Cracking a skill-specific interview, like one for Power Line Construction and Repair, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Power Line Construction and Repair Interview

Q 1. Describe your experience with different types of power line conductors.

Power line conductors are the heart of the electricity transmission and distribution system. My experience encompasses a wide range, including Aluminum Conductor Steel-Reinforced (ACSR), All-Aluminum Conductor Steel-Reinforced (AACSR), and various types of aluminum conductors. ACSR, for instance, is incredibly common due to its high strength-to-weight ratio, making it ideal for long spans and challenging terrain. The steel core provides tensile strength, while the aluminum provides the conductivity. AACSR offers similar benefits but without the steel core, which is advantageous in certain corrosive environments. I’ve also worked extensively with different alloys of aluminum conductors designed for specific applications, such as those with enhanced corrosion resistance in coastal areas or increased conductivity for high-capacity lines. Choosing the right conductor involves careful consideration of factors like voltage, current capacity, span length, environmental conditions, and cost.

- ACSR: The workhorse, balancing strength and conductivity.

- AACSR: A lighter option, preferred in specific conditions.

- Aluminum conductors (various alloys): Offering specialized properties tailored to the environment.

Q 2. Explain the process of installing a new power pole.

Installing a new power pole is a multi-stage process demanding precision and safety. It begins with site preparation – surveying the location, ensuring proper clearance from structures and vegetation, and excavating the hole to the appropriate depth. The hole needs to be deep enough to ensure stability and consider the soil type. Next, the pole is carefully positioned and plumbed using a level and temporary bracing. We then use concrete – typically a specialized high-strength mix – to fill the hole, ensuring the pole remains perfectly vertical. After the concrete sets (usually 24 hours minimum, depending on the mixture and weather conditions), we remove the bracing and begin attaching the crossarms and insulators. Finally, the conductors are strung and connected, and the whole assembly is inspected rigorously for any potential issues. The entire process requires coordination between multiple teams and adherence to strict safety regulations.

Q 3. What safety measures do you employ when working on energized lines?

Safety is paramount when working with energized lines. We utilize various methods to mitigate risk, including but not limited to:

- Rubber gloves and sleeves: These provide insulation to prevent electrical shock.

- Insulated tools: All tools used are specifically designed to withstand the voltage levels.

- Protective clothing: This includes flame-resistant clothing, safety helmets, and eye protection.

- Grounding: Before any work begins, the lines are grounded to ensure there’s no unexpected voltage present.

- Lockout/Tagout procedures: This ensures the power is physically disconnected and cannot be inadvertently turned back on.

- Hot-line tools: These specialized tools allow for working on energized lines while maintaining a safe distance from the conductors. This involves techniques like using insulated sticks to manipulate conductors or utilizing live-line clamps for attaching equipment.

- Spotters: Having another crew member spot the work ensures a secondary layer of safety and prevents accidents.

Regular safety training and stringent adherence to safety protocols are vital components of our work culture.

Q 4. How do you identify and resolve common power line faults?

Identifying and resolving power line faults requires a systematic approach. We start with identifying the area experiencing the outage using sophisticated monitoring systems and customer reports. Then, we use a variety of diagnostic tools, including fault locators and infrared cameras, to pinpoint the exact location and type of fault. Common faults include broken conductors, damaged insulators, tree contact, and animal interference. Resolving the fault depends on its nature; it could involve replacing a broken conductor, repairing or replacing a damaged insulator, removing tree limbs, or repairing damaged equipment. In many cases, we must de-energize the line to ensure safety before conducting repairs. Advanced fault detection technology is vital for minimizing outage duration and restoring power quickly and efficiently.

Q 5. Describe your experience with different types of insulators.

Insulators play a crucial role in preventing electrical current from flowing to the supporting structures, preventing dangerous short circuits. I’ve worked with various insulator types, including:

- Pin-type insulators: Simple and effective for lower voltage lines.

- Suspension insulators: Used for high-voltage lines, consisting of multiple insulator units strung together for increased voltage withstand capabilities. They are more resilient to damage compared to pin type.

- Strain insulators: Used at points of high tension, such as dead-ends and angles.

- Post insulators: Used in switchgear and substations, designed for higher voltage levels.

Choosing the right insulator depends on voltage levels, environmental factors (such as pollution and temperature extremes), and mechanical stresses.

Q 6. What are the common causes of power outages and how are they addressed?

Power outages are caused by a variety of factors. Severe weather events (storms, high winds, ice storms) are frequently to blame, causing damage to lines and equipment. Equipment failures, such as transformer malfunctions or broken switches, can also trigger outages. Other common causes include tree contact, animal interference, and human error. Addressing power outages involves a multi-pronged approach. First, we prioritize safety, ensuring the affected area is secure before any repair attempts. Next, we dispatch crews to assess the damage and initiate repairs. The extent of repairs, whether it’s a simple conductor repair or a more extensive equipment replacement, depends on the cause and the severity of the damage. Modern SCADA (Supervisory Control and Data Acquisition) systems play a critical role in monitoring the grid and identifying outage locations, allowing for faster response times and improved restoration efficiency.

Q 7. Explain the process of stringing power lines.

