Feeling uncertain about what to expect in your upcoming interview? We’ve got you covered! This blog highlights the most important Print Production and File Management interview questions and provides actionable advice to help you stand out as the ideal candidate. Let’s pave the way for your success.

Questions Asked in Print Production and File Management Interview

Q 1. Explain the difference between CMYK and RGB color spaces.

CMYK and RGB are two different color models used to represent colors digitally. RGB (Red, Green, Blue) is an additive color model, meaning colors are created by adding light. It’s used for screens, like computer monitors and televisions. Think of shining a red, green, and blue flashlight onto a white wall; the overlapping areas create other colors. CMYK (Cyan, Magenta, Yellow, Key – black) is a subtractive color model used for printing. It works by subtracting light from a white surface. Ink is applied to paper, and the colors mix to create the final image. The key difference is their application: RGB for light emission, CMYK for ink absorption.

For example, pure white in RGB is (255, 255, 255), representing the maximum intensity of red, green, and blue light. In CMYK, pure white is (0, 0, 0, 0), representing no ink. Similarly, pure black in RGB is (0, 0, 0), while in CMYK it’s typically (0, 0, 0, 100), using black ink for a deeper, more accurate black. Converting between these color spaces requires careful consideration to avoid color shifts, and proper color management profiles are crucial to ensure accuracy.

Q 2. Describe your experience with various print finishing techniques.

My experience with print finishing techniques is extensive, encompassing a wide range of processes. I’ve worked with various binding methods such as saddle stitch (perfect for brochures), perfect binding (ideal for books), wire-o binding (for notebooks), and case binding (for high-end books). I’m also proficient in various paper finishing techniques, including die-cutting (creating custom shapes), embossing/debossing (adding texture), foil stamping (applying metallic accents), and UV coating (providing a protective glossy finish).

I’ve been involved in projects requiring sophisticated finishing such as lamination (matt or gloss), and spot UV coating (selective gloss application for highlighting specific areas). One memorable project involved creating a unique textured business card using a combination of embossing and a custom-designed die-cut. Understanding the capabilities and limitations of each finishing technique is crucial to achieving the desired aesthetic and functionality for a project. I always consult with the client to ascertain their needs and the budget constraints before selecting the appropriate techniques.

Q 3. What file formats are best suited for print production?

For print production, the best file formats are generally those that preserve vector information (for text and graphics) and high-resolution raster images (for photographs).

- PDF (Portable Document Format): This is the industry standard. It’s universally compatible and preserves vector and raster data, including embedded fonts and color profiles. Using a press-ready PDF with all necessary elements reduces errors.

- TIFF (Tagged Image File Format): Excellent for high-resolution images, especially photographs. It supports various color spaces (CMYK is preferred for print) and compression options. Lossless compression retains image quality.

- EPS (Encapsulated PostScript): Suitable for vector-based illustrations and logos. It preserves vector information well.

Avoid using formats like JPEG for print production as compression introduces artifacts that become apparent at high resolutions.

Q 4. How do you ensure color accuracy in print projects?

Ensuring color accuracy is paramount in print production. This involves a multi-step process:

- Color Profile Management: Using the correct color profiles (ICC profiles) for both the monitor and the printing press is critical. These profiles translate colors between devices accurately.

- Proofing: Soft proofs (on-screen previews) are useful but not foolproof. Hard proofs, such as color-managed print proofs from a professional printer, provide a much more accurate representation of the final product.

- Communication: Clear communication with the printer is vital. Providing detailed instructions and color specifications prevents misunderstandings.

- Calibration: Regularly calibrating your monitor to industry standards (e.g., using a colorimeter) ensures that on-screen colors closely match reality.

- Color Standards: Using industry-standard color systems like Pantone for specific colors guarantees consistency across different print runs.

For example, in a recent project involving a corporate brochure with specific brand colors, I ensured that the Pantone color references were accurately implemented in the design and confirmed with the printer using a calibrated proof. This prevented any discrepancies and ensured that the final print matched the client’s brand identity precisely.

Q 5. What is your experience with color profiles and their management?

