Are you ready to stand out in your next interview? Understanding and preparing for Produce Safety Alliance (PSA) Certification interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Produce Safety Alliance (PSA) Certification Interview

Q 1. Explain the seven principles of the Hazard Analysis and Critical Control Points (HACCP) system.

The Hazard Analysis and Critical Control Points (HACCP) system is a preventative food safety management system. It’s based on identifying potential hazards and establishing controls to prevent them from occurring. The seven principles are:

- Conduct a hazard analysis: Identify potential biological, chemical, and physical hazards that could occur at each step of the produce production process, from planting to consumption. For example, Salmonella contamination during harvesting is a biological hazard.

- Determine critical control points (CCPs): Identify steps in the process where controls can be applied to prevent or eliminate hazards or reduce them to acceptable levels. A CCP might be washing produce after harvesting to eliminate soil-borne pathogens.

- Establish critical limits for each CCP: Set specific measurable limits for each CCP. This might be a temperature limit during storage or a chlorine concentration during washing.

- Establish monitoring procedures: Develop a system to regularly monitor CCPs to ensure limits are met. This could involve regular temperature checks and chlorine testing.

- Establish corrective actions: Create procedures to follow if a CCP is not under control. For instance, if the temperature in a storage facility rises above the critical limit, the produce should be moved to a cooler location.

- Establish verification procedures: Implement methods to ensure that the HACCP plan is working effectively. This could include regular audits and review of records.

- Establish record-keeping and documentation procedures: Maintain records of all monitoring, corrective actions, and verification activities. These records are crucial for traceability and demonstrating compliance.

Q 2. Describe the key provisions of the Food Safety Modernization Act (FSMA) Produce Rule.

The Food Safety Modernization Act (FSMA) Produce Rule aims to prevent contamination of produce before it reaches consumers. Key provisions include:

- Agricultural Water: Requires growers to implement measures to ensure agricultural water used in the production of produce is safe. This involves testing and monitoring water quality.

- Biological Soil Amendments: Sets requirements for the safe use of manure and compost as soil amendments to prevent contamination with pathogens.

- Worker Health and Hygiene: Requires farms to implement worker health and hygiene practices to minimize the risk of contamination from workers.

- Harvesting Practices: Outlines practices for harvesting produce in a way that minimizes contamination, including proper equipment sanitation and handling procedures.

- Packinghouse Operations: Addresses sanitation and hygiene practices in packinghouses to prevent contamination of produce during packing.

- Science-based Mitigation Strategies: Encourages the use of science-based approaches to prevent contamination. For example, using approved sanitation chemicals.

- Record-Keeping: Requires growers to maintain records to demonstrate compliance with the rule. These records might include water testing results, worker health records, and sanitation logs.

Essentially, the rule shifts the focus from responding to contamination to preventing it proactively.

Q 3. What are the requirements for agricultural water used in the production of produce?

Agricultural water used in produce production must be safe to prevent contamination. Requirements often involve:

- Testing: Regular testing for microbial contamination, such as E. coli and other pathogens. The frequency of testing depends on factors like the water source and intended use.

- Monitoring: Continuous monitoring of water quality parameters such as turbidity (cloudiness), pH, and temperature. Changes in these parameters could indicate potential contamination.

- Source Water Assessment: Evaluating the source of water for potential risks and vulnerabilities. Identifying potential sources of contamination like animal waste is vital.

- Water Treatment: Employing appropriate water treatment methods if testing reveals contamination. These methods could include chlorination, filtration, or UV disinfection.

- Protection from Contamination: Implementing measures to protect water sources from contamination, such as excluding animals from water sources and maintaining appropriate distances from potential pollutants.

The specific requirements may vary depending on factors like the type of produce grown, the water source, and the intended use of the water.

Q 4. How do you implement worker health and hygiene practices on a farm?

Implementing worker health and hygiene practices is crucial for preventing produce contamination. This includes:

- Handwashing: Providing readily accessible handwashing stations with soap and running water, and ensuring workers understand the importance of frequent handwashing.

- Protective Clothing: Providing clean protective clothing, such as gloves, aprons, and hairnets. Regular changes of clothing are important.

- Training: Providing comprehensive training to workers on proper handwashing techniques, hygiene practices, and reporting illness.

- Health Monitoring: Establishing procedures for monitoring worker health and excluding ill workers from the production process.

- Illness Reporting: Establishing a clear system for workers to report any illness or symptoms to prevent potential contamination.

- Waste Disposal: Providing appropriate waste disposal methods to prevent the spread of contaminants.

- Toilet Facilities: Ensuring adequate and clean toilet facilities are available, positioned to minimize contamination risk.

Think of it like this: each worker is a potential vector for contamination. Strict hygiene practices minimize this risk.

Q 5. What are the critical control points for preventing microbial contamination during harvesting?

Critical control points during harvesting that prevent microbial contamination include:

- Pre-harvest Sanitation: Cleaning equipment and tools before harvesting to eliminate existing pathogens.

- Worker Hygiene: Enforcing handwashing and protective clothing requirements to prevent contamination from workers.

- Harvesting Techniques: Employing careful harvesting techniques to minimize physical damage to produce, which can create entry points for microbes.

- Post-harvest Handling: Handling the harvested produce carefully and promptly to prevent cross-contamination. This includes avoiding contact with the ground.

- Field Sanitation: Maintaining field sanitation to prevent contamination from soil, water, or wildlife.

- Equipment Cleaning: Thorough cleaning and sanitizing of harvesting equipment after each use. This can prevent the spread of pathogens between fields and harvests.

Imagine harvesting tomatoes – a single cut or bruise can become an entry point for bacteria if sanitation isn’t properly maintained. Each step is critical.

