Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Printing Industry Experience interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Printing Industry Experience Interview

Q 1. Explain the difference between offset and digital printing.

Offset and digital printing are two distinct methods for mass producing printed materials, each with its own strengths and weaknesses. Offset printing, the more traditional method, uses an indirect printing process. Ink is transferred from a plate to a rubber blanket and then to the printing surface (paper, etc.). This allows for high-volume, high-quality prints at a lower cost per unit, particularly for larger runs. Think of it like making copies using a stamp – the stamp (plate) gets ink, transfers it to a surface (blanket), and then transfers it to the paper.

Digital printing, on the other hand, is a direct imaging process. The image is printed directly onto the substrate. This is ideal for short runs, personalized items, and when fast turnaround times are needed because there is no plate-making involved. It’s more like using a high-resolution inkjet printer, where the image is created directly on the paper. Digital is often more expensive per unit for large runs due to material costs, but significantly more economical for smaller projects.

- Offset: High volume, low cost per unit, superior color accuracy (especially for complex jobs), longer setup time

- Digital: Low volume, higher cost per unit (for larger runs), faster turnaround, easy to personalize, variable data printing capability

Q 2. Describe your experience with color management systems (e.g., Pantone, CMYK).

Color management is critical in the printing industry to ensure consistent color reproduction across different devices and materials. I have extensive experience with both Pantone Matching System (PMS) and CMYK color models. Pantone is a spot color system, meaning each color has its own unique formulation, ensuring accurate and consistent color reproduction, even across different printing processes. It’s ideal for brand consistency where exact color matching is paramount, particularly for logos and corporate branding. I’ve used Pantone books extensively to match client specifications precisely.

CMYK (Cyan, Magenta, Yellow, and Key – Black) is a subtractive color model used in offset printing. It involves mixing varying percentages of these four process colors to create a wide range of hues. Accurate CMYK color management requires careful profile creation and calibration of printing equipment to achieve the desired results. I’ve worked extensively with color profiles and software to fine-tune CMYK output for optimal color fidelity. I regularly use software like Adobe Acrobat Pro and other RIP software to manage color profiles, calibrate output, and make necessary adjustments to ensure accuracy and consistency.

Q 3. What types of printing presses have you operated?

Throughout my career, I’ve operated a variety of printing presses, gaining proficiency in both offset and digital technologies. My experience includes operating Heidelberg Speedmaster offset presses (various models), as well as several different digital presses such as Xerox iGen and HP Indigo machines. This diverse experience allows me to adapt to different printing needs and efficiently manage projects regardless of the press type involved. I am proficient in the setup, operation, and maintenance of these presses, including troubleshooting common issues.

Q 4. How do you ensure consistent print quality?

Consistent print quality is paramount. My approach involves a multi-faceted strategy focusing on pre-press preparation, press operation, and quality control. In pre-press, ensuring the digital files are correctly prepared with appropriate color profiles and high resolution is crucial. During the press run, regular color checks using color bars and test prints are essential. Maintaining proper ink levels, consistently monitoring the paper feed, and regularly calibrating the press are vital. Post-press quality checks examine the finished product for any inconsistencies or defects. Documenting each step, and utilizing a color management system throughout the process are key to ensuring long-term consistency and traceability. Think of it like baking a cake – you need the right ingredients (pre-press), the right oven temperature (press operation), and a final taste test (quality control) to guarantee a perfect result.

Q 5. Describe your experience with pre-press processes.

My pre-press experience is extensive, encompassing all stages from file preparation and imposition to platemaking. I’m proficient in using Adobe Creative Suite (Photoshop, Illustrator, InDesign) for preparing files for printing, ensuring they meet the necessary specifications for resolution, color space, and bleed. I understand the critical importance of proper imposition, ensuring efficient use of paper and accurate page arrangement. My experience includes working with both digital and traditional platemaking techniques. I’ve managed the creation of plates for offset presses, ensuring accurate registration and quality. I’m familiar with different file formats (PDF, TIFF, etc.) and can troubleshoot any pre-press issues that may arise to ensure a smooth and efficient printing process.

Q 6. What is your experience with different finishing techniques (e.g., binding, lamination)?

I possess a broad understanding of various finishing techniques, crucial for producing a high-quality final product. My experience includes different binding methods, such as perfect binding (for books and magazines), saddle stitch binding (for brochures), and wire-o binding (for notebooks). I’m also proficient in various lamination techniques, including gloss and matte lamination for adding protection and enhancing the visual appeal. In addition, I am familiar with die-cutting, embossing, and other specialized finishing processes. The choice of finishing depends greatly on the project’s specifications and the desired outcome. For example, a glossy lamination is appropriate for marketing materials that require visual appeal, while a matte lamination is more suitable for applications where a less reflective finish is preferred.

Q 7. How do you handle a printing job that is behind schedule?

