Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Pulverizing Equipment Operation interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Pulverizing Equipment Operation Interview

Q 1. Describe the different types of pulverizers and their applications.

Pulverizers come in various types, each designed for specific applications based on material properties and desired particle size. The choice depends heavily on factors like material hardness, moisture content, and the required fineness of the final product.

- Hammer Mills: These use high-speed hammers to impact and shatter materials. They’re ideal for relatively soft and brittle materials like grains, coal, and some plastics. Imagine a high-powered blender, but much more robust and designed for tougher jobs.

- Roller Mills: These employ rollers to crush and grind materials between rotating surfaces. They are excellent for harder materials like ores and cement clinker, offering precise control over particle size. Think of it like a giant, industrial rolling pin that crushes materials to a fine powder.

- Ball Mills: These use tumbling steel balls inside a rotating cylinder to grind materials through impact and attrition. They are well-suited for very fine grinding of materials like pigments, minerals, and ceramics. Picture a giant, rotating drum filled with steel balls that pulverize the material within.

- Jet Mills: These utilize high-velocity air streams to impact and break down materials. They are particularly effective for fine grinding of soft materials and those sensitive to heat, such as pharmaceuticals or food products. This is like a powerful air blast that breaks down the material into tiny pieces.

- Ultrafine Pulverizers: As the name suggests, these are designed to create extremely fine powders, commonly used in industries like nanotechnology and advanced materials processing. These operate under precise conditions to control the final particle size distribution.

The selection of a pulverizer often involves a careful consideration of these different mechanisms and their suitability for the specific application.

Q 2. Explain the principle of size reduction in pulverizing.

Size reduction in pulverizing relies on several fundamental principles, all involving the application of forces to break down larger material chunks into smaller particles. These forces can be compressive, impact, shear, or attrition forces.

- Compression: Crushing the material between two surfaces, like in roller mills.

- Impact: Striking the material with high-speed objects, as seen in hammer mills.

- Shear: Cutting or tearing the material through the action of moving surfaces, as in some types of cutting mills.

- Attrition: Grinding the material through friction and abrasion from rubbing against other particles, a key principle in ball mills.

The effectiveness of size reduction depends on the type of pulverizer, the material properties (hardness, toughness, friability), and the operating parameters (speed, feed rate, etc.). For example, a hard material may require a roller mill or a ball mill, while a softer material might be effectively processed in a hammer mill.

Q 3. How do you ensure the safety of operating pulverizing equipment?

Safety during pulverizer operation is paramount. A multi-layered approach is essential, encompassing equipment design, operating procedures, and regular maintenance.

- Lockout/Tagout Procedures: Strict adherence to lockout/tagout procedures is crucial before any maintenance or repair work is performed. This prevents accidental start-ups and injuries.

- Personal Protective Equipment (PPE): Operators must always wear appropriate PPE, including safety glasses, hearing protection, respirators (to prevent inhalation of dust), and sturdy footwear. In many cases, full body protection suits might be necessary.

- Regular Inspections: Regular inspections of the equipment for wear and tear, loose components, and other potential hazards are essential to prevent failures. This might include visual checks and potentially vibration monitoring.

- Emergency Shutdown Systems: Functional emergency stop buttons and other safety interlocks must be regularly checked and maintained to ensure rapid shutdowns in case of emergencies.

- Dust Collection: Effective dust collection systems are necessary to prevent dust explosions and exposure to harmful particulates. Regular cleaning and maintenance of the dust collection system are paramount.

- Training: Thorough training for operators is essential, covering safe operating procedures, emergency response protocols, and the identification of potential hazards.

Safety is a continuous process and should not be treated as a one-time activity. A robust safety culture is critical for a successful and safe operation of pulverizing equipment.

Q 4. What are the common safety hazards associated with pulverizers?

Pulverizers present several significant safety hazards:

- Dust Explosions: Fine particles suspended in the air can create highly explosive mixtures, especially in the presence of ignition sources.

- Rotating Parts: High-speed rotating components, such as hammers, rollers, or grinding balls, pose a significant risk of entanglement or impact injuries.

- Material Handling: Handling raw materials and finished products can lead to cuts, abrasions, or other injuries if proper precautions aren’t taken.

- Noise Pollution: The operation of pulverizers generates considerable noise, potentially leading to hearing loss if proper hearing protection is not used.

- Fire Hazards: Some materials processed in pulverizers can be flammable, increasing the risk of fire.

- Equipment Failures: Mechanical failures can lead to unexpected releases of materials, causing injuries or damage.

