Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Produce Trimming interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Produce Trimming Interview

Q 1. What are the common types of produce you have experience trimming?

Throughout my career, I’ve gained extensive experience trimming a wide variety of produce. This includes leafy greens like lettuce, spinach, and kale; root vegetables such as carrots, potatoes, and beets; fruits like strawberries, melons, and apples; and even more delicate items like asparagus and herbs. My experience spans different scales, from small-scale operations to large-scale commercial processing.

- Leafy Greens: Requires careful attention to remove wilted or damaged leaves, while maintaining the integrity of the head or bunch.

- Root Vegetables: Involves trimming off the tops and ends, sometimes peeling or scrubbing depending on the application. Imperfections and blemishes need to be carefully considered.

- Fruits: Techniques vary greatly depending on the fruit. For example, strawberries need careful removal of stems and damaged parts, while melons require trimming off damaged sections or removing the rind.

Q 2. Describe your experience with different trimming techniques.

My experience encompasses several trimming techniques, each optimized for specific produce and desired outcome. I’m proficient in:

- Hand Trimming: This is crucial for delicate items and requires precision and speed. I can quickly and efficiently remove blemishes and unwanted parts while minimizing waste.

- Mechanical Trimming: I have experience operating various automated trimming machines, including conveyor belt systems and specialized knives for high-volume processing. This requires a strong understanding of machine operation and safety protocols.

- Combination Trimming: Often, a combination of hand and mechanical trimming is the most efficient and effective approach. For example, pre-trimming with a machine followed by hand-finishing to ensure high-quality results.

The choice of technique depends on factors like the type of produce, the desired level of precision, production volume, and available resources.

Q 3. How do you ensure the quality and safety of trimmed produce?

Ensuring the quality and safety of trimmed produce is paramount. My approach involves a multi-pronged strategy:

- Careful Selection: Starting with high-quality produce is crucial. I inspect each item carefully for damage, disease, or pest infestation before trimming.

- Hygiene Practices: Maintaining strict hygiene throughout the process is essential to prevent contamination. This includes frequent handwashing, use of sanitized tools, and adherence to all food safety regulations.

- Temperature Control: Maintaining appropriate temperature during processing prevents bacterial growth and preserves the freshness of the produce. Cold storage is vital, especially for perishable items.

- Post-Trimming Inspection: A final inspection after trimming ensures that the produce meets quality standards and is free from any contaminants or defects.

I’m familiar with all relevant food safety regulations and best practices, including HACCP (Hazard Analysis and Critical Control Points).

Q 4. What are the key sanitation practices you follow during produce trimming?

Sanitation is integral to my workflow. I follow a rigorous protocol that includes:

- Handwashing: Frequent and thorough handwashing with soap and water, especially before and after handling produce.

- Equipment Sanitation: Regular sanitization of all trimming tools and equipment using appropriate food-grade sanitizers.

- Work Surface Cleaning: Keeping work surfaces clean and disinfected to prevent cross-contamination.

- Waste Disposal: Proper disposal of trimmed waste to avoid attracting pests and maintaining a clean work environment.

- Personal Protective Equipment (PPE): Wearing appropriate PPE, such as gloves and hairnets, is crucial to maintain hygiene and prevent contamination.

I strictly adhere to all company and regulatory sanitation guidelines.

Q 5. Explain your experience with using different trimming tools.

My experience with trimming tools is extensive and includes:

- Knives: From standard paring knives to specialized trimming knives, I am adept at using different types of knives for various produce. Proper knife handling and sharpening techniques are crucial for efficiency and safety.

- Shears: Especially useful for trimming herbs and leafy greens, ensuring clean cuts while maintaining the integrity of the leaves.

- Mechanical Trimmers: I’m experienced operating various automated trimming machines, including conveyor belt systems and specialized knives designed for high-volume processing. This includes understanding maintenance and safety protocols.

- Peeling Machines: For root vegetables, these machines significantly increase efficiency. I am familiar with different types and their operational requirements.

Selecting the right tool for the job is key to maximizing efficiency and minimizing waste.

Q 6. How do you handle produce with blemishes or imperfections?

