Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Produce Handling Techniques interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Produce Handling Techniques Interview

Q 1. Explain the proper temperature range for storing different types of produce.

Proper temperature management is crucial for maintaining the quality and extending the shelf life of produce. Different fruits and vegetables have optimal temperature ranges, and storing them outside these ranges can lead to rapid spoilage. Think of it like Goldilocks and the Three Bears – it needs to be just right!

- High-Temperature Produce (e.g., Tomatoes, Bananas, Avocados): These generally require temperatures between 65°F and 75°F (18°C and 24°C). Storing them colder can lead to chilling injury, manifesting as discoloration and textural changes.

- Medium-Temperature Produce (e.g., Berries, Grapes, Melons): These thrive in temperatures between 32°F and 41°F (0°C and 5°C). However, even slight temperature fluctuations can impact their quality.

- Low-Temperature Produce (e.g., Leafy Greens, Root Vegetables): These can tolerate colder temperatures, typically between 32°F and 36°F (0°C and 2°C). Proper humidity is also vital for these items to prevent wilting.

It’s important to note that these are general guidelines. Specific temperature requirements can vary depending on the specific variety and maturity of the produce. Always consult reliable resources like the USDA or industry best practice guides for precise recommendations.

Q 2. Describe the process of receiving and inspecting incoming produce shipments.

Receiving and inspecting incoming produce shipments is a critical step in ensuring product quality and safety. A thorough inspection minimizes losses and helps prevent issues further down the line. Imagine it as a quality control checkpoint at the beginning of a marathon – fixing problems early prevents bigger setbacks later.

- Verification: First, we verify that the shipment matches the purchase order in terms of quantity, variety, and condition.

- Visual Inspection: Next, a careful visual examination is conducted. We check for any signs of damage, bruising, decay, or pest infestation. We’re looking for external signs of spoilage.

- Temperature Check: Using calibrated thermometers, we verify that the produce has been transported and stored at the appropriate temperature throughout the supply chain. This includes checking the temperature of the transport vehicle and the produce itself.

- Documentation: All findings are meticulously documented, including any discrepancies or issues. This documentation serves as a record for tracking quality and addressing potential problems with suppliers.

- Rejection/Acceptance: Based on the inspection, we decide whether to accept or reject the shipment. Rejected shipments are returned to the supplier with a detailed explanation of the reasons for rejection.

This multi-step process ensures only high-quality produce reaches our storage and processing areas. Regular training for staff on proper inspection techniques is key to maintaining consistency and effectiveness.

Q 3. How do you identify and handle produce that is nearing its expiration date?

Identifying and handling near-expiration produce requires a proactive approach focused on minimizing waste and ensuring food safety. It’s about managing inventory efficiently and understanding the produce’s natural life cycle.

- FIFO (First-In, First-Out) System: Implementing a strict FIFO system is paramount. This means that the oldest produce is always used or sold before the newer stock. Think of it as a queue – the first one in is the first one out.

- Visual Inspection and Quality Checks: Regular inspections are crucial. We look for signs of spoilage like discoloration, softening, wilting, or unusual odors. This helps identify items nearing expiration quickly.

- Prioritization and Sales Strategies: Near-expiration produce can be prioritized for immediate use or offered at discounted prices to speed up sales. This prevents waste while still allowing the customer to benefit.

- Creative Repurposing: Depending on the type of produce, we can explore creative ways to repurpose it. For example, slightly overripe fruits can be used in jams or smoothies. This strategy helps maximize the value of all items.

Proper communication is key. Clear labeling and staff training are essential to ensure everyone is aware of the importance of using older stock first.

Q 4. What are the key indicators of produce spoilage, and how do you address them?

Recognizing signs of spoilage is a critical skill for maintaining produce quality and preventing foodborne illnesses. It’s like being a produce detective, noticing subtle clues before the problem becomes obvious.

- Visual Cues: Discoloration, bruising, wilting, mold growth, and unusual blemishes are all visual indicators.

- Textural Changes: Softening, shriveling, or becoming slimy are clear signs that the produce is deteriorating.

- Odor: An unpleasant or unusual odor is often a strong indicator of spoilage. Sour, fermented, or putrid smells are significant red flags.

Addressing Spoilage:

- Immediate Removal: Spoiled produce should be immediately removed from storage and disposal areas to prevent contamination of other items.

- Proper Disposal: Dispose of spoiled produce according to local regulations and food safety guidelines. This may involve composting, incineration, or other appropriate methods.

- Root Cause Analysis: Investigate the cause of the spoilage to prevent similar issues in the future. Was it improper storage, temperature fluctuations, or damage during handling?

By carefully observing these indicators and acting promptly, we can minimize the spread of spoilage and maintain high standards of food safety and quality.

Q 5. What are your strategies for minimizing produce waste and maximizing shelf life?

