The thought of an interview can be nerve-wracking, but the right preparation can make all the difference. Explore this comprehensive guide to Poultry Nutrition and Feed Formulation interview questions and gain the confidence you need to showcase your abilities and secure the role.

Questions Asked in Poultry Nutrition and Feed Formulation Interview

Q 1. Explain the difference between metabolizable energy (ME) and digestible energy (DE) in poultry feed.

Both metabolizable energy (ME) and digestible energy (DE) are measures of the energy available to poultry from feed, but they differ in what they account for. Digestible energy (DE) represents the energy in the feed that is absorbed by the bird after accounting for fecal losses. Think of it as the energy the bird successfully extracts from the feed after digestion. Metabolizable energy (ME), on the other hand, is a more refined measure. It accounts for not only fecal losses but also urinary and gaseous energy losses. So, ME reflects the net energy available to the bird for maintenance, growth, and production after all these energy losses. ME is generally preferred in poultry nutrition because it gives a more accurate picture of the energy truly available to the bird for its bodily functions. For instance, if a feed sample has a DE of 2800 kcal/kg and an ME of 2500 kcal/kg, the difference (300 kcal/kg) represents the energy lost through urine and gases.

Q 2. What are the essential amino acids for poultry, and why are they crucial?

Poultry, like all animals, require essential amino acids – those they cannot synthesize on their own and must obtain from their diet. These are crucial for growth, feather development, egg production, and overall health. The essential amino acids for poultry are:

- Methionine

- Lysine

- Arginine

- Threonine

- Tryptophan

- Valine

- Isoleucine

- Leucine

- Phenylalanine

- Histidine

A deficiency in even one essential amino acid can limit the bird’s ability to use other nutrients effectively, leading to stunted growth, reduced egg production, poor feather quality, and increased susceptibility to disease. Think of it like building a house – you need all the essential bricks (amino acids) to build a strong and complete structure (a healthy bird). The most commonly limiting amino acids in poultry diets are methionine and lysine; careful attention must be paid to their inclusion levels in feed formulations.

Q 3. Describe the role of calcium and phosphorus in poultry nutrition.

Calcium (Ca) and phosphorus (P) are essential minerals playing crucial roles in poultry nutrition, particularly in bone formation, eggshell quality, and overall skeletal health. Calcium is the primary structural component of bones, while phosphorus is vital for bone mineralization and energy metabolism. In laying hens, calcium is especially critical for eggshell formation; a deficiency can lead to thin or weak eggshells, resulting in breakage and economic losses. The Ca:P ratio in the diet is also critical; an appropriate balance is necessary for optimal absorption and utilization. A typical ideal ratio is often around 2:1 (Ca:P), though this can vary slightly based on the bird’s age and physiological status. Inadequate levels of either mineral can result in rickets (bone deformities) or soft-shelled eggs, among other problems. Therefore, precise management of calcium and phosphorus levels is vital in poultry feed formulation.

Q 4. How do you formulate a poultry feed to meet specific nutrient requirements?

Formulating a poultry feed to meet specific nutrient requirements is a complex process that involves several steps. First, we define the target bird: species (chicken, turkey, duck etc.), age (starter, grower, finisher), and production goals (meat production, egg laying, etc.). Next, we consult nutrient requirement tables from reliable sources (e.g., NRC) to determine the nutrient needs for that specific bird category. Then, we select suitable feed ingredients with known nutrient compositions. This selection will consider cost-effectiveness and ingredient availability. Using specialized software (or manual calculations) we formulate a diet that blends the selected ingredients at the proper proportions to satisfy the nutrient requirements (e.g., amino acids, energy, vitamins, minerals) while meeting constraints on cost or other factors (like palatability). Finally, we assess the formulated diet to confirm its feasibility, nutrient levels and then proceed to the production and quality control.

For example, a grower phase diet for broilers might require a higher protein level (around 20%) compared to a finisher diet (around 16%) as the bird’s growth rate decreases during the finishing period.

Q 5. What are the common feed ingredients used in poultry diets?

The selection of feed ingredients depends largely on cost, availability, and nutritional value. Common ingredients include:

- Grains: Corn, sorghum, wheat, barley – these are primary energy sources.

- Oilseeds: Soybean meal, canola meal, sunflower meal – excellent sources of protein.

- Animal By-products: Meat and bone meal, fish meal – protein supplements, but their use is often regulated due to potential disease transmission concerns.

- Mineral Supplements: Limestone (calcium), dicalcium phosphate (calcium and phosphorus) – supply essential minerals.

- Vitamin Premixes: Provide essential vitamins in a concentrated form.

- Amino Acid Supplements: Methionine, lysine – commonly added to meet specific requirements.

- Other ingredients: Brewers’ rice, wheat middlings, rice bran – provide additional energy and nutrients. Some formulations may also include probiotics or prebiotics to improve gut health.

The specific combination and proportions of these ingredients vary greatly depending on the bird’s age, physiological state, and production objectives.