Color profiles (ICC profiles) are crucial for consistent color reproduction across different devices. My experience encompasses creating, assigning, and managing these profiles. I understand that each device (monitor, scanner, printer) has a unique color space and response curve. A color profile acts as a translator, mapping colors between these different spaces. Incorrect profile management can lead to significant color shifts, which is why I always ensure that the correct profiles are embedded in the files sent to the print house. I also often work with printers to ensure the use of compatible profiles to achieve the highest level of color accuracy. If discrepancies appear, I use profiling tools and communication to resolve inconsistencies.

For instance, I’ve encountered situations where a client’s monitor wasn’t calibrated, leading to inaccurate color perception. By providing them with guidelines on monitor calibration and using soft proofs that consider the printer’s profile, we were able to reach a mutual understanding and achieve the intended color representation in the final print.

Q 6. Explain your workflow for preparing files for offset printing.

My workflow for preparing files for offset printing follows a meticulous process:

- Design and File Preparation: I ensure all images are high-resolution (at least 300 DPI) and in the CMYK color space. All fonts are outlined to avoid font substitution issues. Images are properly sized and positioned according to the print specifications.

- Preflighting: I perform a thorough preflight check using dedicated software to identify and correct potential problems (missing fonts, low-resolution images, color space inconsistencies, etc.).

- Imposition: The pages are arranged for efficient printing on the press sheets, following the printer’s specifications (e.g., imposition settings for a 4-color press). This may involve using imposition software.

- Color Management: I embed the correct ICC profiles, specifying the intended output color space.

- File Packaging: All necessary files (images, fonts, and the final PDF) are carefully packaged and organized in a clearly labeled folder for delivery to the printer.

- Communication: Clear communication with the printer is vital throughout the process to ensure that they understand the specifications, and to address any questions or potential issues.

This structured workflow minimizes errors and ensures a smooth and efficient printing process. Regularly reviewing this workflow helps me refine my approach and learn from any issues encountered to improve future projects.

Q 7. How do you handle preflighting and quality control of print files?

Preflighting and quality control are integral parts of my workflow. I use dedicated preflighting software to automatically check files for common issues such as:

- Missing fonts: The preflight will flag any missing or incorrect fonts.

- Low-resolution images: Images below 300 DPI are identified and flagged for replacement.

- Color space inconsistencies: The software checks for RGB images instead of CMYK.

- Overprint issues: It checks if elements are set to overprint that shouldn’t be, which can lead to unexpected color mixing.

- Bleed and margins: Checks if images extend past the trim marks (bleed) and are within the safe margin.

Beyond automated checks, I also manually review the final files to ensure that everything is exactly as designed and ready for print. This might include checking for any spelling or grammatical errors, ensuring image quality meets the standards, and verifying the overall design adheres to the client’s requirements. A combination of automated and manual quality control steps significantly improves the quality of the final product and reduces the chance of costly printing mistakes.

Q 8. Describe your experience with different types of printing presses.

My experience encompasses a wide range of printing presses, from traditional offset lithography to modern digital printing technologies. Offset presses, the workhorses of large-scale commercial printing, utilize plates to transfer ink onto a rubber blanket and then onto the paper. I’ve worked extensively with perfecting presses, capable of printing on both sides of the sheet simultaneously, increasing efficiency. I’m also proficient with sheet-fed presses, ideal for shorter runs and various paper sizes, and web offset presses, suited for high-volume printing of newspapers and magazines. In the digital realm, I’ve operated high-volume inkjet printers and toner-based digital presses, perfect for personalized marketing materials or on-demand printing. Each press type has its own strengths and weaknesses; choosing the right one depends heavily on factors like print volume, desired quality, and budget.

For example, I once managed a project requiring a large number of high-quality brochures. While digital printing would have been faster for smaller batches, the volume justified the use of a sheet-fed offset press, ensuring consistent color and a lower per-unit cost. Conversely, for a time-sensitive, personalized direct mail campaign, high-speed inkjet printing was the clear choice.

Q 9. How do you manage large volumes of print files efficiently?

Managing large volumes of print files efficiently requires a structured approach. This starts with a robust file naming convention – consistently using client names, project codes, and file types (e.g., ClientA_ProjectX_Final.pdf). Next, I leverage a digital asset management (DAM) system to organize files, allowing for easy retrieval and version control. Cloud storage, integrated with the DAM, provides redundancy and accessibility. Workflow automation tools play a crucial role, automating tasks like pre-flight checks and file conversion. Finally, regular backups are essential – both local and offsite – to protect against data loss.

