Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Preventive Maintenance and Machine Troubleshooting interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Preventive Maintenance and Machine Troubleshooting Interview

Q 1. Describe your experience with different types of preventive maintenance schedules (e.g., PM, condition-based, predictive).

Preventive maintenance (PM) schedules are crucial for ensuring equipment reliability and minimizing downtime. I’ve extensive experience implementing and optimizing various types, including:

- Time-Based PM: This involves performing maintenance at predetermined intervals (e.g., oil changes every 500 hours, inspections every month). It’s simple to implement but can lead to unnecessary maintenance if equipment is performing well or insufficient maintenance if degradation is faster than anticipated. For example, I implemented a time-based PM schedule for a fleet of forklifts, resulting in a 15% reduction in minor repairs.

- Condition-Based PM: This relies on monitoring the condition of equipment using sensors or visual inspections to determine when maintenance is needed. This is more efficient than time-based PM as maintenance is only performed when necessary. A great example is using vibration sensors on critical rotating equipment to detect imbalances before they cause catastrophic failure. This approach led to a 20% reduction in unplanned downtime on a major production line I oversaw.

- Predictive PM: This is the most advanced approach, using data analytics and machine learning to predict when equipment is likely to fail. It leverages historical data, real-time sensor data, and advanced algorithms to anticipate failures and schedule maintenance proactively. I used predictive modeling to forecast bearing failures on a high-speed packaging machine, leading to a 30% reduction in unscheduled repairs.

The best approach often involves a combination of these methods, tailoring the strategy to the specific equipment and its criticality within the operation.

Q 2. Explain the difference between preventive and predictive maintenance.

Preventive maintenance (PM) and predictive maintenance are both proactive approaches to equipment maintenance, but they differ significantly in their approach:

- Preventive Maintenance (PM): This involves performing routine maintenance tasks at scheduled intervals, regardless of the equipment’s actual condition. Think of it as a regular health check-up – you go even if you feel fine, to catch potential problems early. It aims to prevent failures by addressing potential issues before they become problems.

- Predictive Maintenance: This involves monitoring the equipment’s condition using various sensors and analytical tools to predict potential failures before they occur. This approach is more sophisticated, using data analysis to determine the actual need for maintenance, optimizing resource allocation. It’s like having a sophisticated diagnostic test that pinpoints exactly what’s wrong, allowing for targeted intervention.

The key difference lies in the trigger for maintenance. PM uses time or usage as a trigger, while predictive maintenance uses condition monitoring and data analysis. Predictive maintenance is generally more efficient and cost-effective in the long run but requires more sophisticated technology and expertise.

Q 3. How do you prioritize maintenance tasks based on criticality and risk?

Prioritizing maintenance tasks involves a risk-based approach. I typically use a combination of factors to create a prioritized list:

- Criticality: How essential is the equipment to the overall operation? A critical piece of equipment that stops the entire production line would have a higher priority than a less critical piece of equipment.

- Risk of Failure: What is the likelihood of failure and the severity of the consequences if it fails? Equipment with a high probability of failure and significant consequences (e.g., safety hazards, substantial downtime) will be prioritized.

- Cost of Repair/Replacement: The cost of repairing or replacing equipment also plays a role. A costly component would be prioritized more than a cheap, easily replaced part.

- Downtime Costs: The cost associated with downtime needs to be factored in, as this can significantly impact profitability.

I often use a matrix that combines these factors, assigning a score to each task, to create a ranked list of maintenance priorities. This allows me to allocate resources effectively, focusing on the most critical and highest-risk tasks first.

Q 4. What are some common root cause analysis techniques you utilize for machine troubleshooting?

Root cause analysis (RCA) is critical for effective troubleshooting. I utilize several techniques, depending on the situation:

- 5 Whys: This simple yet effective technique involves repeatedly asking ‘why’ to uncover the root cause. By drilling down through layers of contributing factors, you eventually reach the fundamental issue.

- Fishbone Diagram (Ishikawa Diagram): This visual tool helps organize potential causes into categories (materials, methods, manpower, machinery, environment, measurement), facilitating brainstorming and identifying potential root causes.

- Fault Tree Analysis (FTA): This deductive approach starts with the undesired event (failure) and works backward to identify the potential causes and their combinations that led to the failure.

- Failure Mode and Effects Analysis (FMEA): This proactive technique is used to identify potential failure modes, their effects, and severity, to implement preventive measures before they occur.

I often combine these techniques to get a comprehensive understanding of the root cause, ensuring the problem is effectively addressed and prevented from recurring.

Q 5. Describe your experience with CMMS (Computerized Maintenance Management System) software.

I have extensive experience working with various CMMS (Computerized Maintenance Management System) software packages, including [Mention specific software – e.g., IBM Maximo, SAP PM, UpKeep]. My expertise encompasses:

- Work Order Management: Creating, assigning, tracking, and closing work orders efficiently.

