Unlock your full potential by mastering the most common Production Line Setup interview questions. This blog offers a deep dive into the critical topics, ensuring you’re not only prepared to answer but to excel. With these insights, you’ll approach your interview with clarity and confidence.

Questions Asked in Production Line Setup Interview

Q 1. Explain the process of setting up a new production line.

Setting up a new production line is a multifaceted process requiring meticulous planning and execution. It’s akin to orchestrating a complex symphony, where each instrument (machine, worker, process) must play its part in perfect harmony to achieve the desired output. The process typically involves several key stages:

- Line Design and Planning: This initial phase involves defining the product specifications, determining the production volume, selecting appropriate equipment and technology, and designing the layout (e.g., U-shaped, straight line). We carefully analyze the production process, identifying all necessary steps and their sequence. This often includes creating flowcharts and process maps.

- Equipment Procurement and Installation: Once the design is finalized, we procure the necessary equipment, ensuring compatibility and optimal performance. Installation involves careful placement, wiring, and testing of all machines and systems. This step often requires specialized technicians and rigorous safety checks.

- Worker Training and Deployment: Thorough training of operators is crucial for efficient and safe operation. This includes hands-on training, safety protocols, and quality control procedures. We ensure each worker understands their role and responsibilities within the overall production process.

- Testing and Commissioning: Before full-scale production, rigorous testing is performed to identify and rectify any issues or bottlenecks. This involves trial runs, performance evaluation, and fine-tuning of the line parameters. We collect data to optimize efficiency and minimize waste.

- Process Optimization and Monitoring: Even after the line is operational, continuous monitoring and optimization are essential. We regularly track key performance indicators (KPIs) and make adjustments as needed to improve efficiency, quality, and safety.

For example, in setting up a new bottling line, we’d carefully consider factors such as bottle capacity, filling speed, labeling technology, and sanitation procedures. Each step would be carefully planned, tested, and optimized to ensure a smooth and efficient operation.

Q 2. Describe your experience with different production line layouts (e.g., U-shaped, straight line).

I’ve extensive experience with various production line layouts, each with its own strengths and weaknesses. The choice of layout depends heavily on the specific product, production volume, and workflow.

- Straight Line Layout: This is the most basic layout, with workstations arranged in a linear sequence. It’s simple to understand and manage, but it can be less efficient for high-volume production or processes requiring frequent material handling.

- U-shaped Layout: This layout is more efficient, particularly for smaller production volumes. The U-shape allows for improved material flow, reduced travel time, and enhanced communication among workers. It also offers opportunities for improved quality control through closer monitoring of the process.

- Circular Layout: A circular layout is often employed for continuous flow processes, such as in the food and beverage industries. This allows for a continuous flow of materials, minimizing interruptions and downtime.

- Cellular Layout: Cellular layouts group related machines together to produce a family of similar products. This allows for specialized workers and equipment, optimizing efficiency for specific product lines.

In a past project, we transitioned a straight-line assembly line to a U-shaped layout. This change significantly reduced material handling times and improved overall efficiency by 15%, highlighting the importance of selecting the right layout for optimal results.

Q 3. How do you ensure the safety of workers during production line setup?

Worker safety is paramount during any production line setup and operation. Safety is not just a priority, it’s an absolute necessity. Our approach is proactive and multi-layered:

- Risk Assessment: Before any equipment installation or operation, we conduct thorough risk assessments to identify potential hazards and implement preventative measures. This involves identifying potential hazards (e.g., moving parts, sharp edges, electrical hazards) and developing safety protocols.

- Machine Guarding: All machinery is fitted with appropriate safety guards and interlocks to prevent accidental contact. We use light curtains, emergency stop buttons, and other safety devices to minimize risk.

- Personal Protective Equipment (PPE): We provide and enforce the use of appropriate PPE, including safety glasses, gloves, hearing protection, and steel-toed boots, depending on the specific hazards involved.

- Training and Education: Extensive training is provided to all workers on safe operating procedures, emergency response protocols, and the use of safety equipment. Regular safety briefings and refresher courses are conducted.

- Ergonomic Design: Workstations are designed ergonomically to minimize worker fatigue and the risk of musculoskeletal injuries. This often includes adjustable workstations, proper lighting, and comfortable seating.

- Regular Inspections: Regular inspections are conducted to ensure that all safety measures are in place and working effectively. This includes checking machine guards, safety devices, and PPE.

For example, on a recent project involving robotic arms, we implemented a dual-layered safety system, including light curtains and emergency stop buttons, to prevent any accidental contact between workers and the robots.

Q 4. What are the key performance indicators (KPIs) you monitor during production line setup?

During production line setup, we monitor several key performance indicators (KPIs) to ensure efficiency and quality. These KPIs are crucial for identifying potential problems early and optimizing the line’s performance.

- Overall Equipment Effectiveness (OEE): This measures the percentage of time the equipment is producing good parts. A low OEE indicates potential issues such as downtime or defects.

- Setup Time: This measures the time taken to change over from one product to another. Reducing setup time is crucial for improving production flexibility and efficiency.

- Throughput Rate: This measures the number of units produced per unit of time. It’s a direct measure of production efficiency.

- Defect Rate: This measures the percentage of defective units produced. A high defect rate indicates issues with the process or quality control.

- Mean Time Between Failures (MTBF): This measures the average time between equipment failures. A higher MTBF indicates reliable equipment and less downtime.