Minimizing waste and maximizing shelf life are paramount for economic and environmental sustainability. It requires a holistic approach that addresses every stage of the produce handling process. We aim to get the most out of every item!

- Careful Procurement: Ordering only what is needed and predicting demand accurately minimizes excess stock.

- Optimal Storage Conditions: Maintaining precise temperatures and humidity levels throughout the storage process extends shelf life significantly.

- Proper Handling Techniques: Gentle handling prevents bruising and damage, which accelerates spoilage. This involves appropriate packaging and transport methods.

- FIFO Implementation: A well-executed FIFO system is essential for prioritizing older stock and preventing waste.

- Creative Repurposing: Finding alternative uses for near-expiration produce, such as making jams, sauces, or soups.

- Regular Inventory Management: Accurate tracking of inventory helps with forecasting and minimizing overstocking.

- Staff Training: Educating staff on proper handling, storage, and identification of spoiled produce.

By implementing these strategies, we create a system where every effort is made to prevent unnecessary waste, enhance the quality of our products, and improve overall efficiency.

Q 6. Describe your experience with FIFO (First-In, First-Out) inventory management.

FIFO (First-In, First-Out) is the cornerstone of our inventory management system. It’s like a well-organized queue – the first item in is the first item out. This ensures that the oldest produce is used first, minimizing the risk of spoilage and maximizing freshness.

In practice, we label all incoming produce with its arrival date. We arrange storage areas so that newer items are placed behind older ones. During picking or stock rotation, staff are explicitly instructed to select the oldest items first. This is regularly monitored through spot checks and inventory audits to ensure compliance.

Benefits of a well-implemented FIFO system include:

- Reduced spoilage and waste

- Improved inventory accuracy

- Enhanced food safety

- Increased efficiency in stock management

We regularly review and refine our FIFO implementation to adapt to seasonal variations in produce availability and changing customer demand. This ensures that our system remains efficient and effective in minimizing losses and optimizing our produce handling processes.

Q 7. Explain your understanding of proper sanitation and hygiene practices in produce handling.

Sanitation and hygiene are non-negotiable in produce handling. It’s crucial not only for maintaining the quality of the produce but also for preventing foodborne illnesses. Think of it as the foundation for everything else – without proper hygiene, all other efforts can be compromised.

- Handwashing: Frequent and thorough handwashing with soap and warm water is essential. This includes after handling any potentially contaminated item or surface.

- Surface Cleaning and Sanitization: All work surfaces, equipment, and storage areas must be regularly cleaned and sanitized using approved food-grade sanitizers. This eliminates bacteria and other microorganisms.

- Pest Control: Implementing effective pest control measures is critical to prevent contamination. Regular inspections and the use of appropriate pest control products are essential.

- Personal Protective Equipment (PPE): Employees should use appropriate PPE, such as gloves and hairnets, to prevent contamination from hair, skin oils, and other sources.

- Temperature Control: Maintaining proper temperatures throughout the handling process helps to inhibit bacterial growth.

- Cross-Contamination Prevention: Careful separation of raw and ready-to-eat produce is necessary to avoid cross-contamination.

- Waste Management: Proper disposal of waste and spoiled produce prevents attracting pests and maintaining a clean environment.

Regular training and adherence to strict hygiene protocols are crucial for a safe and efficient produce handling operation. Our staff undergoes regular training on these procedures to reinforce best practices and ensure consistent implementation.

Q 8. How do you maintain proper humidity levels for optimal produce storage?

Maintaining proper humidity levels is crucial for preserving the freshness and quality of produce. Think of it like maintaining the right hydration levels for your skin – too dry, and it cracks; too wet, and it becomes soggy. Produce behaves similarly. Optimal humidity prevents wilting, shriveling, and decay. We achieve this through various methods, primarily using controlled atmosphere storage (CAS) and humidity-controlled rooms.

Controlled Atmosphere Storage (CAS) involves carefully regulating the levels of oxygen, carbon dioxide, and nitrogen within a storage environment to slow down respiration in the produce. This, in turn, helps retain moisture. For example, apples stored in a CAS environment will retain their crispness and juiciness for much longer than those stored in ambient air.

Humidity-Controlled Rooms utilize humidifiers and evaporative coolers to maintain consistent relative humidity levels (typically between 90-95% for many leafy greens, and lower for other produce depending on the type and its sensitivity to moisture). Regular monitoring with hygrometers is essential to ensure the set points are consistently met. These rooms often incorporate specialized ventilation systems to prevent condensation and potential fungal growth.

The specific humidity requirement varies greatly depending on the type of produce. Leafy greens, for example, require higher humidity than root vegetables. This highlights the importance of tailored storage solutions for different types of produce to maximize shelf life.

Q 9. What are the common types of produce damage and how can they be prevented?

