The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Print and digital production knowledge interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Print and digital production knowledge Interview

Q 1. Explain the difference between offset and digital printing.

Offset and digital printing are two distinct methods for mass producing printed materials, differing significantly in their processes and resulting outputs. Offset printing, the more traditional method, uses a plate-making process where an image is transferred from a plate to a rubber blanket and then onto the printing substrate (paper, etc.). This indirect transfer allows for high-volume, high-quality printing at a lower cost per unit, especially for larger runs. Think of it like using a stamp: you make one master stamp (the plate) and can print many times with it. Digital printing, on the other hand, prints images directly onto the substrate using toner or inkjet technology. This eliminates the plate-making stage, making it ideal for short runs, personalized pieces, and quick turnaround times. Imagine using a inkjet printer, directly printing your document.

Here’s a table summarizing the key differences:

| Feature | Offset Printing | Digital Printing |

|---|---|---|

| Printing Method | Indirect (plate to blanket to substrate) | Direct (toner/inkjet to substrate) |

| Cost per Unit | Lower for large runs | Higher for large runs, lower for small runs |

| Setup Costs | Higher | Lower |

| Turnaround Time | Longer | Faster |

| Run Length | Best for large runs (thousands) | Best for small to medium runs (hundreds) |

| Customization | Limited | High degree of customization possible |

Q 2. What are the key considerations for choosing between print and digital media for a marketing campaign?

Choosing between print and digital media for a marketing campaign depends on several factors: budget, target audience, campaign goals, and the message itself.

- Budget: Offset printing offers better cost-effectiveness for large-scale campaigns with high print volumes. Digital is more cost-effective for smaller, targeted campaigns or personalized materials.

- Target Audience: Consider your audience’s demographics and media consumption habits. Older demographics may still prefer print materials, while younger audiences might be more receptive to digital campaigns.

- Campaign Goals: Are you aiming for brand awareness, lead generation, or driving sales? Print can be effective for creating tangible brand presence, while digital allows for more immediate engagement and tracking.

- Message: The complexity and visual richness of the message also play a role. High-quality photography and detailed graphics are better reproduced in offset printing. Digital is excellent for fast-changing messages or dynamic content.

For example, a national product launch might utilize offset printing for brochures and posters, supplemented by targeted digital ads and email campaigns. Conversely, a local business promoting a flash sale might find digital media through social media and email marketing the most efficient approach.

Q 3. Describe your experience with color management and proofing.

Color management and proofing are crucial for ensuring consistent and accurate color reproduction across different devices and media. My experience encompasses the entire workflow, from profile creation and color calibration to soft proofing and hard proofing. I’m proficient in using color management software like X-Rite i1Profiler and ColorSync Utility to create and manage ICC profiles for printers and monitors. I understand the importance of using standard color spaces like CMYK for print and sRGB for digital, as well as the nuances of color gamut and color transformations.

Soft proofing involves reviewing a digital representation of the final print on screen, using software that simulates the printing process. Hard proofing, on the other hand, involves creating a physical sample print on the press for final approval, and I have a lot of experience creating these and comparing them to digital proofs to ensure accuracy. I have worked with a variety of proofing methods including contract proofing and digital proofing, which is becoming more common.

In a recent project, we experienced a significant color shift between our soft proofs and the first press run. Through careful analysis, we discovered a mismatch between the monitor’s ICC profile and the printer’s profile. After correcting the profiles and rerunning the job, the color accuracy was restored. This highlights the importance of robust color management throughout the production process.

Q 4. How do you manage large volumes of digital assets?

Managing large volumes of digital assets requires a structured and organized approach. I typically employ a combination of digital asset management (DAM) systems and a well-defined file naming convention. DAM systems like Adobe Experience Manager or Bynder provide centralized storage, metadata tagging, version control, and easy searchability. A consistent naming convention (e.g., ClientName_ProjectName_Date_Version.ext) is crucial for quick retrieval and avoids confusion. Additionally, I regularly conduct audits to remove redundant or obsolete files to maintain efficiency and reduce storage costs.

For example, I organized all the assets for a large packaging design project using a DAM system. Each asset had specific metadata tags indicating the client, project, file type, date, and the designer’s name, which significantly simplified collaboration and the approval process.

Q 5. What file formats are best suited for print production?

The best file formats for print production prioritize color accuracy, resolution, and compatibility with prepress software. Generally, vector formats and high-resolution raster formats are preferred:

- Vector Formats (e.g., .AI, .EPS, .PDF): These are resolution-independent, meaning they can be scaled to any size without losing quality. This is ideal for logos, illustrations, and typography.

- High-Resolution Raster Formats (e.g., .TIFF, .PSD): For photographic images, a resolution of at least 300 DPI (dots per inch) is recommended for high-quality print reproduction. TIFF offers superior image quality with lossless compression, while PSD allows for layer editing if necessary.

- PDF/X-1a or PDF/X-4: These PDF formats are specifically designed for print production, ensuring reliable color management and data integrity.

Avoiding formats like JPEG (lossy compression) for print is crucial to maintain sharpness and avoid artifacts. Choosing the correct file format is paramount for a smooth print workflow.

