Are you ready to stand out in your next interview? Understanding and preparing for Proficient in the use of heavy equipment and construction tools interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Proficient in the use of heavy equipment and construction tools Interview

Q 1. Describe your experience operating a bulldozer.

My experience with bulldozers spans over ten years, encompassing various projects from land clearing and road construction to site preparation for building foundations. I’m proficient in operating both crawler and wheel bulldozers, understanding the nuances of each type for different terrain and tasks. For instance, on a recent highway project, I used a crawler bulldozer to efficiently move large volumes of earth and rock across uneven terrain, its tracked undercarriage providing superior stability and traction. In contrast, for a smaller site development project involving relatively flat land, a wheel bulldozer proved faster and more maneuverable for fine-grading and material spreading. I’m adept at blade techniques like pushing, angling, and sloping, ensuring accurate earthmoving and precision grading. Safety is paramount, and I consistently adhere to all site regulations and best practices when operating this powerful machine.

Q 2. Explain the pre-operation checks you perform on an excavator.

Pre-operation checks on an excavator are crucial for safety and operational efficiency. My routine is thorough and follows a checklist. It starts with a visual inspection, looking for any signs of damage, leaks, or loose parts. This includes checking the tracks or wheels for wear and tear, the condition of the hydraulic lines and hoses, and the integrity of the boom, stick, and bucket. Next, I check all fluid levels – hydraulic oil, engine oil, coolant – ensuring they’re within the acceptable range. I then test the emergency shut-off system and all control functions, verifying smooth movement in all directions. I also make sure the lights, horn, and warning devices are functioning correctly. Finally, I inspect the area around the excavator to identify any potential hazards like overhead obstructions or underground utilities before beginning work. It’s like a pilot performing pre-flight checks – essential for a safe and successful operation.

Q 3. How do you ensure the safety of yourself and others while operating heavy equipment?

Ensuring safety is my top priority, both for myself and others on the site. I follow a multi-layered approach. First, thorough pre-operation checks are vital, as I mentioned earlier. Second, I maintain constant awareness of my surroundings, including the location of other equipment, workers, and potential obstacles. I use mirrors and cameras whenever possible to improve visibility. Clear communication is key – I regularly communicate with the site supervisor and other operators, especially during complex maneuvers. Before starting any movement, I sound my horn and visually check the intended path. Maintaining safe operating speeds, adjusting to terrain conditions, and never exceeding the machine’s capabilities are essential. I also adhere strictly to all safety regulations and site-specific rules, such as wearing appropriate personal protective equipment (PPE) at all times. Ultimately, a safe working environment is a collaborative effort, and I actively contribute to that goal.

Q 4. What are the different types of excavators and their applications?

Excavators come in various types, each designed for specific applications.

- Hydraulic Excavators: The most common type, using hydraulics to power the boom, stick, and bucket. They’re versatile and used for digging, trenching, lifting, and demolition. These are further classified by their size and undercarriage: crawler excavators (tracked) for rough terrain and wheel excavators for smoother surfaces and faster road travel.

- Long-Reach Excavators: Modified hydraulic excavators with extended booms, ideal for deep excavations or working in confined spaces, such as dredging or demolition in urban areas.

- Mini Excavators: Smaller, compact versions suitable for confined spaces like urban construction or landscaping.

- Cable Excavators: Less common now, using cables and drums for movement rather than hydraulics. These are usually found in specialized applications.

Q 5. Describe your experience with different types of loaders.

My experience with loaders encompasses various types, each having unique strengths.

- Wheel Loaders: These are highly versatile, used extensively in construction, demolition, and material handling. I’m experienced in operating both small skid-steer loaders for precise work in tight spaces and large articulated loaders for bulk material movement, like on a large-scale earthmoving project. Their maneuverability and speed make them efficient for loading trucks and moving materials across a job site.

- Backhoe Loaders: A combination of a backhoe and a front loader, providing both digging and loading capabilities. These are useful in situations requiring both tasks, such as utility work or smaller construction projects where bringing multiple machines isn’t practical.

- Telehandlers: These loaders have a telescopic boom, providing reach and height advantages, making them suitable for material handling at height, like placing precast concrete elements on a building project or lifting materials over obstacles.

Q 6. How do you handle equipment malfunctions during operation?

Equipment malfunctions can occur, and I’m trained to handle them safely and efficiently. The first step is to immediately shut down the machine and assess the situation. If the problem is minor and I’m trained to fix it, I might attempt a quick repair, after ensuring the safety of myself and others. For example, a simple hydraulic leak might be addressed temporarily with the appropriate sealant until a proper repair can be scheduled. However, for more serious issues, I immediately report it to the supervisor and follow the established procedures for maintenance and repair. Safety is paramount, and I never attempt a repair beyond my training and competency. I also document the malfunction thoroughly, including the time, the problem, and any actions taken. Waiting for qualified professionals to address any major mechanical issue ensures the machine’s longevity and safety.