Q 6. Explain the importance of pre-harvest activities in ensuring food safety.

Pre-harvest activities are crucial for ensuring food safety because they lay the foundation for a safe crop. They significantly impact the overall quality and safety of the final product. Key aspects include:

- Soil Health Management: Healthy soil reduces the risk of pathogen growth. This includes appropriate soil amendments, crop rotation, and pest management.

- Pest and Disease Management: Implementing integrated pest management (IPM) strategies to minimize pest and disease pressures, reducing the need for harmful chemicals and lowering the risk of contamination.

- Irrigation Water Management: Using safe irrigation water and implementing appropriate irrigation practices to prevent contamination.

- Fertilizer Management: Using appropriate fertilizers to support healthy plant growth and to prevent contamination from chemical residues.

- Crop Rotation and Cover Cropping: These methods help maintain healthy soil and reduce pest and disease pressures.

If you don’t start with a healthy field, you’re increasing the chances of problems later on. It’s about preventing problems before they even arise.

Q 7. Describe different types of biological hazards found in produce and their control measures.

Produce can be contaminated by various biological hazards, including:

- Bacteria: Salmonella, E. coli, Listeria monocytogenes are examples. These can cause severe illnesses. Control measures include proper sanitation, refrigeration, and cooking.

- Viruses: Norovirus and Hepatitis A are examples. These are often transmitted through contaminated water or human contact. Handwashing and proper sanitation are crucial for control.

- Parasites: Toxoplasma gondii (found in cat feces) and cyclospora are examples. Controlling contamination often requires careful management of animal waste and proper irrigation practices.

- Fungi: Molds and yeasts can cause spoilage and mycotoxin production. Proper storage, humidity control, and good sanitation help control fungal growth.

Control measures often involve a combination of strategies including good agricultural practices, sanitation, proper handling, and appropriate storage conditions. The specific approach will depend on the hazard and the type of produce.

Q 8. What are the requirements for maintaining records for produce safety?

Maintaining accurate and readily available records is crucial for demonstrating compliance with the Produce Safety Rule. The specific records required depend on the size and complexity of your operation, but generally include:

- Farm maps and field records: Showing the location of crops, irrigation sources, and potential contamination risks.

- Water source testing results: Demonstrating the safety of water used for irrigation and washing produce.

- Worker health and training records: Verifying that employees have received necessary training on food safety practices and that any illnesses are appropriately addressed.

- Harvesting and packing records: Detailing procedures and ensuring proper handling practices.

- Pest control records: Documenting the application of pesticides and other pest control measures, ensuring compliance with regulations.

- Compost and manure management records: Showing safe handling and application to prevent contamination.

- Equipment cleaning and sanitation logs: Demonstrating that equipment is regularly cleaned and sanitized to prevent cross-contamination.

Think of these records as your operation’s food safety diary. They’re essential for tracing problems, demonstrating compliance to auditors, and protecting your brand and consumers. For example, if a foodborne illness outbreak is linked to your produce, thorough records will help pinpoint the source and prevent future incidents.

Q 9. Explain the importance of traceability in a produce operation.

Traceability in produce operations is the ability to track a product from its origin (seed or planting) through each step of production, processing, and distribution until it reaches the consumer. It’s like a detailed history of the produce’s journey.

Why is it important? If a food safety problem arises, traceability allows for rapid identification and removal of the affected products from the marketplace, limiting potential harm and preventing widespread contamination. It also helps manage recalls more efficiently and reduces economic losses. Imagine a scenario where a batch of lettuce is contaminated. With robust traceability, you can quickly isolate the specific farm field, harvest date, and even the packing line involved, preventing a larger recall.

Implementing traceability often involves using lot codes, tracking numbers, and record-keeping systems. The more detailed the tracking, the better equipped you are to respond to a crisis.

Q 10. How do you conduct a thorough farm assessment for produce safety?

A thorough farm assessment for produce safety is a systematic evaluation of your operation to identify potential hazards and vulnerabilities in your food safety system. It’s a proactive approach, not just a reaction to problems. The assessment should include:

- Site Inspection: A walkthrough of the entire farm, including fields, packing facilities, storage areas, and water sources. Look for potential sources of contamination – animal activity, improper waste disposal, contaminated water, etc.

- Water Quality Assessment: Testing the source and quality of water used for irrigation and washing produce to ensure it’s safe and meets regulatory standards.

- Worker Practices Evaluation: Observing workers to assess their hygiene practices, training, and adherence to food safety protocols. Do they wash their hands properly? Are they using appropriate gloves?

- Equipment and Facility Review: Inspecting equipment and facilities for cleanliness and proper maintenance. Are there procedures in place to regularly sanitize equipment?

- Pest and Wildlife Management Analysis: Evaluating strategies to manage pests and wildlife that could potentially contaminate the produce.

- Review of Records and Procedures: Examining existing records to assess compliance with food safety regulations and standard operating procedures.

The goal is not to find fault, but to identify areas for improvement. A thorough assessment will help to proactively address potential risks and build a strong food safety system.

Q 11. What are the common challenges associated with implementing produce safety practices?

Implementing produce safety practices can present several challenges:

- Cost: Implementing and maintaining a robust food safety system requires investment in infrastructure, training, testing, and record-keeping.

- Labor: Adherence to rigorous protocols requires additional time and labor, potentially increasing operational costs.

- Training: Ensuring all workers receive adequate training on food safety principles and practices can be challenging, especially with a fluctuating workforce.

- Technological limitations: Smaller farms may lack access to sophisticated technology for testing, record-keeping, and traceability.

- Weather events: Extreme weather conditions can negatively impact produce safety, making it difficult to maintain optimal conditions.