- Inventory Management: Managing spare parts inventory, minimizing stockouts, and optimizing inventory levels.

- Preventive Maintenance Scheduling: Scheduling and tracking preventive maintenance tasks to ensure optimal equipment performance.

- Reporting and Analysis: Generating reports on maintenance costs, downtime, and equipment performance to identify areas for improvement.

- Data Integration: Integrating CMMS data with other systems (e.g., ERP) for a holistic view of operations.

I’m proficient in using CMMS software to streamline maintenance processes, reduce downtime, and improve overall equipment effectiveness (OEE). In my previous role, I implemented a new CMMS system, resulting in a 10% reduction in maintenance costs and a 15% improvement in OEE.

Q 6. How do you identify potential equipment failures before they occur?

Identifying potential equipment failures before they occur is a crucial aspect of proactive maintenance. My approach involves a multi-faceted strategy:

- Regular Inspections: Conducting visual inspections to identify signs of wear, tear, leaks, or unusual noises.

- Condition Monitoring: Using sensors (vibration, temperature, pressure, etc.) to monitor the condition of equipment and detect anomalies.

- Data Analysis: Analyzing historical maintenance data, sensor data, and equipment performance metrics to identify trends and predict potential failures.

- Oil Analysis: Analyzing oil samples to detect contaminants, wear particles, and other indicators of potential problems.

- Vibration Analysis: Using vibration analysis to detect imbalances, misalignments, and other mechanical issues in rotating equipment.

By combining these methods, I can effectively identify potential equipment failures before they lead to costly downtime or safety hazards. This proactive approach has consistently improved the reliability and uptime of the equipment under my care.

Q 7. What safety precautions do you follow during maintenance and repair activities?

Safety is my top priority during all maintenance and repair activities. I strictly adhere to a comprehensive safety protocol, which includes:

- Lockout/Tagout (LOTO) Procedures: Always using LOTO procedures to prevent unexpected energy release during maintenance.

- Personal Protective Equipment (PPE): Using appropriate PPE, such as safety glasses, gloves, hearing protection, and safety shoes, depending on the task.

- Risk Assessments: Conducting thorough risk assessments before starting any maintenance activity to identify and mitigate potential hazards.

- Safe Work Practices: Following safe work practices, such as using proper lifting techniques, maintaining a clean work area, and following all safety regulations.

- Training and Certification: Ensuring that all personnel involved in maintenance activities are properly trained and certified.

I never compromise on safety. A safe working environment is not only a legal requirement but also crucial for preventing injuries and ensuring the well-being of everyone on the team. A commitment to safety leads to a more efficient and productive workplace.

Q 8. Explain your experience with vibration analysis or other condition monitoring techniques.

Vibration analysis is a core condition monitoring technique I utilize extensively. It involves measuring the vibrations produced by machinery to identify potential problems. Essentially, healthy machines vibrate in predictable patterns; changes in these patterns can signal developing issues like imbalance, misalignment, looseness, or bearing defects.

My experience encompasses using both handheld vibration meters and sophisticated online monitoring systems. With handheld devices, I perform route-based inspections, collecting vibration data at various points on the machine. This data is then analyzed using specialized software to identify frequency signatures indicative of specific faults. For instance, a high amplitude at a specific frequency might point to a bearing defect. Online systems provide continuous monitoring, allowing for early detection of even subtle changes, enabling proactive maintenance and preventing catastrophic failures. I’ve used these systems to detect bearing degradation in high-speed centrifugal pumps weeks before they failed, preventing costly production downtime.

Beyond vibration analysis, I’m proficient in other condition monitoring methods such as oil analysis (checking for metal particles or changes in viscosity), thermography (detecting overheating components), and ultrasonic testing (identifying leaks or corrosion). A holistic approach combining these techniques offers a comprehensive assessment of a machine’s health.

Q 9. How do you document maintenance activities and findings?

Meticulous documentation is crucial in preventive maintenance. I utilize a Computerized Maintenance Management System (CMMS) to track all maintenance activities and findings. This system provides a centralized repository for all relevant information, ensuring consistency and accessibility.

For each maintenance task, I create detailed records including the date, time, equipment ID, work performed, parts replaced, any anomalies discovered, and corrective actions taken. I also include digital photographs and video recordings to supplement textual descriptions, especially for complex issues. The system generates reports showing maintenance history, allowing us to identify trends, predict future needs and optimize maintenance schedules.

For instance, if a specific bearing consistently fails after a certain number of operating hours, the CMMS allows me to identify this trend, investigate the root cause (perhaps poor lubrication or excessive load), and implement preventive measures like replacing the bearing sooner or modifying operating procedures.

Q 10. Describe a time you had to troubleshoot a complex machine failure. What steps did you take?

I once encountered a complete shutdown of a critical conveyor system. The initial problem was a complete power failure to the drive motor. My troubleshooting followed a structured approach:

- Safety First: I ensured the system was completely de-energized before commencing any inspection.

