Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Power Quality Testing and Analysis interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Power Quality Testing and Analysis Interview

Q 1. Explain the difference between harmonic distortion and interharmonic distortion.

Both harmonic and interharmonic distortion relate to the presence of unwanted frequencies in the power system, but they differ in their frequency characteristics. Harmonic distortion involves frequencies that are integer multiples of the fundamental frequency (typically 50Hz or 60Hz). For example, the 3rd harmonic is three times the fundamental frequency. Interharmonic distortion, on the other hand, involves frequencies that are not integer multiples of the fundamental frequency. These are often caused by non-linear loads with complex switching patterns. Think of it like this: harmonics are like perfectly tuned musical notes related to the base note, while interharmonics are like notes that are slightly off-key.

Imagine a perfectly sinusoidal waveform representing ideal power. Harmonic distortion adds ‘bumps’ at frequencies that are multiples of the fundamental (e.g., 150Hz for a 50Hz system), while interharmonic distortion adds bumps at frequencies in between these multiples. This can create more complex waveform shapes, potentially leading to increased equipment stress and malfunction.

Q 2. Describe various power quality disturbances and their effects on equipment.

Power quality disturbances can significantly impact equipment reliability and lifespan. Some common disturbances include:

- Voltage Sags/Dips: Short-duration reductions in voltage amplitude. These can cause data loss in computers and process interruptions in industrial machinery. A sag might be as short as a few cycles and as long as a few seconds. Imagine dimming your lights for a moment; that’s a sag.

- Voltage Swells/Surges: Brief increases in voltage amplitude. These can lead to insulation damage and equipment burnout. Think about a sudden and brief increase in brightness of a light bulb – that’s a surge.

- Voltage Transients (Spikes): Very short-duration, high-amplitude voltage pulses. These are often caused by lightning strikes or switching operations and can destroy sensitive electronics. It’s like a very sharp and intense spike in voltage.

- Harmonics: As mentioned earlier, these are integer multiples of the fundamental frequency. High levels of harmonics can cause overheating in transformers and motors, leading to premature failure.

- Interharmonics: Non-integer multiples of the fundamental frequency, contributing to waveform distortion and equipment malfunction.

- Notches: Brief interruptions in the voltage waveform. These can be caused by faults or switching operations and can disrupt sensitive processes.

- Flicker: A perceptible fluctuation in the light intensity caused by voltage variations. While not directly damaging equipment, flicker can be irritating and affect productivity.

The effects of these disturbances vary greatly depending on the equipment’s sensitivity and the severity and duration of the event. Sensitive electronic equipment is particularly vulnerable, while more robust equipment might tolerate minor disturbances without issue.

Q 3. What are the common methods for measuring power quality parameters?

Measuring power quality parameters requires specialized instruments. Common methods include:

- Power Quality Analyzers: These devices directly measure voltage, current, power, harmonics, and other parameters, providing detailed data on power quality events.

- Oscilloscope: This instrument visually displays voltage and current waveforms over time. It’s invaluable for identifying transient events and waveform distortions. It shows you the precise shape of the waveform, allowing you to spot subtle anomalies.

- Power Meters: These devices measure active and reactive power, power factor, and other fundamental power parameters. While less sophisticated than power quality analyzers, they provide a valuable overview of power consumption.

- Clamp Meters: These allow contactless measurement of current, providing a quick way to assess current levels.

The choice of measurement method depends on the specific needs of the power quality study. For comprehensive analysis, a power quality analyzer is essential. For specific tasks, such as identifying transient events, an oscilloscope may be sufficient.

Q 4. How do you identify the source of a power quality problem?

Identifying the source of a power quality problem requires a systematic approach. It often involves:

- Data Acquisition: Gathering comprehensive power quality data using appropriate measurement techniques (as described above).

- Data Analysis: Analyzing the data to identify the type, magnitude, and frequency of power quality disturbances. This may involve using specialized software to process the data.

- Correlation: Correlating the disturbances with equipment operation and other events. For instance, does a specific disturbance occur only when a particular machine is running?

- Load Studies: Conducting load studies to assess the impact of individual loads on the power system.

