The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Proofing and Color Verification interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Proofing and Color Verification Interview

Q 1. Explain the difference between soft proof and hard proof.

The core difference between a soft proof and a hard proof lies in the medium used for color visualization. A soft proof is a digital representation of your final printed output, viewed on a monitor. Think of it as a preview – a digital ‘mock-up’ of your printed piece. A hard proof, on the other hand, is a physical print produced on the same press and with the same materials that will be used for the final print run. It’s the closest you can get to seeing the final product before the actual large-scale printing begins.

Soft proofs are convenient and cost-effective for early-stage reviews and multiple iterations. They allow for quick feedback and adjustments without incurring the expense of physical prints. However, they can be susceptible to inaccuracies depending on monitor calibration and profile settings. Hard proofs, while more expensive, offer a much more reliable representation of the final printed color because they account for the inherent color shifts in the printing process itself. They are crucial for ensuring accuracy when color precision is paramount, such as in packaging or high-end print work.

Imagine you’re baking a cake. A soft proof is like looking at a picture of the cake in a recipe book; you get a general idea, but it doesn’t capture the true texture or taste. A hard proof is like baking a small version of the cake to taste-test it before making the full-sized one; it’s a much more accurate preview of the final product.

Q 2. Describe your experience with various color spaces (e.g., RGB, CMYK, Pantone).

My experience with color spaces is extensive, encompassing the three most prevalent systems: RGB, CMYK, and Pantone. RGB (Red, Green, Blue) is an additive color model, predominantly used for digital displays like monitors and screens. It’s built on the principle that combining these three primary colors at varying intensities creates a wide spectrum of colors. RGB values range from 0-255 for each color component (e.g., #FF0000 for pure red).

CMYK (Cyan, Magenta, Yellow, Key/Black) is a subtractive color model used primarily in printing. Here, colors are created by subtracting light from white, resulting in a different color spectrum than RGB. The conversion from RGB to CMYK often leads to some color shift, as the color gamuts are not identical. This is a crucial aspect of print proofing, where accurate color representation is essential.

Pantone Matching System (PMS) is a spot color system that defines a specific color with a unique number. Unlike RGB and CMYK, PMS colors are pre-mixed and applied directly without relying on subtractive or additive processes. This makes them particularly useful when consistent, precise color reproduction is critical – think corporate branding or luxury packaging. Managing color consistency across these different color spaces requires a deep understanding of color management workflows and dedicated color profiling.

Q 3. How do you identify and correct color inconsistencies in print materials?

Identifying and correcting color inconsistencies in print requires a systematic approach. It starts with a thorough comparison between the soft proof, hard proof (if available), and the final printed output. I use colorimetric measuring devices like spectrophotometers to quantitatively analyze color differences, expressed as Delta E values (ΔE). A lower ΔE indicates better color match.

The process involves:

- Visual Inspection: A careful observation for any obvious color deviations.

- Instrumental Measurement: Utilizing a spectrophotometer to capture precise color data and compare against target values.

- Delta E Analysis: Analyzing the ΔE values to determine the magnitude of color differences. A ΔE of less than 1 is generally considered imperceptible, while values above 3 signify a noticeable difference.

- Color Correction: Adjusting the color profile, ink settings, or even the design files based on the findings. This could involve changing CMYK values, adjusting the dot gain compensation, or even re-evaluating the paper stock.

- Re-Proofing: Creating new soft and/or hard proofs to verify the effectiveness of the corrections.

For example, if a particular Pantone color appears too saturated in the print, adjustments could be made to the CMYK equivalents or the ink density to achieve a closer match. The iterative process of measurement, analysis, and correction is crucial for achieving acceptable color accuracy.

Q 4. What are the common causes of color shifts during the printing process?

Several factors can cause color shifts during printing:

- Ink Variations: Inconsistent ink viscosity, age, or improper mixing can lead to color variations.

- Dot Gain: The spreading of ink dots during printing, leading to darker printed colors than intended. This is influenced by paper type and ink properties.

