Are you ready to stand out in your next interview? Understanding and preparing for Prop Design and Construction interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Prop Design and Construction Interview

Q 1. Describe your experience with various prop fabrication techniques.

My experience spans a wide range of prop fabrication techniques, from traditional methods to advanced digital fabrication. I’m proficient in sculpting with materials like foam, clay, and epoxy putty; mold-making and casting using techniques like latex, resin, and fiberglass; woodworking with various tools and finishes; and metalworking, including welding and soldering. I also have extensive experience with 3D modeling and printing, allowing for precise and complex designs. For example, I recently created a highly detailed dragon sculpture for a fantasy film using a combination of 3D printing for intricate details and foam sculpting for the larger body sections. My experience also includes painting, texturing, and weathering techniques, ensuring props are both aesthetically pleasing and believable within their context.

- Sculpting: Foam, clay, epoxy putty

- Mold-making & Casting: Latex, resin, fiberglass

- Woodworking: Various techniques and finishes

- Metalworking: Welding, soldering

- 3D Modeling & Printing: Precision and complex designs

- Painting, Texturing & Weathering: Realism and believability

Q 2. What materials are best suited for creating a realistic-looking weapon prop?

The best material for a realistic-looking weapon prop depends on the specific weapon and desired level of detail. However, some excellent choices include: For firearms, high-density polyurethane foam is a popular option due to its lightweight nature and ease of carving. This can then be coated with a durable resin for added strength and realism. For swords or other bladed weapons, fiberglass reinforced resin is a great choice because it’s strong, relatively lightweight, and can be shaped to replicate intricate details. Metal can be used for added authenticity, but it needs to be handled safely and often requires more specialized skills. Crucially, it’s essential to always clearly mark the prop as a replica to avoid any confusion or accidents.

- High-density polyurethane foam: Lightweight, easy to carve, durable with resin coating

- Fiberglass reinforced resin: Strong, lightweight, detailed shapes

- Metal: Authentic look, requires specialized skills, safety paramount

Q 3. How do you ensure the safety of props during production?

Safety is paramount in prop construction. My process includes several key steps to mitigate risks. First, I always use appropriate safety gear, including eye protection, respirators (especially when working with resins or paints), and gloves. Second, I carefully handle potentially dangerous materials and tools, following all manufacturer instructions. Third, I ensure that all props are clearly marked as replicas, either through visible markings or documentation. This is crucial to avoid confusion and accidents. For weapons, I often incorporate safety features such as dulling the edges or points and reinforcing weak areas to prevent breakage. Finally, thorough inspections are conducted throughout the entire process to identify and rectify any potential safety hazards before the prop is used.

Q 4. Explain your process for sourcing and acquiring prop materials.

Sourcing materials is a crucial part of the process. I usually begin with a detailed list of materials needed, based on the prop design. I then research suppliers, comparing prices and quality. For specialized materials, I might need to contact specific manufacturers directly. For common materials like wood or foam, I typically source from local suppliers to reduce shipping costs and lead times. I always maintain records of all materials purchased, including invoices and safety data sheets (SDS), for budgeting and traceability purposes. Maintaining strong relationships with suppliers is key to ensuring timely delivery and access to unique or hard-to-find materials.

Q 5. Describe your experience with budgeting and cost control in prop construction.

Budgeting and cost control are essential aspects of prop construction. I start by creating a detailed breakdown of anticipated costs, including materials, labor, and any necessary specialized tools or services. Throughout the project, I carefully track expenses against the budget, making adjustments as needed. I explore cost-effective alternatives when possible without sacrificing quality. For example, I might substitute a less expensive but equally effective material or explore alternative fabrication techniques to reduce labor costs. Regular monitoring and proactive cost management help ensure that projects remain within the allocated budget.

Q 6. How do you handle unexpected design changes or material shortages?

Unexpected design changes or material shortages require flexibility and problem-solving skills. If a design change occurs, I first assess the impact on the overall project timeline and budget. This could involve renegotiating deadlines or finding alternative materials. In case of material shortages, I explore alternative suppliers or substitute materials while maintaining the quality and integrity of the prop. For instance, if a specific type of wood isn’t available, I might find a suitable alternative with similar properties and adjust the design accordingly. Effective communication with the client or project manager is crucial to ensure everyone is informed and agrees on the solution.

Q 7. Explain your understanding of prop aging and weathering techniques.

Prop aging and weathering techniques are essential for creating realism. Techniques vary depending on the material and desired effect. For wood, I might use techniques like sanding, staining, and applying washes to simulate age and wear. For metal, I might use paints, rust effects, and patinas to create a weathered look. For foam, I might use various paints and texturing techniques to simulate damage or decay. I also consider the environment the prop is intended for when choosing techniques; a prop for a desert setting requires different weathering effects than one for a humid jungle. The goal is to create a believable aged appearance that enhances the storytelling of the piece.

Q 8. How do you maintain the integrity of delicate or antique props?