Produce damage can significantly reduce shelf life and marketability. Common types include physical damage (bruising, cuts, punctures), physiological disorders (e.g., chilling injury, internal browning), and microbial spoilage (caused by bacteria, fungi, and yeasts).

- Physical Damage: This often occurs during harvesting, handling, and transportation. Careful harvesting techniques, proper cushioning during transport, and the use of appropriate containers help prevent this. For example, using padded bins and avoiding rough handling can reduce bruising in delicate berries.

- Physiological Disorders: These are often temperature-related. Chilling injury, for example, can cause discoloration and tissue breakdown in tropical fruits stored at temperatures too low for them. Understanding the temperature requirements of different produce is essential to prevent this type of damage. Pre-cooling techniques are crucial to quickly reduce the temperature of harvested produce to its ideal storage temperature.

- Microbial Spoilage: This is minimized through proper sanitation practices at all stages – from the field to the retail shelves. This includes cleaning equipment, using clean containers, and maintaining cold chain integrity. Employing effective pest control measures to keep insects out also helps preventing decay and reduce microbial growth.

Prevention involves a multifaceted approach encompassing careful handling, proper storage conditions, and sanitation measures throughout the supply chain. This needs a collaborative effort between producers, transporters, and retailers.

Q 10. Describe your experience with different produce packaging techniques.

My experience encompasses a wide range of produce packaging techniques, each tailored to the specific needs of different products. The goal is always to maximize shelf life, minimize damage, and enhance the appeal to the consumer.

- Modified Atmosphere Packaging (MAP): This involves altering the gas composition within the packaging to slow down respiration and extend shelf life. For example, many ready-to-eat salads are packaged using MAP to maintain freshness. The precise gas mixture (e.g., reduced oxygen, increased carbon dioxide) varies depending on the type of produce.

- Ethylene Absorbers: Ethylene is a plant hormone that accelerates ripening and senescence. Ethylene absorbers in packaging effectively remove this gas, extending the shelf life of sensitive produce, such as bananas or avocados. The duration of effectiveness for these absorbers varies, so it’s important to monitor and to ensure they are sufficiently effective.

- Sustainable Packaging: There’s a growing emphasis on sustainable materials, like biodegradable plastics or compostable packaging, to reduce environmental impact. This also includes optimizing packaging sizes to reduce waste and improve efficiency.

- Traditional Packaging: Methods like using mesh bags for onions or crates for heavier produce like watermelons are still widely used, particularly where the produce needs good ventilation.

Choosing the appropriate packaging method requires careful consideration of factors such as the type of produce, its sensitivity to environmental conditions, and the desired shelf life. This is a critical decision that impacts the quality of the produce that reaches the consumer.

Q 11. How do you ensure the traceability of produce throughout the supply chain?

Traceability is essential for ensuring food safety and maintaining consumer confidence. It involves the ability to track produce from its origin (farm) to the point of sale. This is achieved through various methods:

- Lot Codes and Batch Numbers: Each batch of produce is assigned a unique code that can be traced back to its origin, including the farm, harvesting date, and other relevant information. These codes are typically printed on packaging labels or recorded in databases.

- RFID (Radio-Frequency Identification) Technology: RFID tags attached to containers or pallets can provide real-time tracking of produce during transportation and storage. This allows for precise monitoring of location and temperature.

- Blockchain Technology: This emerging technology offers a secure and transparent way to record and share information about produce throughout the supply chain, enhancing traceability and improving accountability.

- GPS Tracking: This technology is often integrated into transportation, allowing the monitoring of location, speed, and temperature during transport. This is extremely beneficial for ensuring the products arrive to their destination maintaining the cold chain.

Effective traceability systems require collaboration across the entire supply chain, including producers, processors, distributors, and retailers. A robust system ensures quick identification of the source of any contamination or quality issues, protecting consumers and preventing widespread recalls.

Q 12. Explain your understanding of food safety regulations and best practices related to produce.

My understanding of food safety regulations and best practices for produce is comprehensive. I am familiar with regulations such as the Food Safety Modernization Act (FSMA) in the US and equivalent regulations in other countries. These regulations cover various aspects of produce safety, including:

- Good Agricultural Practices (GAPs): These guidelines cover aspects of farming practices that promote food safety, such as proper irrigation and fertilizer management, pest control, and worker hygiene.

- Hazard Analysis and Critical Control Points (HACCP): HACCP is a systematic approach to identifying and controlling potential hazards in the production process. This involves a risk assessment and the establishment of critical control points to ensure food safety.

- Sanitation and Hygiene: Maintaining high levels of sanitation throughout the entire process is essential. This includes proper cleaning and disinfection of equipment, facilities, and transportation vehicles. Regular employee training on hygiene practices is also critical.

- Temperature Control: Maintaining appropriate temperatures during harvesting, storage, and transportation is essential to prevent microbial growth and maintain the quality of produce.

