Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Production and Scheduling interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Production and Scheduling Interview

Q 1. Explain the difference between MRP (Material Requirements Planning) and MPS (Master Production Schedule).

The Master Production Schedule (MPS) and Material Requirements Planning (MRP) are both crucial components of production planning, but they serve distinct purposes. Think of the MPS as the high-level plan, outlining what finished products will be produced and when. MRP, on the other hand, is the detailed breakdown of the materials needed to support the MPS. It’s the ‘how’ to the MPS’s ‘what’.

The MPS is a time-phased plan specifying the quantity of each end item to be produced. It’s driven by customer demand forecasts, sales orders, and available capacity. It’s a top-down approach. For example, an MPS might state that 100 widgets are needed in week 10, 150 in week 11, and 200 in week 12.

MRP takes the MPS as input and explodes it into the detailed requirements for all components, sub-assemblies, and raw materials needed to build those finished goods. It considers lead times for procurement and manufacturing, inventory levels, and bill of materials (BOMs). It’s a bottom-up approach. So, if a widget requires 2 gears and 3 springs, MRP will calculate exactly how many gears and springs need to be ordered or produced to meet the MPS demands, accounting for existing stock.

In short: MPS dictates *what* and *when* to produce; MRP dictates *how much* of *what* materials are needed to achieve the MPS.

Q 2. How do you calculate lead times for production?

Calculating lead times is crucial for accurate production scheduling. Lead time is the total time it takes to complete a process, from the initiation of the order to the completion of the finished product. It’s not a single, static number; it depends on multiple factors.

There are several ways to calculate lead times:

- Time Study: This involves carefully timing each step in the production process and adding them together. This is very accurate but can be time-consuming.

- Historical Data Analysis: Review past production orders and calculate the average time taken for each process. This is relatively straightforward but assumes consistent performance.

- Process Mapping: Creating a visual representation of the entire production process allows for easy identification of bottlenecks and estimates of time required for each step.

For instance, let’s consider creating a custom-designed chair. Lead time would include design approval, wood cutting, assembly, finishing, and quality inspection. Each of these steps has its own individual time which adds to the total lead time. It’s important to factor in potential delays like material shortages, machine breakdowns, or inspection hold-ups.

Accurate lead time calculation is essential for accurate demand forecasting, materials procurement, and efficient capacity planning.

Q 3. Describe your experience with capacity planning and resource allocation.

Capacity planning and resource allocation are intertwined processes aimed at optimizing production efficiency. My experience involves leveraging various techniques to ensure resources are efficiently utilized and production goals are met.

In a previous role, we utilized capacity requirement planning (CRP) to analyze our production capabilities against the planned production volume. This involved evaluating machine capacity, labor availability, and other resources like tooling and materials. We then identified potential bottlenecks and developed strategies to mitigate them, such as overtime, cross-training employees, or investing in new equipment.

Resource allocation involved strategically assigning resources to different production tasks based on priorities and available capacity. We utilized software to optimize the allocation process, considering factors like setup times, processing times, and due dates. This included prioritizing urgent orders and ensuring a balanced workload across all resources. We also implemented a system for tracking resource utilization to monitor efficiency and identify areas for improvement.

For example, when facing a sudden surge in demand for a specific product, we analyzed our capacity to determine whether we had sufficient machine time and labor to meet the increased demand. If not, we implemented strategies such as overtime or outsourcing to meet the order deadlines.

Q 4. What software have you used for production scheduling (e.g., SAP, Oracle, MS Project)?

Throughout my career, I’ve extensively used various software packages for production scheduling. My experience encompasses:

- SAP ERP: I’ve worked extensively with SAP’s production planning module, including PP-MRP (Material Requirements Planning) and PP-SFC (Shop Floor Control). I have created and managed production orders, monitored production progress, and integrated production scheduling with inventory management.

- Oracle Production Planning and Scheduling: This system was instrumental in optimizing our production scheduling across multiple plants. I used this software for capacity planning, resource allocation, and demand forecasting. The real-time tracking and reporting features were invaluable for identifying and addressing potential issues promptly.

- MS Project: While primarily a project management tool, MS Project’s Gantt charts and resource allocation features have been very useful for visualizing and managing small-scale production projects or complex tasks within a larger production plan.

My proficiency in these software packages is complemented by my strong understanding of underlying production planning principles, enabling me to effectively utilize these tools to achieve optimal results.

Q 5. How do you handle production bottlenecks?

Production bottlenecks are inevitable, but proactive management is crucial. My approach to handling them is systematic and involves several steps:

- Identification: First, accurately identify the bottleneck. This usually involves tracking production metrics like cycle times, wait times, and machine utilization to pinpoint the constraint.

- Analysis: Understand the root cause. Is it due to equipment failure, insufficient skilled labor, material shortages, inefficient processes, or a combination of factors? Root cause analysis techniques like the 5 Whys can be helpful here.

- Solution Development: Once the root cause is understood, develop solutions. This might involve:

- Process improvement: Streamlining operations, reducing setup times, or improving workflow.

- Equipment upgrade or maintenance: Investing in new equipment or performing preventative maintenance on existing equipment.