Handling a behind-schedule printing job requires a calm and decisive approach. First, I would assess the cause of the delay – was it due to unforeseen technical issues, material shortages, or client revisions? Once the root cause is identified, I’d prioritize tasks and allocate resources effectively. This might involve adjusting the press schedule, potentially bringing in additional staff or outsourcing certain tasks, and communicating transparently with the client about the revised timeline, providing realistic expectations. In many cases, prioritizing the most critical aspects of the job, perhaps delivering partial orders first, can mitigate the overall impact of the delay. It’s crucial to remain proactive, adapting the strategy as needed, ensuring customer satisfaction while maintaining quality standards.

Q 8. What software programs are you proficient in (e.g., Adobe Creative Suite, RIP software)?

My software proficiency spans the entire Adobe Creative Suite, including InDesign, Photoshop, Illustrator, and Acrobat. I’m highly skilled in these programs, leveraging their capabilities for pre-press preparation, image editing, and file management. Beyond the Creative Suite, my expertise extends to Raster Image Processors (RIPs) such as those from EFI Fiery and Kodak Prinergy. I’m adept at color profile management, job setup, and troubleshooting within these RIP environments. For example, I frequently use InDesign to create complex layouts for brochures and then utilize Photoshop to retouch high-resolution images for optimal print quality. The RIP software is crucial for converting digital files into instructions for the printing press, and my experience ensures accurate color reproduction and efficient workflow.

Furthermore, I’m proficient in various job management and workflow automation software tailored to the printing industry, which helps streamline the production process and reduce errors. This includes experience with MIS (Management Information Systems) software to track jobs, costs, and materials effectively.

Q 9. How do you troubleshoot printing problems?

Troubleshooting printing problems is a systematic process. I start by identifying the type of issue: is it a color problem, registration issue, paper jam, or something else? My approach involves a series of checks, starting with the simplest solutions and moving to more complex ones.

- Visual Inspection: I begin by visually inspecting the print for obvious defects such as banding, streaks, or misregistration.

- File Review: I review the print file itself to check for potential issues such as low-resolution images, missing fonts, or incorrect color profiles.

- RIP settings: If the problem is related to color, I examine the RIP settings, checking color profiles, ink limits, and other parameters. For instance, incorrect color profiles can lead to significant color shifts, while incorrect ink limits might cause banding or streaking.

- Hardware Check: I then move to inspecting the printing hardware – checking the condition of the print heads, rollers, and paper path. A clogged print head can cause streaks, while worn rollers may lead to registration problems.

- Paper Quality and Environmental Factors: I also consider the paper stock and environmental conditions, as humidity and temperature can impact print quality.

For example, if I’m facing a banding issue, I would systematically check the print heads for clogs, the ink levels, the RIP settings for ink limits, and even the paper moisture content. Through a methodical approach and experience, I can quickly pinpoint the root cause and implement a solution.

Q 10. Describe your experience with different types of paper and substrates.

My experience with paper and substrates is extensive. I’ve worked with a wide variety of papers, from standard offset paper to specialized substrates like textured stocks, canvas, and synthetics. I understand the characteristics of different paper weights, finishes (coated, uncoated, matte, gloss), and their suitability for various printing processes.

- Paper Weight: Knowing the weight (e.g., 80lb, 100lb) is crucial for selecting the appropriate printing process and ensuring the final product is durable enough.

- Paper Finish: Different finishes affect how ink is absorbed and the overall aesthetic. Glossy paper offers vibrant colors, while matte papers provide a more sophisticated look.

- Substrate Types: Working with substrates like canvas or synthetics requires understanding their specific handling and printing needs. For example, canvas requires specialized inks and printing techniques to avoid damage.

For instance, if a client requests a high-quality, premium feel, I would recommend a thicker, textured paper stock like a linen or cotton paper. Conversely, for a high-volume, economical print job, a standard coated paper would be the best choice. Understanding the nuances of different paper types allows me to advise clients on the best options for their project, within their budget constraints.

Q 11. Explain your understanding of print finishing processes.

Print finishing significantly enhances the final product’s quality and appeal. My experience encompasses a wide array of finishing techniques, including:

- Cutting & Trimming: Precise cutting to achieve desired dimensions and straight edges.

- Folding: Various folding techniques, such as letter folds, gate folds, and Z-folds, depending on design.

- Binding: Different binding methods like saddle-stitch (stapling), perfect binding (gluing), wire-o binding, and case binding for books and magazines. The choice depends on the number of pages and desired aesthetic.

- Laminating: Applying a protective film to enhance durability and water resistance.

- Die-cutting: Creating custom shapes and designs by cutting through the paper.

- Embossing & Debossing: Adding texture and visual depth using pressure.

I understand the implications of each finishing technique on the final product’s cost, turnaround time, and overall impact. For example, while perfect binding is suitable for larger documents, saddle-stitch is more economical for smaller brochures. Selecting the right finishing method is critical in achieving the desired outcome and client satisfaction.

Q 12. How do you manage inventory of printing supplies?

Managing printing supply inventory requires a well-organized and efficient system. I typically employ a combination of methods to ensure we have sufficient supplies on hand without excessive storage costs. This includes:

- Regular Stock Audits: Performing regular physical checks of inventory levels.