- Compliance: Keeping abreast of ever-changing regulations and demonstrating compliance can be overwhelming.

Overcoming these challenges often involves seeking support from extension services, industry associations, and collaborating with other growers to share best practices and resources.

Q 12. Explain your understanding of GAPs (Good Agricultural Practices).

Good Agricultural Practices (GAPs) are a set of principles and procedures for producing safe and high-quality agricultural products. They encompass a wide range of practices aimed at minimizing risks of contamination and ensuring food safety throughout the production process. GAPs are a proactive approach to food safety, aiming to prevent contamination rather than reacting to it.

GAPs cover many aspects, including:

- Soil health: Maintaining healthy soil to reduce the risk of contamination.

- Water management: Ensuring safe water sources and avoiding contamination of irrigation water.

- Pest management: Implementing integrated pest management (IPM) strategies to reduce reliance on pesticides and minimize residues.

- Worker hygiene: Establishing clear hygiene protocols to prevent contamination from human sources.

- Harvesting and handling: Following safe harvesting and handling practices to prevent contamination during and after harvest.

- Equipment sanitation: Regularly cleaning and sanitizing equipment to prevent cross-contamination.

Adherence to GAPs not only ensures food safety but also improves the quality and consistency of produce, leading to better market access and consumer confidence.

Q 13. How would you address a suspected food safety incident?

Addressing a suspected food safety incident requires a rapid and organized response. Here’s a step-by-step approach:

- Isolate the suspected product: Immediately remove the suspected product from the market and trace its origin.

- Notify relevant authorities: Contact your local health department, FDA, or other regulatory bodies, as appropriate.

- Conduct a thorough investigation: Determine the source of the contamination and identify any contributing factors.

- Implement corrective actions: Put measures in place to prevent future incidents.

- Communicate with customers: Transparency is key; communicate clearly with customers about the situation and any necessary precautions.

- Maintain accurate records: Document all aspects of the incident, investigation, and corrective actions.

Prompt action is crucial in minimizing potential harm and maintaining consumer confidence. Thorough record keeping is essential for demonstrating compliance and preventing future incidents. A suspected incident requires immediate and decisive action.

Q 14. Describe the process for handling a worker illness related to produce production.

Handling a worker illness related to produce production requires a multi-faceted approach that prioritizes worker health and food safety.

- Immediate Action: Remove the affected worker from the production area and provide necessary medical attention.

- Assess the Risk: Determine if the illness could be foodborne and if there’s a potential risk of contamination of produce.

- Notification: Report the illness to your supervisor and relevant authorities, as required by regulations.

- Traceability: If there is a potential for contamination, use your traceability system to identify all produce potentially affected by the ill worker.

- Sanitation: Thoroughly sanitize all areas and equipment the ill worker came into contact with.

- Record Keeping: Maintain detailed records of the illness, actions taken, and any affected produce.

- Worker Education: Reinforce the importance of reporting illnesses promptly and emphasize hygiene and food safety protocols.

This process demonstrates a commitment to worker well-being and food safety, minimizing risks and maintaining consumer trust. Proactive measures and thorough documentation are key to effective management.

Q 15. What is your experience with pesticide safety and application?

My experience with pesticide safety and application is extensive, encompassing both practical application and theoretical understanding gained through my PSA certification and years of working in the field. I’m proficient in selecting the appropriate pesticide for specific pests and crops, understanding label instructions meticulously, and adhering strictly to safety regulations such as Personal Protective Equipment (PPE) usage – this includes respirators, gloves, and coveralls. I understand the importance of Integrated Pest Management (IPM), prioritizing non-chemical methods like crop rotation and biological controls whenever possible. I’m also trained in proper pesticide disposal methods and record-keeping, crucial for compliance and environmental protection. For instance, I’ve successfully implemented an IPM program on a lettuce farm, reducing pesticide use by 30% while maintaining yield and quality. This involved introducing beneficial insects and adjusting irrigation practices to create a less favorable environment for target pests.

Career Expert Tips:

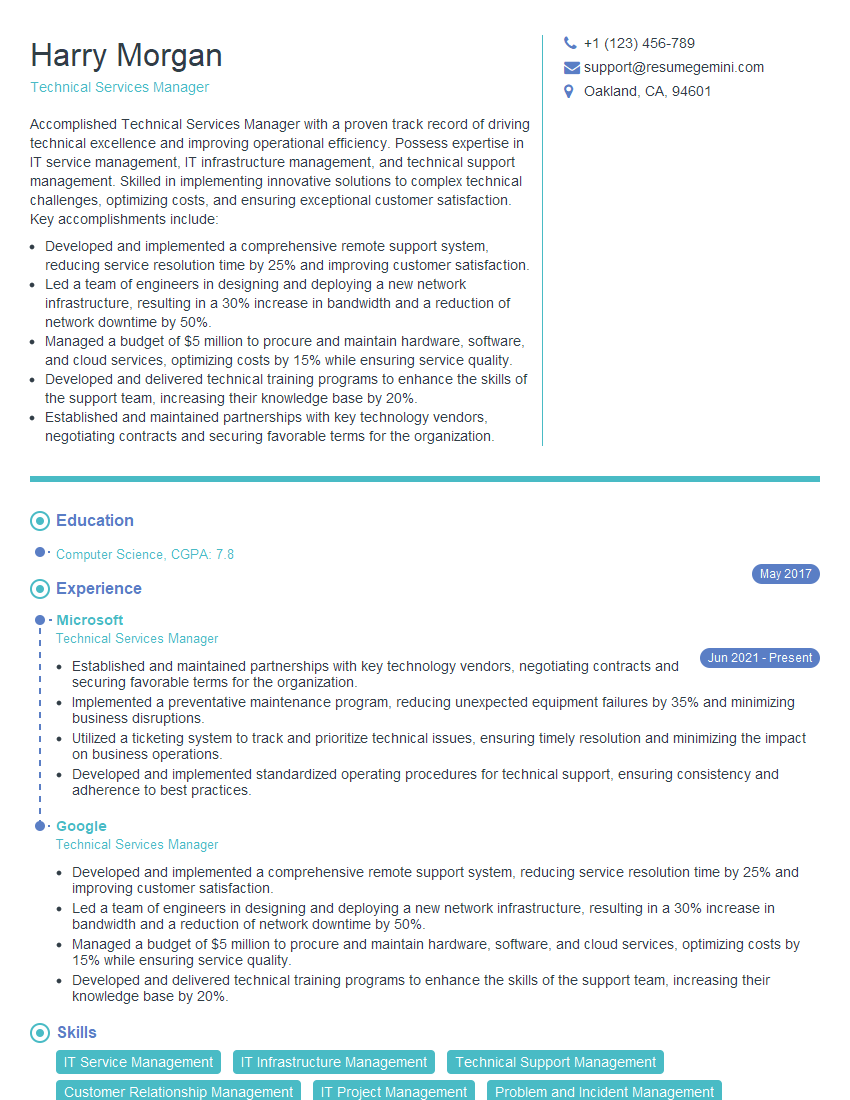

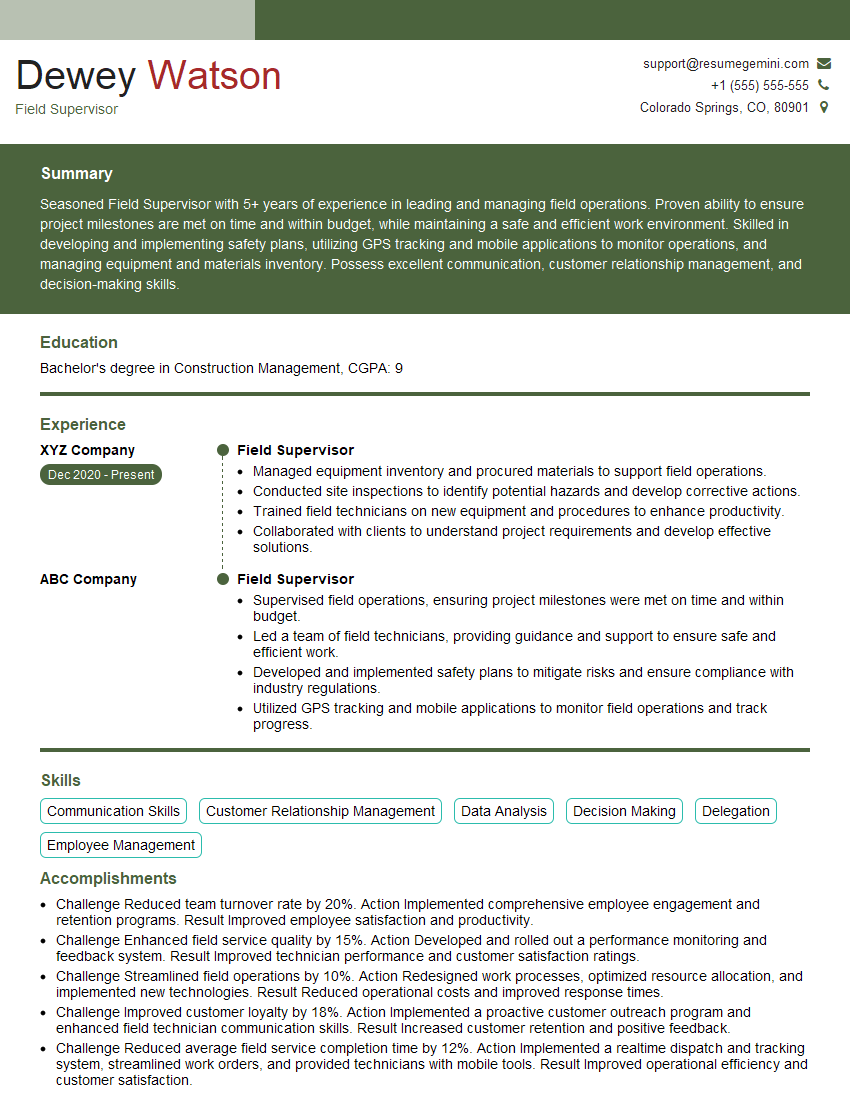

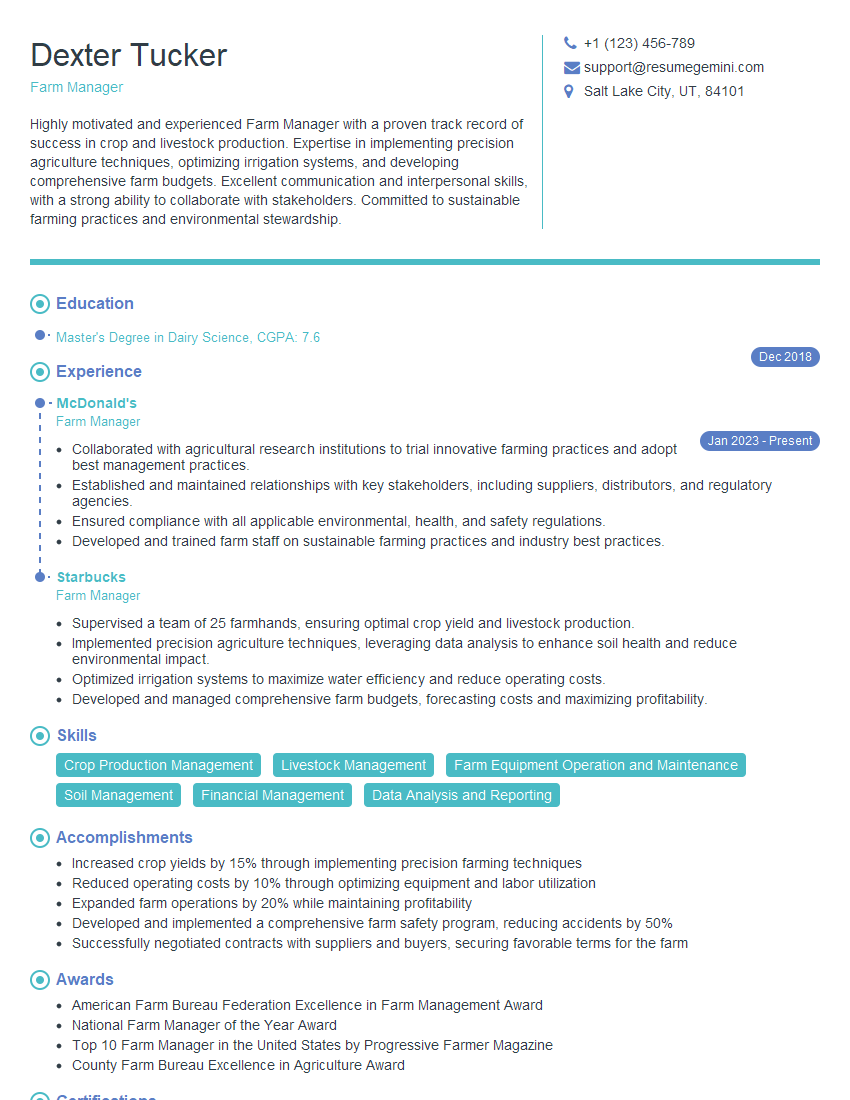

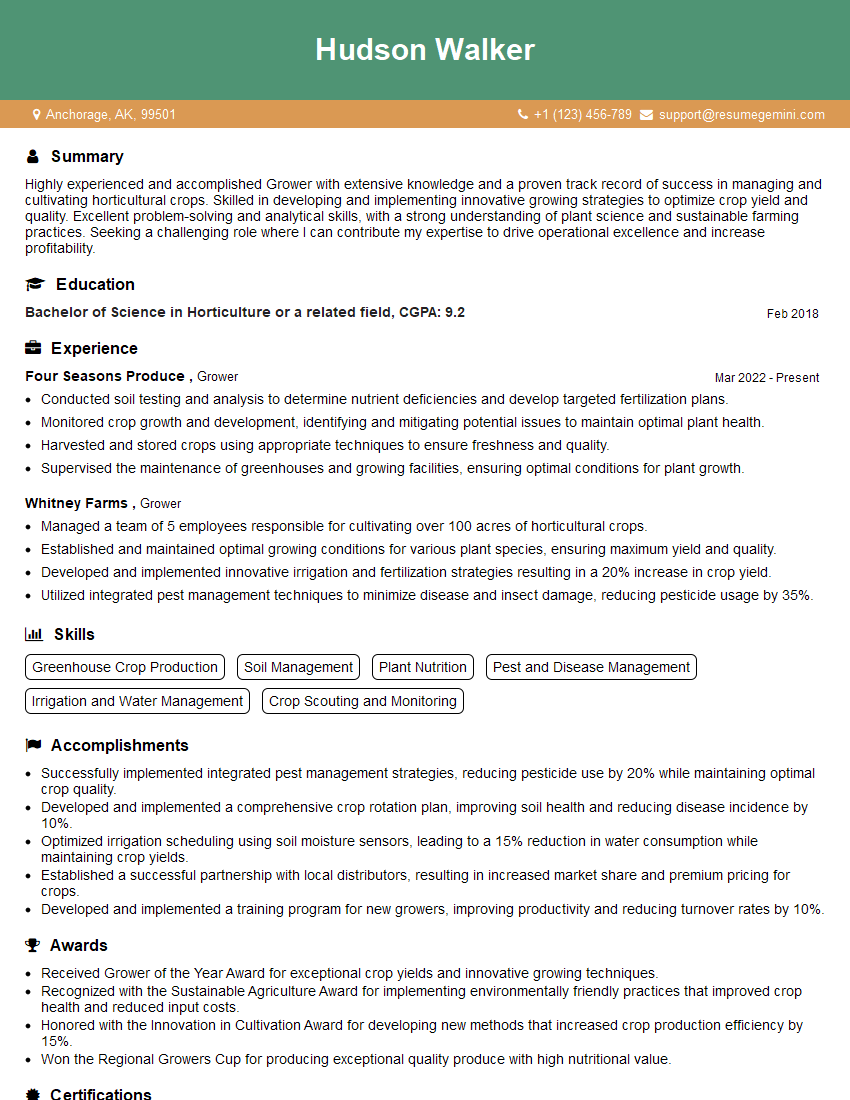

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure effective sanitation of equipment and facilities?

Effective sanitation is paramount in produce safety. My approach involves a multi-step process, beginning with a thorough cleaning of all equipment and facilities. This includes removing visible soil and debris using high-pressure water jets. Then, we use a detergent-based wash, followed by a sanitizing rinse, typically with a chlorine solution, according to established concentrations and contact times – this varies based on the surface material and the severity of the soiling. All equipment must be thoroughly dried to prevent recontamination. We maintain detailed sanitation logs, documenting the cleaning agents used, times, and personnel involved. For example, in processing lettuce, our sanitation protocols involve dismantling harvesting equipment after each use for a complete clean, ensuring that every crevice is thoroughly sanitized to prevent bacterial contamination.