Understanding these hazards and implementing appropriate safety measures is vital to prevent accidents and ensure a safe working environment.

Q 5. What are the different types of mills used in pulverizing?

Many different types of mills are employed in pulverizing, each with specific design features and applications:

- Ball Mills: As mentioned earlier, these use tumbling balls for grinding. They’re versatile and suitable for a wide range of materials.

- Rod Mills: Similar to ball mills but use rods instead of balls, often used for coarser grinding.

- Hammer Mills: Employ high-speed hammers for impact crushing.

- Roller Mills: Use rotating rollers for compression and crushing.

- Attrition Mills: Utilize friction between surfaces to grind materials.

- Ultrafine Mills: Designed for producing extremely fine powders.

- Jet Mills: Use high-velocity air streams for impact grinding.

- Vertical Roller Mills: Operate vertically, with rollers grinding material against a stationary surface.

The choice of mill depends on factors like the material’s hardness, the desired particle size, and the throughput requirements.

Q 6. Explain the concept of particle size distribution and its importance.

Particle size distribution (PSD) refers to the range of particle sizes present in a pulverized material and their relative proportions. It’s typically represented by a graph showing the percentage of particles within specific size ranges (e.g., microns or millimeters).

PSD is crucial because it significantly impacts various properties of the material, such as:

- Reactivity: Finer particles typically have a larger surface area, leading to increased reactivity in chemical processes.

- Flowability: A well-defined PSD is essential for good flowability, crucial in many industrial processes.

- Packing Density: PSD affects how tightly particles pack together, influencing bulk density and storage efficiency.

- Product Quality: In many applications, a specific PSD is required to meet quality standards, such as in the production of pharmaceuticals or pigments.

For example, in cement production, a precise PSD is needed to ensure the correct setting time and strength of the cement. Similarly, in pharmaceutical manufacturing, the PSD of drug powders greatly impacts their dissolution rate and bioavailability.

Q 7. How do you troubleshoot common problems in pulverizing equipment?

Troubleshooting pulverizing equipment involves a systematic approach to identify and resolve issues. It often starts with a thorough assessment of the problem and then moves to targeted investigations.

Step-by-step troubleshooting strategy:

- Identify the problem: What specifically is going wrong? Is the output particle size incorrect? Is the throughput too low? Are there vibrations or unusual noises?

- Gather data: Collect relevant data such as feed rate, mill speed, power consumption, and the PSD of the output material. This provides a baseline for comparison.

- Check the obvious: Begin with simple checks, such as ensuring adequate feed material, checking for blockages, and verifying proper lubrication. This often quickly reveals easy fixes.

- Inspect the components: Visually inspect critical components like hammers, rollers, grinding balls, screens, and bearings for wear, damage, or misalignment. Check for any unusual wear patterns which could be indicative of problems in the system.

- Check operational parameters: Review and adjust operational parameters such as mill speed, feed rate, and air flow (if applicable) to see if this improves the situation. The optimal parameters depend heavily on the type of mill and material being processed.

- Consult manuals and experts: Refer to the equipment’s operation and maintenance manual for troubleshooting guides. Consult with experienced engineers or technicians if the problem remains unresolved.

Remember that safety is the utmost priority during troubleshooting. Always follow lockout/tagout procedures and wear appropriate PPE before attempting any repairs or adjustments.

Q 8. How do you maintain and perform preventative maintenance on pulverizers?

Preventative maintenance on pulverizers is crucial for ensuring consistent performance, safety, and longevity. It’s not just about fixing breakdowns; it’s about preventing them. A robust preventative maintenance program involves a combination of scheduled inspections, lubrication, and component replacement.

- Regular Inspections: Visual inspections should be carried out daily to check for wear and tear on components such as hammers, screens, and bearings. Look for signs of excessive wear, cracks, or misalignment. Pay close attention to vibration levels – increased vibration can signal impending failure.

- Lubrication: Proper lubrication of bearings and moving parts is essential to reduce friction and extend their lifespan. Follow the manufacturer’s recommendations for the type and frequency of lubrication. Over-lubrication can be as damaging as under-lubrication.

- Component Replacement: Replace worn-out components proactively according to a scheduled maintenance plan. Waiting until a component fails completely can lead to costly downtime and damage to other parts of the pulverizer. For example, worn hammers should be replaced before they become too blunt to effectively pulverize material, and screens need replacing when they become clogged or excessively worn, reducing the particle size consistency of the output.

- Motor and Drive Maintenance: Regular checks on the motor and drive system, including belts, pulleys, and couplings, are vital. Look for signs of slippage, wear, or damage.