- Site Inspection: A physical inspection of the electrical system to identify potential sources of problems, such as loose connections, faulty equipment, or aging infrastructure.

Often, a combination of these techniques is necessary to pinpoint the source. Consider it like detective work: you gather clues (data), analyze them, and use your experience to find the culprit.

Q 5. Explain the significance of Power Factor Correction (PFC).

Power Factor Correction (PFC) is crucial for improving the efficiency and stability of the power system. The power factor is a measure of how effectively the power is used. A low power factor indicates that a significant portion of the power is reactive power, which does not contribute to useful work but still stresses the electrical system. This results in increased energy bills and potential problems with overheating and equipment damage.

PFC improves the power factor by reducing reactive power. This is typically achieved by installing capacitor banks or other reactive power compensation devices. By correcting the power factor, you reduce the current flowing through the system for the same amount of real power, thereby reducing losses and improving system efficiency. Think of it like improving the efficiency of your car engine; you get more miles per gallon (useful work) by reducing energy loss.

Q 6. What are the different types of power quality analyzers and their capabilities?

Power quality analyzers come in various types, each with its capabilities:

- Basic Power Quality Analyzers: These measure fundamental power parameters, such as voltage, current, power, and power factor. They are often suitable for basic monitoring and troubleshooting.

- Advanced Power Quality Analyzers: These provide more extensive measurements, including harmonics, interharmonics, flicker, transients, and other disturbances. They often have more advanced data logging and analysis capabilities.

- Portable Power Quality Analyzers: These are smaller and more easily transportable than larger units, making them ideal for field work and site surveys.

- Multimeter with Power Quality Capabilities: These devices combine basic multimeter functionality with some power quality measurements, offering a cost-effective option for less demanding applications.

The choice depends on your application. A basic analyzer might suffice for simple monitoring, whereas advanced features are needed for in-depth diagnostics and investigations.

Q 7. Describe your experience with power quality mitigation techniques.

My experience encompasses a wide range of power quality mitigation techniques. I’ve worked on projects involving:

- Installation of capacitor banks for power factor correction: This is a common and effective method for improving the power factor and reducing reactive power flow.

- Installation of surge protective devices (SPDs): These devices protect equipment from voltage transients caused by lightning strikes or switching operations. We’ve seen significant reductions in equipment failures after implementing robust SPD systems.

- Active power filters (APFs): These advanced devices actively compensate for harmonics and other disturbances, offering precise and adaptive mitigation. They are especially valuable in applications with significant harmonic generation.

- Uninterruptible power supplies (UPS): These provide backup power during outages and protect equipment from voltage sags, swells, and interruptions. We often use them to protect critical loads.

- Voltage regulation systems: These systems maintain a constant voltage level, protecting equipment from voltage fluctuations. I’ve worked on projects where voltage regulators significantly improved the reliability of sensitive equipment.

The selection of mitigation techniques depends on the specific power quality problems identified, the type of equipment, and the overall budget. Often, a combination of techniques is necessary to achieve optimal results. The key is to adopt a holistic approach considering both the immediate problem and the long-term reliability of the power system.

Q 8. How do you interpret power quality data and generate reports?

Interpreting power quality data involves a systematic approach combining automated analysis with expert judgment. First, the raw data – voltage, current, frequency, power factor, etc. – acquired from monitoring devices is processed to identify events and calculate key parameters. This often involves filtering out noise and using algorithms to detect disturbances.

For example, we might identify sags, swells, harmonics, or interruptions. Then, these events are categorized and their severity is assessed based on their duration, magnitude, and frequency of occurrence. This assessment is guided by relevant standards and client-specific thresholds.

Finally, a report is generated summarizing the findings, including statistical summaries (average THD, number of sags/swells), visualizations (waveforms, histograms), and an interpretation of the data’s implications for the client’s equipment and operations. The report includes recommendations for mitigation strategies, if necessary, perhaps involving improved grounding, harmonic filtering, or the installation of surge protection devices.