Adherence to these regulations and best practices is not just legally mandated but also crucial for maintaining consumer trust and safeguarding public health. The consequences of failure to comply can be severe and widespread, including product recalls, reputational damage and legal penalties.

Q 13. How do you handle customer complaints regarding produce quality?

Handling customer complaints regarding produce quality is a critical aspect of maintaining customer satisfaction and brand reputation. My approach is systematic and focuses on resolution and prevention:

- Listen and Empathize: The first step is to actively listen to the customer’s complaint and acknowledge their concerns. Showing empathy and understanding is crucial in diffusing the situation.

- Gather Information: Collect detailed information about the complaint, including the type of produce, date of purchase, location of purchase, and specifics about the quality issue. This information helps in determining the root cause.

- Investigate the Issue: Based on the gathered information, launch an internal investigation to determine the cause of the complaint. This may involve inspecting the produce, reviewing records, and talking with relevant personnel within the supply chain.

- Offer Resolution: Depending on the findings of the investigation, offer appropriate compensation or resolution, such as a refund, replacement, or a discount on future purchases. The goal is to make things right for the customer.

- Prevent Future Issues: Following the resolution, take steps to prevent similar complaints in the future. This might include improving quality control procedures, retraining staff, or addressing issues in the supply chain.

Transparent communication throughout the process is vital. Keeping customers informed and taking proactive measures to address their concerns demonstrate a commitment to quality and customer service.

Q 14. Describe your experience with inventory control systems for produce.

Effective inventory control systems are crucial for managing produce efficiently, minimizing waste, and ensuring supply meets demand. My experience includes utilizing both manual and automated systems:

- Manual Systems: These involve physically tracking inventory levels through regular stock counts, spreadsheets, and visual inspection. While simple, this method can be time-consuming and prone to human error. I have used these systems effectively in smaller-scale operations.

- Automated Systems: These utilize software programs and barcodes or RFID tags to track inventory in real-time. This allows for accurate monitoring of stock levels, automatic reordering, and integration with point-of-sale systems. The accuracy and efficiency of such automated systems is a key advantage for scaling operations. I have experience with systems utilizing barcode scanning at various stages of the handling process.

- First-In, First-Out (FIFO) Method: Regardless of the system used, applying the FIFO method is essential to ensure that the oldest produce is sold first, minimizing waste due to spoilage. Proper labeling and organized storage are key to effectively implementing FIFO.

The choice of inventory control system depends on the scale of the operation and the specific needs of the business. However, the overall goal is to have a system that provides accurate, timely, and efficient tracking of produce inventory, minimizing spoilage and ensuring a smooth supply chain.

Q 15. How do you manage peak seasons and high volumes of produce?

Managing peak seasons requires a multifaceted approach. It’s like orchestrating a symphony – each instrument (staff, equipment, processes) must play in harmony. We begin with accurate forecasting, analyzing historical data to predict demand surges. This informs our staffing levels – we may temporarily hire additional hands or implement overtime schedules. Next, we optimize our supply chain, working closely with growers to ensure sufficient produce arrives on time. We also leverage technology – automated sorting and packing systems can significantly increase throughput during peak periods. Finally, flexible scheduling and efficient workflows are crucial. For example, we might prioritize the highest-demand items or implement staggered shifts to manage the influx of produce.

For instance, during the summer tomato season, we might pre-plan for a 30% increase in volume, securing extra refrigerated storage space and adding a second packing line. We’d also communicate anticipated workload increases to our staff well in advance.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What are your strategies for maintaining a safe and efficient working environment in a produce handling facility?

Safety is paramount. We maintain a safe environment through rigorous training, providing employees with comprehensive instruction on proper lifting techniques, equipment operation, and hygiene protocols. We regularly inspect equipment, ensuring everything is in optimal working order. We employ a color-coded system for identifying different hazard areas, such as wet floors or areas with heavy machinery. We emphasize teamwork and open communication – encouraging employees to report any potential hazards immediately. Our facility includes clearly marked emergency exits, ample lighting, and ergonomic workstations to minimize risks of injury. Regular safety meetings reinforce best practices and keep safety top-of-mind.

Efficiency is boosted by well-organized workflows. We utilize lean methodologies to minimize wasted movement and maximize throughput. Clear signage, optimized layout, and well-maintained equipment are essential. For example, a streamlined workflow might involve strategically placing packing stations near the receiving area, minimizing travel time.

Q 17. Explain your experience with different types of produce handling equipment (e.g., forklifts, conveyors).

