Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Product Hazard Identification interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Product Hazard Identification Interview

Q 1. Describe your experience conducting hazard analyses using a specific methodology (e.g., FMEA, HAZOP).

My extensive experience in product hazard analysis heavily involves utilizing Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Study (HAZOP) methodologies. FMEA is a proactive, systematic approach where we examine each component and process of a product to identify potential failure modes, their effects, and the severity of those effects. I’ve used this extensively for everything from medical devices to automotive parts. For instance, in analyzing a new electric toothbrush, we’d meticulously go through each part – the motor, battery, bristles, casing – considering what could go wrong (e.g., motor overheating, battery leakage, bristle breakage). We then assign severity, occurrence, and detection ratings to each potential failure to calculate a Risk Priority Number (RPN). A high RPN indicates the need for immediate action. HAZOP, on the other hand, is more focused on process hazards and deviations. I’ve employed HAZOP on complex manufacturing processes, asking ‘what if’ questions around each stage to uncover potential hazards. For example, in a chemical mixing process, a HAZOP might uncover the risk of an exothermic reaction if temperatures weren’t controlled properly. Both FMEA and HAZOP provide a structured framework to systematically identify, analyze, and mitigate hazards, crucial for product safety and reliability. They allow for collaborative work, fostering a shared understanding of the risks involved.

Q 2. Explain the difference between a hazard and a risk.

The difference between a hazard and a risk is crucial. A hazard is simply a potential source of harm. It’s the inherent danger present. Think of it as the ‘what’. For example, a sharp knife is a hazard; a high voltage wire is a hazard; a malfunctioning battery is a hazard. A risk, however, is the chance that a hazard will cause harm. It’s the ‘how likely’ and ‘how bad’ combined. Risk combines the likelihood of the hazard occurring (probability) and the severity of the consequences (impact) if it does. So, the risk of cutting yourself with a sharp knife is high if you’re not careful (high probability, high severity). The risk of electric shock from a high voltage wire is also high if you touch it (high probability, potentially high severity). The risk associated with a malfunctioning battery depends on factors such as where and how it’s used. Using a simple equation: Risk = Probability x Severity

Q 3. How do you prioritize hazards identified during a risk assessment?

Prioritizing hazards identified during a risk assessment is paramount. We typically use a risk matrix, which visually represents the probability and severity of each hazard. The matrix typically uses scales (e.g., low, medium, high for both probability and severity). Hazards are plotted on the matrix based on their assigned probability and severity scores. Hazards falling into the high-probability/high-severity quadrant are prioritized first. This requires a systematic approach, often involving quantitative or semi-quantitative assessments. I often use a combination of methods: Firstly, assigning numerical scores to probability and severity allows for objective comparison. Secondly, we consider factors such as the potential for widespread harm or environmental impact. We also consult relevant regulatory requirements and industry best practices, factoring in legal considerations and customer safety expectations. The prioritization process needs to be documented meticulously, ensuring transparency and traceability. Ultimately, the goal is to allocate resources effectively to mitigate the most critical risks.

Q 4. What are some common hazards associated with [specific product category, e.g., consumer electronics]?

Consumer electronics present a range of potential hazards. Some common ones include:

- Electrical Shock: Faulty wiring, inadequate insulation, or damaged power supplies can lead to electrical shock, potentially fatal.

- Fire Hazards: Overheating batteries, short circuits, and improperly designed power adapters pose significant fire risks.

- Burns: Overheating devices, such as chargers or laptops, can cause burns. Even the surface temperature of some devices can be high enough to cause burns on extended contact.

- Mechanical Hazards: Sharp edges, small parts that could be swallowed (especially in children’s electronics), and moving parts present mechanical hazards.

- Chemical Hazards: Batteries contain hazardous chemicals that can leak or explode, and certain plastics may release harmful substances when heated or damaged.

- Radiation Hazards: While generally low, some devices emit electromagnetic radiation (EMR), exceeding limits in certain usage scenarios, posing health concerns over prolonged exposure.