Handling produce with blemishes or imperfections requires careful judgment. My approach considers several factors:

- Severity of the Blemishes: Minor blemishes may be trimmed away, while severe damage might necessitate discarding the entire piece.

- Type of Produce: The acceptable level of imperfection varies widely depending on the type of produce and intended use. For example, minor blemishes might be acceptable for processing into juice, but not for retail sale.

- Trimming Techniques: Careful trimming can often salvage produce with minor imperfections, minimizing waste.

- Sorting and Grading: Produce is often sorted into grades based on quality. Blemished produce might be downgraded and used for different applications.

The goal is to maximize yield while maintaining quality standards.

Q 7. What are the yield loss prevention measures you implement during trimming?

Minimizing yield loss is a critical aspect of efficient produce trimming. My strategies include:

- Proper Trimming Techniques: Using precise techniques to remove only the necessary portions minimizes waste.

- Sharp Tools: Sharp knives and shears make cleaner, more efficient cuts, reducing the amount of produce lost during trimming.

- Careful Handling: Avoid bruising or damaging the produce during handling to reduce unnecessary waste.

- Optimized Workflows: Efficient workflows and equipment selection minimize downtime and maximize processing speed.

- Waste Reduction Strategies: Finding alternative uses for trimmed waste, such as composting or creating secondary products (e.g., vegetable stock), can further reduce losses.

Regularly monitoring yield loss and adjusting processes helps maintain efficiency and profitability.

Q 8. How do you identify and remove spoiled or damaged produce?

Identifying and removing spoiled or damaged produce is crucial for maintaining food safety and quality. It’s a multi-sensory process. I begin by visually inspecting each piece of produce, looking for signs of bruising, discoloration, mold growth (fuzzy patches, discoloration), cuts, or insect damage. I also check for soft spots, indicating internal spoilage. A slight sniff can help detect off-odors indicative of decay. For example, a slightly mushy texture coupled with a sour smell on a strawberry points towards spoilage. Any produce showing these signs is immediately discarded, ensuring it doesn’t contaminate other items. The removal process involves using a sharp knife to carefully cut away the damaged area, ensuring a clean cut, which helps to prevent further decay. If the damage is extensive, the entire piece is discarded. This careful selection ensures only the highest-quality produce makes it to the next stage of processing.

Q 9. What are the different quality standards you adhere to while trimming?

Adhering to strict quality standards is paramount in produce trimming. These standards encompass several aspects. Firstly, the produce must be free from any visible signs of spoilage or damage, as discussed earlier. Secondly, the trimming process itself must maintain the integrity of the product; cuts should be clean, even and minimize waste. We aim for consistent size and shape wherever possible, according to pre-defined specifications for the final product (e.g., uniform lettuce leaves for salads, standardized carrot slices for packaging). Thirdly, hygiene standards are critical, ensuring the trimmed produce is free from any contaminants. This includes adhering to strict handwashing protocols, using sanitized tools and maintaining a clean work environment. We follow industry-best practices (like those set by the FDA and USDA) to ensure the highest level of quality and safety.

Q 10. Describe your experience with various types of cutting tools.

My experience with various cutting tools is extensive. I’m proficient in using a range of knives, from small paring knives for delicate work like trimming strawberries, to larger chef’s knives for efficient processing of bulk items such as melons or cabbages. I also have experience with specialized tools like mandolines for creating uniform slices and vegetable peelers for quick and efficient removal of skins. The selection of the right tool depends heavily on the type of produce and the desired outcome. For example, a serrated knife is excellent for cutting through tough-skinned produce like tomatoes without crushing them, whereas a smooth-bladed knife is preferred for more delicate items. Regular sharpening and maintenance are crucial for ensuring efficiency and preventing accidents. Dull blades require more force, increasing the risk of damage to the produce and injuries to the handler.

Q 11. How do you maintain hygiene and prevent cross-contamination while trimming?