My experience encompasses a broad range of produce handling equipment. I’m proficient in operating and maintaining forklifts, ensuring safe and efficient transportation of pallets. I’m also well-versed in using conveyors – both belt and roller – to move produce smoothly through the processing and packing lines. I understand the importance of regular maintenance for all equipment, performing routine checks and scheduling timely repairs to prevent downtime. I’m familiar with automated sorting machines that use optical sensors to grade produce by size and quality, significantly increasing efficiency compared to manual sorting. I’ve also worked with specialized equipment like palletizers and shrink-wrappers, crucial for efficient packaging. Experience with these diverse technologies allows me to optimize workflows and select appropriate equipment for various tasks.

Q 18. How do you manage staff and delegate tasks effectively in a busy produce department?

Effective staff management during busy periods relies on clear communication, delegation, and teamwork. I utilize a combination of approaches to ensure tasks are completed efficiently. First, I create detailed task lists with clear responsibilities assigned to each team member. This ensures everyone understands their role and contributes effectively. Second, I leverage cross-training to ensure employees can handle multiple tasks, creating flexibility during peak periods. Third, I foster a collaborative environment where team members can assist one another, especially during rushes. Open communication channels are maintained, allowing me to address concerns or adapt strategies as needed. Regular feedback sessions ensure individual goals align with overall team objectives.

For example, during harvest season, I might assign team leaders who oversee specific areas, providing a decentralized approach to task management. This enhances responsiveness and minimizes bottlenecks.

Q 19. What is your experience with pest control and prevention in produce handling?

Pest control is crucial to maintaining produce quality and safety. We use an integrated pest management (IPM) approach, prioritizing prevention over reactive measures. This involves maintaining a clean and sanitary facility, regularly inspecting for signs of infestation, and implementing preventative measures like sealing cracks and crevices. We employ biological controls whenever possible, such as introducing beneficial insects to control pest populations. We partner with licensed pest control professionals for regular inspections and treatments, strictly adhering to regulations and food safety guidelines. Thorough documentation of all pest control activities is essential for traceability and compliance.

For example, we might use pheromone traps to monitor insect populations and deploy targeted treatments only when necessary, minimizing the use of harmful chemicals.

Q 20. How do you ensure the accurate labeling and pricing of produce?

Accurate labeling and pricing are critical for maintaining customer trust and complying with regulations. We utilize a combination of manual and automated labeling systems. For manual labeling, we have standardized templates and procedures to ensure consistency. For automated labeling, we integrate our labeling system with our inventory management software, automatically updating labels with product information and pricing. Regular audits and cross-checking ensure accuracy. Our systems track expiry dates, origin, and other relevant information, guaranteeing traceability and compliance with food safety standards.

For example, a barcode scanner reads product information, triggering the automated labeling system to apply the correct label with price and other relevant data.

Q 21. What are your strategies for preventing cross-contamination in produce handling?

Preventing cross-contamination is paramount. We enforce strict hygiene protocols, including handwashing stations, sanitation of equipment, and color-coded cutting boards to prevent mixing of different produce types. We maintain separate areas for handling raw and ready-to-eat produce. We utilize dedicated equipment for different product types to prevent cross-contamination. All surfaces are regularly sanitized, and staff are trained to follow proper cleaning procedures. Our facility layout is designed to minimize the potential for cross-contamination by establishing clear workflows and separation zones. Regular internal audits and adherence to HACCP (Hazard Analysis and Critical Control Points) principles ensure continuous improvement.

For example, we might use separate color-coded knives and cutting boards for raw and ready-to-eat vegetables, reducing the risk of transferring bacteria.

Q 22. Describe your experience with various methods of produce preservation.

Produce preservation is crucial for maintaining quality and extending shelf life. My experience encompasses a range of methods, categorized broadly into pre-harvest, harvest, and post-harvest techniques.

- Pre-harvest: This involves optimizing growing conditions, selecting appropriate cultivars resistant to diseases and pests, and employing sustainable agricultural practices. For example, proper irrigation scheduling minimizes stress on plants, leading to healthier produce with longer shelf life.

- Harvest: Careful harvesting at optimal maturity minimizes physical damage and enzymatic activity that leads to spoilage. Techniques include using appropriate tools and employing trained personnel. I’ve worked extensively with minimizing bruising during harvest, a key factor in extending shelf life.

- Post-harvest: This stage is where a multitude of preservation methods are applied. These include:

- Cooling: Rapid cooling using hydrocooling or forced-air cooling slows down respiration and microbial growth. I’ve implemented and managed hydrocooling systems in large-scale operations, significantly reducing spoilage rates.

- Modified Atmosphere Packaging (MAP): This technique alters the gaseous environment within packaging to slow respiration and inhibit microbial growth. I’ve worked with various gas mixtures for different produce types to optimize shelf life. For example, using a higher nitrogen and lower oxygen atmosphere for leafy greens.

- Controlled Atmosphere Storage (CAS): This involves storing produce in a controlled environment with reduced oxygen and increased carbon dioxide levels, significantly extending shelf life. I’ve overseen the management of CAS facilities for various fruits and vegetables, resulting in substantial cost savings due to reduced waste.

