front, side, and top, while an isometric drawing provides a single, angled view that shows all three dimensions simultaneously.

Orthographic plumbing drawings use multiple views (plan, elevation, section) to show the layout of pipes, fixtures, and other components. They are precise and detailed, ideal for construction and fabrication. Imagine a detailed blueprint of your kitchen showing the location of each pipe and fitting. That’s an orthographic view.

Isometric plumbing drawings offer a three-dimensional perspective, allowing for a more intuitive understanding of the system’s spatial arrangement. They’re particularly useful for visualizing complex pipe runs and confirming clearances. Think of it as a 3D model rendered from a particular angle, showing the pipe’s path clearly.

In short, orthographic drawings prioritize accuracy and precision, while isometric drawings prioritize visualization and understanding.

Q 2. Describe your experience with various CAD software used for plumbing design (AutoCAD, Revit, etc.).

My experience encompasses a wide range of CAD software used in plumbing design. I’m highly proficient in AutoCAD, leveraging its powerful drafting capabilities for creating precise 2D drawings, including detailed plans, sections, and elevations. I’ve extensively used its features for annotating drawings, creating schedules, and generating detailed reports.

Furthermore, I’m skilled in Revit, a Building Information Modeling (BIM) software. Revit’s strength lies in its ability to create intelligent 3D models, enabling better coordination with other disciplines like architectural and structural engineering. This significantly reduces clashes and improves efficiency. I use Revit to model complex plumbing systems, create accurate quantities for materials, and generate detailed fabrication drawings. I find its ability to link drawings and schedules invaluable for managing large projects.

Beyond AutoCAD and Revit, I have working knowledge of other software such as Autodesk Inventor for advanced 3D modeling and MicroStation, which I’ve used on specific projects requiring specific industry standards.

Q 3. How do you ensure accuracy and consistency in your plumbing drawings?

Accuracy and consistency in plumbing drawings are paramount for successful project execution. My approach involves a multi-pronged strategy:

- Strict adherence to standards: I consistently follow industry standards and building codes (e.g., ASME, IAPMO) to ensure uniformity and compliance.

- Layered drawings: I create drawings using multiple layers categorized by system type (e.g., sanitary, drainage, vent) and component type. This improves clarity and facilitates easy modifications.

- Regular checks and reviews: I meticulously review all drawings for errors and inconsistencies, employing both manual and software-based checks. Peer reviews are also critical in catching potential oversights.

- Using templates and styles: I utilize predefined templates and styles for text, dimensions, and symbols to ensure a consistent look and feel across all drawings.

- Parameterization in BIM software: In Revit, I leverage the power of parameters to link data and ensure consistency. Changes in one part of the model are automatically reflected elsewhere, preventing errors.

This comprehensive approach ensures the production of accurate and reliable plumbing drawings that minimize construction errors and delays.

Q 4. What are the standard symbols and conventions used in plumbing drawings?

Plumbing drawings rely on a set of standardized symbols and conventions for clarity and efficiency. These symbols represent pipes, fixtures, valves, fittings, and other components. Here are some common examples:

🛉(Circle): Fixture such as a toilet or sink.|---(Line): Pipe run. Thickness represents diameter.⇪(Valve Symbol): Type varies depending on the specific valve.↻(Elbow): Angle indicated in drawing.⇨(Tee Junction): Shows branch connections.

These symbols, along with clear annotations, dimensions, and specifications, ensure that everyone involved in the project understands the design intentions. The specific standard might vary depending on the region (e.g., ANSI, ISO).

Q 5. Explain your process for creating a detailed plumbing plan for a residential building.

Creating a detailed plumbing plan for a residential building involves a systematic process:

- Gather information: This includes reviewing architectural plans, understanding client requirements, and identifying all fixtures and appliances.

- Develop plumbing system layout: I determine the optimal placement of pipes, fixtures, and vents, considering factors like accessibility, code compliance, and space limitations.

- Prepare rough sketches: Initial sketches are created to visualize the proposed layout and make adjustments before creating detailed drawings.

- Create detailed drawings: Using CAD software (e.g., AutoCAD or Revit), I create precise 2D drawings that include detailed annotations, dimensions, specifications, and symbols.