Q 6. Explain the concept of nutrient digestibility and its importance.

Nutrient digestibility refers to the proportion of a nutrient in the feed that is actually absorbed and utilized by the bird. It’s expressed as a percentage. For example, if a feed contains 100g of protein, and the bird absorbs 80g, the protein digestibility is 80%. High nutrient digestibility is essential because it translates directly to better feed efficiency. Birds can then achieve their growth or production targets using less feed, reducing overall feed costs and environmental impact. Digestibility varies depending on several factors, including the type of feed ingredient (some grains are more digestible than others), the bird’s age (young birds often have lower digestibility), and the bird’s overall health (digestive issues reduce nutrient absorption).

Assessing nutrient digestibility involves laboratory methods, like analyzing fecal samples to determine nutrient losses. Formulators use digestibility data to adjust nutrient levels in the feed formulations, ensuring the birds receive the required amount of nutrients despite differences in ingredient digestibility. Higher digestibility can also mean reduced nutrient excretion, minimizing environmental pollution from poultry farms.

Q 7. How do you determine the nutrient requirements of poultry at different growth stages?

Nutrient requirements of poultry vary considerably across different growth stages. This is because birds have different metabolic needs depending on whether they are rapidly growing, laying eggs, or maintaining body weight. We determine these requirements through a combination of approaches:

- Growth Trials: Controlled experiments are conducted where birds of different ages are fed various diets, monitoring their growth, feed intake, and body composition. This helps determine the optimal nutrient levels needed for each growth phase (starter, grower, finisher).

- Literature Review and Databases: Researchers and organizations (e.g., the National Research Council (NRC) in the US) compile data from numerous studies to develop nutrient requirement tables. These tables provide guidelines on the nutrient needs of poultry at various ages and physiological conditions.

- Meta-Analysis: This statistical technique integrates findings from multiple studies to provide more robust estimates of nutrient requirements, accounting for variability in experimental designs and environmental factors.

This information is then used in feed formulation to ensure that the diet precisely meets the specific nutrient demands at each growth stage, optimizing efficiency and minimizing nutrient deficiencies or excesses.

Q 8. What are the factors that influence feed intake in poultry?

Feed intake in poultry is a complex process influenced by a variety of factors, broadly categorized as environmental, nutritional, and physiological.

- Environmental Factors: These include temperature, light intensity and duration (photoperiod), and access to feed and water. Extreme temperatures, for example, can significantly reduce feed intake as birds prioritize thermoregulation. Similarly, inadequate lighting can decrease activity and thus feed consumption.

- Nutritional Factors: The nutrient composition of the feed itself plays a crucial role. Palatability (taste and texture), nutrient density, and the presence of antinutritional factors can all impact feed intake. A highly palatable feed will naturally encourage higher consumption, while a nutrient-deficient diet might lead to compensatory intake attempts.

- Physiological Factors: The bird’s age, health status, and stage of production (e.g., growth, egg laying) are critical. Younger birds generally consume more feed relative to their body weight than older birds. Illness, stress, and parasitic infections can all significantly depress appetite. In laying hens, feed intake is directly linked to egg production; high egg production requires higher feed intake.

For instance, a broiler farmer might observe reduced feed intake during a heatwave and adjust ventilation and potentially offer cooler water to improve consumption. Similarly, a layer farmer might increase the nutrient density of the diet during peak laying to support higher egg production.

Q 9. What are the common mycotoxins found in poultry feed, and how do they affect poultry health?

Mycotoxins are toxic secondary metabolites produced by fungi that contaminate feed ingredients, posing significant risks to poultry health. Some of the most common mycotoxins found in poultry feed include aflatoxins, ochratoxins, fumonisins, zearalenone, and trichothecenes.

- Aflatoxins: Primarily produced by Aspergillus species, aflatoxins are potent hepatocarcinogens (liver cancer causing agents) and immunosuppressants. They reduce growth performance, egg production, and immune function in poultry.

- Ochratoxins: Produced by Aspergillus and Penicillium species, ochratoxins primarily affect the kidneys, causing nephropathy and reduced performance.

- Fumonisins: Produced by Fusarium species, fumonisins are associated with pulmonary edema (fluid in the lungs) and liver damage in poultry.

- Zearalenone: Also produced by Fusarium species, zearalenone is an estrogenic mycotoxin, causing reproductive issues in both male and female birds.

- Trichothecenes: Produced by various Fusarium species, trichothecenes cause gastrointestinal problems, immunosuppression, and reduced growth.

The effects of mycotoxins often manifest as reduced growth rates, poor feed conversion ratios, decreased egg production, immune deficiency, increased mortality, and even liver and kidney damage. Prevention strategies include proper storage of feed ingredients, use of mycotoxin binders in feed, and selecting high-quality ingredients from reputable suppliers.

Q 10. Describe the process of feed manufacturing, from raw materials to finished product.

