Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Proper Equipment Handling interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Proper Equipment Handling Interview

Q 1. Describe your experience with pre-operational equipment checks.

Pre-operational equipment checks are crucial for ensuring safe and efficient operation. Think of it like a pilot performing a pre-flight checklist – it’s a systematic process to identify potential issues before they become hazards. My experience encompasses a rigorous multi-step approach, varying slightly depending on the equipment type, but always including visual inspections for damage, fluid level checks (oil, coolant, hydraulics), testing of operational controls (lights, brakes, safety mechanisms), and a review of any recent maintenance or repair records.

For example, when operating a forklift, I would check the tires for wear and tear, ensure the mast is properly aligned, test the horn and lights, verify the hydraulic fluid levels, and inspect the safety cage and seatbelts. If any abnormality is detected, I meticulously document it and report it immediately before proceeding.

Another example would be with a construction excavator. I’d inspect the tracks for damage, check the engine oil and coolant, test the bucket operation and hydraulics, and make sure all safety interlocks are functioning correctly.

Q 2. Explain the importance of following safety regulations when operating equipment.

Following safety regulations when operating equipment isn’t just about avoiding penalties; it’s about preventing injuries, fatalities, and property damage. Equipment can be incredibly dangerous if misused. Imagine a speeding car without brakes – that’s the potential risk without adherence to safety protocols.

Regulations often cover aspects like personal protective equipment (PPE) – think hard hats, safety glasses, gloves, and high-visibility clothing. They also dictate operational procedures, such as maintaining safe distances from others, using designated pathways, and following lockout/tagout procedures during maintenance. Ignoring these regulations can lead to serious consequences, both personally and professionally. Proper training and consistent reinforcement are critical to cultivate a safety-first mindset.

Q 3. How do you identify and report equipment malfunctions?

Identifying and reporting equipment malfunctions is a critical aspect of proactive maintenance and safety. My approach involves a combination of regular inspections, attentive operation, and immediate reporting of any anomalies. If I notice unusual sounds, vibrations, leaks, or performance issues, I immediately stop the equipment and conduct a thorough inspection.

Reporting is done through the established channels – typically a documented report filled out and submitted to my supervisor or a designated maintenance team. This report should meticulously detail the malfunction, including the type of equipment, the specific problem observed, the date and time, and any steps taken to mitigate the issue. Photos or videos can also be very useful to document the problem. The goal is to provide sufficient information for prompt repair and prevent further incidents.

Q 4. What are the common causes of equipment accidents, and how can they be prevented?

Common causes of equipment accidents often stem from human error, inadequate training, and poor maintenance. Rushing, fatigue, improper training and a lack of focus are all significant factors contributing to accidents. Poorly maintained equipment can lead to mechanical failures, resulting in malfunctions and potentially hazardous situations. Furthermore, a lack of adherence to safety regulations and poor communication among personnel working with equipment can also contribute to accidents.

Preventing these accidents requires a multifaceted approach. This involves providing comprehensive training, enforcing safety regulations, establishing clear communication protocols, and implementing a robust preventative maintenance program. Regular inspections, prompt repairs, and a culture of safety awareness within the workplace are paramount in mitigating risks.

Q 5. Describe your experience with different types of equipment.

My experience spans a variety of equipment types, including forklifts, excavators, loaders, bulldozers, aerial lifts, and various smaller tools and machinery. I’m proficient in operating these machines safely and efficiently. Each equipment type requires specific operating procedures, safety precautions, and maintenance practices. For example, operating a forklift requires a different skill set than operating an excavator, and knowledge of the nuances of each is critical for safe operation.

My experience extends beyond basic operation; I also understand the technical aspects of the equipment, including their mechanical components and safety systems. This allows me to conduct effective pre-operational checks and immediately recognize signs of malfunction. I am equally comfortable working with both heavy machinery on construction sites and more specialized equipment depending on the project requirements.

Q 6. How do you ensure the safe operation of heavy machinery?

Ensuring the safe operation of heavy machinery requires a combination of technical expertise, adherence to safety regulations, and a strong safety culture. Think of it as a layered approach: First, thorough training and certification are essential. Next, regular pre-operational checks are mandatory to detect potential problems early. Moreover, operating heavy machinery requires a clear understanding of the terrain, surrounding environment, and the potential hazards it presents. This includes being aware of other workers, obstacles, and potential blind spots.

Furthermore, maintaining a safe distance from bystanders and using appropriate signaling devices are crucial for preventing accidents. In addition, following lockout/tagout procedures during maintenance is non-negotiable for ensuring safety and preventing accidents during repair or maintenance operations. All personnel involved must strictly adhere to these procedures to prevent catastrophic failures. Finally, a strong safety culture, reinforced by leadership and regular training, forms the backbone of safe heavy machinery operation.