Imagine managing 1000+ files for a large-scale event. Without a systematic approach, locating the correct version of a file would be a nightmare. My system allows me to find the ‘ClientB_EventY_Poster_v3.pdf’ instantly.

Q 10. What software do you use for print file preparation and management?

My expertise extends to various software applications crucial for print file preparation and management. Adobe Creative Suite (InDesign, Photoshop, Illustrator) is fundamental for designing and preparing print-ready files. I use pre-flight tools such as PitStop Pro to thoroughly check files for errors, ensuring color profiles, bleeds, and resolution are correct before sending them to the press. For efficient file management and collaboration, I’m adept at using cloud-based storage platforms like Dropbox and Google Drive, and DAM systems like Canto or Bynder. Furthermore, I utilize imposition software, such as imposition software from companies like Heidelberg, to arrange pages efficiently on printing sheets before sending to the press. This minimizes paper waste and maximizes efficiency.

Q 11. How do you troubleshoot common print-related issues?

Troubleshooting print-related issues requires a systematic approach. I start by identifying the problem: is it a design flaw, a software glitch, a press malfunction, or a problem with the paper stock? I check for common issues like incorrect color profiles, insufficient resolution, missing or incorrect bleeds, font issues, or file corruption. Tools like pre-flight software help identify these problems early. If the issue is press-related, I’ll collaborate with the press operator to determine the cause, which could range from incorrect ink settings to a mechanical problem with the press itself. I meticulously document each step of the troubleshooting process, ensuring issues are resolved efficiently and can be avoided in future projects. It’s a process of careful observation, testing, and collaboration.

For example, if I see banding in a print job, I might first investigate the paper stock for inconsistencies, then check the press’s ink density settings before examining the design file for potential issues with color gradients or image resolution.

Q 12. Explain your understanding of imposition and its importance in printing.

Imposition is the process of arranging pages of a document in the correct order and orientation on printing sheets before they are sent to the press. It’s crucial for efficiency and minimizing waste. Think of it like a puzzle: imposition software arranges the individual pieces (pages) to create complete sheets that, when printed, can be folded, bound, and trimmed into the final product. This is especially vital for multi-page documents like brochures, books, and magazines. Incorrect imposition results in pages being out of order or missing, leading to costly reprints.

For instance, a 24-page brochure might require careful imposition to ensure that when the printed sheets are folded and trimmed, the pages fall in the correct sequence. Specialized software handles this complex arrangement, significantly simplifying the process and improving efficiency.

Q 13. How familiar are you with different types of paper stocks and their uses?

My familiarity with paper stocks is extensive. I understand the properties of various types, including coated and uncoated papers, their weight (basis weight), texture (e.g., smooth, textured), and finish (e.g., gloss, matte). Coated papers offer vibrant color reproduction, suitable for high-impact projects like brochures and magazines, whereas uncoated papers provide a more natural look and feel, ideal for stationery or letterheads. I also have experience with specialty stocks like recycled paper, textured papers, and metallic papers, each with unique properties impacting the final product’s appearance and feel. Selecting the appropriate paper stock is critical; it influences both the aesthetic appeal and the longevity of the printed piece. Choosing the wrong paper for a project can significantly impact the final outcome, both aesthetically and functionally.

For example, a luxury invitation would benefit from a thick, high-quality textured paper stock, while a high-volume flyer might utilize a more economical uncoated paper.

Q 14. Describe your experience with managing print projects from start to finish.

Managing print projects from start to finish involves a structured, multi-stage process. It begins with a thorough understanding of the client’s needs – their vision, budget, and deadlines. I then work with the design team to create print-ready files, ensuring they meet the required specifications. This involves selecting the appropriate printing method, paper stock, and finishing options. Next, I oversee the pre-press stage, including file preparation, color management, and imposition. I then monitor the printing process, ensuring quality control throughout. Finally, I oversee post-press activities like finishing (folding, binding, cutting) and delivery. Throughout the process, clear communication with clients and the printing team is paramount. Successful project management relies on meticulous planning, proactive problem-solving, and a strong focus on quality and efficiency.

In a recent project for a major conference, I successfully managed the design, printing, and distribution of thousands of promotional materials, meeting tight deadlines and delivering high-quality results within budget. The process involved meticulous planning, close communication with multiple stakeholders and effective use of project management tools.

Q 15. What is your experience with die-cutting and other finishing techniques?