- Data Security and Privacy Breaches: While not a traditional physical hazard, the improper handling of personal data presents a significant risk in many connected devices.

Identifying these hazards requires a comprehensive approach, incorporating both design review and testing, paying close attention to all aspects of materials, construction, and use.

Q 5. Describe your experience with regulatory requirements related to product safety (e.g., CE marking, UL standards).

My experience encompasses various regulatory requirements related to product safety. I’m well-versed in CE marking (for products sold within the European Economic Area), which demonstrates compliance with EU directives related to health, safety, and environmental protection. Understanding the specific directives applicable to a particular product category is paramount. I’ve also worked extensively with UL standards (Underwriters Laboratories), particularly in North America, ensuring products meet their rigorous safety standards for various applications. Additionally, I’m familiar with other relevant standards, such as those set by the FCC (Federal Communications Commission) for electromagnetic compatibility and the FDA (Food and Drug Administration) for medical devices. My work includes not only ensuring our products meet the minimum requirements but also adhering to best practices and exceeding expectations where possible. This often involves staying updated on changes in regulations and proactively adapting our design and testing processes.

Q 6. How do you document and communicate hazard identification findings?

Documenting and communicating hazard identification findings is essential for transparency and accountability. We maintain a comprehensive hazard log, detailing each identified hazard, its potential consequences, the assigned risk level (using a risk matrix), and proposed mitigation strategies. This documentation also includes details of any tests or analysis conducted. Communication is multifaceted: internally, we use project management software to track and communicate findings across design, engineering, and management teams. This helps facilitate collaboration and effective risk management. Externally, findings relevant to regulatory compliance are included in technical files for auditors and authorities. We also create concise summaries for stakeholders, tailoring the information to their needs and technical understanding. In cases where significant risks remain after mitigation, we clearly communicate those residual risks, including the necessary precautions and safety instructions for users.

Q 7. Explain your approach to validating the effectiveness of safety controls.

Validating the effectiveness of safety controls is a crucial step, ensuring that our mitigation efforts truly reduce the identified risks. Our approach is multi-pronged. Firstly, we conduct design reviews to ensure the controls are appropriately implemented and function as intended. This involves simulating potential hazard scenarios and reviewing the control’s response. Secondly, we perform rigorous testing, including functional testing, environmental testing (e.g., temperature, humidity, vibration), and reliability testing. This helps verify the control’s robustness and resilience under various conditions. We might use simulations or modeling to estimate control effectiveness before physical testing. Finally, we frequently monitor performance in the field, tracking incidents and evaluating the effectiveness of controls in real-world usage scenarios. This ongoing monitoring helps us identify any unexpected issues or areas where improvements are necessary. The overall goal is to ensure that safety controls are effective, reliable, and demonstrably reduce risk to an acceptable level.

Q 8. How do you handle disagreements with other team members regarding hazard assessment?

Disagreements in hazard assessment are inevitable, given the multifaceted nature of risk evaluation. My approach centers on collaborative problem-solving and respectful communication. First, I ensure everyone understands the established methodology and criteria we’re using for hazard identification. Then, I encourage open discussion, where each team member clearly articulates their rationale and supporting evidence for their assessment. We utilize a structured approach, often involving a risk matrix to visually compare different perspectives and quantify the level of risk. If a consensus can’t be reached, I facilitate a review of all available data and potentially consult with a senior engineer or external expert. The goal is not to win an argument but to arrive at the most accurate and thorough hazard assessment, prioritizing safety. Documenting all discussions and the final consensus is paramount for transparency and accountability.

Q 9. Describe a situation where you had to identify and mitigate a critical hazard.