- Develop schedules: I create schedules of fixtures, valves, and pipes, providing a comprehensive list of materials for procurement.

- Review and revision: The drawings are thoroughly reviewed for accuracy, compliance, and clarity, and revisions are made as needed.

- Finalization and issuance: Once approved, the final drawings are issued to the contractors for construction.

Throughout this process, I maintain close communication with the client and other stakeholders to ensure that the design meets their needs and adheres to all applicable codes and regulations.

Q 6. How do you incorporate building codes and regulations into your plumbing drawings?

Incorporating building codes and regulations into plumbing drawings is crucial for ensuring a safe and compliant installation. I accomplish this by:

- Familiarizing myself with local codes: I thoroughly research and understand all relevant codes and regulations in the project’s jurisdiction (e.g., International Plumbing Code, local amendments).

- Designing to meet code requirements: I ensure that the proposed plumbing system meets all requirements for venting, drainage, water pressure, fixture sizing, material specifications, etc.

- Including code references on drawings: I include notes and references to specific code sections on the drawings where relevant, clarifying design decisions based on code mandates.

- Utilizing code-compliant details: I incorporate standardized details and symbols consistent with local building codes.

- Regular code compliance checks: Throughout the design process, I perform multiple checks to confirm that the design remains compliant with all applicable regulations.

This rigorous approach minimizes the risk of non-compliance and ensures the project’s long-term success.

Q 7. Describe your experience with creating plumbing isometrics.

Creating plumbing isometrics is a specialty that requires meticulous attention to detail and a thorough understanding of three-dimensional spatial relationships. My experience involves:

- Using specialized software: Software like AutoCAD and Revit, provide tools specifically designed to create isometric views. I’ve utilized these tools to generate accurate and easily understandable isometric representations of complex piping systems.

- Accurate dimensions and labeling: I precisely measure and label all components, pipe sizes, slopes, and fittings in the isometric drawing. Clear labeling prevents misinterpretations and ensures proper installation.

- Isometric views for complex situations: I use isometric drawings extensively to clarify routing in congested areas, visualize pipe penetrations through walls and floors, and show the relationships between different sections of a plumbing system.

- Coordination with other disciplines: Isometric drawings often serve as a crucial communication tool for coordinating plumbing with structural, mechanical, and electrical systems, preventing design clashes.

My skill in creating isometric drawings allows for a clear visualization of complex pipework, contributing to a more efficient and less error-prone installation process. It’s an essential tool for ensuring accurate fabrication and installation.

Q 8. How do you manage revisions and updates to plumbing drawings?

Managing revisions and updates to plumbing drawings requires a systematic approach to ensure accuracy and prevent errors. I typically use a revision control system, often integrated within my CAD software (like AutoCAD or Revit). Each revision is assigned a unique number or letter, clearly documented with the date, description of changes, and the author’s initials. This ensures a clear audit trail. For example, revision ‘A’ might reflect changes to pipe sizes based on a revised load calculation, while revision ‘B’ might incorporate feedback from the structural engineer regarding pipe support locations.

Furthermore, I maintain a comprehensive drawing register, a spreadsheet or database that lists all drawings, their revisions, and the status of each. This allows for easy tracking and ensures everyone is working from the most up-to-date version. Cloud-based solutions further enhance collaboration and version control, preventing conflicts and promoting efficient teamwork.

- Version Control Software: Using software like Autodesk Vault or similar systems streamlines the revision process, allowing multiple users to access and modify drawings while maintaining a complete history.

- Detailed Revision Logs: Each change, no matter how minor, is documented, including the reason behind the change and the impact assessment.

- Distribution Control: I ensure only the latest approved revisions are distributed to relevant stakeholders, minimizing confusion and preventing work based on obsolete information.

Q 9. How do you handle conflicts between different trades’ drawings (e.g., electrical, HVAC)?

Conflicts between different trades’ drawings are common, and addressing them requires clear communication and coordination. My approach involves regular meetings with other trades’ representatives (electrical, HVAC, structural engineers) at key stages of the project. We use a collaborative platform—often a shared cloud storage location—to compare drawings and identify clashes early in the design process. For example, an HVAC duct might conflict with a proposed plumbing pipe run.