- Inventory Management Software: Using software to track stock levels, reorder points, and supplier information. This allows for automated reordering when stocks fall below a certain level, avoiding stockouts.

- Predictive Ordering: Based on past usage and future project estimations, anticipating demand to avoid delays.

- Supplier Relationships: Maintaining strong relationships with suppliers to secure timely deliveries and negotiate favorable pricing.

- Storage Optimization: Organizing the storage area to ensure easy access to frequently used supplies and minimize waste.

For instance, our inventory software automatically sends alerts when ink levels for a particular color drop below a predetermined threshold, triggering a reorder with our preferred supplier. This automated system prevents costly production delays due to unexpected shortages.

Q 13. How do you handle customer complaints regarding print quality?

Handling customer complaints regarding print quality requires a professional and empathetic approach. My strategy involves the following steps:

- Active Listening: Carefully listening to the client’s concerns and allowing them to fully express their dissatisfaction without interruption.

- Understanding the Issue: Seeking clarity on the specific problem by asking clarifying questions about the nature of the defect, the affected areas, and the context of the print job.

- Investigating the Root Cause: Systematically investigating the issue, reviewing the print file, checking the print settings, and examining the final product. This could involve analyzing the color profile, resolution, or other potential factors.

- Offering a Solution: Proposing a fair and reasonable solution, whether it be reprint, partial refund, or a discount on future services. The goal is customer satisfaction and retention.

- Following Up: Following up with the client after the solution is implemented to ensure they are satisfied with the outcome.

For example, if a client complains about inaccurate colors in a brochure, I would first listen to their concerns, then examine the original print file for any potential errors. I would then check the used color profile and the RIP settings. Depending on the root cause, the solution could range from a simple reprint with a corrected profile to an in-depth explanation of the technical limitations and a compromise on a discount for future orders.

Q 14. What is your experience with quality control procedures?

My experience with quality control (QC) is a cornerstone of my work. I understand that maintaining high standards is critical to client satisfaction and the reputation of any printing business. My approach to QC involves multiple checkpoints throughout the production process:

- Pre-press Inspection: Thoroughly reviewing files for errors before printing, including checking color accuracy, image resolution, and text clarity.

- Proofing: Using soft proofing and hard proofing techniques to verify the accuracy of colors and design before production. A soft proof is a digital preview, and a hard proof is a printed sample.

- In-process Monitoring: Observing the printing process for any issues and correcting them as they arise. This could involve adjusting ink settings, checking paper alignment, or maintaining consistent machine parameters.

- Final Inspection: Carefully inspecting the final printed output for defects such as misregistration, color inconsistencies, or damage. This is often done using a standardized checklist to ensure comprehensive quality checks.

- Statistical Process Control (SPC): Using data analysis tools to identify trends in defects and make adjustments to production processes to prevent future issues.

My goal is not only to catch defects but to implement preventative measures to reduce errors. By regularly reviewing data from our QC checks and analyzing trends, we’ve been able to significantly improve our print quality and reduce waste.

Q 15. Describe your experience with different types of inks.

My experience encompasses a wide range of inks, each with its own unique properties and applications. I’ve worked extensively with:

- Water-based inks: Eco-friendly and commonly used for packaging and some commercial printing, offering vibrant colors but with limitations in durability and water resistance.

- Solvent-based inks: Known for their exceptional durability and vibrant color saturation, these are often used in outdoor signage and applications requiring high resistance to fading and scratching. However, they require careful handling due to their volatile organic compounds (VOCs).

- UV-curable inks: These inks cure instantly upon exposure to ultraviolet light, leading to incredibly fast turnaround times and exceptional scratch resistance. I’ve used them extensively in high-quality packaging and promotional materials.

- Vegetable-based inks: Increasingly popular for their eco-friendliness, these inks offer a good balance between vibrant color and environmental responsibility. Their performance can sometimes be slightly less vibrant than solvent-based inks, but the environmental benefits often outweigh that consideration.

Choosing the right ink depends heavily on the substrate (the material being printed on), the final application (indoor vs. outdoor), the desired durability, and of course, the client’s budget and environmental concerns. For example, I once had a client requesting long-lasting outdoor banners; solvent-based inks were the clear choice for their superior weather resistance. Conversely, for a children’s book project, we opted for water-based inks to ensure safety and minimize environmental impact.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with print estimating and costing.

Print estimating and costing is crucial for profitability and client satisfaction. My process involves a detailed breakdown of several key factors:

- Material Costs: This includes the cost of paper, ink, and any special materials like foil or embossing plates. I meticulously track pricing from my suppliers to ensure accuracy.

- Labor Costs: This considers the time required for pre-press (design, file preparation), printing, finishing (cutting, binding, etc.), and quality control. I utilize historical data and industry standards to estimate labor time efficiently.

- Machine Costs: This accounts for the operational cost of the printing equipment, including maintenance, energy, and depreciation. We regularly analyze machine efficiency to refine these estimates.

- Overhead Costs: This encompasses rent, utilities, insurance, and administrative expenses. These are factored into the overall cost calculation, ensuring the final price covers all business expenses.