Q 7. What are your methods for maintaining equipment in optimal working condition?

Maintaining equipment in optimal working condition is an ongoing process that focuses on preventative maintenance, regular inspections, and prompt repairs. It’s not just about fixing things when they break; it’s about preventing breakdowns in the first place. This involves adhering to manufacturer’s recommended maintenance schedules, which typically include regular lubrication, fluid changes, and inspections for wear and tear.

My approach involves creating and meticulously maintaining a logbook for each piece of equipment, documenting all maintenance activities, inspections, and repairs. This logbook becomes a valuable tool for tracking equipment history, identifying trends, and scheduling necessary interventions. It also helps in adhering to regulatory requirements for maintaining records. Regular cleaning of the equipment is also a key component to ensure proper function and longevity.

Q 8. Explain your understanding of load capacity and its importance.

Load capacity refers to the maximum weight or load an equipment piece can safely handle without structural damage or operational failure. Understanding load capacity is paramount for preventing accidents, equipment damage, and injuries. It’s like knowing the weight limit of a bridge – exceeding it has catastrophic consequences.

For example, a forklift has a specified load capacity printed on its data plate. Operating it beyond that limit could lead to tipping, component failure, or even collapse. Similarly, a crane’s load capacity varies depending on the boom length and angle, and these factors must be carefully considered before lifting.

In my experience, I always double-check the load capacity before any lifting operation and ensure the load is properly distributed to avoid exceeding the limits. Using load indicators and employing a spotter are also crucial parts of safe operation.

Q 9. How do you handle unexpected equipment failures?

Unexpected equipment failures demand a swift and methodical response prioritizing safety. My approach involves a three-step process:

- Immediate Action: Immediately shut down the equipment using the emergency stop button or appropriate isolation procedures. Clear the area of personnel to prevent injury.

- Assessment: Assess the situation to determine the nature and extent of the failure. If possible, document observations, including photos or video evidence of the failure.

- Reporting and Repair: Report the failure to the appropriate supervisor and maintenance personnel. Follow the company’s established procedures for equipment repair and maintenance. Ensure the equipment undergoes thorough inspection and repair before being put back into service.

For instance, during a previous role, a hydraulic failure occurred on a large excavator. I immediately shut down the machine, cleared the area, and reported the issue to my supervisor. Maintenance personnel identified a leak in a hydraulic line, repaired it, and tested the system before the machine was cleared for operation again.

Q 10. Describe your experience with lockout/tagout procedures.

Lockout/Tagout (LOTO) procedures are crucial for preventing accidental equipment startup during maintenance or repair. My experience with LOTO involves a thorough understanding of the process, encompassing identification of energy sources, isolation, lockout devices application, and verification. This is about ensuring that no energy source can accidentally start the machine while it’s being worked on – preventing serious injury or death.

The process generally involves:

- Energy Isolation: Identifying all energy sources (electrical, hydraulic, pneumatic) connected to the equipment and safely isolating them.

- Lockout/Tagout Device Application: Applying appropriate lockout devices (locks and/or tags) to the energy isolation points, ensuring that only authorized personnel can release the locks.

- Verification: Testing the isolated equipment to confirm it is completely de-energized.

- Tagout Removal: Only the person who applied the lockout device can remove it after confirming that work is complete and the equipment is safe to restart.

I’ve personally participated in numerous LOTO procedures on various pieces of equipment, always emphasizing the importance of strict adherence to the established protocol, documentation, and teamwork to ensure everyone’s safety.

Q 11. How do you prioritize safety during equipment operation?

Prioritizing safety during equipment operation is not an option – it’s a necessity. My approach incorporates several key strategies:

- Pre-operational Checks: Performing thorough pre-operational checks before each use to identify any potential hazards or equipment malfunctions.

- Safe Operating Procedures: Adhering to established safety procedures and guidelines for each piece of equipment.

- Personal Protective Equipment (PPE): Consistently using appropriate PPE, such as safety glasses, hard hats, gloves, and steel-toe boots.

- Awareness of Surroundings: Maintaining constant awareness of the surrounding environment, including other workers, pedestrians, and obstacles.

- Reporting Hazards: Reporting any unsafe conditions or potential hazards immediately to the appropriate personnel.

Think of it like driving a car – regular maintenance, understanding the controls, and observing traffic laws all contribute to safe operation. Similarly, with equipment operation, regular checks, adherence to procedures, and continuous awareness dramatically reduce the risks of accidents.

Q 12. What are your strategies for preventing equipment damage?

Preventing equipment damage involves a proactive and preventative approach. My strategies include:

- Regular Maintenance: Implementing a robust preventative maintenance schedule to address potential issues before they cause significant damage.