Maintaining hygiene and preventing cross-contamination are top priorities. Our process begins with thorough handwashing before starting work and at regular intervals throughout the day. We utilize separate cutting boards for different types of produce to prevent cross-contamination, for instance, a dedicated board for raw vegetables and another for ready-to-eat items. Cutting tools are thoroughly washed and sanitized after each use, or even between different types of produce depending on the level of contamination risk. Our work area is kept meticulously clean, regularly wiped down, and all waste is disposed of promptly. We also wear appropriate protective gear, like gloves and hairnets, to minimize the risk of contamination from our person to the food. These procedures are not just good practice but are essential for meeting food safety regulations.

Q 12. Explain your knowledge of food safety regulations related to produce handling.

My understanding of food safety regulations concerning produce handling is comprehensive. I am familiar with the FDA’s Food Safety Modernization Act (FSMA), specifically the Produce Safety Rule, which outlines the standards for agricultural water, worker health and hygiene, and the prevention of contamination at the farm level and beyond. I’m also familiar with HACCP (Hazard Analysis and Critical Control Points) principles, which allow us to identify potential hazards throughout the produce trimming process and put in place measures to control them. This includes proper temperature control, avoiding cross-contamination, and ensuring proper sanitation at all stages. Compliance with these regulations is crucial for preventing foodborne illnesses and maintaining a safe food supply. Regular training and updates on these regulations keep my knowledge current and ensure best practices are always followed.

Q 13. How do you handle different produce based on varying levels of ripeness?

Handling produce based on varying ripeness requires a nuanced approach. Overripe produce is more prone to bruising and spoilage, requiring extra care during trimming. I handle them gently to avoid damaging the already delicate texture. Underripe produce, on the other hand, might require a firmer touch. For example, trimming a perfectly ripe mango involves a gentler hand than trimming a firmer, less-ripe one. The trimming technique also adapts—a firmer mango might require a sharper knife to cleanly cut through the skin. Understanding the optimal ripeness for different produce is crucial for achieving the best results. We often consult ripeness charts and receive guidance from the produce suppliers to ensure we’re handling each type optimally.

Q 14. How do you ensure efficient and timely completion of trimming tasks?

Efficient and timely completion of trimming tasks relies on effective organization and planning. This begins with proper assessment of the volume and type of produce requiring processing. I prioritize tasks based on urgency and shelf life to ensure the most perishable items are processed first. Maintaining a clean and organized workspace aids efficiency by minimizing the search time for tools and materials. Using appropriate tools for the job (as discussed earlier) significantly speeds up the process. Working methodically and avoiding distractions are vital. In high-volume settings, teamwork and clear communication between team members are crucial for optimizing workflow. Tracking progress against schedules allows for identification of bottlenecks and implementation of adjustments as needed to consistently meet deadlines.

Q 15. What is your experience with working in a team setting during produce trimming?

Teamwork is crucial in produce trimming, where efficiency and speed are paramount. In my previous role at Green Valley Farms, we operated as a highly coordinated unit. We had a lead trimmer who assigned tasks based on individual strengths and the day’s workload. For example, someone particularly skilled with delicate strawberries would handle them, while others tackled larger quantities of hardier vegetables like broccoli. We frequently rotated tasks to prevent monotony and ensure everyone was proficient in handling various produce. Regular communication, whether through brief check-ins or a quick signal to indicate a problem, was key to maintaining a smooth workflow. This collaborative approach allowed us to maintain consistent quality and significantly improve our overall output.

We also employed a system where we supported each other during peak times. If one station experienced a backlog, others would assist until the workload balanced out. This prevented bottlenecks and ensured timely completion of tasks. This collaborative spirit fosters a positive and efficient working environment, ultimately benefiting the entire team and the company.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you manage your workload when facing time constraints?

Managing workload under time constraints requires a strategic approach. My strategy centers on prioritizing tasks based on urgency and importance. I use a simple system of categorizing tasks: urgent/important, important/not urgent, urgent/not important, and neither. This helps me focus my energy where it’s most needed. For instance, if we have a large order of lettuce needing trimming before shipment, that takes priority over less time-sensitive tasks. I also break down large tasks into smaller, manageable chunks. This makes the overall job less daunting and allows for more efficient progress tracking.