Q 6. Explain your experience with prepress processes.

Prepress processes encompass all the steps taken before the actual printing begins. My experience includes file preparation, trapping, color separation, imposition, and platemaking (for offset printing). File preparation involves checking resolution, color profiles, fonts, and image quality, ensuring all elements meet print specifications. Trapping involves creating slight overlaps between colors to prevent gaps during printing, crucial for crisp and clean results. Color separation converts a full-color image into individual CMYK plates for offset printing.

Imposition arranges pages in a specific order for efficient printing and binding. Finally, for offset, platemaking creates the printing plates based on the prepared files. I’m experienced using software such as Adobe Acrobat, Adobe Illustrator, and various RIP (Raster Image Processors) and prepress workflow management systems. I’ve had to troubleshoot issues like font errors, low-resolution images, and missing color profiles many times, always finding solutions to keep projects moving forward.

Q 7. Describe your workflow for managing a print project from start to finish.

My workflow for managing a print project follows a structured process:

- Project Initiation: Client briefing, gathering requirements (specifications, design files, deadlines, quantities).

- Prepress: File preparation, color management, trapping, imposition, and proof approval. If necessary, I will work with clients to create mockups and test prints to make sure they approve of the final result before we move to full production.

- Production: Overseeing the printing process, ensuring adherence to quality standards, and managing timelines. I’m familiar with a variety of printing methods, and choose the best one to match the client’s needs.

- Quality Control: Performing quality checks throughout the process, reviewing proofs and final printed materials to identify and correct any inconsistencies.

- Finishing & Delivery: Overseeing any finishing (binding, cutting, laminating), packaging, and delivery to the client. I make sure all materials are packaged correctly and meet the client’s shipping specifications.

- Post-Project Analysis: Reviewing the project timeline, budget, and feedback to improve future processes.

This approach ensures efficiency, collaboration, and a high-quality end product. Each step involves close communication with the client and the printing team, always focusing on meeting expectations and delivering a successful project.

Q 8. How do you ensure the quality of print materials?

Ensuring print quality is a multifaceted process that starts long before the press even runs. It involves meticulous attention to detail at every stage, from design and pre-press to printing and finishing.

- High-Resolution Files: We begin by verifying the source files have the necessary resolution (at least 300 DPI for print) and color mode (CMYK for print). Low-resolution images will result in pixelation and blurry output.

- Color Management: Accurate color representation is critical. We utilize color profiles (e.g., ICC profiles) to ensure consistency between the digital design and the final printed piece. This involves proofing on a calibrated monitor and potentially creating soft proofs for client approval.

- Pre-flight Checks: Before sending files to the printer, a thorough pre-flight check is essential. This automated process identifies potential issues such as missing fonts, embedded images, incorrect color spaces, and bleeds that might not be apparent otherwise. It’s like a final health check for the file before surgery.

- Proofing: We always produce hard or soft proofs for client approval. This allows them to see the final product before committing to a large print run. Color variations can be identified and adjustments made at this stage. A hard proof is physically printed, while a soft proof is a digital representation.

- Press Checks: On larger jobs, a press check is done early in the printing process to verify color accuracy, registration (alignment of colors), and overall print quality. Adjustments are made on the press to refine the print job before proceeding with the full run.

By implementing these checks and balances, we minimize the chances of errors and ensure consistent, high-quality output, reducing costly reprints and delays.

Q 9. What are your experiences with various finishing techniques (e.g., binding, die-cutting)?

Finishing techniques add the final touches to a print project, transforming a simple printed sheet into a professional, high-impact piece. My experience encompasses a wide range of techniques:

- Binding: I’m proficient in various binding methods, including saddle stitch (for brochures), perfect binding (for books and magazines), wire-o binding (for calendars and notebooks), and case binding (for high-end books). The choice depends on the project’s requirements and budget. For example, saddle stitch is cost-effective for smaller booklets, while case binding is suitable for larger projects requiring durability.

- Die-cutting: Die-cutting allows for creating custom shapes and designs, adding a unique touch. I’ve worked on projects involving intricate die-cuts, from simple shapes to complex, multi-layered designs. It’s important to accurately design the die-cut and select an experienced vendor to get high-quality results.

- Folding and Creasing: Proper folding and creasing is essential for ensuring a clean, professional finish. Different types of folds (e.g., parallel, gate, Z-fold) can be used depending on the project’s requirements. We need to account for the paper weight and type to prevent tearing or cracking during folding.

- Laminating: Applying a protective layer of film enhances durability and gives a glossy or matte finish. Different types of laminates are available, including gloss, matte, and soft-touch, each with its own characteristics and applications.

I understand the implications of each technique on the final product’s look, feel, and cost, ensuring that we select the most appropriate and efficient method for each project.

Q 10. How familiar are you with different print substrates?

Familiarity with different print substrates is crucial for choosing the right material for a specific project. The substrate significantly impacts the final product’s look, feel, and cost.

- Paper: I have experience with various paper types, including coated (glossy or matte), uncoated (absorbent), textured, and specialty papers (e.g., recycled, linen). The choice depends on factors like print quality, desired finish, and budget. For instance, coated paper produces vibrant colors but can be more expensive than uncoated paper.

