Cracking a skill-specific interview, like one for Press Operating, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Press Operating Interview

Q 1. Describe your experience with different types of printing presses.

My experience encompasses a wide range of printing presses, from traditional offset lithographic presses to modern digital printing systems. I’ve worked extensively with Heidelberg Speedmaster and Komori Lithrone offset presses, renowned for their precision and high-volume capabilities. These presses are perfect for large-scale projects requiring consistent color reproduction and high-quality output. I’m also proficient with various digital printing technologies, including Xerox iGen and HP Indigo presses, which excel in short-run, personalized printing and fast turnaround times. Each press type presents unique challenges and opportunities. For instance, offset requires meticulous platemaking and ink management, while digital requires a thorough understanding of RIP settings and media compatibility. My experience spans across various press sizes and configurations, allowing me to adapt to different job requirements.

Q 2. Explain the process of setting up a printing press for a specific job.

Setting up a printing press for a specific job is a meticulous process requiring precision and attention to detail. It begins with a thorough review of the job specifications, including the design, paper stock, ink colors, and quantity. Next, I’d prepare the press for the specific job. This might involve changing plates (for offset), loading the appropriate paper, adjusting the ink keys, and setting the correct register. For offset, this involves carefully mounting the plates onto the press cylinders, ensuring accurate alignment to avoid misregistration. With digital presses, I’d load the correct paper and configure the RIP (Raster Image Processor) with the appropriate color profiles and settings for the chosen substrate. Once the press is prepared, I perform test prints to verify color accuracy, registration, and overall print quality. Adjustments are made iteratively until the desired results are achieved. This rigorous setup ensures a smooth, efficient printing process and minimizes waste and errors.

Q 3. How do you ensure color accuracy and consistency during printing?

Maintaining color accuracy and consistency is critical in printing. I achieve this through a multi-faceted approach. First, I use calibrated color management systems (CMS) throughout the workflow, from design to printing. This ensures that the colors viewed on screen accurately reflect the printed output. I also rely on color standards, such as Pantone matching systems, to achieve precise color replication. During press setup, I utilize color bars and test prints to meticulously adjust the ink densities and color balances. Regular monitoring of the press’s color output and making adjustments as needed ensures consistent color throughout the print run. Finally, I maintain a comprehensive log of color settings and adjustments for each job, providing a valuable reference for future projects and ensuring reproducibility. Think of it like baking a cake – the recipe (color profile) is crucial, but careful monitoring and adjustments (ink settings) are equally important to achieve the desired result.

Q 4. What are the common causes of print defects, and how do you troubleshoot them?

Print defects can stem from various sources. Common issues include misregistration (images not aligning correctly), color inconsistencies, slurring (blurred images), hickeys (small ink spots), and paper jams. Troubleshooting starts with a systematic approach. I visually inspect the printed sheets to identify the type and location of the defect. For misregistration, I examine the plate alignment and cylinder settings. Color inconsistencies might require adjusting ink densities or verifying color profiles. Slurring often points to issues with dampening or inking systems. Hickeys might indicate debris in the ink or rollers. Paper jams require careful examination of the paper path and feeding mechanisms. I often work backwards, starting from the final output to pinpoint the source of the problem, employing a combination of observation, adjustment, and replacement of components where necessary. My troubleshooting skills enable me to quickly resolve issues, minimizing downtime and waste.

Q 5. Describe your experience with different types of inks and coatings.

My experience includes working with a wide array of inks and coatings. I’m familiar with various types of offset inks, including UV cured inks which offer quick drying times and improved durability, and conventional inks that provide a softer, more absorbent feel on the paper. I also have experience with aqueous coatings for a water-based finish and UV coatings for a more glossy, protective finish. The choice of ink and coating depends heavily on the job’s requirements – the substrate, the desired finish, and budget constraints. For instance, UV inks are ideal for high-quality packaging, while conventional inks are often preferred for brochures that require a softer touch. Understanding the properties and limitations of different inks and coatings is vital for delivering high-quality printed materials.