Q 7. What are the common causes of equipment breakdowns and how do you prevent them?

Equipment breakdowns are often due to a combination of factors.

- Lack of preventative maintenance: Regular inspections, lubrication, and fluid changes are crucial. Skipping these can lead to premature wear and tear and catastrophic failures.

- Operator error: Overloading the machine, improper operation, or ignoring warning signs can cause damage.

- Environmental factors: Exposure to harsh weather conditions or demanding terrains can accelerate wear and tear.

- Age and wear: Older equipment is more prone to breakdowns due to natural degradation of components.

Q 8. Explain your experience with preventative maintenance on heavy equipment.

Preventative maintenance is crucial for extending the lifespan of heavy equipment and preventing costly breakdowns. My approach is proactive, focusing on regular inspections and scheduled servicing based on the manufacturer’s recommendations and operational hours.

- Daily Inspections: Before each shift, I perform a thorough visual inspection, checking fluid levels (oil, coolant, hydraulic fluid), tire pressure, belts, hoses, and any signs of leaks or damage. I document any issues in a logbook. For example, I once noticed a slight oil leak on a bulldozer which, if ignored, could have led to a catastrophic engine failure. I reported it immediately and it was repaired preventing further damage.

- Scheduled Maintenance: I adhere strictly to the manufacturer’s recommended maintenance schedules, which typically include things like oil changes, filter replacements, grease lubrication, and component inspections. This involves systematically checking and replacing parts at specific intervals. For instance, I’ve followed detailed procedures for replacing the hydraulic filters on excavators, a process requiring precision and safety precautions.

- Lubrication: Regular lubrication is vital for moving parts. I use the correct grease for each component to minimize friction and wear. Incorrect lubrication can lead to premature failure of bearings and other components.

This systematic approach ensures equipment operates at peak efficiency, minimizing downtime and maximizing safety. A well-maintained machine is a safe machine.

Q 9. Describe your knowledge of load capacity and stability.

Understanding load capacity and stability is paramount for safe and efficient operation. Load capacity refers to the maximum weight a piece of equipment can safely lift or carry, while stability relates to the machine’s resistance to tipping or overturning. Ignoring either can lead to serious accidents.

- Load Charts: I always consult the load charts specific to the equipment I’m operating. These charts provide precise data on safe lifting capacities at different boom angles and outreach distances. For example, lifting a heavy load with a long reach requires a significantly lower load capacity than lifting the same weight closer to the machine.

- Center of Gravity: I carefully consider the center of gravity of both the machine and the load. Distributing the weight evenly and keeping the load close to the machine improves stability. I avoid uneven loads that might shift the center of gravity, increasing the risk of tipping. I remember once a coworker tried to lift a very uneven load and the crane started to tip until we carefully repositioned it.

- Ground Conditions: The ground conditions significantly affect stability. I assess the terrain carefully before undertaking any lifting or movement, avoiding unstable ground like soft soil or slopes. Using mats or other ground stabilization techniques might be necessary in some cases.

By diligently following these guidelines, I ensure the safe and efficient operation of heavy equipment, minimizing the risks associated with overloading or instability.

Q 10. How do you ensure compliance with safety regulations during operations?

Safety is my top priority. I meticulously follow all relevant safety regulations, including OSHA (Occupational Safety and Health Administration) standards and company-specific safety procedures.

- Personal Protective Equipment (PPE): I always wear appropriate PPE, including hard hats, safety glasses, gloves, steel-toed boots, and high-visibility clothing. The type of PPE varies based on the specific task and environmental conditions.

- Pre-Operational Checks: Before starting any work, I perform a comprehensive pre-operational check of the equipment, ensuring all safety mechanisms are functioning correctly. This includes checking brakes, lights, horns, and emergency stops.

- Site Safety: I actively monitor my surroundings, ensuring a safe working environment for myself and others. I properly secure the work area, utilize warning signs and signals, and communicate with other workers to avoid accidents. I follow all traffic rules, especially on construction sites with limited space and moving equipment.

- Emergency Procedures: I am familiar with all emergency procedures and know how to respond to various situations, such as equipment malfunctions or injuries. I always know where the nearest fire extinguisher and first-aid kit are located.

Consistent adherence to safety protocols is not just a rule; it’s an ingrained habit, ensuring a safe working environment for everyone.

Q 11. What is your experience with GPS-guided heavy equipment?

I have significant experience operating GPS-guided heavy equipment, which enhances both precision and efficiency. This technology uses satellite signals to guide the machine, allowing for highly accurate movements and grading.

- Grading and Excavation: GPS guidance improves the accuracy of grading and excavation tasks, minimizing the need for manual adjustments and reducing material waste. I’ve used GPS-guided excavators to dig precise trenches for utility lines, a task requiring high accuracy.