Maintaining the integrity of delicate or antique props requires a meticulous and respectful approach. It’s about preserving their historical significance and artistic value while ensuring they remain safe and usable for their intended purpose. Think of it like caring for a precious heirloom – it needs careful handling and appropriate storage.

- Careful Handling: Always use clean, soft gloves when handling delicate props to avoid transferring oils or dirt. Support the entire piece, avoiding pressure on any fragile parts.

- Appropriate Storage: Store props in a climate-controlled environment, away from direct sunlight, extreme temperatures, and humidity. Individual pieces might require custom-made cradles or protective cases. For example, a delicate porcelain doll might need to be stored in acid-free tissue paper within a padded box.

- Regular Inspection and Conservation: Regularly inspect the props for signs of damage or deterioration. Minor repairs, like tightening loose joints or cleaning delicate surfaces, should be done by a trained conservator to prevent irreversible damage. A professional can also provide guidance on long-term preservation strategies. Consider a small investment in professional restoration as necessary.

- Transportation and Display: Use proper padding and support during transportation, and design secure display systems that minimize risk of damage. Avoid placing fragile items in high-traffic areas. For large scale displays, consider seismic bracing, especially if there’s any earthquake risk.

For example, when working on a period drama, I once had to handle a collection of antique glassware. Each piece was carefully cleaned, individually wrapped in acid-free tissue paper, and then stored in custom-made foam inserts within locked cases. This approach ensured the props were protected from any potential damage throughout the production.

Q 9. Describe your experience working with different types of wood for prop construction.

My experience with different wood types for prop construction is extensive. The choice of wood significantly impacts the final look, durability, and workability of the prop. I consider factors like grain, density, durability, and cost when making a selection.

- Hardwoods (e.g., Oak, Mahogany, Cherry): These are denser, more durable, and resistant to wear and tear, making them ideal for props that will see a lot of handling or have to withstand environmental stresses. However, they can be more challenging to carve and are more expensive.

- Softwoods (e.g., Pine, Fir, Cedar): These are lighter, easier to work with, and less expensive, suitable for props where weight and intricate detail are less critical. However, they are more prone to scratches and dents.

- Engineered Woods (e.g., Plywood, MDF): These are manufactured from wood fibers or veneers, offering good stability and strength at a lower cost. They are excellent for creating complex shapes or large panels. However, their surface finish and longevity can vary.

For example, I used solid oak for constructing a medieval-style throne, ensuring its stability and lasting impact. On the other hand, I chose pine for creating a series of rustic crates for a Western-themed production, prioritizing ease of construction and a specific aesthetic.

Q 10. How do you create props that are both aesthetically pleasing and structurally sound?

Creating props that are both aesthetically pleasing and structurally sound requires a balance of artistic vision and engineering principles. It’s about understanding the limitations of materials and employing sound construction techniques to ensure the prop’s longevity and safety.

- Design for Functionality: Consider how the prop will be used and the stresses it will endure. A prop sword needs to be sturdy and balanced enough for use by actors; an intricate chair needs to safely support weight.

- Material Selection: Choose materials appropriate for the design and intended use, taking into account weight, durability, and aesthetic requirements.

- Sound Construction: Utilize robust joinery techniques (e.g., mortise and tenon, dovetail, biscuits) to ensure strength and stability. Reinforce weak points with additional supports or bracing.

- Finish and Detailing: A well-executed finish can enhance both the aesthetic appeal and the durability of the prop. Consider using appropriate sealants, paints, or stains to protect the materials from damage.

For instance, when crafting a large wooden chest, I would use strong mortise and tenon joints for the frame, reinforced with internal bracing and a sturdy lock mechanism. The exterior would receive a durable stain and varnish to protect the wood while enhancing the aesthetic appeal.

Q 11. Explain your experience with using 3D modeling software for prop design.

I have extensive experience using 3D modeling software, primarily Blender and Cinema 4D, for prop design. These tools enable me to create highly detailed and accurate models, explore different design iterations quickly, and facilitate collaboration with other team members.

- Conceptualization and Design: 3D modeling allows me to translate initial sketches and ideas into detailed 3D models, visualizing the final product in three dimensions and identifying potential design flaws before physical construction begins.

- Prototyping and Iteration: I use 3D modeling to create virtual prototypes that can be easily modified and refined, allowing for experimentation with different shapes, materials, and textures. This significantly reduces time and resources wasted on physical prototypes.

- Collaboration and Communication: 3D models can be shared with clients, directors, and other team members for feedback and approval, ensuring everyone is on the same page. This also helps streamline the entire design and production process.

- Fabrication Assistance: 3D models can be directly used for CNC machining or 3D printing, facilitating the creation of complex shapes and highly detailed parts.

For example, when designing a futuristic weapon, I used Blender to create a detailed 3D model, allowing for adjustments to the weapon’s ergonomics, detailing of intricate textures and mechanics before committing to physical construction. This process enabled me to test the model’s functionality and aesthetics in virtual environment prior to fabrication.