- Cardboard and Board Stock: These thicker substrates are used for packaging, displays, and business cards. Different weights and finishes are available to meet various needs; for example, thicker board stock is more durable for packaging and protects the product.

- Vinyl: This durable material is suitable for outdoor signage, banners, and decals. Its weather resistance makes it ideal for applications exposed to the elements.

- Canvas: High-quality canvas is used for fine art prints offering a premium, textured look and feel.

Understanding the characteristics of each substrate allows me to make informed recommendations to clients, ensuring the selected material aligns with their needs and budget. For instance, using a cheaper paper than required may result in poor print quality or unsatisfactory final product.

Q 11. What software are you proficient in for print and digital production?

Proficiency in relevant software is essential for efficient and accurate print and digital production. My skillset includes:

- Adobe Creative Suite (Photoshop, Illustrator, InDesign): These are industry-standard tools for designing and preparing print-ready files. I’m proficient in using all aspects of these applications, from creating layouts and manipulating images to preparing files for print.

- Adobe Acrobat Pro: Essential for creating and managing PDF files, ensuring they’re optimized for print or digital distribution. I’m skilled in creating accessible PDFs and implementing pre-flight checks.

- QuarkXPress: While InDesign has gained significant market share, I am also proficient in QuarkXPress for desktop publishing. This experience enables me to seamlessly work with clients who prefer or have legacy projects using this software.

- Color Management Software: I’m experienced with color management software like X-Rite i1Profiler for ensuring consistent color across different devices and production stages.

My strong foundation in these software packages enables me to efficiently produce high-quality materials for print and digital media, adapt to various client requirements and deliver projects promptly.

Q 12. Describe a time you had to troubleshoot a print production issue.

In a recent project involving a large-format poster print, we encountered a significant color shift during the print process. The colors were noticeably off from the approved proof.

My initial troubleshooting steps involved:

- Reviewing the print files: I meticulously re-examined the print-ready files, ensuring no errors had been introduced since the final proof.

- Checking the press settings: We confirmed the press was calibrated correctly, verifying the color profiles and ink levels.

- Inspecting the ink and paper: We examined the ink and paper used, looking for any inconsistencies that might have caused color discrepancies.

- Collaboration with the printing team: I worked closely with the printing team, sharing information and insights about the approved proof and the discrepancies. We tested different settings on the press to identify the source of the problem.

After a thorough examination, we discovered the issue was linked to a slight variation in the paper batch. Using a fresh batch of paper from the same supplier resolved the color issue. This highlighted the importance of using consistent materials throughout the production process and the value of maintaining strong working relationships with printers. This experience reinforced the importance of comprehensive checks and open communication throughout the production process.

Q 13. How do you handle a project with tight deadlines?

Handling tight deadlines requires a proactive and organized approach. My strategy involves:

- Prioritization: We immediately prioritize tasks based on their urgency and importance using tools like Gantt charts or Kanban boards. This ensures we focus on the most critical aspects first.

- Clear Communication: Open and transparent communication with the client and the team is essential. Regular updates help manage expectations and identify potential roadblocks early on.

- Efficient Workflow: Streamlined workflows and automated processes, where possible, help eliminate unnecessary delays. Utilizing project management software aids in tracking progress and identifying potential bottlenecks.

- Resource Allocation: Effective resource allocation, including personnel and equipment, ensures optimal efficiency. We ensure we have the necessary team members and equipment available to meet the deadline.

- Contingency Planning: We always build in contingency time to account for unforeseen delays. This reduces stress and enables us to handle unexpected issues effectively.

By combining effective planning with a flexible and adaptable approach, we consistently deliver high-quality work, even under tight deadlines. My approach is to focus on delivering what is critical and managing client expectations rather than sacrificing quality.

Q 14. What are your experiences with print estimating and budgeting?

Print estimating and budgeting are critical for project success and profitability. My experience involves:

- Gathering Information: The process begins with thorough information gathering, understanding the project’s scope, including the quantity, size, paper type, finishing techniques, and any special requirements. The more detail, the more accurate the estimate.

- Cost Calculation: This involves calculating the costs of materials, labor, and overhead based on industry-standard pricing and my experience. I can estimate the amount of materials required and their cost, the printing time and associated labour costs, and any additional processing or finishing costs.

- Profit Margin: A realistic profit margin is included to ensure the project is profitable. The margin needs to account for unexpected costs and risk.

- Presenting the Estimate: A clear and detailed estimate is presented to the client, outlining all costs and any assumptions made. This prevents misunderstandings and provides transparency.

- Budget Tracking: During the project, we track costs to ensure they remain within the budget. This involves regular monitoring of material usage, labor hours, and any unforeseen expenses.

Accuracy is paramount in estimating and budgeting. Inaccurate estimates can lead to project losses, while overly inflated estimates can cost the client unnecessary money. My approach prioritizes realistic and transparent estimations, fostering trust and strong client relationships.

Q 15. Explain your understanding of color profiles (e.g., CMYK, RGB).

Color profiles are essentially sets of data that define how colors are represented on different devices. Think of them as dictionaries that translate color between the digital world (your screen) and the physical world (printed materials). The two most common are RGB and CMYK.