Q 17. Describe your understanding of the various types of produce and their specific safety considerations.

Different produce types present unique safety considerations. Leafy greens, for instance, are particularly susceptible to bacterial contamination like E. coli and Salmonella, necessitating stringent sanitation practices throughout the growing and harvesting process. Root vegetables may harbor soilborne pathogens, requiring careful washing and potentially treatment with UV light. Fruits with delicate skins, like berries, are easily bruised and susceptible to mold growth, requiring gentle handling and rapid processing. Each produce type’s specific characteristics influence its vulnerability to various hazards. For example, tomatoes need careful handling during harvest to avoid bruising, while leafy greens require careful washing to remove soil and pathogens. I’m adept at identifying these vulnerabilities and tailoring my safety protocols to minimize risk.

Q 18. What are the potential hazards associated with irrigation water?

Irrigation water can pose several hazards to produce safety. Contamination with pathogens (like E. coli, Salmonella) from animal waste, human sewage, or runoff from contaminated fields is a significant concern. High levels of minerals, like salts, can also affect plant growth and potentially accumulate in the produce. Pesticides or other chemicals present in the water source can contaminate the crops. We routinely test our irrigation water for pathogens and chemical residues, and we implement practices to prevent contamination, such as using treated wastewater or constructing appropriate barriers to prevent runoff. For instance, we regularly test our irrigation water quality and implemented a system of water filtration to reduce the risk of contamination from surface runoff.

Q 19. How do you monitor and control pests on a farm?

Pest monitoring and control is a crucial aspect of produce safety. I utilize an Integrated Pest Management (IPM) approach, emphasizing preventative measures like crop rotation, using pest-resistant varieties, and creating a habitat less hospitable to pests through proper sanitation and weed control. Monitoring involves regularly inspecting crops for pest activity, using traps and visual assessments. When pests are detected, we prioritize non-chemical controls like introducing beneficial insects or applying targeted pesticides only when necessary and according to label instructions. Regular monitoring is critical to prevent infestations and ensure the safety and quality of produce. For instance, we use pheromone traps to monitor for certain moth populations and only apply targeted insecticides when thresholds are exceeded. This minimizes pesticide use while effectively controlling pest populations.

Q 20. What are the various methods for preventing and controlling wildlife intrusion?

Preventing and controlling wildlife intrusion involves a combination of strategies. Physical barriers such as fences, nets, and bird netting are effective at preventing access to crops. Repellents, both visual (like reflective tapes) and olfactory (like strong-smelling compounds), can deter animals. Proper waste disposal is essential to prevent attracting animals. In addition, habitat modification, such as removing brush near fields, can make the area less attractive to wildlife. For example, we have installed electric fencing around our fields to deter deer and used bird netting to protect our berry crops. These proactive measures protect our yields and the quality of the produce from wildlife damage.

Q 21. How do you ensure proper storage and transportation of harvested produce?

Proper storage and transportation are critical to maintain the quality and safety of harvested produce. Harvested produce should be handled gently to avoid damage. Appropriate cooling methods, such as refrigeration or hydrocooling, are employed immediately after harvest to slow down microbial growth and extend shelf life. During transportation, produce should be kept at the correct temperature and protected from physical damage. We maintain detailed records of temperature throughout the process. For example, our harvested lettuce is hydro-cooled immediately after harvesting to maintain freshness and transported in refrigerated trucks to the processing facility to ensure consistent cold chain integrity and prevent spoilage.

Q 22. Describe your experience with developing and implementing a food safety plan.

Developing and implementing a food safety plan, especially within the context of Produce Safety Alliance (PSA) guidelines, is a multi-step process. It begins with a thorough hazard analysis, identifying potential biological, chemical, and physical hazards at every step of the produce production process, from planting to harvest and packaging. This involves considering factors like water sources, soil contamination, worker hygiene, and equipment sanitation.

Next, I develop preventative controls – measures to minimize or eliminate these hazards. This might involve implementing good agricultural practices (GAPs), such as using clean water for irrigation, preventing cross-contamination, and properly handling and storing produce. I then document all these controls in a written food safety plan, a crucial element for compliance and traceability. Finally, I train all workers on the plan, ensure monitoring procedures are in place (e.g., temperature logs, water testing), and conduct regular internal audits to verify that the plan is effectively implemented.

For instance, in one project, we identified a potential risk of E. coli contamination from irrigation water. Our solution involved implementing a water testing program and switching to a cleaner water source, fully documented in the food safety plan.

Q 23. What is your approach to training workers on food safety procedures?

My approach to worker training emphasizes practical application and clear communication. I don’t just provide information; I ensure workers understand the ‘why’ behind each procedure. I use a multi-faceted approach including classroom training, hands-on demonstrations, and job shadowing. The training is tailored to each worker’s role and responsibilities within the operation.

For example, harvest crew training would focus on proper handwashing, avoiding cross-contamination between fields, and safe harvesting techniques. Packaging workers would receive training on proper sanitation procedures for equipment and packaging materials. I also use visual aids like diagrams, checklists, and videos to improve comprehension and retention. Regular quizzes and assessments ensure understanding and reinforce key concepts. I always encourage questions and feedback, creating a safe space for workers to express concerns.

Q 24. How do you effectively communicate food safety information to workers?

Effective communication is key to a robust food safety program. I use a variety of methods tailored to the workers’ literacy levels and preferred learning styles.

- Visual aids: Diagrams, flowcharts, and pictures are incredibly effective in conveying complex processes clearly.