- Profit Margin: A crucial component, this ensures profitability while remaining competitive. The margin percentage is adjusted based on project complexity and client relationships.

I often utilize specialized software to assist with this process. These programs allow for quick calculations and accurate estimations based on various project parameters. This helps me provide clients with transparent and competitive quotes.

Q 17. How do you prioritize tasks in a high-pressure environment?

Prioritizing in a high-pressure environment demands a structured approach. I employ a combination of techniques:

- Prioritization Matrix: I use a matrix categorizing tasks based on urgency and importance (e.g., urgent/important, important/not urgent, etc.). This helps me focus on the most critical tasks first.

- Time Blocking: I allocate specific time blocks for different tasks, ensuring efficient time management and preventing task switching.

- Delegation: When possible, I delegate tasks to capable team members, optimizing workflow and allowing me to focus on high-priority items.

- Communication: Open and clear communication with the team and clients is crucial. This helps to manage expectations, address potential roadblocks proactively, and prevent misunderstandings.

- Regular Breaks: Short, regular breaks are essential for maintaining focus and preventing burnout. This ensures sustained productivity throughout the day.

For instance, during a particularly busy period with multiple deadlines, I used the prioritization matrix to identify the most urgent client requests, ensuring on-time delivery of critical projects while delegating less urgent tasks effectively.

Q 18. How do you maintain and clean printing equipment?

Maintaining and cleaning printing equipment is vital for optimal performance, print quality, and longevity. This involves a multi-step process:

- Daily Cleaning: This includes removing excess ink, paper dust, and debris from the machine surfaces. Specific procedures vary depending on the equipment (e.g., cleaning rollers, ink ducts, etc.).

Regular cleaning and maintenance not only extend the life of the equipment but also ensures consistent print quality. A neglected machine leads to poor print quality, increased downtime, and potentially costly repairs.

Q 19. Explain your understanding of color profiles and their importance in printing.

Color profiles are crucial in printing for ensuring color accuracy across different devices and stages of production. A color profile is essentially a digital description of a color space, defining how colors are represented in a specific device (e.g., monitor, printer). Understanding color profiles is vital for achieving color consistency from design to print.

Without proper color management using color profiles, you can experience significant color variations. For instance, a color that looks vibrant on your screen might appear dull or completely different when printed without a matching color profile.

In my work, I utilize ICC (International Color Consortium) profiles. These ensure that the colors are accurately translated from the digital design file to the printed output. The process involves assigning the correct ICC profile to the design file and ensuring that the printer driver is also set to utilize the correct profile. This ensures that the final printed product matches the designer’s intent as closely as possible.

Mismatched profiles can lead to costly reprints and dissatisfied clients. It’s a critical aspect of ensuring high-quality, consistent color reproduction across all projects.

Q 20. What is your experience with die-cutting or embossing?

I have considerable experience with both die-cutting and embossing, two finishing techniques that add significant value and sophistication to printed products.

- Die-cutting: This process uses a sharp, custom-made die to cut intricate shapes or patterns into the printed material. I’ve used this extensively for creating custom shapes for business cards, labels, and promotional materials. It allows for unique designs and packaging that stand out from the competition.

- Embossing: This technique uses pressure to create a raised or indented design on the material. This adds a tactile element, enhancing the visual appeal and perceived quality of the printed piece. I’ve employed embossing to give packaging a premium feel or to add subtle detail to invitations and other high-end print projects.

Both die-cutting and embossing require specialized equipment and expertise. Accurate die creation and precise machine setup are critical for achieving clean, consistent results. I have experience working with various materials and creating custom dies to match client specifications. For example, I once worked on a project that required intricate die-cuts for a promotional campaign; the end result was eye-catching and highly effective.

Q 21. Describe your experience with large format printing.

Large format printing involves printing on large-scale substrates, such as banners, posters, and vehicle wraps. My experience in this area includes:

- Working with various large format printers: I am proficient with both solvent and UV-curable printers, understanding their unique capabilities and limitations. The choice of printer often depends on the application (indoor vs. outdoor) and the desired print quality and durability.

- Media selection: Choosing the correct substrate is crucial for the project’s success. This involves considering factors like durability, weather resistance, and the intended application. For example, vinyl is commonly used for outdoor signage due to its weather resistance, while fabric might be preferred for indoor banners.

- Image preparation and scaling: Large format printing requires careful attention to image resolution and scaling to ensure high-quality results. I possess expertise in preparing files for optimal output on various printer models.

- Color management: Maintaining consistent color is crucial in large-format printing, just as in smaller formats. I utilize color profiles to ensure consistent color reproduction across all projects.

I’ve worked on a wide range of large-format projects, from eye-catching storefront signage to large-scale event banners. Understanding the nuances of large-format printing—including material selection, appropriate printing techniques, and proper color management—is crucial for delivering high-quality, visually impactful results.

Q 22. What is your experience with variable data printing?