- Improved Efficiency: By automating certain movements, GPS-guided equipment increases productivity. Tasks that previously required multiple passes can often be completed in fewer passes with GPS guidance, saving time and fuel.

- Data Collection: Many GPS systems also provide data logging capabilities, tracking the equipment’s movements, productivity, and other relevant metrics. This information can be invaluable for project management and analysis.

The precision and efficiency gains from GPS-guided equipment are significant. It represents a substantial advancement in construction technology and I have the training to use it safely and effectively.

Q 12. How do you interpret blueprints and construction plans?

Interpreting blueprints and construction plans is a fundamental skill for operating heavy equipment. I can accurately read and understand plans, identifying key elements such as dimensions, elevations, grades, and utility locations.

- Scale and Dimensions: I can accurately interpret the scale of the plans and translate the dimensions into real-world measurements. This involves understanding the relationship between the drawing and the actual site.

- Elevation and Grades: I can read and understand elevation markings and grade lines to ensure accurate grading and leveling of the site. For example, I would use these specifications when operating a grader to ensure correct slope and surface level.

- Utility Locations: I can identify the location of underground utilities, such as pipes, cables, and conduits, to avoid damage during excavation or other operations. This is done by using plans, markers or any communication with the construction manager.

My ability to interpret these plans ensures accurate and efficient execution of construction tasks.

Q 13. Describe your experience working with different types of terrain.

I have extensive experience operating heavy equipment on a variety of terrains, including everything from level surfaces to challenging slopes and rough terrain. My experience ensures I can adjust my operating techniques for each condition.

- Level Ground: Operating on level ground is generally straightforward, but still requires precision and awareness of surroundings. I maintain consistent speed and avoid any abrupt maneuvers.

- Slopes: Operating on slopes requires extra caution. I always assess the stability of the ground and choose the correct path to minimize the risk of tipping or slippage. The machine’s center of gravity is carefully managed to prevent roll overs.

- Rough Terrain: Operating on rough terrain demands careful control and experience. I adjust my speed, select appropriate gear ranges, and maneuver cautiously to avoid damage to the equipment or the site. I use specialized attachments when dealing with rocky ground or difficult situations.

Adaptability is key when operating heavy equipment in varying conditions; experience allows me to choose appropriate equipment and techniques to ensure safety and efficiency.

Q 14. How do you handle challenging weather conditions while operating equipment?

Operating heavy equipment in challenging weather conditions requires additional care and attention to safety. My experience includes work in various types of inclement weather.

- Rain: In rain, reduced visibility and slick conditions require slower speeds and increased caution. I use extra lighting when visibility is diminished. I also ensure good traction and avoid sharp turns.

- Snow and Ice: Operating in snow and ice demands even greater caution, as these conditions drastically reduce traction and increase the risk of skidding or slipping. I utilize tire chains when appropriate and reduce speeds significantly.

- Extreme Temperatures: Extreme heat or cold can affect both the equipment’s performance and the operator’s safety. I take regular breaks in extreme heat and wear appropriate clothing in extreme cold to maintain personal safety. I am also well-versed in how extreme temperatures affect the equipment’s operation and performance.

Safety always comes first when operating in challenging weather. I adapt my operating techniques and use appropriate safety precautions to ensure safe operation and minimize risks. Experience allows me to quickly assess weather conditions and determine if operation is safe or if it needs to be postponed.

Q 15. What is your experience with different types of attachments for heavy equipment?

My experience with heavy equipment attachments is extensive, encompassing a wide range of applications. I’m proficient with various types, including buckets (ranging from standard digging buckets to specialized ones like demolition or ditch-cleaning buckets), rippers (for breaking up hard ground), augers (for drilling holes), hammers (for breaking concrete or rock), and grapple attachments (for handling logs or scrap metal). I understand the importance of selecting the correct attachment for the job and am experienced in safely attaching and detaching them.

For instance, on a recent project involving utility trenching, I utilized a narrow ditch-cleaning bucket on an excavator to ensure precise and efficient trenching around existing underground utilities. This minimized the risk of damage and ensured the project stayed on schedule. Another time, I used a hydraulic hammer to demolish a section of old concrete foundation, significantly speeding up the demolition phase compared to manual methods. My experience extends to understanding the limitations of each attachment and adapting my technique to maximize efficiency and safety.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you communicate effectively with other crew members on a construction site?

Effective communication on a construction site is paramount for safety and productivity. I believe in clear, concise communication, using a combination of verbal and non-verbal cues. Before starting any task, I always clarify instructions with the foreman or supervisor, ensuring complete understanding of the scope of work and potential hazards. I also utilize hand signals and radio communication when necessary, particularly in noisy environments where verbal communication might be challenging.

