Cracking a skill-specific interview, like one for Precision Painting, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Precision Painting Interview

Q 1. Describe your experience with different paint application techniques.

Precision painting relies on mastering various application techniques to achieve flawless results. My experience encompasses brushwork, rolling, and spraying, each suited to different surfaces and projects.

- Brushwork: This traditional method offers exceptional control, ideal for intricate details, trim work, and achieving specific textures. I’m proficient with various brush types, from fine-tipped sable brushes for delicate lines to wider bristle brushes for larger areas. For instance, I’ve used fine brushes to meticulously paint intricate floral designs on a client’s antique furniture.

- Rolling: Rolling is efficient for large, flat surfaces like walls. The technique involves using rollers with different nap lengths (the thickness of the fibers) depending on the surface texture. A longer nap is suitable for rough surfaces, while a shorter nap works best for smooth walls. I consistently achieve even coverage and minimize roller marks through proper technique and careful selection of roller covers.

- Spray Painting: Spray painting provides a smooth, even finish, especially beneficial for large surfaces or projects needing a consistent coat. I’m experienced with various spray equipment, including airless sprayers and HVLP (High Volume Low Pressure) sprayers, adjusting the settings to match the paint type and surface. For example, I used an HVLP sprayer to achieve a flawless finish on a large exterior wall, ensuring minimal overspray and waste.

Q 2. How do you ensure precise color matching?

Precise color matching is crucial for a professional finish. My approach involves a multi-step process to guarantee accuracy:

- Color Samples: I always start by taking color samples from the existing paint or a provided reference. If it’s a custom color, I use a color matching system, like those offered by major paint manufacturers, to generate a precise formula.

- Test Areas: Before committing to the full project, I always test the mixed color on a hidden area to ensure it perfectly matches the desired shade under the specific lighting conditions of the room. This helps account for variations in light sources impacting perceived color.

- Multiple Mixing Batches: I prepare paint in smaller batches to ensure consistency in color throughout the project. Mixing large quantities at once risks slight variations in shade due to inconsistencies in the mixing process.

- Quality Paint and Pigments: Using premium-quality paints and pigments contributes significantly to color accuracy and longevity.

Through this systematic approach, I guarantee that the final color matches the client’s expectations and looks impeccable.

Q 3. Explain your process for surface preparation before painting.

Thorough surface preparation is paramount; it’s the foundation of a long-lasting and beautiful paint job. My process includes these key steps:

- Cleaning: The surface must be clean and free of dust, dirt, grease, and mildew. I use appropriate cleaners, depending on the surface type, to remove any contaminants. For example, I use a degreaser for kitchen cabinets and a mildew cleaner for bathroom walls.

- Repairing: I carefully fill any holes or cracks using appropriate fillers and allow them to dry completely before sanding them smooth. This ensures a seamless surface for painting.

- Sanding: Sanding creates a smooth, even surface to ensure proper paint adhesion. I use different grits of sandpaper, starting with coarser grits to remove imperfections and finishing with finer grits for a smooth finish. I use dust collection systems during sanding, to control dust for health and environmental concerns.

- Priming: Priming is crucial for optimal paint adhesion and to even out the surface, particularly when painting over dissimilar materials or dark colors. I choose primers specifically formulated for the surface type and intended paint.

This careful preparation guarantees a professional finish and extends the lifespan of the paint job.

Q 4. What types of safety precautions do you take while painting?

Safety is my top priority. I consistently follow these precautions:

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including safety glasses, respirators (especially when spraying), gloves, and protective clothing to prevent exposure to paint, dust, and fumes.

- Ventilation: When working indoors, I ensure adequate ventilation to remove paint fumes and prevent buildup of harmful particles. This often includes opening windows and using fans.

- Proper Disposal: I dispose of paint and other materials according to local regulations and environmental guidelines. This includes using appropriate containers for waste paint, solvents, and other materials.

- Fire Safety: I take precautions when working with flammable materials, such as paint thinners and solvents, ensuring they are stored and used in a well-ventilated area, away from ignition sources.

- Working at Heights: When working at heights, I utilize proper safety equipment, such as harnesses and scaffolding, ensuring compliance with all safety standards.

Adhering to these safety procedures safeguards both my well-being and that of those around me.

Q 5. What is your experience with different types of paints (e.g., acrylic, enamel, lacquer)?

My experience encompasses a wide range of paint types, each with unique properties and applications:

- Acrylics: Water-based, low-odor, and easy to clean up, acrylics are versatile and suitable for various surfaces, including walls, trim, and furniture. They are a popular choice for their durability and relatively quick drying time.

- Enamels: Oil-based enamels offer exceptional durability and a smooth, hard finish, ideal for high-traffic areas or surfaces that require a protective coating. However, they have a longer drying time and require solvents for cleanup.

- Lacquers: Fast-drying and durable, lacquers are often used for furniture and trim. They provide a high-gloss finish and can be applied in thin coats, but require specialized equipment and careful application due to their rapid drying time. They also tend to be more expensive than acrylics or enamels.

I select the appropriate paint type based on the specific project requirements, considering factors like durability, surface type, desired finish, and environmental concerns.

Q 6. How do you handle imperfections or mistakes during the painting process?