Q 12. How do you translate 2D design concepts into 3D prop constructions?

Translating 2D design concepts into 3D prop constructions involves a multi-step process that integrates both artistic skill and technical understanding.

- Understanding Perspective and Scale: Accurately interpreting 2D drawings or sketches requires a good understanding of perspective and scale. Measurements and proportions must be carefully transferred to the 3D model.

- 3D Modeling Techniques: Appropriate 3D modeling techniques, like extrusion, revolving, and sculpting, are used to create the 3D shapes from the 2D designs. This might involve using reference images or creating custom 3D primitives.

- Material Considerations: The choice of materials in the 3D construction should complement the 2D design concept. For instance, a rough, textured surface in a 2D drawing might be replicated using a particular type of wood or material in the 3D prop.

- Iteration and Refinement: The 3D model is continuously refined and adjusted based on the original 2D concept, ensuring the final 3D prop accurately represents the initial design.

For instance, when converting a detailed architectural drawing of a miniature house into a 3D model, I meticulously measured the dimensions from the blueprint and used a combination of extrusion and Boolean operations in my 3D modeling software to create accurate representations of walls, roof and other features before printing a miniature model based on the digital design.

Q 13. Describe your experience with working on large-scale prop projects.

I have extensive experience working on large-scale prop projects, which requires meticulous planning, resource management, and a strong understanding of construction techniques. The challenges are different compared to smaller projects; logistics, material sourcing, and safety become even more critical.

- Detailed Planning: Large-scale projects necessitate comprehensive planning, including detailed blueprints, material lists, and construction schedules. This often involves collaborating with engineers and other specialists.

- Specialized Equipment: Large-scale projects might require specialized tools and equipment, like cranes, forklifts, or large-scale CNC machines. Ensuring proper safety measures for their use is paramount.

- Teamwork and Coordination: Effective communication and collaboration are vital when working with large teams. Clear roles, responsibilities, and deadlines are crucial for successful project execution.

- Transportation and Assembly: Transporting and assembling large props often presents logistical challenges. Careful planning is needed to ensure the prop arrives safely and can be efficiently assembled on site.

For example, I was involved in creating a giant mechanical spider for a film. This involved intricate design, fabrication of individual components in separate locations, and on-site assembly requiring a team and substantial planning for transporting and assembling its multi-ton body.

Q 14. How do you manage multiple prop projects simultaneously?

Managing multiple prop projects simultaneously requires efficient organization, prioritization, and effective time management. It’s like juggling multiple balls – you need to keep them all in the air without letting any drop.

- Project Prioritization: Prioritize projects based on deadlines, resource availability, and client importance. Use project management tools like Trello or Asana to track progress and allocate resources effectively.

- Delegation and Teamwork: Delegate tasks to team members with the appropriate skills and experience. Clear communication and regular updates are crucial to ensure everyone is working towards the same goals.

- Time Management Techniques: Employ time management techniques such as time blocking, Pomodoro, or Eisenhower Matrix to maximize productivity and allocate time efficiently.

- Regular Review and Adjustment: Regularly review project progress and make necessary adjustments to the schedule or resource allocation to stay on track. Flexibility and adaptability are key when managing multiple projects.

For instance, I once managed three concurrent projects: a large-scale set piece, a series of small props, and a detailed miniature model. Using a project management software, I broke down tasks, assigned responsibilities, and tracked progress on a daily basis, ensuring all projects met their deadlines without compromising quality.

Q 15. What software or tools are you proficient in for prop design and construction?

My proficiency in prop design and construction spans a wide range of software and tools. For 3D modeling and design, I’m highly skilled in programs like Blender and Maya, using them to create detailed models from concept sketches to production-ready assets. I’m also proficient in ZBrush for sculpting intricate details, and Substance Painter for texturing, giving props a realistic and believable look. For 2D design work, I use Adobe Photoshop and Illustrator extensively for concept art, blueprints, and technical drawings. Finally, I’m adept at using CAD software like Fusion 360 for creating precise measurements and technical drawings, especially useful when working with complex mechanical props or architectural elements. This diverse skillset allows me to handle any prop design challenge, from a simple wooden box to a complex, multi-part mechanism.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with collaborating with other departments on set.

Collaboration is paramount in prop creation. I have extensive experience working closely with various departments, including art departments for design approvals and consistency with overall set aesthetics, the construction department for feasibility and logistical planning, and the wardrobe department to ensure props complement the costumes. For instance, on a recent project involving a Victorian-era study, I collaborated with the art department to finalize the design of a grandfather clock, ensuring its style matched the period setting. Then, I worked with the construction team to determine the best materials and construction techniques for a functional yet visually accurate clock, coordinating timelines to ensure everything was ready for filming. I find that clear communication, proactive problem-solving, and a collaborative spirit are key to successful inter-departmental workflows.

Q 17. How do you communicate effectively with directors and other crew members?