Variable data printing (VDP) is a powerful technique that allows for personalized content on each printed piece within a single print run. Instead of printing the same information on every item, VDP uses databases to dynamically populate fields like names, addresses, product details, or even personalized images. Think of it like a mail merge on steroids, but applied to a wide range of print applications.

My experience with VDP spans several years and includes managing projects for large-scale direct mail campaigns, personalized brochures, and even customized packaging. For example, I once worked on a project for a major retailer to print personalized coupons based on individual customer purchase history. This involved integrating a robust database management system with our printing workflow, ensuring accurate data mapping and flawless execution. We saw a significant increase in redemption rates compared to generic coupon campaigns.

I’m proficient in handling various data formats, ensuring data integrity and efficient integration with different printing technologies, from inkjet to toner-based systems. I also have experience troubleshooting data-related issues and implementing quality control measures to guarantee accurate and consistent results.

Q 23. How do you ensure that a print job meets the client’s specifications?

Ensuring a print job meets client specifications is paramount. It’s a multi-step process that begins long before the ink hits the paper. It starts with a thorough review of the client’s brief, including detailed discussions about their objectives, target audience, and desired outcomes. We meticulously analyze the provided artwork, ensuring it meets print-ready specifications – resolution, color profiles, bleeds, and font embedding are crucial.

We then create a detailed pre-press checklist, which involves a series of proofing stages. This might include a digital proof, a hard copy proof (e.g., a color-accurate inkjet proof), and a final press proof to confirm color accuracy and overall quality. Each stage involves client approval, allowing for iterative adjustments and preventing costly errors further down the line.

Finally, we implement rigorous quality control measures throughout the entire production process, regularly checking for consistency and identifying any deviations from the client’s specifications. For example, we might use color management software to ensure precise color reproduction or perform regular checks of the print quality during the run itself. Open communication with the client is crucial at every stage to maintain transparency and address any concerns proactively.

Q 24. Explain your understanding of different print finishing options.

Print finishing options significantly enhance the visual appeal, functionality, and durability of printed materials. My experience encompasses a wide range of finishing techniques, each catering to different needs.

- Cutting and Trimming: Precision cutting ensures clean edges and accurate sizing, vital for brochures, business cards, and flyers.

- Folding and Creasing: Transforming flat sheets into intricate folded pieces like brochures, leaflets, or maps, creasing helps prevent cracking during folding.

- Binding: Options include saddle-stitch (for booklets), perfect binding (for books), wire-o binding (for notebooks), and case binding (for high-end books). The choice depends on the project requirements and budget.

- Laminating: Adding a protective film to enhance durability and water resistance; choices range from matte to gloss finishes.

- Die-cutting: Creating custom shapes and designs by cutting beyond the standard rectangular format, adding a unique touch to business cards or packaging.

- Embossing and Debossing: Adding raised or indented textures to create a tactile and sophisticated finish.

- Spot UV Coating: Applying a glossy UV coating to specific areas for a high-gloss effect and visual interest.

Selecting the appropriate finishing options is a critical part of the design process. It depends on the project’s goals, target audience, and the desired overall impact. For instance, a high-end corporate brochure might necessitate embossing and lamination, while a simple flyer might only require folding and trimming.

Q 25. How do you stay updated with the latest printing technologies?

Staying current in the rapidly evolving printing industry requires a proactive approach. I regularly attend industry trade shows and conferences, such as drupa and Graph Expo, to network with industry leaders and learn about the latest advancements. This gives me first-hand experience with new technologies and allows me to connect with equipment manufacturers and software providers.

I actively subscribe to industry publications and online resources, including trade journals and websites specializing in printing technology. I also follow key influencers and thought leaders on social media platforms relevant to the industry. Furthermore, I participate in online webinars and workshops hosted by equipment vendors and industry associations, allowing for continuous professional development.

Finally, I actively seek out opportunities for hands-on experience with new technologies whenever possible. For example, I’ve recently been involved in a project using augmented reality technology to enhance print marketing campaigns – this demonstrates a commitment to continuous learning and adaptation to technological advancements.

Q 26. Describe your experience with print workflow management software.

I have extensive experience with various print workflow management software, including MIS (Management Information Systems) solutions like PrintSmith and Tharstern. These systems are crucial for streamlining pre-press, press, and post-press operations, improving efficiency, and reducing errors. My expertise encompasses using these systems to manage jobs, track costs, schedule production, and generate reports.

For example, I’ve used PrintSmith to manage complex print jobs involving variable data printing, ensuring accurate tracking of data files, timely completion, and efficient resource allocation. I’m comfortable with various aspects of the software, including job estimation, scheduling, and reporting, and can effectively leverage its features to optimize the workflow and enhance productivity.

Beyond MIS systems, I’m also familiar with pre-press software like Adobe Acrobat and preflight software to ensure files meet print-ready specifications, and with color management software, guaranteeing accurate color reproduction across different devices. My experience includes integrating various software solutions to create a seamless and efficient workflow, from initial design to final delivery.

Q 27. What are your salary expectations?

My salary expectations are commensurate with my experience and skills in the printing industry, and reflective of the current market rate for a professional with my qualifications. I’m open to discussing this further based on the specifics of the role and compensation package offered.