Within the crew, I maintain open communication, promptly reporting any potential safety concerns or equipment malfunctions. I actively listen to my colleagues and offer assistance when needed, fostering a collaborative and supportive team environment. For example, if I see a crew member struggling with a task, I’ll offer assistance or suggest a more efficient approach, prioritizing teamwork and problem-solving.

Q 17. Explain your experience with different types of cranes and their applications.

My experience encompasses several crane types, including tower cranes, mobile cranes, and crawler cranes. Tower cranes are ideal for high-rise construction, offering exceptional lifting capacity at significant heights. I’m familiar with their assembly, disassembly, and operation, including understanding load charts and swing radius limitations. Mobile cranes provide versatility for various projects, offering greater mobility than tower cranes but with limitations on lift height. Crawler cranes, with their robust track system, are perfect for challenging terrains and heavy-duty lifting applications.

For example, I worked on a high-rise building project where a tower crane was essential for lifting structural steel and other heavy materials to upper floors. On another project involving the construction of a bridge, a crawler crane proved indispensable for lifting heavy pre-fabricated bridge sections across the river. I understand the specific applications and limitations of each crane type, always prioritizing safety procedures and adhering to all regulations.

Q 18. Describe your experience with hydraulic systems on heavy equipment.

Hydraulic systems are fundamental to the operation of most heavy equipment. My understanding encompasses the entire system, from hydraulic pumps and reservoirs to valves, actuators, and cylinders. I’m experienced in diagnosing problems related to pressure, flow, and leaks, and understand the importance of maintaining proper fluid levels and cleanliness. I also understand how hydraulic systems can impact the performance and efficiency of the equipment.

For instance, I know how to interpret pressure gauges to identify potential problems, like a failing pump or a restricted valve. I also know how to check hydraulic fluid levels, ensuring that they are within the recommended range, and I’m experienced in identifying and addressing leaks promptly to prevent further damage and downtime. I understand the importance of preventative maintenance to ensure the continued efficient operation of the hydraulic systems.

Q 19. How do you troubleshoot hydraulic leaks or malfunctions?

Troubleshooting hydraulic leaks and malfunctions involves a systematic approach. First, I’d identify the type of leak (external or internal) and its location. External leaks are usually easier to spot and address, often requiring simple repairs like tightening fittings or replacing seals. Internal leaks are more challenging and may require disassembling components to identify the source.

My troubleshooting process involves checking fluid levels, inspecting hoses and fittings for damage, and testing pressure within the system using appropriate gauges. If the problem is related to a malfunctioning component, I would first attempt to isolate it to determine whether it’s repairable or needs replacement. Always, safety is my priority, and I’d shut down the equipment and follow all safety protocols before attempting any repairs.

Q 20. What is your experience with electrical systems on heavy equipment?

My experience with electrical systems on heavy equipment includes understanding basic circuitry, diagnosing problems with electrical components (motors, switches, lights, etc.), and working safely around high-voltage systems. I understand the importance of preventative maintenance to ensure electrical systems function correctly. I am familiar with various electrical safety procedures and regulations.

For example, I have experience troubleshooting electrical issues such as faulty wiring, blown fuses, or malfunctioning lights. I’m also capable of performing routine maintenance checks on electrical systems to prevent more serious problems. I always use appropriate safety measures when working with electrical components, such as lockout/tagout procedures.

Q 21. How do you handle emergency situations on a construction site?

Handling emergency situations requires quick thinking and a calm demeanor. My approach is based on prioritizing safety. In the event of an accident or equipment malfunction, I would first assess the situation, ensuring the safety of myself and others. I would then take the appropriate actions, contacting emergency services if needed and following established emergency procedures. If an equipment failure occurs, my immediate priority is to secure the equipment and prevent further damage or injury.

I am familiar with various emergency procedures, including first aid and CPR, and I would apply these skills as necessary. Communication is also critical. I would quickly and clearly report the incident to the supervisor and other relevant personnel. My goal is to mitigate the impact of the emergency and restore a safe working environment as quickly and safely as possible.

Q 22. Describe your experience working with different types of soil conditions.

My experience spans a wide range of soil conditions, from well-drained sandy soils to challenging clay and rock formations. Understanding soil type is crucial for selecting the right equipment and adjusting operating techniques. For instance, working with sandy soil requires different bucket strategies compared to heavy clay. In sandy soil, a larger bucket can be used efficiently, maximizing material moved per cycle. However, in heavy clay, a smaller bucket might be necessary to prevent overloading and ensure smooth operation. I’ve worked on projects requiring excavation in highly compacted clay, necessitating the use of a ripper attachment to loosen the material before excavation. Conversely, working with loose, easily erodible soil demands careful excavation to prevent landslides or soil contamination.