During the development of a new medical device, we identified a critical hazard related to the power supply. Initial testing revealed an intermittent short circuit that could potentially lead to overheating and ignition. This posed a significant risk of burns to the patient and medical staff. To mitigate this, we followed a structured risk management process. First, we used Failure Mode and Effects Analysis (FMEA) to thoroughly understand the potential causes and consequences of the short circuit. Next, we implemented a multi-layered approach to mitigation: improved component selection, enhanced circuit design, increased insulation, and added thermal fuses as fail-safes. We then conducted rigorous testing – including thermal cycling and shock tests – to validate the effectiveness of these improvements. Finally, we updated the device’s risk assessment documentation to reflect the implemented changes. Through this process, we successfully eliminated the critical hazard, ensuring the safety of our product.

Q 10. What are some common root causes of product-related accidents?

Many product-related accidents stem from common root causes. These can be broadly categorized into design flaws, manufacturing defects, inadequate training or instructions, and misuse by the end-user.

- Design Flaws: Overlooking ergonomic considerations, using unsuitable materials, or failing to account for foreseeable misuse can all lead to accidents. For instance, a sharp edge on a toy could cause injury.

- Manufacturing Defects: Poor quality control, improper assembly, or using substandard components can result in malfunctions. A cracked weld in a pressure vessel, for example, could lead to catastrophic failure.

- Inadequate Training/Instructions: Poorly written manuals or insufficient training can lead to incorrect operation and subsequent accidents. A user not understanding the safety precautions for operating a machine could be injured.

- End-User Misuse: This involves users ignoring safety instructions, using products in unintended ways, or failing to maintain the product properly. Using a ladder beyond its weight capacity is a clear example.

Q 11. How do you ensure that your hazard identification process is thorough and comprehensive?

Ensuring a thorough hazard identification process requires a multi-pronged strategy. We start with brainstorming sessions involving diverse team members to encourage different perspectives and identify potential hazards from various angles. We then utilize established hazard identification methodologies like HAZOP (Hazard and Operability Study), FMEA (Failure Mode and Effects Analysis), and fault tree analysis. These structured approaches systematically examine the product’s design, manufacturing, operation, and intended use. Furthermore, we incorporate a thorough review of similar products, industry best practices, and relevant safety standards. We actively seek feedback from internal testing and external beta users, allowing real-world usage to reveal potential hazards not easily identified through theoretical analyses. Finally, regular audits and continuous improvement practices are essential to refine and enhance our hazard identification process.

Q 12. How do you stay current with changes in safety regulations and standards?

Staying current with safety regulations and standards is crucial. I actively monitor updates from organizations like OSHA (Occupational Safety and Health Administration), ANSI (American National Standards Institute), and ISO (International Organization for Standardization). This involves regularly checking their websites for published updates and subscribing to relevant newsletters and alerts. I also attend industry conferences and workshops to network with other professionals and learn about emerging safety concerns and best practices. Membership in professional organizations related to product safety provides access to valuable resources and continuing education opportunities. Maintaining a comprehensive library of relevant standards and regulations is also essential for easy reference and efficient compliance.

Q 13. Describe your experience using hazard identification software or tools.

I have extensive experience using various hazard identification software and tools. I’m proficient in utilizing software packages that support FMEA, fault tree analysis, and HAZOP studies, enabling detailed modeling and analysis of complex systems. These tools allow for efficient data management, automated calculations of risk scores, and the creation of comprehensive reports. I’ve used software that allows for collaborative working across teams, enabling efficient sharing of information and collective hazard identification. In addition to dedicated software, I’m comfortable using spreadsheets and databases to manage hazard data and track mitigation actions. My experience spans various software, allowing me to select the most suitable tool based on project needs and complexity.

Q 14. What are your strengths and weaknesses in hazard identification?

My strengths lie in my systematic and thorough approach to hazard identification. I’m adept at applying various methodologies, and I’m comfortable working with diverse teams to achieve consensus. My attention to detail and experience with complex systems enables me to identify subtle hazards that others might overlook. However, like everyone, I have areas for improvement. I am continually working to refine my understanding of emerging technologies and their associated safety implications. Additionally, I strive to improve my communication skills, ensuring the effective dissemination of complex safety information to both technical and non-technical audiences. This is an ongoing process of learning and development.