Stringing power lines is a complex procedure requiring specialized equipment and expertise. It begins with the preparation of the conductors, which often involves cleaning and inspecting them for any defects. Then, using specialized stringing equipment (such as stringing blocks and tensioners), the conductors are pulled across the spans between poles. The tension needs to be carefully controlled to ensure the lines are taut but not overly stressed. We use tension meters to precisely measure and maintain the appropriate tension. Once the conductors are strung, they are connected to the insulators and the terminal structures. The sag in the lines must be carefully calculated to accommodate for temperature variations and ensure sufficient clearance from the ground. The entire process must maintain utmost precision and safety, involving careful coordination among the stringing crew, safety personnel, and other support teams.

Q 8. How do you ensure the safety of yourself and your crew during a power line repair?

Safety is paramount in power line work. It’s not just a checklist; it’s a mindset ingrained from the first day of training. We begin every job with a comprehensive safety briefing, outlining the specific hazards of that day’s tasks. This includes identifying potential fall hazards, energized lines, and the presence of any other potential dangers like nearby structures or weather conditions. We utilize a robust system of permits and clearances before commencing any work on energized equipment, ensuring the power is safely de-energized and grounded. Every crew member wears appropriate Personal Protective Equipment (PPE), including hard hats, safety glasses, arc flash suits, insulated gloves, and safety harnesses. We employ spotters to ensure safe clearances and to watch for any unexpected occurrences. Regular tool inspections and maintenance are crucial. A simple damaged tool can lead to serious injury. For example, I once had a crew member discover a small crack in his insulated pliers. Discovering it before beginning a job prevented a possible electrocution. We regularly review and update our safety procedures and conduct ongoing training to address the most up-to-date safety guidelines.

Q 9. Describe your experience with various types of climbing equipment used in power line work.

My experience with climbing equipment is extensive, encompassing various types suitable for different situations. I’m proficient with both traditional climbing techniques and modern methods utilizing specialized equipment for power line construction and maintenance. This includes using various types of climbing belts, body harnesses, and safety lanyards. I’ve worked with different types of climbing ropes, including synthetic ropes designed for high-strength and abrasion resistance. I’m familiar with a variety of ascenders and descenders, including those specifically designed for working on poles and towers. Moreover, I have expertise using specialized tools for attaching safety lines to structures and ensuring redundancy in the fall protection system. For instance, I’ve used both friction-based and cam-based ascenders, selecting the appropriate one based on the pole’s condition and the specific task at hand. Safety is always paramount when selecting and using these tools – ensuring all equipment is in top working order and regularly inspected for wear and tear.

Q 10. What are the different types of transformers used in power distribution?

Transformers are essential components in power distribution, stepping voltage up or down to meet the needs of different parts of the system. There are several types, each serving a specific purpose. Distribution transformers, commonly found on power poles, typically step down the voltage from higher transmission levels (e.g., 138kV) to lower distribution levels (e.g., 120/240V). These are often pole-mounted and come in various sizes and configurations depending on the power demand of the area they serve. Substation transformers, significantly larger, handle much higher voltages and are responsible for transforming the voltage received from the transmission system. They can be either oil-filled, gas-insulated, or dry-type, depending on voltage levels, capacity and environmental considerations. Another common type is pad-mounted transformers, which are situated in underground vaults for safety and aesthetic reasons. The selection of a specific transformer type depends on factors like voltage levels, capacity, environmental conditions, and the overall system design. I’ve personally worked with all three types extensively in various projects.

Q 11. Explain your understanding of grounding and bonding procedures.

Grounding and bonding are crucial safety measures in power line work, preventing electrical shock and ensuring worker safety. Grounding connects a conductive element to the earth, providing a low-resistance path for fault currents. Bonding connects multiple metallic parts together, ensuring that they’re at the same electrical potential and minimizing the risk of voltage differences. Before working on any electrical equipment, we always ensure proper grounding and bonding. This involves using grounding clamps and conductors to connect the equipment to a known ground point. The process should be meticulously documented, and proper procedures ensure the ground is effective. For example, we use specialized grounding rods and carefully check for proper continuity using a megohmmeter before beginning any work. Failure to follow grounding and bonding procedures could lead to dangerous voltage differentials and potentially fatal electrical shock. This is a non-negotiable step in any line work activity.

Q 12. How do you handle emergency situations during power line work?

Emergency situations are a reality in power line work, so we’re trained to handle them efficiently and safely. Our procedures emphasize clear communication and quick response. If a worker is injured, our first priority is first aid and calling emergency services immediately. In case of equipment failure or an electrical fault, we immediately shut down the affected equipment and withdraw our personnel to a safe distance. We have established protocols for communicating with dispatch, emergency response teams, and our supervisors. We conduct regular emergency drills to ensure everyone is prepared for different scenarios. One scenario I vividly remember involved a fallen power line due to an unexpected storm. The team followed the established emergency protocol, quickly and safely isolating the line before any injury occurred. Our drills and training significantly improve our response times and help minimize risks during emergencies.

Q 13. What is your experience with preventative maintenance on power lines?