Poultry feed manufacturing is a complex process involving several key steps:

- Ingredient Procurement and Handling: This involves sourcing raw materials like grains (corn, soybean meal, wheat), protein sources (fishmeal, meat and bone meal), vitamins, minerals, and additives. Careful quality control is essential at this stage to ensure the safety and nutritional value of the ingredients.

- Ingredient Grinding and Mixing: Raw materials are ground to a consistent particle size to ensure uniform mixing and improve digestibility. Precisely measured amounts of each ingredient are then thoroughly mixed in large mixers to create a homogenous pre-mix.

- Pelleting (Optional): The mixed feed is often pelleted to improve feed handling, reduce waste, and increase feed intake. Pellets are formed under high pressure and temperature, which also helps to gelatinize starch for better digestibility.

- Cooling and Crumbling (Optional): After pelleting, the feed is cooled to prevent spoilage and may be crumbled to smaller sizes for specific bird types (e.g., chicks, layers).

- Quality Control and Packaging: Throughout the process, regular quality checks are performed to ensure the feed meets specified nutritional requirements. The finished feed is then packaged and stored to maintain quality and prevent contamination.

Think of it like baking a cake; you need the right ingredients (raw materials), the correct proportions (mixing), the right cooking method (pelleting/crumbling), and proper storage to get a delicious and safe cake (finished feed).

Q 11. How do you ensure the quality and safety of poultry feed?

Ensuring poultry feed quality and safety requires a multi-faceted approach, starting from raw material selection to finished product distribution.

- Raw Material Quality Control: This involves rigorous testing for nutrient content, mycotoxins, heavy metals, pesticides, and other contaminants. Sourcing from reputable suppliers who adhere to strict quality standards is critical.

- Manufacturing Process Control: Maintaining strict hygiene standards throughout the manufacturing process is essential to prevent contamination. Regular cleaning and sanitation of equipment, as well as employee training on hygiene protocols, are vital.

- Feed Formulation and Analysis: The feed must be precisely formulated to meet the specific nutritional needs of the birds at different life stages and production goals. Regular laboratory analysis of the finished feed ensures it conforms to the formulated specifications.

- Storage and Transportation: Proper storage conditions are necessary to prevent spoilage, insect infestation, and mycotoxin growth. Transportation must be in clean, sealed vehicles to prevent cross-contamination.

- Traceability: A comprehensive traceability system is essential, allowing for quick identification of the origin of feed ingredients and any potential problems.

For example, a feed mill might use near-infrared spectroscopy (NIRS) to rapidly analyze the nutrient content of raw materials and finished feed, or implement a robust pest control program to prevent insect infestations in storage facilities.

Q 12. What are the key indicators of good poultry feed quality?

Several key indicators reflect the quality of poultry feed.

- Nutrient Composition: The feed must contain the correct levels of protein, energy, amino acids, vitamins, and minerals to meet the specific requirements of the bird. Analysis using standard methods is crucial to verify this.

- Palatability: Birds should readily consume the feed. Palatability can be assessed through observation and measurement of feed intake.

- Physical Characteristics: The feed should have the correct particle size and texture appropriate for the bird’s age and type. Pellets should be firm, not crumbling easily.

- Absence of Contaminants: The feed should be free from mycotoxins, pesticides, heavy metals, and other harmful substances. Testing for these contaminants is crucial.

- Microbial Load: The feed should have a low microbial load to prevent spoilage and disease. Regular microbiological analysis helps ensure this.

For instance, a farmer might observe that birds are leaving a significant portion of the feed uneaten, suggesting a palatability problem that needs to be addressed by adjusting the feed formulation or considering alternatives. Conversely, consistently high feed conversion ratios (FCR) indicate a high-quality feed effectively supporting growth.

Q 13. What are the common challenges in poultry nutrition and feed formulation?

Poultry nutrition and feed formulation face numerous challenges.

- Fluctuating Raw Material Prices: The cost of raw materials is highly variable, affecting feed costs and profitability. Strategic sourcing and ingredient substitution are essential to mitigate these price fluctuations.

- Mycotoxin Contamination: Mycotoxins are a major concern, requiring effective prevention and mitigation strategies.

- Antibiotic Resistance: The overuse of antibiotics in poultry production is driving antibiotic resistance, necessitating a shift towards alternative strategies like probiotics and prebiotics.

- Environmental Concerns: Sustainable feed production practices are increasingly important to minimize the environmental footprint of poultry farming. This includes reducing reliance on soy and fishmeal, exploring alternative protein sources, and managing manure appropriately.

- Nutrient Availability: The bioavailability of nutrients in feed can be affected by various factors, such as ingredient processing and interactions between nutrients. Sophisticated feed formulation techniques help optimize nutrient utilization.

For example, a feed formulator might need to replace a costly ingredient with a more affordable substitute without compromising nutritional value, or implement a strategy to reduce mycotoxin contamination in feed ingredients.

Q 14. What is the role of probiotics and prebiotics in poultry nutrition?