- Paper Stock: The paper’s absorbency, brightness, and surface texture all affect how ink is absorbed and how the final color appears. Different paper types require different color profiles.

- Press Calibration: Improper calibration of printing presses affects the accuracy of ink application and dot size.

- Environmental Conditions: Temperature and humidity variations in the print environment can affect ink drying and color rendition.

- Substrate and Ink Interactions: Unforeseen reactions between the ink and the paper or other substrates can result in unexpected color shifts.

Addressing these issues requires careful control over the printing process, including precise ink management, proper press calibration, and meticulous consideration of the chosen substrates and environmental conditions.

Q 5. What is color profiling, and why is it important?

Color profiling is the process of creating a mathematical description – a profile – that characterizes the color behavior of a specific device, such as a monitor, printer, or scanner. It’s like creating a ‘translator’ that allows different devices to understand each other’s color language. Each device has its unique color response, and profiling helps standardize this.

Its importance lies in its ability to improve color consistency across different stages of the production process. Without color profiles, the colors you see on your screen might differ significantly from the printed output. A well-defined profile ensures that the colors intended in the digital design file are accurately represented in the final print, minimizing the color differences and ensuring accurate and consistent results.

Think of it like translating a document from one language to another. The color profile acts as the translator, ensuring that the ‘meaning’ – the color – is accurately conveyed from the digital world to the physical print.

Q 6. Explain your understanding of color calibration and its relevance to proofing.

Color calibration is the process of adjusting a device to meet a predefined standard, ensuring that it displays or reproduces colors accurately. This involves adjusting settings like brightness, contrast, and gamma to match a known standard. Color profiling, as discussed earlier, is closely linked. Calibration helps to ensure your devices have a starting point that can be accurately profiled.

Its relevance to proofing is paramount. An uncalibrated monitor produces inaccurate color representation, leading to flawed soft proofs. Similarly, uncalibrated printers can produce hard proofs that don’t match the intended colors. Therefore, consistent and accurate calibration of monitors and printers is essential for obtaining reliable soft and hard proofs that mirror the final printed output.

Imagine trying to paint a picture using paints that are inconsistently mixed or have faded. Calibration ensures the colors are pure, allowing accurate reproduction, and proofing allows us to check the color accuracy before final execution.

Q 7. How do you handle discrepancies between a soft proof and the final printed output?

Discrepancies between soft proofs and final prints are unfortunately common. Handling them effectively requires a methodical approach:

- Identify the Source: Carefully analyze the differences, determining whether the discrepancies stem from monitor calibration, printer profile issues, differences in paper stock, or other variables.

- Quantitative Analysis: Measure color differences using a spectrophotometer and quantify the Delta E values.

- Investigate the Workflow: Review the entire color management workflow to identify potential bottlenecks or inconsistencies in the process, from the initial design to the final print. Check for proper ICC profiles throughout the chain.

- Refine the Profile: If the source is identified as monitor calibration or printer profile inaccuracies, recalibration and profiling are essential.

- Communicate with Stakeholders: Keep open communication with clients and printers to clearly explain any color deviations and the steps taken to resolve them. Sometimes, minor variations are acceptable, while others require adjustments.

- Document Findings: Maintain detailed records of all measurements, corrections, and communications to ensure transparency and traceability. This is particularly important if discrepancies are recurring.

Often, iterative adjustments are necessary until a satisfactory match is achieved. This process demonstrates my expertise in color management and troubleshooting.

Q 8. What software and tools are you proficient in for proofing and color verification?

My proficiency in proofing and color verification software spans a wide range of industry-standard tools. I’m highly skilled in using color management software like X-Rite i1Profiler for calibrating monitors and devices, ensuring consistent color across the workflow. For digital proofing, I extensively use Adobe Acrobat Pro for PDF creation and review, carefully checking for color accuracy and potential issues. I’m also experienced with specialized software such as Esko Color Engine for prepress and color management in packaging workflows and GMG ColorProof for high-end soft proofing. I’m also comfortable using various image editing software like Adobe Photoshop and Illustrator to make adjustments and verify color accuracy. Finally, I utilize spectrophotometers, such as the X-Rite i1iSis, for precise color measurements.