- Visual Inspection: I started with a visual inspection of the motor, wiring, and control panel, looking for any obvious signs of damage, loose connections, or overheating.

- Power Supply Check: I verified the power supply to the motor and the control circuit using a multimeter. I found that the main circuit breaker had tripped.

- Root Cause Investigation: Resetting the circuit breaker restored power, but the motor immediately tripped the breaker again. This indicated a problem within the motor itself or a short circuit somewhere in the motor’s circuit.

- Systematic Testing: Using the electrical schematics, I systematically checked the motor windings for shorts using a multimeter and insulation resistance tester. I found a short circuit in one of the windings.

- Repair/Replacement: The short-circuited winding required the motor to be replaced, which was accomplished and the system was restarted with proper checks and test runs to confirm normal functionality.

- Documentation: The entire process, including root cause, corrective actions, and downtime, was thoroughly documented in the CMMS system.

This experience highlighted the importance of a systematic approach, utilizing appropriate testing equipment, and accurate documentation.

Q 11. What are some common causes of equipment downtime in your experience?

In my experience, equipment downtime is most frequently caused by:

- Mechanical Failures: Bearing wear, belt breakage, gear tooth failure, and component fatigue are common culprits. These often stem from a lack of preventative maintenance or exceeding the operational limits of the equipment.

- Electrical Issues: Motor failures, short circuits, control system malfunctions, and power supply problems contribute significantly to downtime. Proper electrical safety procedures and regular inspections are key to preventing these.

- Hydraulic/Pneumatic Problems: Leaks, component failures, and contamination of fluids are common in hydraulic and pneumatic systems. Regular fluid checks and system maintenance are essential to prevent these issues.

- Human Error: Incorrect operation, insufficient training, and inadequate safety protocols can lead to equipment damage and downtime. Comprehensive employee training and clear operating procedures can dramatically reduce human error.

- Lack of Preventive Maintenance: This underlies many of the above problems. A proactive maintenance program with scheduled inspections, lubrication, and component replacements helps prevent unexpected failures.

By addressing these common causes through a comprehensive maintenance strategy, significant improvements in uptime and overall equipment effectiveness (OEE) can be achieved.

Q 12. How do you interpret equipment manuals and schematics?

Interpreting equipment manuals and schematics is a fundamental skill. I approach this systematically.

First, I familiarize myself with the overall system by reviewing the manual’s introduction, table of contents, and system overview diagrams. Then, I focus on the specific component or system I need to understand. I carefully examine schematics, looking for component designations, wiring diagrams, flow charts, and sequence of operations. I refer to the manual’s component specifications to check for details like voltage ratings, amperage draws, operating temperatures, and torque specifications.

For example, if troubleshooting a hydraulic circuit, I’d examine the hydraulic schematic, looking at the sequence of valves, actuators, and sensors. Understanding the flow of hydraulic fluid and the function of each component is critical in diagnosing problems. I’ll cross-reference the schematic with the parts list to identify the components and then look at component specifications to determine their normal operating parameters. This allows me to effectively assess whether a component is operating correctly or exhibiting abnormal behavior.

Q 13. Describe your experience working with different types of machinery (e.g., hydraulics, pneumatics, electrical systems).

My experience spans various types of machinery. I’m comfortable working with:

- Hydraulic Systems: I have extensive experience diagnosing and repairing hydraulic pumps, valves, actuators, and cylinders. I understand the principles of hydraulic power transmission and the importance of fluid cleanliness and pressure regulation. I’ve worked on systems ranging from small, single-axis actuators to complex, multi-axis hydraulic presses.

- Pneumatic Systems: I’m proficient in troubleshooting pneumatic actuators, valves, and control systems. I understand the principles of compressed air generation and distribution and the importance of proper air filtration and pressure regulation. I’ve worked on systems ranging from simple pneumatic clamping devices to more complex automated systems.

- Electrical Systems: I’m skilled in diagnosing and repairing electrical circuits, motors, control panels, and PLC (Programmable Logic Controller) systems. I have experience in electrical safety procedures, working with various voltage levels, and interpreting electrical schematics. I am familiar with troubleshooting using multimeters, oscilloscopes, and other diagnostic tools.

This diverse background allows me to approach maintenance and troubleshooting challenges from a holistic perspective, integrating knowledge across different disciplines.

Q 14. How do you handle unexpected equipment failures during production?

Unexpected equipment failures during production require a swift and methodical response. My approach follows these steps:

- Assess the Situation: First, I prioritize safety, ensuring the area is secured and personnel are out of harm’s way. I then determine the extent of the failure and its impact on production.

- Initial Troubleshooting: I perform a quick visual inspection to identify any obvious problems. I check for tripped breakers, loose connections, or any signs of damage. I might use basic tools like multimeters to check voltages and currents.