Example: In a cement plant, a weekly inspection of the pulverizer might involve checking the oil level in the bearings, visually inspecting the hammers for wear, and checking the screen for clogging. A monthly inspection might include a more thorough examination of the motor and drive system.

Q 9. Describe the process of calibrating and validating pulverizing equipment.

Calibrating and validating pulverizing equipment ensures accurate and consistent particle size reduction. Calibration involves adjusting the equipment to meet pre-defined specifications, while validation confirms that the equipment consistently performs as intended.

- Calibration: This typically involves adjusting parameters such as rotor speed, screen size, and feed rate. Calibration procedures are specific to each pulverizer model and should be performed following the manufacturer’s instructions. Often, this involves using calibrated tools and measuring devices to adjust settings and verify their accuracy. For example, adjusting the gap between the hammers and the rotor housing might require precise measurements using calibrated gauges.

- Validation: Validation involves testing the pulverizer’s performance using a representative sample of the material being processed. The particle size distribution of the pulverized material is then analyzed using methods such as sieve analysis or laser diffraction. The results are compared to pre-defined acceptance criteria to ensure that the pulverizer is producing the desired particle size distribution consistently. If the results deviate from the acceptance criteria, adjustments need to be made through recalibration. Regular validation helps document consistent performance.

Example: In a pharmaceutical setting, where precise particle size is critical, a validation process might include several test batches to confirm the pulverizer consistently produces material within a specific particle size range, often documented and tracked using a quality control system.

Q 10. What are the quality control measures in place for pulverized materials?

Quality control for pulverized materials is crucial to ensure that the final product meets the required specifications. Measures include:

- Particle Size Analysis: This is the most important quality control measure, ensuring the product meets the desired particle size distribution. Methods include sieve analysis, laser diffraction, and image analysis.

- Moisture Content Determination: Moisture content affects the flowability and other properties of the pulverized material. This is determined using techniques like oven drying or Karl Fischer titration.

- Chemical Composition Analysis: For certain applications, it’s essential to check the chemical composition of the pulverized material to ensure it meets purity and other requirements. This may involve techniques like X-ray fluorescence (XRF) or inductively coupled plasma mass spectrometry (ICP-MS).

- Visual Inspection: A visual check for foreign material, color consistency, and agglomeration is a straightforward but important QC step.

- Statistical Process Control (SPC): SPC charts help monitor the consistency of the pulverization process over time. This involves tracking key parameters such as particle size, moisture content, and production rate to identify potential issues early on.

Example: In a food processing facility pulverizing spices, visual inspection for foreign objects, particle size analysis to ensure even grinding, and moisture content checks to prevent clumping are all vital QC steps.

Q 11. How do you interpret and respond to control panel alarms?

Control panel alarms indicate potential problems within the pulverizer. How you respond depends on the specific alarm. A well-trained operator understands the meaning of each alarm and has a defined procedure for handling it.

- High Temperature Alarm: This indicates overheating, potentially due to friction, insufficient cooling, or a malfunctioning bearing. First, stop feeding material to the pulverizer. Then, check the cooling system and investigate the source of the heat. Do not attempt repairs while the system is hot.

- Low Oil Pressure Alarm: This signifies low lubricating oil pressure in bearings, indicating potential damage. Stop the pulverizer immediately and check the oil level. Address any leaks or problems with the lubrication system.

- Motor Overload Alarm: This occurs if the motor is drawing too much current. Check for blockages or an unusually high feed rate.

- Vibration Alarm: Increased vibration suggests imbalance, misalignment, or wear in rotating components. Stop the machine and investigate the cause of the vibration before restarting.

Important Note: Always refer to the machine’s specific manual for detailed troubleshooting instructions for each alarm. Safety should always be the priority. If unsure about the cause of an alarm, seek assistance from experienced personnel or contact the equipment manufacturer.

Q 12. What are the factors that affect the efficiency of a pulverizer?

Several factors influence a pulverizer’s efficiency, which refers to its ability to reduce material to the desired particle size at a given rate with minimal energy consumption.

- Material Properties: Hardness, brittleness, moisture content, and particle size distribution of the feed material significantly impact pulverization efficiency. Hard and tough materials require more energy to pulverize.

- Pulverizer Design: The type of pulverizer (impact, attrition, or compression), rotor design, hammer configuration, screen size, and overall machine construction impact efficiency. An optimally designed pulverizer will effectively transfer energy to the material being pulverized.