Die-cutting is a crucial finishing technique in print production where a sharp steel rule die is used to cut shapes, patterns, or perforations into paper, board, or other substrates. My experience encompasses a wide range of die-cutting applications, from simple shapes to intricate designs requiring multiple layers and precise registration. I’ve worked with various die-cutting machines, including flatbed and rotary, and understand the importance of accurate die construction and proper material selection for optimal results. Beyond die-cutting, I’m proficient in other finishing techniques such as embossing (creating raised or indented designs), debossing (the reverse of embossing), foil stamping (applying metallic or colored foil to enhance a design), and varnishing (applying a protective or aesthetic coating). I’ve managed projects involving complex combinations of these techniques, ensuring seamless integration to achieve the desired visual and tactile effects.

For instance, on a recent project for a luxury packaging company, we used a combination of die-cutting, foil stamping, and embossing to create intricate, high-end packaging for a premium chocolate brand. The precision required for the foil stamping to align perfectly with the die-cut shapes and embossed details was crucial for the product’s success. Careful planning and collaboration with the die-maker were key to achieving the desired outcome.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle revisions and changes to print projects?

Handling revisions and changes is a standard part of print production, and I have a systematic approach to managing them effectively. My process begins with clear communication; I ensure all changes are documented, ideally via a formal change request form, specifying the nature of the change, its impact on the schedule and budget, and any necessary approvals. Using a version control system for files is vital. This allows for easy tracking of revisions and a clear audit trail. I use descriptive file naming conventions (e.g., Project_Name_v2_Final.pdf) to avoid confusion. For complex projects, I might utilize collaborative platforms to share changes and comments in real time, ensuring transparency among all stakeholders. Any changes impacting the print process are meticulously assessed to ensure feasibility and minimize delays. If necessary, I’ll provide revised estimates and timelines to reflect the adjustments.

A recent project involved multiple design revisions. We used a collaborative online platform to manage the changes, enabling clients to review and approve revisions quickly. This ensured transparency and reduced the risk of miscommunication.

Q 17. Explain your experience with print estimating and cost analysis.

Print estimating and cost analysis are critical for profitability and accurate client communication. My experience includes detailed cost breakdowns considering various factors such as paper type and quantity, ink costs (spot vs. process color), printing method (offset, digital, etc.), finishing options (die-cutting, lamination, binding), and labor. I utilize specialized estimating software to streamline this process and ensure accuracy. I’m adept at analyzing different pricing models and identifying the most cost-effective approach without compromising quality. I also factor in potential risks and contingencies, building a buffer into the estimate to account for unforeseen circumstances. My process involves careful analysis of the project specifications, obtaining accurate quotes from vendors, and presenting a clear, transparent cost breakdown to the client.

For example, when estimating a large-scale offset printing project, I meticulously calculated costs based on the paper weight, quantity, number of colors, and finishing requirements. I compared quotes from multiple vendors to ensure the best price while maintaining quality standards.

Q 18. How do you maintain accurate records of print production and files?

Maintaining accurate records is paramount in print production. I employ a combination of digital and physical record-keeping methods. All project files are stored in a structured digital asset management system (DAM) with appropriate metadata (client name, project name, file type, date, version number). The DAM system allows for easy searching, retrieval, and version control. Physical records, such as purchase orders, invoices, and production reports, are stored in a secure, organized physical archive. I regularly back up both digital and physical records to prevent data loss. I use a robust project management software to track project milestones, timelines, costs, and communication throughout the entire production lifecycle. This system ensures a complete and auditable record of every print project.

This robust system allows me to quickly locate any file or document needed, ensuring efficient project management and minimizing the risk of errors.

Q 19. How familiar are you with different print workflows (e.g., JDF)?

I’m familiar with various print workflows, including JDF (Job Definition Format), which is a standardized XML-based language for describing print jobs. JDF allows for seamless communication and data exchange between different systems in the print production process, from prepress to press to postpress. Understanding JDF and other workflow technologies (like PDF/X standards) allows for automation, improving efficiency and reducing errors. I have experience working with prepress systems that integrate with JDF, facilitating automated job submissions and tracking. I also understand the importance of utilizing workflows that adhere to industry best practices to ensure consistency and quality control throughout the process. This includes understanding different color management systems and ensuring color consistency across various stages of production.