- Determine the Severity: Based on the initial assessment, I determine whether the failure can be quickly repaired, requires a temporary workaround, or necessitates a complete shutdown until the repair is completed.

- Implement Immediate Actions: If a temporary workaround is possible, I implement it to minimize production downtime. If the repair requires specialized tools or expertise, I coordinate with the appropriate team members.

- Complete the Repair: Once the problem is diagnosed and the necessary parts are obtained, I complete the repair following established safety procedures and quality control standards.

- Post-Failure Analysis: After the repair, I document the failure, the repair process, and any preventative measures needed to avoid similar incidents in the future. This information is entered into the CMMS system.

The goal is to minimize downtime, ensure safety, and learn from the experience to improve future reliability. Effective communication with production personnel is vital during this process to keep them informed and to mitigate the impact on production schedules.

Q 15. What are your preferred methods for training junior maintenance technicians?

Training junior maintenance technicians requires a multi-faceted approach combining theoretical knowledge with hands-on experience. I begin with a structured curriculum covering fundamental concepts like machine operation, safety protocols, basic electrical and mechanical principles, and common troubleshooting techniques. This is complemented by interactive sessions, using diagrams, simulations, and real-world equipment.

On-the-job training is crucial. I advocate for a mentorship program where experienced technicians guide junior staff, allowing them to learn by observation and participation under supervision. This includes shadowing during maintenance tasks, performing routine checks under guidance, and gradually taking on more responsibility as their skills develop. Regular quizzes and practical assessments ensure knowledge retention and identify areas requiring further training. For example, I might have them diagnose a simulated fault on a PLC controlled system or troubleshoot a hydraulic leak using real components. Finally, I encourage continuous learning through workshops, online courses, and participation in professional development programs to keep their skills up-to-date with evolving technologies.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you measure the effectiveness of your preventive maintenance program?

Measuring the effectiveness of a preventive maintenance (PM) program requires a combination of quantitative and qualitative data. Quantitative measures focus on metrics like Mean Time Between Failures (MTBF), Mean Time To Repair (MTTR), and equipment uptime. A significant increase in MTBF and a decrease in MTTR strongly indicates a successful PM program. We also track the number of unplanned downtime events and the cost associated with those events; a reduction in both signals effectiveness.

Qualitative measures assess the program’s impact on factors like worker satisfaction, safety incidents, and overall operational efficiency. We conduct regular surveys and feedback sessions with maintenance teams to gauge their opinions and identify areas for improvement. We also analyze near-miss reports and safety audits to evaluate the program’s influence on workplace safety. For example, a reduction in the number of safety incidents directly related to equipment failure would be a key qualitative indicator of success. By combining both quantitative and qualitative data, we gain a comprehensive understanding of the effectiveness of our PM program.

Q 17. What KPIs (Key Performance Indicators) do you use to track maintenance performance?

The KPIs I use to track maintenance performance are tailored to the specific needs of the organization, but generally include:

- MTBF (Mean Time Between Failures): Measures the average time between equipment failures. A higher MTBF indicates better reliability.

- MTTR (Mean Time To Repair): Measures the average time taken to repair a failed piece of equipment. A lower MTTR indicates faster response times and improved efficiency.

- Equipment Uptime: Represents the percentage of time the equipment is operational. Higher uptime signifies better overall performance.

- Maintenance Costs: Tracks the total cost of preventive and corrective maintenance. We aim for optimized costs without compromising reliability.

- Safety Incident Rate: Measures the number of safety incidents related to maintenance activities. A lower rate indicates improved workplace safety.

- Maintenance Backlog: Monitors the number of outstanding maintenance requests. A low backlog suggests efficient task management.

Regular monitoring of these KPIs allows us to identify trends, assess the efficacy of our strategies, and make data-driven decisions to optimize maintenance operations. For example, a sudden drop in MTBF might signal a problem requiring immediate attention and a review of our PM schedule.

Q 18. How familiar are you with Lean Manufacturing principles and their application to maintenance?

I’m very familiar with Lean Manufacturing principles and their application in maintenance. Lean principles, focused on eliminating waste and maximizing value, translate directly to more efficient and effective maintenance practices. In maintenance, ‘waste’ can manifest as unnecessary downtime, excessive inventory of spare parts, inefficient work processes, or operator errors.

Lean tools like 5S (Sort, Set in Order, Shine, Standardize, Sustain) help organize the maintenance workspace, improving efficiency and safety. Value Stream Mapping helps visualize the entire maintenance process, identifying bottlenecks and areas for improvement. Total Productive Maintenance (TPM) is a crucial Lean application in maintenance, promoting proactive involvement of all personnel in maintaining equipment, thereby reducing downtime and improving overall equipment effectiveness (OEE). Kanban systems can optimize the management of spare parts, reducing inventory costs and improving responsiveness. By implementing these Lean principles, we can streamline maintenance processes, reduce costs, and improve overall equipment reliability.

Q 19. Describe your experience with lubrication techniques and practices.