Effective communication is the cornerstone of my approach. With directors, I use clear and concise language, focusing on practicality and solutions. I often present design options visually, using mood boards and sketches to convey my ideas effectively, supplementing with technical details as needed. With crew members, I value open communication, ensuring everyone understands their roles and responsibilities. I facilitate regular check-ins and actively seek feedback, encouraging a collaborative environment where everyone feels comfortable voicing their concerns. For instance, if a director requests a specific prop modification, I’ll clarify the request, offer alternative solutions, and then provide a detailed timeline for implementation.

Q 18. Explain your problem-solving skills in relation to prop construction challenges.

Problem-solving is an integral part of prop construction. I approach challenges systematically. Firstly, I analyze the problem thoroughly, identifying the root cause and constraints. Then, I brainstorm potential solutions, weighing their practicality and cost-effectiveness. Finally, I select the best solution, implementing and testing it rigorously. For example, when tasked with creating a prop sword that needed to look authentic yet be safe for actors, I opted for a lightweight, durable foam core construction covered with fiberglass and a realistic paint job. This solved the challenge of realism and safety simultaneously. My approach centers around finding creative solutions while adhering to safety regulations and budgetary constraints.

Q 19. How do you handle feedback on your prop designs?

I value feedback as an opportunity for improvement. I approach feedback constructively, listening attentively and asking clarifying questions to fully understand the concerns. I then analyze the feedback, determining whether it addresses functionality, aesthetics, or feasibility. For instance, if a director finds a prop too bulky, I might explore ways to reduce its size while maintaining its visual appeal. I document all feedback, revisions, and final decisions to improve future projects. My goal is to turn feedback into positive improvements and create the best possible prop.

Q 20. Describe your experience with prop maintenance and repair.

Prop maintenance and repair are crucial for maintaining the integrity and longevity of props, particularly during long shoots. I’m experienced in various repair techniques, from simple fixes like tightening screws or replacing broken parts to more complex repairs like restoring damaged finishes or rebuilding sections. For example, I’ve repaired antique furniture props by carefully patching cracks, reinforcing joints, and applying appropriate finishes. I also implement preventative maintenance measures, such as regular inspections and cleaning, to minimize damage and extend the life of props. This proactive approach reduces downtime and ensures props remain in optimal condition throughout the production.

Q 21. What is your understanding of prop safety regulations?

Understanding prop safety regulations is crucial. My knowledge encompasses various aspects, including material safety data sheets (MSDS) for handling potentially hazardous materials, proper handling procedures for sharp objects and pyrotechnics, and compliance with regulations regarding flammability and structural integrity. I prioritize safety in all aspects of prop design and construction, using appropriate safety gear and adhering to all safety protocols. I’m familiar with industry best practices and local regulations to minimize the risk of accidents and injuries on set. This ensures a safe working environment for everyone involved in the production.

Q 22. How do you ensure the accuracy and historical fidelity of period props?

Ensuring the accuracy and historical fidelity of period props requires meticulous research and attention to detail. It’s like being a detective, piecing together clues from various sources to reconstruct the past. My process begins with extensive research into the specific time period and style. This includes consulting historical photographs, documents, museum artifacts, and relevant books and publications. I pay close attention to even the smallest details – the type of wood used, the style of hinges on a door, the fabric patterns on upholstery.

For example, when recreating a Victorian-era writing desk, I wouldn’t just look at the overall design. I’d delve into the specifics: the type of wood commonly used (mahogany, perhaps, or walnut), the methods of joinery (dovetail joints were popular), and the style of hardware. I might even examine surviving examples in museums to understand the wear and tear that would be expected on a piece of that age. Then, I painstakingly recreate these features using appropriate materials and techniques. This approach ensures the prop is not only visually accurate but also reflects the craftsmanship of its era.

Q 23. Explain your process for creating props from scratch using blueprints or sketches.

Creating props from scratch, whether from blueprints or sketches, is a multi-step process that requires both artistic vision and technical skill. It’s similar to following a recipe, but the recipe is a blueprint and the ingredients are wood, metal, fabric, etc.

- Step 1: Analysis and Material Selection: I begin by thoroughly studying the blueprints or sketches to understand the prop’s dimensions, materials, and construction details. This phase informs my material choices, ensuring I select materials that are historically accurate (if applicable) and functionally appropriate.

- Step 2: Construction: This is where the hands-on work begins. Depending on the complexity of the prop, I might employ various techniques: woodworking, metalworking, upholstery, painting, and more. Accuracy is paramount; I meticulously follow the design specifications, paying close attention to measurements and details.

- Step 3: Finishing: This stage involves applying finishes to enhance the prop’s appearance and durability. This might involve staining, painting, varnishing, or other treatments. The choice of finish depends on the material and the desired aesthetic.

- Step 4: Quality Control: A final inspection is critical. I carefully check the prop for accuracy, durability, and overall quality. This includes ensuring all parts are securely fastened and the finish is even and flawless.