In a previous role, we implemented a JDF-based workflow which significantly streamlined our production process, reducing turnaround times and improving overall efficiency.

Q 20. What is your experience with MIS (Management Information Systems) in print?

My experience with MIS (Management Information Systems) in print involves utilizing software solutions to manage various aspects of the print business, including estimating, job tracking, production scheduling, inventory management, and financial reporting. These systems provide crucial data for decision-making and business intelligence. I’m proficient in using MIS systems to track key performance indicators (KPIs), analyze production efficiency, and identify areas for improvement. This includes generating reports on production costs, profitability, and customer satisfaction. I understand the importance of data integrity and accurate record-keeping within the MIS system to ensure reliable data analysis.

For example, in a previous position, I used an MIS system to track production times, identify bottlenecks, and optimize workflow processes, resulting in a 15% increase in production efficiency.

Q 21. How do you prioritize tasks and manage deadlines in a high-pressure environment?

Prioritizing tasks and managing deadlines in a high-pressure environment requires a structured approach. I utilize project management methodologies such as Kanban or Agile to visualize workflow, track progress, and identify potential bottlenecks. I begin by breaking down large projects into smaller, manageable tasks, assigning priorities based on urgency, dependencies, and impact. I use project management software to track deadlines, assign responsibilities, and monitor progress. Regular communication with team members and clients is crucial to keep everyone informed and aligned. Proactive risk management is essential; I identify potential problems early and develop contingency plans to mitigate disruptions. In high-pressure situations, adaptability and flexibility are paramount; I’m prepared to adjust priorities as needed based on evolving circumstances.

I often use a prioritized task list and a project timeline to visually track progress and ensure all deadlines are met, even amidst competing priorities. Clear communication with my team and clients ensures everyone is aware of any potential challenges and allows for collaborative problem-solving.

Q 22. Describe your experience with automated print workflows.

Automated print workflows are the backbone of efficient and high-volume print production. They streamline the entire process, from file submission to final output, minimizing manual intervention and human error. My experience encompasses implementing and managing systems that automate tasks such as preflighting, imposition, color management, and job ticketing. This involves using software like PitStop Pro for preflighting, imposition software like Impose or Enfocus Switch, and workflow automation tools like MIS (Management Information Systems) like PrintSmith or Thar.

For example, in a previous role, we implemented a fully automated workflow for our direct mail campaigns. This involved integrating our CRM with our print MIS, automatically generating print-ready files based on customer data, sending those files to our prepress system for automated checks, and finally triggering the print job on our digital presses. This reduced turnaround time by 50% and significantly minimized errors.

Another example involves the use of JDF (Job Definition Format) and JMF (Job Messaging Format) based workflows. These standardized formats allow seamless communication between different software and hardware components in the print production process, enabling complete automation of complex jobs.

Q 23. How do you ensure the security and integrity of print files?

Security and integrity of print files are paramount, especially when dealing with sensitive information. My approach involves a multi-layered strategy. This begins with secure file transfer protocols like SFTP (Secure File Transfer Protocol) to prevent unauthorized access during transmission. Once received, files are stored in secure network locations with access control lists (ACLs) limiting access only to authorized personnel. Regular backups are crucial; we typically use a 3-2-1 backup strategy (3 copies on 2 different media, with 1 offsite).

Watermarking sensitive files before sending them to external vendors is another tactic. Furthermore, we meticulously track all file versions and changes using version control systems, ensuring accountability and allowing for easy rollback if necessary. Finally, implementing robust access controls and regular security audits help prevent data breaches and maintain the integrity of our print files. Think of it like a bank vault – multiple layers of protection to prevent unauthorized access.

Q 24. Explain your experience with different types of printing processes.

My experience spans a wide range of printing processes, encompassing both digital and offset printing methods. In digital printing, I’m proficient with various technologies including inkjet, toner-based printers (like Xerox and HP Indigo presses), and large-format inkjet printers used for banners and signage. I understand the intricacies of each technology, including its strengths, weaknesses, and optimal applications. For example, inkjet is great for variable data printing, while toner-based presses excel in high-quality, short-run projects.

With offset printing, I’m familiar with the complete process, from platemaking and press operation to finishing. I understand the distinctions between sheetfed and web offset printing and how to select the optimal method based on project requirements (e.g., volume, paper type, color complexity). I’ve worked with different offset presses, understanding their capabilities and limitations in terms of color accuracy, speed, and substrate compatibility.