Preventative maintenance is key to ensuring the reliability and safety of power lines. It involves regularly inspecting lines for signs of wear and tear, damage, and corrosion. We use specialized tools and equipment to assess the condition of insulators, conductors, and supporting structures. This may involve visual inspection, infrared thermography to detect potential overheating issues, and testing of insulation resistance. This can involve trimming trees or vegetation near lines and repairing or replacing damaged components before they pose a safety hazard. A proactive approach significantly reduces the risk of outages, minimizes safety hazards, and improves the lifespan of power lines. I’ve overseen numerous preventative maintenance programs and have seen firsthand how this approach dramatically reduces costly emergency repairs and ensures reliable power distribution.

Q 14. Describe your understanding of the National Electrical Code (NEC) as it relates to power line construction.

The National Electrical Code (NEC) provides the minimum safety standards for electrical installations. My understanding of the NEC, as it applies to power line construction, covers a wide range of aspects. This includes safety clearances, conductor sizing, grounding requirements, insulation specifications, and protection against overcurrents and surges. Compliance with the NEC ensures the safety of workers and the public. We adhere to all relevant articles of the NEC during design, construction, and maintenance of power lines. We regularly review updates to the NEC to remain compliant and incorporate the most current safety practices into our work. A significant aspect is adhering to the safety clearances dictated by the NEC, ensuring a safe working distance from energized conductors. For example, we ensure that all equipment and personnel maintain proper distances during construction and maintenance of power lines, which directly impacts the safety of all involved. Non-compliance with the NEC is not an option in our field.

Q 15. How familiar are you with various types of aerial lifts and bucket trucks?

My familiarity with aerial lifts and bucket trucks is extensive. I’ve operated and maintained various models throughout my career, from smaller, articulating boom lifts ideal for intricate work in confined spaces, to larger, heavier-duty units for accessing taller structures and wider spans. Understanding the operational limits of each type – including weight capacities, reach, and stability – is crucial. For instance, I’ve used a Versalift articulating boom to work on densely packed urban lines where maneuverability was key, and a larger, telescoping boom truck for highway line maintenance requiring more reach. Safety procedures, including pre-operational inspections, proper load distribution, and emergency shutdown protocols, are second nature to me.

- Articulating Boom Lifts: Excellent for navigating obstacles and reaching various angles.

- Telescoping Boom Lifts: Offer greater vertical reach, ideal for taller structures.

- Insulated Aerial Devices (IADs): Specifically designed for working on energized lines, offering critical protection from electrical hazards.

Regular maintenance and inspections, including checking hydraulic fluid levels, tire pressure, and the integrity of the boom and basket, are paramount to safe operation. I’m proficient in both routine maintenance and troubleshooting mechanical issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain the process of terminating power lines.

Terminating power lines involves safely connecting or disconnecting conductors to equipment or other lines. The process depends on the voltage level and type of termination. It’s a critical procedure requiring precision and adherence to safety protocols to prevent electrical shock, arc flash, or equipment damage.

Here’s a general outline:

- Safety First: De-energize the line completely and apply appropriate lockout/tagout procedures. Verify the line is de-energized using a voltage tester.

- Preparation: Gather necessary tools and materials, including appropriate connectors, crimpers, tensioners, and grounding equipment.

- Connection/Disconnection: Depending on the termination type (e.g., compression connectors, splices, connectors using heat-shrink tubing), carefully connect or disconnect conductors, ensuring a secure and reliable connection. The method employed will depend on the specific design and voltage of the lines involved. For example, high-voltage lines require specialized connectors and techniques to ensure safe and reliable operation.

- Testing: After termination, thoroughly test the connection using appropriate tools to verify continuity and absence of shorts or opens.

- Documentation: Meticulously document the entire process, including the date, time, location, individuals involved, and any issues encountered.

Proper termination is essential for the reliability and safety of the power system. Improper termination can lead to power outages, equipment damage, and potentially dangerous situations. I’ve personally terminated lines ranging from low-voltage residential services to high-voltage transmission lines, always prioritizing safety and precision.

Q 17. What is your experience with working at heights and using fall protection equipment?

Working at heights is an inherent part of power line construction and repair, and safety is my top priority. I’m extensively trained and experienced in utilizing various fall protection equipment and techniques. My experience encompasses working with harnesses, lanyards, lifelines, and anchor points. I’m adept at setting up fall arrest systems, ensuring proper anchor placement, and conducting regular inspections of all equipment to prevent any hazards.

I always follow strict procedures, such as performing thorough pre-work inspections of all equipment, employing a buddy system whenever possible, and receiving necessary training on all equipment before its use. I’m also familiar with various rescue techniques and emergency procedures in case of a fall. There’s a saying in our line of work: ‘A fall is a failure of the system, not the person.’ Regular inspections, proper equipment use, and meticulous planning are key to preventing falls.

Q 18. Describe your experience with using various hand tools and power tools in power line work.

My experience with hand and power tools is comprehensive. I’m proficient in using a wide range of tools, including:

- Hand Tools: Lineman’s pliers, wire cutters, screwdrivers, wrenches, tape measures, shovels, etc.

- Power Tools: Drills, grinders, saws, impact wrenches, crimpers, and specialized tools like tensioners for stringing conductors.

I understand the safe and efficient operation of each tool, including proper maintenance and preventative measures to ensure their longevity and reliability. For example, understanding the differences between various types of wire cutters is crucial for cleanly cutting specific gauge wire, and using the right tensioner for the cable type ensures optimal line strength.