- Simple language: I avoid technical jargon and explain concepts in straightforward terms, using relatable examples.

- Interactive training: Hands-on exercises and role-playing help workers apply their knowledge practically.

- Multiple formats: Combining classroom sessions with online modules or short videos caters to various learning preferences.

- Regular updates: I regularly communicate changes in procedures or regulations to ensure everyone stays informed.

- Feedback mechanisms: I encourage workers to provide feedback and report any issues or concerns, fostering a culture of open communication.

For example, instead of just saying “maintain proper hygiene,” I demonstrate proper handwashing techniques and explain why it is crucial for preventing contamination.

Q 25. How do you conduct internal audits to ensure compliance with food safety regulations?

Internal audits are essential for ensuring ongoing compliance with food safety regulations and identifying areas for improvement. My approach to conducting internal audits involves a systematic review of all aspects of the food safety plan. This includes a detailed review of documentation, observation of practices in the field, and interviews with workers.

I use pre-defined checklists based on the food safety plan and relevant regulations like the FDA’s Produce Safety Rule. The checklist includes specific criteria for each area of the operation, enabling a consistent and objective assessment. I also use photos and videos to document observations. Following the audit, I produce a detailed report that summarizes findings, identifies non-compliances, and recommends corrective actions. Corrective actions are then implemented, documented, and verified through follow-up audits. The process is cyclical, continuously improving food safety protocols.

Q 26. What are your strengths and weaknesses in relation to food safety expertise?

My strengths lie in my thorough understanding of the Produce Safety Rule and my ability to translate complex regulations into practical, easy-to-understand procedures for farm workers. I am adept at building strong working relationships with farm operators and workers and am highly organized and detail-oriented, ensuring comprehensive implementation of food safety plans. I also possess excellent communication and training skills.

One area for improvement is expanding my knowledge of specific emerging food safety technologies, particularly in the area of rapid pathogen detection. While I understand the principles, more in-depth knowledge would enhance my ability to advise clients on the most cutting-edge techniques.

Q 27. Describe a situation where you had to solve a food safety problem. What steps did you take?

At one farm, we experienced a significant increase in the number of customer complaints regarding bruised produce. This wasn’t a safety hazard per se, but it impacted product quality and customer satisfaction.

My first step was to analyze the problem. We conducted interviews with harvest workers, reviewed harvest records, and observed the harvesting process. This revealed that a newly implemented harvesting tool was causing more bruising than the previous method. Next, we held a retraining session with the workers, focusing on the correct use of the new tool, and we adjusted the harvesting schedule to avoid peak sun hours, reducing stress on the produce. We also revised our post-harvest handling procedures to identify and remove bruised produce more efficiently. The result was a significant reduction in bruising and an increase in customer satisfaction.

Q 28. How do you stay updated on the latest food safety regulations and best practices?

Staying updated in the ever-evolving field of food safety requires a multi-pronged approach. I regularly review updates and guidance documents from the FDA, including the Produce Safety Rule. I actively participate in professional organizations like the Produce Safety Alliance, attending workshops, webinars, and conferences. I also subscribe to relevant food safety publications and journals.

Furthermore, I maintain professional networks with other food safety experts, sharing information and insights to stay current on best practices. This continuous learning ensures that my knowledge and practices remain current and aligned with the latest advancements in food safety regulations and technology.

Key Topics to Learn for Produce Safety Alliance (PSA) Certification Interview

- Agricultural Water Management: Understand sources of water contamination, water testing methods, and best practices for irrigation water management to ensure produce safety. Consider how you would troubleshoot a contamination event.

- Biological Hazards: Learn about common pathogens (e.g., *Salmonella*, *E. coli*) and their routes of contamination in produce. Be prepared to discuss preventative measures and sanitation procedures to minimize risk.

- Harvesting and Packing: Master the principles of safe harvesting practices, including worker hygiene, equipment sanitation, and proper handling to prevent contamination during and after harvest. Think through scenarios involving equipment malfunctions and how to address them.

- Good Agricultural Practices (GAPs): Familiarize yourself with the core principles of GAPs and their integration into a comprehensive produce safety plan. Be ready to explain how specific GAPs address potential hazards.

- Produce Safety Rule (PSR): Understand the key requirements of the Food Safety Modernization Act (FSMA) Produce Safety Rule and how it applies to different types of produce operations. Think about the implications of non-compliance.

- Hazard Analysis and Critical Control Points (HACCP): Grasp the fundamentals of HACCP principles and their application to produce safety. Practice identifying potential hazards and establishing critical control points to manage them effectively.

- Recordkeeping and Documentation: Understand the importance of meticulous recordkeeping to demonstrate compliance with regulations and trace potential contamination sources. Be prepared to discuss the types of records required and how to maintain them.