- Irradiation: This method uses ionizing radiation to eliminate microorganisms and extend shelf life, though its application depends on consumer acceptance and regulatory compliance. I have experience evaluating the efficacy and safety of irradiation for specific produce types.

- Chemical treatments: Certain chemicals like fungicides or wax coatings can be used to prevent spoilage and maintain freshness, though careful consideration must be given to residue limits and consumer safety. I’ve been involved in ensuring adherence to all safety regulations when using these methods.

My experience spans various produce types, from delicate berries to sturdy root vegetables, and I adapt my approach based on the specific needs of each product.

Q 23. How do you manage the transportation of temperature-sensitive produce?

Transporting temperature-sensitive produce requires meticulous planning and execution. The core principle is maintaining the cold chain, ensuring consistent low temperatures from harvest to the point of sale.

- Refrigerated Transportation: This is the most critical aspect. I ensure appropriate refrigeration units are used, with consistent monitoring of temperature throughout the transit. Regular calibration and maintenance of these units are essential. For long-distance transport, I’ve used reefer trucks equipped with GPS tracking and temperature data loggers to ensure continuous monitoring and prompt response to any deviations.

- Proper Packaging: Selecting suitable packaging materials helps maintain temperature and protects produce from physical damage. Insulated containers and breathable packaging can significantly contribute to maintaining quality. I have experience selecting packaging based on factors like the type of produce, transport distance, and environmental conditions.

- Route Planning: Efficient route planning minimizes transit time, reducing the risk of temperature fluctuations. I incorporate real-time traffic data and weather forecasting into route optimization, particularly for time-sensitive shipments.

- Pre-cooling: Rapid cooling before loading into refrigerated transport is critical for temperature-sensitive items. Hydrocooling or vacuum cooling are effective methods for pre-cooling that I have utilized extensively.

Effective communication throughout the supply chain is crucial. I establish clear communication protocols with all stakeholders, including growers, transporters, and distributors, ensuring everyone understands temperature requirements and reporting procedures. Any temperature deviation is immediately addressed through corrective actions.

Q 24. What is your experience with using technology to improve efficiency in produce handling (e.g., inventory management software)?

Technology plays a vital role in improving efficiency in produce handling. My experience includes using various software solutions for inventory management, traceability, and quality control.

- Inventory Management Software: I’ve utilized systems like

[Software Name Example]to track produce inventory in real-time, optimizing stock levels, minimizing waste, and predicting demand. This allows for proactive ordering and prevents stockouts or overstocking. - Traceability Systems: Implementing blockchain technology or other traceability systems allows for tracking produce from farm to table, enhancing food safety and accountability. In case of contamination or quality issues, rapid identification and recall of affected batches are essential. I have experience implementing and managing these systems, ensuring data accuracy and seamless integration with supply chain partners.

- Data Analytics: Analyzing data from various sources – such as temperature sensors, inventory systems, and quality assessments – enables identification of areas for improvement and prediction of potential issues. This data-driven approach ensures optimized operations and efficient resource allocation.

- Automated Systems: I am familiar with automated sorting and grading systems, which improve efficiency and reduce labor costs. These systems use image recognition and other technologies to sort produce based on size, quality, and other criteria.

The use of technology has consistently improved our operational efficiency, reduced waste, and enhanced overall product quality. I am always eager to explore and implement new technologies that can further streamline operations and improve our processes.

Q 25. Describe a time you had to solve a problem related to produce quality or spoilage.

During a particularly hot summer, we experienced unusually high spoilage rates in our shipment of strawberries. Initial investigations pointed towards inadequate cooling during transportation.

Problem-solving steps:

- Data Analysis: We analyzed temperature data loggers from the affected shipments to pinpoint the exact point of temperature failure.

- Root Cause Identification: We discovered that a malfunctioning refrigeration unit in one of the trucks had caused a significant temperature increase, leading to rapid spoilage.

- Corrective Actions: We immediately replaced the faulty unit and implemented more stringent preventative maintenance schedules for all refrigeration units.

- Process Improvement: We introduced a new protocol requiring secondary temperature checks at key points in the transportation route, as well as real-time monitoring of all trucks using GPS tracking.

- Communication: We communicated the issue and corrective actions to all stakeholders, ensuring that best practices were understood and adopted across the supply chain.

This experience highlighted the importance of proactive monitoring, preventative maintenance, and effective communication in managing produce quality. Following the implementation of these improvements, we observed a significant reduction in spoilage rates.

Q 26. How do you stay updated on the latest best practices and regulations in produce handling?

Staying updated on the latest best practices and regulations is paramount in this field. I utilize a multi-faceted approach:

- Professional Organizations: I actively participate in organizations like the United Fresh Produce Association and other relevant industry groups. These organizations offer valuable insights through conferences, publications, and networking opportunities.