Safety procedures are paramount, and I always use the correct personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection when operating power tools. One instance that highlights my experience involved troubleshooting a faulty grounding system in a rural area. Using a combination of hand tools and specialized test equipment, we were able to identify and repair the issue efficiently, minimizing downtime.

Q 19. How do you interpret power line schematics and blueprints?

Interpreting power line schematics and blueprints is a fundamental skill in my profession. I can easily read and understand one-line diagrams, three-line diagrams, and detailed construction drawings. These documents provide critical information, including conductor sizes, voltage levels, equipment locations, and grounding systems.

For example, I can identify the different components of a substation from a schematic, understand the routing of conductors on a one-line diagram, and use construction drawings to understand the physical layout of poles, conductors, and supporting structures. I’m also capable of identifying potential conflicts or design flaws, and communicating those issues to engineers or supervisors to mitigate any potential issues. Accurate interpretation prevents costly mistakes during construction and repair, ensuring both safety and efficiency.

Q 20. What is your experience with using testing equipment to diagnose power line problems?

Diagnosing power line problems often requires the use of specialized testing equipment. I’m proficient in using various meters, such as clamp meters for measuring current, voltage testers for verifying voltage levels, and insulation resistance testers for checking the condition of insulation. I understand the principles behind each piece of equipment and how to interpret the results.

For instance, I’ve used a hi-pot tester to test the insulation resistance of high-voltage cables before energizing a new section of power line. I’ve also used a clamp meter to identify overloaded circuits, a crucial step in preventing equipment failure and potential safety hazards. Understanding the results from testing equipment requires a thorough understanding of electrical theory. This is combined with practical experience in interpreting the readings in the context of the power system’s operation. Accurately interpreting this data and acting upon it has been vital to my success in troubleshooting and repairing power line issues.

Q 21. Explain your understanding of the impact of weather conditions on power line operations.

Weather conditions significantly impact power line operations. Extreme weather, such as high winds, heavy snow, ice storms, and lightning strikes, can cause power outages, damage to equipment, and create hazardous working conditions. Understanding this impact is crucial for safe and efficient work planning.

For example, high winds can cause conductors to sway and potentially cause damage to structures or even cause lines to fall. Ice accumulation can increase the weight on lines and cause them to break. Lightning strikes pose a significant risk to both personnel and equipment. Therefore, we incorporate weather forecasts into our daily operations, adjusting schedules and employing appropriate safety precautions based on current and forecasted conditions. This might include delaying work during severe weather, employing additional safety measures, or using specialized equipment designed for working in inclement weather.

Safety during inclement weather is paramount. I’m trained in appropriate safety protocols, including the use of specialized weather protection gear and understanding the unique hazards associated with various weather events.

Q 22. Describe your experience with working in confined spaces.

Working in confined spaces, such as manholes or underground vaults during cable repair, is a common aspect of power line construction and repair. Safety is paramount. Before entering any confined space, we conduct thorough atmospheric testing to check for the presence of hazardous gases like methane or hydrogen sulfide. We also ensure proper ventilation and use appropriate personal protective equipment (PPE), including respirators, hard hats, and safety harnesses with fall protection.

I’ve personally worked in numerous confined spaces, including underground vaults during cable replacement projects. One memorable experience involved replacing a section of damaged cable in a particularly cramped manhole. Following all safety protocols, we carefully accessed the manhole, tested the atmosphere, established ventilation, and then proceeded with the replacement using specialized tools designed for confined space work. The entire process emphasized careful coordination and adherence to strict safety measures to prevent accidents.

- Atmospheric testing before entry

- Use of appropriate PPE

- Establishing proper ventilation

- Careful coordination between team members

Q 23. How do you maintain accurate records and documentation of work performed?

Maintaining accurate records is crucial for accountability, troubleshooting, and future maintenance. We utilize a combination of digital and paper-based documentation methods. For every job, we complete detailed work orders, including the date, location, crew involved, work performed, materials used, and any challenges encountered. We use digital systems like tablets or laptops to record progress in real-time, capture photos and videos of the work site and completed tasks, and then upload the data to a central database. This database enables easy retrieval of job histories for analysis or future reference.

For example, during a recent transmission line repair, we used a tablet to capture images of the damaged conductor before and after repair. We then documented the splicing techniques employed, the type and quantity of materials used, and the total time spent on the repair. This detailed documentation facilitated efficient reporting to the client and provided valuable data for future analysis and maintenance scheduling.

Q 24. What is your experience with working on underground power cables?

My experience with underground power cables encompasses installation, repair, and maintenance. This includes working with various cable types, from low-voltage distribution cables to high-voltage transmission cables. The process involves utilizing specialized equipment like cable locators, trenching machines, and cable pulling equipment. Safety protocols are stringent due to the potential for electrocution and ground faults. We always follow strict procedures for excavation, cable handling, and grounding to prevent accidents.

One significant project involved replacing a section of aging underground cable in a busy city center. The challenge was to minimize disruption to traffic and pedestrian access while adhering to strict safety regulations. We employed directional drilling techniques to install the new cable, reducing the need for extensive open-trench excavation. This approach minimized disruption and ensured the safety of both our workers and the public.