Probiotics and prebiotics are increasingly recognized for their positive roles in poultry nutrition and gut health.

- Probiotics: These are live microorganisms (bacteria or yeasts) that, when administered in adequate amounts, confer a health benefit to the host. In poultry, probiotics help improve gut microbiota balance, enhance nutrient digestibility, and strengthen the immune system. They can reduce the incidence of enteric diseases and improve feed efficiency.

- Prebiotics: These are non-digestible food ingredients that promote the growth of beneficial bacteria in the gut. They act as a substrate for probiotics, helping them thrive and positively influence gut health. Common prebiotics include fructooligosaccharides (FOS) and mannan-oligosaccharides (MOS).

By improving gut health, probiotics and prebiotics contribute to improved feed efficiency, reduced disease incidence, enhanced immune function, and better overall poultry performance. They offer a promising avenue for reducing reliance on antibiotics in poultry production, aligning with sustainability and consumer demands for antibiotic-free poultry.

Q 15. How do you manage feed costs while maintaining optimal nutrient levels?

Managing feed costs while maintaining optimal nutrient levels is a delicate balancing act in poultry production. It’s about finding the most cost-effective ingredient combinations that still meet the bird’s nutritional requirements for optimal growth, egg production, and overall health. This requires a deep understanding of nutrient requirements at different growth stages, ingredient prices, and the availability of alternative feed sources.

- Ingredient Selection: We prioritize using locally sourced ingredients whenever possible to reduce transportation costs. We also explore less expensive, but nutritionally comparable, alternatives. For example, substituting some soybean meal with locally grown sunflower meal or utilizing alternative protein sources like insect meal, while carefully monitoring amino acid profiles to ensure balance.

- Feed Formulation Software: Sophisticated software is crucial. It allows us to optimize formulations based on ingredient prices and nutrient requirements. The software considers the nutritional value of each ingredient and adjusts the ratios to achieve the target nutrient profile at the lowest cost.

- Nutritional Analysis: Regular analysis of feed ingredients and finished feed is essential. This ensures that the actual nutrient content matches the formulated values, preventing nutrient deficiencies and minimizing waste.

- Precision Feeding: Implementing precision feeding strategies can help reduce feed waste. This involves adjusting feed amounts based on the age and production stage of the birds, ensuring they receive only what they need.

For example, in a situation where corn prices are high, we might increase the proportion of sorghum or wheat in the diet while carefully monitoring the overall energy and amino acid balance. The key is constant monitoring and adjustment based on market fluctuations and bird performance.

Career Expert Tips:

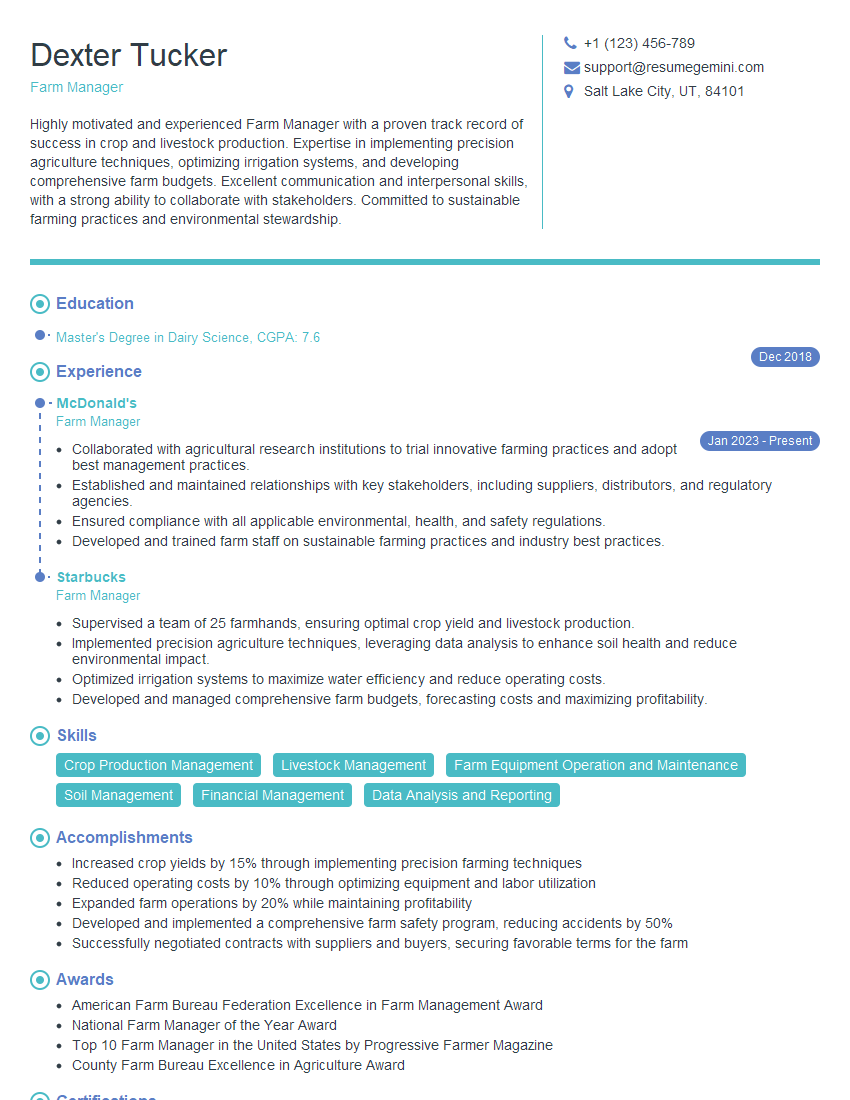

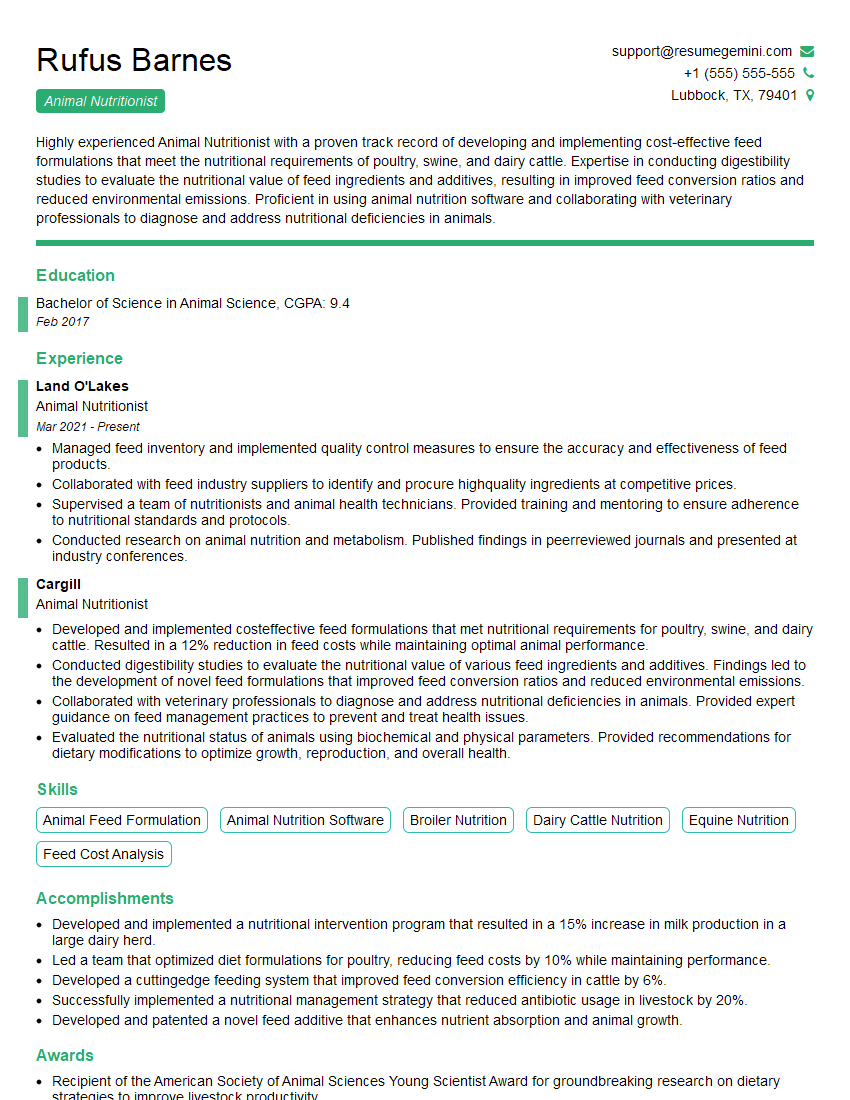

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the concept of feed conversion ratio (FCR) and its significance.

Feed Conversion Ratio (FCR) is a crucial performance indicator in poultry farming. It measures the efficiency of feed utilization by calculating the amount of feed needed to produce a unit of weight gain (for meat birds) or a unit of egg production (for layers). A lower FCR signifies better feed efficiency, indicating healthier birds and lower production costs.

Calculation: FCR is calculated as: FCR = Total feed consumed / Total weight gain (or egg production)

Significance: A low FCR translates directly to higher profitability. It means less feed is required to produce the same output, resulting in significant cost savings. FCR is also an indicator of bird health and the efficacy of the feeding program. Problems such as disease, poor feed quality, or nutritional deficiencies will negatively impact FCR.

Example: If two flocks of broilers consume 2 kg and 2.5 kg of feed, respectively, to produce 1 kg of weight gain, the FCR for the first flock is 2:1 (better), while the second flock has an FCR of 2.5:1 (less efficient). This indicates that the first flock’s feeding program is more effective.

Q 17. What are the effects of nutrient deficiencies on poultry health and performance?