To resolve these conflicts, we prioritize a collaborative problem-solving approach. We explore alternative routings, adjust the design of affected systems, or identify compromises that accommodate all parties’ needs while adhering to building codes and safety regulations. Detailed coordination drawings are then created to reflect the agreed-upon solutions. We document all changes, solutions and agreements clearly for all involved parties, often using a detailed clash detection report produced by our BIM software.

Think of it like building with LEGOs; each trade is building their part, and we need to ensure all pieces fit together seamlessly.

Q 10. Explain your understanding of pipe sizing and calculations.

Pipe sizing is critical for ensuring adequate water flow and pressure throughout the plumbing system. This involves applying principles of fluid mechanics and utilizing established standards and codes (like the IAPMO and ASME codes). The calculation process typically considers factors such as:

- Flow Rate: The volume of water required by fixtures and appliances. (e.g., gallons per minute or liters per second)

- Pressure Drop: The reduction in pressure due to friction as water flows through the pipes.

- Pipe Material and Diameter: Different pipe materials offer varying levels of friction resistance, and the diameter significantly impacts flow rate.

- Fixture Units (FU): A standardized unit representing the water demand of a fixture, used to calculate the total load on the system.

I utilize specialized software and online calculators that incorporate these factors to determine the appropriate pipe diameter for each section of the plumbing system. Manual calculations using Darcy-Weisbach or Hazen-Williams equations can also be used. I always ensure the selected pipe size meets code requirements and provides sufficient capacity to handle peak demand without excessive pressure loss.

Q 11. What are your preferred methods for creating plumbing schedules and specifications?

Creating plumbing schedules and specifications is a crucial part of the design process, ensuring consistency and clarity throughout the project. My preferred method is using the built-in scheduling tools within my CAD software (like Revit). These tools automate the process of generating detailed schedules which list pipe sizes, materials, fittings, and other components used in the system.

I also develop comprehensive specifications that complement the schedules, providing detailed information about the materials, installation methods, testing procedures, and quality standards for each component. For instance, a pipe specification might include details about its material (e.g., CPVC), its pressure rating, and required certifications. The specification clarifies all details not shown on the drawings.

Maintaining a robust database of standard specifications is important to ensure consistency across projects and efficiency in creating new projects. This ensures everyone involved understands the exact requirements for each item and reduces the likelihood of errors.

Q 12. How familiar are you with plumbing fixtures and their specifications?

I possess extensive familiarity with plumbing fixtures and their specifications. My knowledge encompasses various types of fixtures, including toilets, sinks, showers, bathtubs, and faucets, as well as their water consumption rates, installation requirements, and relevant certifications (like WaterSense or EPA certifications).

I understand the importance of selecting fixtures that meet the project’s requirements and comply with accessibility standards (ADA compliance) and water conservation regulations. I regularly consult manufacturer catalogs and specification sheets to select suitable fixtures and incorporate them into the design. This includes understanding the different types of valves, their operation, and the implications for the overall system design. My approach always prioritize selecting fixtures that are both functional and aesthetically pleasing to meet the client’s requirements.

Q 13. Explain your experience with creating detailed plumbing sections and elevations.

Creating detailed plumbing sections and elevations is essential for visualizing the three-dimensional arrangement of pipes and fittings. I use CAD software to create precise sections and elevations, showcasing the location of pipes, their connection points, and their relationship to other building elements. This includes detailing the pipe supports, hangers, and other structural elements that are crucial to the safe and proper installation of the system.

For example, a section through a wall might show how pipes penetrate the wall, the insulation used, and the fire-stopping measures taken. Elevations, meanwhile, provide a clear view of the vertical routing of pipes, displaying their changes in elevation and their connections to fixtures. Using various annotation techniques and callouts to ensure that critical details are communicated clearly. This provides crucial information for the contractors during installation and aids in preventing clashes and mistakes.

Q 14. Describe your approach to creating a detailed plumbing plan for a commercial building.

Creating a detailed plumbing plan for a commercial building is a complex process that requires a systematic approach. It begins with a thorough understanding of the building’s requirements, including the number of occupants, the types of plumbing fixtures, the anticipated water demands, and the location of utilities. This is followed by a site survey and analysis of the existing infrastructure.