Q 15. How do you balance the cost of implementing safety measures with the level of risk?

Balancing cost and risk in implementing safety measures requires a risk-based approach. We can’t eliminate all risks, as that’s often impractical and prohibitively expensive. Instead, we prioritize hazards based on their likelihood and severity. This is often visualized using a risk matrix.

For example, a risk matrix might categorize hazards as High, Medium, or Low based on the probability of occurrence and the severity of the consequences. High-risk hazards warrant significant investment in safety measures, even if costly. Medium-risk hazards might involve a cost-benefit analysis, weighing the expense of mitigation against the potential cost of an incident. Low-risk hazards may require minimal intervention, focusing on readily available and cost-effective controls.

A crucial element is using quantitative data whenever possible. This includes historical data on incident rates, failure analysis, and testing results. This data-driven approach allows for informed decision-making, ensuring resources are allocated effectively.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Explain your experience with different hazard identification techniques (e.g., checklists, fault tree analysis).

My experience encompasses a range of hazard identification techniques. Checklists are a fundamental tool, providing a structured approach to identifying known hazards specific to a product or industry. I’ve used checklists for everything from simple hand tools to complex medical devices, ensuring all potential hazards within a predefined scope are considered. Checklists are particularly effective for routine tasks and preventing oversights.

Fault Tree Analysis (FTA) is a more sophisticated technique. FTA works backward from an undesired event (e.g., a product malfunction) to identify all the contributing factors. It graphically represents these factors, revealing potential failure points and dependencies. I’ve used FTA to investigate the root cause of past incidents and proactively identify potential failures in new product designs. For instance, in a recent project involving a robotic arm, FTA helped pinpoint a potential electrical short as the primary contributor to a catastrophic failure scenario.

Beyond these, I’m also proficient in Hazard and Operability studies (HAZOP) and Failure Modes and Effects Analysis (FMEA), both of which provide more detailed assessments of system failures and their potential effects.

Q 17. Describe a time when you had to make a critical decision regarding product safety.

During the development of a children’s toy, we discovered a potential choking hazard. Initial designs included small, detachable parts that could easily be swallowed by young children. While the initial design was aesthetically pleasing and met other performance requirements, the risk of serious harm was unacceptable.

The decision was made to redesign the toy, even though this delayed the product launch and increased costs. We explored various alternatives, eventually opting for a design that eliminated the detachable parts without sacrificing the toy’s functionality. This involved extensive design iteration and testing to ensure the new design met all safety standards. While difficult, prioritizing child safety was the clear and only responsible decision.

This experience reinforced the importance of integrating safety considerations from the very beginning of the design process, not as an afterthought. It also highlighted the value of robust risk assessment and communication amongst the entire design and development team.

Q 18. How do you integrate hazard identification into the product development lifecycle?

Hazard identification is seamlessly integrated throughout the product development lifecycle (PDLC). It begins in the conceptual design phase, where potential hazards are identified through brainstorming sessions, preliminary risk assessments, and regulatory review of standards. During the design and development phase, detailed hazard analysis techniques like FMEA or FTA are employed, allowing us to systematically identify and mitigate risks.

Prototyping and testing phases provide opportunities for hazard identification through practical evaluation. We conduct rigorous testing to validate the effectiveness of implemented safety measures and identify any unexpected hazards. This data feeds back into the design process for further iteration and refinement. Finally, pre-production and post-market surveillance continuously monitor product performance and user experience, identifying potential hazards that might emerge in real-world usage.

Q 19. How do you communicate safety information to different stakeholders (e.g., engineers, consumers)?

Communicating safety information effectively to different stakeholders requires tailoring the message to their specific needs and understanding. For engineers, technical reports, FMEA documentation, and detailed risk assessments are crucial. The focus here is on providing precise data and clear technical specifications to facilitate proactive hazard mitigation.