Beyond these core methods, I have working knowledge of screen printing and specialized techniques like embossing and die-cutting, understanding the need to match the printing process to the project’s needs.

Q 25. How familiar are you with Pantone matching system?

I’m very familiar with the Pantone Matching System (PMS). It’s a crucial tool for ensuring color consistency across different printing methods and materials. I understand how to specify Pantone colors in design files, ensuring accurate color reproduction. This is especially important for branding and corporate identity work, where consistent color is vital.

My experience involves working directly with Pantone color books and using software that supports Pantone libraries to create color separations. I understand the limitations of Pantone matching, particularly when converting PMS colors to CMYK for offset printing or RGB for digital printing. I know how to handle color conversions to minimize color discrepancies and how to utilize color management profiles to achieve the best possible match.

For instance, I’ve often had to work with clients who provide PMS color specifications. My role is to ensure the design file accurately reflects these specifications and that the printing process is capable of producing the required colors within acceptable tolerances.

Q 26. What steps do you take to prevent print errors and ensure quality?

Preventing print errors and ensuring quality is a proactive process that starts long before the press even runs. It begins with a thorough preflight check of all files using tools like PitStop Pro to identify potential problems such as missing fonts, low-resolution images, and color space issues. This is followed by a careful review of the design itself for any potential problems. Then, creating a robust imposition plan, considering the material, finish, and press limitations. Color proofing is a critical step, using both soft proofing and hard proofing methods (e.g., contract proofs) to validate color accuracy.

During the printing process itself, regular quality checks are essential, involving visual inspections of print sheets and measuring color accuracy using a spectrophotometer. This helps catch errors early and prevent costly reprints. Effective communication with the print operators is crucial to identify and correct any issues immediately. Finally, post-press quality control involves a final inspection of the finished product to ensure that the print quality and finishing meet the specifications.

Think of it like building a house; you wouldn’t start constructing without blueprints and inspections throughout the process. Similarly, a layered approach is essential to preventing errors and ensuring a quality print product.

Q 27. Describe a time you had to solve a complex print-related problem.

One time, we faced a critical deadline for a large-scale brochure printing project. Just hours before the press was scheduled to run, we discovered a significant color shift in the final proof compared to the client’s approved proofs. The shift was subtle but noticeable, especially in the brand’s signature color. It was a complex issue, because the initial files were meticulously color managed and the color profile seemed flawless.

To solve this, I initiated a methodical troubleshooting process. We checked the entire print workflow, from file preparation to the output device’s ICC profile, and then examined every aspect of the color management setup. After careful analysis, we discovered that a subtle change in the press’s calibration settings had caused the discrepancy. By restoring the calibration to its previous state and doing a controlled reprint of a test sheet, we confirmed the issue was resolved. We then implemented additional measures to prevent similar issues in the future, including more frequent press calibrations and double-checking the calibration settings before every significant print job. The project was completed on time and to the client’s satisfaction.

Q 28. How do you stay up-to-date with the latest trends in print production?

Staying current in the dynamic print production industry is crucial. I utilize several methods to remain up-to-date on the latest trends and technologies. This includes subscribing to industry publications such as Print Magazine and WhatTheyThink, attending industry conferences and tradeshows like drupa (when it’s held), and actively participating in online communities and forums dedicated to print production.

I also follow influential print production professionals and companies on social media platforms like LinkedIn and Twitter, providing insights into new technologies and market trends. Additionally, I actively pursue continuous learning through online courses and webinars offered by organizations like the PIA (Printing Industries of America) and other print industry-related institutions. This ensures I am always equipped with the latest knowledge and skills to tackle any printing challenge efficiently and effectively.

Key Topics to Learn for Print Production and File Management Interview

- Pre-press Preparation: Understanding file formats (PDF, TIFF, JPEG, etc.), color spaces (CMYK, RGB), resolution requirements, and image editing for print.

- File Management Systems: Experience with digital asset management (DAM) systems, file naming conventions, organization strategies, and efficient workflow processes to ensure project accuracy and timely delivery.

- Print Production Processes: Knowledge of different printing methods (offset, digital, large format), finishing techniques (binding, lamination, die-cutting), and understanding the stages involved in print production from initial design to final product.