Imperfections and mistakes are inevitable, but addressing them promptly is key. My approach involves:

- Immediate Correction: If I notice a mistake while the paint is still wet, I can usually correct it by gently wiping it away and reapplying the paint. For larger areas, I might use a putty knife to carefully scrape the paint before reapplication.

- Sanding and Recoating: For dried paint imperfections, I’ll carefully sand the area smooth and then re-apply a thin coat of paint to blend it seamlessly.

- Touch-Ups: For minor blemishes that cannot be easily corrected, I’ll perform touch-ups after the main painting is completed, using a small brush or spray gun to seamlessly blend the color.

- Professional Repair: In cases of significant damage or imperfections that require more extensive repair, I may need to call in specialized services for repairs such as plaster repairs, drywall repair, and wood repair before repainting.

My goal is always to deliver a flawless final product, and I’m prepared to address any issues that arise.

Q 7. Describe your experience with spray painting equipment.

I’m proficient with various spray painting equipment, including airless and HVLP sprayers. My expertise includes:

- Airless Sprayers: These are powerful and efficient for large-scale projects. I understand how to adjust the pressure and nozzle size to control the paint flow and achieve a consistent finish. Their power makes them suitable for coating larger areas faster than an HVLP sprayer, particularly for exterior applications.

- HVLP Sprayers: These offer finer control and produce less overspray, making them suitable for detailed work and delicate surfaces. They are also more environmentally friendly due to reduced paint waste.

- Equipment Maintenance: I understand the importance of regular equipment maintenance, including cleaning, lubricating, and replacing worn parts to ensure optimal performance and longevity. This ensures consistency and high quality of the spray application.

- Safety Procedures: I always prioritize safety when using spray equipment, wearing appropriate PPE and ensuring proper ventilation.

My proficiency in using different spray equipment allows me to adapt to the specific needs of each project, ensuring the highest quality results.

Q 8. How do you maintain your painting tools and equipment?

Maintaining painting tools and equipment is crucial for achieving high-quality finishes and extending their lifespan. It’s a multi-step process that I religiously follow.

- Immediately after use: I clean all brushes, rollers, and spray equipment thoroughly with the appropriate solvent (water for water-based paints, mineral spirits for oil-based). This prevents paint from hardening and ruining the tools. I then rinse them with clean water or solvent and allow them to dry completely before storing.

- Regular maintenance: I regularly inspect my tools for wear and tear. Damaged bristles on brushes are trimmed, and worn roller sleeves are replaced. Spray gun nozzles are cleaned meticulously to ensure consistent paint flow and prevent clogging.

- Proper storage: Tools are stored in a clean, dry place, protected from extreme temperatures and humidity. Brushes are stored bristle-side up to prevent deformation. Spray guns are disassembled and cleaned thoroughly before storage.

- Specialized care: For specialized tools, like airless sprayers, I follow the manufacturer’s instructions for cleaning and maintenance, often involving flushing with solvents and inspecting seals for wear. This ensures consistent performance and prevents costly repairs.

Think of it like this: treating your tools well is like treating a prized possession. A little care goes a long way in ensuring they perform their best, saving you money and frustration in the long run.

Q 9. What is your understanding of paint viscosity and its importance?

Paint viscosity, simply put, is the thickness or thinness of the paint. It’s absolutely critical for achieving a professional finish. Too thick, and the paint will be difficult to apply, leading to brushstrokes and an uneven surface. Too thin, and it will run, drip, and lack opacity.

I determine the ideal viscosity through a combination of methods: checking the manufacturer’s recommendations on the paint can, using a viscosity cup (which measures the time it takes for a certain volume of paint to flow through a small hole), and through visual inspection. I often adjust viscosity by adding thinner (for thicker paints) or a retarder (to slow down drying time and improve flow).

For example, when painting trim, I prefer a slightly thicker consistency to get a nice, smooth finish without runs. For larger surfaces like walls, a slightly thinner consistency ensures better coverage and a more even application. It’s a delicate balance, and experience plays a huge role in getting it just right. The wrong viscosity can lead to rework, which impacts both efficiency and the final quality.

Q 10. How do you manage multiple painting projects simultaneously?

Managing multiple painting projects simultaneously requires careful planning and organization. I use a project management system that includes:

- Detailed scheduling: I create a schedule outlining the timeline for each project, allocating specific days and times for each task. This avoids scheduling conflicts and ensures efficient resource allocation.

- Prioritization: Projects are prioritized based on deadlines, client needs, and urgency. This ensures that the most critical projects receive the necessary attention.

- Resource allocation: I carefully allocate materials, tools, and personnel to each project, making sure that each one has the resources needed to complete it on time.

- Communication: Consistent communication with clients is key. I keep them updated on the progress of their projects, addressing any concerns promptly.

- Teamwork: When necessary, I coordinate with my team, assigning tasks based on individual skills and availability. This ensures that everyone knows their role and contributes effectively.

A recent example involved managing three projects simultaneously: a large commercial building, a residential repaint, and a small custom cabinet job. Through careful scheduling, prioritization, and communication, I successfully completed all three projects on time and to the client’s satisfaction.

Q 11. What are the different types of finishes you are experienced with?