- Industry Publications: I regularly read trade publications and journals dedicated to produce handling and postharvest technology. This keeps me abreast of the latest research, innovations, and emerging trends.

- Government Agencies: I monitor updates and changes from relevant government agencies, such as the Food and Drug Administration (FDA), ensuring compliance with food safety regulations and best practices.

- Online Resources: I utilize reputable online resources and databases for information on new technologies, research findings, and industry best practices.

- Conferences and Workshops: Attending industry conferences and workshops is crucial for staying ahead of the curve and networking with other professionals in the field.

Continuous learning is essential to ensuring the highest standards of produce quality and safety.

Q 27. What are your salary expectations for this role?

My salary expectations for this role are in the range of $[Lower Bound] to $[Upper Bound] annually, depending on the specific responsibilities and benefits package. This range is based on my experience, skills, and the current market rates for similar roles.

Q 28. Do you have any questions for me?

I have a few questions:

- What are the company’s specific goals and priorities regarding produce quality and sustainability?

- What opportunities are there for professional development and advancement within the company?

- What is the company culture like, and how does it support employee growth and collaboration?

Key Topics to Learn for Produce Handling Techniques Interview

- Receiving and Inspection: Understanding quality standards, proper identification of produce, and documenting receiving processes. Practical application: Efficiently assessing the quality and quantity of incoming produce shipments and identifying potential issues.

- Storage and Preservation: Knowledge of optimal storage temperatures, humidity levels, and the use of controlled atmosphere storage (CAS) techniques. Practical application: Minimizing spoilage and maximizing shelf life through appropriate storage practices.

- Handling and Transportation: Safe and efficient handling methods to prevent damage, including proper lifting techniques, use of appropriate equipment, and understanding transportation regulations. Practical application: Reducing waste and maintaining produce quality during transport.

- Cleaning and Sanitization: Implementing effective cleaning and sanitization procedures to prevent contamination and maintain food safety standards. Practical application: Understanding and applying best practices to minimize bacterial growth and ensure product safety.

- Quality Control and Assurance: Implementing procedures to monitor and maintain produce quality throughout the handling process. Practical application: Identifying and addressing quality issues promptly to minimize losses.

- Waste Reduction Strategies: Implementing techniques to minimize produce waste at every stage of the handling process, from receiving to consumption. Practical application: Developing and implementing strategies to reduce spoilage and improve overall efficiency.

- Food Safety Regulations and Compliance: Understanding and adhering to relevant food safety regulations and industry best practices. Practical application: Ensuring compliance with all relevant regulations and maintaining a safe working environment.

- Inventory Management: Utilizing effective inventory control methods to track produce quantities, monitor stock levels, and predict future needs. Practical application: Optimizing stock levels to minimize waste and ensure sufficient supply.