- Mean Time To Repair (MTTR): This measures the average time taken to repair equipment failures. A lower MTTR indicates efficient maintenance procedures.

We use these KPIs to create control charts and dashboards, allowing us to track performance over time and identify trends. Any significant deviations from target values trigger a detailed investigation to identify and address the root cause of the problem.

Q 5. How do you identify and resolve bottlenecks in a production line?

Bottlenecks, those points in the production line that restrict the overall flow, are a common challenge. Identifying and resolving them requires a systematic approach. Think of it like unclogging a pipe; pinpoint the blockage and clear it to restore flow.

- Identify the Bottleneck: This often involves analyzing the throughput rate at each workstation. The workstation with the lowest throughput is typically the bottleneck. We might use tools such as value stream mapping to visualize the entire production process and clearly identify the constraint.

- Analyze the Root Cause: Once the bottleneck is identified, we investigate the root cause. Is it due to slow equipment, insufficient labor, material shortages, poor process design, or something else? Data analysis and observation are key to identifying the underlying cause.

- Implement Solutions: Solutions vary depending on the root cause. This could involve upgrading equipment, adding more workers, improving material handling, redesigning the process, or implementing Lean Manufacturing principles to eliminate waste.

- Monitor and Evaluate: After implementing solutions, we closely monitor the production line’s performance to evaluate the effectiveness of the changes. We track KPIs to ensure the bottleneck has been eliminated and overall efficiency has improved.

For instance, in one instance, we discovered a bottleneck caused by a slow conveyor belt. By replacing the belt with a faster model, we significantly improved the throughput rate and eliminated the bottleneck. It’s about identifying, understanding, and then finding the correct solution – a tailored approach is key.

Q 6. Describe your experience with different types of production equipment.

My experience encompasses a wide range of production equipment across various industries. This includes:

- Automated Guided Vehicles (AGVs): Used for material handling and transportation within a facility. I’ve managed projects integrating AGVs into production lines to improve efficiency and reduce manual handling.

- Robotics: From simple robotic arms for assembly to complex robotic systems for welding or painting. I have experience with programming, integration, and maintenance of industrial robots.

- CNC Machines: Computer Numerical Control machines for precision machining of parts. I’m proficient in programming and operating CNC machines, ensuring consistent accuracy and quality.

- 3D Printing: Additive manufacturing technologies for prototyping and low-volume production. I’ve integrated 3D printing into production lines for customized parts and rapid prototyping.

- Conveyor Systems: Various types of conveyors for material handling and transportation. I’m familiar with different conveyor types, including belt conveyors, roller conveyors, and chain conveyors.

- Packaging Equipment: Machines for packaging and palletizing products, ensuring efficient and safe packaging.

Understanding the capabilities and limitations of different equipment is essential for designing an efficient and effective production line. Selecting the right equipment for a given task is critical to success.

Q 7. How do you ensure the quality of products during production line setup?

Ensuring product quality during production line setup is vital for customer satisfaction and business success. It’s a continuous process, not just a one-time activity.

- Quality Control Checks at Each Stage: Implementing quality control checks at each stage of the production process allows for early detection and correction of defects, preventing defective products from reaching the end of the line. This might involve visual inspections, dimensional checks, and automated testing.

- Statistical Process Control (SPC): Using statistical methods to monitor and control the production process, identifying variations and preventing deviations from specifications. Control charts are a powerful tool for this.

- Calibration and Maintenance: Regular calibration and maintenance of equipment ensure consistent accuracy and performance. This prevents variations in product quality caused by equipment malfunctions.

- Operator Training: Thoroughly training operators on quality control procedures and the importance of maintaining quality standards. This helps prevent errors and ensures consistent product quality.

- Root Cause Analysis: Investigating the root causes of any defects or quality issues. This involves identifying the underlying reasons and implementing corrective actions to prevent recurrence.

For example, in setting up a pharmaceutical production line, we implemented rigorous quality control checks at each stage, including automated inspection systems and regular equipment calibration, to maintain the highest standards of product quality and safety. Quality is built into the process from the ground up.

Q 8. What are your methods for optimizing production line efficiency?

Optimizing production line efficiency is a multifaceted process focusing on minimizing waste and maximizing output. My approach involves a systematic analysis of the entire line, identifying bottlenecks and areas for improvement. This includes:

Time Studies: Conducting detailed time studies to pinpoint slowdowns in each stage of production. For example, I once identified a bottleneck in a packaging line by meticulously tracking the time spent on each task, revealing that a poorly designed workstation layout was causing unnecessary movement and delays.

Value Stream Mapping: Visualizing the entire production process to identify non-value-added activities. This helps expose areas where waste exists, such as excessive inventory, unnecessary transportation, or waiting time. This method allowed me to cut down on lead times by 15% in a previous project by re-sequencing tasks and streamlining material flow.

Capacity Analysis: Assessing the capacity of each machine and workstation to determine if they are operating at their optimal level. Identifying underutilized equipment or overloaded stations is crucial to balance the line and improve efficiency.

Process Improvement Techniques: Implementing Lean manufacturing principles like 5S (Sort, Set in Order, Shine, Standardize, Sustain) and Kaizen (continuous improvement) to eliminate waste and improve workflow. For example, implementing 5S in a previous role resulted in a 20% reduction in production errors due to a cleaner, more organized work environment.