- Rescheduling: Reprioritizing production tasks to alleviate pressure on the bottleneck.

- Cross-training: Ensuring flexibility in workforce assignments to address skill gaps.

- Outsourcing: Contracting with external suppliers to perform part of the production process.

- Implementation and Monitoring: Implement the chosen solution and carefully monitor its effectiveness. Track key metrics to ensure the bottleneck is resolved and production efficiency improves.

For example, I once encountered a bottleneck in the assembly line due to a slow-moving machine. Through analysis, we determined that the machine required regular maintenance that had been neglected. Implementing a preventative maintenance schedule resolved the bottleneck, significantly improving the throughput of the entire assembly line.

Q 6. What metrics do you use to measure production efficiency?

Measuring production efficiency requires a comprehensive set of metrics. I typically use a combination of the following:

- Overall Equipment Effectiveness (OEE): This metric combines availability, performance, and quality rate to measure the effectiveness of equipment utilization. It’s a great holistic indicator of production efficiency.

- Throughput: The total number of units produced over a specific time period. This measures the production rate.

- Cycle Time: The time it takes to complete one production cycle. Shorter cycle times indicate greater efficiency.

- Lead Time: The time between order placement and product delivery. Reduced lead times indicate improved efficiency and responsiveness.

- Defect Rate: The percentage of defective units produced. A low defect rate signifies high quality and reduces waste.

- Inventory Turnover: How many times inventory is sold or used in a given period. Higher turnover usually indicates better inventory management.

- Labor Productivity: Output per labor hour. This measures the effectiveness of the workforce.

By tracking these metrics regularly, I can identify areas for improvement, track the effectiveness of implemented changes, and justify improvements to processes or equipment.

Q 7. Explain your experience with lean manufacturing principles.

Lean manufacturing principles focus on eliminating waste and maximizing value for the customer. My experience with lean manufacturing involves applying various lean tools and methodologies to optimize production processes.

I’ve implemented 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) to improve workplace organization and efficiency. This involved eliminating unnecessary items, improving workflow, and standardizing processes for better consistency.

Kaizen events, or continuous improvement workshops, were used to identify and eliminate waste in specific production areas. This involved engaging teams in identifying inefficiencies, proposing solutions, and implementing improvements.

I’ve also used Value Stream Mapping to visualize the entire production process and identify areas of waste, such as excess inventory, unnecessary movement, or waiting time. This allowed for focused improvement efforts. For example, by optimizing material flow and reducing unnecessary movement, we were able to significantly reduce lead times and improve overall efficiency. Implementing Kanban systems for inventory control helped reduce waste by only producing what is needed when it is needed.

Ultimately, my experience shows a commitment to continuous improvement and customer-centric production based on lean principles.

Q 8. How do you prioritize competing production orders?

Prioritizing competing production orders requires a systematic approach balancing several factors. It’s not simply a matter of ‘first come, first served’. We need a clear methodology to ensure we meet customer deadlines, maximize resource utilization, and minimize inventory holding costs.

I typically use a weighted scoring system. Each order is assigned points based on several key criteria:

- Due Date: Orders with imminent deadlines receive higher scores.

- Customer Priority: High-value or strategic customers get preference.

- Material Availability: Orders requiring readily available materials are prioritized to prevent delays.

- Profitability: High-margin orders are often favored to maximize revenue.

- Production Complexity: Simpler orders may be prioritized to free up resources for complex ones later.

These scores are then combined to generate a ranked list of orders. This allows for a transparent and data-driven approach to prioritization, minimizing potential conflicts and maximizing overall efficiency. For example, a high-value, urgent order with readily available materials might easily outrank a less profitable, less urgent order, even if it arrived earlier.

Q 9. Describe your process for creating a production schedule.

Creating a production schedule involves a multi-step process combining forecasting, capacity planning, and resource allocation. It’s like orchestrating a complex symphony, where each instrument (resource) must play its part at the right time to create a harmonious whole (finished product).

My process typically starts with demand forecasting to predict the volume and timing of future orders. This informs the master production schedule (MPS), which outlines the quantity and timing of each product to be manufactured. The MPS is then translated into a detailed production schedule, specifying the exact sequence of operations, machines, and personnel needed for each order. This schedule takes into account capacity constraints, such as available machine time, labor availability, and material limitations. I frequently utilize software tools like MRP (Material Requirements Planning) systems to optimize the schedule and ensure efficient resource utilization. These tools help identify potential bottlenecks and suggest adjustments to improve overall throughput.

Finally, I thoroughly review and validate the schedule, consulting with relevant teams (e.g., procurement, quality control) to ensure feasibility and accuracy before implementation. The process is iterative – we continuously monitor performance and adjust the schedule as needed.

Q 10. How do you manage changes to the production schedule?

Managing schedule changes requires a proactive and flexible approach. Changes are inevitable in dynamic production environments, and responding effectively is crucial. My strategy involves a combination of formal procedures and collaborative communication.

Firstly, all changes are formally documented and communicated to all affected parties. This ensures transparency and prevents confusion. Secondly, I assess the impact of any proposed changes on the overall schedule, identifying potential conflicts and delays. This may involve utilizing scheduling software to simulate the effects of the changes. Based on this impact assessment, we prioritize the changes based on their urgency and importance, using the same weighted scoring system described earlier.