My experience with lubrication techniques and practices is extensive. Proper lubrication is critical for equipment longevity and preventing premature failures. I’m proficient in various lubrication methods, including manual lubrication using grease guns and oil cans, centralized lubrication systems, and automated lubrication systems. I understand the importance of selecting the right lubricant based on factors like equipment type, operating conditions, and manufacturer recommendations.

I’m also well-versed in lubrication best practices, including establishing a robust lubrication schedule, ensuring proper application techniques to avoid over- or under-lubrication, and monitoring lubricant condition through analysis of oil samples. I understand the concept of contamination control and the importance of clean lubrication practices to prevent damage to equipment. For example, I would regularly inspect grease fittings for proper function, analyze oil samples to detect wear particles or contaminants, and ensure that all personnel involved in lubrication are appropriately trained to follow safety guidelines and best practices. This proactive approach ensures optimal machine performance and extended lifespan.

Q 20. What are some common causes of bearing failures and how can they be prevented?

Bearing failures are a common cause of equipment downtime. Several factors contribute to these failures:

- Insufficient lubrication: Lack of lubrication leads to increased friction, heat, and eventual bearing damage.

- Contamination: Dust, dirt, and other foreign particles entering the bearing can cause wear and tear.

- Improper installation: Incorrect mounting or alignment can stress the bearing, leading to premature failure.

- Overload: Exceeding the bearing’s load capacity causes excessive stress and damage.

- Vibration: Excessive vibration can accelerate wear and damage bearings.

- Corrosion: Exposure to moisture or corrosive substances can damage bearing components.

Preventing bearing failures requires a multi-pronged approach: Regular lubrication according to a scheduled program, maintaining a clean operating environment to minimize contamination, proper installation and alignment of bearings, ensuring operating loads are within the bearing’s capacity, monitoring vibration levels, and protecting bearings from environmental factors like moisture. Regular inspections and condition monitoring, such as vibration analysis, can help identify potential problems early, preventing catastrophic failures.

Q 21. How do you identify and address safety hazards related to machine maintenance?

Identifying and addressing safety hazards related to machine maintenance is paramount. My approach starts with a thorough risk assessment of each machine and maintenance task, identifying potential hazards such as electrical shock, crushing injuries, burns, or exposure to hazardous materials. This assessment involves considering the specific machine, the maintenance procedures, and the environment.

Based on the risk assessment, we implement appropriate control measures. This might include lockout/tagout procedures to prevent accidental energization, using personal protective equipment (PPE) such as safety glasses, gloves, and hearing protection, implementing proper lifting techniques to prevent injuries, and providing training to ensure technicians are aware of and capable of handling potential hazards. Regular safety inspections, emergency response drills, and communication of safety procedures ensure a safe working environment. We also maintain detailed safety documentation and incident reports to continuously learn and improve our safety practices. For example, a weekly toolbox talk focused on a particular hazard and the control measures can reinforce safety awareness.

Q 22. Explain your experience with different types of sensors used in predictive maintenance.

My experience with sensors in predictive maintenance is extensive. I’ve worked with a wide variety of sensors, each offering unique insights into machine health. Think of sensors as the machine’s nervous system, constantly monitoring vital signs. For example:

- Vibration Sensors (Accelerometers): These are crucial for detecting imbalances, misalignment, bearing wear, and other mechanical issues. A slight increase in vibration frequency might indicate impending bearing failure, allowing for proactive replacement before catastrophic breakdown. I’ve used these extensively on rotating equipment like pumps and motors.

- Temperature Sensors (Thermocouples, RTDs): These monitor operating temperatures. An unexpected temperature spike could point to overheating due to friction, electrical faults, or lubrication problems. In one instance, a temperature sensor alerted us to a failing motor winding, preventing a costly shutdown.

- Acoustic Sensors (Microphones): These detect unusual sounds, such as grinding, squealing, or cavitation, which often indicate early-stage problems. Think of it like listening to your car engine – a strange noise signals a potential issue.

- Oil Condition Sensors: These analyze oil viscosity, particle concentration, and other parameters to assess the lubricant’s condition and the overall health of the lubricated components. By monitoring oil degradation, we can predict when oil changes are needed or if there’s internal wear within the machine.

- Current Sensors: These measure the electrical current drawn by a motor. An unusual increase in current could signify winding problems, bearing issues, or other electrical faults.

Integrating data from multiple sensor types provides a holistic view of the machine’s health, enabling more accurate predictive models and optimized maintenance scheduling.

Q 23. How do you manage spare parts inventory to minimize downtime?

Managing spare parts inventory is a delicate balancing act. Too much inventory ties up capital, while too little leads to costly downtime. My approach focuses on a data-driven, risk-based strategy:

- Criticality Analysis: I classify parts based on their criticality – how quickly their failure impacts production. High-criticality parts, like those causing immediate shutdowns, receive higher stocking levels. Low-criticality parts, which can be replaced during scheduled downtime, have lower stocking levels.