- Operating Parameters: Rotor speed, feed rate, and screen opening size affect efficiency. An excessively high feed rate can overload the pulverizer, reducing its efficiency and increasing wear. Similarly, incorrect rotor speed can reduce the pulverization rate and impact the particle size distribution.

- Maintenance: Regular maintenance ensures that the pulverizer is operating at peak efficiency. Worn components reduce efficiency and may lead to increased energy consumption.

Example: A pulverizer processing wet clay will require more energy and potentially operate at lower efficiency than one processing dry, brittle material. A well-maintained pulverizer will consistently operate at higher efficiency than a neglected one.

Q 13. How do you handle material jams or blockages in the pulverizer?

Material jams or blockages are common issues in pulverizers. The handling procedure depends on the type of blockage and the specific pulverizer design. Safety is paramount; always ensure the equipment is turned off and locked out before attempting to clear a blockage.

- Identify the Blockage Location: Determine the location of the blockage using visual inspection and listening for unusual sounds.

- Safe Access: Access the blockage area safely, following all lockout/tagout procedures. Use appropriate personal protective equipment (PPE).

- Removal Methods: Depending on the location and type of material, you might use compressed air, a cleaning rod, or other tools to clear the blockage. Never use excessive force, as this could damage the pulverizer. For stubborn blockages, you may need to partially disassemble parts of the pulverizer. This should only be done by trained personnel.

- Preventative Measures: Once the blockage is cleared, assess the root cause to prevent future occurrences. This might involve adjustments to the feed rate, material handling, or screen size.

Example: If a blockage occurs in the screen, you might carefully use a compressed air gun or a cleaning rod to dislodge the clumped material. If a large piece of material jams the feed chute, you might need to manually remove it from the chute, taking care not to damage the pulverizer’s components.

Q 14. Explain the difference between impact, attrition, and compression pulverization.

Three main types of pulverization exist: impact, attrition, and compression. They differ in their mechanisms for particle size reduction.

- Impact Pulverization: This involves striking the material with high-velocity hammers or other impactors. The kinetic energy of the impact breaks down the material. Examples include hammer mills and impactors. They’re effective for brittle materials.

- Attrition Pulverization: This uses the shearing and rubbing action between particles to reduce their size. The material is subjected to repeated frictional forces, causing it to break down. Examples include roller mills and attritors. This method is suitable for softer, more pliable materials.

- Compression Pulverization: This uses compressive forces to break down the material. The material is squeezed between rollers or other compression elements. Examples include roller mills and compression mills. This method is often used for materials that are relatively soft and easily compressed.

Example: A hammer mill (impact) might be used to pulverize coal, while a roller mill (compression/attrition) might be better suited for grinding grain.

Q 15. Describe your experience with different types of pulverizer feed systems.

Pulverizer feed systems are crucial for efficient and safe operation. The choice of system depends heavily on the material’s properties (e.g., size, moisture content, abrasiveness) and the desired throughput. I’ve worked extensively with several types:

Gravity Feed: Simple and cost-effective for free-flowing materials. Think of a hopper feeding material into a mill. However, it’s limited by the material’s flowability; clogging can occur with sticky materials. I’ve used this successfully with limestone and certain dry ores.

Screw Feeders: Ideal for handling materials with varying flow characteristics. The screw pushes the material into the pulverizer, ensuring a consistent feed rate. This is beneficial for materials prone to bridging or arching, a common problem I’ve encountered with damp coal. Accurate control of the feed rate is a key advantage.

Belt Conveyors: Used for high-throughput operations and handling larger quantities of material. They are particularly useful when transporting material from a stockpile or over longer distances. I’ve utilized belt conveyors in cement plants to supply raw materials to large hammer mills.

Pneumatic Conveyors: Employ compressed air to transport materials, especially suitable for fine, dry materials. This method minimizes material degradation during transport. I’ve seen pneumatic systems used with fine powders in the pharmaceutical industry to feed to air-swept mills.

Selecting the appropriate feed system is vital for optimizing pulverizer performance and preventing operational issues.