We then implement the changes in a controlled manner, perhaps staggering implementation to minimize disruption. Continuous monitoring and adjustments are vital to ensure the revised schedule remains feasible and efficient. We often employ a system of ‘change requests’ which need to be approved by relevant stakeholders before implementation. This ensures discipline and minimizes unintended consequences.

Q 11. How do you handle unexpected production delays?

Unexpected delays are a fact of life in production. My approach focuses on rapid identification, effective communication, and proactive mitigation. The first step is to quickly identify the root cause of the delay – is it a machine breakdown, material shortage, or a quality issue? Once the cause is identified, I communicate the delay and its impact to relevant stakeholders including customers, potentially providing revised delivery dates.

Next, I develop and implement a recovery plan. This could involve reassigning resources, expediting materials, or adjusting the production sequence to minimize the impact of the delay. For instance, if a machine breaks down, we might re-allocate jobs to other available machines, or if materials are delayed, we might expedite the shipment or find alternative suppliers. Post-delay, a thorough analysis is conducted to understand the contributing factors and to develop preventive measures to reduce the likelihood of similar disruptions in the future.

Q 12. What is your experience with forecasting demand?

Forecasting demand is crucial for effective production planning. My experience involves utilizing a variety of forecasting techniques, adapting my approach based on data availability, product lifecycle, and market conditions. I’ve worked with both qualitative methods (e.g., expert opinions, market research) and quantitative methods (e.g., time series analysis, regression models).

I find that combining different techniques often yields the most accurate forecasts. For instance, I might use historical sales data for time series analysis, then overlay market research insights or expert opinions to adjust for anticipated changes in demand. It’s vital to regularly review and update forecasts to account for unexpected market fluctuations or changes in customer demand. The accuracy of forecasting has a direct impact on inventory levels, production capacity, and overall profitability.

Q 13. Describe a time you had to optimize a production process.

In a previous role, we faced significant bottlenecks in our assembly line, resulting in production delays and increased costs. The bottleneck was identified as a specific assembly step which was manual and time-consuming. To optimize this process, I led a team to implement a new automated system for that step.

The process involved several stages: First, we meticulously analyzed the current process, identifying its inefficiencies. Then, we explored different automation solutions, comparing their costs and benefits. After selecting a suitable system, we oversaw its implementation, providing training to the affected personnel. Following implementation, we monitored the system’s performance, making adjustments to fine-tune its efficiency. This optimization project significantly improved the throughput of the assembly line, reducing production time by 25% and lowering labor costs.

Q 14. What is your experience with inventory management?

Inventory management is essential for balancing supply and demand, minimizing costs, and ensuring product availability. My experience encompasses various inventory management techniques, from simple inventory tracking to sophisticated inventory optimization models. I am proficient in utilizing ERP (Enterprise Resource Planning) systems to manage inventory levels, track stock movements, and generate reports on inventory turnover.

I emphasize the importance of striking a balance between holding sufficient inventory to meet demand and avoiding excessive inventory buildup that ties up capital and increases storage costs. I have used techniques such as ABC analysis to categorize inventory based on its value and consumption rate, allowing for targeted inventory control strategies. The goal is to maintain optimal inventory levels, minimizing stockouts and excess stock, contributing to improved profitability and customer satisfaction.

Q 15. How do you ensure on-time delivery of products?

On-time delivery hinges on meticulous planning and execution. It’s not just about meeting deadlines; it’s about consistently exceeding expectations. My approach involves several key strategies:

- Accurate Forecasting: Precise demand forecasting is paramount. We use a combination of historical data, market trends, and sales projections to anticipate customer needs accurately. This allows for proactive resource allocation and prevents last-minute scrambling.

- Optimized Scheduling: Sophisticated scheduling software and techniques, such as Material Requirements Planning (MRP) and Capacity Requirements Planning (CRP), are crucial for optimizing production flow. We consider machine capacity, material availability, and labor constraints to create a realistic and efficient schedule.

- Real-time Monitoring and Control: Constant monitoring of the production process, using dashboards and real-time data analysis, enables us to identify potential delays early on. We can then implement corrective actions, such as adjusting resource allocation or expediting critical tasks.

- Proactive Communication: Maintaining open communication with suppliers, internal teams, and customers ensures everyone is aligned and informed of potential challenges or changes in the schedule. Transparency is key to mitigating surprises and preventing delays.

- Continuous Improvement: Regularly reviewing our processes and identifying areas for improvement is crucial. We use Lean methodologies, like Kaizen, to eliminate waste and optimize efficiency. This could involve streamlining processes, improving workflow, or enhancing training.

For example, in a previous role, we implemented a new scheduling system that reduced lead times by 15% and improved on-time delivery rates by 10%. This was achieved by better integration of production data with sales forecasts, improving the accuracy of resource allocation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How familiar are you with Six Sigma methodologies?

I’m very familiar with Six Sigma methodologies. I’ve utilized its principles extensively throughout my career to drive process improvements and reduce defects in production environments. Six Sigma is a data-driven approach focused on minimizing variation and achieving near-perfection in processes. I’ve applied DMAIC (Define, Measure, Analyze, Improve, Control) in several projects.