Q 6. How do you maintain the quality of printed materials throughout the production process?

Maintaining the quality of printed materials throughout the production process is a continuous effort. It involves several key practices, starting with careful material selection—ensuring the paper stock and inks are suitable for the project. Regular cleaning and maintenance of the press are crucial to prevent defects and ensure consistent output. This includes cleaning rollers, replacing worn parts, and checking for any signs of wear and tear. Monitoring the printing process itself—keeping a close eye on ink levels, color consistency, and registration—is vital. Finally, a rigorous quality control process involving regular inspection of the printed sheets is essential to detect and correct any defects before they become widespread. This might include spot-checking at the start, mid-run, and end of the printing process. This holistic approach ensures that the final product meets the client’s specifications and exceeds their expectations.

Q 7. What safety procedures do you follow when operating a printing press?

Safety is paramount when operating printing presses. I strictly adhere to all company safety protocols and follow established safety procedures. This includes wearing appropriate personal protective equipment (PPE), such as safety glasses, gloves, and hearing protection. I regularly inspect the press for any potential hazards, such as loose parts or damaged components. Before starting any work, I ensure the press is properly grounded and that all safety guards are in place. I carefully follow lockout/tagout procedures when performing maintenance or repairs. Moreover, I regularly receive safety training and refreshers on the correct handling of chemicals and materials used in the printing process. Safety isn’t just a guideline—it’s an ingrained part of my work ethic.

Q 8. Explain your experience with pre-press and post-press operations.

My experience encompasses the entire printing process, from pre-press to post-press. Pre-press involves all the steps before the actual printing begins. This includes preparing the artwork, creating printing plates (using technologies like CtP – Computer-to-Plate), and ensuring the files are optimized for the press. I’m proficient in using Adobe Creative Suite and other design software for pre-flight checks and file preparation. For example, I’ve worked extensively on ensuring accurate color profiles (like CMYK) match the client’s expectations. Post-press is everything that happens after printing. This includes cutting, folding, binding, finishing (e.g., lamination, embossing), and packaging. I’ve managed projects involving various binding techniques like saddle stitch, perfect binding, and wire-o, selecting the optimal method based on the job specifications and budget. I’ve also overseen the quality control checks at each stage of post-press to ensure final product consistency.

- Pre-press example: Troubleshooting a low-resolution image provided by a client, advising them on sourcing a higher-resolution file to achieve print quality.

- Post-press example: Optimizing the cutting and folding process to minimize waste and maximize efficiency in a large-scale magazine printing project.

Q 9. How do you handle press malfunctions and downtime?

Press malfunctions are inevitable, but effective troubleshooting minimizes downtime. My approach involves a systematic process: First, I identify the problem by carefully observing the press’s behavior—listen to unusual sounds, examine the print quality for defects, and check ink flow. Then, depending on the issue, I might address it myself (e.g., cleaning a clogged ink duct, adjusting paper feed), or escalate it to a technician if it involves complex mechanical or electrical problems. We have a comprehensive preventative maintenance program to minimize malfunctions. Documentation is crucial – I maintain detailed logs of maintenance and repairs to anticipate future problems and track trends. One time, a sudden power surge affected our press’s control system. Quickly assessing the situation, I isolated the problem and contacted our electrician. With prompt action, the downtime was only an hour, preventing significant production delays. We also have a backup press for critical jobs to mitigate risks.

Q 10. Describe your experience with different paper stocks and their impact on printing.

