The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Proficiency in Grading Cotton According to Domestic and International Standards interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Proficiency in Grading Cotton According to Domestic and International Standards Interview

Q 1. Describe the different systems used for grading cotton (e.g., USDA, other international systems).

Cotton grading systems are crucial for standardizing quality assessment and facilitating fair trade. The most widely recognized system is the USDA (United States Department of Agriculture) system, which uses a combination of fiber properties (length, strength, micronaire, color, and leaf grade) to assign a grade. This system is influential globally, setting a benchmark for many international transactions. However, other countries and regions have their own systems, often adapted to their specific cotton varieties and market needs. For example, India utilizes its own grading system emphasizing staple length and strength, reflecting their production and market priorities. Similarly, the China National Cotton Standard focuses on specific quality parameters aligned with their domestic textile industry needs. These various systems often share similarities in the key fiber properties they assess but differ in their specific scales and weighting of those properties. The key is understanding the nuances of each system to accurately interpret quality assessments in diverse international markets.

Q 2. Explain the key fiber properties assessed during cotton grading.

Assessing cotton quality involves a multifaceted evaluation of its fiber properties. Fiber length determines the yarn’s fineness and strength, directly impacting the quality of the final textile product. Fiber strength, measured by the force needed to break a fiber, is critical for durability. Micronaire indicates fiber maturity and fineness, influencing yarn softness and spinning performance. Color is assessed using standardized scales, and its uniformity directly affects the appeal and value of the final fabric. Lastly, leaf grade, or the amount of extraneous matter (leaves, trash, etc.), impacts the cleanliness and ease of processing. All these properties, assessed individually and in combination, contribute to the overall quality grading of the cotton.

Q 3. How do you determine cotton fiber length and strength?

Determining fiber length and strength requires specialized instruments. Fiber length is commonly measured using the High Volume Instrument (HVI), a sophisticated machine that processes a representative cotton sample and calculates the average length, length uniformity, and other length-related parameters. Think of it like measuring the height of many students – the HVI gives us an average height and tells us how much the heights vary. Fiber strength is measured using an instron tensile tester. This device grips individual fibers and applies force until they break, recording the force required. The result is expressed as a strength value, which indicates how much tension the fibers can withstand. Both these methods offer accurate and standardized measurements, crucial for reliable quality assessment.

Q 4. What are the implications of micronaire readings in cotton quality?

Micronaire readings provide crucial insights into fiber maturity and fineness. It’s a measure of the air permeability of compressed cotton fibers, essentially indicating the fiber’s thickness and maturity. An ideal micronaire range often falls between 3.5 and 4.5, representing a balance of strength, softness, and spinnability. Readings outside this range can signify problems. Low micronaire (less mature fibers) can lead to weak yarns and poor spinning performance, while high micronaire (overly mature fibers) can result in harsh, stiff fabrics. Micronaire is a critical parameter used in conjunction with other fiber properties to determine overall cotton quality and suitability for specific textile applications. For example, a finer yarn may require cotton with a lower micronaire value.

Q 5. Explain the difference between staple length and fiber length.

While related, staple length and fiber length are distinct concepts. Staple length refers to the length of a cotton fiber as it exists in its raw, unprocessed form. It is a visual assessment, often obtained by pulling a tuft of fibers and observing their length. It’s the way experienced graders historically assess length. In contrast, fiber length refers to the actual length of individual fibers after being processed and measured by instruments like the HVI. This provides a more precise and objective measurement. Think of it as the difference between estimating someone’s height by looking at them versus measuring it with a tape measure. The HVI provides a more accurate and reliable fiber length measurement, useful for consistent quality control.

Q 6. How do you identify and assess cotton impurities?

Identifying and assessing cotton impurities is crucial for determining its quality and processability. Impurities include various materials such as leaf fragments, seed coat fragments, motes (small immature seeds), and trash (foreign materials like dirt and sticks). Assessment involves visual inspection, often using standardized scales that categorize the level of contamination. For example, the USDA system utilizes leaf grade, which represents the percentage of leaf and other foreign matter present. Quantitative analysis might involve weighing the amount of trash or mechanically separating impurities from the cotton fibers. The presence and level of impurities directly affect the quality of the yarn and fabric produced, as well as the efficiency of the spinning process. High levels of impurities can cause breakage during processing, leading to waste and lower quality products.