Q 9. Describe your experience with different proofing methods (e.g., contract proof, digital proof).

My experience encompasses various proofing methods. Contract proofs, which are physical prints created on a press similar to the final production run, offer the closest representation of the final product. They are invaluable for ensuring accurate color reproduction and catching potential issues like dot gain or ink trapping before mass production. Digital proofs (soft proofs), on the other hand, provide a digital representation of the final product. These are generally faster and more cost-effective than contract proofs and are created using specialized software. I’ve utilized both soft proofs using GMG ColorProof, simulating different printing processes, and hard proofs using various inkjet and laser printers. The choice between these methods depends on factors like budget, the complexity of the job, and the client’s requirements. For instance, a high-value project with critical color accuracy might necessitate a contract proof, whereas a simpler job might be adequately reviewed using a soft proof.

Q 10. How would you identify and resolve a problem with moiré patterns in a print job?

Moiré patterns, those unwanted interference patterns that appear as wavy lines or textures in print, are usually caused by the interaction between the image’s frequency and the screen’s ruling (line screen frequency). Identifying the problem involves carefully examining the digital file at 100% zoom, looking for these characteristic patterns, particularly in areas with fine detail or repeating elements. Resolution of moiré patterns requires a multi-pronged approach. First, changing the angle of the screen can sometimes alleviate the issue, if possible working with different angles (15°, 30°, 45°) in the print setup to see which minimizes the problem. Second, increasing the screen frequency (the number of lines per inch) might reduce its visibility; however this can affect the quality. Third, adjusting the image itself, such as blurring fine details or altering the image’s frequency (using filters in Photoshop or other image editing software), is often effective. Finally, in some cases, re-shooting the original image with higher resolution to avoid aliasing can be required.

Q 11. Explain your process for reviewing and approving press proofs.

My process for reviewing and approving press proofs is meticulous and systematic. I start by carefully comparing the proof to the approved digital file, noting any discrepancies in color, registration (alignment of colors), or sharpness. I use a calibrated monitor and spectrophotometer to perform objective color measurements to ensure accurate color reproduction. I create detailed notes documenting any deviations, including precise color coordinates (e.g., using L*a*b* values) for any color discrepancies. I then communicate these findings clearly and concisely to the prepress team and the client, proposing solutions to resolve any issues before final production. Approval is only granted once all discrepancies are resolved to my satisfaction and meet the client’s specifications.

Q 12. How do you handle communication with designers and clients regarding color accuracy?

Communication is paramount for ensuring color accuracy. With designers, I emphasize the importance of using a consistent color profile throughout the design process and using color management tools. I encourage them to provide color specifications using a standardized system such as Pantone or L*a*b* values. With clients, I use clear, non-technical language to explain color concepts, showing them examples of color variations and explaining the limitations of color reproduction. I often provide color charts or samples to help them visualize the expected outcome. Regular check-ins throughout the project help manage expectations and catch any color-related problems early. This proactive communication approach ensures everyone is on the same page, reducing the risk of costly rework.

Q 13. Describe your experience with Pantone matching system.

I have extensive experience with the Pantone Matching System (PMS). I understand the importance of using Pantone colors for consistent branding and accurate color reproduction across different print and digital media. I’m adept at using the Pantone color books and software to identify and specify Pantone colors, understanding the limitations of spot colors versus process colors and how this might affect the print result. I regularly use Pantone color references in proofing workflows, using spectrophotometers to verify the accuracy of Pantone spot colors in press proofs and ensuring consistency between the desired Pantone color and the final print.

Q 14. What is your understanding of colorimetric data and its use in proofing?