For consumers, communication focuses on clarity and simplicity. We use user manuals with clear warnings and instructions, employing visual aids and plain language. Product labels clearly display any safety warnings or certifications. Marketing materials highlight safety features without being misleading or using technical jargon. We also provide accessible channels for reporting safety concerns and providing feedback.

Q 20. What are the limitations of each hazard identification technique you are familiar with?

Checklists, while effective for identifying known hazards, have limitations. They rely on pre-defined criteria and may miss unforeseen hazards or those outside the checklist’s scope. Over-reliance on checklists can lead to complacency.

Fault Tree Analysis (FTA) is powerful but can become complex and time-consuming for systems with numerous interacting components. It also requires expertise to construct and interpret the analysis, and it’s limited to identifying hazards related to the specific undesired event being investigated.

HAZOP and FMEA, while comprehensive, require substantial effort and expertise to execute effectively. They can become overly intricate and time-intensive for less complex products. The quality of the analysis is strongly dependent on the experience and judgment of the analysts.

Q 21. How do you identify and assess hazards related to the use of materials in a product?

Identifying and assessing hazards related to materials involves a multi-step process. Firstly, we identify all materials used in the product, paying close attention to their chemical composition, physical properties, and potential degradation over time. Secondly, we assess the potential hazards associated with each material. This may include toxicity, flammability, biocompatibility, and environmental impact.

We consult material safety data sheets (MSDS) for detailed information on each material’s hazards and recommended handling procedures. We also consider potential interactions between different materials within the product, identifying any potential synergistic hazards (e.g., reactions that could produce toxic fumes).

Testing plays a crucial role. We conduct various tests to evaluate material properties and their response under different conditions (e.g., exposure to heat, moisture, or chemicals). This data informs the design and selection of appropriate safety measures to mitigate risks associated with the materials.

Q 22. How do you incorporate user feedback into your hazard identification process?

User feedback is crucial for a comprehensive hazard identification process. It provides a perspective often missed by internal teams, revealing unexpected uses or misuse of the product that might lead to unforeseen hazards. We actively solicit feedback through various channels, including surveys, online forums, social media monitoring, and direct customer interviews. For example, if we’re designing a children’s toy, we might conduct focus groups with parents and children to observe how they interact with the product and identify potential hazards that might not be apparent through engineering testing alone. This feedback is then systematically analyzed, categorized, and integrated into our hazard risk assessment matrix. If a significant hazard is identified through user feedback, we’ll immediately initiate a hazard investigation and implement necessary corrective actions.

- Surveys: Targeted questions to gauge user experiences and potential issues.

- Social Media Monitoring: Tracking online conversations about the product to identify emerging concerns.

- Customer Support Interactions: Analyzing reported incidents and user complaints.

Q 23. Describe your understanding of different risk matrices and their applications.

Risk matrices are essential tools for prioritizing hazards based on their likelihood and severity. A common type is a simple 2×2 matrix plotting likelihood (e.g., low, medium, high) against severity (e.g., minor injury, serious injury, fatality). The resulting quadrants prioritize hazards: High likelihood/high severity hazards require immediate attention, while low likelihood/low severity hazards may warrant less urgent action. More sophisticated matrices incorporate numerical scales for likelihood and severity, allowing for more precise risk scoring. For instance, we might use a matrix with a severity scale from 1-5 and a likelihood scale from 1-5, resulting in a risk score from 1 to 25. Hazards scoring above a pre-defined threshold trigger immediate action. Furthermore, different risk matrices can be tailored to the specific product and context. For a medical device, the severity scale might focus on patient harm and potential for death. For a children’s toy, the focus might be on choking hazards, lacerations, and ingestion of small parts. We regularly review and refine our chosen matrices to ensure they remain relevant and effective.

Q 24. How do you handle situations where a hazard cannot be completely eliminated?