Q 28. What are your long-term career goals in the printing industry?

My long-term career goals involve continued growth within the printing industry, focusing on leadership roles that leverage my expertise and experience. I’m particularly interested in contributing to the adoption of sustainable printing practices and exploring emerging technologies in personalized and interactive print media. I aspire to lead and mentor teams, driving innovation and efficiency while ensuring high-quality output. Ultimately, I aim to become a recognized expert and influencer in the field, contributing to the evolution of the printing industry.

Key Topics to Learn for Printing Industry Experience Interview

- Pre-press Processes: Understanding file preparation, color management (CMYK, Pantone), image resolution, trapping, and imposition. Practical application: Describe your experience preparing files for different printing methods (offset, digital, large format).

- Printing Processes: Knowledge of various printing techniques (offset lithography, digital printing, screen printing, flexography). Practical application: Explain the strengths and weaknesses of each method and when you’d choose one over another based on project requirements.

- Post-press Processes: Familiarity with finishing techniques like cutting, folding, binding, laminating, and die-cutting. Practical application: Describe your experience troubleshooting issues in post-press and ensuring quality control.

- Color Management and Quality Control: Understanding color profiles, proofing methods, and quality control procedures. Practical application: Explain how you’ve ensured color accuracy and consistency throughout a printing project.

- Print Finishing and Binding: Expertise in various binding methods (perfect binding, saddle stitch, wire-o) and finishing techniques. Practical application: Discuss your experience selecting the appropriate binding and finishing options for different projects.

- Press Operation & Maintenance (if applicable): For press operators, demonstrate understanding of press setup, maintenance, and troubleshooting. Practical application: Detail your experience maintaining press equipment and resolving operational issues.

- Print Production Management: Project scheduling, budgeting, client communication, and problem-solving. Practical application: Describe your experience managing multiple projects simultaneously and meeting tight deadlines.

- Sustainability in Printing: Awareness of eco-friendly printing practices and materials. Practical application: Discuss your experience implementing sustainable practices in a printing environment.

- Industry Software & Technology: Proficiency in relevant software (RIP software, prepress design software, workflow management systems). Practical application: Showcase your proficiency in the software you’ve used.