Colorimetric data, expressed in numerical values (like L*a*b*, XYZ, or CMYK), provides a precise and objective measurement of a color’s properties. In proofing, colorimetric data is crucial for verifying the accuracy of color reproduction. Spectrophotometers measure the colorimetric data of printed proofs and compare it to the target color values from the digital file. These comparisons ensure that the printed colors accurately represent the intended design. Deviations, if any, can be quantified precisely, allowing for targeted adjustments in the printing process. Tools like color management software then use colorimetric data to create color profiles and transform colors between different color spaces, optimizing color consistency across different devices and printing processes.

Q 15. What quality control checks do you perform during the proofing process?

Proofing involves a multi-stage quality control process to ensure the final printed product matches the digital design. My checks start with a visual inspection for obvious errors like typos or misplaced elements. Then, I meticulously verify colors against a pre-approved color profile, often using a calibrated monitor and software like X-Rite i1Profiler or Datacolor SpyderX. I also check for accurate registration (how precisely colors and elements align), image sharpness, and the overall tonal balance. For complex jobs, I’ll use a soft proofing system that simulates the printing process and paper type to predict the final output accurately. I always document every step of the proofing process, including any discrepancies found and their resolution.

- Visual Inspection: Checking for layout errors, text accuracy, and obvious color discrepancies.

- Color Verification: Using calibrated monitors and software to compare digital proofs with the approved color profiles (e.g., Pantone or CMYK).

- Soft Proofing: Simulating the printing process on-screen to anticipate any color shifts or issues before actual printing.

- Registration Check: Ensuring colors and elements align perfectly.

- Documentation: Maintaining a detailed record of all proofing stages and any identified issues.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you ensure color consistency across different printing methods?

Maintaining color consistency across different printing methods (offset, digital, large format) is paramount. This requires careful color management throughout the entire workflow. We start by using a standardized color profile (like a Pantone-coated profile) for design and proofing. This profile dictates the precise color values. When the design is ready for print, we utilize a color conversion system to translate this profile into the specific color space of the printing method (e.g., CMYK for offset). Color calibration of the printing devices is critical, regularly performed using spectrophotometers and software. Proofs are then produced using the same printing method and materials as the final job to verify the color match. Regular color checks throughout the print run prevent significant deviations.

For example, a Pantone color may appear slightly different on a digital press compared to offset due to different ink and paper properties. By creating color profiles for each printing method and using a calibrated workflow, we mitigate these variations.

Q 17. Describe a situation where you had to troubleshoot a color-related issue. How did you solve it?

I once encountered a situation where a client’s logo, designed in RGB, resulted in a significantly desaturated cyan in the final offset print compared to the soft proof. The initial assumption was an issue with the printing plates. However, upon closer investigation, we found that the problem stemmed from incorrect color conversion during pre-press. The RGB color profile hadn’t been properly converted to a CMYK profile appropriate for offset printing, resulting in a loss of vibrancy.

To solve this, I meticulously reviewed the color management settings in the pre-press workflow. We recalibrated the conversion settings using industry-standard methods and created a new CMYK profile based on the offset printing process’s characteristics. We then produced a new soft proof, and after a successful test print, proceeded with the full print run. Thorough documentation of the corrected settings prevented similar issues in future projects.

Q 18. What are some common pitfalls to avoid in the proofing process?

Common pitfalls in the proofing process include:

- Uncalibrated monitors: Using uncalibrated monitors for color-critical work leads to significant inconsistencies and errors.

- Incorrect color profiles: Failing to use the appropriate color profiles for the design, proofing, and printing methods.

- Ignoring soft proofing: Not using soft proofing to predict potential print issues before the actual print job.

- Poor communication: Lack of clear communication between designers, pre-press, and printers leads to misunderstandings about color expectations.

- Ignoring dot gain: Not compensating for dot gain, leading to darker and less accurate colors in the final print.

Avoiding these issues requires meticulous planning, careful calibration of equipment, and clear, documented communication across teams.

Q 19. How do you manage large volumes of files requiring proofing and color verification?