My experience encompasses a wide range of paint finishes, each with unique properties and applications:

- Matte: Offers a low-sheen, velvety finish, excellent for hiding imperfections in walls but less durable.

- Eggshell: A slightly more durable finish than matte, with a subtle sheen, offering a balance between durability and hide.

- Satin: More durable and washable than eggshell, with a soft sheen, often used in kitchens and bathrooms.

- Semi-gloss: A higher sheen finish, offering good durability and washability, popular for trim work and doors.

- Gloss: The highest sheen finish, very durable and easy to clean, ideal for high-traffic areas and surfaces needing frequent cleaning.

Choosing the right finish depends heavily on the project requirements and the client’s preferences. I always discuss the options with my clients, explaining the pros and cons of each before making a decision.

Q 12. Explain your experience with masking and protecting areas from paint.

Masking and protection are paramount in precision painting. I use a variety of techniques to ensure only the intended areas are painted:

- Painter’s tape: I use high-quality painter’s tape for sharp lines and edges, carefully applying it to avoid wrinkles or gaps that could lead to bleeding. Different tapes are used depending on surface type (e.g., delicate surfaces vs. sturdy trim).

- Drop cloths: Large surfaces are fully covered with drop cloths to protect floors and furniture. I prefer canvas drop cloths for superior protection.

- Plastic sheeting: Used for covering delicate items or larger areas that require more robust protection. Secured with tape to avoid shifting.

- Masking film: For precise masking of windows, doors, and intricate designs.

- Caulk: Before painting, I caulk gaps and cracks to prevent paint from bleeding into unwanted areas.

Proper masking is an investment in time and materials that prevents costly mistakes and rework. I’ve seen projects where inadequate masking has resulted in hours of extra work to correct bleed-through and other issues, highlighting the importance of meticulous preparation.

Q 13. How do you ensure a consistent finish across large surfaces?

Achieving a consistent finish across large surfaces requires a systematic approach:

- Even paint application: Maintaining a consistent wet edge and overlapping each stroke slightly prevents lap marks and ensures uniform color and texture. This involves working in manageable sections.

- Proper lighting: Good lighting allows me to identify any inconsistencies in the finish, allowing for immediate correction. I often use multiple light sources to ensure complete coverage.

- Surface preparation: Thorough preparation is crucial. This includes cleaning, priming (when necessary), and sanding to achieve a smooth, even surface before painting. Skipping this step can lead to inconsistencies despite the best painting technique.

- Consistent technique: Whether using brushes, rollers, or spray equipment, maintaining a consistent application technique is crucial. This requires practice and experience.

- Multiple coats: Applying multiple thin coats, allowing each to dry properly before applying the next, provides better coverage and a more even finish than applying one thick coat.

Think of it like baking a cake; you need the right ingredients, the right temperature, and the right technique to get a consistent, delicious result. The same applies to painting.

Q 14. What is your experience with different types of paint spray guns?

My experience includes working with various types of paint spray guns, each with its own advantages and disadvantages:

- HVLP (High Volume Low Pressure): Offers excellent atomization and less overspray, making it efficient and environmentally friendly. Ideal for fine finishing and detailed work.

- Airless spray guns: Delivers a high volume of paint at high pressure, providing quick coverage for large areas. Best suited for exterior painting and large-scale projects but requires careful control to avoid overspray.

- Conventional spray guns (pressure feed): These use compressed air to atomize the paint. Offer good control but require more skill and maintenance than other types. Often used for automotive and custom finishes.

The choice of spray gun depends on the project requirements, the type of paint being used, and the desired finish. I select the appropriate gun based on the project needs, ensuring the best possible results.

Q 15. How do you deal with challenging paint substrates (e.g., metal, wood, plastic)?

Successfully painting different substrates requires understanding their unique properties. Metal surfaces often need a specialized primer to prevent rust and ensure proper adhesion. I typically use a zinc-rich primer for optimal corrosion resistance. Wood surfaces need to be properly prepared; this includes sanding to achieve a smooth surface and applying a wood primer to seal the wood and prevent the absorption of paint, which can lead to uneven finishes. Plastic, depending on the type, might require a plastic-specific adhesion promoter or primer to ensure the paint bonds effectively. For instance, polypropylene plastics can be notoriously difficult to paint and require a specialized primer and potentially a higher-quality paint with strong adhesion properties. In each case, thorough surface preparation is key – cleaning, sanding, and sometimes even etching – before applying the primer and topcoat.

For example, on a metal gate project, I first used a wire brush to remove any loose rust, then applied a zinc-rich primer followed by two coats of high-quality exterior paint. With a wooden cabinet, I sanded down any rough patches, applied a stain-blocking primer, and finished with multiple coats of durable cabinet paint.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with different types of paint thinners and reducers?

My familiarity with paint thinners and reducers is extensive. Understanding their purpose and application is critical for achieving the desired paint viscosity and preventing issues such as wrinkling or sagging. Thinners, like mineral spirits or lacquer thinner, are used to clean brushes and equipment and can also thin highly viscous paints, although using the appropriate reducer is often preferred for a more professional and controlled thinning process. Reducers, on the other hand, are specifically formulated for a particular paint type (e.g., acrylic lacquer reducer, urethane reducer) to adjust the viscosity without compromising the paint’s integrity or final finish. Using the wrong thinner can damage the paint film or alter the chemical properties, negatively impacting the final outcome. For example, using mineral spirits on a water-based paint is counterproductive.