Furthermore, I’m adept at multitasking while maintaining accuracy. For example, I might trim one type of produce while simultaneously weighing and packing another. Maintaining a constant flow of work prevents bottlenecks, which often arise from delaying tasks.

Q 17. How do you deal with unexpected challenges or equipment malfunctions?

Dealing with unexpected challenges is part of the job. During my time at Fresh Harvest, we experienced a sudden power outage that halted our automated conveyor belt. Our immediate response was to switch to manual trimming, a less efficient but still viable method. The team quickly adapted, redistributing workload and maintaining communication to minimize downtime. The problem was addressed through prioritizing tasks and effective communication to avoid delays.

Regarding equipment malfunctions, I have experience troubleshooting minor issues like blade dulling or conveyor belt adjustments. I know how to identify the problem, alert the supervisor, and implement temporary solutions while waiting for maintenance. For example, if a blade is dull, I know to switch to a spare or use a different technique to ensure quality and efficiency aren’t compromised. Being proactive and problem-solving oriented is crucial in this fast-paced environment.

Q 18. Describe your experience using weighing scales and other measuring devices.

I’m proficient in using various weighing scales and measuring devices. My experience includes using digital scales for precise weight measurements, often required for packaging and inventory management. I understand the importance of calibrating scales regularly to ensure accuracy. I’ve also used rulers and calipers for measuring produce dimensions, particularly important for cutting uniform sizes.

Understanding the limitations of each device is key. For instance, digital scales can be affected by environmental factors like temperature and humidity, so I’m mindful of these potential sources of error. I’m always careful to zero out the scale before each weighing and ensure that the device is correctly calibrated before beginning the weighing process. Accuracy in measurement is key to meeting customer specifications and avoiding waste.

Q 19. What is your experience with adhering to specific production targets or quotas?

Meeting production targets and quotas is a regular part of my work. I achieve this through efficient work habits, effective time management, and consistent monitoring of my progress. I often use a visual aid like a checklist to keep track of completed tasks and adjust my pace accordingly. If I notice I’m falling behind, I immediately assess the situation, identify the bottleneck, and implement a solution; whether it involves prioritizing tasks, requesting assistance, or simply refining my technique.

For instance, at one point I was tasked with trimming a large quantity of asparagus within a tight deadline. I prioritized the trimming process and collaborated with my team to optimize the workflow. We divided the tasks strategically, and by consistently monitoring our progress and adjusting our pace when needed, we successfully completed the order on time and met the quota. This approach involves proactive planning, focused execution, and adaptive problem-solving.

Q 20. Explain your knowledge of different produce varieties and their respective trimming requirements.

My knowledge of produce varieties and their trimming requirements is extensive. I understand that different produce requires different handling and trimming techniques. For example, delicate berries require gentle handling to avoid bruising, while tougher vegetables like broccoli may require more aggressive trimming to remove imperfections. I’m familiar with the specific trimming needs of various fruits and vegetables, including removing stems, leaves, blemishes, and damaged areas.

Understanding the seasonal availability of produce is also important. For instance, the trimming requirements for summer squash are different from winter squash, which might need more preparation due to their thicker skin. Furthermore, recognizing spoilage signs and quickly removing affected produce is vital to prevent contamination and maintain food safety standards. My experience encompasses a broad range of produce, from delicate herbs and leafy greens to root vegetables and hard-shelled fruits.

Q 21. How do you maintain a clean and organized work area during trimming?

Maintaining a clean and organized workspace is not only important for hygiene and food safety but also for efficiency. My approach is multifaceted. I start with a clean work surface before I begin trimming. I use appropriate containers for discarded waste, ensuring proper segregation for composting or disposal. As I work, I regularly clear away debris and discarded produce to prevent build-up. I also organize my tools and materials systematically, keeping frequently used items within easy reach. This streamlined approach minimizes wasted time searching for tools and materials.

At the end of my shift, I thoroughly clean my workstation, including wiping down surfaces and sterilizing tools. This prevents cross-contamination and ensures that the next shift starts with a clean and safe workspace. A clean work area is not just about hygiene; it’s about efficiency and preventing errors. This methodical approach is essential for maintaining a high standard of hygiene and efficiency in produce trimming.