Q 7. What are the visual indicators of cotton quality?

Visual inspection remains an essential part of cotton quality assessment, especially for experienced graders. Key indicators include fiber color, luster, and cleanliness. Cotton with a bright, uniform color is generally considered superior. Luster, or the shine of the fiber, is also an indicator of maturity and quality. A dull appearance often suggests poor quality. The absence of visible trash and foreign matter (leaf, seed coat fragments) indicates good cleanliness. Visual assessment provides an initial impression of quality and often guides further instrumental testing. Experienced graders can identify subtle variations in color and luster that signal variations in quality. This visual expertise is often crucial in situations where rapid assessment is necessary, such as in buying and selling cotton at the marketplace.

Q 8. Describe the process of preparing a cotton sample for grading.

Preparing a cotton sample for grading is crucial for obtaining accurate and reliable results. It’s akin to preparing a chef’s ingredient – the better the preparation, the better the final product. The process involves several key steps:

- Sampling: A representative sample needs to be drawn from the entire cotton bale. This is typically done using a core sampler that extracts a core from different parts of the bale to ensure diverse fiber representation. The amount of sample required varies depending on the testing method and the standards being used.

- Cleaning: The sample is then cleaned to remove any extraneous material like leaves, dirt, seeds, or other debris that can skew the grading results. This is often achieved using a cotton cleaner or by hand-picking for smaller samples. Think of this as removing the imperfections before you judge the true quality of the fabric.

- Conditioning: The cleaned sample is then conditioned to reach standard atmospheric conditions of temperature and relative humidity. This standardization is essential because moisture content significantly impacts fiber properties. A standard conditioning chamber ensures uniformity across samples before grading.

- Weighing: After conditioning, the sample is weighed precisely. The weight is used to calculate various quality parameters. A precise scale is a must-have for accurate results.

- Preparation for testing: Finally, the conditioned sample is prepared for various tests such as fiber length, strength, micronaire, and color. This might involve preparing tufts for fiber testing or preparing a representative sample for color assessment. This stage is critical for ensuring that each test accurately reflects the overall quality.

Each step needs meticulous attention to detail; a mistake here can result in inaccurate grading.

Q 9. How do you handle discrepancies in grading results?

Discrepancies in grading results can arise from several sources, including sampling errors, variations in testing methods, or even differences in grader interpretations. Resolving these discrepancies requires a systematic approach:

- Review the samples and procedures: The first step involves meticulously reviewing the entire process, from sampling to testing. Were the samples representative? Were the procedures followed correctly? Were the machines calibrated accurately?

- Retesting: If there are doubts about the results, the samples may be retested, either by the same grader or by an independent grader. This will help pinpoint any discrepancies.

- Comparison with standards: Grading results should be consistently compared to the relevant international or domestic standards (e.g., USDA standards). This step helps to determine if the results are within acceptable ranges.

- Calibration checks: Regular calibration of the instruments used in grading is essential. If any machine is malfunctioning, it would cause significant discrepancies.

- Independent arbitration: In cases of significant discrepancies, especially in high-value transactions, independent arbitration might be necessary to resolve the matter. A third-party expert, agreed upon by both involved parties, would analyze the results and provide a final ruling.

Transparency and clear documentation are key to handling such situations. A well-maintained log of the entire grading process can help avoid future disputes.

Q 10. What are the common grading defects found in cotton?

Cotton grading defects can significantly reduce its value. These defects can be categorized into various types:

- Fiber defects: These include short fibers, weak fibers, immature fibers, and excessively fine or coarse fibers. This impacts the yarn’s strength and overall quality.

- Color defects: These involve variations in color, staining, or discoloration of the fiber. Off-white or yellow discoloration drastically reduces the grade.

- Trash content: This includes foreign materials such as leaf, stem, seed coat, and dirt which reduce fiber purity and processing efficiency.