Nutrient deficiencies have severe consequences for poultry health and performance. The specific effects vary depending on the deficient nutrient and the severity of the deficiency. However, common outcomes include:

- Growth retardation: Deficiencies in essential amino acids, energy, or minerals like calcium and phosphorus can significantly hinder growth in young birds.

- Reduced egg production and quality: In layers, deficiencies affect egg production, shell quality, and egg size. For example, calcium deficiency leads to thin-shelled or shell-less eggs.

- Impaired immune function: Deficiencies in vitamins (like Vitamin A, E, and D) and trace minerals weaken the immune system, making birds more susceptible to diseases.

- Skeletal deformities: Deficiencies in calcium, phosphorus, and Vitamin D lead to bone abnormalities like rickets or osteomalacia.

- Increased mortality: Severe deficiencies can cause widespread metabolic disorders and ultimately lead to death.

- Reduced feed efficiency: Deficiencies often lead to poorer feed conversion ratios, increasing production costs.

Example: A deficiency in methionine, an essential amino acid, will limit protein synthesis, hindering growth and potentially leading to feather abnormalities in broilers. Similarly, a Vitamin A deficiency might cause respiratory problems and eye issues.

Q 18. What is the impact of dietary fat on poultry health and egg production?

Dietary fat plays a crucial role in poultry health and egg production. It’s a concentrated energy source, providing more than twice the energy of carbohydrates or proteins. The type and amount of fat included in the diet significantly affect the bird’s overall performance and product quality.

- Energy Source: Fat provides a significant portion of the bird’s energy requirements, particularly during periods of high energy demand, such as egg production or rapid growth.

- Carrier for Fat-Soluble Vitamins: Fat acts as a carrier for fat-soluble vitamins (A, D, E, and K), enhancing their absorption and utilization.

- Egg Quality: The inclusion of appropriate fats in layer diets improves egg yolk color, improves shell quality, and increases egg size. The fatty acid profile of the diet influences the composition of the egg yolk, impacting its nutritional value.

- Insulation and Protection: Fat deposits provide insulation and protect against cold stress.

- Potential Negative Impacts: Excessive fat can lead to obesity, reduced feed efficiency, and digestive problems. Also, the type of fat is important; using fats rich in saturated fatty acids may negatively impact health compared to unsaturated fats.

Example: Including appropriate amounts of vegetable oils (rich in unsaturated fatty acids) in layer diets improves egg yolk color and overall egg quality. Conversely, excessive saturated fats can lead to increased abdominal fat in broiler chickens.

Q 19. Describe different feed delivery systems for poultry.

Several feed delivery systems are used for poultry, each with its advantages and disadvantages. The choice depends on factors like bird age, housing type, and production goals.

- Manual Feeding: This involves distributing feed manually using buckets or troughs. It’s suitable for small-scale operations but is labor-intensive and less efficient for larger farms.

- Automated Feeders (Trough Feeders): These systems distribute feed automatically through a network of troughs. They are efficient for larger flocks and provide uniform feed distribution. However, they require initial investment and regular maintenance.

- Pan Feeders: These are used typically for young chicks and allow for better control over feed intake.

- Tube Feeders: Used in broiler operations to deliver feed directly to the birds. They are ideal for reducing feed wastage and promoting even growth.

- Computerized Systems: Advanced systems monitor feed consumption and adjust feed delivery based on real-time data. This ensures optimal feed management and reduces wastage. These systems can even integrate with environmental monitoring to adjust feed delivery according to temperature and other environmental factors.

The selection of the appropriate feed delivery system is crucial for optimizing feed utilization and minimizing waste, ultimately impacting the profitability of the operation.

Q 20. How do you incorporate phytase in poultry feed formulation?

Phytase is an enzyme added to poultry feed to enhance the bioavailability of phosphorus. Phytic acid (phytate) is the primary form of phosphorus in many plant-based feed ingredients like soybean meal and corn. However, it is not readily available to birds, as they lack the necessary enzymes to break it down. Phytase helps overcome this limitation.

Incorporation: Phytase is incorporated into poultry feed formulations as a feed enzyme. The amount added depends on several factors including the phytate content of the feed ingredients, the bird’s age, and the desired level of phosphorus release. Commercial phytase products are available in liquid or solid forms.

Benefits: The primary benefit is improved phosphorus utilization. This allows for a reduction in the amount of inorganic phosphorus added to the feed, reducing feed costs and minimizing environmental pollution caused by phosphorus excretion.

Formulation Process: The inclusion rate of phytase is typically determined during the feed formulation process using specialized software. This software considers the phytate levels in the feed ingredients and calculates the optimal amount of phytase needed to achieve the desired level of available phosphorus. Phytase is typically added during the feed mixing process.

Example: A feed formulation might include a certain amount of soybean meal that is relatively high in phytate. Adding phytase helps to unlock the phosphorus bound up in the phytate, making it available to the birds. This allows for a reduction in the amount of inorganic phosphorus, leading to a more environmentally friendly and cost-effective feed.