- Proper Operation: Operating equipment according to manufacturer instructions and established best practices.

- Environmental Protection: Protecting equipment from harsh weather conditions (sun, rain, extreme temperatures) through proper storage and use of protective covers.

- Operator Training: Ensuring all operators receive comprehensive training on the proper operation and maintenance of the equipment.

- Proper Cleaning and Storage: Cleaning equipment after each use and storing it in a secure and appropriate location.

For instance, regularly lubricating moving parts prevents wear and tear, while storing equipment indoors prevents corrosion and damage from the elements. Investing in training ensures operators understand the importance of proper operation and maintenance, leading to longevity and reduced repair costs.

Q 13. Explain your experience with different types of lifting equipment.

I have extensive experience with various types of lifting equipment, including:

- Overhead Cranes: Experienced in operating various types of overhead cranes, including gantry cranes and jib cranes, understanding load charts, and proper rigging techniques.

- Forklifts: Proficient in operating different types of forklifts, ensuring safe load handling, and maintaining awareness of weight capacity and stability limits.

- Hoists: Familiar with chain hoists, electric hoists, and hand winches, adhering to safety regulations and proper inspection procedures.

- Jacks: Experienced with hydraulic and mechanical jacks, including proper placement and load distribution to prevent accidents.

My experience extends to the correct use of slings, chains, and other rigging components, ensuring appropriate selection based on the load characteristics and lifting environment. It’s vital to know the limitations and capabilities of each type of equipment to guarantee safe and efficient operation.

Q 14. How familiar are you with the use of Personal Protective Equipment (PPE)?

I am highly familiar with the use of Personal Protective Equipment (PPE) and its critical role in preventing workplace injuries. My understanding encompasses the selection, proper use, inspection, and maintenance of various PPE items. This isn’t just about wearing the equipment, but understanding why we wear it and its limitations.

My experience includes the consistent use of:

- Hard hats: Protecting against falling objects and impacts.

- Safety glasses or goggles: Protecting against flying debris and chemical splashes.

- Hearing protection: Reducing exposure to excessive noise levels.

- Gloves: Protecting hands from cuts, abrasions, chemicals, and extreme temperatures.

- Safety footwear: Protecting feet from crushing hazards and punctures.

- High-visibility clothing: Enhancing visibility in low-light conditions or areas with heavy traffic.

I believe that the proper use of PPE is an essential aspect of a comprehensive safety program and contributes significantly to the overall safety of the workplace.

Q 15. Describe your experience with equipment maintenance logs and records.

Equipment maintenance logs and records are crucial for tracking the health and performance of machinery, ensuring safety, and complying with regulations. My experience involves meticulously documenting all maintenance activities, including preventative maintenance schedules, repairs, inspections, and any part replacements. This documentation typically includes date, time, equipment ID, performed actions, parts used, and the technician’s signature. I utilize both digital and paper-based systems depending on the context and client requirements. For example, in one project involving a fleet of forklifts, I implemented a digital log using a dedicated software, allowing for easy data analysis and reporting on maintenance costs and equipment downtime. In another project involving older machinery, I maintained paper logs, ensuring they were securely stored and easily accessible.

- Preventative Maintenance: Scheduled lubrication, filter changes, and inspections are recorded to prevent major breakdowns.

- Corrective Maintenance: Repairs resulting from malfunctions, including the nature of the problem, the repair steps, and parts replaced, are detailed.

- Data Analysis: Regular review of the logs helps identify patterns in equipment failure, allowing for proactive maintenance strategies to minimize downtime and optimize maintenance schedules.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle equipment repairs and maintenance requests?

Handling equipment repairs and maintenance requests involves a systematic approach. First, I prioritize requests based on urgency and potential safety risks. A critical failure might require immediate action, while routine maintenance can be scheduled. Then, I assess the problem, either through direct observation or by discussing the issue with the reporting personnel. This involves understanding the symptoms, the context of the failure, and any recent changes that might have contributed to it. Once the problem is understood, I plan the repair or maintenance tasks. This might involve ordering parts, scheduling downtime, and ensuring the necessary tools and safety equipment are available. After the repair or maintenance is complete, I thoroughly document the work completed and ensure all safety checks are passed before the equipment is returned to service.

For example, when a conveyor belt system malfunctioned due to a broken pulley, I first assessed the immediate risk (potential for injury from moving parts), then secured the area, ordered a replacement pulley, and completed the repair adhering to all safety protocols. The repair was documented completely including photographs.

Q 17. What is your experience with different types of power sources (e.g., hydraulic, electric)?

I have extensive experience working with various power sources, including hydraulic, electric, pneumatic, and internal combustion engines. Understanding the principles of each power source is critical for safe and effective equipment operation and maintenance.