Next Steps

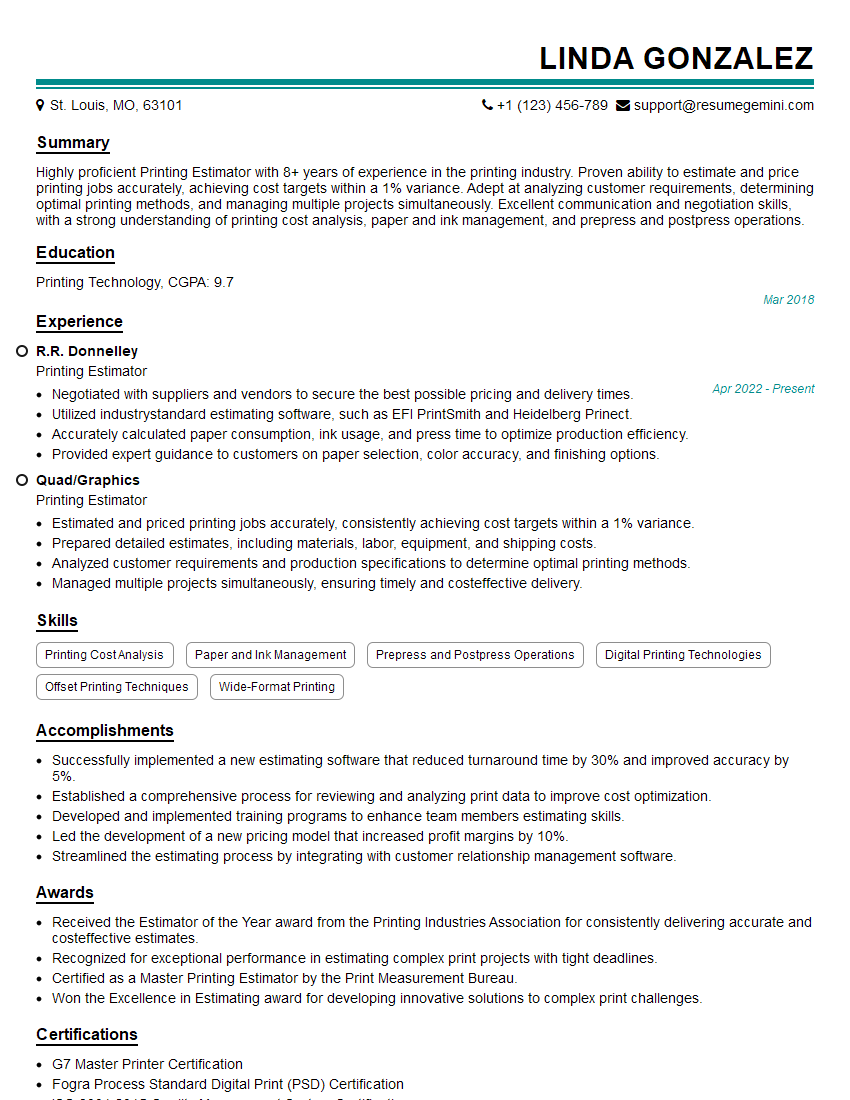

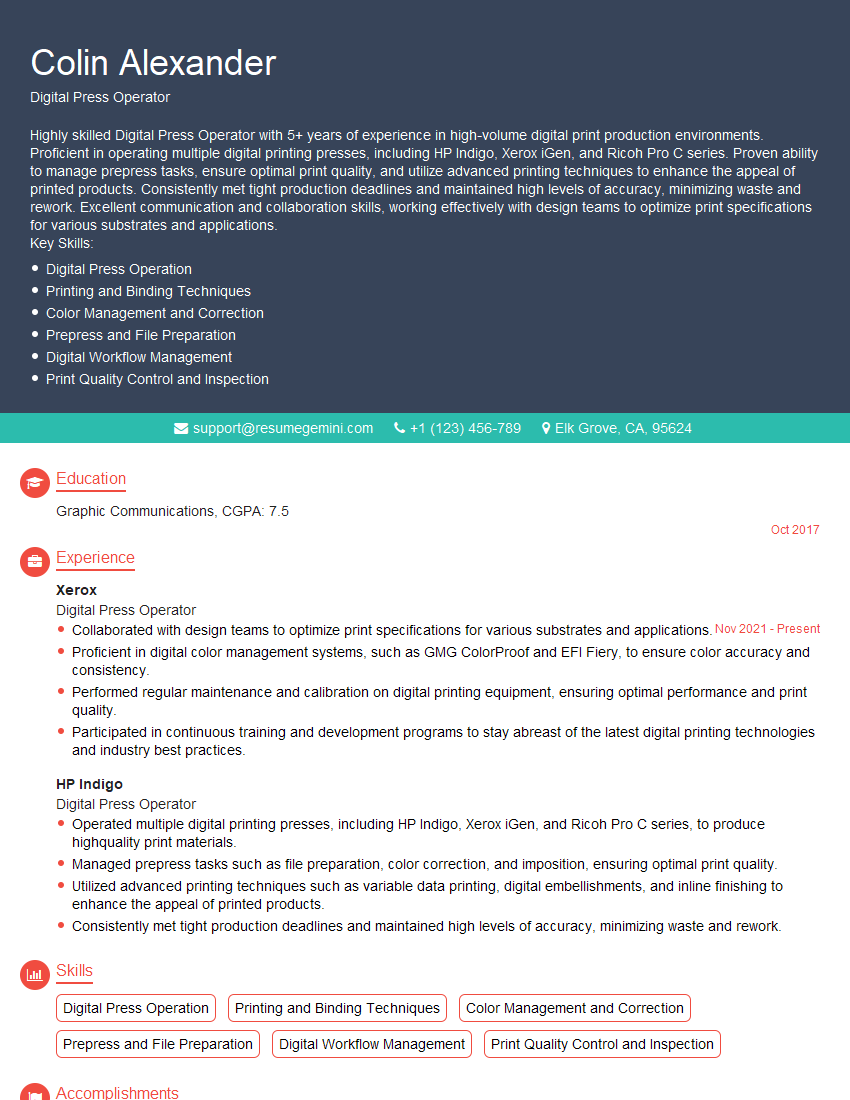

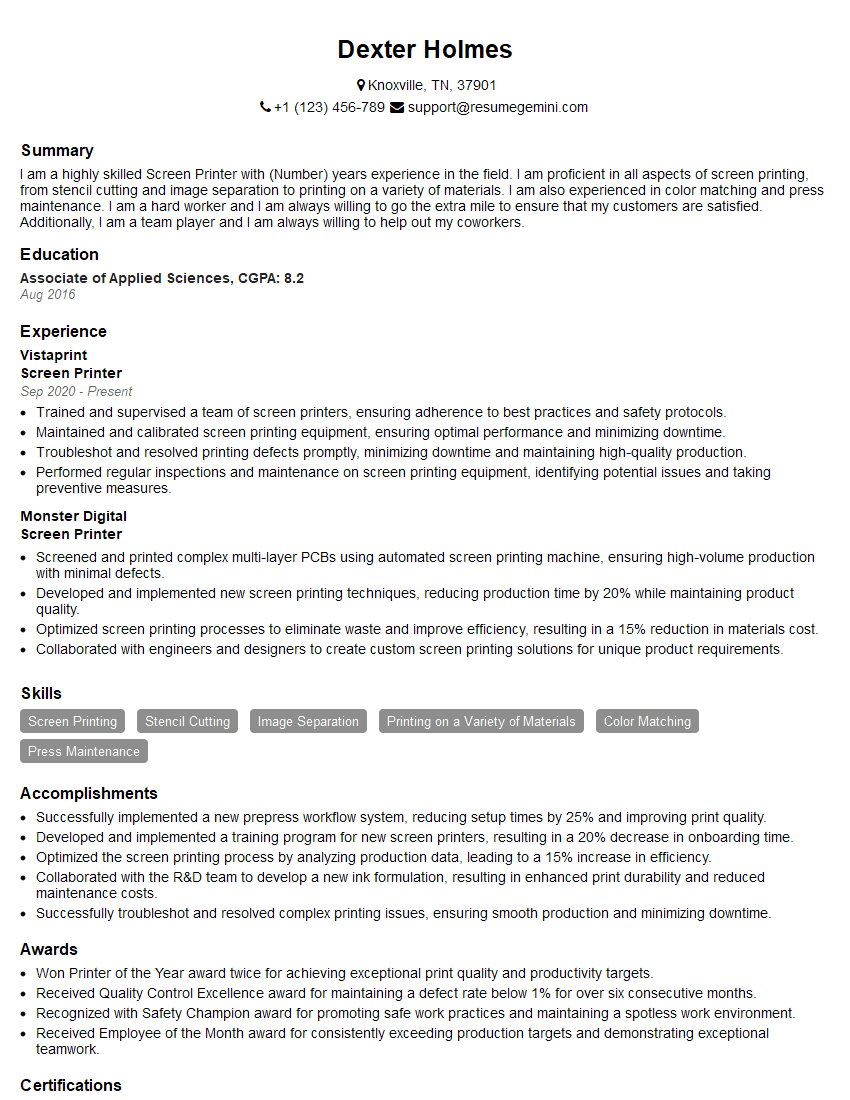

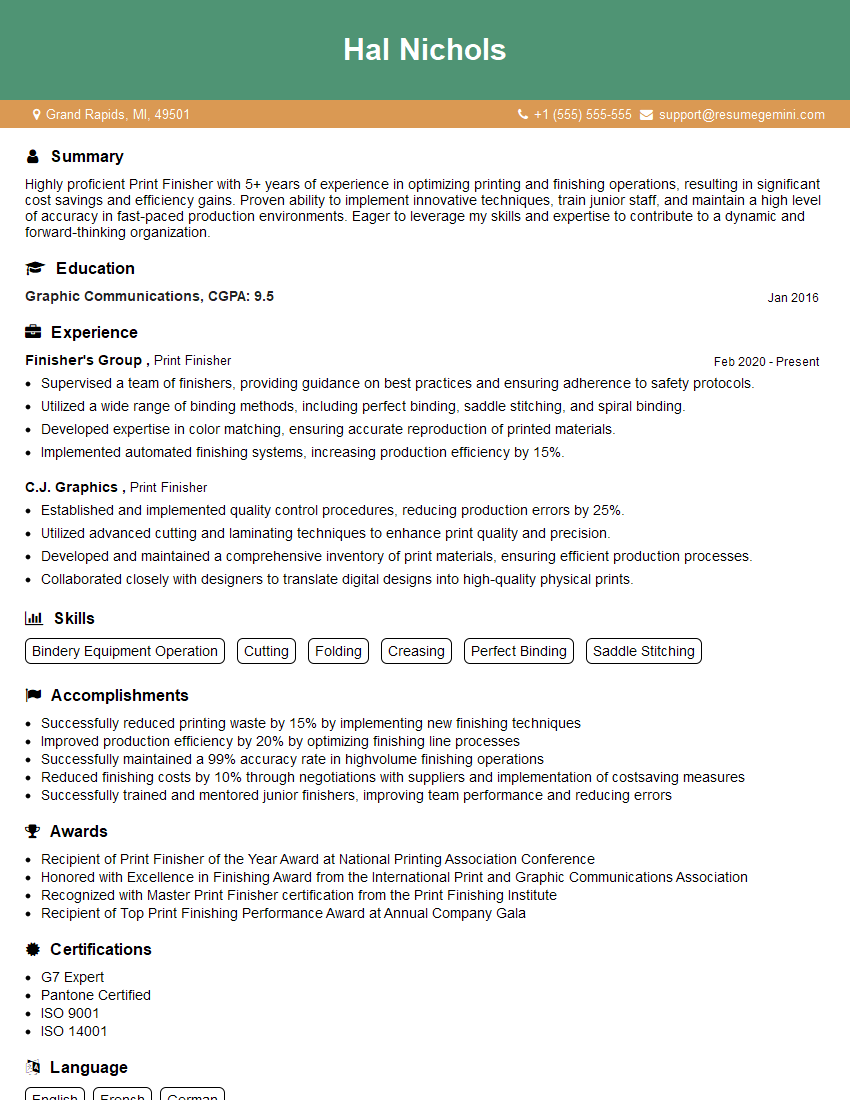

Mastering Printing Industry Experience is crucial for career advancement, opening doors to higher-paying roles and leadership positions. A strong, ATS-friendly resume is your first step to showcasing your skills and experience to potential employers. ResumeGemini can help you craft a compelling resume that highlights your unique qualifications and gets noticed by recruiters. We provide examples of resumes tailored to Printing Industry Experience to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good