For instance, if I’m building a chair from a blueprint, I would carefully cut and shape the wood components, ensuring accurate joinery. Then, I’d assemble the pieces, add upholstery if required, and finish the chair with appropriate stain and varnish.

Q 24. How do you manage time constraints and deadlines in prop construction?

Managing time constraints is a crucial aspect of prop construction. It’s like running a marathon; pacing and strategy are essential. My approach involves meticulous planning, prioritization, and efficient workflow.

- Detailed Scheduling: I break down large projects into smaller, manageable tasks with specific deadlines. This allows for better tracking of progress and identification of potential delays early on.

- Prioritization: I focus on critical tasks first, ensuring that the most essential aspects of the prop are completed on time. This is crucial, particularly when working with multiple projects simultaneously.

- Efficient Resource Allocation: I carefully manage materials and tools to avoid delays caused by shortages or equipment malfunctions. This also includes assembling a skilled team, if needed, to efficiently divide workload.

- Communication: Open and frequent communication with the production team or client is key to managing expectations and addressing any unexpected challenges or delays promptly.

For example, if I’m facing a tight deadline for a complex prop, I might enlist the help of other skilled artisans to share the workload, ensuring timely completion without sacrificing quality.

Q 25. Describe a challenging prop project and how you overcame the difficulties.

One particularly challenging project involved recreating a 17th-century Dutch merchant’s desk for a historical drama. The challenge lay in the intricacy of the marquetry (inlaid wood veneer) work. The original blueprints were incomplete, and finding comparable examples proved difficult.

To overcome this, I employed a multi-pronged approach: I began by studying existing pieces of similar style and period from museums and private collections, analyzing their construction techniques and decorative elements. I then consulted with a specialist in historical marquetry to gain expertise in the traditional techniques and materials. Finally, I used digital modeling to create a complete and accurate blueprint, incorporating elements from my research and allowing me to meticulously plan the marquetry pattern before beginning the actual construction. The result was a historically accurate and stunning piece that perfectly captured the spirit of the era.

Q 26. What are some common mistakes to avoid when creating props?

Several common mistakes can derail a prop project. These include:

- Insufficient Research: Failing to adequately research the historical accuracy or technical specifications of a prop can result in inaccuracies and inconsistencies.

- Poor Material Selection: Using inappropriate materials can compromise the prop’s durability, longevity, and overall aesthetic.

- Ignoring Scale and Proportion: Improper scaling can lead to a prop that looks out of place in the setting.

- Rushing the Process: Cutting corners or neglecting quality control can result in a poorly made prop that is fragile or inaccurate.

- Lack of Planning: Insufficient planning can lead to costly delays and setbacks.

Avoiding these mistakes requires careful planning, thorough research, and a commitment to quality craftsmanship. It’s like building a house; a solid foundation is essential for a sturdy structure.

Q 27. What are your salary expectations for this role?

My salary expectations are commensurate with my experience and skillset in the field of prop design and construction. Given my extensive experience in creating historically accurate and complex props, and considering the industry standard for professionals with similar qualifications, I am seeking a salary range of [Insert Salary Range Here]. I am also open to discussing a comprehensive compensation package that includes benefits and bonuses.

Q 28. What are your long-term career goals in prop design and construction?

My long-term career goals involve continuing to hone my skills in prop design and construction, while also expanding my knowledge and expertise into new areas. I am particularly interested in exploring the use of advanced technologies, like 3D printing and digital fabrication, in prop creation. Furthermore, I aspire to take on more challenging and high-profile projects, potentially working on larger-scale productions and collaborating with other talented professionals in the industry. Ultimately, I aim to contribute to the continued advancement of prop design and construction, leaving my mark on the field and inspiring future generations.

Key Topics to Learn for Prop Design and Construction Interview

- Design Principles and Aesthetics: Understanding fundamental design principles like scale, proportion, and composition, and applying them to create visually appealing and functional props. Consider how different design styles (e.g., period-specific, futuristic) impact prop construction.

- Materials and Fabrication Techniques: Familiarity with a range of materials (wood, metal, plastics, resins, fabrics) and their properties. Demonstrate knowledge of various construction methods including woodworking, metalworking, sculpting, molding, and painting. Be prepared to discuss cost-effective material choices and sustainable practices.

- Blueprint Reading and Technical Drawings: Ability to interpret technical drawings, blueprints, and 3D models to accurately construct props. This includes understanding dimensions, material specifications, and assembly instructions.

- Budgeting and Project Management: Experience with estimating material costs, labor hours, and overall project budgets. Demonstrate an understanding of project timelines, resource allocation, and problem-solving within budgetary constraints.

- Safety Regulations and Practices: Knowledge of relevant safety regulations and best practices for working with various materials and tools. This includes appropriate safety equipment and procedures to prevent accidents.

- Collaboration and Communication: Experience working effectively in a team environment, communicating design ideas and construction plans clearly with designers, other craftspeople, and project managers.