For instance, a report might highlight consistently high levels of harmonic distortion caused by a specific type of nonlinear load. The report would then recommend harmonic filtering or load balancing as a solution. The level of detail and technical depth in the report is tailored to the client’s technical expertise and the purpose of the analysis.

Q 9. What are the IEEE standards relevant to power quality?

Several IEEE standards are crucial for power quality assessment. IEEE 519-2014, “Recommended Practices and Requirements for Harmonic Control in Electrical Power Systems,” is fundamental, defining limits for harmonic currents and voltages injected into power systems by different types of loads. This standard is essential for determining compliance with power quality requirements.

IEEE 1159-2019, “Recommended Practice for Monitoring Electric Power Quality,” provides guidance on monitoring methods, data acquisition, and analysis techniques. It helps standardize power quality measurements and ensures consistency across different monitoring systems.

Other relevant standards include IEEE C37.111-2019 concerning transient overvoltages and switching surges and various standards addressing specific power quality events like flicker, interruptions, and voltage variations.

Adherence to these standards is critical for consistent and reliable power quality assessments, ensuring that the results are comparable and meaningful across various projects and geographical locations.

Q 10. Explain the concept of Total Harmonic Distortion (THD).

Total Harmonic Distortion (THD) quantifies the harmonic content of a waveform relative to its fundamental frequency component. In simpler terms, it measures how much a waveform deviates from a perfect sine wave. A perfect sine wave has a THD of 0%, while a distorted waveform will have a higher THD value.

THD is expressed as a percentage and is calculated for both voltage and current. High THD indicates the presence of significant harmonic currents or voltages, which can lead to equipment malfunction, overheating, and reduced efficiency. Harmonics are created by nonlinear loads such as rectifiers, variable speed drives, and switching power supplies.

For example, a THD of 5% in voltage signifies that the harmonic components contribute 5% of the total voltage magnitude. Acceptable THD levels depend on the specific application and are often dictated by standards like IEEE 519. Exceeding these limits can result in penalties or necessitate corrective actions.

Q 11. What is the significance of flicker and how is it measured?

Flicker is a perceptual phenomenon characterized by unwanted fluctuations in light intensity caused by voltage variations in the power system. It primarily impacts lighting loads, leading to discomfort and potentially even affecting visual performance. In industrial settings, it could lead to reduced productivity.

Flicker is significant because it affects human well-being and productivity. It’s particularly crucial in facilities like hospitals and operating theaters where stable light is critical. Excessive flicker can also cause damage to sensitive equipment.

Flicker is measured using specialized instruments called flicker meters that quantify the perceived severity of flicker using a metric called the ‘Short Term Flicker Severity’ (Pst) and ‘Long Term Flicker Severity’ (Plt). These values are based on the statistical analysis of voltage fluctuations and their impact on the human visual system. The measurements take into account the frequency and magnitude of voltage variations.

Q 12. How do you analyze power quality data using software tools?

Software tools play a vital role in power quality data analysis. These tools automate data processing, identification of events, and report generation, significantly increasing efficiency and accuracy. Popular software packages incorporate advanced algorithms for detecting various power quality disturbances.

The analysis typically begins with data import from monitoring devices. The software then cleans and filters the data, identifies events (sags, swells, harmonics, etc.), and calculates key parameters like THD, RMS values, and event durations. Visualization features allow users to view waveforms, histograms, and other plots which aids in the interpretation of the data.

Many software packages allow for customization of settings and reporting formats to suit specific needs. For example, users can define thresholds for different events and generate customized reports including statistical summaries and recommendations based on analysis results. This facilitates easier diagnosis of power quality problems.

Examples of such software include Power Monitoring Software by Fluke, DEIF’s Power Quality Software, and other specialized packages from various manufacturers. The selection of the software depends on the specific needs of the project, features offered by the software, and the user’s experience.

Q 13. Describe your experience with transient voltage surges and their impact.

Transient voltage surges are sudden, short-duration increases in voltage that can significantly impact electrical equipment. These surges can originate from various sources, including lightning strikes, switching operations, and faults within the power system.