Different paper stocks significantly influence the final print quality. I’m experienced with a wide range, from coated (glossy or matte) to uncoated (off-set), and specialty papers like textured or recycled options. Coated papers provide a smoother surface for vibrant colors and sharp images; however, they can be more expensive. Uncoated papers offer a more natural, rustic feel, ideal for certain projects but might not reproduce fine detail as effectively. The paper’s weight (gsm – grams per square meter) impacts the feel and the press’s capabilities. Heavier stocks require adjustments to the press’s settings to prevent jams and ensure consistent feeding. The paper’s porosity affects ink absorption – highly absorbent papers might result in feathering or bleed, requiring adjustments to ink density and drying time. For instance, a brochure designed for a high-end client might use a premium coated paper with a high gsm for a luxurious feel, while a flyer might use a more economical uncoated paper.

Q 11. How do you calculate the required amount of ink and paper for a specific job?

Calculating ink and paper requirements necessitates precise estimations. We use a combination of job specifications (quantity of printed sheets, dimensions, and paper weight) and historical data. For paper, the calculation is fairly straightforward: Total sheets needed = (Number of copies * Number of pages per copy) + wastage (usually 5-10%). Ink estimation is slightly more complex. It considers the ink coverage percentage (based on the design’s complexity), press type, and ink viscosity. We utilize press-specific software and formulas that factor in these parameters. For example, a job requiring 5000 copies of a 4-page brochure on 150gsm paper would have its paper needs calculated, and the ink requirements determined by evaluating the design, considering its color density and the desired vibrancy.

Q 12. What is your experience with maintaining press rollers and blankets?

Maintaining press rollers and blankets is critical for consistent print quality and press longevity. Regular cleaning is paramount – we use specialized cleaning solutions to remove ink and debris, which prevents buildup and ensures even ink distribution. We check rollers for wear and tear, replacing them when necessary. Blankets, which transfer the image from the plate to the paper, need frequent inspection for scratches, damage, and proper registration. A damaged blanket leads to blurry images and misregistration. We have a scheduled maintenance program with detailed checklists to ensure every component is thoroughly inspected and cleaned. I’ve been trained on identifying wear patterns and taking corrective action to avoid costly downtime. A proactive maintenance approach keeps our presses running smoothly and reduces unexpected repair costs.

Q 13. How familiar are you with various types of platemaking technology?

I’m familiar with various platemaking technologies, particularly Computer-to-Plate (CtP) systems, which have replaced traditional methods. CtP offers faster turnaround times, improved accuracy, and enhanced efficiency. I have experience with different CtP technologies, including thermal plates and violet plates. Thermal plates use heat to expose the image on the plate, while violet plates use a laser to expose a photosensitive layer. The choice depends on factors like the printing press, the type of ink used, and the budget. For example, thermal plates are generally faster but might not offer the same longevity as violet plates. Understanding these differences enables me to select the optimal platemaking technology for a specific job, ensuring consistent and high-quality prints. My knowledge extends to managing the platemaking workflow, which includes pre-press file preparation, plate exposure, and quality control before mounting on the press.

Q 14. Describe your experience with quality control procedures in printing.

Quality control is an integral part of my work. Our quality control procedures begin in pre-press, verifying file accuracy and color profiles. During the printing process, we regularly check color consistency, registration (alignment of colors), and print sharpness. This includes visual inspection and using densitometers (measuring ink density) and spectrophotometers (measuring color accurately). Post-press quality control involves checking for defects in cutting, binding, and finishing. We also conduct random sampling checks of the final product to ensure consistency. We maintain detailed records of all quality control checks, enabling us to track trends, identify potential problems early, and continuously improve our processes. If defects are found, we investigate the root cause and implement corrective actions to prevent recurrence. This commitment to quality control ensures customer satisfaction and maintains our reputation for providing high-quality printed products.

Q 15. How do you monitor and adjust ink density during printing?

Monitoring and adjusting ink density is crucial for achieving consistent and high-quality prints. We use several methods, starting with pre-press checks to ensure the digital file is correctly calibrated. During the printing process, we rely on both visual inspection and technical tools.

Visual Inspection: I regularly check color patches or test prints against a color reference chart. This helps me identify if the ink is too light (under-inking), too dark (over-inking), or if there’s an uneven distribution of ink across the printed area. For instance, if a red logo appears duller than expected, I’d visually assess the ink density and check for any potential issues like clogged rollers or ink fountain settings.