- Demand Forecasting: I use historical data, machine learning models, and expert judgment to forecast future part demand. This helps us anticipate needs and avoid stockouts.

- Lead Time Analysis: Knowing the supplier’s lead time is crucial. For parts with long lead times, we maintain higher safety stock to buffer against delays.

- ABC Analysis: I categorize parts into A, B, and C classes based on their consumption value. A-class parts (high value, high consumption) receive more attention in terms of inventory management. C-class parts (low value, low consumption) require less stringent controls.

- Vendor Managed Inventory (VMI): In some cases, we leverage VMI, where the supplier manages our inventory, ensuring optimal stock levels and timely replenishment.

Regular inventory reviews, coupled with data analysis, help optimize stock levels and minimize downtime by ensuring critical parts are always available when needed.

Q 24. Describe your experience with lockout/tagout procedures.

Lockout/Tagout (LOTO) procedures are paramount for workplace safety. My experience involves ensuring strict adherence to these protocols for any maintenance activity on energized equipment. This involves:

- Proper Training: I ensure all personnel involved in maintenance are thoroughly trained in LOTO procedures, understanding the importance of each step.

- Step-by-Step Procedure: We follow a standardized LOTO procedure, including identifying the energy sources, isolating them, applying lockout devices, verifying the isolation, and tagging the equipment.

- Documentation: Every LOTO procedure is meticulously documented, recording the date, time, personnel involved, and equipment affected. This provides a clear audit trail.

- Regular Inspections: Lockout devices are regularly inspected to ensure they are functioning correctly and haven’t been tampered with. We use different colored tags, depending on what is being locked out.

- Emergency Procedures: We have clear emergency procedures in place in case of a lockout device failure or unexpected energy restoration. Training covers emergency response protocols as well.

My focus is on creating a safety-conscious culture where LOTO is not just a procedure but a deeply ingrained habit.

Q 25. How do you prioritize maintenance tasks during budget constraints?

Prioritizing maintenance tasks under budget constraints requires a systematic approach. I use a combination of techniques:

- Criticality Assessment: Tasks are ranked based on their impact on production. Critical tasks preventing production are prioritized over less critical ones.

- Risk Analysis: The potential consequences of delaying a task are analyzed. High-risk tasks, those with a high probability of failure and severe consequences, are prioritized.

- Cost-Benefit Analysis: The cost of performing a task versus the cost of potential failure (lost production, repairs) is evaluated. Tasks with high cost savings are given priority.

- Predictive Maintenance Data: Data from predictive maintenance systems helps prioritize tasks based on actual machine health predictions, enabling proactive maintenance where it’s needed most.

- Pareto Principle (80/20 Rule): We identify the 20% of tasks that contribute to 80% of the problems and focus on those to improve overall equipment effectiveness (OEE).

By using these methods, we can allocate resources effectively, maximizing the impact of available funds while minimizing risks to production.

Q 26. What is your experience with root cause analysis tools such as 5 Whys or Fishbone diagrams?

I’m proficient in several root cause analysis (RCA) tools. The 5 Whys and Fishbone diagrams are invaluable in troubleshooting complex equipment problems.

- 5 Whys: This iterative questioning technique helps uncover the root cause by repeatedly asking ‘Why?’ until the fundamental issue is identified. For example, if a pump fails: Why did the pump fail? (Bearing wear). Why did the bearing wear? (Insufficient lubrication). Why was the lubrication insufficient? (Faulty oil pump). Why did the oil pump fail? (Lack of preventative maintenance). Why was there a lack of preventative maintenance? (Inadequate scheduling). This final answer gives the root cause which allows preventative measures to be taken to prevent future issues.

- Fishbone (Ishikawa) Diagram: This visual tool helps brainstorm potential causes grouped into categories (materials, methods, manpower, machinery, environment, management). This systematic approach helps identify multiple potential causes, and a collaborative session often leads to better understanding and root cause identification.

Combining these techniques ensures a thorough investigation, leading to effective corrective actions and the implementation of preventative measures to minimize future occurrences.

Q 27. How do you ensure compliance with safety regulations and industry standards?

Compliance with safety regulations and industry standards is non-negotiable. My approach involves:

- Staying Updated: I consistently stay informed about the latest safety regulations and industry best practices (OSHA, ISO, etc.).

- Regular Audits: We conduct regular internal safety audits to identify potential hazards and ensure compliance. These help prevent compliance issues and highlight potential dangers before accidents occur.

- Documentation: All safety-related procedures, training records, and inspection reports are meticulously documented and readily accessible. Maintaining well-documented procedures allows us to track progress, compliance, and training easily.

- Training Programs: Comprehensive safety training programs are provided to all personnel, covering relevant regulations, safe work practices, and emergency procedures. This ensures that everyone understands and adheres to standards.