The impact of transient voltage surges can range from minor glitches to catastrophic equipment failure. Sensitive electronic equipment is particularly vulnerable, as surges can damage semiconductor devices and integrated circuits. The severity of the damage depends on the magnitude, duration, and impedance of the surge.

During my career, I’ve encountered numerous cases where transient voltage surges have caused significant damage to industrial control systems, leading to production downtime and costly repairs. One particular incident involved a lightning strike that caused multiple surge arresters to fail, resulting in substantial damage to a manufacturing plant’s PLC system.

Proper surge protection is crucial to mitigate the impact of transient voltage surges. This includes the use of surge protection devices (SPDs) at various points in the electrical system, effective grounding, and proper equipment design. Regular inspection and maintenance of SPDs are essential to ensure their effectiveness.

Q 14. Explain the use of power quality monitoring devices and their applications.

Power quality monitoring devices are instruments used to measure and record various electrical parameters relevant to power quality. These devices range from simple voltage and current meters to sophisticated systems capable of recording a wide range of parameters with high accuracy.

Applications of these devices are diverse. They are used in various settings, from small-scale residential installations to large industrial facilities. Common applications include:

- Identifying power quality problems: Detecting voltage sags, swells, harmonics, and other disturbances.

- Troubleshooting equipment malfunctions: Determining whether power quality issues are responsible for equipment failures.

- Compliance with standards: Ensuring compliance with power quality standards and regulations.

- Predictive maintenance: Identifying potential power quality issues before they cause significant problems.

- Load studies: Analyzing power consumption patterns and identifying potential areas for efficiency improvements.

The choice of monitoring device depends on the specific application and the required level of detail. Some devices provide basic measurements, while others can record extensive data, including waveforms and harmonic content. Advanced systems may incorporate data logging and communication capabilities to allow for remote monitoring and analysis.

Q 15. What are the different types of power quality disturbances that can affect industrial plants?

Industrial plants face a variety of power quality disturbances that can significantly impact productivity and equipment lifespan. These disturbances can be broadly categorized into voltage variations, harmonic distortions, and transient events.

- Voltage variations: These include voltage sags (temporary reduction in voltage), swells (temporary increase in voltage), and interruptions (complete loss of voltage). Imagine a rollercoaster; a sag is a dip, a swell is a peak, and an interruption is the ride stopping completely.

- Harmonic distortions: These are unwanted sinusoidal waveforms superimposed on the fundamental frequency (typically 50Hz or 60Hz), caused by non-linear loads like variable speed drives and rectifiers. Think of it like adding unwanted noise to a pure musical tone.

- Transient events: These are short-duration voltage spikes or surges that can damage sensitive equipment. These are like sudden, powerful electrical jolts.

- Frequency variations: Changes in the power system’s frequency can also negatively impact equipment performance. This is less common but can be caused by grid instability.

- Unbalanced voltages: Unequal voltages across the three phases of a power system. This can lead to inefficient operation and overheating of equipment.

Understanding these different types is crucial for effective power quality monitoring and mitigation strategies.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience in diagnosing and resolving power quality issues in industrial settings.

Throughout my career, I’ve been involved in numerous power quality investigations and remediation projects across diverse industrial settings, including manufacturing plants, data centers, and refineries. My approach typically follows a structured methodology:

- Data Acquisition: This involves deploying power quality monitoring equipment (e.g., power meters, oscilloscopes) to capture detailed waveform data over a period of time. This data helps pinpoint the nature and frequency of the disturbances.

- Data Analysis: I utilize specialized power quality analysis software to examine the collected data, identifying the root causes of power quality problems. This might involve analyzing harmonic content, calculating voltage sag/swell magnitudes and durations, and evaluating voltage unbalance.

- Root Cause Identification: Based on the data analysis, I determine the source of the power quality issue. This often requires close collaboration with plant engineers and maintenance staff to understand the plant’s electrical infrastructure and load profiles. For example, a recurring voltage sag might be traced to a faulty motor starter, while harmonic distortion could be linked to a specific piece of equipment.

- Mitigation Strategy Development: Once the root cause is identified, I design and recommend appropriate mitigation strategies, which may include installing power factor correction capacitors, harmonic filters, uninterruptible power supplies (UPS), or upgrading electrical equipment.