- Hydraulic Systems: I’m proficient in identifying potential leaks, understanding pressure regulation, and recognizing signs of hydraulic fluid contamination. Safety protocols surrounding high-pressure hydraulic systems are paramount.

- Electric Systems: I’m familiar with various electrical safety measures, including lockout/tagout procedures, proper grounding techniques, and the identification of electrical hazards. Understanding voltage levels and circuit diagrams is essential for troubleshooting and repair.

- Pneumatic Systems: I am experienced with compressed air systems, including understanding pressure regulators, air filters, and the importance of maintaining proper air pressure to avoid damage or malfunction.

- Internal Combustion Engines: I understand the principles of operation, maintenance schedules for oil changes, filter replacements, and the importance of regular inspections. Safety measures surrounding exhaust fumes and hot surfaces are crucial.

This diverse experience allows me to adapt to different equipment and environments. For example, while working on a construction site, I diagnosed a malfunction in a hydraulic excavator, tracing the problem to a faulty pressure relief valve and successfully completing the repair.

Q 18. Describe your experience with equipment operation in confined spaces.

Operating equipment in confined spaces presents unique challenges and requires strict adherence to safety protocols. Before entering any confined space, a thorough risk assessment is mandatory, including checking for hazardous atmospheres (lack of oxygen, presence of flammable gases), potential for entrapment, and access/egress points. Appropriate personal protective equipment (PPE), such as respirators, safety harnesses, and communication systems, must be used. Furthermore, a trained attendant should be present outside the confined space to monitor conditions and provide assistance if needed. Equipment should be selected appropriately for the space and thoroughly inspected before operation. In addition, regular communication with the attendant is essential to ensure ongoing safety and awareness of conditions inside the space. I have significant experience in confined space entry procedures, including following all applicable regulations and standards.

For example, during an inspection of an underground pipeline, I followed all safety procedures, including gas detection, utilizing appropriate PPE, and maintaining constant communication with my attendant. The equipment used was specifically chosen for its compact size and maneuverability within the confined space.

Q 19. How do you ensure the safe transportation of equipment?

Safe transportation of equipment is crucial to prevent damage and accidents. My approach prioritizes securing the equipment appropriately, using the right method of transport based on equipment size and weight. This includes using proper tie-down techniques, ensuring the equipment’s center of gravity is correctly balanced, and using appropriate padding or bracing to prevent shifting during transport. The method of transport should be appropriate for the terrain and conditions. For heavy or oversized equipment, special permits and escorts might be needed. Before transporting, a thorough pre-transport inspection should be carried out to identify any potential hazards or issues.

For example, when transporting a large generator, I ensured it was secured to a flatbed trailer using multiple tie-down straps, with additional padding to prevent damage during transit. I also confirmed the route was suitable for the size and weight of the equipment and acquired any necessary permits.

Q 20. How do you communicate effectively with others regarding equipment operation?

Effective communication is essential for safe and efficient equipment operation. I prioritize clear and concise communication, using both verbal and written methods. Before any operation begins, I discuss the task with relevant personnel, ensuring everyone understands their roles and responsibilities. During operation, I maintain open communication channels to address any concerns or unexpected issues promptly. After completion, I provide a thorough debriefing, highlighting any issues encountered and lessons learned. I also actively listen to others’ concerns and ensure that all safety issues are addressed immediately. A clear communication plan and established procedures greatly minimize misunderstandings and improve collaboration among the team.

For example, before operating a crane, I would discuss the lift plan with the crane operator, rigger, and spotter, ensuring everyone understands the load weight, the lift path, and the necessary safety precautions. During the lift, constant communication is maintained through hand signals and radio communication to ensure everyone is aware of the crane’s position and movement.

Q 21. What are your strategies for managing risks associated with equipment operation?

Managing risks associated with equipment operation involves a multi-layered approach. This starts with a thorough risk assessment, identifying potential hazards like electrical shock, falls, entanglement, and equipment malfunction. Then, I implement control measures to mitigate those risks. These measures can be hierarchical, starting with elimination of the hazard (if possible), then substitution of a less hazardous alternative, engineering controls (guarding, interlocks), administrative controls (training, procedures), and finally, personal protective equipment (PPE) as the last line of defense. Regular equipment inspections, maintenance, and operator training are key components of risk management. Furthermore, incident reporting and investigation are crucial to learning from past mistakes and preventing future incidents. A proactive and preventative approach is crucial to maintaining a safe working environment.

For example, when working with a scissor lift, I would first ensure the area below is clear of personnel, implement outriggers for stability, and check the lift’s safety mechanisms before operating. Regular inspections of the lift’s hydraulic system and safety components would also be implemented.

Q 22. How do you adapt to different types of equipment and operating procedures?