Next Steps

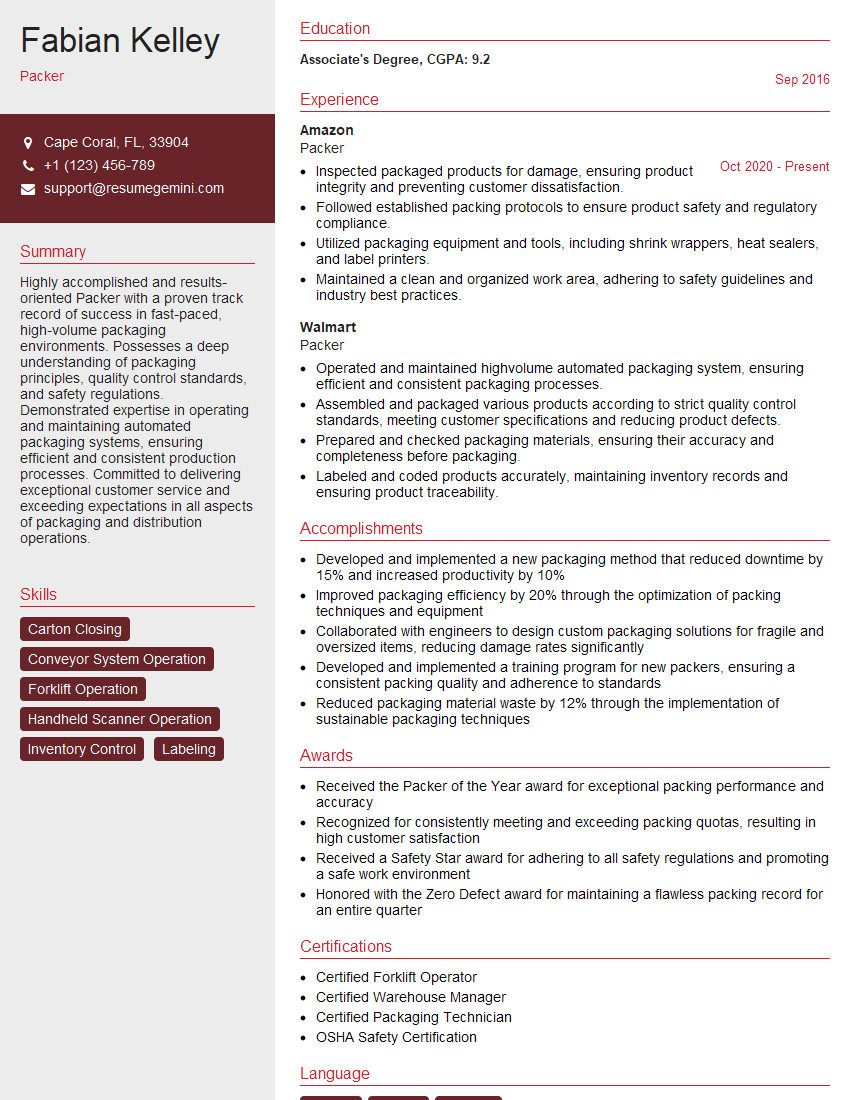

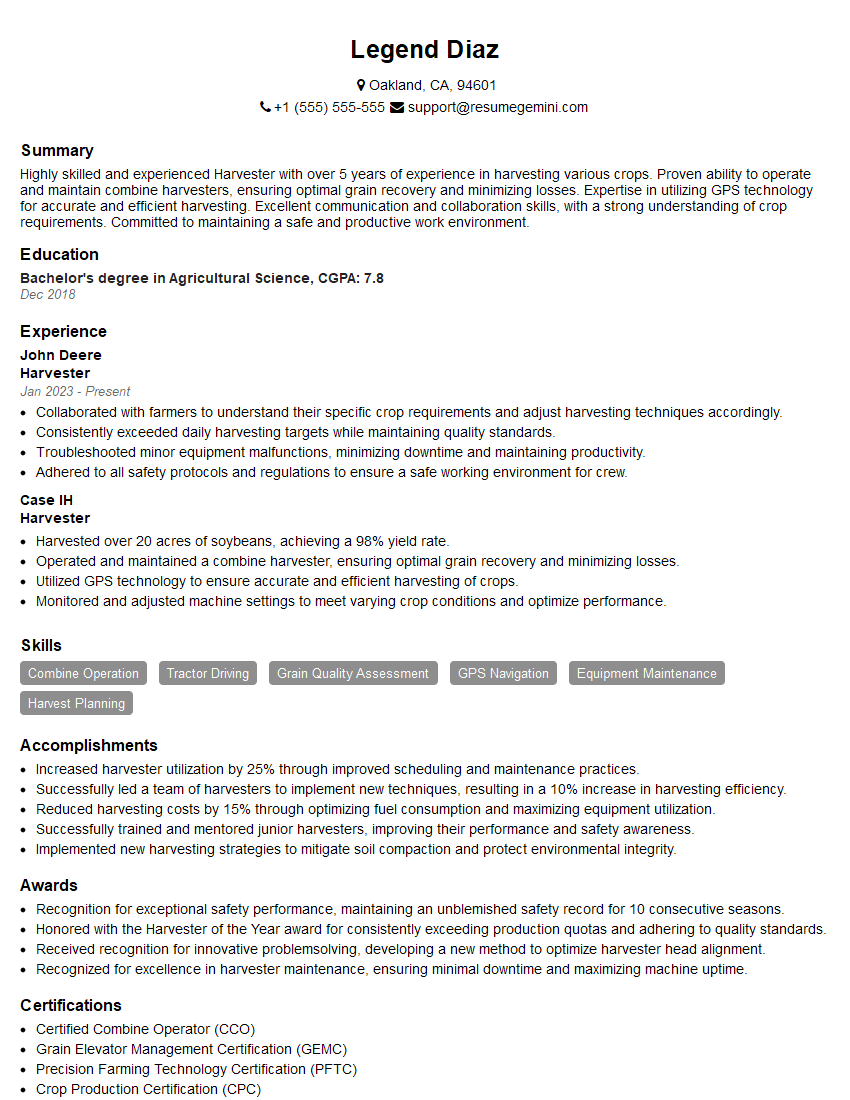

Mastering the Produce Safety Alliance (PSA) Certification significantly enhances your career prospects in the food safety industry, opening doors to diverse and rewarding opportunities. To maximize your job search success, creating a strong, ATS-friendly resume is crucial. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your PSA certification and relevant experience. Examples of resumes specifically designed for candidates with PSA certification are available through ResumeGemini to help guide your resume creation. Invest the time to craft a compelling resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good