- RGB (Red, Green, Blue): This is an additive color model used for screens. It works by combining red, green, and blue light to create a wide spectrum of colors. The more light, the brighter the color. Think of your computer monitor or phone screen; it uses RGB.

- CMYK (Cyan, Magenta, Yellow, Key [Black]): This is a subtractive color model used for printing. It works by subtracting colors from white light to create the desired hue. The more ink applied, the darker the color. Imagine mixing paints – you start with white and add colors to darken it. This is how CMYK works.

The key difference lies in how colors are produced. RGB works with light, while CMYK works with ink. This means an image looking vibrant on screen (RGB) might appear duller or different when printed (CMYK), unless proper color management, using color profiles, is implemented. Therefore, converting a digital image from RGB to CMYK requires a color profile to ensure accurate color representation in print.

For instance, a bright, vibrant green in RGB might translate to a slightly muted green in CMYK, if the conversion isn’t properly managed. Using a specific color profile helps maintain color accuracy as much as possible across this transition.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure brand consistency across print and digital materials?

Maintaining brand consistency across print and digital materials requires meticulous planning and execution. It starts with establishing a comprehensive brand style guide.

- Brand Style Guide: This crucial document dictates all aspects of your brand’s visual identity, including logo usage (versions for different applications), font selection (primary, secondary, and tertiary fonts), color palettes (CMYK and RGB values), and image styles (photography, illustration).

- Centralized Asset Management: All brand assets – logos, fonts, color palettes, approved imagery – should be stored in a central location, readily accessible to all designers and stakeholders. This prevents the use of outdated or inconsistent versions.

- Template Creation: Using pre-designed templates for both print (brochures, business cards) and digital (email newsletters, website banners) ensures consistency in layout, typography, and branding elements.

- Proofing and Approvals: A rigorous proofing process involving multiple checks is crucial to catch discrepancies before materials go to print or are published online.

For example, imagine a company with a specific shade of blue in its logo. The style guide would specify the exact CMYK and RGB values for this blue. Every piece of marketing material, whether a printed brochure or a digital banner, must use this precise color to maintain visual consistency and brand recognition.

Q 17. How do you manage version control in a print/digital project?

Version control in print and digital projects is critical to prevent chaos and ensure everyone is working with the most up-to-date files. This is typically managed using version control systems.

- Version Control Systems (VCS): Tools like Git (for digital projects) offer robust version control. For print projects, a well-organized file naming convention (e.g., ‘brochure_v1_final.indd’) is often employed along with a shared cloud storage system to track changes.

- Naming Conventions: Adopting a consistent file-naming system (e.g., Project Name_Version Number_Date_Description) provides clarity and allows easy identification of different versions.

- Cloud-Based Storage: Using cloud storage (like Dropbox, Google Drive, or specialized solutions) facilitates collaboration and allows multiple users to access and work on files simultaneously. Changes are easily tracked.

- Proofing and Approval Workflow: Documenting changes, approvals, and rejections using version control helps track the journey of the project and prevents confusion.

In practice, this might involve saving each significant revision of a design file with an incremental version number. If an error is made in version 3, you can easily revert back to version 2 without losing progress. This is essential for collaborative projects with multiple designers or stakeholders.

Q 18. Describe your experience with print vendor management.

Print vendor management involves more than just sending files to a printer. It requires careful planning, communication, and quality control throughout the entire process.

- Vendor Selection: Choosing the right printer depends on factors like print volume, required quality, turnaround time, and budget. This often involves requesting quotes and samples from multiple vendors.

- Pre-press Communication: Clear communication is key. Provide the printer with detailed specifications, including color profiles, paper stock, finishing requirements, and quantities. Confirming these details in writing avoids costly mistakes.

- Proofing and Approvals: Always request proofs (digital or physical) before proceeding with large print runs. This allows for catching potential errors early on, saving both time and money.

- Quality Control: Inspecting the final print products carefully upon delivery is crucial to ensure that the output matches the approved proofs and meets the required quality standards.

- Relationship Building: Maintaining strong relationships with reliable printers leads to smoother workflows, quicker turnaround times, and better support.

For example, I’ve managed print projects by working closely with a printer to ensure that the color profile used (e.g., US Web Coated (SWOP) v2) produces the intended results. This involved sending them color calibration data and having them review proofs before proceeding to a large print run.

Q 19. What are some common challenges in print and digital production?

Print and digital production present unique challenges. Some common ones include:

- Color Management: Achieving accurate color consistency across different devices and printing processes remains a persistent challenge. Even with careful profile management, slight variations can occur.

- File Compatibility: Dealing with various file formats and ensuring compatibility across software and devices can be time-consuming and lead to errors.

- Deadlines and Time Constraints: Meeting tight deadlines in a fast-paced environment often requires careful planning and prioritization.

- Client Revisions: Managing and incorporating numerous client revisions while maintaining project timelines and budget can be stressful.

- Software Glitches and Technical Issues: Unexpected software crashes or technical problems can disrupt the workflow and delay production.

- Print Defects: Issues like color inconsistencies, misregistration (colors not aligning perfectly), or damaged prints can occur and need to be addressed efficiently.