Adapting to new equipment and procedures involves a structured approach. First, I meticulously review all provided documentation, including manuals, safety protocols, and operating instructions. This ensures a thorough understanding of the equipment’s functionalities, limitations, and safety features. Then, I’ll conduct a hands-on familiarization, starting with a simulated run-through if possible, before progressing to actual operation under supervision. I actively seek clarification on any ambiguities and don’t hesitate to ask questions. For example, when transitioning from operating a standard forklift to a reach truck, I would focus on the extended reach capabilities and the unique safety considerations involved, like the increased risk of tip-over and the importance of precise load placement. This careful, step-by-step process minimizes errors and ensures safe and efficient operation.

Q 23. Explain your experience with using specialized tools and equipment.

My experience encompasses a wide range of specialized tools and equipment. I’ve worked extensively with heavy machinery, including excavators, bulldozers, and cranes, requiring proficiency in operating controls, understanding load capacities, and adhering to stringent safety regulations. I’m also experienced with precision instruments like laser levels and surveying equipment, used for precise measurements and land-grading projects. Furthermore, my experience includes the use of specialized tools for maintenance and repair, such as diagnostic equipment for identifying mechanical faults and hand tools for precise repairs. For example, during a construction project, I utilized a GPS-guided excavator to ensure precise trench digging for utility lines, reducing errors and improving efficiency. Each piece of equipment demands specific training and a keen eye for detail.

Q 24. How do you stay updated on new equipment and safety regulations?

Staying current in this field is crucial. I actively participate in industry-specific training courses and workshops offered by manufacturers and regulatory bodies. I regularly review updated safety manuals and regulations from OSHA and other relevant agencies. Professional journals, online resources, and manufacturer websites are also valuable sources of information on new technologies and best practices. For instance, I recently completed a course on the updated safety regulations for operating aerial work platforms, incorporating new technology and preventative measures into my procedures. Continuous learning ensures I’m proficient in using the latest equipment and upholding the highest safety standards.

Q 25. What is your approach to troubleshooting equipment problems?

My troubleshooting approach is systematic and methodical. First, I carefully observe the equipment’s behavior, noting any unusual sounds, vibrations, or malfunctions. Next, I consult the equipment’s manual and any available diagnostic tools to pinpoint the problem. If the issue persists, I follow a logical process of elimination, checking all possible causes – electrical components, hydraulic systems, mechanical parts – before attempting any repairs. For example, if a forklift experiences a sudden loss of power, I would systematically check the battery level, the charging system, the main power switch, and the control circuits before involving more advanced diagnostics or calling for professional help. This systematic approach ensures efficient and effective problem-solving while minimizing downtime.

Q 26. Describe your experience with working in a team environment to operate equipment.

Teamwork is essential in equipment operation, especially in large-scale projects. I have extensive experience collaborating effectively with colleagues, including engineers, technicians, and other operators. Effective communication, clear task assignments, and mutual respect are vital. During a recent bridge construction project, I worked as part of a crew, coordinating with a crane operator to precisely position prefabricated bridge segments. Clear communication through hand signals and radio ensured safe and efficient placement, demonstrating successful teamwork under challenging conditions. Collaboration also allows us to leverage everyone’s expertise for efficient problem-solving and enhanced safety.

Q 27. How would you respond to an emergency situation involving equipment malfunction?

My response to equipment malfunctions causing an emergency would be immediate and focused on safety. First, I’d shut down the equipment following established safety procedures. This is paramount to prevent further damage or injuries. Next, I would secure the area, warning others of the danger. Then, I’d assess the situation, determining the extent of the malfunction and any immediate risks. Finally, I’d report the incident using established channels, notifying supervisors and emergency services as needed, while adhering to all safety protocols. This proactive and systematic approach ensures both immediate safety and effective incident management.

Q 28. Explain your understanding of different types of equipment failures and their root causes.

Equipment failures can stem from various causes, broadly categorized as mechanical, electrical, or hydraulic. Mechanical failures could involve wear and tear, component fatigue (like broken gears or cracked shafts), or improper lubrication. Electrical failures might be caused by short circuits, faulty wiring, or damaged control systems. Hydraulic failures could result from leaks, contamination, or pump malfunctions. For example, a repetitive clicking sound in a piece of machinery might indicate a worn gear, while loss of hydraulic pressure would point toward a leak or pump problem. Understanding these root causes necessitates a solid understanding of the equipment’s design and operational principles. Identifying these problems early through regular maintenance and checks can prevent significant failures and downtime.

Key Topics to Learn for Proper Equipment Handling Interview

- Equipment Selection and Inspection: Understanding criteria for selecting the right equipment for a task, including safety considerations and proper pre-use inspection procedures. Practical application: Describing your process for checking a forklift for safety issues before operation.