When a hazard cannot be eliminated entirely, we focus on mitigation strategies to reduce the risk to an acceptable level. This involves a multi-pronged approach. First, we implement engineering controls – modifications to the product design itself to reduce the hazard. For example, adding safety guards to machinery or making a product more durable to prevent breakage. Second, administrative controls are put in place, such as improved warnings, safer work procedures, or enhanced training for users. Third, personal protective equipment (PPE) might be necessary if the risk remains too high, like providing safety glasses to workers or requiring appropriate clothing while using certain machinery. We document all mitigation measures, regularly evaluate their effectiveness, and continuously improve them as necessary. The goal is to reach the lowest achievable level of residual risk while balancing practicality, cost, and user experience.

Q 25. How do you ensure that your hazard identification process is objective and unbiased?

Objectivity and unbiased hazard identification is paramount. We achieve this through several methods. First, we utilize diverse teams with members from different backgrounds (engineering, design, marketing, etc.), ensuring a broader range of perspectives. Second, we employ structured hazard analysis methods, such as Failure Modes and Effects Analysis (FMEA) and Hazard and Operability Studies (HAZOP), which offer a standardized approach to hazard identification, minimizing individual biases. Third, we utilize data-driven methods whenever possible, basing our assessments on factual evidence rather than speculation. For example, using reliability data for component failure rates or incident reports to understand potential issues. Fourth, we encourage open discussions and debate within the team, fostering a culture where dissenting viewpoints are valued and incorporated into the analysis. Regular audits of our process help ensure continuous improvement and maintain objectivity.

Q 26. Describe your experience with conducting post-incident investigations.

Post-incident investigations are crucial learning opportunities. My approach involves a systematic process following a standardized protocol. The first step is securing the scene (if applicable) and gathering evidence. This includes collecting physical samples, interviewing witnesses, and reviewing any available data such as usage logs, maintenance records, or product documentation. The investigation team will reconstruct the events leading to the incident, identifying the root cause and contributing factors. We utilize various analytical tools, such as fault tree analysis (FTA) or the ‘5 Whys’ technique, to uncover the underlying issues. The findings are meticulously documented in a report which includes recommendations to prevent similar incidents in the future. These recommendations might involve design changes, revised procedures, or improved training. Finally, the effectiveness of implemented corrective actions is monitored, and the process is revisited as necessary.

Q 27. Explain your approach to developing and implementing safety training programs.

Safety training programs must be tailored to the specific hazards associated with the product and the target audience. My approach starts with a needs assessment to identify knowledge gaps and training requirements. We then develop training materials that are engaging, easy to understand, and relevant to the user’s role and experience level. This can involve various methods, including interactive presentations, hands-on workshops, videos, and online modules. Training is regularly reviewed and updated to reflect changes in the product, industry best practices, or regulatory requirements. We conduct regular assessments of training effectiveness through testing, observation, and performance evaluation to ensure that users understand and apply safety procedures correctly. For instance, if we design industrial machinery, the training will cover safe operational procedures, lockout/tagout procedures, and the identification and response to potential hazards. For consumer products, the focus might be on safe usage instructions, warnings, and handling of potential risks.

Q 28. How do you ensure that your hazard identification process is aligned with company policies and procedures?

Alignment with company policies and procedures is ensured through integration of our hazard identification process into the overall product development lifecycle. We ensure that our methodologies comply with relevant regulations, industry standards (like ISO 14971 for medical devices), and company-specific guidelines. Our process is documented, regularly audited, and subject to management review. This documentation includes hazard reporting procedures, risk assessment methods, and mitigation strategies. We actively collaborate with legal, compliance, and other relevant departments to ensure the hazard identification process supports the overall corporate safety strategy and that our approach meets all regulatory requirements. Deviation from established procedures requires documented justification and approval from appropriate authorities. Regular audits ensure compliance and pinpoint areas for improvement.

Key Topics to Learn for Product Hazard Identification Interview

- Hazard Identification Methodologies: Understand various approaches like HAZOP (Hazard and Operability Study), FMEA (Failure Mode and Effects Analysis), FTA (Fault Tree Analysis), and checklists. Focus on their strengths and weaknesses and when each is most appropriate.