For instance, I once encountered a situation where a client’s last-minute revisions resulted in a tight turnaround time. We had to quickly adapt, prioritize tasks, and leverage our team’s expertise to meet the deadline without compromising quality.

Q 20. How do you prioritize tasks in a fast-paced production environment?

Prioritizing tasks in a fast-paced production environment is crucial. I typically use a combination of techniques:

- Project Management Software: Using tools like Asana, Trello, or Jira allows for effective task assignment, tracking progress, and setting deadlines. This provides a visual overview of tasks and dependencies.

- Prioritization Matrices: Using methods like the Eisenhower Matrix (urgent/important) helps classify and prioritize tasks based on their urgency and importance.

- Time Blocking: Allocating specific time blocks for particular tasks helps maintain focus and prevents multitasking.

- Communication and Collaboration: Open communication with team members and clients is crucial for anticipating potential delays and adjusting priorities as needed.

Imagine a scenario with multiple projects with looming deadlines. Using a project management tool, I’d identify the most critical tasks (those with the closest deadlines and biggest impact) and allocate resources accordingly. Time blocking ensures dedicated time for each high-priority task, reducing distractions and increasing efficiency.

Q 21. How familiar are you with PDF workflows in print production?

PDF workflows are integral to modern print production. I’m highly familiar with them, understanding their importance in ensuring accurate and consistent output.

- Creating Press-Ready PDFs: I’m proficient in creating PDFs that meet the specific requirements of various printing methods, including the correct color space (CMYK), bleed settings, and appropriate resolution.

- PDF/X Standards: I have experience working with various PDF/X standards (like PDF/X-1a, PDF/X-4), which are crucial for ensuring color accuracy and preventing issues during the prepress stage.

- Preflight Checks: I conduct thorough preflight checks to identify and resolve any potential problems (missing fonts, images with low resolution) before sending the files to the printer.

- Digital Proofs: I use PDF proofs for client review and approval, minimizing misunderstandings and ensuring the final printed output aligns with expectations.

For example, creating a press-ready PDF for a large-format print project would involve setting up appropriate bleed margins, embedding fonts, ensuring high-resolution images, and selecting the correct PDF/X standard. This process helps to prevent costly errors during the printing process.

Q 22. Explain your experience with variable data printing.

Variable data printing (VDP) is a powerful technique that allows for personalized content on each printed piece, even within a single print run. Imagine printing thousands of postcards, each addressed to a different recipient with a unique message tailored to their interests. That’s VDP in action. My experience encompasses the entire process, from designing personalized templates using software like Adobe InDesign and integrating data sources like customer databases or CRM systems, to managing the print workflow and ensuring accurate and efficient output.

I’ve worked extensively with different VDP applications, including personalized marketing materials like brochures and direct mail pieces, customized product packaging, and even transactional documents such as personalized invoices and statements. In one project, I managed a campaign involving over 50,000 personalized postcards, each featuring a unique image and personalized message based on the recipient’s purchase history. This required meticulous data management and careful attention to detail to ensure accuracy and avoid errors. I have expertise in handling different data formats, including CSV, XML, and database connections, to ensure seamless data integration into the printing process.

Moreover, I understand the importance of testing and quality assurance in VDP projects. We conduct rigorous proofing and validation steps at each stage to catch potential errors and ensure the final output meets the client’s expectations. This often involves creating test prints with different data sets to identify and rectify any issues before proceeding with the full print run.

Q 23. What is your experience with digital asset management systems (DAM)?

Digital Asset Management (DAM) systems are crucial for organizing, storing, and retrieving digital files efficiently. Think of it as a highly organized library for all your digital assets, including images, videos, documents, and audio files. My experience includes working with various DAM systems, both cloud-based and on-premise solutions.

I’m proficient in using DAM systems to manage large volumes of assets, ensuring easy access for authorized users. This includes implementing metadata tagging and keywording for efficient searching and retrieval. In one project, I managed a DAM system containing over 100,000 high-resolution images, ensuring the right assets were readily available for marketing teams and designers across multiple locations. This required creating a well-defined metadata schema, implementing user permissions, and regularly auditing the system to maintain its integrity and performance.

Furthermore, I understand the importance of version control within a DAM system. This ensures that the latest version of an asset is always available, while maintaining a record of past revisions for reference or rollback if necessary. The use of a DAM greatly streamlined our workflow, improving collaboration and reducing the time spent searching for assets.

Q 24. Describe your experience with imposition and platemaking.

Imposition is the process of arranging pages on a printing sheet to optimize printing efficiency, while platemaking is the creation of printing plates used in offset printing. My experience spans both prepress and press processes, from creating imposition layouts using software like Esko ArtiosCAD to working with platemaking equipment to create high-quality printing plates.

I’m skilled in different imposition techniques, including gang printing (printing multiple jobs on a single sheet), perfect binding imposition, and saddle stitch imposition. The choice of imposition depends on the project’s specifications, including the page count, paper size, and binding type. For example, a booklet requires a different imposition layout compared to a leaflet or a poster. I meticulously check imposition layouts to avoid errors and ensure that pages are in the correct sequence and orientation.