- Safe Operating Procedures: Mastering the specific operating procedures for various types of equipment, adhering to manufacturer guidelines and industry best practices. Practical application: Explaining your approach to operating a crane safely and efficiently, highlighting adherence to load limits and safety protocols.

- Maintenance and Preventative Care: Knowing the importance of routine maintenance, recognizing signs of equipment malfunction, and performing basic preventative care. Practical application: Describing your experience in performing basic maintenance tasks on machinery and identifying potential problems before they escalate.

- Emergency Procedures and Safety Protocols: Understanding emergency shutdown procedures, safety protocols in case of malfunctions or accidents, and appropriate response to different scenarios. Practical application: Explaining your actions in a hypothetical equipment malfunction scenario, emphasizing safety and preventing further incidents.

- Ergonomics and Safe Lifting Techniques: Applying principles of ergonomics to minimize risk of injury during equipment operation and maintenance. Practical application: Describing how you would lift heavy components safely using appropriate lifting techniques and equipment.

- Regulations and Compliance: Familiarity with relevant safety regulations and compliance standards related to equipment handling in your industry. Practical application: Explaining your understanding of OSHA regulations regarding forklift operation or similar industry-specific regulations.

Next Steps

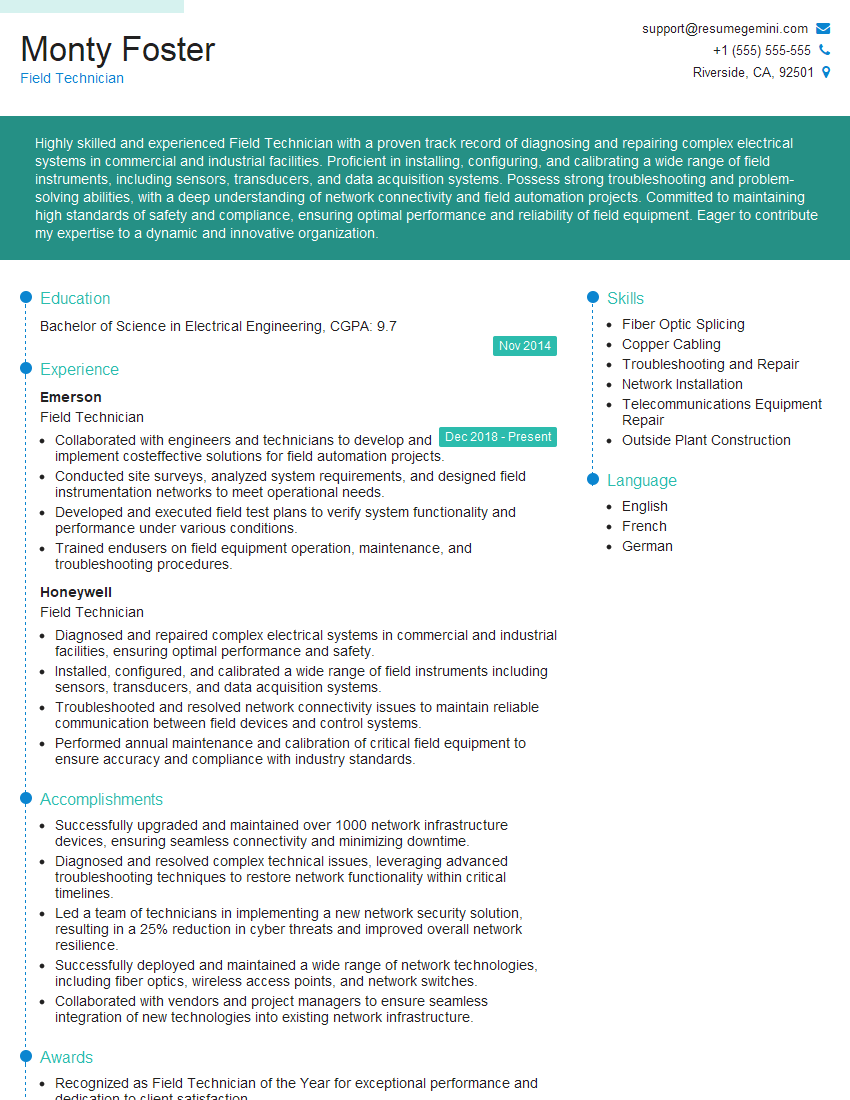