Q 22. How do you minimize waste during the produce trimming process?

Minimizing waste in produce trimming is crucial for both economic and environmental reasons. It involves a multifaceted approach focusing on efficient techniques, proper equipment use, and effective planning.

Precise Trimming Techniques: Instead of aggressively removing large portions, we focus on removing only the necessary parts. For example, with lettuce, we remove only the wilted or damaged outer leaves, leaving the rest intact. With carrots, we trim only the root end and the green tops, avoiding unnecessary cuts into the edible parts.

Utilizing Trimmings: We don’t throw away everything that’s trimmed. Many trimmings can be repurposed. For example, carrot tops can be used in soups or stocks, while vegetable peels can be used for making vegetable broth. This reduces waste and adds value.

Pre-Sorting and Quality Control: Before trimming begins, produce is carefully sorted to remove severely damaged or spoiled items. This prevents wasting time and resources on items that cannot be salvaged.

Proper Storage and Handling: To prevent spoilage, produce is stored under optimal temperature and humidity conditions. This ensures that less produce needs to be discarded due to deterioration.

Inventory Management: Careful inventory control ensures we don’t order or receive more produce than we can process before it spoils. This minimizes the risk of excess and waste.

Q 23. Describe your experience with using and maintaining trimming equipment.

I have extensive experience with various trimming equipment, including automated slicers, conveyor belt systems, and hand tools. My experience encompasses both operation and maintenance. I’m proficient in calibrating and adjusting machines for optimal performance, and I can troubleshoot malfunctions effectively.

Automated Slicers: I’m adept at using automated slicers to achieve consistent and accurate trimming. Regular cleaning and blade sharpening are critical for maintaining the machine’s efficiency and preventing cross-contamination. I meticulously follow manufacturer guidelines for safety procedures.

Conveyor Belt Systems: Working with conveyor systems requires understanding the flow of produce and potential bottlenecks. Regular lubrication and maintenance are crucial for preventing breakdowns and ensuring smooth operation. I can adjust the speed and configuration to match the workload.

Hand Tools: While automated equipment is preferred for high-volume tasks, hand tools are essential for more delicate tasks or handling oddly shaped produce. I ensure all hand tools are sharp and well-maintained to minimize waste and ensure employee safety.

In terms of maintenance, I follow a strict preventative maintenance schedule, including regular cleaning, lubrication, and inspections. This proactive approach extends the life of the equipment and minimizes downtime.

Q 24. How do you handle different types of packaging after trimming?

Packaging after trimming is crucial for maintaining product quality and safety. Different produce requires different packaging based on its characteristics and intended shelf life.

Modified Atmosphere Packaging (MAP): This technique involves packaging produce in a modified atmosphere (reduced oxygen, increased carbon dioxide) to slow down spoilage and extend shelf life. This is commonly used for leafy greens and other high-perishability items.

Vacuum Packaging: This method removes air from the packaging, inhibiting microbial growth and extending shelf life. This is suitable for items like sliced vegetables that are prone to oxidation.

Standard Packaging: This includes clamshells, bags, and boxes. Choosing the right packaging material depends on the produce type, moisture content, and required protection against damage.

We also follow strict guidelines for labeling to ensure accuracy and clarity about product contents and handling instructions. This also helps in proper inventory management and traceability.

Q 25. What are the common hazards in a produce trimming environment and how to mitigate them?

Produce trimming environments present several hazards that need to be addressed proactively.

Sharp Objects: Knives, slicers, and other cutting tools are common hazards. To mitigate this, we mandate the use of cut-resistant gloves, provide regular safety training, and enforce proper tool handling practices. Regular equipment inspections are also crucial.

Slips and Falls: Wet floors and spills are common causes of slips and falls. We address this with regular cleaning and maintenance, providing non-slip mats in areas prone to spills, and ensuring adequate lighting.

Musculoskeletal Injuries: Repetitive motions and heavy lifting can cause musculoskeletal injuries. We address this by providing ergonomic workstations, encouraging regular breaks, and offering employee training on proper lifting techniques.