I always carefully read the product data sheet provided by the paint manufacturer to determine the appropriate thinner or reducer for the specific paint. Precise measurement using measuring cups and scales ensures consistency and avoids problems.

Q 17. Describe your experience working with specialized painting equipment (e.g., HVLP spray guns)?

I have extensive experience operating various specialized painting equipment, including HVLP (High-Volume, Low-Pressure) spray guns, airless sprayers, and electrostatic sprayers. The HVLP spray gun, in particular, is a favorite for its efficiency and reduced overspray, minimizing material waste and creating a smoother, more even finish. This is crucial for achieving professional-grade results. Proper setup and maintenance of these tools are vital. This includes adjusting the air pressure and fluid flow to match the paint’s viscosity and the surface being painted. Airless sprayers are useful for larger projects, allowing for faster coverage, but require more careful technique to avoid runs and sags. Electrostatic sprayers are particularly useful for applying even coats to complex shapes and in reaching hard-to-access areas.

I’ve successfully used an HVLP spray gun on numerous projects, including repainting a large staircase, where the fine atomization of the HVLP provided a perfectly even finish. For large-scale commercial projects, I’ve utilized airless sprayers to accelerate the painting process while ensuring quality.

Q 18. How do you address inconsistencies in paint application or finish?

Addressing inconsistencies in paint application or finish requires a systematic approach. The first step is to identify the root cause. This may involve things like inadequate surface preparation (e.g., insufficient sanding, improper cleaning), incorrect paint viscosity (too thick or too thin), incorrect spray gun settings, inconsistent application technique, or environmental factors such as temperature and humidity. Once the cause is identified, corrective measures can be taken. This could involve re-sanding, applying a new primer coat, adjusting the spray gun settings, using a different application technique, or applying additional coats of paint. In some cases, repainting the affected area might be necessary.

For example, if I notice runs or sags, I might adjust the spray gun settings to reduce the fluid flow or increase the air pressure. If there’s uneven color, it could point to insufficient mixing or uneven application. In such cases, I may need to apply another coat of paint and use a different application method to ensure a uniform finish.

Q 19. What is your experience with troubleshooting paint problems?

Troubleshooting paint problems is a key aspect of my expertise. I approach it methodically. First, I thoroughly examine the problem area to pinpoint the issue—is it a discoloration, peeling, cracking, or uneven finish? This is followed by asking relevant questions: What type of paint was used? What was the surface preparation like? What were the environmental conditions during application? Based on this, I can determine the potential cause. A common problem is using the wrong type of paint for the surface or environmental conditions. Other issues might stem from poor surface preparation or incorrect application techniques. The solution often involves addressing the root cause; this might include using a different primer, sanding the surface more thoroughly, or employing a different painting technique.

For example, if paint is peeling, it could indicate poor adhesion due to inadequate surface cleaning or insufficient drying time between coats. I would diagnose the specific problem by carefully examining the paint and substrate. If the problem is caused by moisture, remediation efforts might involve addressing the source of the moisture. Then, the damaged paint would be removed, the substrate properly treated, and repainted.

Q 20. Describe your knowledge of different types of paint drying systems.

My understanding of paint drying systems encompasses several methods, each with its own advantages and limitations. Air drying is the most common method, relying on natural air circulation and evaporation. Forced air drying, using fans or heaters, accelerates the drying process and is suitable for larger projects or when faster turnaround is needed. Infrared (IR) drying utilizes infrared radiation to heat the paint directly, facilitating faster drying and reducing the overall drying time significantly. UV (Ultraviolet) curing systems use UV radiation to cure specific types of paints (like UV-curable coatings), resulting in extremely rapid curing times and durable finishes. The selection of a drying system depends on factors such as project size, paint type, and desired drying time.

For instance, in a small-scale project, air drying might suffice. For larger projects with tight deadlines, using forced-air drying or IR drying systems would be beneficial. UV curing is reserved for specialized projects using specific types of UV-curable paints.

Q 21. How do you determine the appropriate paint thickness for a given project?

Determining the appropriate paint thickness is crucial for achieving a high-quality, durable finish. The thickness depends on several factors, including the type of paint, the substrate, and the desired finish. Too thin a coat might result in poor coverage and an uneven finish, while too thick a coat can lead to runs, sags, and longer drying times. Manufacturer guidelines on the paint can and label provide a starting point. However, practical experience and understanding of paint behavior are essential for fine-tuning the thickness. It’s often best to apply multiple thin coats rather than one thick coat. This allows each coat to dry properly, improving adhesion and resulting in a more durable and visually appealing finish.

I use a wet film thickness gauge to precisely measure the thickness of each coat during application. By monitoring the wet film thickness, I can ensure consistency across the entire project and avoid common thickness-related problems. This is particularly crucial for projects with stringent quality standards and specific thickness requirements.

Q 22. What methods do you use for cleaning up after a painting project?