Next Steps

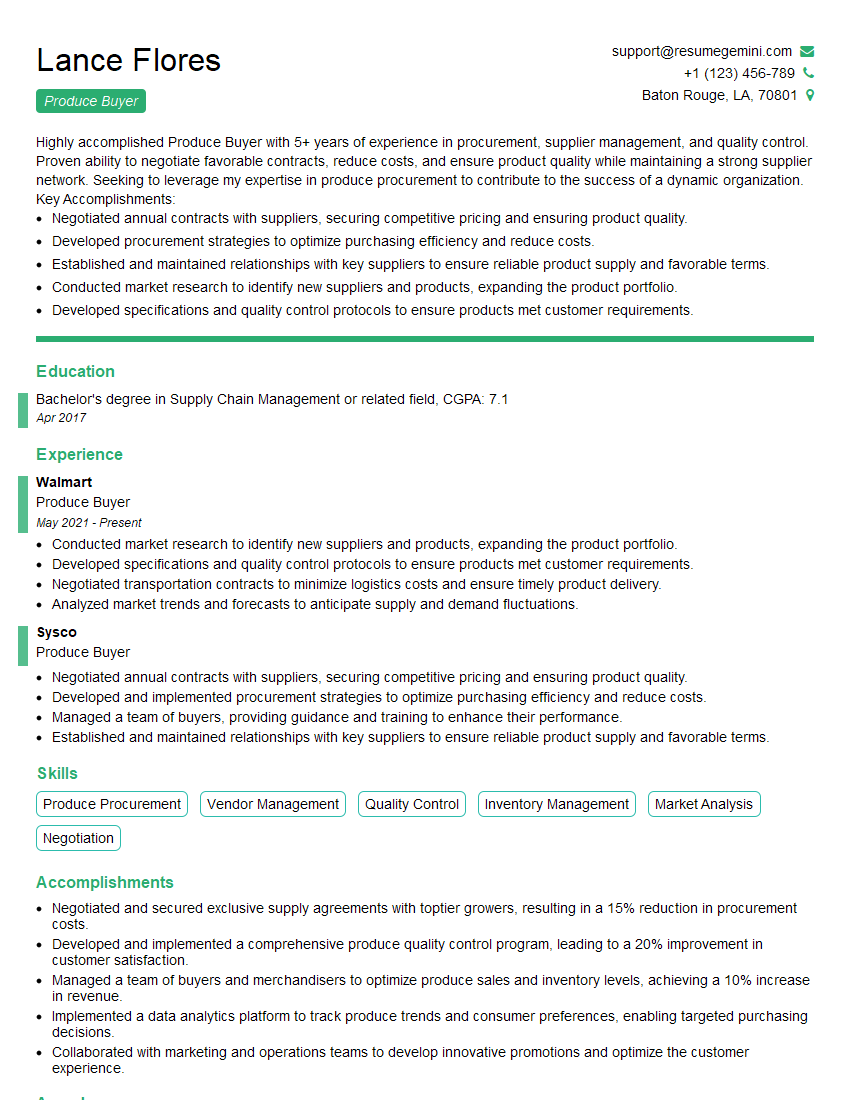

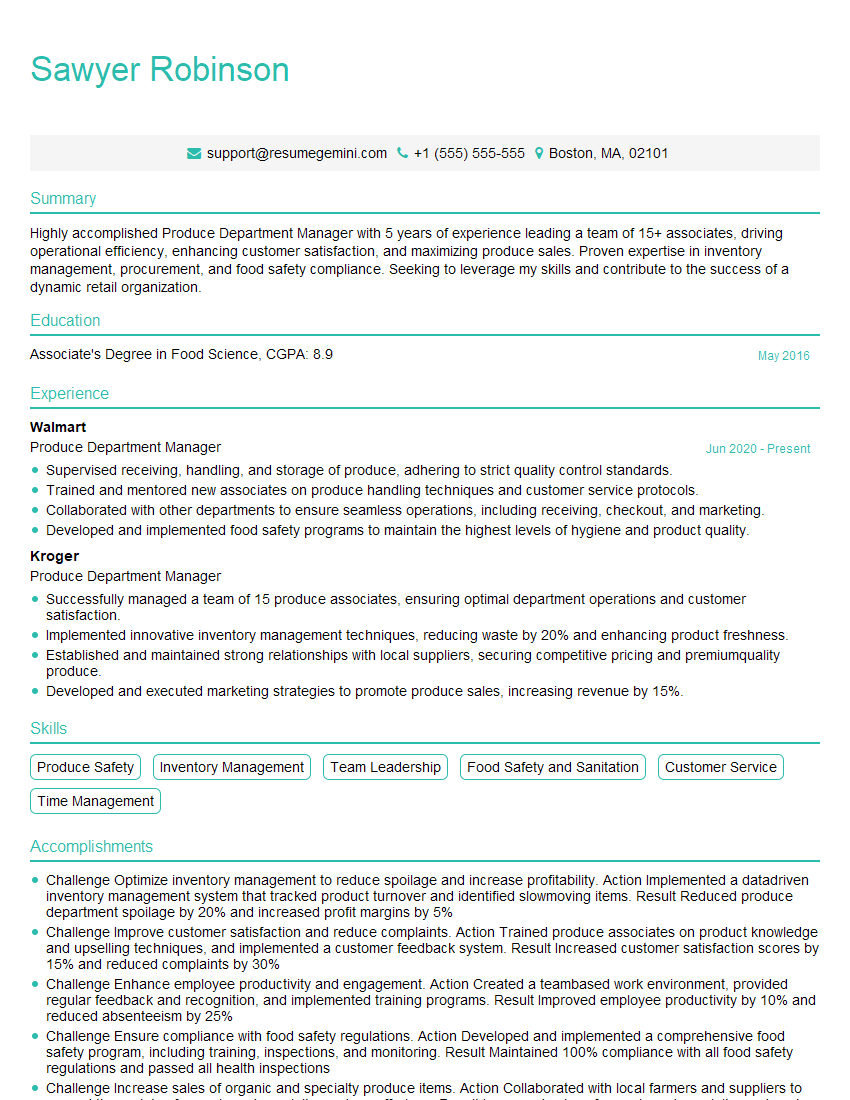

Mastering Produce Handling Techniques is crucial for career advancement in the food industry, opening doors to supervisory roles and enhanced earning potential. An ATS-friendly resume is vital for securing interviews. To significantly boost your job prospects, we recommend using ResumeGemini to craft a compelling and effective resume. ResumeGemini offers a streamlined process and provides examples of resumes specifically tailored to showcasing expertise in Produce Handling Techniques. Take the next step towards your dream career – build your best resume with ResumeGemini.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good