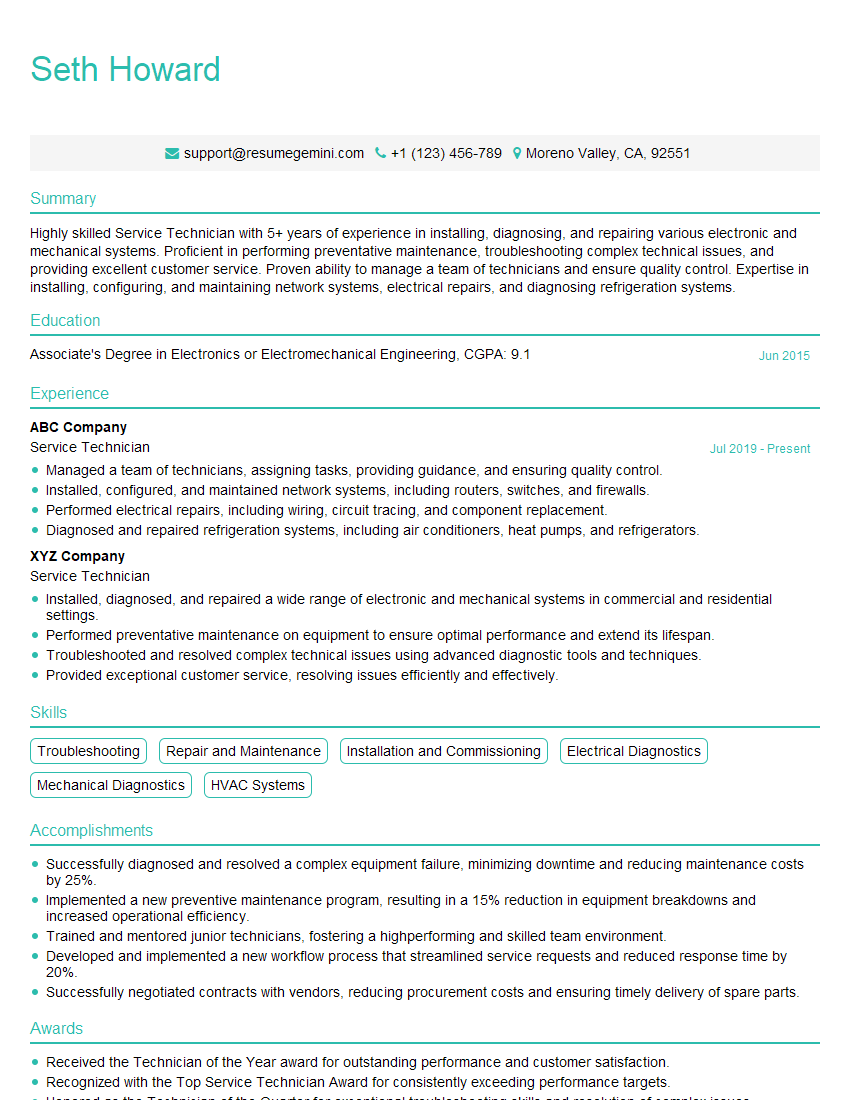

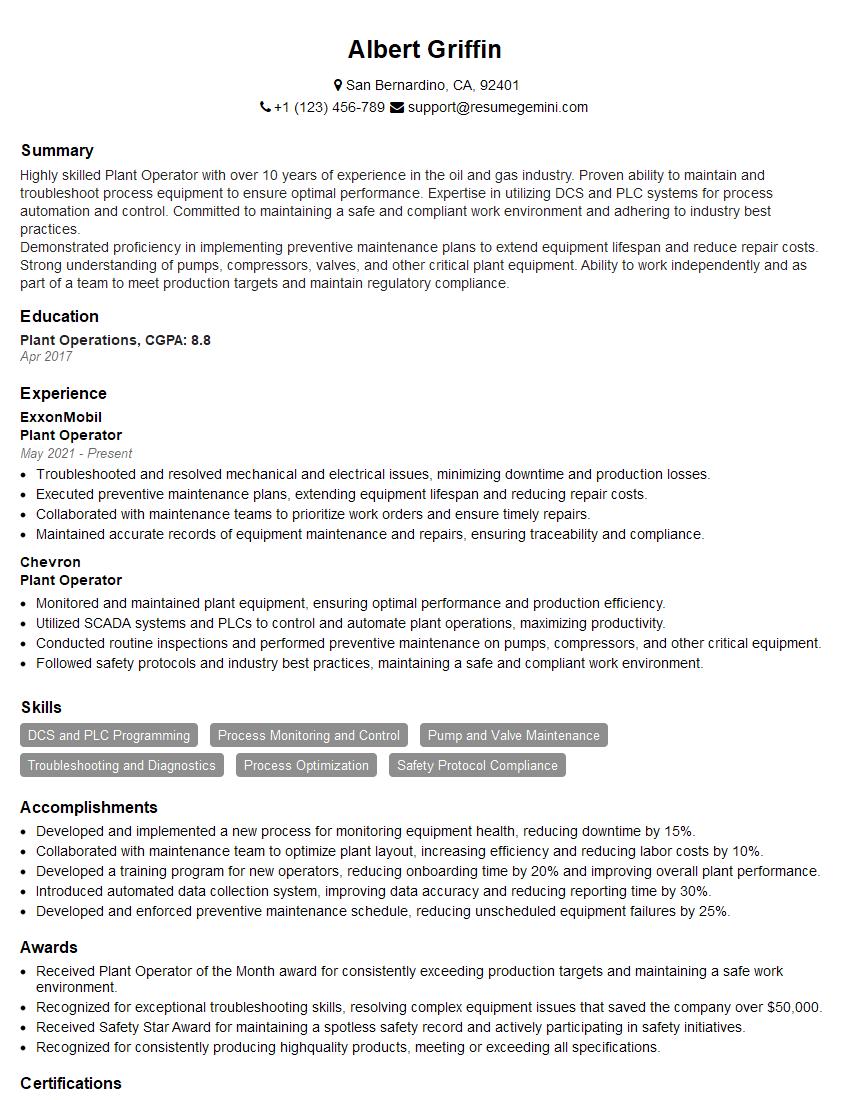

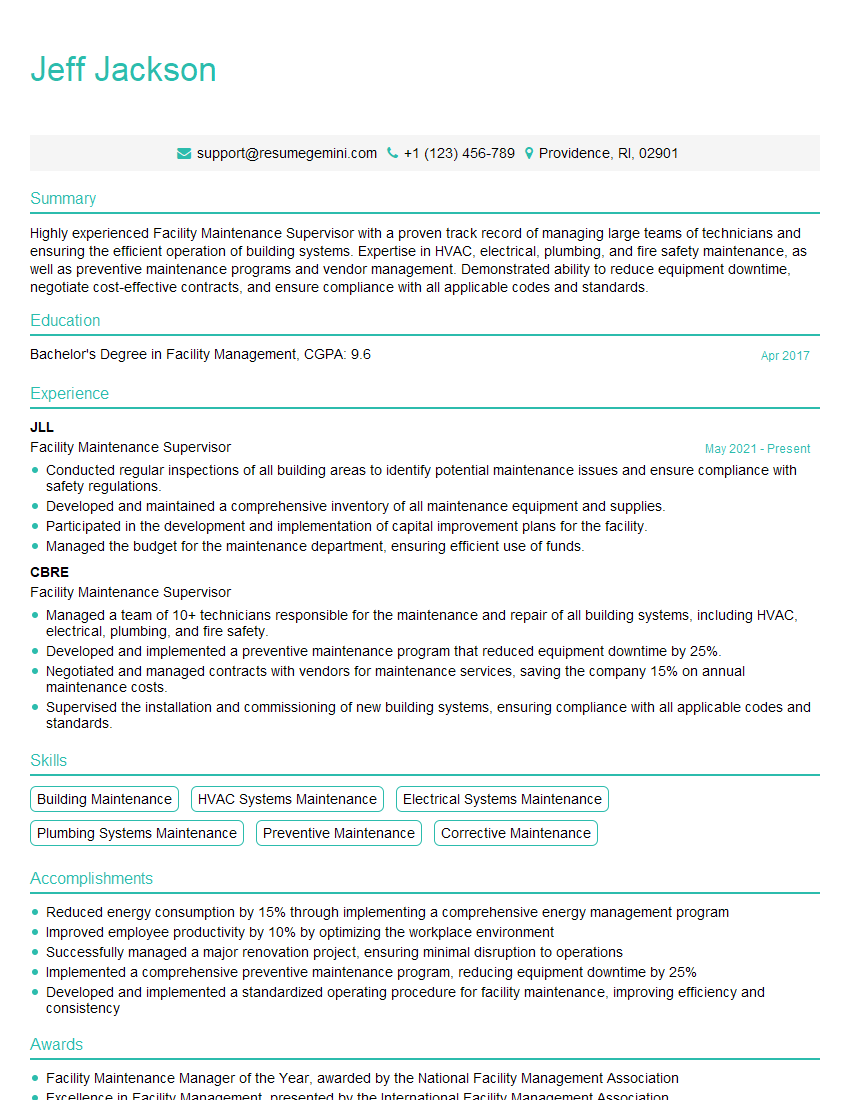

Mastering Proper Equipment Handling is crucial for career advancement in many fields, showcasing your commitment to safety and efficiency. A strong resume is your key to unlocking opportunities. Creating an ATS-friendly resume significantly increases your chances of getting noticed by recruiters. To help you craft a compelling and effective resume, we recommend using ResumeGemini. ResumeGemini provides a user-friendly platform and offers examples of resumes tailored specifically to Proper Equipment Handling, helping you present your skills and experience in the best possible light. Take the next step in your career journey today!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good