Q 25. Describe your experience with power line inspections and maintenance.

Power line inspections and maintenance are vital for ensuring the reliable delivery of electricity and preventing outages. Inspections involve visual assessments, infrared thermography (to detect overheating), and sometimes drone inspections for hard-to-reach areas. We check for signs of wear and tear, corrosion, damage from weather or wildlife, and potential hazards. Maintenance work can range from simple repairs to major upgrades, such as replacing aging conductors or insulators.

During routine inspections, we use specialized tools and equipment, including binoculars and infrared cameras, to identify potential problems. For example, we recently detected a small crack in a high-voltage insulator during a routine inspection. This seemingly minor issue could have led to a significant failure if left unaddressed. We promptly replaced the insulator, preventing a potential power outage.

Q 26. What is your familiarity with different types of splicing techniques?

I am proficient in various splicing techniques for different types of conductors. These include mechanical splices (using compression connectors or sleeves), soldered splices, and exothermic welding. The choice of technique depends on the type of conductor (aluminum, copper, etc.), voltage level, and environmental conditions. Each technique requires specific tools and procedures to ensure a reliable and safe connection.

For instance, when working with high-voltage aluminum conductors, we often use exothermic welding to create a strong and durable splice that is resistant to corrosion. For lower-voltage copper conductors, mechanical splices with compression connectors may be sufficient. Proper preparation of the conductor ends and adherence to manufacturer’s instructions are critical for achieving a successful splice in all cases.

Q 27. How do you ensure compliance with OSHA regulations on power line safety?

OSHA regulations are paramount in power line safety. We adhere to all relevant standards, including those related to working near energized lines, lockout/tagout procedures, personal protective equipment (PPE), and confined space entry. Regular safety training is mandatory for all crew members, covering both theoretical knowledge and hands-on practice. We also conduct pre-job safety briefings to review specific hazards and safety protocols for each task.

For example, before working near any energized lines, we implement a robust lockout/tagout procedure to ensure that the power is safely de-energized. Every crew member involved in the process understands and adheres to the specific safety measures and protocols in place. All work is performed with appropriate PPE, including rubber gloves, insulating tools, and safety harnesses.

Q 28. Explain your problem-solving approach when facing unexpected challenges during a power line repair.

My approach to problem-solving during unexpected challenges involves a structured process:

- Assessment: First, I carefully assess the situation, identifying the specific problem and its potential impact.

- Safety First: I prioritize safety and take immediate steps to mitigate any potential hazards. This might involve de-energizing lines or implementing additional safety precautions.

- Resource Evaluation: I evaluate the available resources – personnel, tools, and materials – to determine the best course of action.

- Solution Development: I explore potential solutions, considering factors like time constraints and the availability of resources. This often involves consulting with experienced colleagues or supervisors.

- Implementation and Monitoring: I implement the chosen solution, carefully monitoring its effectiveness and making adjustments as needed.

- Documentation: I thoroughly document the problem, the solution implemented, and the outcome.

For example, during a line repair, we unexpectedly encountered a damaged underground cable. After assessing the situation and ensuring safety, we utilized ground-penetrating radar to determine the cable’s exact location and extent of damage. We then coordinated with the utility company and implemented a repair plan, carefully documenting all steps of the process.

Key Topics to Learn for Power Line Construction and Repair Interview

- Safety Regulations and Procedures: Understanding OSHA regulations, lockout/tagout procedures, and safe work practices is paramount. This includes knowing how to identify and mitigate hazards on the job site.

- Pole Top Rescue and Resuscitation: Be prepared to discuss techniques for rescuing injured workers from poles and performing CPR/First Aid in challenging environments.

- Conductor Installation and Splicing: Demonstrate knowledge of various splicing techniques for different conductor types (copper, aluminum, etc.) and the tools used in the process. This includes understanding the importance of proper tension and sag.

- Transformer Installation and Maintenance: Explain the process of installing and maintaining transformers, including testing procedures and troubleshooting common issues.

- Underground Cable Installation and Repair: Discuss the methods used for installing and repairing underground cables, including trenching, cable pulling, and fault location techniques.

- Electrical Theory Fundamentals: A solid understanding of Ohm’s Law, Kirchhoff’s Laws, and basic AC/DC principles is essential for troubleshooting and problem-solving.

- Troubleshooting and Diagnostics: Be ready to discuss your approach to diagnosing faults in power lines, including the use of diagnostic tools and testing equipment.

- Equipment Operation and Maintenance: Familiarize yourself with the operation and maintenance of common tools and equipment used in power line construction and repair (e.g., bucket trucks, digger derricks, various hand tools).

- Project Management and Teamwork: Highlight your ability to work effectively in a team, manage time efficiently, and contribute to project success within budget and timeline constraints.

- Blueprint Reading and Interpretation: Demonstrate your ability to read and interpret electrical schematics and blueprints to understand project requirements.