My platemaking experience includes working with both conventional and computer-to-plate (CTP) systems. CTP significantly improved efficiency and precision in the platemaking process, reducing turnaround time and minimizing errors. I’m familiar with various plate types and their respective properties, and I select the most appropriate plate type based on the job’s requirements and the printing press’s capabilities. Proper platemaking ensures sharp images and consistent color reproduction.

Q 25. How do you ensure accessibility in your digital designs?

Accessibility in digital design is crucial to ensure that content is usable by everyone, including individuals with disabilities. I incorporate accessibility best practices into all my designs, ensuring that they meet WCAG (Web Content Accessibility Guidelines) standards. This involves careful consideration of several factors:

- Color Contrast: Using sufficient contrast between text and background colors to ensure readability for people with low vision.

- Alternative Text for Images: Providing descriptive alternative text (alt text) for images to convey their meaning to users who cannot see them.

- Keyboard Navigation: Designing interfaces that are fully navigable using only a keyboard, allowing users with motor impairments to interact with the content.

- Screen Reader Compatibility: Ensuring that the design’s structure and content are correctly interpreted by screen readers, assisting visually impaired users.

- Font Size and Style: Using legible fonts and ensuring that text size can be easily adjusted.

For example, when designing a website, I carefully choose color combinations that meet the required contrast ratios, and I ensure that all images have descriptive alt text. This meticulous attention to detail ensures that everyone can easily access and understand the information presented. I utilize tools and validators to verify adherence to WCAG guidelines, and I continually update my knowledge of accessibility best practices to stay ahead of industry standards.

Q 26. What are your experiences with different printing techniques (e.g., screen printing, flexography)?

My experience encompasses a variety of printing techniques, each with its own unique characteristics and applications. Let’s explore a few:

- Screen Printing: A versatile method ideal for creating vibrant designs on various substrates, including apparel, posters, and signage. I have experience in setting up screens, mixing inks, and achieving consistent print quality. It’s perfect for detailed artwork and limited edition runs.

- Flexography: A cost-effective technique for high-volume printing, often used for packaging and labels. It’s known for its speed and ability to print on flexible materials. I’ve worked with flexographic presses, understanding the intricacies of plate mounting, ink selection, and press adjustments for optimal results. The process demands careful consideration of ink viscosity and pressure for accurate printing on various substrates.

- Offset Lithography: The workhorse of commercial printing, offering high-quality results for large-scale projects. I understand the principles of offset printing, including platemaking, color management, and press operation. This is the method I’ve used most frequently for brochures, magazines, and other high-volume print projects.

Understanding the strengths and limitations of each technique allows me to choose the most appropriate method for a particular project, considering factors like print quality, budget, quantity, and substrate. For example, screen printing is excellent for unique, high-quality designs on T-shirts, while flexography is more suitable for large-scale packaging projects.

Q 27. How do you stay current with the latest trends in print and digital production?

Staying current in the dynamic world of print and digital production requires continuous learning and engagement. I employ several strategies to stay informed:

- Industry Publications and Websites: I regularly read trade publications and online resources, such as Print Magazine, WhatTheyThink, and industry blogs, to stay abreast of technological advancements, design trends, and industry news.

- Conferences and Workshops: Attending industry events provides opportunities to network with peers and learn from experts about the latest technologies and best practices.

- Professional Organizations: Membership in relevant professional organizations, such as associations focused on graphic design or printing technologies, provides access to resources, networking opportunities, and educational materials.

- Online Courses and Tutorials: I actively pursue online courses and tutorials to enhance my skills in specific software applications or printing techniques. This allows for continuous skill development and expansion of my knowledge base.

- Experimentation and Hands-on Experience: I actively seek opportunities to experiment with new technologies and processes. This practical experience complements theoretical learning and fosters innovation.

This multi-faceted approach ensures I’m equipped to leverage the latest technologies and best practices to provide optimal solutions for my clients, always staying ahead of the curve in this ever-evolving field.

Key Topics to Learn for Print and Digital Production Knowledge Interview

- Pre-press Preparation: Understanding file formats (PDF, TIFF, JPEG, etc.), color profiles (CMYK, RGB), image resolution, and bleed/trim settings. Practical application: Troubleshooting file issues to ensure print quality and efficiency.

- Print Production Processes: Familiarity with different printing methods (offset, digital, large format), binding techniques, and finishing options (lamination, embossing, etc.). Practical application: Selecting the optimal printing method and finishing for a specific project based on budget, quantity, and desired outcome.

- Digital Production Workflow: Knowledge of digital asset management, workflow automation tools, and version control systems. Practical application: Streamlining the digital production process for faster turnaround times and reduced errors.

- Color Management: Understanding color spaces, color correction techniques, and proofing methods to ensure consistent color reproduction across different mediums. Practical application: Solving color discrepancies between digital and print outputs.

- Print and Digital Quality Control: Identifying and resolving common print and digital production issues, such as banding, moiré patterns, and pixelation. Practical application: Implementing quality control measures to guarantee high-quality final products.

- File Optimization: Techniques for optimizing image and file sizes for web and print to ensure efficient delivery and reduced storage space. Practical application: Balancing image quality with file size for optimal web performance and print quality.