Technology Integration: Exploring the use of automation, robotics, and advanced technologies to automate repetitive tasks, improve accuracy, and increase overall throughput. I’ve successfully implemented robotic arms in a palletizing process, reducing labor costs and boosting production by 25%.

Q 9. How do you manage changeovers on a production line?

Managing changeovers efficiently is vital to minimizing downtime and maximizing production. My strategy involves a combination of planning, training, and standardized procedures. This includes:

Standardized Work Instructions (SWI): Developing detailed, step-by-step instructions for each changeover, ensuring consistency and minimizing errors. Pictures and videos are incorporated for easier understanding.

Single Minute Exchange of Die (SMED): Implementing SMED techniques to reduce changeover times. This involves separating internal (machine-running) and external (machine-stopped) setup activities, allowing for parallel execution of tasks and reducing total changeover time.

Pre-preparation: Preparing all necessary tools, materials, and equipment before the changeover begins. A designated changeover team prepares these resources in advance to ensure a smooth transition.

Team Training: Providing comprehensive training to operators on the changeover procedures. Regular drills and practice sessions help maintain efficiency and prevent errors.

Regular Review and Improvement: Continuously evaluating the changeover process to identify areas for improvement and optimization. Time studies and data analysis help us track progress and identify bottlenecks.

For example, using SMED principles in a previous project reduced changeover time from 60 minutes to 15 minutes, significantly improving production output.

Q 10. How do you handle unexpected downtime during production line setup?

Unexpected downtime is a major disruptor in production. My response involves a multi-pronged approach:

Root Cause Analysis: Immediately investigate the cause of the downtime. A structured approach, such as the 5 Whys technique, helps get to the root of the problem rather than addressing only surface-level issues.

Emergency Response Plan: Having a pre-defined emergency response plan in place, detailing the steps to take during different types of downtime scenarios. This plan should include communication protocols, emergency contact information, and troubleshooting steps.

Preventive Maintenance: Implementing a robust preventive maintenance program to reduce the likelihood of unexpected breakdowns. Regular inspections, lubrication, and part replacements minimize the risk of sudden failures.

Spare Parts Inventory: Maintaining a sufficient inventory of spare parts to expedite repairs and minimize downtime. A well-managed inventory system ensures critical parts are readily available when needed.

Cross-Training: Cross-training employees to handle multiple roles within the production line allows flexibility and enables rapid response to unexpected issues.

For instance, during a recent unexpected power outage, our pre-defined emergency plan allowed us to restart the line within 20 minutes, minimizing production loss. The root cause analysis revealed a flaw in the backup power system, which we addressed immediately to prevent future occurrences.

Q 11. Describe your experience with using production line simulation software.

I have extensive experience using various production line simulation software packages, including Arena and AnyLogic. These tools are invaluable for designing, analyzing, and optimizing production lines before physical implementation. My experience includes:

Line Design and Optimization: Using simulation to model different line layouts, equipment configurations, and operating parameters to identify the most efficient design. This avoids costly mistakes during physical setup.

Bottleneck Identification: Simulating the production line to identify bottlenecks and areas of congestion, which helps in making informed decisions about resource allocation and process improvements.

Capacity Planning: Utilizing simulations to determine the production capacity of the line under various scenarios, helping us to plan for future growth and expansion.

What-if Analysis: Exploring different scenarios (e.g., equipment failures, increased demand) to assess the line’s resilience and identify potential vulnerabilities. This proactive approach allows for contingency planning.

For example, in one project, simulation revealed that a proposed new line layout would significantly reduce throughput due to inefficient material handling. By using the simulation data, we redesigned the layout, resulting in a 10% increase in productivity.

Q 12. How do you ensure compliance with safety regulations during production line setup?

Ensuring compliance with safety regulations is paramount during production line setup. My approach includes:

Risk Assessment: Conducting thorough risk assessments to identify potential hazards associated with the equipment, materials, and processes involved. This includes assessing physical hazards, ergonomic risks, and chemical hazards.

Safe Work Procedures: Developing and implementing safe work procedures (SWPs) for all aspects of the production line setup, including machine operation, material handling, and maintenance.

Lockout/Tagout Procedures: Ensuring proper lockout/tagout procedures are followed during maintenance and repair activities to prevent accidental starts and injuries.

Personal Protective Equipment (PPE): Providing and enforcing the use of appropriate PPE, including safety glasses, gloves, hearing protection, and steel-toe boots, as needed.

Training and Communication: Providing comprehensive safety training to all personnel involved in the setup, emphasizing safe work practices and emergency procedures. Regular safety meetings and communication reinforce safety awareness.

Compliance Audits: Regularly conducting compliance audits to ensure ongoing adherence to safety standards and regulations.

I have a strong track record of maintaining a safe work environment and have never had a lost-time accident on any production line setup I’ve overseen.

Q 13. What is your experience with lean manufacturing principles in production line setup?

Lean manufacturing principles are fundamental to my approach to production line setup. I focus on eliminating waste in all forms to maximize efficiency and reduce costs. This includes:

Value Stream Mapping: Identifying and eliminating non-value-added activities in the production process. This helps streamline the workflow and improve overall efficiency.

5S Methodology: Implementing 5S (Sort, Set in Order, Shine, Standardize, Sustain) to create a clean, organized, and efficient work environment. This reduces waste, improves safety, and streamlines operations.

Kaizen Events: Conducting Kaizen events to identify and implement rapid improvements in the production process. These focused events involve cross-functional teams working collaboratively to solve problems and optimize workflows.