- Damage: This can include fiber damage from harvesting, handling, or storage. Physical damage decreases the spinnability and overall quality.

- Moisture content: Although not a defect in itself, an excessive moisture content can affect the grade by creating conditions for microbial growth and impacting fiber strength.

The presence and severity of these defects determine the final grade assigned to the cotton.

Q 11. Explain the impact of weather conditions on cotton quality.

Weather conditions, particularly during the growing season, profoundly impact cotton quality. Think of it like nurturing a delicate plant; the right environment is crucial for optimal growth and health.

- Rainfall: Adequate rainfall is essential for proper plant development, but excessive rain can lead to fungal diseases and reduced fiber quality. Too little rain leads to stunted growth and lower yields.

- Temperature: High temperatures during boll development can negatively affect fiber length and strength, while unusually low temperatures can damage the plant. Optimal temperatures are essential for optimal growth.

- Sunlight: Sufficient sunlight is needed for photosynthesis and fiber development. Lack of sunlight can result in weak fibers and poor quality.

- Humidity: High humidity promotes the growth of diseases and pests, impacting fiber quality. It also affects the post-harvest storage and handling of the cotton.

Farmers often use various strategies to mitigate the impact of adverse weather conditions, such as employing drought-resistant varieties or implementing irrigation systems. Understanding the weather’s impact is key to producing high-quality cotton.

Q 12. How do you interpret cotton grading certificates?

Cotton grading certificates are crucial documents that summarize the quality characteristics of a cotton bale. Interpreting them requires understanding the parameters used and the grading system employed (e.g., USDA, international standards).

A typical certificate will include:

- Grade: This indicates the overall quality classification of the cotton, often based on several parameters.

- Fiber length: This parameter indicates the average length of the fibers in the sample.

- Fiber strength: This reflects the tensile strength of the fibers, an essential indicator of yarn strength.

- Micronaire: This measures the fineness and maturity of the fibers.

- Color: This assesses the whiteness or discoloration of the fibers.

- Trash content: This quantifies the amount of foreign material present in the sample.

- Moisture content: This indicates the percentage of water present in the cotton.

- Other parameters: Depending on the standards used, additional parameters might be included.

By understanding each parameter’s significance, you can accurately assess the cotton’s suitability for various textile applications. For instance, a high fiber length and strength are desirable for premium yarn production.

Q 13. What are the international standards for cotton trading?

International standards for cotton trading ensure fairness, transparency, and consistency in quality assessment worldwide. These standards are vital for smooth trade between countries and eliminate confusion in defining and evaluating cotton quality.

Key international standards include:

- USDA (United States Department of Agriculture) Standards: These are widely used, especially in the United States and are often referenced globally. They define various cotton grades based on fiber properties such as length, strength, micronaire, and color.

- ISO (International Organization for Standardization) Standards: ISO provides international standards covering various aspects of textile testing, which indirectly impacts cotton grading.

- Other Regional Standards: Some regions have their own standards, often based on or adapted from the USDA or ISO standards. These regional variations may reflect local preferences or variations in cotton types.

These standards are regularly updated to reflect advancements in testing technology and changes in market demands. Adherence to these standards is essential to ensure accuracy and reliability in trading.

Q 14. How do different cotton varieties impact grading results?

Different cotton varieties significantly impact grading results due to inherent variations in their fiber properties. Think of it like different fruit varieties; each has its unique characteristics.

Factors influenced by variety include:

- Fiber length: Some varieties naturally produce longer fibers than others. Long-staple cotton typically commands a higher price due to its superior quality.

- Fiber strength: Fiber strength varies among varieties. Strong fibers are essential for producing high-quality yarns.

- Micronaire: Fiber fineness and maturity are also genetically influenced.

- Color: Some varieties are naturally whiter than others, impacting the final grade.

- Maturity: Fiber maturity is linked to the development of the cotton boll. Early maturing varieties might have different fiber properties compared to late maturing varieties.

Graders need to be aware of the specific characteristics of different cotton varieties to accurately assess their quality. They often refer to variety-specific data to adjust their grading according to the variety being evaluated.