- Implementation and Verification: The chosen mitigation measures are implemented, and post-implementation monitoring is carried out to verify the effectiveness of the solution and ensure that power quality has improved to an acceptable level. This is critical to ensure the long-term success of the project.

For instance, in one project at a large manufacturing facility, we identified significant harmonic distortion originating from a bank of variable frequency drives. By installing passive harmonic filters, we successfully reduced the harmonic distortion, preventing further equipment damage and improving overall power quality.

Q 17. What are the common causes of voltage sags and swells?

Voltage sags and swells are temporary reductions and increases in voltage, respectively. They are often caused by events on the power system that affect the balance between supply and demand.

- Sags: Common causes include starting large motors (creating a sudden increase in demand), short circuits, or faults on the power system. Think of it like suddenly turning on many high-wattage appliances at once. The power system momentarily struggles to supply the demand.

- Swells: These are often caused by the sudden disconnection of a large load (like a motor switching off), or by a temporary reduction in the load on the power system. Switching off many high-power appliances could result in a momentary swell as the system re-balances.

- Other factors that can contribute to both include problems with transformers, capacitor banks, and even switching transients within the facility.

Identifying the specific cause requires thorough analysis of the power quality data, along with an understanding of the plant’s electrical system.

Q 18. Explain the use of different types of filters in power quality improvement.

Power quality filters are crucial for mitigating harmonic distortion and other power quality issues. Different types of filters are used depending on the nature and severity of the problem:

- Passive Filters: These are typically tuned circuits consisting of inductors and capacitors designed to absorb specific harmonic frequencies. They are relatively simple and cost-effective but may only address a limited range of harmonics. Think of it like a sieve, catching only certain sizes of particles (harmonics).

- Active Filters: These use sophisticated electronics to actively counteract harmonic currents, providing more precise and flexible harmonic compensation. They can handle a wider range of harmonics and are more adaptable to changing load conditions. This is like having an active noise-cancellation system, precisely counteracting unwanted sounds (harmonics).

- Hybrid Filters: These combine aspects of both passive and active filters, leveraging the advantages of each technology. They offer a good compromise between cost and performance. This is a combination of the sieve and noise cancellation, providing a robust solution.

The choice of filter depends on factors such as the type and magnitude of harmonic distortion, budget constraints, and the specific requirements of the application. Often, a combination of different filters might be necessary to comprehensively address power quality issues.

Q 19. What is the difference between a voltage dip and a voltage interruption?

Both voltage dips and voltage interruptions represent a reduction in voltage, but their duration distinguishes them:

- Voltage Dip (Sag): A temporary reduction in voltage lasting for a short period (typically less than 1 minute). This is like a brief flicker of a light bulb.

- Voltage Interruption: A complete loss of voltage for a period of time. This can be anything from a few milliseconds to an extended outage. This is like the light bulb turning off completely.

The impact on equipment differs greatly depending on the duration of the event. Short dips might cause only minor glitches, while longer interruptions can lead to data loss, equipment damage, or even complete system shutdown.

Q 20. Explain your understanding of power system grounding and its impact on power quality.

Power system grounding is a critical aspect of power quality, influencing the safety and performance of the electrical system. It provides a path for fault currents to flow, protecting equipment and personnel from dangerous voltages. The grounding method significantly impacts power quality:

- Solid grounding: provides a direct path to earth for fault currents, offering excellent protection but potentially leading to high fault currents and increased stress on the system. Think of it as a very short and sturdy path for the current.

- Resistance grounding: introduces a resistance in the grounding path, limiting the fault current but potentially compromising the speed of fault clearing. This is like placing a small obstacle in the current’s path.

- Reactance grounding: uses a reactor to limit the fault current, providing a balance between protection and stress on the system. This acts as a more controlled obstacle.

- Ungrounded system (or isolated): These are used in specific situations where high fault currents are particularly dangerous. However, they offer limited protection and are less common in industrial settings. This is like not having a path to ground at all.