Next Steps

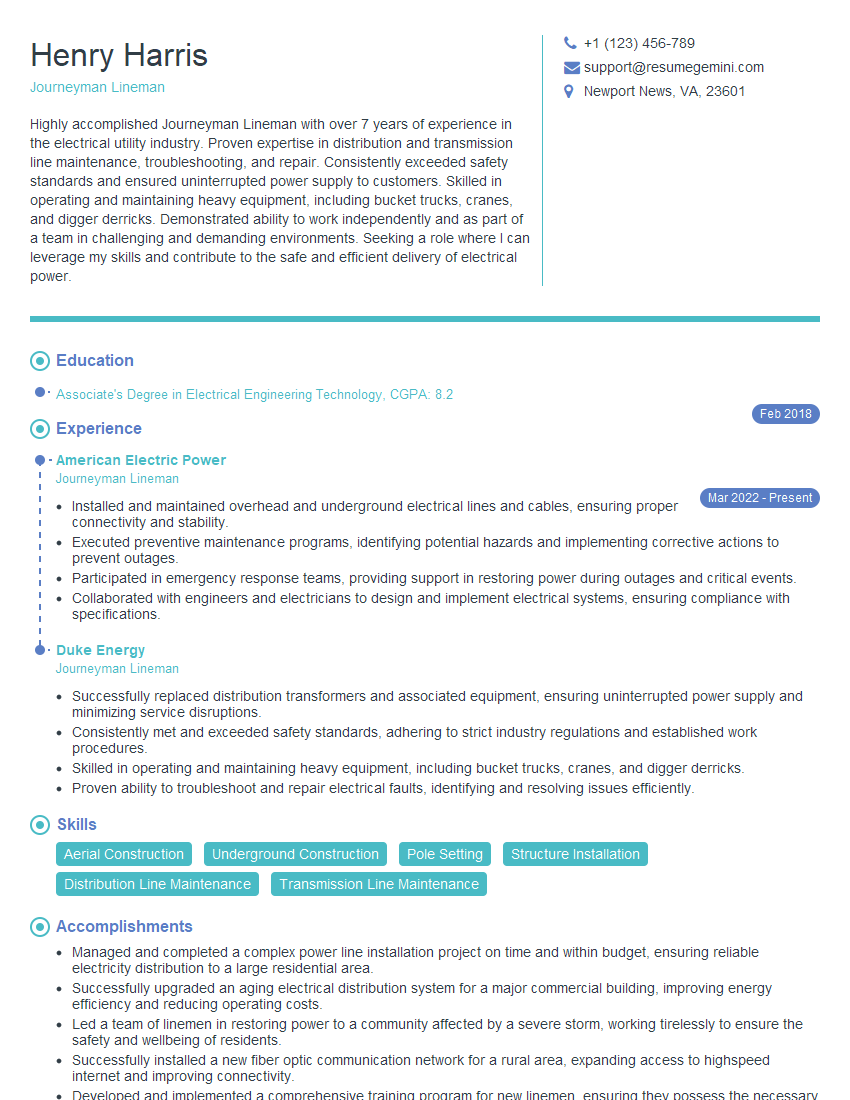

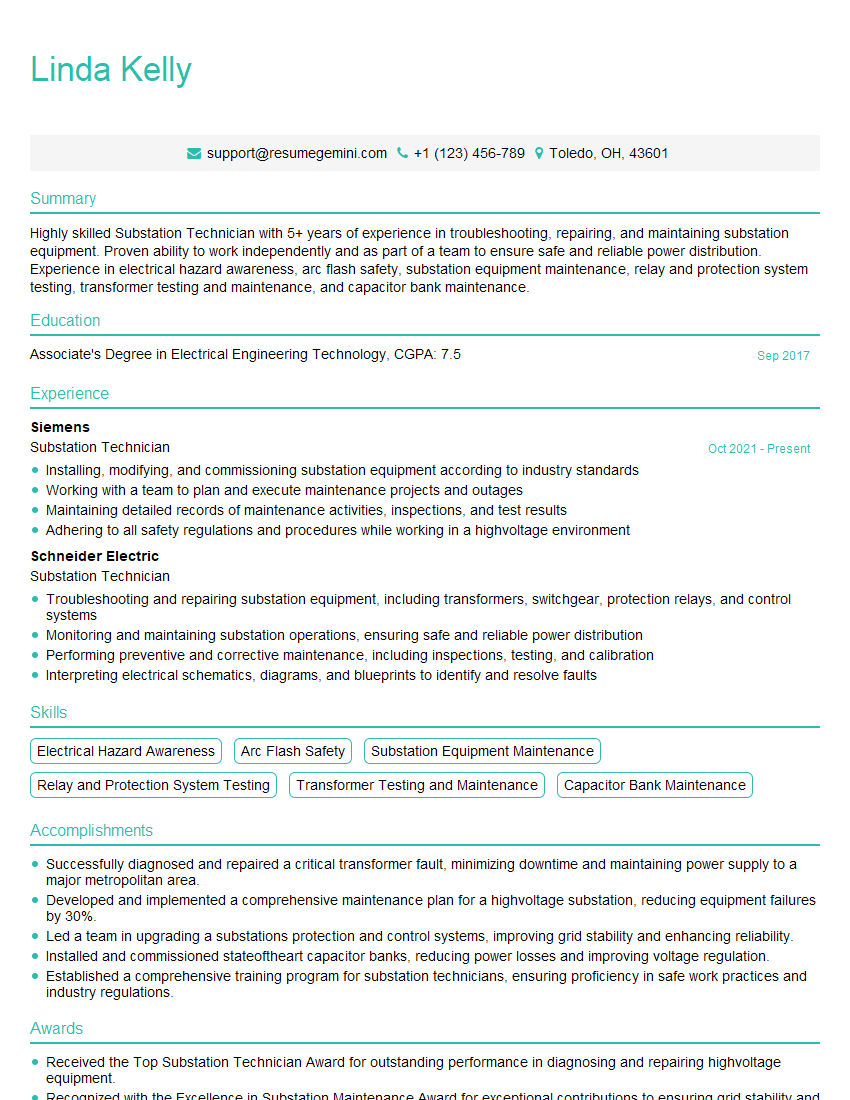

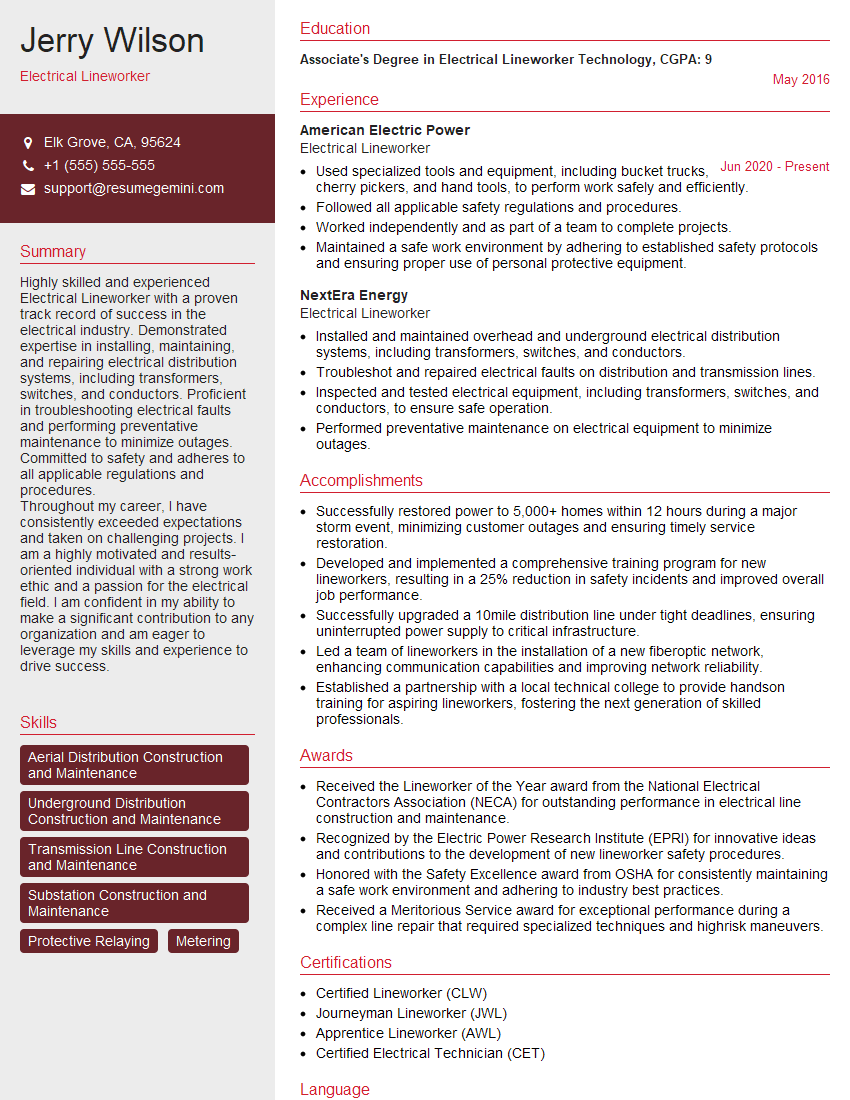

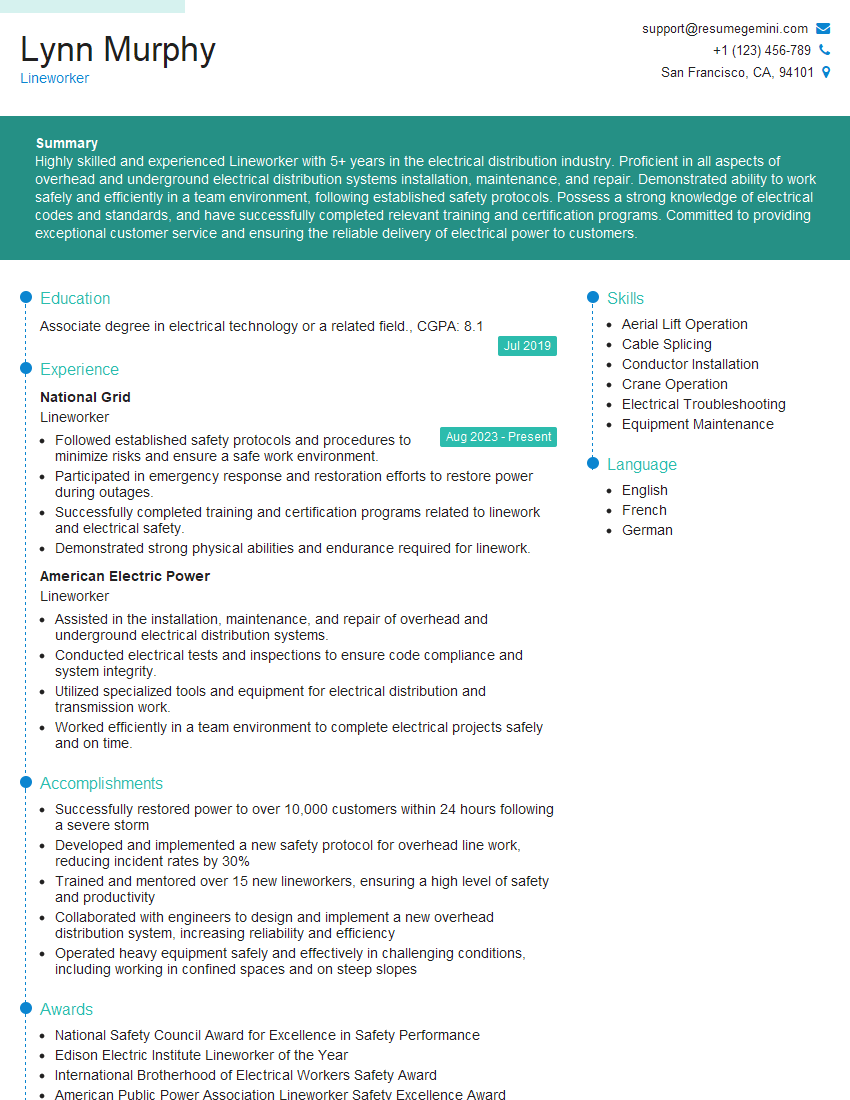

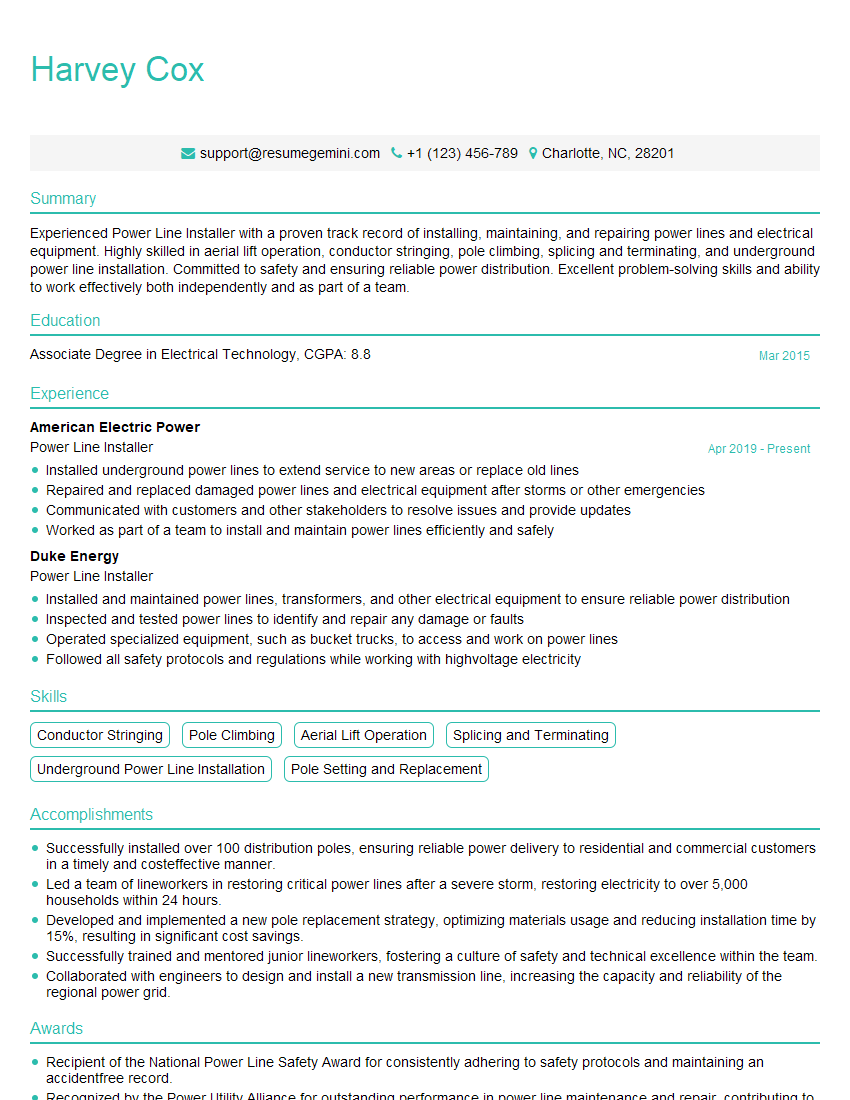

Mastering Power Line Construction and Repair opens doors to a rewarding career with excellent growth potential. This field demands skilled professionals committed to safety and efficiency. To stand out, create an ATS-friendly resume that showcases your qualifications effectively. ResumeGemini is a trusted resource for building professional resumes that grab recruiters’ attention. Take advantage of their tools and resources, including examples of resumes tailored to Power Line Construction and Repair, to create a compelling application that highlights your expertise and experience.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good