Q 21. What are the environmental considerations in poultry feed formulation?

Environmental considerations are becoming increasingly important in poultry feed formulation. The goal is to minimize the environmental impact of poultry production throughout the feed lifecycle.

- Phosphorus Reduction: Reducing phosphorus in feed, as previously discussed through phytase addition, significantly minimizes phosphorus excretion into the environment. Excess phosphorus can lead to water pollution and eutrophication.

- Sustainable Sourcing of Ingredients: Prioritizing sustainable and responsibly sourced feed ingredients reduces the environmental burden associated with deforestation, pesticide use, and greenhouse gas emissions from agriculture.

- Reducing Greenhouse Gas Emissions: Choosing ingredients and feed production processes with lower carbon footprints can contribute to a reduction in overall greenhouse gas emissions.

- Waste Management: Effective management of feed waste from farms helps prevent environmental contamination.

- Antibiotic Reduction: Minimizing the use of antibiotics in poultry production, through improved nutrition and biosecurity measures, reduces the risk of antibiotic resistance development and its subsequent impact on the environment.

Example: Substituting fishmeal with alternative protein sources like insect meal not only reduces pressure on wild fish stocks but also helps decrease the overall environmental impact of feed production. Similarly, selecting locally sourced ingredients reduces transportation emissions.

Q 22. Explain the concept of amino acid balance in poultry diets.

Amino acid balance in poultry diets refers to providing the right ratio of essential and non-essential amino acids to meet the bird’s specific needs at different growth stages. It’s not just about providing enough of each amino acid, but ensuring the proportions are optimal for protein synthesis. Think of it like baking a cake – you need the right amount of each ingredient, not just a pile of flour and sugar. A deficiency in even one essential amino acid (like lysine, methionine, or tryptophan) can limit growth and overall productivity, regardless of the abundance of other amino acids. An imbalance can lead to inefficient protein utilization, reduced growth rate, impaired immune function, and poorer feed conversion ratio (FCR). We achieve this balance through careful feed formulation, utilizing various feed ingredients with differing amino acid profiles. For example, soybean meal is rich in lysine, while fishmeal contributes methionine. Sophisticated feed formulation software helps us model and optimize amino acid profiles to meet the specific requirements of the poultry species and age.

Q 23. How do you assess the nutritional quality of feed ingredients?

Assessing the nutritional quality of feed ingredients involves a combination of laboratory analysis and historical data. We analyze the crude protein content (using the Kjeldahl method, for instance), amino acid profile (using HPLC or other chromatographic methods), energy content (using bomb calorimetry), fiber content, mineral content, and vitamin levels. Additionally, mycotoxin analysis is crucial to ensure feed safety. Beyond lab results, we consider the ingredient’s source, storage conditions, and history. For example, a soybean meal sample with a high percentage of damaged kernels might indicate poor processing and potentially lower digestibility. We might also rely on third-party certifications or quality control reports from reputable suppliers. Ultimately, it’s a holistic approach, combining quantitative data with qualitative assessments to ensure the integrity and consistency of the feed ingredients.

Q 24. What are the regulatory requirements for poultry feed labeling and safety?

Regulatory requirements for poultry feed labeling and safety vary by country, but generally involve specific guidelines regarding ingredient declaration, guaranteed analysis (minimum levels of protein, fat, fiber, etc.), and the absence of prohibited substances. Labels must clearly identify the feed type (e.g., broiler starter, layer mash), the species it’s intended for, and the manufacturer’s information. There are strict regulations on the presence of contaminants like mycotoxins, heavy metals, and pesticides. Many jurisdictions also have specific rules regarding antibiotic use and genetically modified organisms (GMOs) in poultry feed. These regulations are crucial for ensuring consumer safety, preventing economic losses due to disease outbreaks, and maintaining fair trading practices. Non-compliance can result in significant penalties.

Q 25. How do you handle feed ingredient shortages and price fluctuations?

Feed ingredient shortages and price fluctuations are major challenges. Our approach involves developing robust sourcing strategies, diversifying our suppliers, and securing contracts with alternative suppliers when possible. We use market analysis tools to monitor price trends and anticipate potential shortages. When facing shortages of a key ingredient, we might explore substituting with similar ingredients, adjusting the formulation to minimize the impact on nutrient balance, or using enzyme supplementation to enhance the digestibility of alternative ingredients. For instance, if soybean meal prices spike, we might increase the proportion of other protein sources like sunflower meal, while carefully adjusting the amino acid profile to maintain balance. This requires expertise in feed formulation and a deep understanding of ingredient interactions. Furthermore, we continually evaluate alternative, more affordable ingredients without compromising nutritional value and bird performance.

Q 26. Describe the use of feed additives in poultry nutrition.

Feed additives play a vital role in optimizing poultry nutrition and health. They include:

- Enzymes: Improve nutrient digestibility, enhancing the bioavailability of nutrients.