Q 15. What are the legal implications of inaccurate cotton grading?

Inaccurate cotton grading can have serious legal ramifications, impacting both buyers and sellers. Contracts often specify grade standards, and a misclassification can constitute a breach of contract. This can lead to costly litigation, where the aggrieved party might sue for damages related to the difference in price between the graded and actual quality. For instance, a buyer receiving lower-quality cotton than agreed upon might claim financial losses due to reduced yield or processing difficulties. Similarly, a seller might face legal action if their cotton is downgraded unfairly, leading to a loss of revenue. Furthermore, depending on the jurisdiction and the nature of the misrepresentation, criminal charges related to fraud or mislabeling might be filed.

The legal consequences often depend on the demonstrable intent behind the misgrading. Accidental errors due to human fallibility might have less severe consequences compared to deliberate misgrading for personal gain. Thorough documentation, adherence to established grading protocols, and reliable testing methods are crucial to mitigating legal risks in the cotton industry.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with different cotton grading instruments.

My experience encompasses a wide range of cotton grading instruments, both traditional and high-tech. I’m proficient with the use of High Volume Instrument (HVI) systems which provide objective measurements of fiber properties like length, strength, uniformity, and micronaire. These instruments are invaluable for precise and repeatable grading. I also have hands-on experience with the traditional methods involving visual assessment of fiber color, cleanliness, and maturity, alongside tactile evaluation of staple length and strength. These methods, while subjective, are still crucial, particularly for assessing certain aspects that aren’t fully captured by HVI data, like subtle variations in color or the presence of neps (small knots in the fiber).

Furthermore, I’ve worked with various other devices like scales for moisture content determination and fiber testing equipment designed to quantify various fiber characteristics. My understanding of the limitations and strengths of each instrument allows for a comprehensive and balanced approach to grading cotton.

Q 17. How do you ensure the accuracy and consistency of your grading?

Ensuring accuracy and consistency in cotton grading requires a multi-faceted approach. It begins with rigorous calibration of all instruments, adhering to manufacturers’ guidelines and industry best practices. Regular calibration checks using certified standards are essential to maintain precision over time. Beyond instrumentation, I meticulously follow established grading standards (e.g., USDA standards for the US, or those of the International Cotton Advisory Committee for international trade). I maintain detailed records of each grading, including sample IDs, instrument readings, and my subjective assessments, facilitating traceability and potential review if needed.

Furthermore, I participate in inter-laboratory comparisons and proficiency testing programs to benchmark my grading against other experts in the field. This provides external validation and highlights areas for improvement. Finally, a commitment to continuous learning and professional development is vital in staying abreast of evolving methodologies and technological advances within cotton grading.

Q 18. How do you maintain your knowledge of evolving cotton grading standards?

The cotton grading landscape is dynamic, with technological advancements and evolving standards continually influencing best practices. I actively maintain my knowledge through several channels. I am a member of relevant professional organizations such as the American Society of Agricultural and Biological Engineers (ASABE), and I regularly attend industry conferences and workshops. This provides networking opportunities and access to the latest research and updates on grading protocols. I also subscribe to industry publications and journals, keeping myself informed about changes in standards and new technologies. Online resources and training modules offered by organizations like the USDA provide valuable continuing education opportunities. Finally, I maintain a network of colleagues and experts in the field, allowing for the exchange of information and best practices.

Q 19. What are the key differences between US and international cotton grading standards?

While both US and international cotton grading systems aim to standardize quality assessment, significant differences exist. The US system, primarily based on USDA standards, emphasizes fiber properties like length, strength, micronaire, and color, often categorized using descriptive terms (e.g., ‘Middling,’ ‘Strict Low Middling’). International standards, often influenced by the ICAC, might utilize similar parameters but can incorporate different scales or classification systems depending on the specific region or trading partner. For example, some international standards might place greater emphasis on certain properties based on the type of textile being produced, reflecting specific regional industrial requirements. Differences in terminology and grade descriptors can also lead to complexities when trading internationally.