Technical Tools: Many modern presses utilize densitometers, which precisely measure ink density. These instruments provide numerical data (in dot gain percentage) to objectively assess ink coverage. Based on these readings, adjustments are made to the ink fountain keys, which control the amount of ink transferred to the rollers and subsequently to the printing plate. It’s a delicate balance – small adjustments can make a significant difference. I also analyze color profiles provided by the customer and tailor my density adjustments accordingly.

Example: If the densitometer shows a reading that indicates under-inking on a cyan area, I’d carefully increase the ink fountain key for cyan, observing the result on subsequent test prints until the desired density is reached. This iterative process ensures a precise and consistent result across the entire print run.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with maintaining a clean and organized workspace.

Maintaining a clean and organized workspace is paramount for efficiency and safety in a pressroom environment. A cluttered space leads to delays, accidents, and inconsistencies in print quality. My approach is multifaceted:

- Regular Cleaning: I dedicate time at the end of each shift to clean my work area, including wiping down the press, removing waste materials, and organizing tools. This prevents ink build-up and ensures the press operates smoothly.

- Systematic Organization: I have a designated place for all my tools and materials. This makes it quick and easy to find what I need, minimizing downtime. For example, inks are stored in a clearly labelled rack, and cleaning materials are within arm’s reach.

- Waste Management: I follow a strict protocol for discarding waste, separating different types of materials for proper recycling. This not only keeps my workspace tidy but also contributes to environmental sustainability.

- Preventive Maintenance: Regularly cleaning the press prevents larger problems from developing. This includes checking and cleaning the rollers, dampening system, and ink fountain. Proactive cleaning minimizes delays later on.

I believe a clean and organized workspace fosters safety and reduces potential hazards like slips, trips and falls. It’s all about promoting efficiency and creating a positive, productive environment.

Q 17. How do you prioritize tasks and manage your time effectively during a busy shift?

During a busy shift, effective task prioritization and time management are key. I use a combination of techniques:

- Prioritization Matrix: I identify urgent and important tasks using a matrix (urgent/important). This helps me focus on the most critical jobs first, ensuring timely completion of deadlines.

- Job Scheduling: I work closely with the scheduling team to understand the priority of each print job, ensuring jobs are tackled in the correct sequence.

- Time Blocking: I allocate specific time slots for different tasks. This prevents me from getting sidetracked and maintains focus. For example, I might dedicate the first hour to setting up the press for a high-priority job.

- Delegation: If possible, I delegate simpler tasks to assistants, allowing me to focus on the more complex or time-sensitive aspects of the job.

- Proactive Problem Solving: I anticipate potential issues and take steps to prevent delays. This might include checking ink levels or pre-checking materials before starting a new job.

This structured approach helps me manage even the most demanding shifts while ensuring all jobs are completed efficiently and to the highest standards.

Q 18. What is your experience with different types of printing plates?

My experience encompasses various printing plate types, each with its own characteristics and applications:

- Conventional Plates (Letterpress): These are usually made of metal and require a significant amount of physical pressure for image transfer. I have experience with plate preparation, ensuring they are correctly mounted and inked for consistent printing.

- Offset Plates (Aluminum): These are the most common type used in offset printing. I’m proficient in handling different types, including thermal, photopolymer, and CTP (Computer-to-Plate) plates. My experience includes plate mounting, exposure to UV light or chemicals, and processing for optimal print quality.

- Flexographic Plates (Polymer): Used in flexible packaging printing, these plates are typically photopolymer-based and are known for their durability and ability to print on various substrates. I’m familiar with plate mounting and troubleshooting common issues, such as plate defects or improper registration.

Understanding the properties of different plates is vital for choosing the right one for each job and optimizing the printing process. I always ensure the plates are properly stored to prevent damage and maintain their quality.