Managing large volumes of files requires a structured, automated approach. We utilize a Digital Asset Management (DAM) system to organize and track files efficiently. This system allows for metadata tagging (like client name, project details, and approval status) facilitating quick retrieval and searchability. We employ automated workflows for proofing, using software that allows for batch processing and automated color checks. This streamlined process enhances efficiency and reduces manual intervention, minimizing errors and improving turnaround times.

Furthermore, we utilize cloud-based collaborative platforms for sharing proofs and collecting client feedback, allowing for efficient communication and approval cycles.

Q 20. What is your understanding of dot gain and its impact on color accuracy?

Dot gain is the increase in the size of printed dots compared to the size of dots on the film or plate. It’s a natural occurrence in offset printing, primarily due to the ink spreading on the paper’s surface. This increase in dot size results in a darker printed output than what was intended on the design. Dot gain impacts color accuracy because it shifts the color values toward darker tones. For instance, a cyan dot intended to be 50% might print as 60% due to dot gain, making the final color darker and less vibrant than the design intended.

To compensate for dot gain, we utilize color correction techniques during pre-press. This involves adjusting the design’s color values to anticipate the dot gain effect during printing, thereby ensuring the final output matches the approved design.

Q 21. Explain the relationship between resolution and color accuracy.

Resolution and color accuracy are closely related. Higher resolution images contain more data, allowing for smoother gradations and more accurate representation of color. Low-resolution images have fewer data points and thus result in color banding (visible steps in color transitions) and a less accurate representation of subtle color shifts. Think of it like painting a picture – a high-resolution image is like using many small brushstrokes to create smooth transitions, while a low-resolution image uses large, visible brushstrokes, making it difficult to portray fine details and accurate colors.

For optimal color accuracy, using high-resolution images (at least 300 DPI for print) is crucial. This minimizes the appearance of color banding and allows for a more precise representation of the color information in the design.

Q 22. What is your experience with color management software (e.g., Adobe Acrobat, X-Rite i1Profiler)?

My experience with color management software is extensive. I’m proficient in Adobe Acrobat Pro, utilizing its PDF creation and editing capabilities for accurate color representation and preflighting. This includes checking for embedded profiles, color space conversions, and potential issues. I’m also highly skilled with X-Rite i1Profiler, a crucial tool for creating custom ICC profiles. This ensures accurate color representation from my scanner, monitor and printer, and allows for consistent color reproduction across various devices and print methods. I’ve used i1Profiler to profile numerous devices, from high-end proofing systems to more modest desktop printers, optimizing color accuracy in each case. For example, I recently used i1Profiler to create a custom profile for a new wide-format printer, resulting in a significant improvement in color accuracy for large-format prints compared to using the printer’s generic profile.

Q 23. How do you verify the accuracy of color separations?

Verifying the accuracy of color separations is a critical step. I typically start by examining the separations visually, checking for unexpected color shifts or banding. However, relying solely on visual inspection is insufficient. I use a spectrophotometer to measure the color density of each separation, comparing the readings against the expected values from the color profile. Any significant deviation flags potential problems. For instance, if the cyan separation is consistently over-saturated, it could indicate an issue with the plate or printing press. This methodical approach minimizes surprises during the print run. I also often utilize software like Adobe Acrobat Pro to check the output as a composite file, ensuring the separation process created a correctly combined color image. Finally, I frequently perform test prints to further verify the accuracy, comparing the test print to my digital reference.

Q 24. Explain your understanding of different paper types and their impact on color reproduction.

Different paper types significantly affect color reproduction. Coated papers, with their smooth surface, offer better ink adhesion and sharper details, resulting in more vibrant and saturated colors. However, they can sometimes appear too glossy. Uncoated papers, on the other hand, provide a more natural look and feel with a softer color reproduction. Their porous nature absorbs ink, leading to less vibrancy but a more subdued, often more aesthetically pleasing result. Think of the difference between a glossy magazine print (coated) and a matte art print (uncoated). I take into account the paper’s brightness (ISO brightness), opacity, and absorbency when choosing profiles and making color adjustments. For example, a high-brightness coated paper might need less ink to achieve the target color compared to a lower-brightness uncoated paper.