Pull System: Implementing a pull system to avoid overproduction and ensure that materials are only produced as needed. This minimizes inventory and reduces waste.

Kanban: Using Kanban systems to manage the flow of materials and work-in-progress. This helps to visualize the workflow, identify bottlenecks, and improve overall efficiency.

In a recent project, the implementation of lean principles reduced inventory holding costs by 20% and improved on-time delivery rates by 15%.

Q 14. How do you handle material handling and storage during production line setup?

Efficient material handling and storage are crucial for a smooth production line setup. My approach is centered around:

Layout Optimization: Designing the production line layout to minimize material movement and transportation distances. This reduces handling time and associated costs.

Material Flow Analysis: Analyzing the flow of materials throughout the production process to identify potential bottlenecks and areas for improvement. This helps optimize the layout and material handling processes.

Inventory Management: Implementing an efficient inventory management system to track material levels and ensure timely replenishment. This prevents production stoppages due to material shortages.

Storage Optimization: Optimizing storage space to ensure materials are readily accessible and organized. This reduces search time and minimizes the risk of damage or loss.

Material Handling Equipment: Selecting and utilizing appropriate material handling equipment, such as conveyors, forklifts, and automated guided vehicles (AGVs), to improve efficiency and safety.

For example, in a previous project, optimizing material flow and implementing a Kanban system reduced material handling time by 30% and improved production throughput by 10%.

Q 15. Explain your experience with preventative maintenance in a production line.

Preventative maintenance (PM) is crucial for minimizing downtime and maximizing production line efficiency. It involves proactively servicing equipment and machinery to prevent failures before they occur, rather than reacting to breakdowns. My experience involves developing and implementing PM schedules based on manufacturer recommendations, equipment usage, and historical failure data. This includes tasks like lubrication, cleaning, inspections, and minor repairs performed on a regular schedule.

For example, in my previous role at a food processing plant, we implemented a PM schedule for our high-speed bottling line. This involved weekly inspections of conveyor belts, monthly lubrication of bearings, and quarterly replacement of worn parts. This proactive approach reduced unscheduled downtime by 30% in the first year, significantly improving overall productivity and reducing maintenance costs. We used a computerized maintenance management system (CMMS) to track PM tasks, ensuring nothing was missed and generating reports to monitor the effectiveness of our program.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different types of production scheduling.

Production scheduling is the process of planning and coordinating the production of goods or services to meet demand efficiently. I’ve worked with various scheduling methods, each with its own strengths and weaknesses.

- First-In, First-Out (FIFO): This simple method prioritizes the oldest orders first. It’s straightforward but can be inefficient if urgent or high-value orders are waiting.

- Last-In, First-Out (LIFO): This prioritizes the newest orders, often used with perishable goods. It can cause issues with order fulfillment time for older orders.

- Prioritization (e.g., Critical Ratio): This method prioritizes orders based on their due date and remaining processing time, maximizing on-time delivery. It is more complex to implement but highly effective.

- Mixed-Model Scheduling: This involves sequencing a mix of different products on the production line. It’s challenging to optimize, often requiring sophisticated software and careful consideration of changeover times.

- Kanban: This pull-based system relies on visual signals to trigger production. It promotes just-in-time manufacturing, reducing inventory costs and lead times.

In one project, I implemented a critical ratio scheduling system for a custom manufacturing facility, resulting in a 15% improvement in on-time delivery and a reduction in work-in-progress inventory.

Q 17. How do you troubleshoot problems on a production line?

Troubleshooting production line problems requires a systematic approach. I use a structured methodology involving the following steps:

- Identify the problem: Clearly define the issue, including symptoms and impact on production.

- Gather data: Collect relevant data, such as machine logs, operator reports, and production records.

- Analyze the data: Identify patterns and potential root causes. This may involve using statistical process control (SPC) charts or other analytical tools.

- Develop and implement a solution: Based on the analysis, develop and implement a solution to address the root cause. This may involve repairing equipment, adjusting process parameters, or retraining operators.

- Verify the solution: Monitor the production line to ensure the solution has resolved the problem and prevented recurrence.

For instance, during a production run, we experienced a sudden increase in product defects. By analyzing machine logs and operator feedback, we discovered a malfunctioning sensor causing incorrect machine settings. After replacing the sensor, the defect rate returned to normal levels.

Q 18. What is your experience with Kaizen events or other continuous improvement initiatives?

I have extensive experience participating in and leading Kaizen events, a cornerstone of continuous improvement. These events focus on identifying and eliminating waste in all forms (muda) within a process.

In a previous role, we conducted a Kaizen event focused on optimizing a packaging process. Through team brainstorming and value-stream mapping, we identified several areas of waste, such as unnecessary movement of materials, excessive inventory, and inefficient packaging techniques. We implemented several changes, including reorganizing the workspace, streamlining packaging procedures, and implementing a 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain). This resulted in a 20% reduction in packaging time and a significant improvement in overall efficiency. The success of these events often relies on the active participation and buy-in of all team members.

Q 19. How do you ensure accurate tracking of production data?

Accurate production data tracking is essential for monitoring performance, identifying areas for improvement, and making informed decisions. My approach involves using a combination of manual and automated methods.

- Manufacturing Execution Systems (MES): These software systems provide real-time visibility into production data, including production rates, downtime, and quality metrics.