Cleaning up after a precision painting project is crucial for maintaining a professional image and ensuring client satisfaction. It’s not just about tidiness; it’s about minimizing environmental impact and preventing damage. My cleanup process is meticulous and follows these steps:

- Immediate Cleanup: Throughout the project, I regularly remove paint spills and drips immediately using appropriate solvents and rags. This prevents the paint from drying and becoming difficult to remove.

- Surface Protection Removal: Carefully remove all drop cloths, masking tape, and plastic sheeting. Dispose of them properly according to local regulations.

- Detailed Cleaning: I meticulously clean all surfaces, including windows, floors, and trim, using appropriate cleaning solutions. This includes removing any stray paint splatters or dust particles.

- Tool Cleaning: All brushes, rollers, and other painting tools are thoroughly cleaned with the correct solvent, rinsed, and stored properly to maintain their longevity.

- Waste Disposal: All paint waste, including rags and used solvents, is disposed of according to environmental regulations (more on this in the next answer). I utilize labeled containers and ensure proper disposal at designated facilities.

For example, on a recent project involving intricate woodwork, I used specialized cleaning agents to remove any paint residue from the delicate carvings without causing damage. The client was particularly impressed by the attention to detail in the cleanup process.

Q 23. What is your experience with environmental regulations regarding paint disposal?

I’m well-versed in environmental regulations regarding paint disposal. My approach is always proactive and compliant. I understand that improper disposal can have serious environmental consequences. My practice includes:

- Using Low-VOC Paints: I prioritize using low-volatile organic compound (VOC) paints whenever possible. These paints release fewer harmful chemicals into the atmosphere.

- Proper Waste Segregation: I meticulously segregate different types of paint waste, including oil-based, water-based, and aerosol paints. Each type requires specific disposal methods.

- Designated Disposal Facilities: I utilize only licensed and approved facilities for paint waste disposal. I maintain records of all waste disposal activities for audit purposes.

- Hazardous Waste Handling: I’m trained in handling hazardous waste, such as solvents and used paint thinner, ensuring safe storage and transportation to designated facilities.

- Staying Updated: I regularly check local, state, and federal regulations to stay informed about any changes in paint disposal laws and best practices.

For instance, I recently completed a project where we had leftover spray paint. Rather than simply discarding it, I followed the strict guidelines for aerosol paint disposal, which included puncturing the cans and properly labeling them for hazardous waste pickup. This demonstrated a strong commitment to environmental responsibility.

Q 24. Explain your process for inspecting finished work for quality defects.

Inspecting finished work is paramount to ensuring high-quality, precision painting. My inspection process is thorough and multi-faceted:

- Visual Inspection: I perform a detailed visual inspection of the entire painted area under various lighting conditions, checking for evenness of color, brushstrokes, roller marks, drips, runs, or any imperfections.

- Surface Examination: I carefully examine the surface texture for any inconsistencies, bumps, or imperfections in the paint film. I feel the surface for smoothness.

- Edge Examination: I pay special attention to edges and corners, ensuring sharp lines and clean transitions between colors or different paint types.

- Color Matching: I carefully review the color consistency throughout the painted area, ensuring it matches the client’s specified color or design.

- Photography: I often take high-resolution photos to document the completed work and to easily identify any minor imperfections that might be missed during the initial inspection.

In one project, a slight imperfection was found only upon careful inspection under a different light source. We were able to quickly correct it, ensuring the client received a flawless finish. This methodical approach highlights my commitment to perfection.

Q 25. How do you handle pressure and meet tight deadlines in a fast-paced work environment?

Precision painting often requires working under pressure and adhering to tight deadlines. My ability to manage this pressure stems from:

- Effective Planning: I carefully plan the project in advance, considering all aspects, from material procurement to scheduling, to ensure efficient workflow.

- Prioritization: I prioritize tasks based on urgency and importance, focusing on critical aspects first, minimizing delays.

- Efficient Work Habits: I maintain a highly organized and efficient workspace, optimizing my movements to minimize time wastage.

- Communication: I maintain open communication with clients and team members, proactively addressing any potential issues that could impact the timeline.

- Problem-Solving: I have a proven ability to think on my feet and creatively solve unforeseen problems without sacrificing quality or deadlines.

Recently, I successfully completed a large commercial project with a tight deadline, by prioritizing tasks and working additional hours, while maintaining my commitment to superior quality. The client was extremely pleased with both the speed and the immaculate results.

Q 26. How do you prioritize tasks and manage your time effectively?

Effective time management and task prioritization are fundamental to success in precision painting. My strategy is based on:

- Project Breakdown: I start by breaking down the project into smaller, manageable tasks, creating a detailed checklist.

- Time Estimation: I realistically estimate the time needed for each task, factoring in potential delays or unforeseen issues.

- Scheduling: I use scheduling tools and techniques to create a timeline and allocate specific times for each task.

- Regular Monitoring: I regularly monitor my progress against the schedule, making adjustments as needed to stay on track.

- Delegation (where applicable): When working as part of a team, I effectively delegate tasks to ensure optimal efficiency.

For instance, on a multi-room painting job, I created a detailed schedule, allocating specific days for preparation, priming, painting coats, and cleaning. This approach ensured a smooth and timely completion of the entire project.

Q 27. What are your strengths and weaknesses related to precision painting?