Next, I develop a preliminary design based on these requirements, employing the principles of pipe sizing and layout discussed earlier. This includes developing a comprehensive plumbing system consisting of water supply, drainage, and venting systems. I use CAD software to create detailed drawings, ensuring that all elements of the plumbing system are accurately depicted, including pipe sizes, materials, fittings, and fixture locations. This also involves coordination with other trades, addressing potential clashes and integrating the plumbing system with other building services.

Finally, the design undergoes thorough review and revision to ensure compliance with all relevant building codes, regulations, and client requirements. This iterative process ensures the delivery of a comprehensive plumbing plan that functions efficiently and safely and meets the needs of the building’s users.

Q 15. How do you ensure your drawings are easily understandable for contractors?

Creating easily understandable plumbing drawings for contractors hinges on clarity, precision, and adherence to industry standards. Think of it like a well-written recipe – if the instructions are unclear, the end result won’t be what you intended. My approach involves several key strategies:

- Clear and Concise Labeling: Every pipe, fitting, valve, and fixture is meticulously labeled with its size, material, and function. For example, a 2-inch diameter PVC drain pipe would be clearly marked as ‘2” PVC DRAIN’.

- Detailed Isometric Drawings: Isometric views provide a three-dimensional representation, making it easy to visualize the spatial relationships between different components. This is crucial for avoiding clashes during installation.

- Consistent Use of Symbols and Legends: I use standardized symbols as per industry best practices (like ANSI or other relevant standards) and include a comprehensive legend to explain each symbol. This ensures consistent understanding across the team.

- Detailed Specifications: Separate specifications documents provide supplementary information, like material requirements, manufacturer preferences, and pressure ratings. This avoids cluttering the drawings themselves.

- Revision Control: Every revision is carefully tracked and documented. This ensures everyone is working with the latest and most accurate version of the drawings.

- Use of Annotations and Callouts: Annotations clearly indicate details about specific aspects of the design, clarifying anything that might be ambiguous in the drawing itself. For example, a callout might highlight a specific type of valve required.

For instance, on a recent project involving a complex rainwater harvesting system, I used detailed isometric drawings combined with a comprehensive legend, which greatly facilitated communication between the design team and the contractors. This resulted in a smooth and efficient installation process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are the key considerations for designing plumbing systems for accessibility?

Designing accessible plumbing systems is critical for inclusivity and requires careful consideration of the needs of people with disabilities. It’s about ensuring everyone can safely and independently use bathroom facilities and other plumbing fixtures. Key considerations include:

- Clearance Requirements: Sufficient maneuvering space around toilets, sinks, and showers must be provided, as per ADA (Americans with Disabilities Act) or other relevant accessibility guidelines. This often involves larger clearances than standard designs.

- Grab Bars: Strategically placed grab bars in bathrooms, especially near toilets and showers, offer essential support for people with mobility limitations. The drawings must clearly indicate their location, size, and mounting details.

- Accessible Fixtures: Using fixtures that comply with accessibility standards is essential. This includes appropriately sized and positioned sinks, toilets with adequate height and reach, and roll-in showers with appropriate thresholds.

- Accessible Faucet Controls: Faucet controls must be easy to operate, including lever handles for those with limited dexterity. The drawings should specify the type and location of these controls.

- Accessible Controls for Water Heaters and other Fixtures: Temperature controls for water heaters should ideally be placed outside the typical reach of children and also be accessible for those in wheelchairs or with other mobility challenges.

In a recent project, I designed a fully accessible bathroom for a community center. The drawings incorporated detailed dimensions to ensure compliance with ADA guidelines, including proper clearances for wheelchair access and the placement of grab bars and accessible faucets.

Q 17. How do you incorporate sustainable design principles into your plumbing drawings?

Incorporating sustainable design principles into plumbing drawings is crucial for reducing environmental impact and conserving resources. My approach focuses on several key aspects:

- Water Conservation: Specifying low-flow fixtures (toilets, showerheads, faucets) significantly reduces water consumption. Drawings would clearly indicate the flow rate of each fixture (e.g., 1.6 gallons per flush toilet).