Improper grounding can lead to voltage imbalances, increased neutral currents, and higher susceptibility to surges, all negatively impacting power quality. The selection of the grounding method depends on factors like the size and type of the system, safety requirements, and the specific power quality challenges.

Q 21. How do you assess the impact of power quality problems on equipment reliability?

Assessing the impact of power quality problems on equipment reliability involves a multi-faceted approach:

- Data Analysis: Analyze power quality data to correlate specific disturbances (e.g., sags, surges, harmonics) with equipment malfunctions or failures. This helps establish a direct link between power quality issues and reliability problems.

- Equipment Sensitivity Assessment: Evaluate the sensitivity of different pieces of equipment to various power quality disturbances. Some equipment is more vulnerable to sags, others to harmonics, and some to surges. This can be determined through manufacturer’s specifications or through field testing.

- Failure Mode Effects Analysis (FMEA): Conduct an FMEA to identify potential failure modes due to power quality issues and assess their impact on overall equipment reliability. This involves systematically identifying potential failure causes, their effects, and their likelihood of occurrence.

- Statistical Analysis: Use statistical methods to quantify the relationship between power quality events and equipment failures. This can involve calculating failure rates, mean time between failures (MTBF), and other reliability metrics.

For example, if data shows a correlation between frequent voltage sags and premature failure of a specific type of motor, this indicates a need to mitigate the voltage sags to improve the motor’s reliability. Implementing solutions like UPS or voltage regulators can significantly enhance equipment longevity and reduce downtime.

Q 22. What is your experience with different types of power quality standards (e.g., IEC, ANSI)?

My experience with power quality standards spans both IEC and ANSI standards. I’m intimately familiar with IEC 61000-4 series, which covers electromagnetic compatibility (EMC) and includes specific standards for various power quality disturbances like surges, dips, and harmonics. For instance, IEC 61000-4-5 addresses surge immunity testing. Similarly, I have extensive experience with ANSI standards, primarily those published by IEEE, such as IEEE 519, which focuses on harmonic limits in power systems. Understanding these standards is crucial for specifying appropriate testing procedures, evaluating equipment compliance, and interpreting test results. I’ve directly applied these standards in numerous projects, ensuring compliance with local regulations and best practices.

For example, in a recent project involving a sensitive manufacturing facility, we used IEC 61000-4-15 to assess the susceptibility of their equipment to fast transients, and based on the results, implemented appropriate mitigation strategies. This involved careful consideration of the specific standards relevant to the client’s industry and location.

Q 23. Describe your experience with power factor correction techniques (e.g., capacitor banks, active PFC).

Power factor correction (PFC) is critical for improving power system efficiency and reducing energy costs. I have extensive experience with both capacitor banks and active power factor correction (APFC) systems. Capacitor banks are a passive solution offering cost-effective correction for predominantly lagging power factors, often due to inductive loads like motors. However, they have limitations, particularly with harmonic distortion and varying loads. I’ve designed and implemented numerous capacitor bank installations, carefully sizing them based on load profiles and harmonic analysis to avoid resonance issues.

Active PFC, on the other hand, offers more sophisticated control, dynamically adjusting to load changes and actively compensating for harmonics. I’ve worked with various APFC technologies, including those employing IGBTs and advanced control algorithms. The choice between capacitor banks and APFC often depends on budget, the nature of the load, and the level of harmonic distortion present. For example, in a data center project, the critical nature of uptime and sensitivity to harmonics dictated the choice of an APFC system over a simpler capacitor bank solution.

Q 24. How do you determine the appropriate size and type of power quality mitigation equipment?

Determining the appropriate size and type of power quality mitigation equipment requires a systematic approach. It starts with a comprehensive power quality study, identifying the types and magnitudes of disturbances present. This analysis guides the selection of suitable mitigation equipment. For instance, if the primary concern is harmonic distortion, the solution might involve active harmonic filters or appropriately sized passive filters. If sags and swells are predominant, uninterruptible power supplies (UPS) or voltage regulators might be necessary.