On one project, we encountered unexpected bedrock at a shallow depth. This required a shift in strategy; we had to utilize a rock breaker attachment on our excavator, and subsequently revise the project timeline, updating the project manager and safety officer.

Q 23. How do you estimate the time required to complete a task with heavy equipment?

Accurately estimating task completion time with heavy equipment involves a multi-faceted approach. It’s not just about the machine’s capacity, but also factors like site conditions, material type, weather, and logistical considerations. I begin by breaking down the task into smaller, manageable components. For example, a road construction project is broken down into earthmoving, base preparation, paving and so on. For each component, I consider the volume of material to be moved, the distance to transport it, and the efficiency of the equipment being used. I then factor in potential downtime, including refueling breaks, maintenance, and unexpected delays due to unforeseen ground conditions.

I often utilize historical data from similar projects to refine my estimations. This involves comparing planned versus actual times to identify areas for improvement in future projections. For example, if a particular task consistently runs behind schedule, I analyze the factors leading to the delay and incorporate it into future estimations. This iterative process makes the estimations more accurate over time.

Q 24. What safety measures do you take when working near power lines?

Safety near power lines is paramount. Before starting any work, I always ensure the power lines are identified and their status is confirmed with the utility company. This involves carefully reviewing site plans and conducting a thorough physical inspection of the area. A critical part of this is establishing a safe working distance, which is dictated by both voltage and the specific task. We never operate equipment within the designated safety zone, usually several meters, without proper authorization and safety measures in place. This might involve employing spotters, using non-conductive equipment, or even scheduling work during times when the power lines are de-energized.

In addition to distance, I use non-metallic tools and make sure the equipment is properly grounded to minimize the risk of electrical shock. Training and ongoing safety briefings are vital in reinforcing safe practices, making sure everyone on the site understands the risks and procedures.

Q 25. How do you maintain accurate records of equipment operation and maintenance?

Maintaining accurate records of equipment operation and maintenance is essential for efficient project management and preventative maintenance. I typically use digital record-keeping systems, often integrated into the equipment’s onboard computer systems, if available. These systems log operational hours, fuel consumption, maintenance schedules, and any repairs or incidents. For equipment without onboard systems, I use dedicated logbooks to manually record this information. This detailed record-keeping allows for precise tracking of maintenance intervals, optimizing performance and minimizing unexpected breakdowns. Moreover, it assists in identifying potential equipment problems early, allowing for timely interventions and reducing costly repairs.

The data collected is regularly reviewed to detect patterns and anomalies that might indicate a need for more frequent maintenance or repairs. This proactive approach minimizes downtime and improves overall equipment lifespan.

Q 26. What is your experience with operating equipment in confined spaces?

My experience operating equipment in confined spaces is extensive, and involves strict adherence to safety protocols. Working in these environments presents unique challenges, including limited maneuverability and visibility, and increased risk of accidents. Before entering any confined space, thorough risk assessments are always conducted. This includes evaluating potential hazards like oxygen deficiency, hazardous gases, and structural instability. The appropriate personal protective equipment (PPE), such as respirators and safety harnesses, is worn, and communication systems are established for constant contact with supervisors or spotters outside the confined area. The use of smaller, more compact equipment specifically designed for confined-space operations is often necessary. These considerations are always prioritized to ensure personnel safety and project success.

One project involved excavating a trench in a narrow alleyway between buildings. Because of space limitations, I used a mini-excavator with specialized attachments, and the work was carefully coordinated with spotters to avoid striking obstacles or causing damage to adjacent structures.

Q 27. Describe your experience with operating equipment at night or in low-visibility conditions.

Operating equipment at night or in low-visibility conditions requires extra caution and a different set of procedures. Adequate lighting is crucial; this could involve using high-intensity work lights on the equipment itself, or deploying temporary lighting systems around the work area. Visibility is enhanced through the use of high-visibility clothing, and additional spotters are often deployed to assist the operator in navigating the environment and identifying potential hazards. Moreover, additional care is taken to check the surroundings for obstructions such as equipment, materials, or workers.

I’ve worked on night shifts constructing highway sections, successfully completing the projects safely and efficiently using these safety protocols and specialized lighting systems.

Q 28. What is your experience working with surveying equipment and data?

I have significant experience interpreting and utilizing surveying data to guide equipment operations. This involves understanding and correctly interpreting survey markers, benchmarks, and digital terrain models (DTMs). Accurate placement of equipment and material is crucial, and using surveying data ensures precision in tasks such as grading, excavation, and foundation work. I’m proficient in using common surveying tools like total stations and GPS systems to verify the accuracy of equipment positioning, ensuring alignment with project specifications. My familiarity with surveying software enables me to analyze data, assess discrepancies, and correct any deviation from plans.

For instance, on a recent pipeline project, precise trench excavation was critical. I utilized the provided survey data to guide the excavator, ensuring the trench was dug to the correct depth and alignment, crucial for the safe installation of the pipeline. This prevented costly rework and ensured adherence to stringent safety requirements.