- Greywater Recycling: Where feasible, I incorporate systems for reusing greywater (from showers and sinks) for irrigation or toilet flushing. This requires careful design of piping and filtration systems, all clearly illustrated in the drawings.

- Rainwater Harvesting: Designs often include rainwater harvesting systems to collect and store rainwater for non-potable uses like irrigation or toilet flushing, thereby reducing reliance on municipal water supplies.

- Energy Efficiency: Specifying energy-efficient water heaters (heat pumps or tankless water heaters) is essential to minimize energy usage. The drawings would clearly show the location and type of water heater.

- Material Selection: Prioritizing the use of recycled or sustainably sourced materials for pipes and fittings helps reduce the carbon footprint of the project. The drawings would clearly identify these materials.

For example, in a residential project, I designed a system to collect rainwater from the roof and use it to irrigate the landscaping, thus reducing water consumption significantly. The drawings clearly depicted the collection system, storage tank, and irrigation piping.

Q 18. Describe your experience with using BIM software for plumbing design.

I have extensive experience using Building Information Modeling (BIM) software, primarily Revit, for plumbing design. BIM offers significant advantages in terms of efficiency, collaboration, and accuracy.

- 3D Modeling: BIM allows for the creation of accurate 3D models, enabling better visualization of the plumbing system and early detection of clashes between different building services.

- Coordination with Other Disciplines: BIM facilitates seamless collaboration with architects, structural engineers, and other disciplines. We can easily share and coordinate models, minimizing conflicts and ensuring a smooth design process.

- Quantity Takeoff: BIM automates quantity takeoffs, providing accurate material lists and cost estimates. This improves project budgeting and minimizes material waste.

- Detailed Drawings and Schedules: BIM automatically generates detailed drawings, including plans, sections, and isometrics, as well as schedules of components, simplifying the documentation process.

- Clash Detection: BIM software helps identify potential clashes between plumbing elements and other building components before construction, saving time and money.

In a recent large-scale commercial project, using Revit’s BIM capabilities allowed our team to identify and resolve potential clashes between the plumbing and HVAC systems early in the design process. This avoided costly rework during the construction phase.

Q 19. Explain your understanding of different types of plumbing systems (e.g., drainage, water supply).

Plumbing systems are broadly classified into water supply and drainage systems. Understanding their distinct functions and components is crucial for effective design.

- Water Supply Systems: These systems deliver potable water to fixtures like sinks, toilets, and showers. Key components include:

- Water Meters: Measure water consumption.

- Pipes: Convey water from the main supply to fixtures.

- Valves: Control water flow.

- Fixtures: Provide access to water (sinks, showers, toilets).

- Pressure Reducing Valves: Maintain appropriate water pressure.

- Drainage Systems: These systems remove wastewater and rainwater from the building. Key components include:

- Drains: Collect wastewater from fixtures.

- Pipes: Convey wastewater to the sewer system.

- Traps: Prevent sewer gases from entering the building.

- Vents: Allow air to enter the drainage system, preventing siphoning.

- Cleanouts: Provide access for cleaning and maintenance.

A thorough understanding of both systems is crucial; for example, ensuring proper sizing of supply pipes to prevent low water pressure and correct venting of drainage systems to prevent foul odors.

Q 20. How do you manage large and complex plumbing projects?

Managing large and complex plumbing projects requires a structured and organized approach. My strategy involves several key steps:

- Detailed Project Planning: This includes establishing clear project goals, defining the scope of work, setting deadlines, and allocating resources.

- Work Breakdown Structure (WBS): Breaking down the project into smaller, manageable tasks helps streamline the design and coordination process.

- Team Coordination: Regular meetings and communication with all stakeholders (contractors, clients, other disciplines) are essential to ensure everyone is on the same page.

- BIM Software Utilization: Leveraging BIM capabilities for coordination and clash detection minimizes errors and delays.

- Regular Progress Monitoring: Tracking progress against the project schedule helps identify and address potential problems early on.

- Risk Management: Identifying and mitigating potential risks, such as material shortages or delays, is critical for project success.