Sizing the equipment involves considering peak loads, anticipated future growth, and the desired level of protection. Safety factors are included to account for uncertainties. Software tools are frequently employed for load flow studies and harmonic analysis, ensuring accurate sizing. For example, for a hospital, where continuous power supply is paramount, a robust UPS system with sufficient capacity to cover peak loads and provide extended backup time would be crucial.

Q 25. Explain your experience with power quality studies, including data acquisition, analysis and reporting.

Power quality studies are at the heart of my work. My experience encompasses all stages – from data acquisition and analysis to report generation. Data acquisition typically involves deploying various monitoring equipment, including power quality meters, harmonic analyzers, and data loggers. The choice of equipment depends on the specific parameters to be measured and the duration of the study. I am proficient in deploying both temporary and permanent monitoring systems.

Once data is collected, it is analyzed using specialized software (discussed in the next answer). This analysis includes identifying the types, frequency, and severity of power quality disturbances. Finally, the results are presented in a comprehensive report, outlining the findings, their impact, and recommendations for mitigation. One memorable project involved identifying intermittent voltage sags affecting production line efficiency; the report pinpointed the source and provided cost-effective solutions for improvement.

Q 26. Describe your proficiency in using power quality analysis software (mention specific software if applicable).

I am proficient in using several power quality analysis software packages, including Fluke Power Analyze and Powermetrics. These tools allow for detailed analysis of power quality data, including waveform visualization, harmonic analysis, and power factor calculation. Furthermore, I am experienced in using specialized software for modeling power systems and simulating the impact of various disturbances and mitigation strategies. These capabilities are essential for effective power quality troubleshooting and designing robust mitigation solutions.

For example, using Fluke Power Analyze, I once identified a specific piece of equipment as the culprit for excessive harmonic distortion within a manufacturing plant, leading to targeted mitigation strategies and preventing significant equipment failures. This avoided costly downtime and repairs.

Q 27. What are the key considerations for designing a power quality monitoring system?

Designing a robust power quality monitoring system requires careful consideration of several factors. Firstly, the location of monitoring points is critical; they should be strategically placed to capture representative data from various parts of the power system. Secondly, the choice of monitoring equipment depends on the specific parameters to be monitored, including voltage, current, power, harmonics, and other disturbances. The system should be capable of logging data at appropriate sampling rates and storing it for a sufficient duration.

Data communication and storage are equally important. The system should have reliable communication capabilities to transmit data to a central location for analysis. Finally, data security and access control must be considered to protect sensitive information. A well-designed system provides valuable insights into power quality issues, enabling proactive mitigation and optimized energy management. For instance, a system with remote access capabilities allows for real-time monitoring and faster response times to power quality events.

Q 28. Explain your understanding of the impact of renewable energy sources on power quality.

Renewable energy sources, while beneficial for the environment, can introduce unique power quality challenges. For example, solar photovoltaic (PV) systems can inject high-frequency harmonics into the power system, while wind turbines can cause voltage fluctuations and flicker. The intermittent nature of these sources also leads to variability in power supply, which can stress the grid and necessitate advanced grid management strategies.

Understanding these impacts is crucial for designing effective mitigation strategies. This often involves employing filters to mitigate harmonic distortion, advanced grid control systems to manage voltage fluctuations and ensure grid stability, and sophisticated forecasting models to predict power generation and manage energy storage. Successfully integrating renewable energy sources requires careful consideration of power quality implications throughout the design, implementation, and operation phases. For instance, a thorough power quality study is essential before connecting a large-scale solar farm to the grid to minimize the impact on the distribution network.

Key Topics to Learn for Power Quality Testing and Analysis Interview

- Fundamentals of Power Quality: Understanding voltage sags, swells, harmonics, transients, and their impact on equipment.

- Power Quality Monitoring Techniques: Familiarization with various measurement devices and data acquisition systems, including their capabilities and limitations.

- Data Analysis and Interpretation: Proficiency in analyzing waveform data, identifying power quality disturbances, and interpreting results using specialized software.

- Power Quality Standards and Regulations: Knowledge of relevant industry standards (e.g., IEEE, IEC) and compliance requirements.

- Mitigation Techniques: Understanding and explaining various methods for improving power quality, such as power factor correction, harmonic filtering, and uninterruptible power supplies (UPS).