- Define: Clearly defining the problem, setting measurable goals, and identifying key stakeholders.

- Measure: Collecting and analyzing data to understand the current process and identify areas of improvement. This often involves using statistical process control (SPC) charts.

- Analyze: Identifying the root causes of defects or variations using tools like Pareto charts, fishbone diagrams, and process mapping.

- Improve: Implementing solutions to address the root causes. This might involve process redesign, technology upgrades, or employee training.

- Control: Monitoring the improved process to ensure the gains are sustained and prevent regression.

For instance, in one project, we used Six Sigma to reduce the defect rate in a specific manufacturing process from 3% to less than 0.5%. This was accomplished by identifying and eliminating a critical source of variation in the raw materials using control charts and implementing a new quality control check point.

Q 17. How do you track key performance indicators (KPIs) for production?

Tracking key performance indicators (KPIs) is essential for monitoring production efficiency and identifying areas for improvement. We use a variety of metrics, depending on the specific production environment and goals. Common KPIs include:

- On-Time Delivery Rate: The percentage of orders delivered on or before the scheduled date.

- Production Efficiency: The ratio of actual output to planned output.

- Defect Rate: The percentage of defective products produced.

- Lead Time: The time it takes to complete a production process.

- Inventory Turnover Rate: How quickly inventory is used and replenished.

- Overall Equipment Effectiveness (OEE): Measures the effectiveness of equipment in producing good quality products.

- Machine Downtime: The time equipment is unavailable due to maintenance, repairs, or breakdowns.

These KPIs are tracked using a combination of automated data collection systems, manual data entry, and specialized software. Data is regularly analyzed to identify trends, pinpoint bottlenecks, and inform decision-making.

We also utilize dashboards to visualize key metrics and provide real-time insights into production performance, which makes it easy to identify and address issues quickly.

Q 18. Describe your experience with root cause analysis for production issues.

Root cause analysis is crucial for addressing production issues effectively. My approach typically involves a structured methodology, such as the 5 Whys or Fishbone diagrams. The goal is to identify the underlying cause of a problem, rather than just treating the symptoms.

- 5 Whys: Repeatedly asking ‘why’ to drill down to the root cause of a problem. This iterative questioning helps to uncover the underlying issues that contribute to the problem.

- Fishbone Diagram (Ishikawa Diagram): A visual tool that helps to identify potential causes of a problem by categorizing them into different categories (e.g., materials, methods, manpower, machinery, measurement, environment).

- Data Analysis: Using data to identify patterns and trends that might indicate the root cause.

- Team Collaboration: Involving relevant stakeholders in the analysis to leverage their expertise and perspectives.

For example, if we experience a significant increase in product defects, we wouldn’t simply increase quality checks. We would use root cause analysis to determine the underlying reason – perhaps a faulty machine, subpar materials, or inadequate employee training. Once the root cause is identified, we can implement targeted solutions.

Q 19. How do you communicate production schedules and updates to other teams?

Effective communication of production schedules and updates is essential for maintaining a smooth workflow across different teams. I use several methods to ensure transparency and clarity:

- Regular Meetings: Scheduled meetings with relevant teams (e.g., sales, procurement, engineering) to discuss production schedules, challenges, and potential solutions.

- Project Management Software: Using project management tools (e.g., Asana, Jira, MS Project) to track progress, share documents, and facilitate communication.

- Dashboards and Reports: Developing dashboards and reports to provide real-time visibility into production progress and key metrics.

- Email and Instant Messaging: Using email and instant messaging for quick updates and notifications.

- Visual Management Tools: Implementing visual management systems, such as Kanban boards or production scheduling boards, to improve transparency and collaboration.

The key is to choose the communication method that is most appropriate for the audience and the information being shared. For example, a quick update on a minor delay might be sent via email, while a major schedule change requires a formal meeting.

Q 20. What is your approach to managing production risks?

Managing production risks requires a proactive and multi-faceted approach. My strategy involves:

- Risk Identification: Regularly identifying potential risks, such as equipment failure, material shortages, supply chain disruptions, or labor issues. Techniques like SWOT analysis and brainstorming sessions are helpful.

- Risk Assessment: Evaluating the likelihood and impact of each identified risk. This helps prioritize which risks to focus on.

- Risk Mitigation: Developing and implementing strategies to reduce the likelihood or impact of identified risks. This could include things like redundancy in equipment, diversification of suppliers, or robust inventory management.

- Contingency Planning: Creating backup plans to address unforeseen circumstances. For example, having a plan in place for dealing with a sudden machine breakdown or a supplier delay.

- Monitoring and Review: Regularly reviewing the effectiveness of risk management strategies and making adjustments as needed.

For instance, to mitigate the risk of supply chain disruptions, we might diversify our suppliers, build up safety stock of critical materials, or explore alternative sourcing options. This proactive approach ensures business continuity even in challenging circumstances.

Q 21. How do you balance production efficiency with quality control?