- Troubleshooting and Problem Solving: Ability to identify and resolve construction challenges effectively and efficiently. This includes adapting to unexpected issues and finding creative solutions.

Next Steps

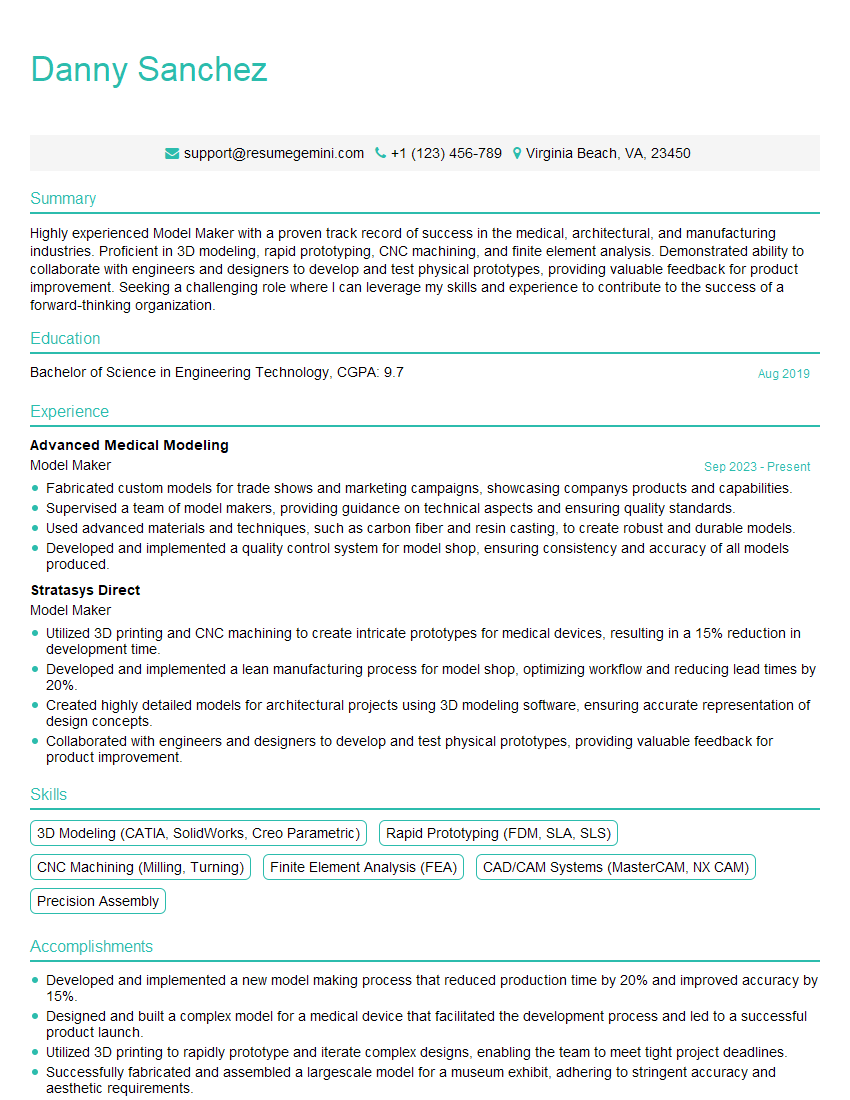

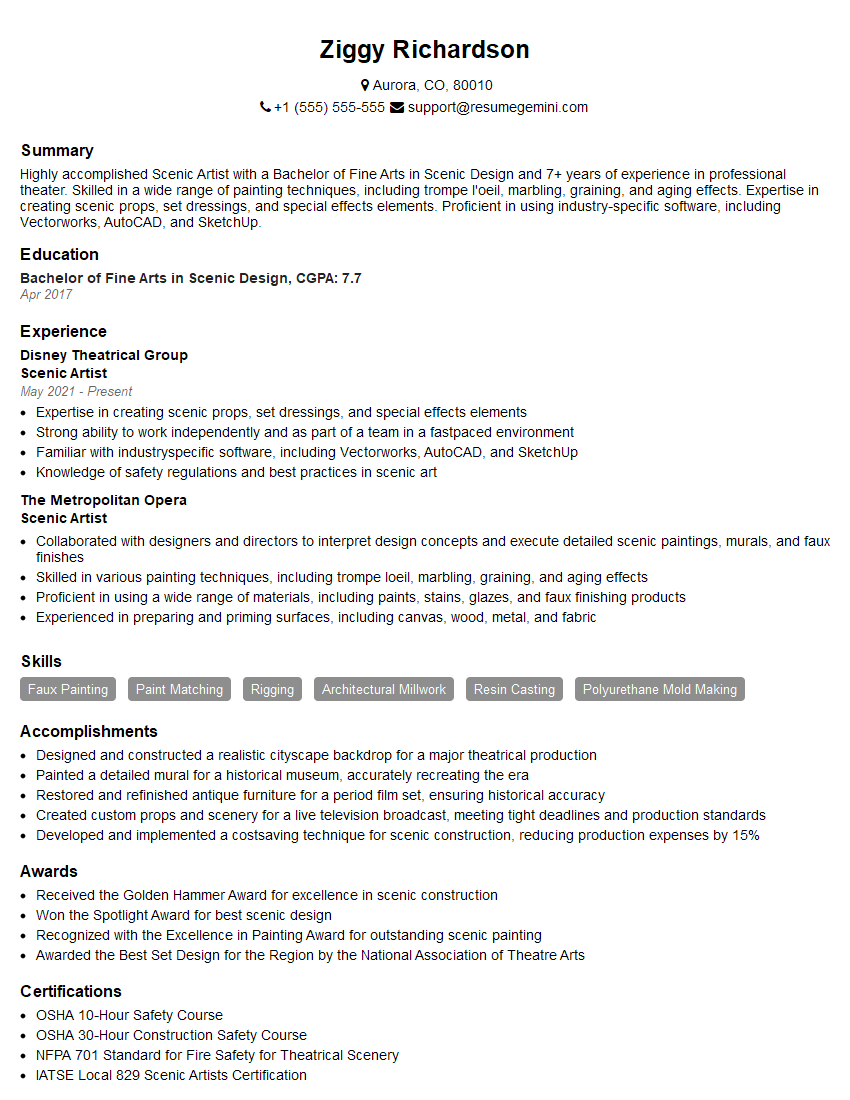

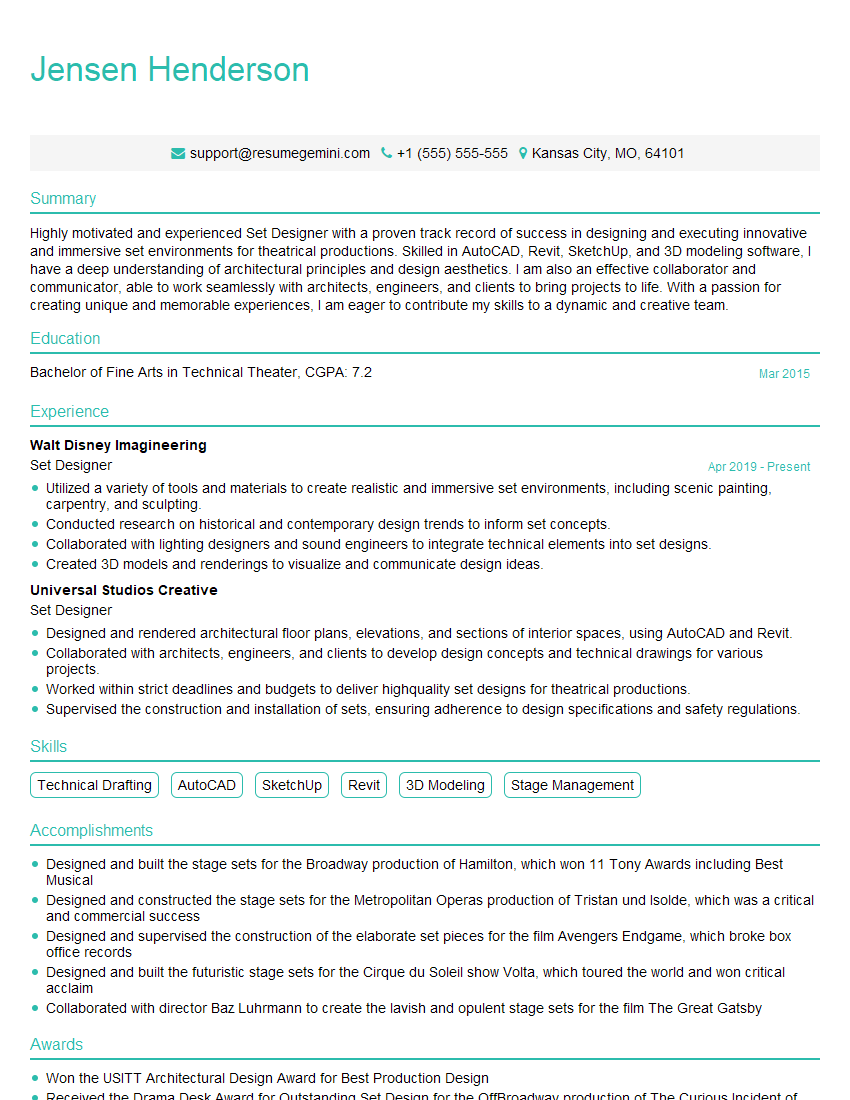

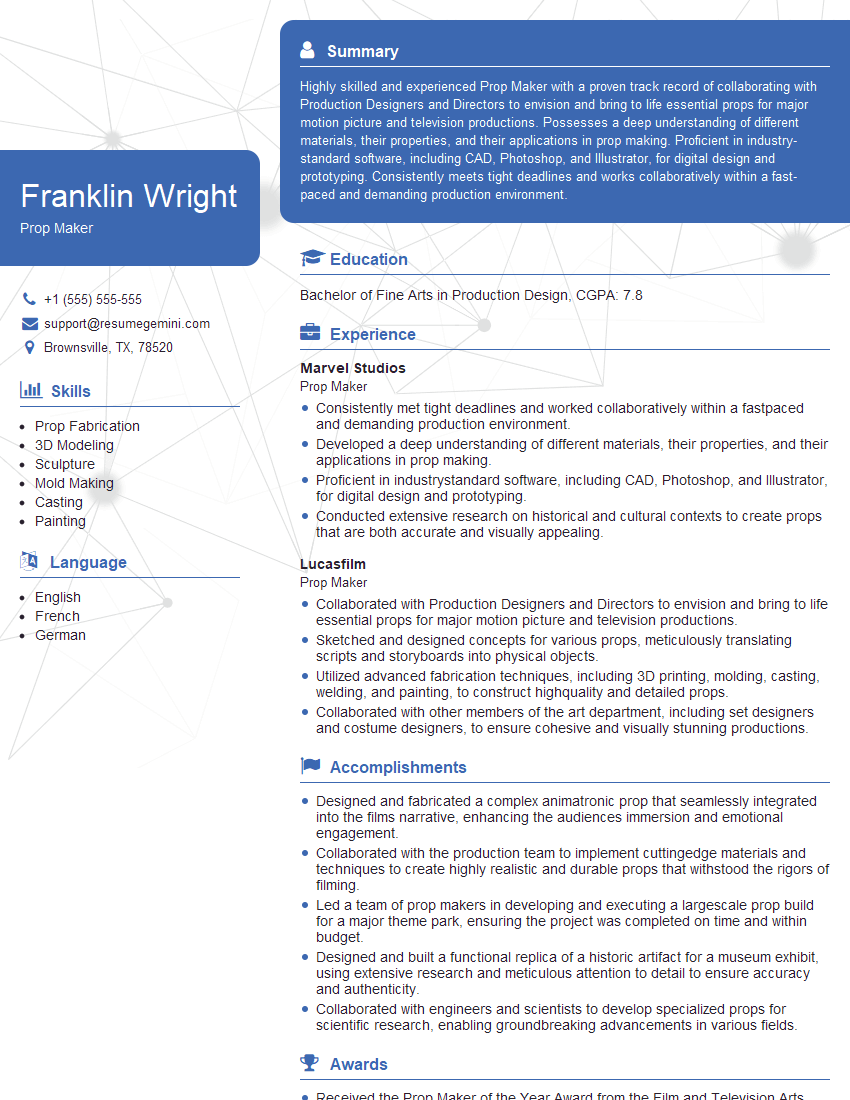

Mastering Prop Design and Construction opens doors to exciting and diverse career paths in film, theatre, television, gaming, and events. A strong understanding of these skills significantly boosts your marketability and earning potential. To maximize your job prospects, focus on creating an ATS-friendly resume that highlights your key achievements and skills. ResumeGemini is a trusted resource to help you build a professional and impactful resume tailored to the specific requirements of Prop Design and Construction roles. Examples of resumes tailored to this field are available for your review. Invest time in crafting a compelling resume; it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