Beyond coated and uncoated, there are numerous other types, each with unique characteristics. Consider textured papers, which add visual interest but can influence ink spread and color saturation, and recycled papers, which often exhibit variations in color and density due to the recycled fiber content. Understanding these variations and selecting appropriate profiles and color settings is crucial for producing the desired outcome.

Q 25. What is your experience with colorimetric measurement devices (e.g., spectrophotometer)?

I have extensive experience using colorimetric measurement devices, primarily spectrophotometers. I regularly use them to measure color values (e.g., L*a*b*, Delta E) of printed samples and compare them to digital references. This helps to quantify color differences and identify potential issues. Different spectrophotometers offer various levels of accuracy and functionality. I am familiar with both handheld and benchtop models and select the appropriate tool based on the specific needs of the project and the level of precision required. For instance, a handheld spectrophotometer is suitable for quick spot checks in the field, while a benchtop spectrophotometer offers higher precision and more detailed analysis for critical color matching tasks. Beyond basic color measurement, I use spectrophotometers with software to produce accurate color reports that document the color values of a project’s different elements, making it easier to identify any potential discrepancies.

Q 26. How do you maintain accurate color standards throughout a print project?

Maintaining accurate color standards throughout a print project requires a multi-pronged approach. It begins with establishing a reliable color reference, often a physical swatch or a digital file with a precisely defined color profile. This reference then guides all subsequent color decisions. I use color management software to transform the digital files to accurately match this reference. Regular calibration and profiling of all output devices (monitors, printers, etc.) are essential. Test prints are produced at regular intervals to confirm that colors remain consistent, and any significant deviations are addressed promptly. Furthermore, proper communication and collaboration with the client are crucial to ensure that we all share a clear understanding of the desired colors and their expectations. Throughout the entire workflow, documentation of all settings and measurements is key for traceability and for resolving future color discrepancies, should they occur.

Q 27. Describe your approach to proofing for different printing substrates (e.g., coated, uncoated paper).

My approach to proofing for different substrates adapts to the specific challenges each presents. For coated papers, the goal is to achieve vibrant and sharp color reproduction. I carefully choose profiles that match the specific paper and the printing method to ensure optimal ink adhesion and minimize dot gain (the spreading of ink on the paper). With uncoated papers, the focus is on achieving a balanced color reproduction without excessive dot gain, which can lead to muddy colors. I select paper and ink profiles that compensate for the increased ink absorption. I might adjust the settings to increase the overall ink coverage to improve saturation. To effectively handle different substrates, I use colorimetric data to refine color consistency across various papers. For example, I might adjust the color settings in my design software to account for the unique characteristics of the substrate before creating a proof. This iterative process ensures the final print closely matches expectations.

Q 28. How do you handle color adjustments in different printing processes (e.g., offset, digital)?

Color adjustments vary significantly between offset and digital printing. Offset printing involves the use of plates, inks, and a press, each with its own unique color characteristics. Precise color management is crucial, as ink behavior on the press can impact final output. I often create color profiles for each press run and carefully calibrate the press to match the intended color profile. Digital printing presents different challenges. While color consistency is generally better than with offset, factors like substrate, toner characteristics, and printer settings still influence the final result. Calibration and profiling of the digital printer is essential, and careful management of color spaces is required to avoid unexpected color shifts. My experience enables me to successfully navigate these differences. For example, I might use a different color profile and adjustment methods when proofing for offset versus digital printing to ensure accurate color reproduction across the printing methods.

Key Topics to Learn for Proofing and Color Verification Interview

- Color Spaces and Profiles: Understanding different color models (RGB, CMYK, LAB) and color profiles (ICC profiles) and their applications in print and digital media. Practical application: Explaining the need for profile conversion and its impact on color accuracy.