- Color Management: Practical application of color profiles, color proofing, and troubleshooting color discrepancies between digital files and printed output. Understanding ICC profiles and their importance.

- Quality Control: Implementing effective quality control measures throughout the print production process to identify and rectify errors before printing. This includes pre-flighting and proofing techniques.

- Problem-Solving & Troubleshooting: Demonstrating the ability to identify and resolve issues related to file compatibility, color inconsistencies, printing errors, and other production challenges.

- Software Proficiency: Highlighting expertise in relevant software such as Adobe Acrobat, InDesign, Illustrator, Photoshop, and other industry-standard applications.

- Print Specifications & Client Communication: Understanding and interpreting client briefs, managing expectations, and effectively communicating technical aspects of print production.

Next Steps

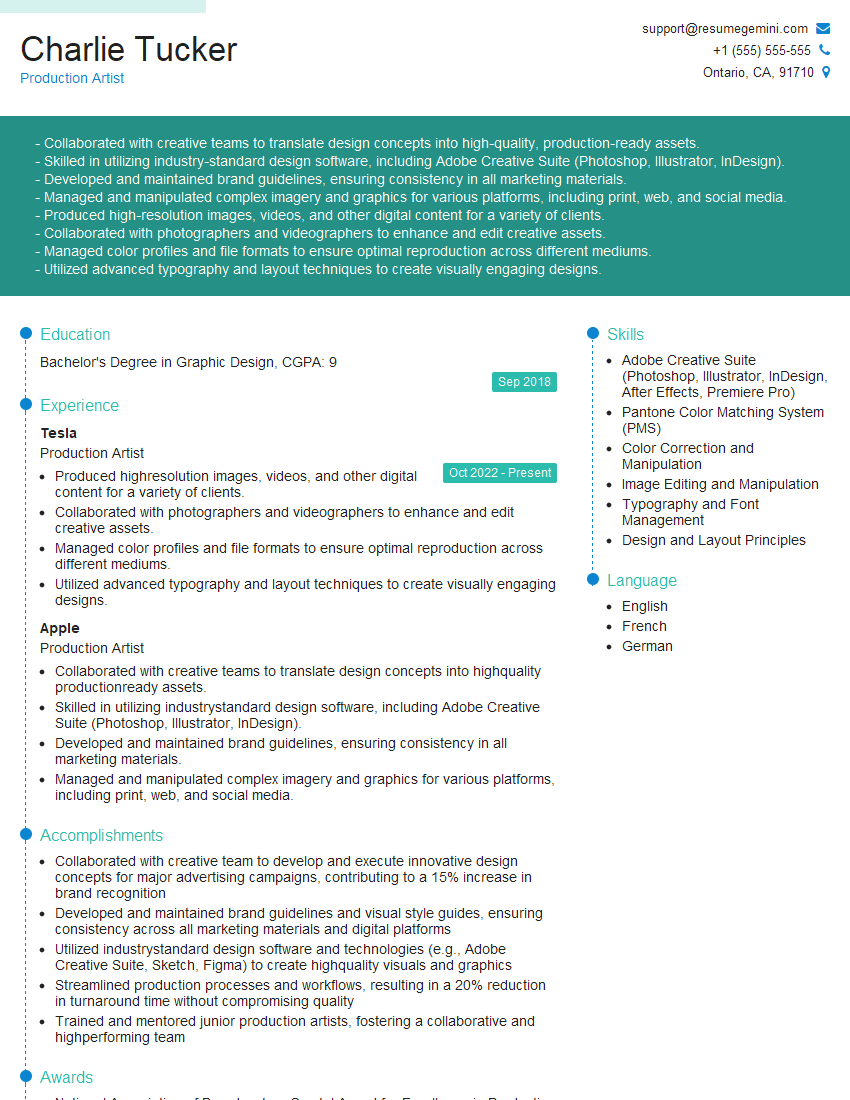

Mastering Print Production and File Management opens doors to exciting career opportunities in a dynamic industry. A strong understanding of these skills significantly enhances your value to potential employers. To maximize your job prospects, crafting an ATS-friendly resume is crucial. This ensures your application gets noticed and considered. We highly recommend using ResumeGemini to build a professional and effective resume that showcases your skills and experience in the best possible light. ResumeGemini provides you with the tools and resources to create a winning resume, and you’ll find examples of resumes tailored to Print Production and File Management available to guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good