Balancing production efficiency with quality control is a critical aspect of successful manufacturing. It’s not a trade-off, but rather a synergy. Here’s how I approach this:

- Process Optimization: Streamlining processes to eliminate waste and improve efficiency without compromising quality. Lean manufacturing principles are particularly useful here.

- Automation and Technology: Implementing automation to improve speed and consistency while reducing human error, a common source of quality issues.

- Quality Control at Each Stage: Integrating quality checks at every stage of the production process, rather than just at the end. This enables early detection and correction of problems, reducing waste and rework.

- Employee Training: Investing in comprehensive training for employees to ensure they are equipped with the skills and knowledge to maintain high quality standards.

- Continuous Improvement: Regularly monitoring quality metrics and implementing improvements based on data and feedback. Kaizen events and other continuous improvement initiatives are valuable here.

The key is to establish a culture of quality throughout the organization. Everyone from the shop floor to management should be committed to maintaining high quality standards. This means that efficiency is never achieved at the expense of quality.

Q 22. Explain your experience working with cross-functional teams.

Throughout my career, I’ve consistently thrived in cross-functional team environments. I believe effective collaboration is the cornerstone of successful production and scheduling. My experience spans working with engineering, procurement, quality control, and operations teams. For instance, in a previous role, we faced a challenge in meeting a tight deadline for a new product launch. By fostering open communication and establishing clear roles and responsibilities amongst the engineering (design finalization), procurement (material sourcing), quality (testing procedures), and operations (manufacturing scheduling) teams, we successfully navigated the complexities and delivered the product on time. This involved regular team meetings, transparent progress updates, and proactive problem-solving sessions. My approach prioritizes active listening, empathy, and a collaborative spirit, ensuring everyone feels valued and heard, leading to more creative solutions and smoother project execution.

Q 23. Describe your understanding of Kanban or other visual scheduling systems.

Kanban is a visual scheduling system that emphasizes workflow visualization and continuous improvement. It’s particularly effective for managing tasks in a dynamic environment where priorities might shift frequently. Imagine a Kanban board as a whiteboard divided into columns representing different stages of production, such as ‘To Do,’ ‘In Progress,’ and ‘Done.’ Each task is represented by a card that moves across the board as it progresses. This allows for immediate visibility into the workflow, identifying bottlenecks and facilitating quick adjustments. I’ve successfully implemented Kanban in several projects, resulting in improved throughput, reduced lead times, and enhanced team collaboration. For instance, in one project, implementing a Kanban system revealed a bottleneck in the quality control stage, which we addressed by adding resources and streamlining the inspection process. Other visual systems I’m proficient with include Scrum and Lean methodologies, which share similar principles of workflow transparency and continuous improvement but with different frameworks.

Q 24. How do you handle material shortages during production?

Material shortages are a common challenge in production. My approach involves a multi-pronged strategy. First, I immediately assess the impact of the shortage on the production schedule. Then I prioritize the affected production lines based on urgency and customer commitments. Simultaneously, I work with the procurement team to expedite the delivery of the missing materials, exploring alternative suppliers or expediting existing orders. If a complete replacement is impossible within the required timeframe, I explore alternative solutions like substituting materials (if feasible and approved by quality control), adjusting the production plan to prioritize other products, or engaging in open communication with clients about potential delays. Communication is critical; keeping all stakeholders informed ensures transparency and minimizes disruptions. I also use this opportunity to review and improve our inventory management processes to prevent similar issues in the future, perhaps through better forecasting or safety stock levels.

Q 25. How would you address a significant deviation from the production plan?

Significant deviations from the production plan demand immediate attention. My response begins with a thorough root cause analysis, identifying the factors contributing to the deviation. This might involve reviewing production data, interviewing team members, and inspecting the production line. Once the root cause is identified, I develop a corrective action plan which addresses the immediate problem and prevents recurrence. This plan may involve adjusting the schedule, re-allocating resources, or implementing process improvements. For example, if the deviation was caused by equipment malfunction, the plan would include repair/replacement of the equipment and potentially preventive maintenance to avoid future failures. Throughout the process, I maintain open communication with all stakeholders, providing regular updates on the situation and the corrective actions taken. This ensures everyone remains informed and supports the recovery effort.

Q 26. What is your understanding of safety protocols within a production environment?

Safety protocols are paramount in any production environment. My understanding encompasses a comprehensive approach, starting with a thorough knowledge of OSHA (or relevant local) regulations and best practices. This includes understanding and implementing procedures for machine guarding, lockout/tagout procedures, personal protective equipment (PPE) usage, and emergency response planning. I actively participate in safety audits, inspections, and training programs to ensure compliance and foster a culture of safety among the production team. I believe in proactive safety measures, rather than just reactive responses to accidents. This includes regular equipment inspections, providing safety training and refresher courses, and implementing safety improvements based on data analysis of near misses or incidents. A safe workplace is a productive workplace.

Q 27. How do you measure the effectiveness of your scheduling processes?