- Software Proficiency: Demonstrated skills in relevant software such as Adobe Creative Suite (Photoshop, Illustrator, InDesign), Acrobat Pro, and potentially other digital asset management or workflow software. Practical application: Efficiently creating and preparing files for print and digital channels.

- Print and Digital Finishing Techniques: Understanding various finishing techniques such as die-cutting, folding, perforating, and binding, as well as digital finishing options like animation and interactive elements. Practical application: Specifying and managing the finishing process for a project, maximizing visual appeal and functionality.

Next Steps

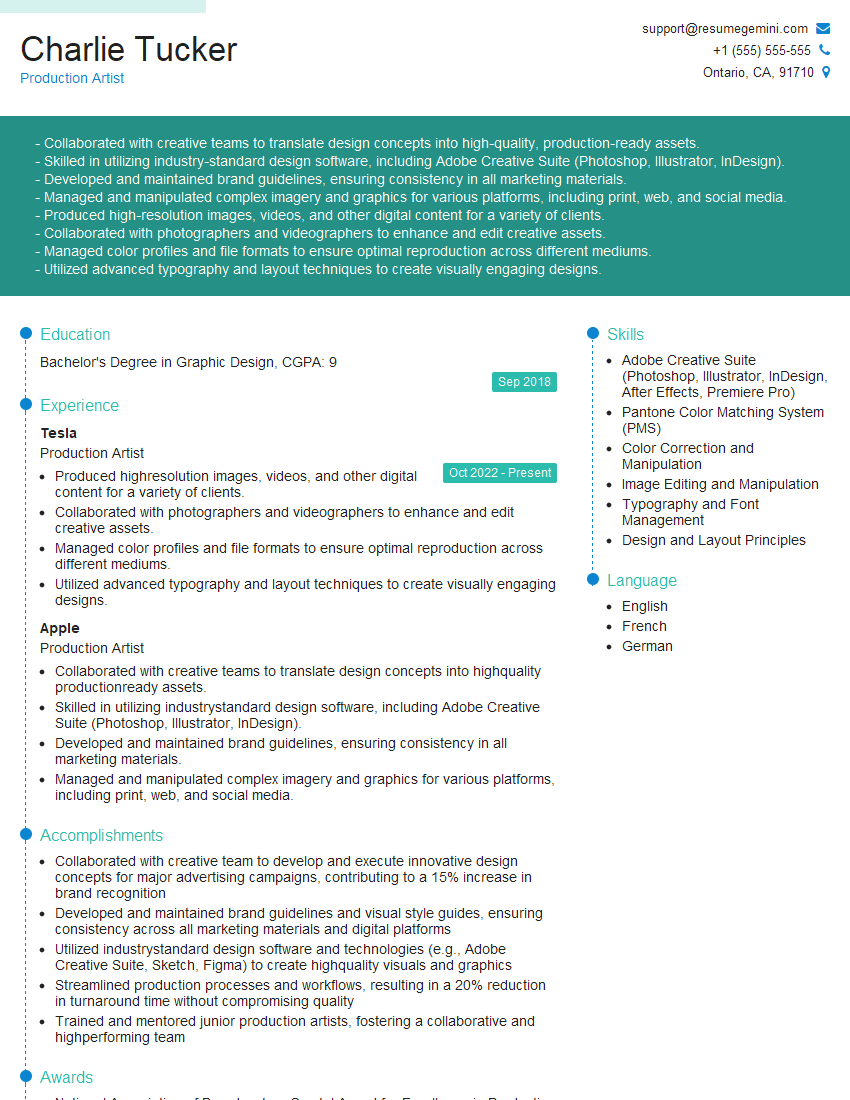