- Case Studies and Problem Solving: Ability to analyze real-world power quality problems, diagnose root causes, and propose effective solutions. This includes understanding the impact on different types of loads.

- Power System Analysis: Basic understanding of power system components and their influence on power quality. This may include load flow analysis and fault studies.

- Reporting and Communication: Effectively communicating technical findings and recommendations to both technical and non-technical audiences.

Next Steps

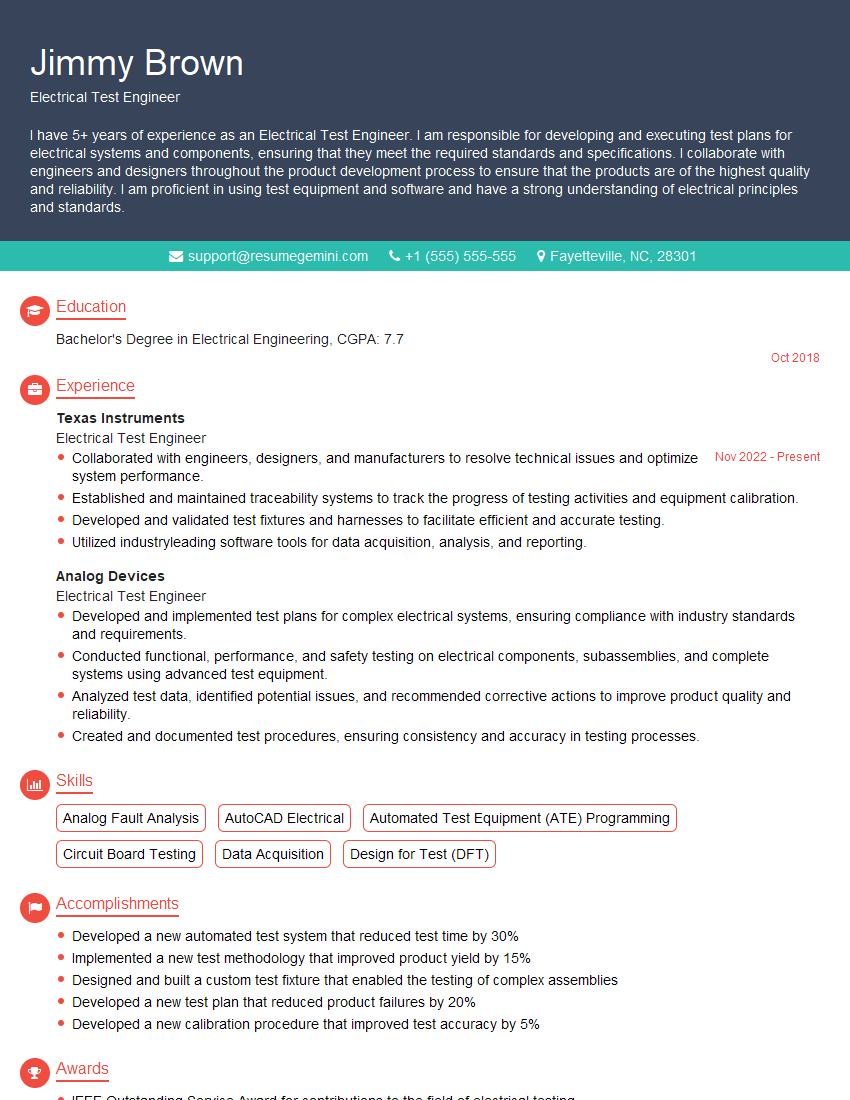

Mastering Power Quality Testing and Analysis opens doors to exciting career opportunities in various industries, offering high demand and excellent growth potential. To maximize your job prospects, it’s crucial to present your skills effectively. Creating an ATS-friendly resume is key to getting your application noticed by recruiters and hiring managers. We highly recommend using ResumeGemini to build a professional and impactful resume that highlights your expertise in Power Quality Testing and Analysis. ResumeGemini offers tools and resources to help you craft a compelling narrative, and we provide examples of resumes tailored to this specific field to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good