Q 19. How do you deal with customer complaints about print quality?

Addressing customer complaints about print quality requires a calm, professional, and systematic approach:

- Active Listening: I carefully listen to the customer’s concerns, asking clarifying questions to fully understand the nature of the problem. Empathy is key to building rapport.

- Problem Identification: I analyze the printed output, comparing it to the original artwork and specifications. This helps me pinpoint the root cause of the issue, be it ink density, registration issues, or other factors.

- Root Cause Analysis: I systematically investigate potential causes. This could include checking the press settings, the quality of the plates, the condition of the inks, or even the pre-press files.

- Solution Implementation: Depending on the issue, I take corrective action, which may involve adjusting press settings, remaking plates, or even re-running the job. If the issue is beyond my control (e.g., a design flaw), I work with the customer to find an agreeable solution.

- Follow-up: After implementing a solution, I follow up with the customer to ensure they are satisfied and to prevent future occurrences of similar problems.

A customer-centric approach, combined with a thorough understanding of the printing process, is essential for effectively resolving these complaints.

Q 20. Describe your experience with different types of finishing equipment.

My experience includes operating a variety of finishing equipment, crucial for transforming printed sheets into final products:

- Cutting Machines: I’m proficient in using guillotine cutters and other cutting tools to accurately trim printed sheets to the required size. This requires precision to avoid waste and maintain consistent output.

- Folding Machines: I have experience with various folding techniques, ensuring the correct folds are made to create brochures, leaflets, or other finished products. Understanding different fold types (e.g., half-fold, tri-fold) is essential.

- Binding Machines: I’m familiar with saddle-stitch binding, perfect binding, and other binding methods. Choosing the appropriate binding technique depends on the product specifications and the number of pages.

- Laminating Machines: I have experience using laminating machines to add a protective layer to printed materials, enhancing their durability and presentation.

The proper use of finishing equipment ensures the final product meets customer expectations for quality and presentation. Regular maintenance of this equipment is also important to ensure smooth operation.

Q 21. How do you manage waste and ensure environmentally friendly practices?

Environmental responsibility is a significant aspect of modern press operation. My approach to waste management includes several key strategies:

- Waste Reduction: I strive to minimize waste by optimizing press settings and ensuring accurate cutting and finishing. This reduces the amount of paper and ink that end up discarded.

- Waste Segregation: I meticulously separate different types of waste, including paper, plastic, metal, and ink cartridges, for proper recycling or disposal according to company policies and local regulations. This is often done using clearly labeled bins.

- Solvent and Ink Management: I handle solvents and inks carefully, following established safety procedures to minimize spills and prevent contamination. This includes using proper storage containers and following instructions for disposal.

- Energy Conservation: I adhere to company protocols for energy conservation, such as turning off machinery when not in use and properly managing the press’s energy consumption. I’m aware of the impact of power usage and strive to use resources efficiently.

- Sustainable Practices: I promote the use of recycled paper and environmentally friendly inks whenever possible, contributing to a more sustainable printing process.

By implementing these practices, I contribute to reducing the environmental footprint of the printing operation.

Q 22. Explain your understanding of color management systems (e.g., CMYK, Pantone).

Color management systems are crucial in ensuring consistent color reproduction across different stages of the printing process. Two key systems are CMYK and Pantone.

CMYK (Cyan, Magenta, Yellow, Key [Black]): This is a subtractive color model used in most printing processes. Each color is a pigment that subtracts light, and combining them creates other colors. For example, Cyan + Magenta = Blue. The accuracy of CMYK depends heavily on the type of inks used and the calibration of the printing press. Differences in ink formulations between manufacturers, or even different batches from the same manufacturer, can lead to color variations. Careful monitoring and profiling are essential to maintain consistent results.