Key Topics to Learn for Proficient in the use of Heavy Equipment and Construction Tools Interview

- Safe Operation Procedures: Understanding and adhering to all safety regulations and protocols for various heavy equipment and tools. This includes pre-operational checks, emergency procedures, and hazard identification.

- Equipment Maintenance and Troubleshooting: Knowledge of routine maintenance tasks, identifying potential mechanical issues, and performing basic repairs or reporting malfunctions effectively.

- Specific Equipment Expertise: Demonstrating proficiency with specific heavy equipment (e.g., excavators, bulldozers, loaders, cranes) and construction tools (e.g., welders, saws, drills) relevant to the target job description. Be prepared to discuss your experience with each.

- Practical Application: Be ready to describe real-world scenarios where you’ve used this equipment, highlighting your problem-solving skills and ability to work efficiently and effectively under pressure.

- Understanding Construction Techniques: Demonstrate knowledge of common construction techniques and how your equipment skills contribute to the overall project success. Consider examples like earthmoving, foundation work, or demolition.

- Blueprint Reading and Site Interpretation: Explain your ability to interpret blueprints and construction plans to effectively operate equipment and execute tasks accurately on-site.

- Teamwork and Communication: Highlight your ability to collaborate effectively with other construction professionals and communicate clearly about progress, challenges, and safety concerns.