we currently offer a complimentary backlink and URL indexing test for search engine optimization professionals.

You can get complimentary indexing credits to test how link discovery works in practice.

No credit card is required and there is no recurring fee.

You can find details here:

https://wikipedia-backlinks.com/indexing/

Regards

NICE RESPONSE TO Q & A

hi

The aim of this message is regarding an unclaimed deposit of a deceased nationale that bears the same name as you. You are not relate to him as there are millions of people answering the names across around the world. But i will use my position to influence the release of the deposit to you for our mutual benefit.

Respond for full details and how to claim the deposit. This is 100% risk free. Send hello to my email id: [email protected]

Luka Chachibaialuka

Hey interviewgemini.com, just wanted to follow up on my last email.

We just launched Call the Monster, an parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

We’re also running a giveaway for everyone who downloads the app. Since it’s brand new, there aren’t many users yet, which means you’ve got a much better chance of winning some great prizes.

You can check it out here: https://bit.ly/callamonsterapp

Or follow us on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call the Monster App

Hey interviewgemini.com, I saw your website and love your approach.

I just want this to look like spam email, but want to share something important to you. We just launched Call the Monster, a parenting app that lets you summon friendly ‘monsters’ kids actually listen to.

Parents are loving it for calming chaos before bedtime. Thought you might want to try it: https://bit.ly/callamonsterapp or just follow our fun monster lore on Instagram: https://www.instagram.com/callamonsterapp

Thanks,

Ryan

CEO – Call A Monster APP

To the interviewgemini.com Owner.

Dear interviewgemini.com Webmaster!

Hi interviewgemini.com Webmaster!

Dear interviewgemini.com Webmaster!

excellent

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good