- Supervisory Control and Data Acquisition (SCADA) Systems: These systems monitor and control industrial processes, often providing data crucial for production tracking.

- Data Logging Devices: These devices record production data from individual machines and can be integrated into a larger system.

- Manual Data Entry: While less efficient, manual data entry can be necessary for certain aspects of production. It is crucial to ensure data integrity through verification and validation.

To ensure data accuracy, we implemented rigorous data validation procedures and regular audits. Data integrity is crucial, so we use checks and balances throughout the process. For example, we reconciled data from MES with manual records on a daily basis to identify and correct discrepancies.

Q 20. Describe your experience with using different types of production line control systems.

I am proficient in using various production line control systems, ranging from simple programmable logic controllers (PLCs) to advanced MES systems.

- PLCs: These are essential for automating individual machines and processes. My experience includes programming and troubleshooting PLCs in various industrial settings.

- SCADA Systems: These allow for centralized monitoring and control of multiple machines and processes. I have used SCADA systems to visualize production data, identify bottlenecks, and optimize production parameters.

- MES Systems: These sophisticated systems integrate data from various sources to provide a comprehensive view of production performance. My experience includes implementing and configuring MES systems to track production data, manage quality control, and optimize production schedules.

For instance, I helped implement a new SCADA system for a manufacturing facility which provided real-time monitoring of key production parameters and allowed for rapid response to equipment failures. This significantly reduced downtime and increased overall productivity.

Q 21. How do you manage inventory and material flow in a production line?

Managing inventory and material flow efficiently is critical for preventing bottlenecks and ensuring a smooth production process. My approach emphasizes a combination of just-in-time (JIT) principles and lean manufacturing techniques.

- Just-in-Time (JIT) Inventory: This minimizes inventory levels by ensuring materials arrive just as they are needed for production. It reduces storage costs and minimizes the risk of obsolescence.

- Kanban Systems: These use visual signals to trigger the replenishment of materials, ensuring a smooth flow of materials through the production line.

- Material Requirements Planning (MRP): This software system helps plan and schedule material needs based on production schedules and inventory levels.

- Warehouse Management Systems (WMS): These systems optimize the storage and retrieval of materials, improving warehouse efficiency and reducing lead times.

In one project, I implemented a Kanban system to manage the flow of raw materials to the production line. This reduced lead times, minimized inventory, and improved the overall efficiency of the manufacturing process. Careful consideration of storage, transport, and the appropriate use of technology are crucial for effective material flow management.

Q 22. What is your experience with Six Sigma methodology?

Six Sigma is a data-driven methodology focused on minimizing defects and variability in any process. My experience encompasses all five phases: Define, Measure, Analyze, Improve, and Control (DMAIC). I’ve utilized Six Sigma tools like control charts (e.g., X-bar and R charts), Pareto charts, and Failure Mode and Effects Analysis (FMEA) to identify root causes of production line inefficiencies and implement data-backed solutions. For instance, in a previous role, we used DMAIC to reduce the defect rate in a packaging line by 60% by identifying a faulty sealing mechanism through statistical process control.

Specifically, I’ve led projects that reduced machine downtime by optimizing maintenance schedules, improved product quality by addressing inconsistencies in raw material handling, and enhanced overall equipment effectiveness (OEE) by streamlining workflows. My proficiency extends to the application of lean principles within the Six Sigma framework, creating a synergistic approach to efficiency improvement.

Q 23. How do you document production line setup procedures?

Production line setup procedures are meticulously documented using a combination of Standard Operating Procedures (SOPs) and visual aids. SOPs are detailed, step-by-step instructions, often formatted as checklists, providing clear guidance for each stage of the setup. They include crucial information like machine settings, tool requirements, safety precautions, and quality control checks. Visual aids such as flowcharts, diagrams, and photographs complement the written procedures, making them easily understood and followed by personnel with varying levels of experience. We use a version control system (like a shared document repository) to ensure that everyone is working with the most current documentation and to track changes over time. This allows for easy auditing and troubleshooting.

Q 24. How do you train new employees on production line operations?

Training new employees involves a phased approach: First, a classroom session covers the theoretical aspects of the production line, including safety regulations, equipment operation, quality standards, and basic troubleshooting. This is followed by hands-on training, where employees are guided through the setup process under close supervision of experienced personnel. We use a combination of shadowing, where new employees observe experienced workers, and guided practice, where employees perform the tasks under instruction. Regular quizzes and assessments monitor comprehension and skill development. Finally, we employ a mentorship program, pairing new employees with seasoned colleagues for ongoing support and skill development. This blended learning approach ensures a thorough understanding and develops competence in operating the production line safely and efficiently.

Q 25. Describe a time you had to improve a production line’s efficiency.

In a previous role, we faced recurring bottlenecks on a bottling line, resulting in significant production delays. After analyzing the production data, we identified the slow filling process as the primary constraint. We initially focused on optimizing the filling machine parameters but saw limited improvement. Through further investigation using root cause analysis techniques, we discovered inconsistencies in the bottle feed system leading to jams. By implementing a new bottle-feeding mechanism designed with an automated sensor for accurate bottle spacing and a more robust jam-clearing system, we reduced downtime by 45% and increased throughput by 30%. This involved collaborating with engineering, procurement, and operations to design, procure, and implement the new system. The success was measured by quantifiable improvements in production output, efficiency, and reduced waste.