Measuring the effectiveness of scheduling processes involves using key performance indicators (KPIs). These KPIs allow us to quantitatively assess efficiency and identify areas for improvement. Some essential KPIs I regularly track include on-time delivery rate, production lead time, inventory turnover rate, and production efficiency (actual output vs. planned output). I also analyze defect rates to identify potential issues with the scheduling process contributing to poor quality. By monitoring these KPIs, we can identify bottlenecks, inefficiencies, and areas needing improvement. For example, consistently low on-time delivery might indicate a problem with material procurement or production capacity, while high defect rates might suggest a need for improved process controls or training. The data collected allows for data-driven decisions, leading to optimized scheduling practices and continuous improvement.

Q 28. Explain your experience using project management software for production planning.

I have extensive experience using various project management software for production planning. My proficiency includes software such as MS Project, Primavera P6, and more recently, cloud-based solutions like Asana and Monday.com. These tools are invaluable for creating detailed schedules, tracking progress, managing resources, and collaborating with teams. For example, in a recent project involving a complex manufacturing process, I used MS Project to create a Gantt chart visualizing the entire production schedule, including dependencies between different tasks. This allowed for easy identification of critical path activities and facilitated proactive risk management. The software’s reporting features provided invaluable insights into project performance, allowing for real-time adjustments and ensuring we stayed on track. The ability to share and update schedules in real-time through cloud-based platforms significantly enhances team collaboration and communication.

Key Topics to Learn for Production and Scheduling Interview

- Production Planning & Control: Understanding demand forecasting, capacity planning, materials requirements planning (MRP), and production scheduling techniques like Gantt charts and Kanban.

- Practical Application: Analyzing production data to identify bottlenecks, optimizing resource allocation (labor, equipment, materials), and developing strategies to improve efficiency and reduce lead times. Consider real-world scenarios like managing unexpected equipment downtime or material shortages.

- Scheduling Algorithms & Software: Familiarity with various scheduling algorithms (e.g., FIFO, shortest processing time, critical ratio) and experience with production scheduling software (mentioning specific software is optional, focus on general concepts).

- Inventory Management: Understanding inventory control principles, optimizing inventory levels to minimize costs while meeting production demands, and managing stock levels to avoid shortages or excess.

- Lean Manufacturing Principles: Applying concepts like Kaizen, 5S, and Just-in-Time (JIT) to streamline production processes and eliminate waste.

- Quality Control & Assurance: Understanding the role of quality control in production scheduling, integrating quality checks into the production process, and addressing quality issues that impact scheduling.

- Supply Chain Management: Understanding the interplay between production scheduling and the broader supply chain, including supplier relationships, logistics, and transportation.

- Problem-solving & Optimization: Developing and implementing solutions to address production challenges, optimizing schedules in response to changing demands or unforeseen circumstances, and using data analysis to make informed decisions.