Foodborne Illnesses: Cross-contamination is a major food safety concern. We use colour-coded cutting boards and knives, ensure proper handwashing practices, and maintain impeccable hygiene standards.

Regular safety audits and employee training sessions on hazard recognition and prevention are integral parts of our safety program.

Q 26. What is your understanding of GMP (Good Manufacturing Practices) in produce handling?

GMP (Good Manufacturing Practices) are essential for maintaining food safety and quality throughout the produce handling process. My understanding encompasses all aspects, from receiving produce to packaging the final product.

Sanitation: Maintaining a clean and sanitized work environment is paramount. This involves regular cleaning and disinfection of surfaces, equipment, and utensils. We adhere to strict protocols for cleaning and sanitizing to eliminate potential hazards.

Personnel Hygiene: Employees are required to follow strict hygiene protocols, including handwashing, wearing appropriate protective clothing, and avoiding cross-contamination. We conduct regular training on proper hygiene practices.

Pest Control: Preventing pest infestations is vital. We implement effective pest control measures, including regular inspections, and use approved pest control products.

Temperature Control: Maintaining correct temperatures throughout the process is crucial for preventing microbial growth. We monitor and log temperatures regularly, ensuring optimal storage and transportation conditions.

Traceability: A robust traceability system is essential for identifying and addressing any potential food safety issues. We use batch numbers, tracking systems and detailed records to ensure complete traceability.

Adherence to GMP ensures product safety, enhances consumer confidence, and helps us avoid potential legal issues.

Q 27. How do you identify and report any food safety issues or concerns?

Identifying and reporting food safety issues is crucial. My approach involves immediate action combined with thorough documentation.

Immediate Action: If I identify a potential food safety issue – such as spoiled produce, cross-contamination, or equipment malfunction – I immediately isolate the affected product, notify my supervisor, and take appropriate corrective actions such as disposal of contaminated items.

Thorough Documentation: I meticulously document the issue, including details of the incident, corrective actions taken, and any preventative measures implemented. I use standard reporting forms and follow company protocols to ensure accuracy and clarity.

Root Cause Analysis: Beyond immediate action, we conduct a root cause analysis to prevent similar incidents from happening in the future. This involves identifying the underlying cause of the problem and implementing effective solutions.

Our company maintains a robust system for reporting and investigating food safety incidents, prioritizing employee safety and product quality.

Q 28. Describe your experience with training new employees on produce trimming techniques.

Training new employees is a critical part of maintaining consistent standards and ensuring a safe working environment. My training program emphasizes both the theoretical and practical aspects of produce trimming.

On-the-Job Training: I start with hands-on training, demonstrating proper trimming techniques using different tools and equipment. I focus on achieving accurate and efficient trimming while emphasizing safety protocols.

Safety Training: Safety is paramount. I emphasize the importance of using protective gear, following safe work practices, and recognizing potential hazards. We cover the proper use and maintenance of all equipment.

Hygiene and GMP Training: We cover proper hygiene practices, including handwashing, using appropriate clothing, and preventing cross-contamination. GMP principles and their application in the produce trimming process are explained thoroughly.

Quality Control Training: Employees are trained to identify and sort out substandard produce, ensuring only high-quality items are processed. They learn how to identify spoilage and damage to minimize waste.

Continuous Feedback and Assessment: I provide regular feedback and assess employee performance, identifying areas for improvement and providing additional support as needed.

My goal is to empower new employees with the knowledge and skills to perform their duties safely, efficiently, and to a consistently high standard.

Key Topics to Learn for Your Produce Trimming Interview

- Produce Handling and Quality Assessment: Understanding the different types of produce, identifying ripeness and quality, and recognizing spoilage indicators.

- Trimming Techniques and Tools: Mastering various trimming methods for different fruits and vegetables, including safe and efficient knife skills and the proper use of specialized equipment.

- Food Safety and Hygiene: Adhering to strict hygiene protocols, including handwashing, sanitation of workspaces, and preventing cross-contamination. Understanding food safety regulations and best practices.