My strengths in precision painting lie in my attention to detail, my commitment to quality, and my ability to handle complex projects. I’m meticulous in my work and consistently strive for perfection. I also excel at problem-solving and adapting to unexpected challenges. A weakness I’m actively working on is delegation; sometimes, I find it difficult to let go of tasks and trust others to complete them to the same high standard I set for myself.

Q 28. How do you stay up-to-date with the latest techniques and technologies in precision painting?

Staying current in precision painting requires continuous learning. I employ several strategies to stay updated:

- Industry Publications: I regularly read industry publications and journals to learn about new techniques, materials, and technologies.

- Online Courses and Workshops: I participate in online courses and workshops to enhance my skills and stay abreast of the latest developments.

- Networking: I actively network with other professionals in the field to exchange knowledge and learn from their experiences.

- Manufacturer Training: I attend training sessions and workshops offered by paint manufacturers to learn about their new products and applications.

- Professional Associations: I’m a member of professional painting associations which provide access to cutting-edge information, conferences, and networking events.

For example, recently I completed a course on advanced spray painting techniques, leading to a significant improvement in my efficiency and the quality of my work on large-scale projects.

Key Topics to Learn for Precision Painting Interview

- Color Theory and Matching: Understanding color harmonies, undertones, and how to accurately mix paints to achieve desired shades. Practical application includes explaining your experience with color matching in different lighting conditions and resolving discrepancies.

- Surface Preparation Techniques: Mastering techniques like cleaning, sanding, priming, and caulking to ensure a smooth, durable finish. Practical application includes detailing your experience with various surface types (wood, drywall, metal) and the appropriate preparation methods for each.

- Paint Application Methods: Understanding different application techniques (brushing, rolling, spraying) and their suitability for various surfaces and paint types. Practical application includes showcasing your proficiency with different tools and techniques and explaining your ability to achieve a professional finish.

- Safety Procedures and Regulations: Knowledge of relevant safety regulations, handling of hazardous materials (paints, solvents), and proper disposal techniques. Practical application involves demonstrating an understanding of workplace safety and your commitment to following best practices.

- Project Management and Estimation: Ability to plan projects, estimate materials and labor costs, and manage time effectively. Practical application includes describing your experience with project planning, budgeting, and adhering to timelines.

- Troubleshooting and Problem-Solving: Identifying and resolving common painting problems, such as uneven application, drips, roller marks, and color inconsistencies. Practical application includes providing examples of how you’ve diagnosed and solved painting challenges on past projects.

- Customer Service and Communication: Effectively communicating with clients, understanding their needs, and maintaining a professional demeanor. Practical application includes describing how you’ve handled client expectations and addressed any concerns during previous projects.