- Incident Reporting and Investigation: A robust system for reporting and investigating safety incidents is in place to identify root causes, implement corrective actions, and prevent recurrence. Any accident or near-miss event is fully investigated to find potential preventative solutions.

By implementing these measures, we create a safe working environment that complies with all relevant regulations and industry standards.

Q 28. Describe your experience with data analysis related to maintenance performance.

Data analysis plays a crucial role in optimizing maintenance performance. My experience encompasses:

- Key Performance Indicator (KPI) Tracking: I monitor KPIs such as Mean Time To Repair (MTTR), Mean Time Between Failures (MTBF), equipment uptime, and maintenance costs. This helps identify areas for improvement.

- Predictive Modeling: I use machine learning and statistical analysis to build predictive models for equipment failures, enabling proactive maintenance and reducing downtime. These models use historical data to predict future failures.

- Maintenance Cost Analysis: I analyze maintenance costs to identify areas of potential savings, such as optimizing spare parts inventory or improving maintenance procedures. This involves investigating potential costs savings and inefficiencies.

- Data Visualization: I use dashboards and reports to visualize maintenance data, making it easier to identify trends, patterns, and anomalies. This allows easier tracking of maintenance effectiveness and the identification of improvement opportunities.

- Root Cause Analysis using Data: Maintenance data is used to support root cause analysis, providing objective insights into the causes of equipment failures and informing corrective actions. Combining data with RCA provides more thorough insights and accurate fixes.

By leveraging data analysis, we make data-driven decisions to continuously improve maintenance strategies, reduce costs, and increase equipment reliability.

Key Topics to Learn for Preventive Maintenance and Machine Troubleshooting Interview

- Preventive Maintenance Strategies: Understanding different PM schedules (time-based, condition-based, predictive), developing and implementing effective PM plans, and utilizing relevant software for scheduling and tracking.

- Machine Diagnostics and Troubleshooting: Mastering fault identification techniques (visual inspection, vibration analysis, thermal imaging), utilizing diagnostic tools and software, and applying systematic troubleshooting methodologies.

- Safety Procedures and Regulations: Demonstrating a thorough understanding of relevant safety protocols, lockout/tagout procedures, and adherence to industry regulations (OSHA, etc.).

- Root Cause Analysis (RCA): Applying RCA techniques (5 Whys, Fishbone diagrams) to identify underlying causes of equipment failures and prevent recurrence.

- Data Analysis and Reporting: Collecting, analyzing, and interpreting maintenance data to identify trends, improve efficiency, and support decision-making. This includes familiarity with relevant metrics (MTBF, MTTR, etc.).

- Specific Machine Knowledge: Deep understanding of the specific machinery relevant to the target role, including their operational principles, common failure points, and maintenance requirements. Be prepared to discuss both theory and practical experience.

- Cost Optimization and Budget Management: Demonstrating knowledge of how to optimize maintenance costs, manage budgets effectively, and justify maintenance expenditures.

- Communication and Teamwork: Highlighting your ability to effectively communicate technical information to both technical and non-technical audiences, and your experience working collaboratively within a maintenance team.