Furthermore, moisture content measurement methods and allowed tolerances might vary, adding another layer of complexity. A thorough understanding of both the US and international standards is necessary to facilitate seamless trade and prevent misunderstandings related to cotton quality.

Q 20. Explain the role of moisture content in cotton grading.

Moisture content significantly impacts cotton grading because it affects almost all fiber properties. Cotton absorbs and releases moisture from the environment, influencing weight and fiber strength. High moisture content leads to an overestimation of weight and can mask other quality deficiencies, whereas low moisture can make the cotton appear weaker and less resilient. Therefore, accurate determination of moisture content is crucial before any other grading parameters are evaluated.

Standard procedures are followed to bring the sample to a standard moisture content, typically around 8%, before grading. This ensures that the measurements of fiber properties are consistent and comparable regardless of the initial moisture level. Variations in moisture content beyond the accepted tolerances can directly impact the final grade assigned, resulting in a price adjustment.

Q 21. How do you handle a situation where a customer disputes a grading result?

Customer disputes regarding grading results are handled with professionalism and transparency. My first step involves a thorough review of the original grading report and the supporting documentation. I then compare the data with the customer’s concerns, carefully considering their points. If discrepancies exist or if there’s a valid reason for the dispute, such as questions about the sampling process or inconsistencies in the testing methods, I initiate an impartial investigation. This might involve re-grading the sample using the same protocols or employing a different method for verification.

If needed, I involve an independent third-party expert to examine the evidence and offer an objective assessment. Open communication with the customer throughout the process is crucial. I explain the methodology, findings, and conclusions clearly, aiming to find a mutually agreeable solution. Documentation of the dispute, investigation, and resolution is meticulously maintained for future reference and to establish accountability.

Q 22. What are the economic consequences of poor cotton quality?

Poor cotton quality has significant economic consequences throughout the entire supply chain. It starts with reduced yields for farmers, impacting their income directly. Lower quality means less efficient processing, leading to higher production costs for mills. This ultimately affects the final product, resulting in lower-quality textiles and potentially impacting the price and marketability of finished goods. For example, if a batch of cotton has high levels of impurities or short fiber length, the yarn produced will be weaker and less consistent, leading to more breaks during weaving and ultimately, a lower-quality fabric that may sell for less or even be unusable.

The economic ripple effect extends to retailers and consumers. Retailers might experience losses due to customer dissatisfaction and returns, while consumers face inferior products at potentially inflated prices. International trade is also impacted; countries exporting low-quality cotton may face reduced demand and lower export earnings, hindering economic growth.

Q 23. Describe your experience with cotton bale sampling procedures.

My experience with cotton bale sampling is extensive, encompassing both domestic and international standards. I’m proficient in various sampling techniques, including the use of various probes and core samplers to extract representative samples from different locations within a bale. The goal is to obtain a sample that accurately reflects the overall quality of the entire bale. I’m familiar with industry best practices ensuring sample integrity and avoiding bias, such as proper labeling, secure storage, and transportation to testing facilities. I meticulously document each sampling event, noting bale identification, date, time, and sampling location, adhering to protocols to ensure traceability and chain of custody.

For example, during my time at [Previous Company Name], I was responsible for training new staff on proper sampling techniques according to USDA standards. We regularly conducted internal audits to ensure consistency and accuracy in our sampling processes. This involved comparing samples from different technicians to identify and correct any inconsistencies. I’ve also dealt with resolving disputes regarding bale quality by carefully examining sampling procedures and ensuring the samples accurately represented the bale’s contents.

Q 24. How would you explain the grading system to a non-technical audience?

Imagine cotton grading as a way of describing how ‘good’ the cotton is. Just like you might grade an apple (e.g., excellent, good, fair), we grade cotton based on several key factors, primarily fiber length, strength, uniformity, color, and trash content (impurities). Higher grades indicate longer, stronger fibers with better uniformity and less trash, making them ideal for producing high-quality yarns and fabrics. Lower grades suggest shorter, weaker fibers with more impurities, leading to lower-quality end products.