Pantone Matching System (PMS): This is a spot color system, offering a pre-defined library of colors, each with its unique Pantone number. Pantone colors are mixed using specific ink formulations to achieve highly accurate and consistent results regardless of the printing press or ink manufacturer. This is ideal for projects where exact color matching is critical, like corporate branding or specific product colors. The downside is that it can be more expensive as the specific ink colors need to be purchased separately for every PMS color used.

Understanding both systems is essential for a press operator to accurately interpret and reproduce designs, accounting for the differences in their color reproduction capabilities. In my experience, I have worked extensively with both systems, ensuring consistency by accurately following color profiles, using color measuring devices to monitor print output and adjusting settings as needed, which ultimately minimizes waste and ensures project deadlines are met.

Q 23. Describe your experience with using press automation and control systems.

I have extensive experience with press automation and control systems. My experience encompasses various levels of automation, from basic pre-set controls to sophisticated computer-aided systems. I’m proficient in operating presses equipped with automated features such as automatic plate changing, color registration systems, and ink and cut-off adjustments. I’ve worked with various control panels and software, including [Mention specific systems used, e.g., Heidelberg Prinect, Komori KP-Connect].

For example, on a recent project involving a high-volume print job, I utilized the press’s automated register controls to maintain precise color registration throughout the run. This reduced manual adjustments, minimizing downtime and improving the overall quality of the print job. I am also comfortable troubleshooting issues with automated systems, analyzing error messages and identifying the source of the problem quickly and efficiently, minimizing production disruptions.

I understand the importance of maintaining the system’s ongoing calibration and regular preventive maintenance to ensure optimal performance. This involves following manufacturer guidelines and keeping detailed records to predict potential malfunctions, thus preventing costly downtime. This proactive approach is integral in reducing waste and maintaining high-quality output.

Q 24. How do you work effectively as part of a team?

I’m a strong team player, comfortable working collaboratively with designers, pre-press operators, and other press operators. I believe effective teamwork is based on clear communication, mutual respect, and a shared commitment to achieving high-quality results. I actively participate in team meetings, offering input and suggestions to ensure efficient workflows.

For example, in one project where we faced a tight deadline, I collaborated closely with the pre-press team to ensure the plates were prepared efficiently. This involved proactively addressing any queries or concerns they had, thereby ensuring no delays arose in the print production process. Open communication is key; I’m comfortable both giving and receiving constructive feedback to help the team improve and enhance overall project effectiveness.

Q 25. What are your strengths and weaknesses as a press operator?

My strengths include my meticulous attention to detail, my problem-solving abilities, and my proactive approach to maintaining press efficiency. I am adept at troubleshooting mechanical issues and quickly identifying the source of print quality problems. I pride myself on producing consistent, high-quality print jobs, always meeting or exceeding expectations.

One area I am continually working on is expanding my knowledge of the latest advancements in print technology. While I am proficient in existing systems, I actively seek out training opportunities to keep my skill set current and broaden my understanding of emerging technologies within the printing sector. This continuous learning helps me to maintain my high level of expertise and improve my effectiveness within the industry.

Q 26. Where do you see yourself in five years?

In five years, I see myself as a highly skilled and versatile press operator, possibly in a supervisory role, mentoring and training newer team members. I’d like to continue developing my expertise in advanced print technologies and potentially specialize in a niche area, like high-end packaging printing or specialized print techniques. My aim is to continue to grow within the company, contributing to the team’s success while further enhancing my technical expertise.

Q 27. What are your salary expectations?

My salary expectations are commensurate with my experience and skills, and I am open to discussing a competitive compensation package based on the specifics of the role and company benefits. I’ve researched industry standards for similarly experienced press operators and am prepared to provide specific figures after learning more about the position’s responsibilities and the overall compensation structure.

Q 28. Do you have any questions for us?

Yes, I have a few questions. First, what are the company’s key performance indicators for press operators? Second, what opportunities for professional development and advancement exist within the company? Third, what type of press technology does the company primarily utilize?

Key Topics to Learn for Press Operating Interview

- Machine Setup and Operation: Understanding the intricacies of various press types (e.g., offset, digital), including setup procedures, adjustments, and troubleshooting common malfunctions.