- Detailed Documentation: Maintaining comprehensive records of design decisions, revisions, and approvals ensures transparency and accountability.

In one large hospital project, I used a WBS to break down the plumbing design into smaller tasks, assigning responsibility to different team members. Regular progress meetings ensured timely completion and addressed any arising issues promptly.

Q 21. How familiar are you with different types of pipe materials and their applications?

Familiarity with different pipe materials and their applications is essential for effective plumbing design. The choice of material depends on factors like pressure, temperature, chemical resistance, and cost.

- Copper: Excellent corrosion resistance, durability, and suitable for potable water supply.

- PVC (Polyvinyl Chloride): Cost-effective, lightweight, and suitable for drainage and non-potable water lines. However, it’s not suitable for high-temperature applications.

- CPVC (Chlorinated Polyvinyl Chloride): Similar to PVC but with higher temperature resistance, making it suitable for hot water lines.

- PEX (Cross-linked Polyethylene): Flexible, easy to install, and resistant to freezing. Often used in radiant heating and water supply systems.

- Cast Iron: Durable and heavy-duty, used for large-diameter drainage lines and sewer connections. However, it can be prone to corrosion.

- Steel: Strong and durable, used for high-pressure applications and underground lines. Requires protection against corrosion.

For instance, in a high-rise building project, we chose copper pipes for the potable water supply lines due to their durability and corrosion resistance, while PVC was used for the drainage system due to its cost-effectiveness. Selecting the right materials is crucial for ensuring the longevity and efficiency of the plumbing system.

Q 22. Describe your experience with clash detection and resolution in plumbing design.

Clash detection is crucial in plumbing design to prevent costly rework during construction. It involves identifying conflicts between plumbing systems and other building services, like HVAC or structural elements. My experience involves utilizing Building Information Modeling (BIM) software to perform 4D and 5D clash detection. This allows for proactive identification of potential issues – such as a pipe running through a structural beam or a vent stack interfering with an elevator shaft – before construction begins.

Resolution strategies vary depending on the severity and nature of the clash. Minor clashes might involve simple adjustments to pipe routing or fixture placement. More significant clashes may require redesigning parts of the system or collaborating with other disciplines to find a mutually agreeable solution. For instance, I once discovered a clash between a large diameter drain line and a main electrical conduit. The solution involved rerouting the drain line slightly, documented with updated drawings and communicated to the electrical engineers to ensure their plans reflected the change.

My process always begins with a thorough review of the model, utilizing automated clash detection tools within the BIM software. I then meticulously investigate each detected clash, assessing the feasibility of various solutions while considering factors such as accessibility, code compliance, and the overall project timeline. The final solution is always documented clearly, with updated drawings communicated to the entire project team.

Q 23. How do you handle changes and revisions during the construction phase?

Handling changes during construction requires a proactive and organized approach. My strategy begins with establishing a clear change order process. All changes, no matter how small, are documented formally, including the reason for the change, the impact on the project schedule and budget, and any necessary revisions to the plumbing drawings and specifications.

I use a version control system for all drawings to ensure everyone is working with the most up-to-date version. This helps prevent confusion and minimizes the risk of errors. Furthermore, I maintain open communication with the contractor and other project stakeholders to facilitate a smooth workflow. For example, if a change requires altering the location of a fixture, I’ll immediately update the drawings and notify the contractor, clarifying the impact on the work schedule and associated costs. Regular site visits are crucial to identify unforeseen issues and adapt accordingly. These changes are then documented and submitted for approval, maintaining a clear audit trail.

Clear communication and well-documented change management are paramount for mitigating disruptions and keeping the project on track. By promptly addressing changes and keeping all parties informed, you can minimize delays and extra costs.

Q 24. What are your strategies for effective collaboration with other engineering disciplines?

Effective collaboration is essential for successful plumbing design. My strategy involves consistent and proactive communication with other engineering disciplines, primarily structural, electrical, and mechanical engineers. I utilize BIM software as a central platform for information sharing, ensuring all disciplines have access to the latest design models. Regular coordination meetings are vital, where we discuss potential clashes, coordinate layouts, and resolve conflicts before they become major issues.