Next Steps

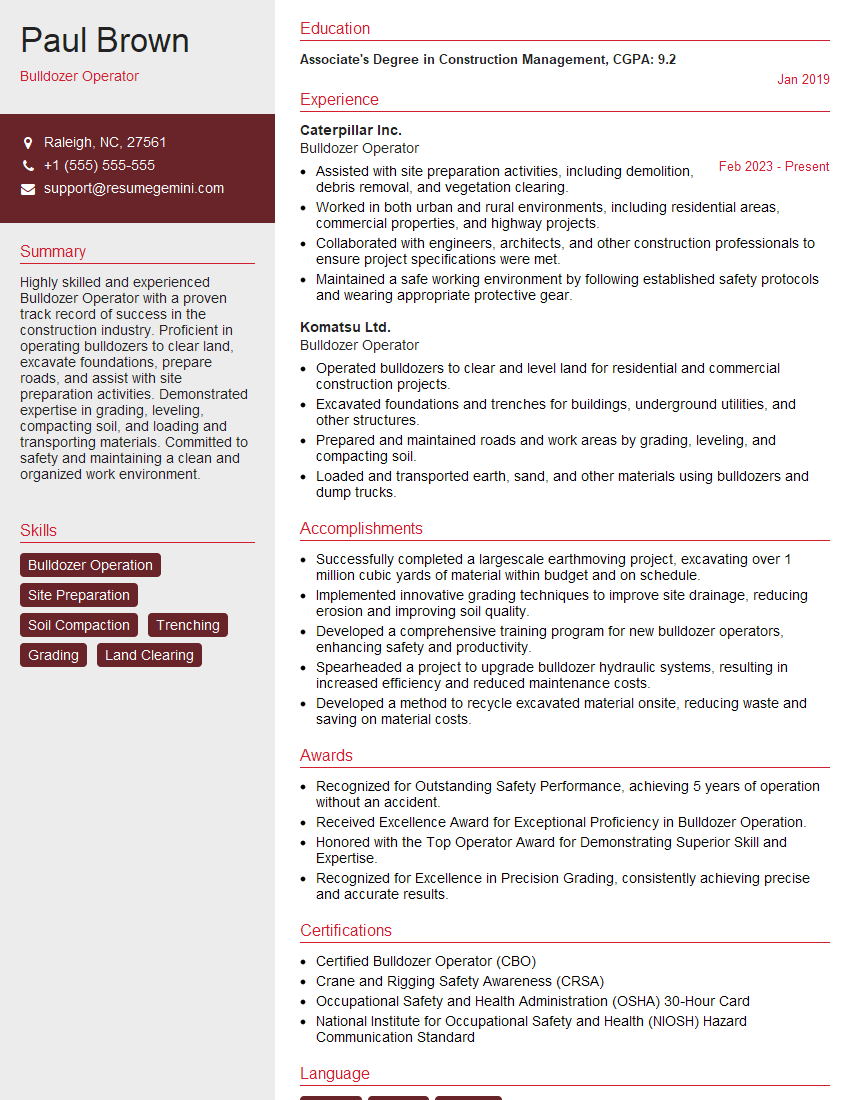

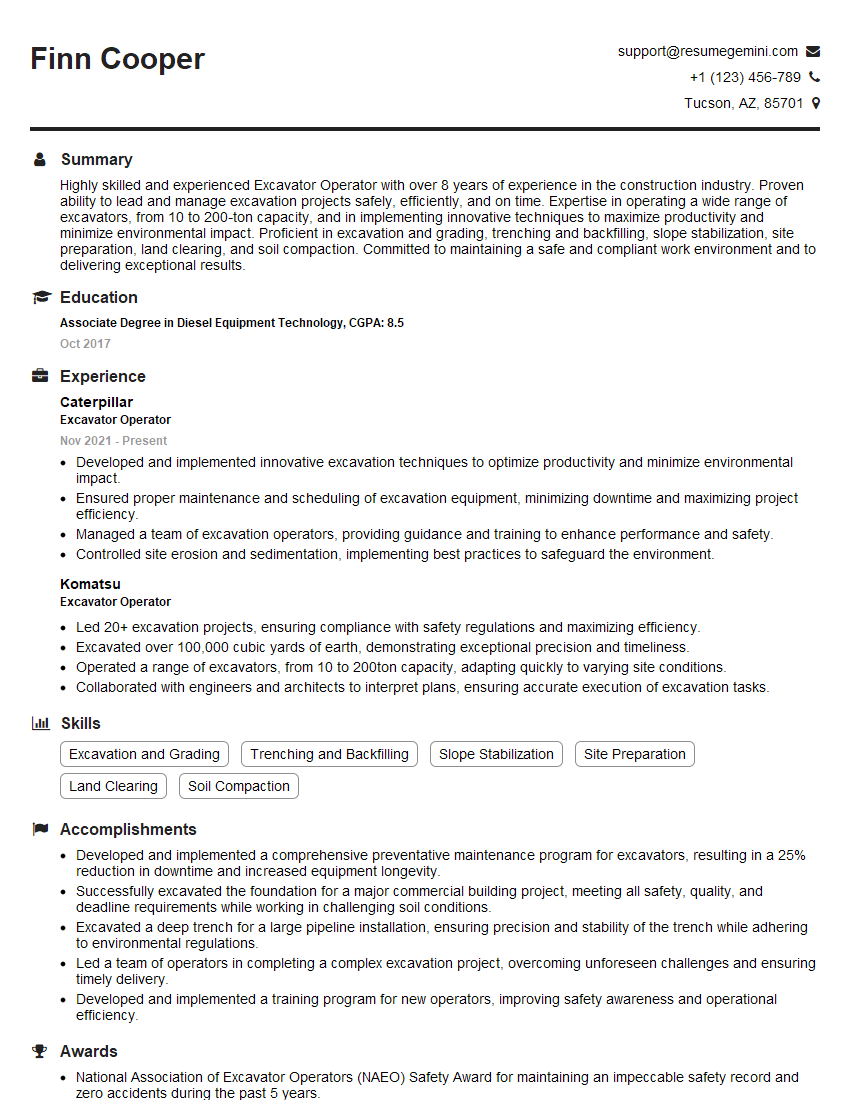

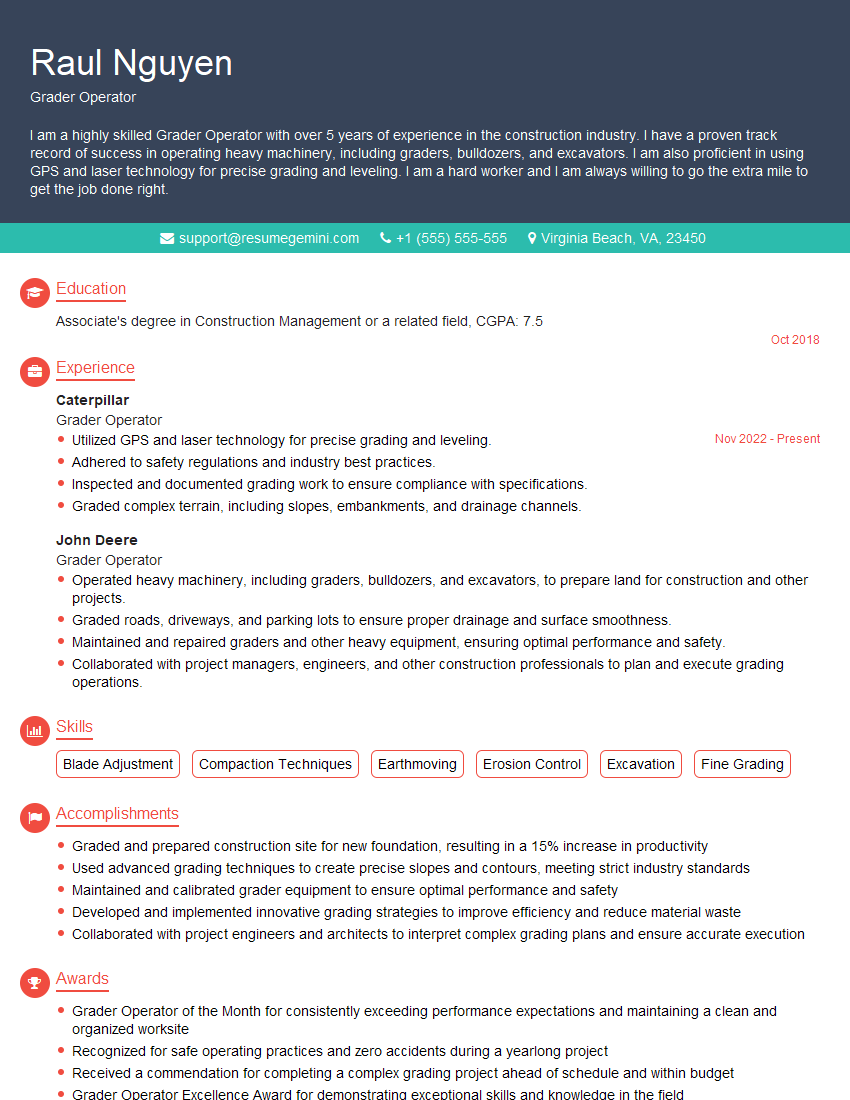

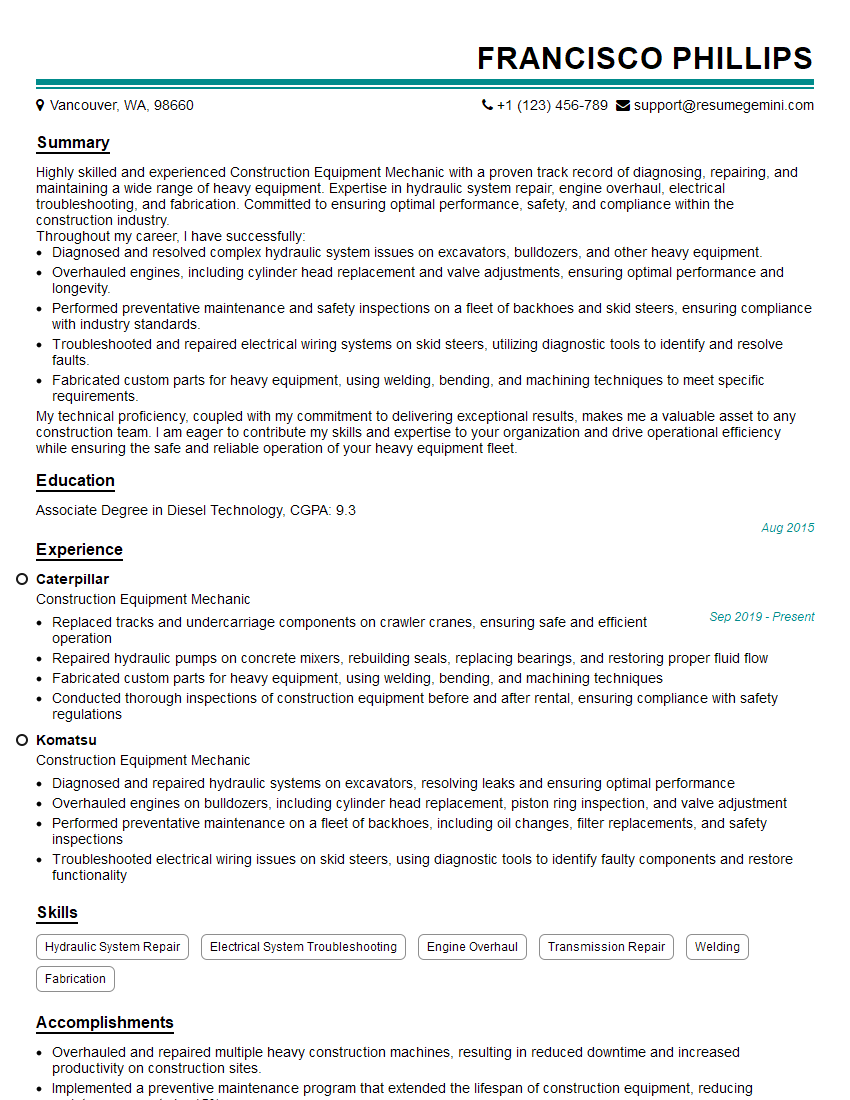

Mastering the proficient use of heavy equipment and construction tools is crucial for career advancement in the construction industry, opening doors to higher-paying roles and increased responsibility. A well-crafted resume is your first step towards securing these opportunities. Make sure your resume is ATS-friendly to maximize its visibility to potential employers. ResumeGemini can help you build a powerful, professional resume that showcases your skills and experience effectively. We offer examples of resumes tailored to highlight proficiency in heavy equipment and construction tools, helping you present yourself in the best possible light.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good