- Proofing Methods: Familiarize yourself with various proofing methods, including soft proofing (on-screen), hard proofing (physical prints), and contract proofing. Practical application: Discussing the advantages and disadvantages of each method and selecting the appropriate method for a given project.

- Color Management Software: Gain proficiency in color management software such as Adobe Acrobat, X-Rite i1Profiler, or other industry-standard tools. Practical application: Describing your experience calibrating monitors, creating custom profiles, and troubleshooting color discrepancies.

- Colorimetric Measurements: Understand the principles of colorimetric measurement and the use of spectrophotometers. Practical application: Explaining how to interpret color data and identify color deviations.

- Print Production Workflow: Familiarize yourself with the complete print production workflow, including prepress, press, and post-press stages, and how color verification plays a critical role at each stage. Practical application: Identifying potential color issues at different stages of the workflow and proposing solutions.

- Troubleshooting and Problem Solving: Develop strong problem-solving skills related to color inconsistencies, mismatches, and other print-related issues. Practical application: Describing your approach to identifying the root cause of a color problem and implementing corrective actions.

- Industry Standards and Best Practices: Stay up-to-date on industry standards and best practices for color management and proofing. Practical application: Demonstrating your knowledge of relevant ISO standards and industry guidelines.

Next Steps

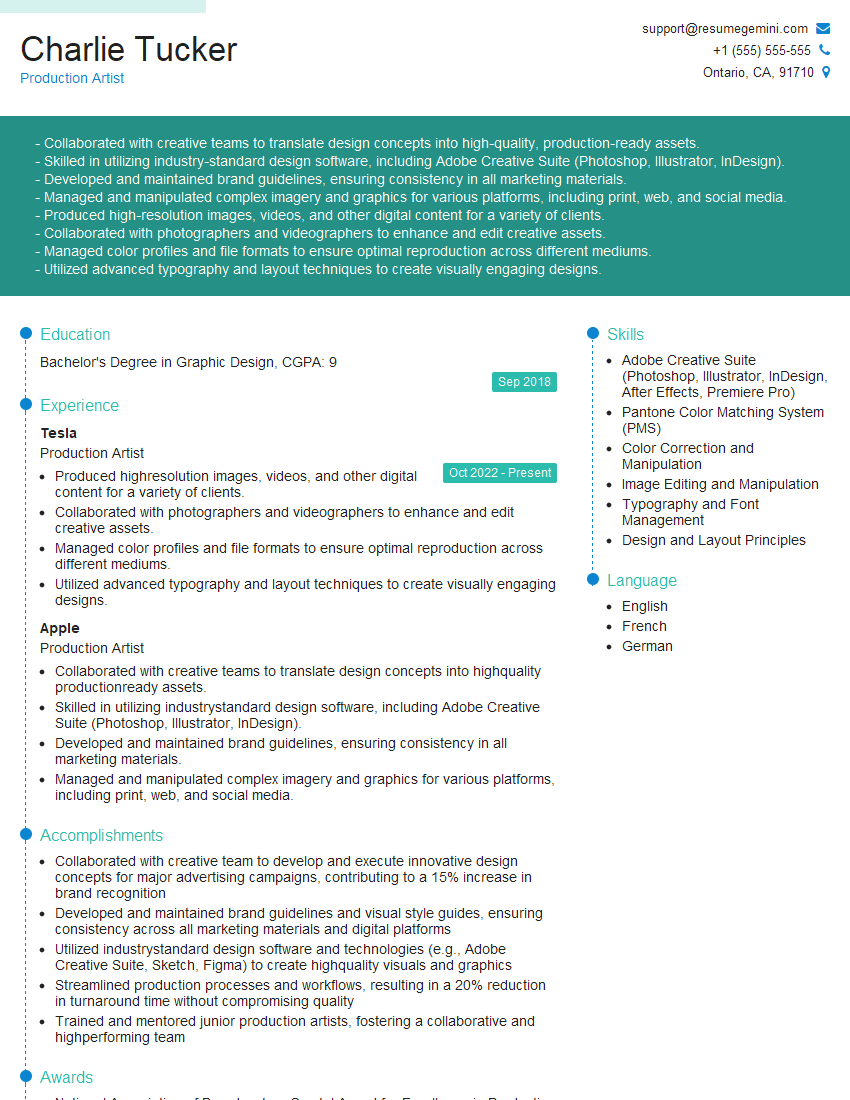

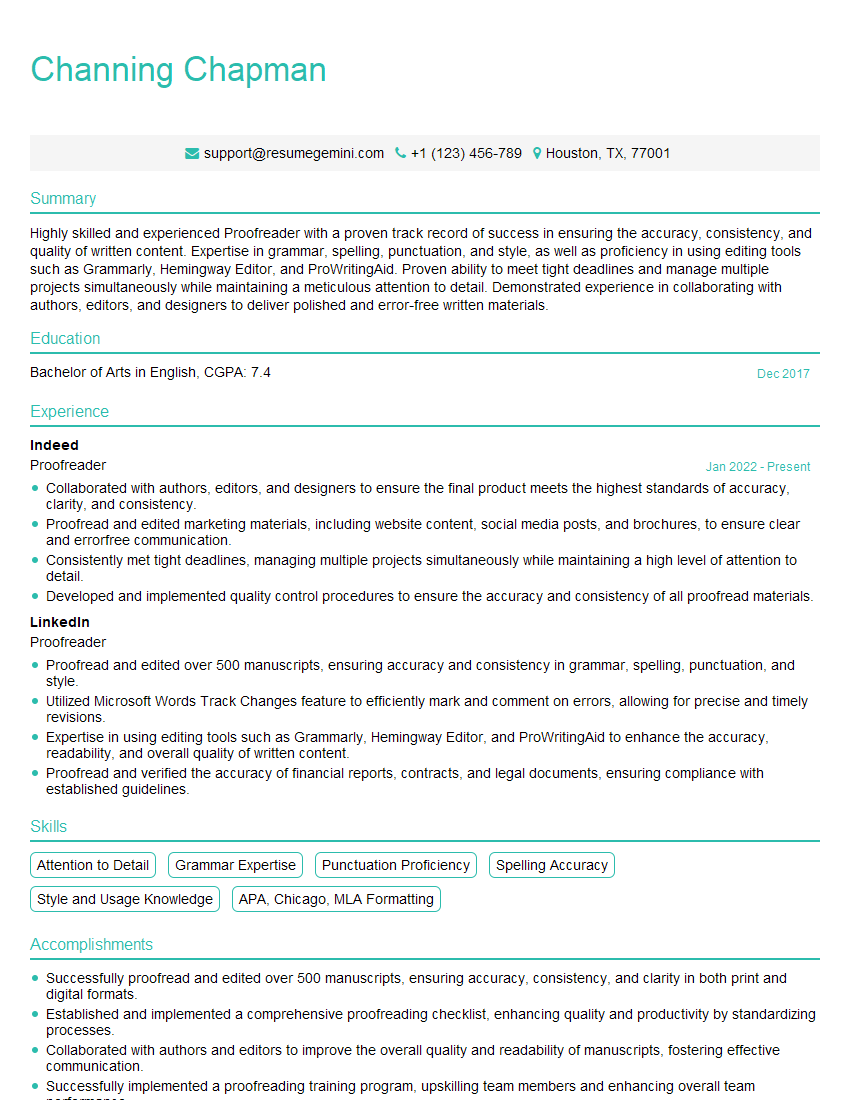

Mastering Proofing and Color Verification opens doors to exciting career opportunities in graphic design, prepress, and print production. A strong understanding of these skills is highly valued by employers. To maximize your job prospects, it’s crucial to present yourself effectively. Creating an ATS-friendly resume is key to getting your application noticed. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to Proofing and Color Verification to give you a head start. Take the next step towards your dream career today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good