- Practical Application: Case Studies: Review case studies demonstrating how hazard identification methodologies are applied in real-world scenarios across different industries (e.g., automotive, pharmaceuticals, food). Analyze the identified hazards and the resulting risk mitigation strategies.

- Risk Assessment and Prioritization: Learn how to quantify and qualify risks associated with identified hazards. Understand concepts like risk matrices and the importance of prioritizing hazards based on severity and likelihood.

- Regulatory Compliance: Familiarize yourself with relevant safety regulations and standards (e.g., ISO 14971 for medical devices) and how they influence product hazard identification processes.

- Communication and Collaboration: Understand the importance of effective communication and collaboration with cross-functional teams (engineering, design, manufacturing) throughout the hazard identification process.

- Root Cause Analysis: Develop your ability to investigate and determine the underlying causes of potential hazards, using techniques such as the “5 Whys” analysis.

- Data Analysis and Interpretation: Learn to analyze data from various sources (e.g., incident reports, test results) to identify potential hazards and trends.

Next Steps

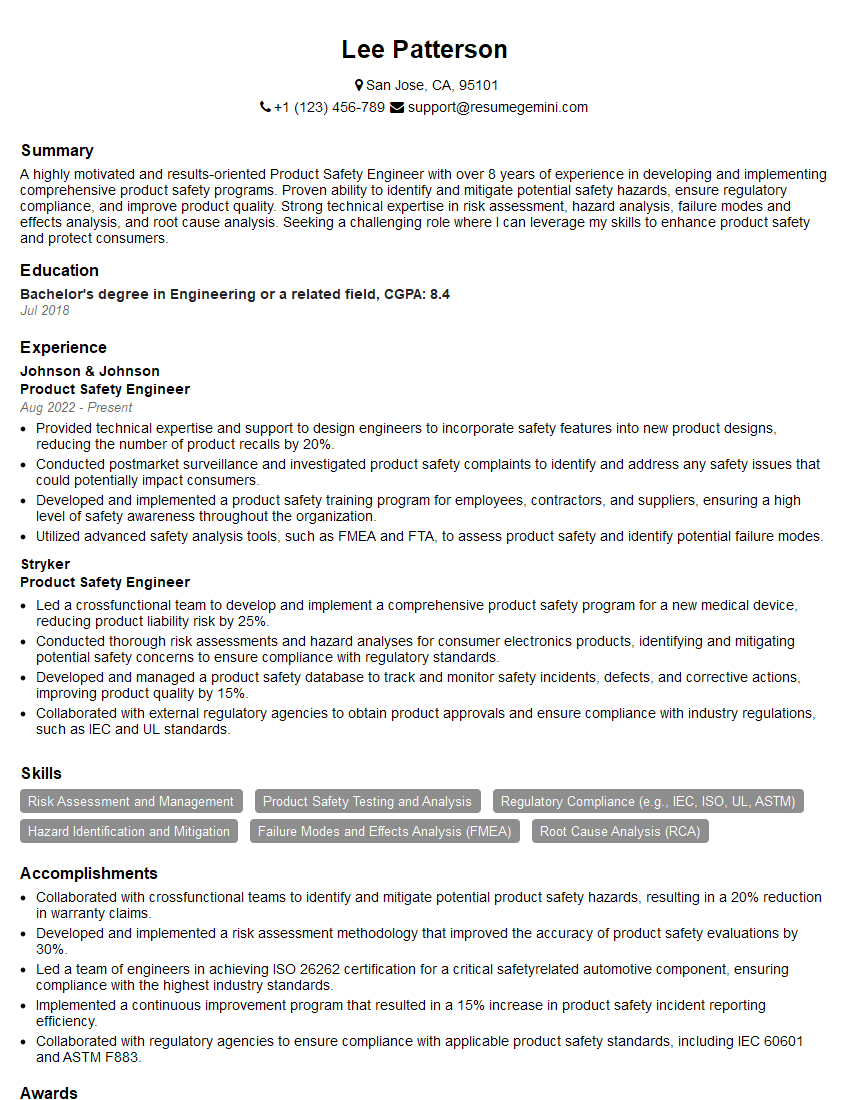

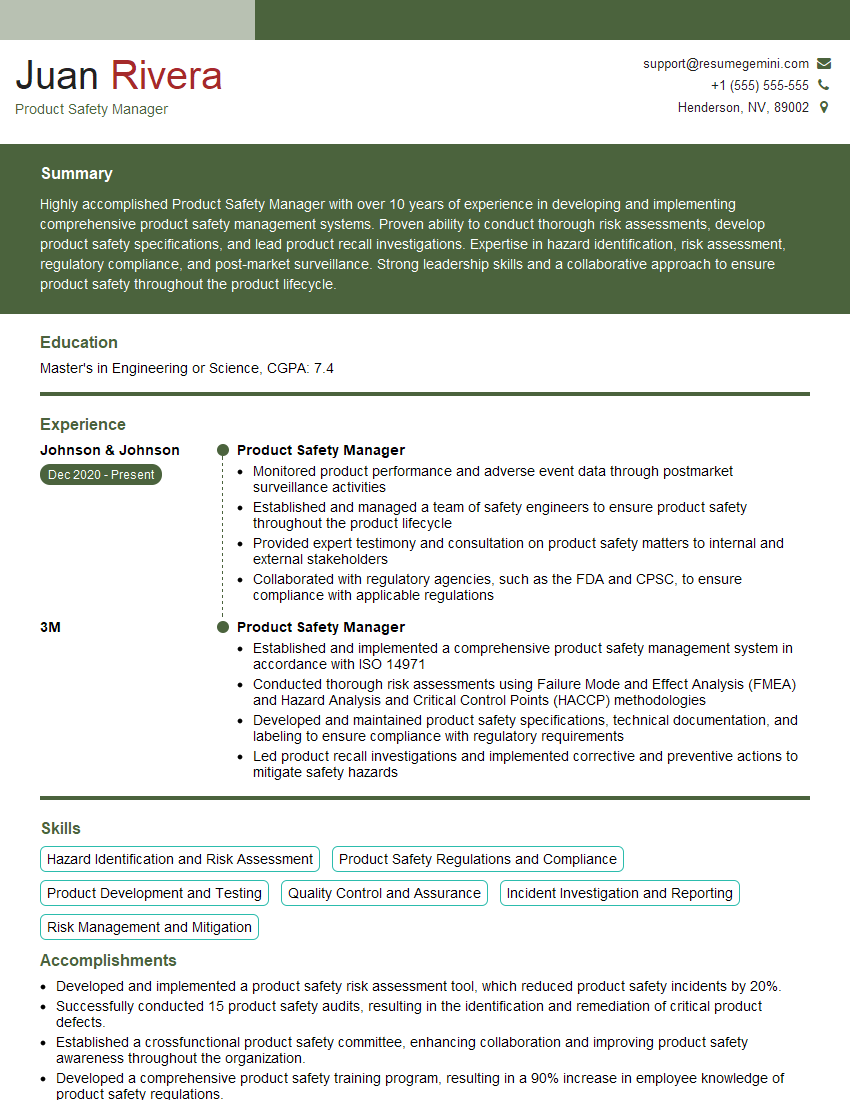

Mastering Product Hazard Identification is crucial for career advancement in safety-critical industries. It demonstrates a commitment to safety and a proactive approach to risk management, making you a highly valuable asset to any organization. To significantly enhance your job prospects, creating a strong, ATS-friendly resume is paramount. ResumeGemini can help you build a professional resume that showcases your skills and experience effectively. We offer examples of resumes tailored to Product Hazard Identification to help you craft a compelling application that grabs the attention of recruiters. Use ResumeGemini to elevate your job search and unlock new opportunities.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good