- Print Quality Control: Mastering techniques for ensuring consistent color accuracy, registration, and print quality throughout the production run. This includes understanding color management systems and identifying and resolving print defects.

- Safety Procedures and Regulations: Demonstrating knowledge of and adherence to all safety protocols related to press operation, including lockout/tagout procedures and proper handling of chemicals and materials.

- Maintenance and Troubleshooting: Familiarization with preventative maintenance schedules, identifying potential mechanical issues, and implementing basic troubleshooting techniques to minimize downtime.

- Production Planning and Scheduling: Understanding the workflow from pre-press to post-press, including job setup, run times, and material management to optimize efficiency.

- Waste Reduction and Sustainability: Demonstrating awareness of environmentally friendly practices, including minimizing waste, conserving resources, and adhering to relevant environmental regulations.

- Industry-Specific Software: Familiarity with relevant software used in press operation, such as pre-press software and press control systems.

- Problem-Solving and Critical Thinking: Highlighting your ability to analyze problems, identify root causes, and develop effective solutions in a fast-paced production environment.

Next Steps

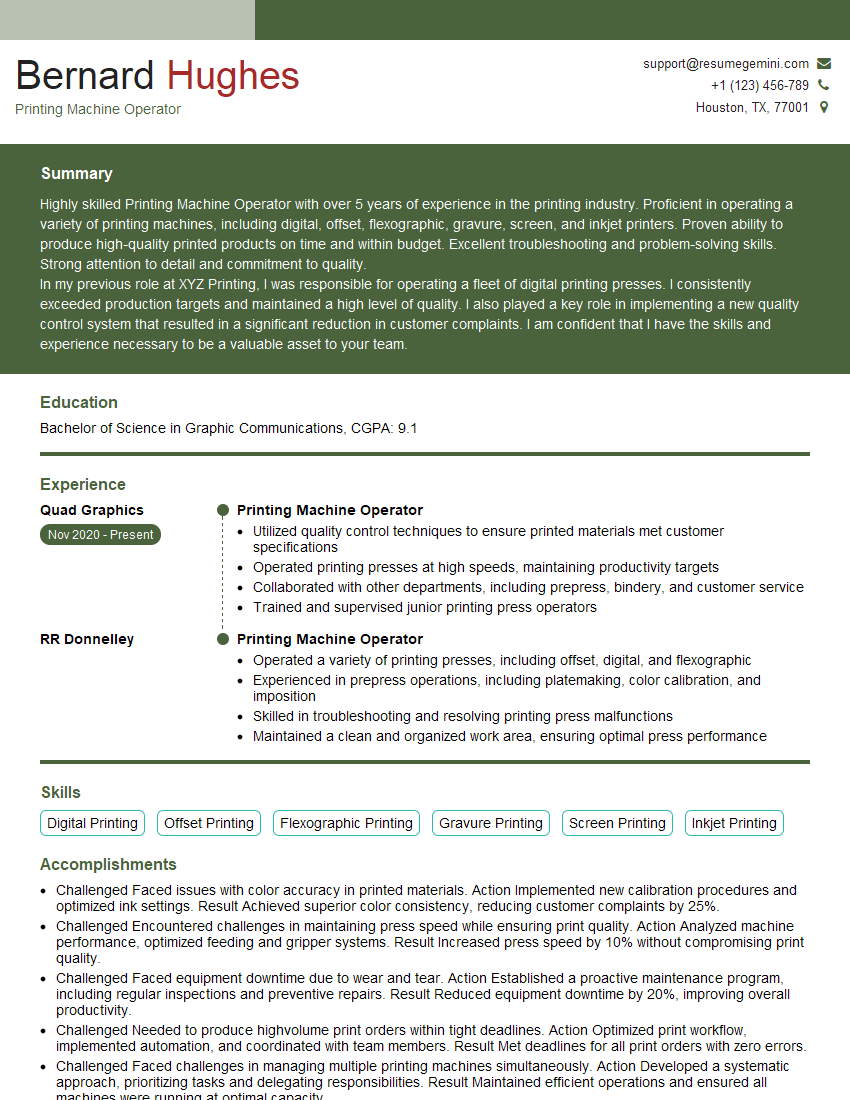

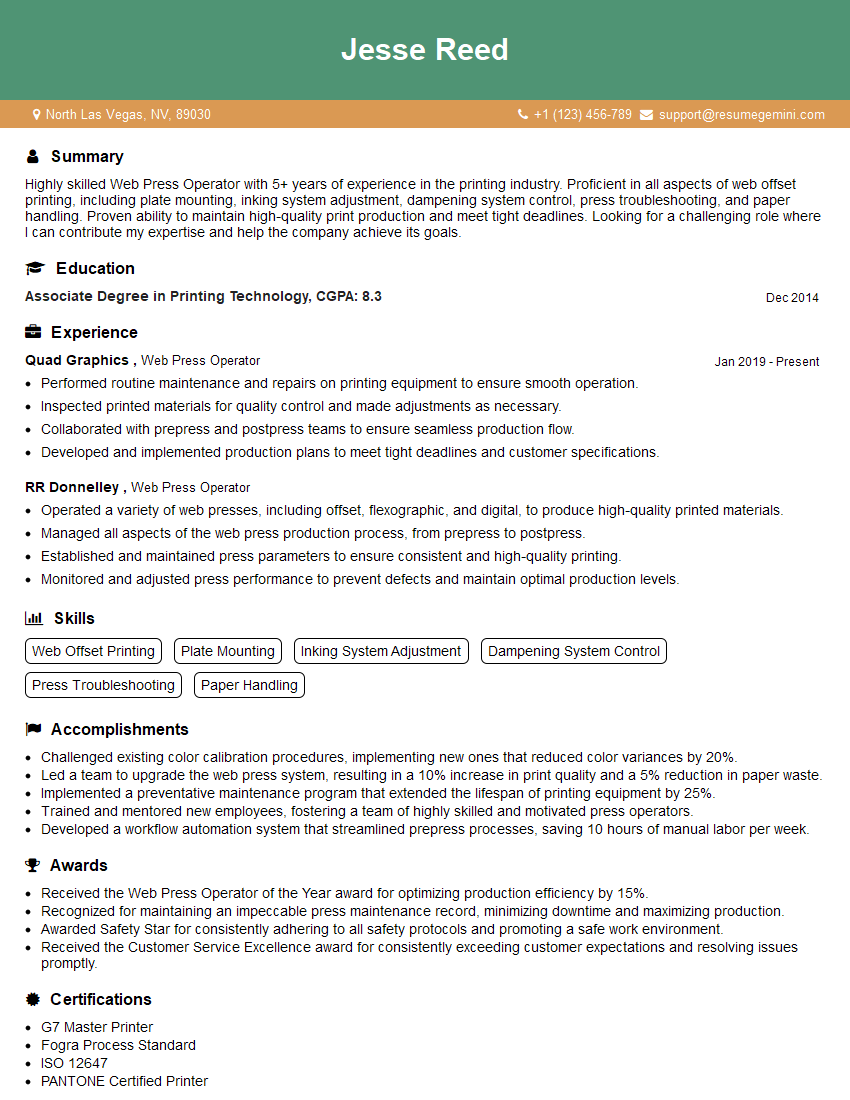

Mastering Press Operating opens doors to exciting career opportunities with excellent growth potential within the printing and publishing industries. To maximize your chances of landing your dream job, invest time in crafting a compelling and ATS-friendly resume that showcases your skills and experience effectively. ResumeGemini is a trusted resource for building professional resumes, and we provide examples of resumes tailored to Press Operating to help you get started. Take advantage of these resources to present yourself in the best possible light and land that interview!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good