- Waste Reduction and Yield Optimization: Implementing strategies to minimize waste during the trimming process, maximizing yield, and understanding cost implications.

- Speed and Efficiency: Developing a rapid and accurate trimming technique while maintaining quality and safety standards. Understanding production targets and timelines.

- Teamwork and Communication: Collaborating effectively with other team members, communicating efficiently, and following instructions accurately.

- Problem-Solving and Adaptability: Identifying and resolving issues encountered during the trimming process, adapting to changing demands and situations, and implementing effective solutions.

Next Steps

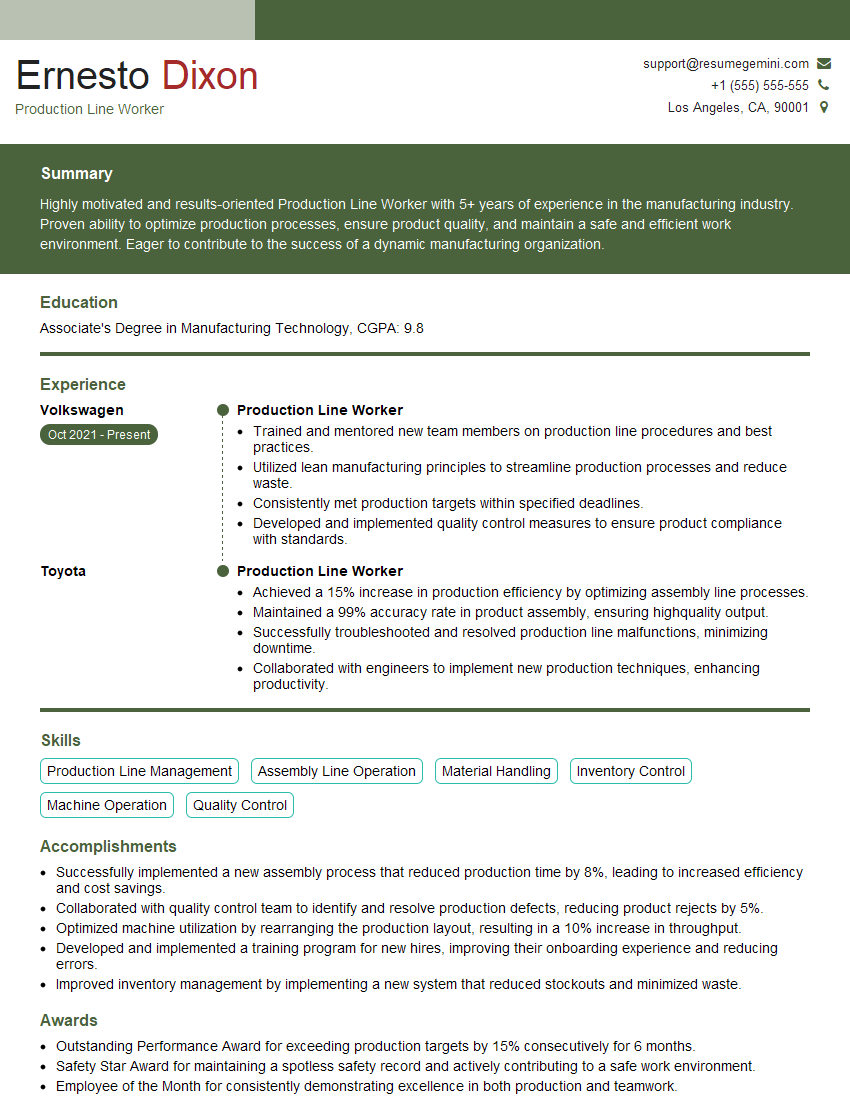

Mastering produce trimming opens doors to a rewarding career with opportunities for advancement and specialization. A strong understanding of these skills demonstrates your commitment to quality, efficiency, and food safety – highly valued attributes in the industry. To significantly boost your job prospects, focus on building an ATS-friendly resume that clearly highlights your qualifications. ResumeGemini is a trusted resource that can help you craft a professional and impactful resume. We offer examples of resumes tailored to Produce Trimming to guide you through the process. Invest time in crafting a compelling resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good