- Probiotics: Improve gut health, enhance immune function, and reduce the need for antibiotics.

- Prebiotics: Stimulate the growth of beneficial bacteria in the gut.

- Acidifiers: Improve gut pH, reducing pathogen colonization.

- Antioxidants: Protect feed ingredients and the bird from oxidative stress.

- Coccidiostats: Prevent coccidiosis, a parasitic disease affecting poultry.

The selection and inclusion of feed additives depend on various factors, including the bird’s age, health status, and environmental conditions. Careful consideration is given to regulatory approvals and potential interactions between different additives. The aim is to use these additives strategically to improve overall bird performance, health, and welfare, often minimizing the environmental impact.

Q 27. Explain the impact of different feeding strategies on poultry growth and health.

Different feeding strategies significantly impact poultry growth and health. Factors such as feed restriction, phase feeding (altering feed composition throughout the bird’s life cycle), and feeding frequency all influence bird performance. For example, phase feeding provides nutrient densities tailored to each growth stage. Young birds require higher energy and protein levels for rapid growth, while older birds need a different balance to support egg production or meat quality. Feed restriction can be employed to manage growth rate or body condition, particularly in certain breeds. However, excessive restriction can negatively impact long-term health. Feeding frequency impacts feed intake and digestion, with more frequent feeding potentially benefiting younger birds. The choice of feeding strategy often depends on the breed, production goals, economic factors, and available resources. Careful monitoring of bird weight, feed conversion ratio, and mortality rates is crucial to optimize feeding strategies for maximum efficiency and welfare.

Q 28. How do you troubleshoot issues related to poultry feed quality and performance?

Troubleshooting poultry feed quality and performance issues requires a systematic approach. We start by assessing:

- Feed composition: Verify the accuracy of feed formulation and ingredient quality through laboratory analysis.

- Bird performance: Monitor growth rates, mortality, feed conversion ratio, and egg production (for layers).

- Environmental factors: Check for factors like temperature, humidity, ventilation, and disease outbreaks that might impact performance.

- Feed handling and storage: Evaluate feed storage conditions and ensure proper handling practices are followed to prevent spoilage or contamination.

Then, we conduct a thorough investigation of potential causes, often involving veterinary consultation if health issues are suspected. For example, a sudden drop in growth rate might be due to a nutrient deficiency, mycotoxin contamination, a disease outbreak, or an issue with feed processing. The systematic approach and a thorough investigation are critical in identifying the root cause and implementing effective corrective actions.

Key Topics to Learn for Poultry Nutrition and Feed Formulation Interview

- Nutrient Requirements of Poultry: Understand the varying nutritional needs of different poultry species (broilers, layers, turkeys) at various life stages, including protein, energy, vitamins, and minerals. Consider how these needs change based on factors like breed, environmental conditions, and production goals.

- Feed Formulation Principles: Master the art of balancing rations to meet specific nutrient requirements cost-effectively. This includes understanding feed ingredient composition, nutrient digestibility, and the use of formulation software.

- Feed Manufacturing Processes: Familiarize yourself with the different stages of feed production, from ingredient sourcing and quality control to mixing, pelleting, and storage. Be prepared to discuss potential challenges and solutions at each stage.

- Feed Quality and Safety: Discuss the importance of mycotoxin contamination, bacterial contamination, and the role of feed additives in maintaining poultry health and flock performance.

- Digestibility and Metabolism: Understand the digestive physiology of poultry and how different feed ingredients are digested and metabolized. Be prepared to discuss the impact of feed processing on nutrient availability.

- Nutritional Diseases and Disorders: Demonstrate knowledge of common nutritional deficiencies and toxicities in poultry, and how these can be prevented through proper feed formulation and management.

- Economic Considerations in Feed Formulation: Discuss the role of ingredient cost, feed efficiency, and market prices in developing cost-effective and profitable feed formulations.

- Sustainable Poultry Nutrition Practices: Explore environmentally friendly approaches to poultry nutrition, such as reducing phosphorus excretion and utilizing alternative feed ingredients.

- Data Analysis and Interpretation: Be ready to discuss how to interpret data from feed analysis, bird performance, and economic assessments to improve feed formulation strategies.

- Problem-Solving and Troubleshooting: Prepare to discuss real-world scenarios, such as dealing with unexpected nutrient deficiencies or addressing production challenges related to feed quality.

Next Steps

Mastering Poultry Nutrition and Feed Formulation is crucial for career advancement in the poultry industry, opening doors to specialized roles and increased earning potential. A strong resume is your key to unlocking these opportunities. Creating an ATS-friendly resume is essential for getting your application noticed by recruiters. ResumeGemini can help you build a professional, impactful resume that highlights your skills and experience effectively. They offer examples of resumes tailored to Poultry Nutrition and Feed Formulation to guide you in creating the perfect application. Take this opportunity to craft a resume that reflects your expertise and secures your dream job!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

good