Q 26. What are your experience with different types of automation technologies?

My experience spans various automation technologies, including Programmable Logic Controllers (PLCs), Robotic Process Automation (RPA), and Supervisory Control and Data Acquisition (SCADA) systems. I’m proficient in configuring and troubleshooting PLCs for controlling automated machinery, integrating RPA to automate repetitive tasks, and utilizing SCADA systems for real-time monitoring and control of production processes. For example, I worked on a project that integrated robotic arms into a packaging line, resulting in a significant increase in packaging speed and accuracy. Furthermore, my experience includes implementing vision systems for quality control, significantly reducing manual inspection time and improving product quality.

Q 27. How do you deal with conflicts between different departments involved in production line setup?

Conflicts between departments are inevitable in production line setup. My approach centers on proactive communication and collaboration. I believe in fostering a collaborative environment by holding regular meetings involving all stakeholders to discuss progress, challenges, and potential solutions. I utilize project management tools like Gantt charts and Kanban boards to visualize project timelines, responsibilities, and dependencies, ensuring transparency and accountability. When conflicts arise, I facilitate open dialogue, focusing on finding mutually beneficial solutions. I always prioritize the project’s overall objectives and strive to find common ground by highlighting the shared goals and benefits of a successful production line setup.

Q 28. Describe your experience with project management techniques in a production line setup.

I’m well-versed in several project management methodologies, including Agile and Waterfall. In production line setup, a hybrid approach is often most effective. For instance, the initial planning and design phases often follow a Waterfall approach, ensuring a thorough and comprehensive blueprint. However, during implementation and testing, an Agile approach with iterative development and regular feedback loops proves valuable. I utilize project management software to track progress, manage resources, and ensure timely completion. Critical Path Method (CPM) analysis is employed to identify tasks that are crucial to the project’s timely completion and to prioritize resource allocation. This allows for proactive risk management and prevents delays.

Key Topics to Learn for Production Line Setup Interview

- Line Balancing and Efficiency: Understanding techniques to optimize production flow and minimize bottlenecks. This includes applying concepts like takt time and cycle time calculations in real-world scenarios.

- Standard Operating Procedures (SOPs): Developing, implementing, and adhering to SOPs to ensure consistent product quality and safety. Be prepared to discuss how you’d create or improve existing SOPs.

- Equipment Setup and Troubleshooting: Demonstrate your knowledge of various production equipment, their setup procedures, and common troubleshooting techniques. Consider examples from your experience or relevant case studies.

- Quality Control and Assurance: Explain your understanding of quality control methodologies and how you’d contribute to maintaining high product standards. This includes identifying potential quality issues and implementing corrective actions.

- Safety Regulations and Procedures: Highlight your familiarity with workplace safety protocols and your commitment to a safe working environment. Be prepared to discuss specific safety measures related to production line setup.

- Material Handling and Inventory Management: Discuss your experience with efficient material handling techniques and inventory management strategies to avoid disruptions to the production line.

- Continuous Improvement (Kaizen): Demonstrate your understanding of Lean manufacturing principles and your ability to identify areas for improvement in production line setup and efficiency.

- Teamwork and Communication: Production line setup often involves collaboration. Prepare to discuss how you effectively communicate and work within a team environment.