I also prioritize clear and concise communication through emails, meeting minutes, and detailed design notes. For instance, when designing a pipe route near a structural column, I’ll directly coordinate with the structural engineer to ensure sufficient clearance and avoid weakening the structural element. This collaborative process often involves reviewing each other’s designs and providing constructive feedback. I frequently utilize markup tools within the BIM software to highlight areas of concern and propose solutions, fostering a collaborative approach to design development.

Q 25. How do you ensure compliance with relevant plumbing codes and standards?

Compliance with plumbing codes and standards is paramount. My approach involves a multi-step process, beginning with a thorough understanding of the relevant codes applicable to the project’s location and building type. This typically includes the International Plumbing Code (IPC) or other local variations. I use code-compliant design practices from the outset, selecting appropriate materials, fixtures, and sizing of pipes and fittings to ensure compliance.

I also utilize design software that incorporates code-checking functionalities to automate some aspects of compliance verification. Throughout the design process, I meticulously review the drawings for compliance with specific code sections, such as those related to water pressure, drainage slopes, venting requirements, and fixture clearances. In addition to software checks, I conduct manual reviews, paying close attention to details such as trap sizing and fixture connections to ensure everything meets or exceeds code requirements. Finally, I always submit the drawings for review by a qualified plumbing engineer or authority having jurisdiction (AHJ) before construction begins. This process helps ensure that the final design adheres to all applicable regulations and avoids costly mistakes later in the project.

Q 26. Explain your experience with creating detailed plumbing details and specifications.

Creating detailed plumbing details and specifications is a critical aspect of my work. My process begins with gathering thorough project requirements and understanding the project’s functional needs. I then use specialized CAD software to create detailed drawings that include dimensions, material specifications, and installation instructions for all plumbing components. These details cover everything from individual fixture connections to complex pipe routing systems.

My specifications clearly outline the type and quality of materials to be used, complying with the project specifications and relevant plumbing codes. For example, a detail might specify the type of pipe (e.g., copper, PVC, or PEX), its diameter, wall thickness, and connection method. The specifications also include information on valves, fittings, and other components. I always ensure that the drawings and specifications are consistent and unambiguous, minimizing the potential for misinterpretations during construction. I believe in using clear and concise language, avoiding jargon where possible, to make the documents easy to understand for all stakeholders involved in the construction process.

Q 27. Describe your process for checking and reviewing plumbing drawings for accuracy and completeness.

Checking and reviewing plumbing drawings requires a meticulous and systematic approach. My process starts with a thorough self-check, using checklists to ensure all aspects of the design have been addressed. This includes verifying compliance with codes, accuracy of dimensions, proper labeling of components, and the completeness of the information provided. I leverage the design software’s built-in verification tools to automatically check for potential errors like inconsistencies in pipe sizing or missing connections.

After my self-check, I conduct a peer review, where a colleague experienced in plumbing design reviews the drawings for accuracy and completeness. This independent review provides a fresh perspective and often catches errors or omissions that I might have missed. Finally, I involve a senior reviewer (often a registered professional engineer) for a final quality check, focusing on code compliance, constructability, and overall design effectiveness. This multi-level review process ensures that the drawings are free of errors, complete, and ready for construction. This rigorous approach minimizes the potential for problems on the construction site, saving time and money.

Key Topics to Learn for Plumbing Drawings Interview

- Plumbing Symbols and Conventions: Understanding the universal language of plumbing drawings, including symbols for fixtures, pipes, valves, and fittings. This forms the foundation for interpreting any drawing.

- Pipe Sizing and Calculations: Applying formulas and industry standards to determine appropriate pipe diameters based on flow rates and pressure requirements. Practical application includes sizing pipes for various plumbing systems in residential or commercial buildings.

- Isometric Drawings and Plan Views: Interpreting both isometric (3D) and plan (top-down) views to visualize the complete plumbing system layout and understand spatial relationships between components.

- Material Specifications: Identifying different pipe materials (e.g., PVC, copper, steel) and their applications based on project requirements and local building codes. Understanding the implications of material choice on system performance and longevity.

- Drainage Systems and Vent Design: Understanding the principles of gravity drainage, venting requirements, and trap design to prevent sewer gases from entering the building. This includes calculations for slope and pipe sizing in drainage systems.