Next Steps

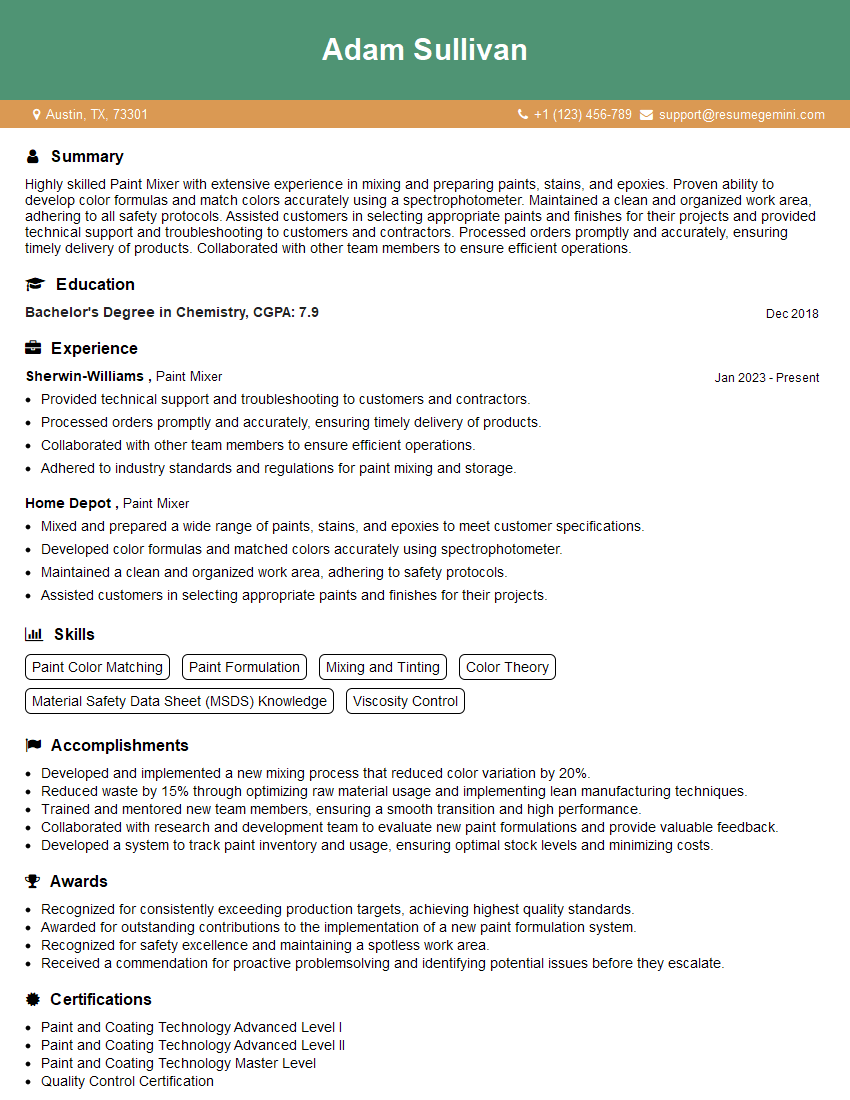

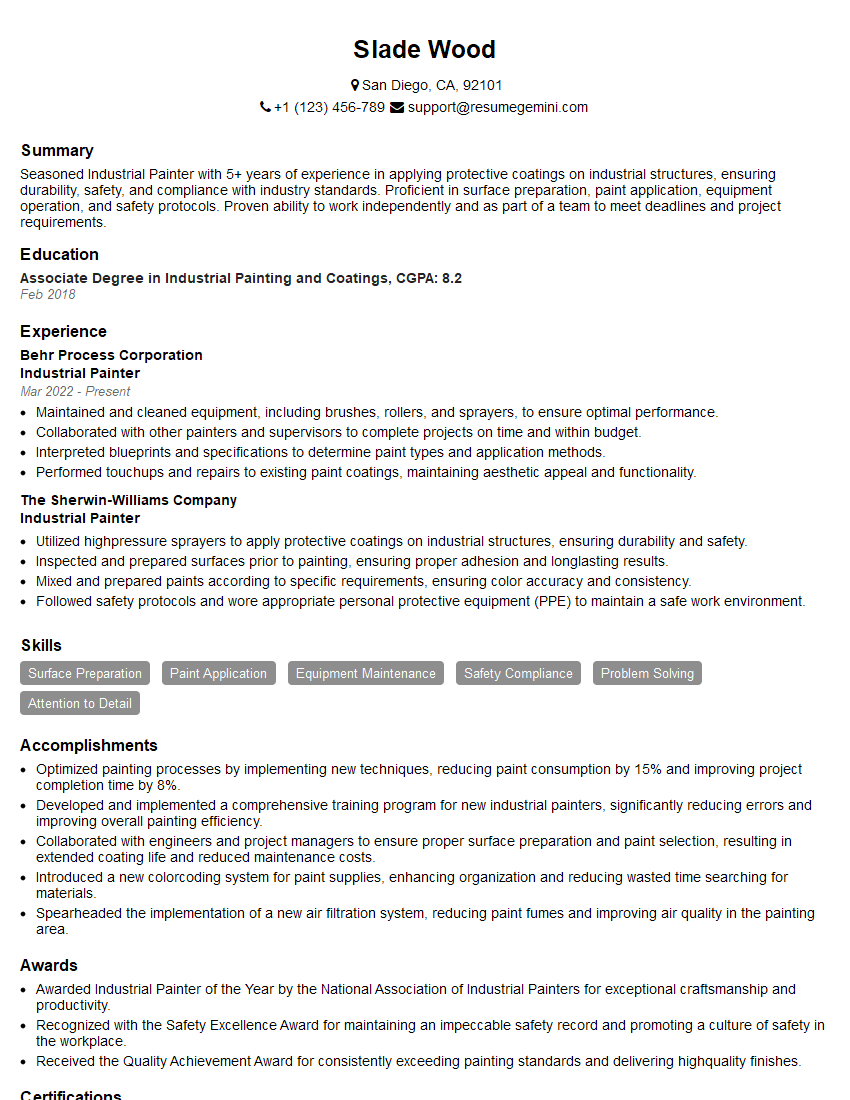

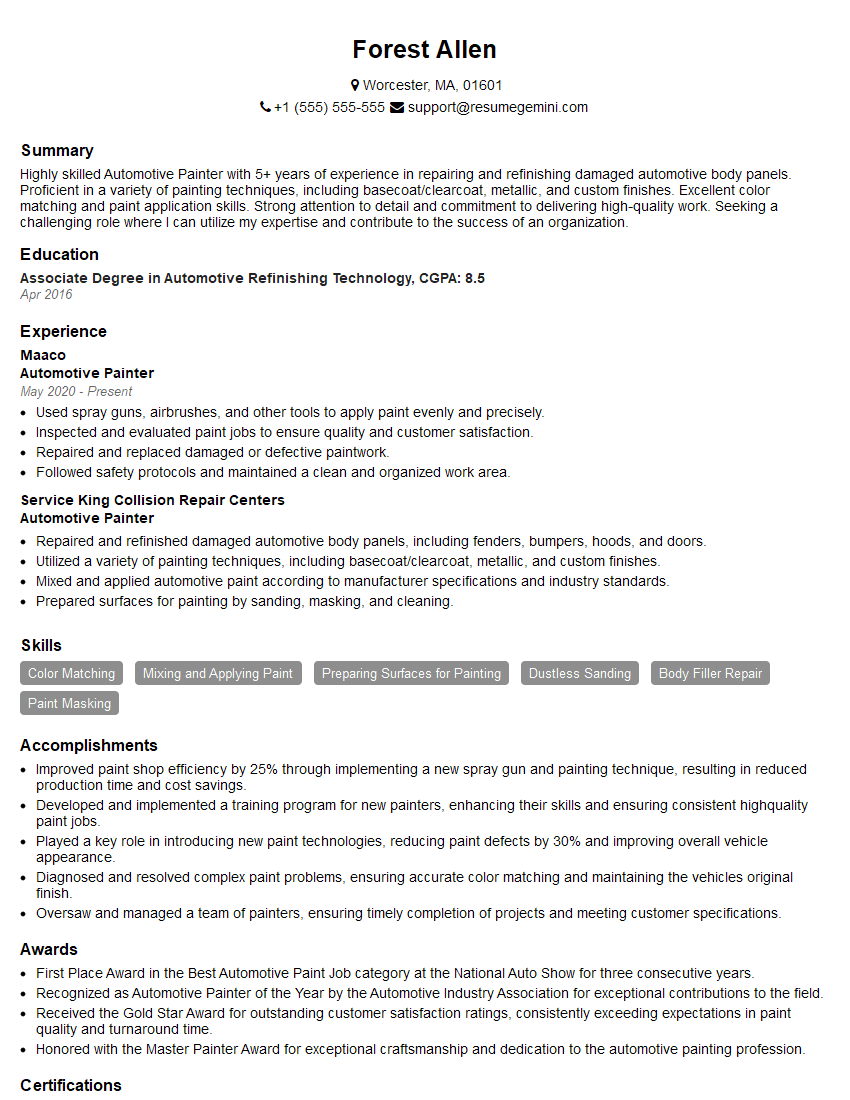

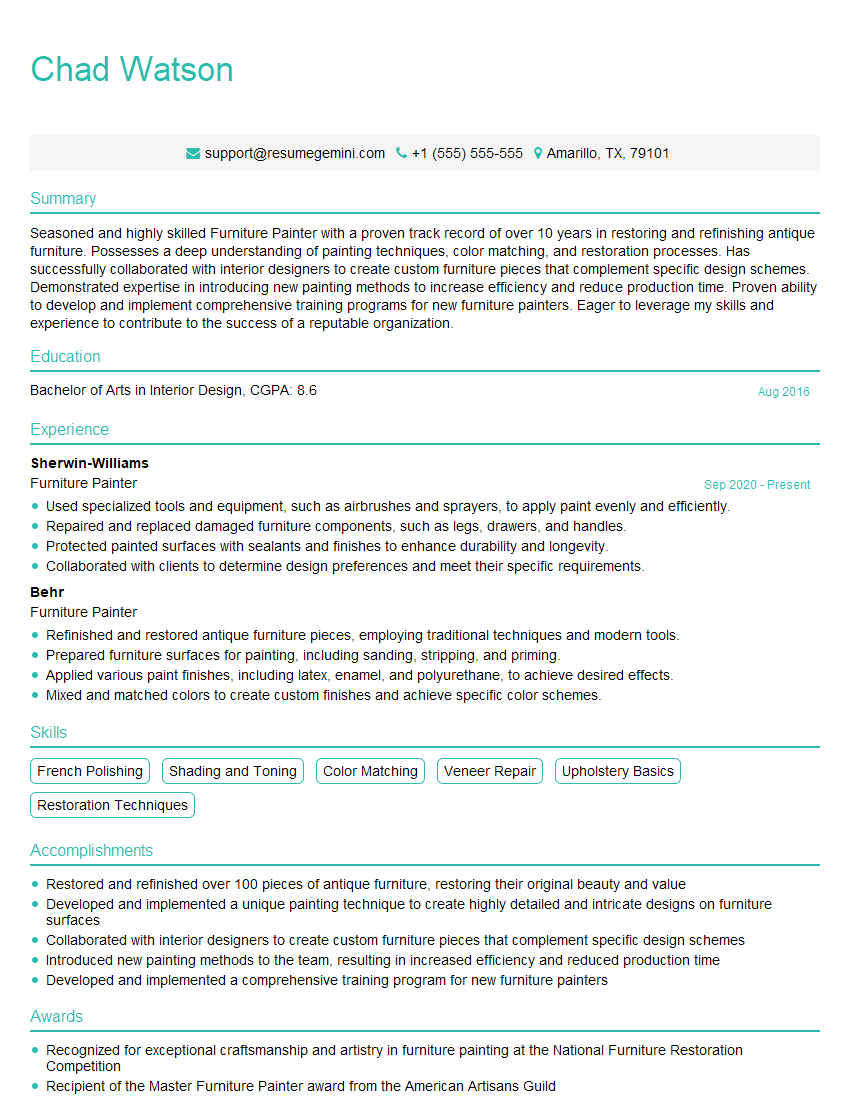

Mastering the skills and knowledge related to precision painting significantly enhances your career prospects within the industry, opening doors to higher-paying roles and increased responsibility. To maximize your chances of landing your dream job, creating an ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional resume tailored to highlight your skills and experience effectively. Examples of resumes tailored to Precision Painting are available to guide you. Invest time in crafting a strong resume – it’s your first impression and a critical step in securing your next opportunity.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good