Think of fiber length as the building blocks of the fabric. Longer fibers create stronger and finer fabrics, whereas short fibers result in weaker, coarser materials. Strength indicates the fiber’s resistance to breaking, directly influencing the durability of the final product. Uniformity refers to how consistent the fiber length is within the sample. Color is important for certain applications, and of course, less trash (seeds, leaves, etc.) means higher quality and less processing needed.

These factors are assessed using specialized equipment, and the final grade is a numerical or letter designation reflecting the overall quality of the cotton. This grade influences the price the farmer receives and the quality of the fabric that will eventually be produced.

Q 25. What are some common challenges faced in cotton grading?

Cotton grading presents several challenges. One common issue is the inherent variability in cotton quality. Even within the same field, factors like weather conditions, soil type, and pest infestation can influence fiber properties, creating inconsistencies within a single bale or across different bales. This makes objective and accurate grading challenging. Another challenge lies in the subjective nature of certain grading aspects, such as color assessment, which can be influenced by lighting conditions and the grader’s individual perception.

Technological limitations also pose a challenge. While technology assists in grading, there’s still a reliance on human expertise, and the accuracy of automated systems can be affected by factors such as instrument calibration and sample preparation. Furthermore, maintaining consistent standards across different grading laboratories and ensuring fair and transparent grading processes to avoid bias or disputes are also important considerations. The emergence of genetically modified cotton varieties also introduces the need for adapting grading standards to evaluate their unique properties.

Q 26. How do you ensure the traceability of cotton through the supply chain?

Traceability in the cotton supply chain is crucial for ensuring quality, sustainability, and ethical sourcing. I utilize various methods to achieve this. Detailed record-keeping is fundamental, starting from the field. This involves meticulously documenting the farm’s location, planting date, variety of cotton, and any treatments applied. Each bale is uniquely identified with a traceable code, linking it back to the farm and specific growing conditions. This information is recorded throughout the entire supply chain – during ginning, transportation, processing, and manufacturing.

Blockchain technology offers a promising solution for enhanced traceability. By recording transactions on a secure, distributed ledger, we can create an immutable record of the cotton’s journey, from field to finished product. This allows for easy verification of origin, quality, and ethical practices throughout the supply chain. Other methods include RFID tags attached to bales, providing real-time tracking and monitoring, or the use of digital platforms and databases that centralize cotton information and allow for tracking from farm to mill. Transparency is key. Open communication with all stakeholders across the supply chain is essential to ensure accurate data recording and the effectiveness of traceability initiatives.

Q 27. Describe your proficiency in using specific cotton grading software or tools.

I’m proficient in using several cotton grading software and tools. I have extensive experience with [Software Name 1], a widely used platform for analyzing fiber properties using high-volume instrument data. This software helps in automating certain aspects of grading, reducing human error and improving efficiency. I’m also familiar with [Software Name 2], a system designed specifically for managing and tracking cotton bales throughout the supply chain. This includes features for quality control, inventory management, and reporting. I’m adept at interpreting the data generated by these systems to make informed decisions regarding cotton quality and pricing.

My experience extends to using various high-volume instruments, including fiber strength testers, length testers, and colorimeters. I understand the principles behind these instruments, their calibration procedures, and the interpretation of their output data. I also have practical experience in using manual grading tools such as the hand-held fiber length sorter, which is essential for verifying machine readings and resolving potential discrepancies.

Q 28. How do you stay updated on new technologies and advancements in cotton grading?

Staying updated on advancements in cotton grading requires a multi-faceted approach. I regularly attend industry conferences and workshops, both domestically and internationally, where I engage with leading researchers and practitioners, learning about new technologies and best practices. I actively subscribe to industry journals and publications, such as [Journal Name 1] and [Journal Name 2], to stay abreast of the latest research and developments. Online resources and professional organizations like [Organization Name] also provide valuable insights and information on current trends and emerging technologies.

Furthermore, I maintain professional networks with experts in the field, participating in online forums and discussions to learn from their experiences and share my own knowledge. I actively seek out training opportunities on new software and instrument technologies to enhance my skills and keep up with evolving standards and regulations within the cotton industry. This continuous learning ensures that I remain at the forefront of cotton grading expertise and effectively adapt to new challenges and opportunities within the industry.