- Fixture Installation and Connections: Knowing the proper methods for connecting fixtures to the plumbing system, including understanding water supply and drainage connections, and ensuring proper clearances.

- Reading and Interpreting Specifications: Deciphering project specifications, understanding the scope of work detailed in plumbing drawings, and identifying any potential discrepancies or conflicts.

- Troubleshooting and Problem Solving: Analyzing plumbing drawings to identify potential problems, such as conflicts, inadequate sizing, or code violations, and proposing solutions.

- Blueprint Reading and Interpretation: Understanding architectural drawings to coordinate plumbing design with other building systems (e.g., electrical, HVAC).

- Plumbing Codes and Regulations: Familiarity with relevant building codes and regulations to ensure designs meet safety and compliance standards.

Next Steps

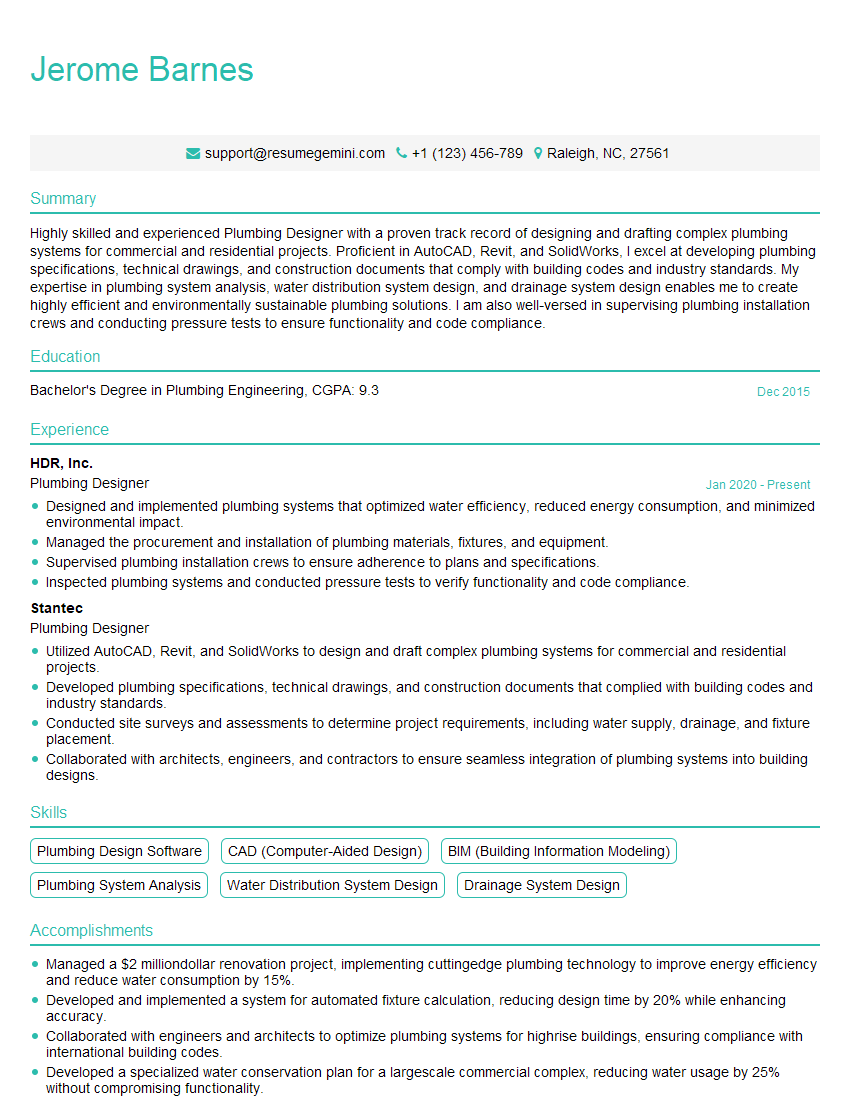

Mastering plumbing drawings is crucial for career advancement in the plumbing industry, opening doors to more senior roles and higher earning potential. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource to help you build a professional and impactful resume. Examples of resumes tailored specifically to Plumbing Drawings professionals are available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good