Next Steps

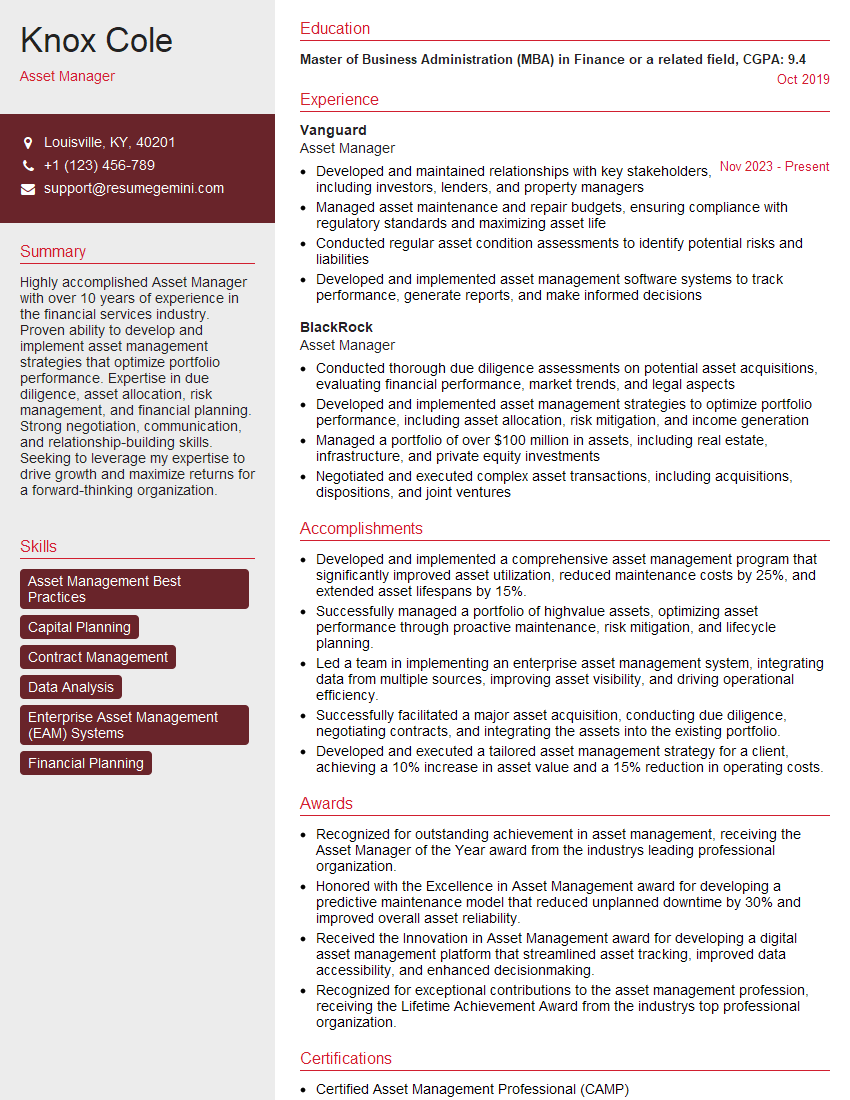

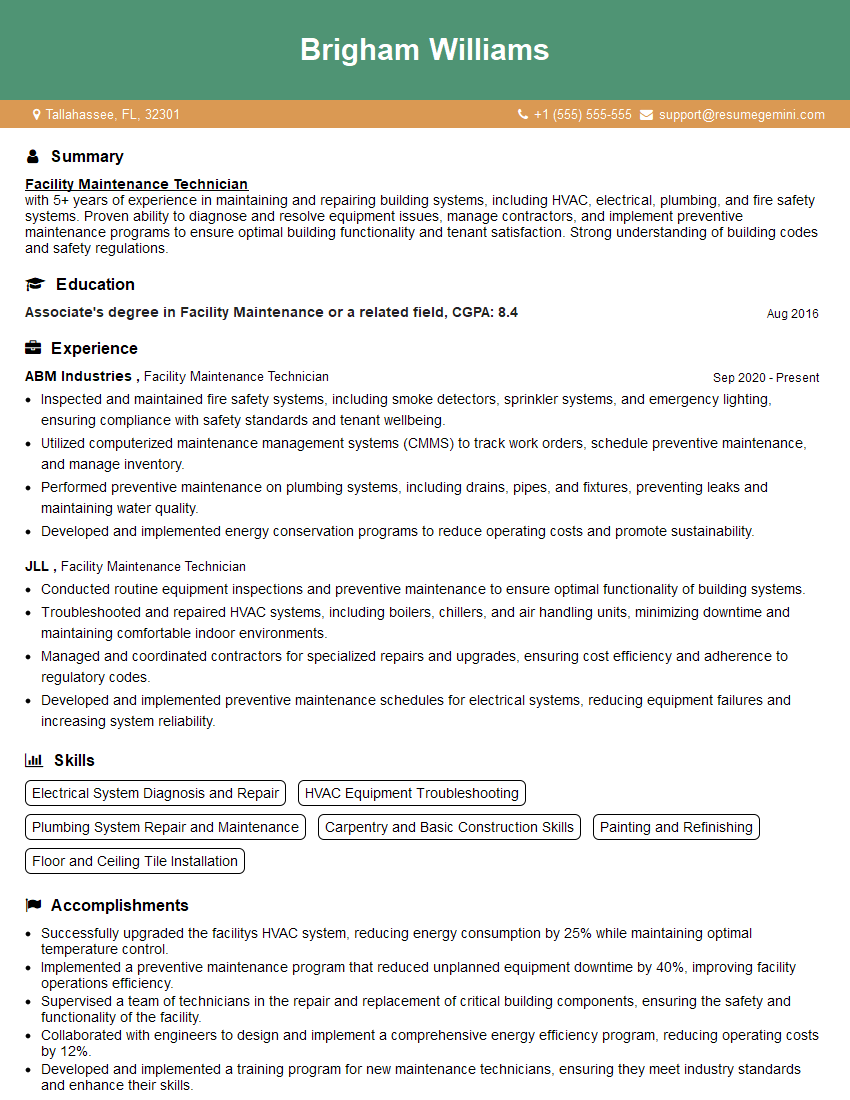

Mastering Preventive Maintenance and Machine Troubleshooting is crucial for career advancement in this field. It demonstrates your commitment to efficiency, safety, and cost-effectiveness. To significantly boost your job prospects, creating a strong, ATS-friendly resume is essential. ResumeGemini can help you build a professional and impactful resume tailored to the specific requirements of your target roles. We offer examples of resumes specifically designed for candidates in Preventive Maintenance and Machine Troubleshooting to help you craft a compelling application that gets noticed.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good