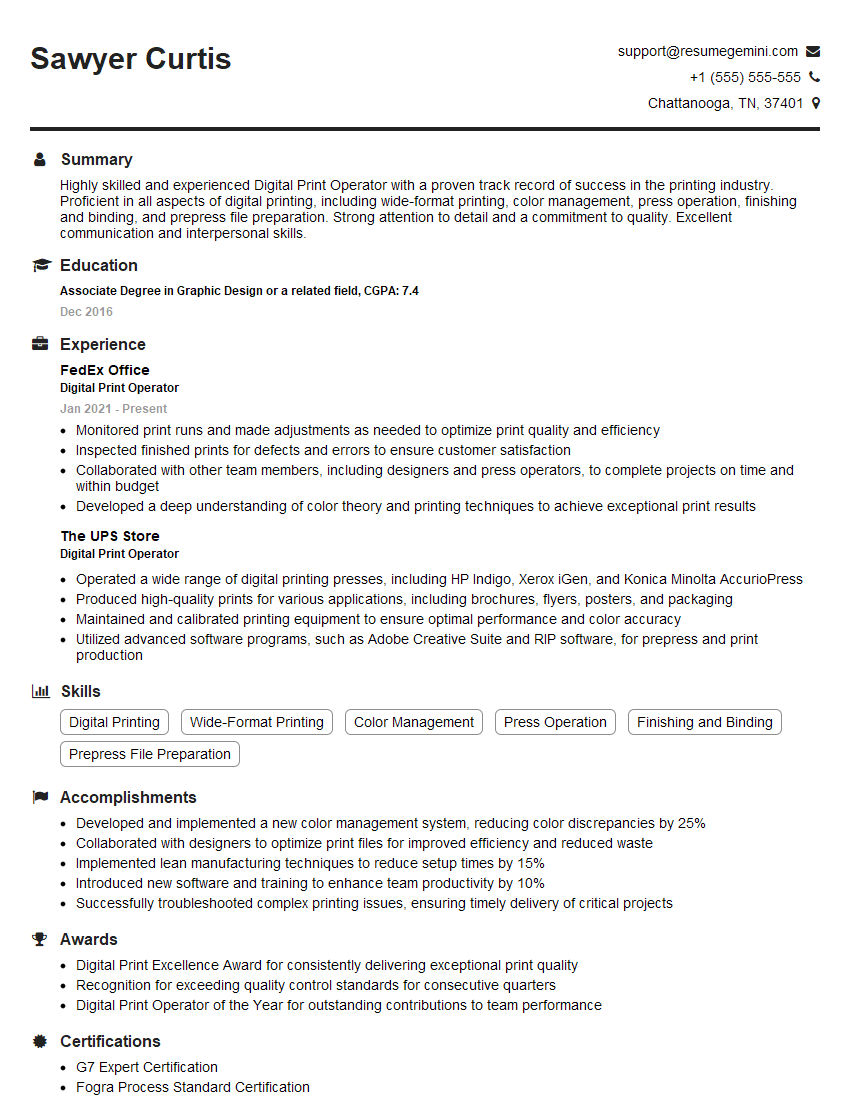

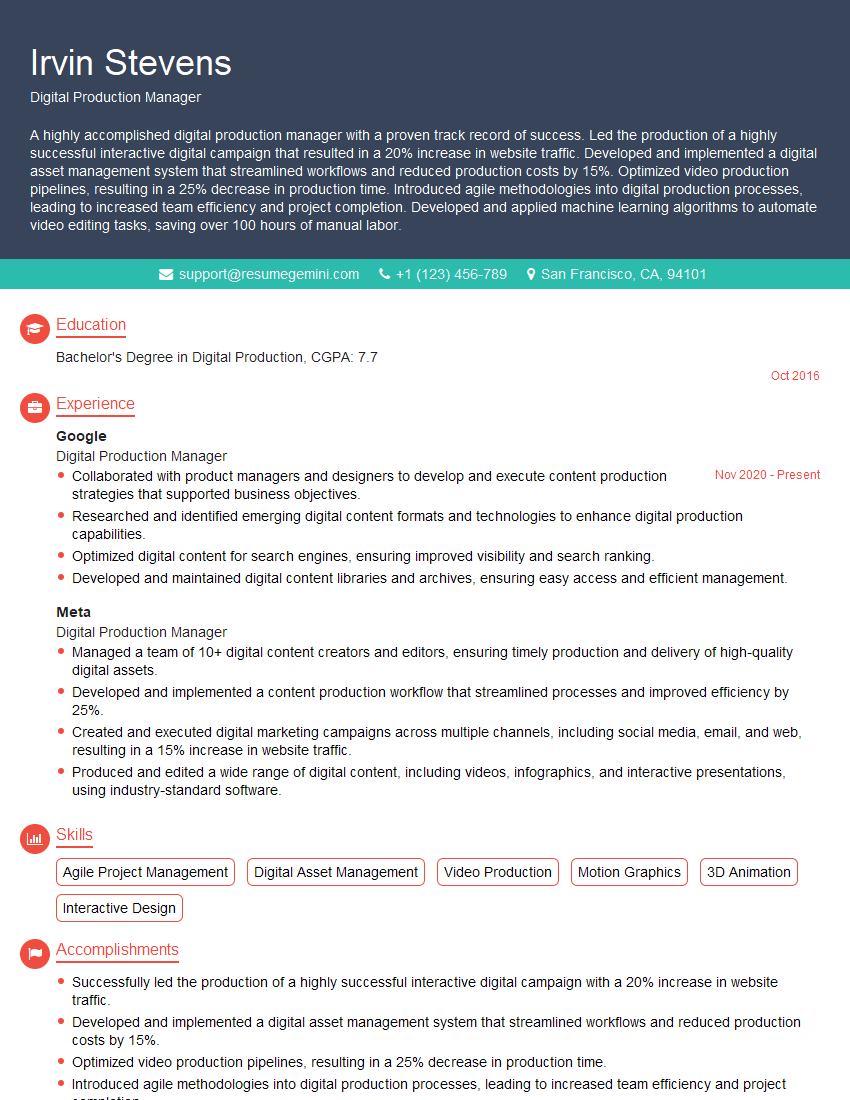

Mastering print and digital production knowledge is crucial for career advancement in this dynamic field. A strong understanding of these processes allows you to contribute effectively to project success, troubleshoot issues efficiently, and demonstrate your expertise to potential employers. To significantly improve your job prospects, focus on creating an ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume, ensuring your qualifications stand out. Examples of resumes tailored to print and digital production knowledge are available to further guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good