Next Steps

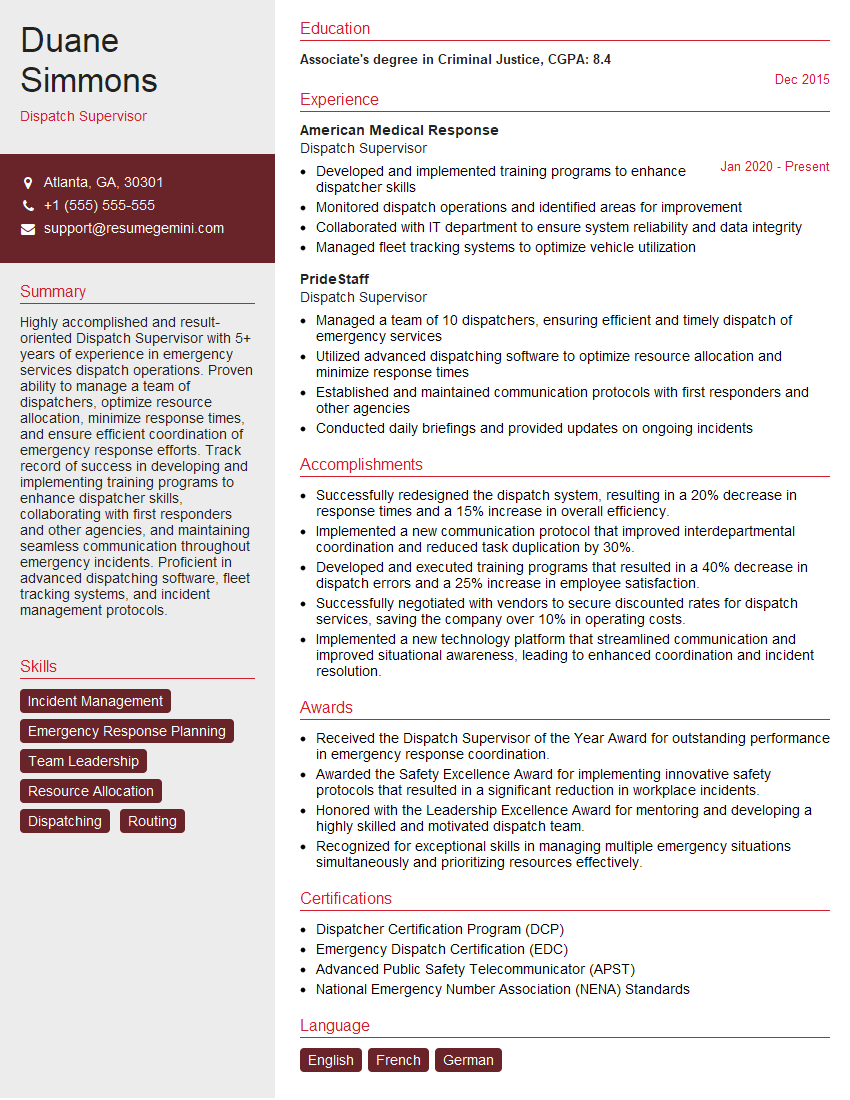

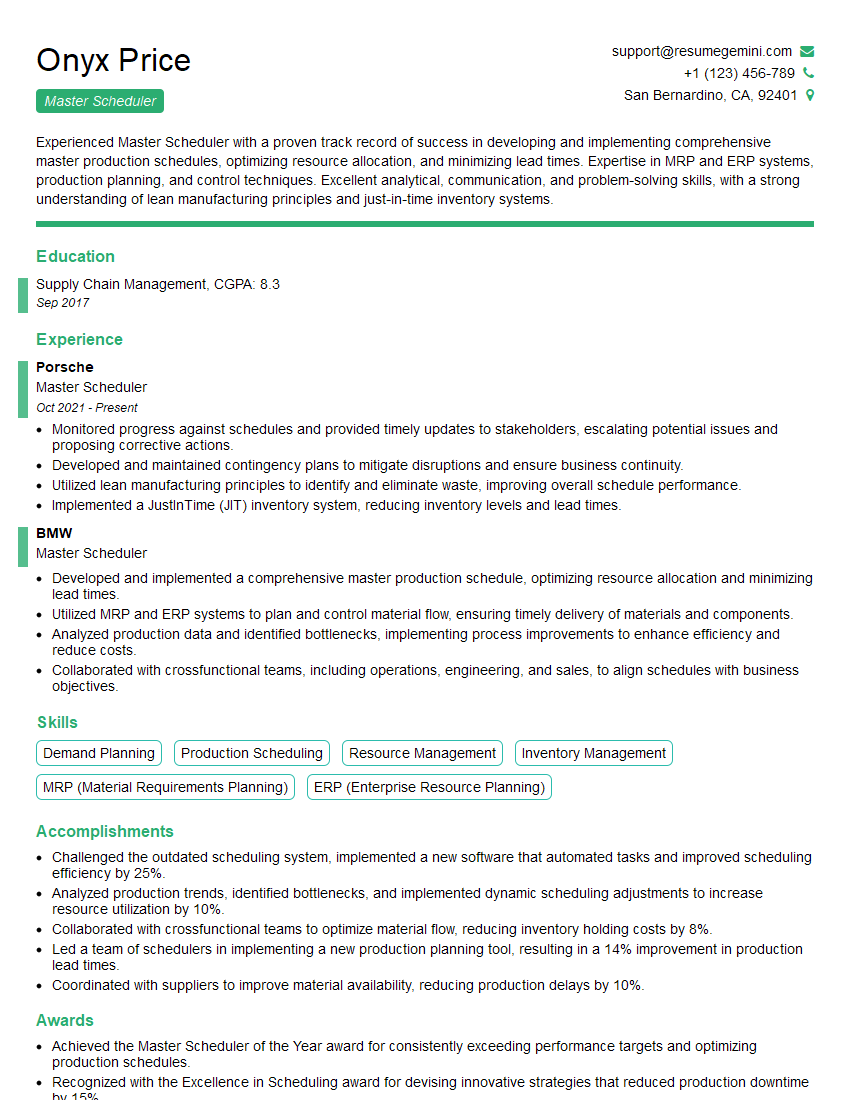

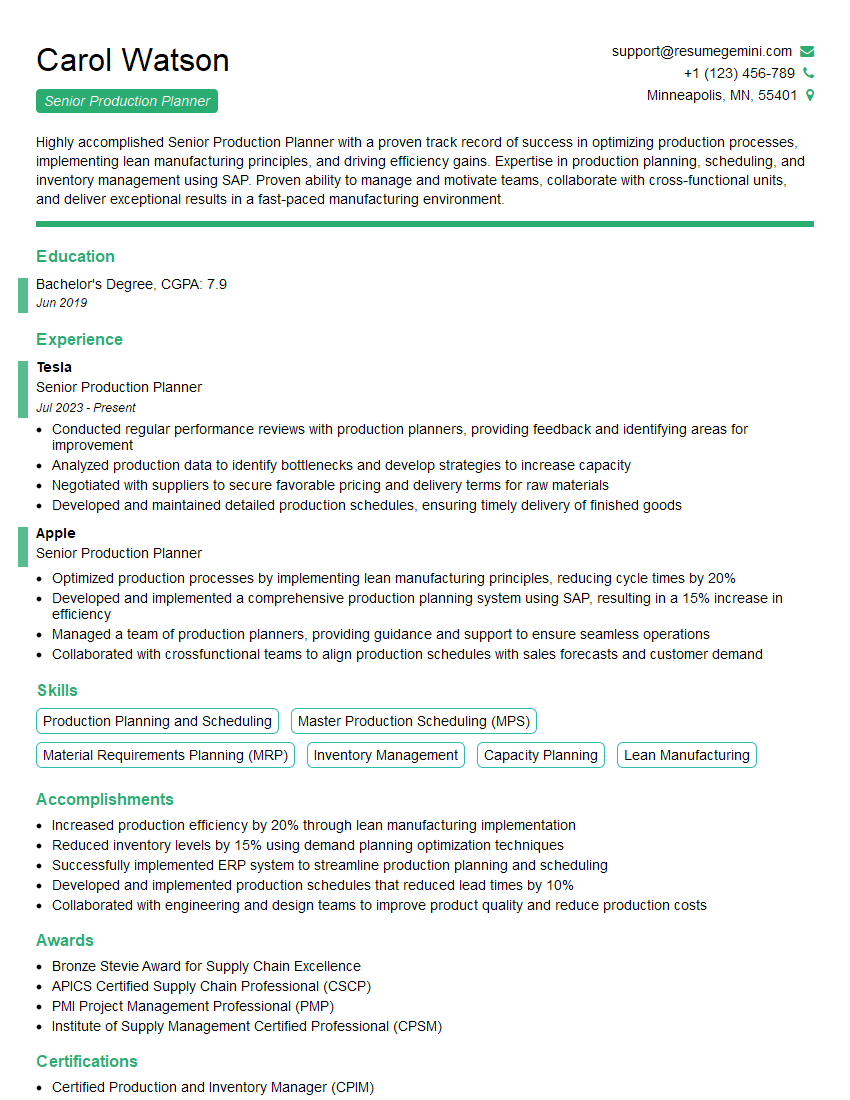

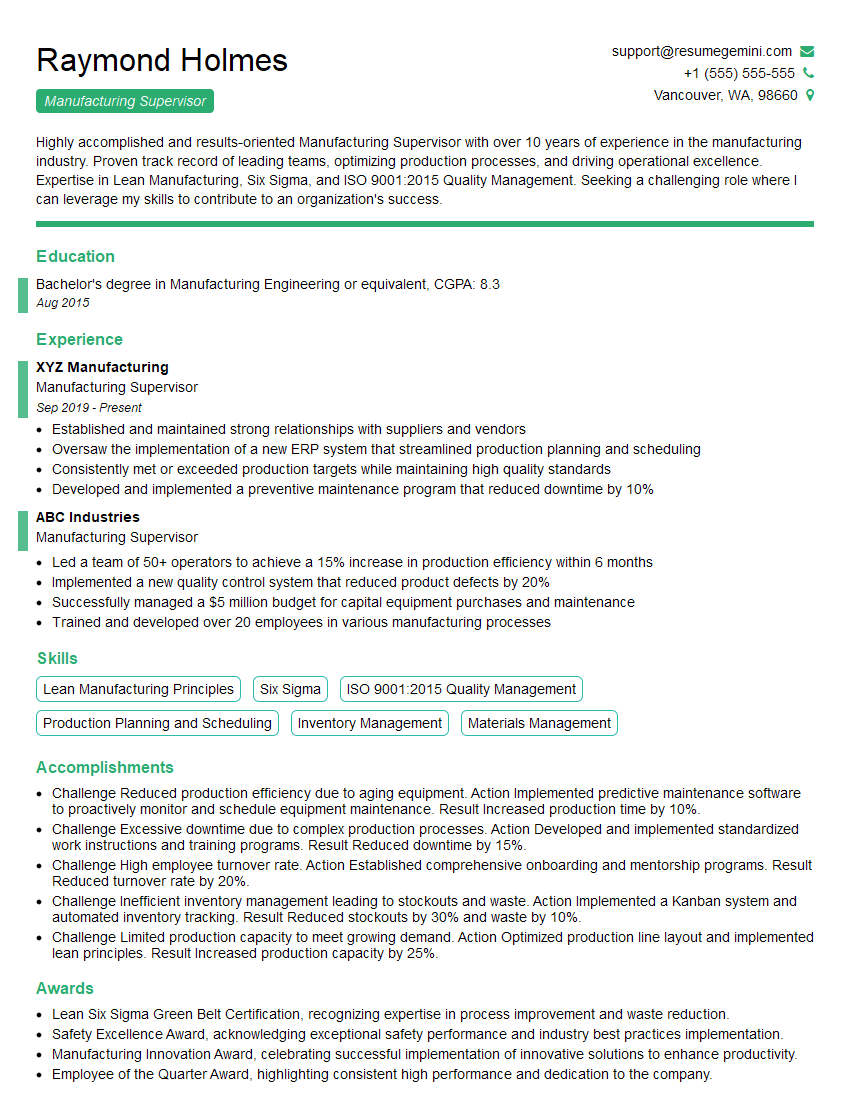

Mastering Production and Scheduling opens doors to exciting career advancements, offering opportunities for increased responsibility, higher salaries, and leadership roles within manufacturing and operations. An ATS-friendly resume is crucial for getting your application noticed. To significantly boost your job prospects, consider crafting a compelling and targeted resume that highlights your skills and experience effectively. ResumeGemini can help you create a professional and impactful resume that showcases your qualifications in the best possible light. Examples of resumes tailored to Production and Scheduling are available to help you get started.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good