Key Topics to Learn for Proficiency in Grading Cotton According to Domestic and International Standards Interview

- Fiber Properties: Understanding staple length, strength, micronaire, color, and maturity – their impact on cotton quality and grade.

- Standard Grading Systems: Familiarization with domestic (e.g., USDA) and international (e.g., ISO) cotton grading systems, including their respective classification criteria and procedures.

- Practical Application: Hands-on experience with cotton grading instruments and techniques, including using high-volume instruments and visual assessment methods. Understanding the interpretation of grading results and their implications for pricing and quality control.

- Quality Control Procedures: Knowledge of sampling techniques, testing protocols, and data analysis in the context of cotton grading to ensure accuracy and consistency.

- International Trade & Standards: Understanding how international standards influence cotton trade, pricing, and quality control across borders. Knowledge of relevant regulations and certifications.

- Problem-Solving: Analyzing discrepancies between grading results and identifying potential sources of error in sampling, testing, or interpretation. Applying critical thinking skills to resolve grading challenges and inconsistencies.

- Technological Advancements: Awareness of emerging technologies used in cotton grading, such as automated grading systems and advanced fiber analysis techniques.

Next Steps

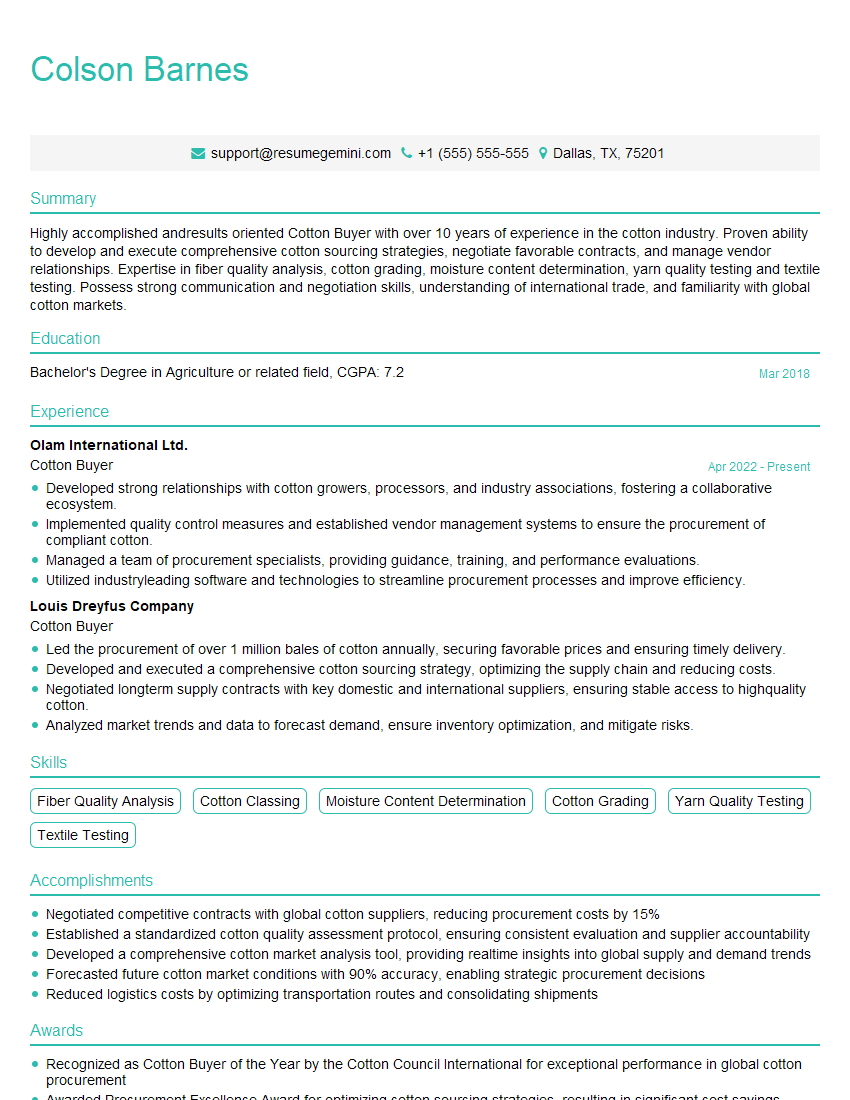

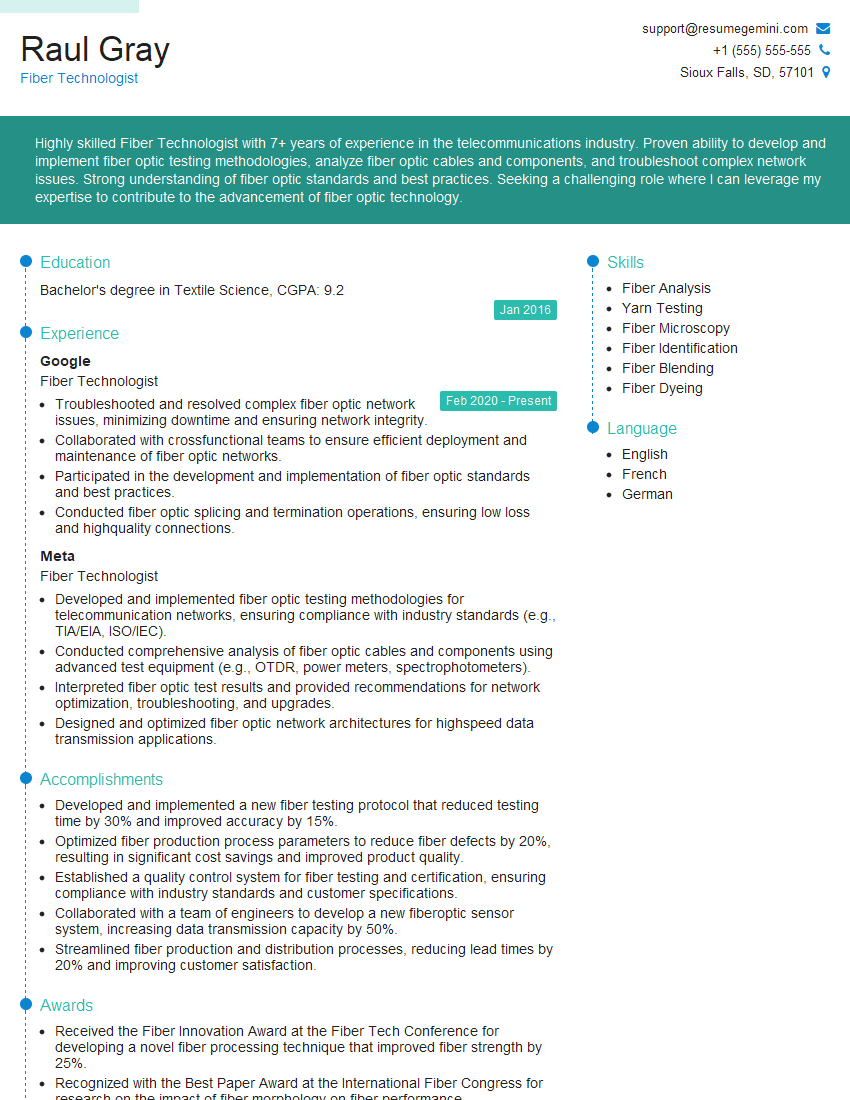

Mastering Proficiency in Grading Cotton According to Domestic and International Standards is crucial for career advancement in the textile industry, opening doors to higher-paying roles and increased responsibility. A strong resume is key to showcasing your expertise and securing your ideal position. To maximize your job prospects, create an ATS-friendly resume that highlights your skills and experience effectively. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to the specific demands of this field. Examples of resumes tailored to Proficiency in Grading Cotton According to Domestic and International Standards are available to guide you through the process. Invest time in crafting a compelling resume – it’s your first impression with potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good