Next Steps

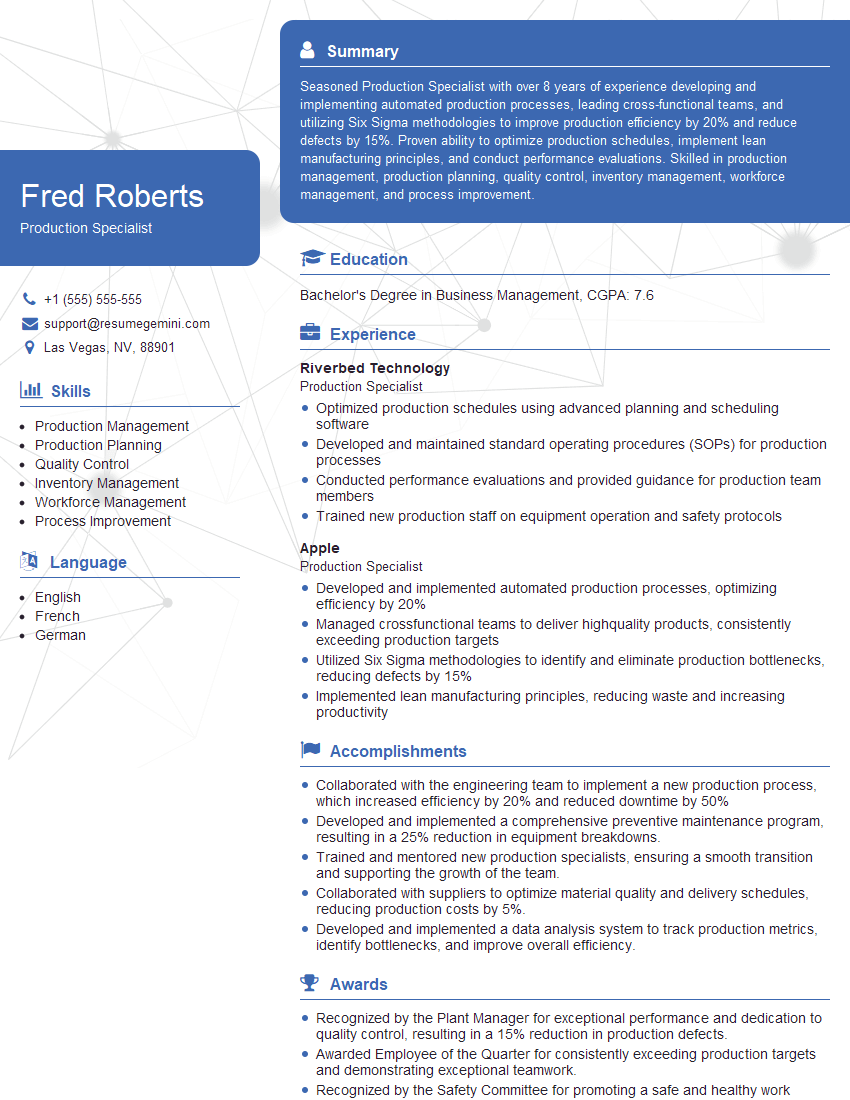

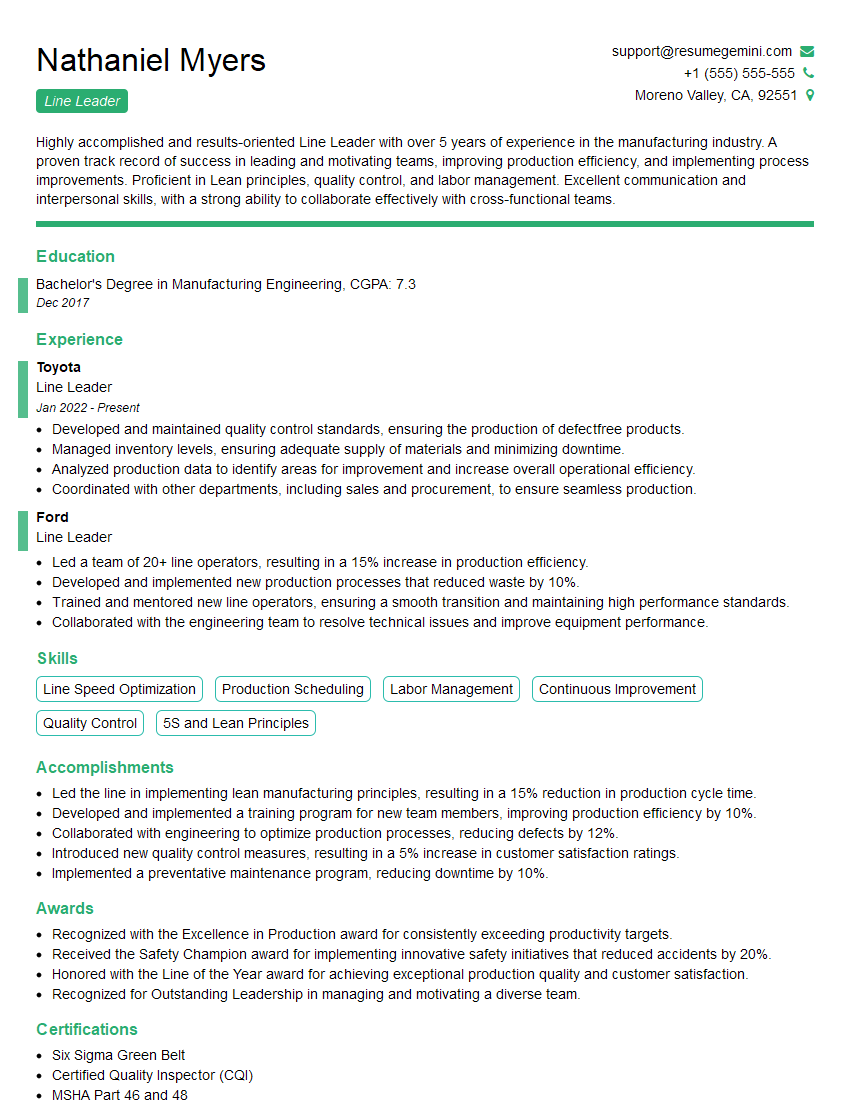

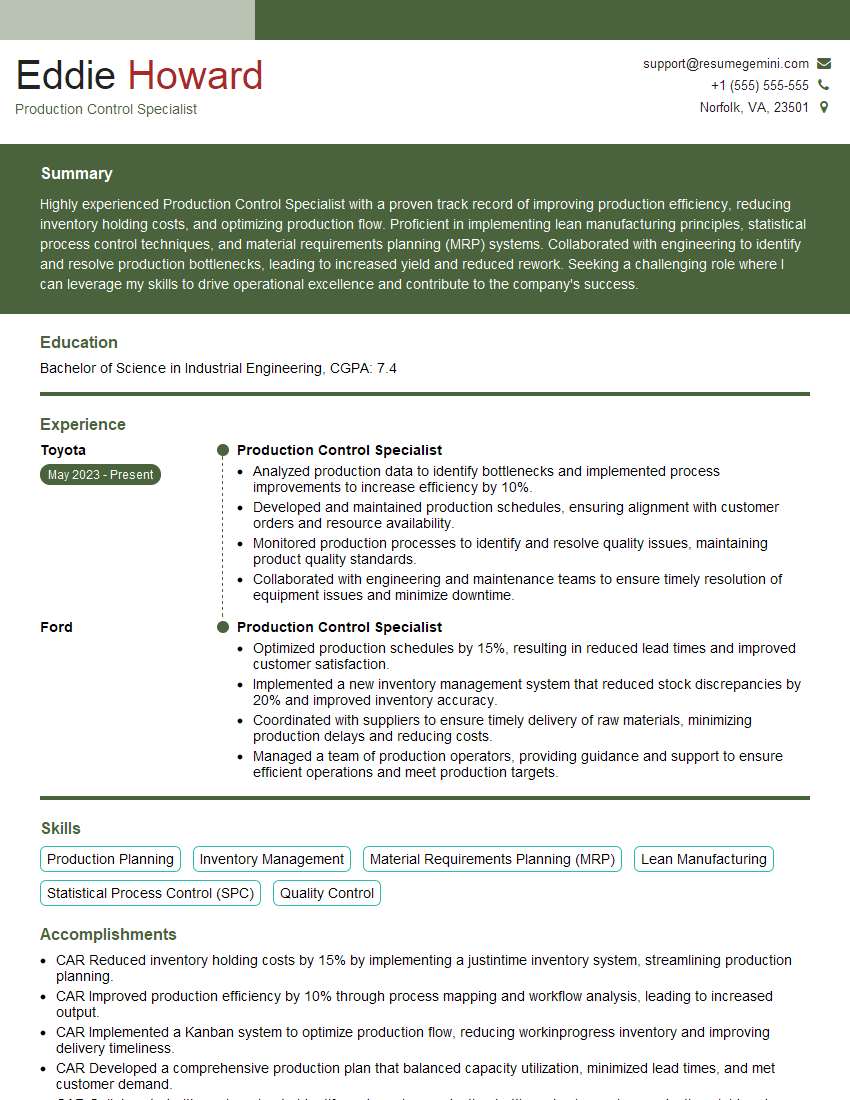

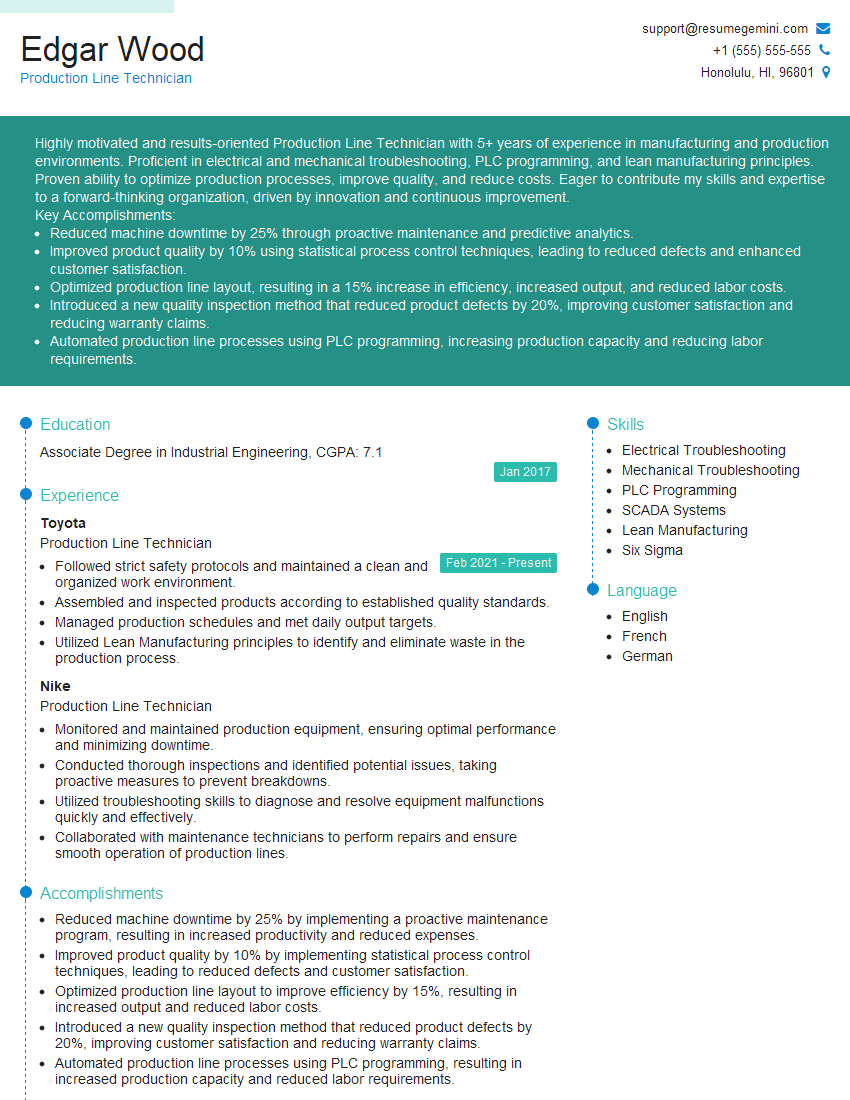

Mastering Production Line Setup opens doors to rewarding careers with excellent growth potential. To maximize your job prospects, it’s crucial to present your skills effectively. An ATS-friendly resume is essential for getting your application noticed by recruiters and hiring managers. We highly recommend using ResumeGemini to craft a professional and impactful resume that highlights your qualifications. ResumeGemini provides examples of resumes tailored to Production Line Setup roles to guide you in creating a winning application. Invest the time to build a strong resume – it’s your first impression!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good