Career Expert Tips:

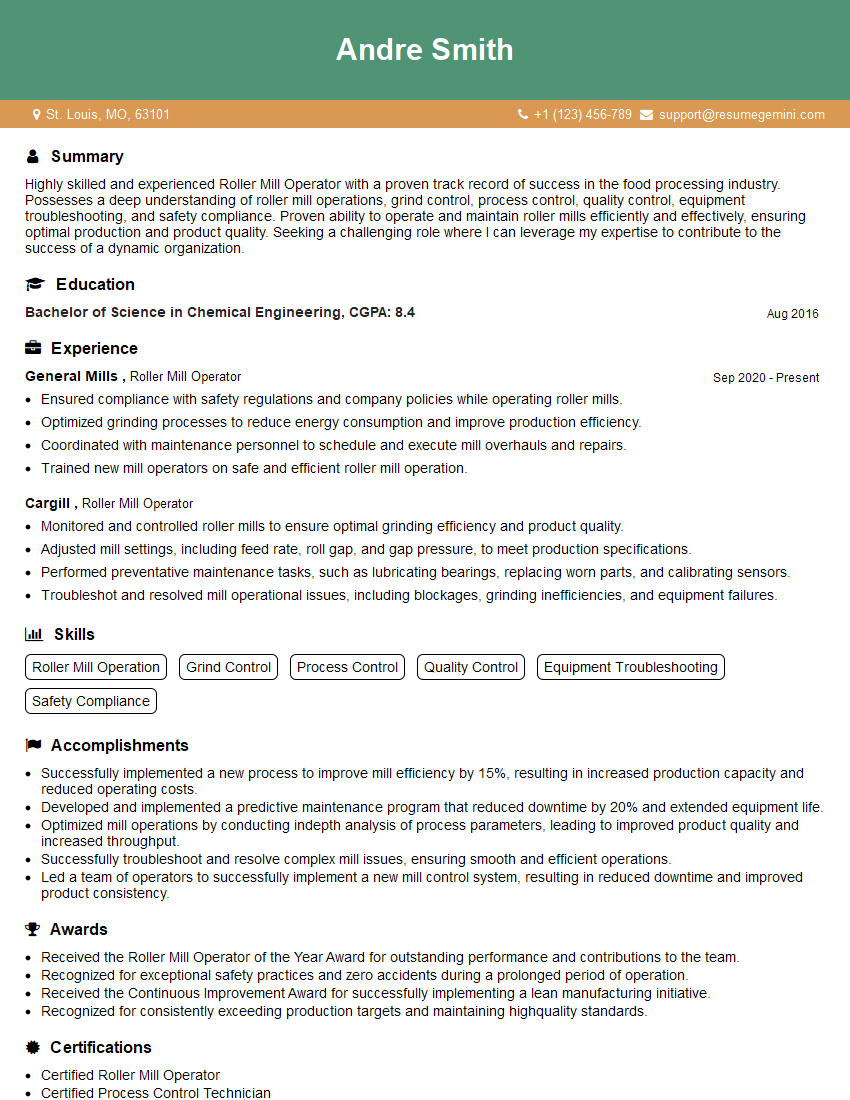

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. What is the role of classifiers in pulverizing operations?

Classifiers are integral to pulverizing operations, ensuring the final product meets the desired particle size distribution. They separate the oversized particles from the fines, sending the oversized particles back to the pulverizer for further processing. This closed-loop system enhances efficiency and product consistency.

Different types of classifiers exist, including air classifiers, which use airflow to separate particles based on their size and density, and screen classifiers, which use mesh screens to separate particles. The choice of classifier depends on factors such as particle size range, material properties, and desired throughput. For instance, in cement production, air classifiers are often used to achieve the fine particle size needed for optimal cement hydration.

Without effective classification, the final product may contain a wide range of particle sizes, compromising its quality and performance in downstream applications. Think of making concrete—inconsistently sized cement would affect the strength and workability of the concrete mix.

Q 17. How do you ensure the consistent quality of the final product?

Maintaining consistent product quality is paramount. It involves a multi-pronged approach:

Regular Monitoring and Calibration: Continuous monitoring of key parameters such as feed rate, mill speed, and classifier settings is crucial. Regular calibration of instruments ensures accurate measurements.

Process Control Systems: Automated control systems help maintain consistent operating parameters, reducing human error. These systems often include feedback loops to adjust settings based on real-time data, like particle size analysis.

Quality Control Testing: Regular sampling and testing of the final product using techniques like sieve analysis and laser diffraction ensure compliance with specified particle size distribution and other quality criteria. We would use statistical process control (SPC) charts to monitor these parameters over time.

Preventive Maintenance: Regular maintenance of the pulverizer and classifier prevents wear and tear, ensuring optimal performance. This includes regular inspections, lubrication, and component replacement as needed.

By implementing these measures, we ensure that the final product consistently meets the required specifications.

Q 18. Describe your experience with various types of pulverized materials.

My experience encompasses a wide range of materials, each presenting unique challenges. I’ve worked with:

Minerals: Limestone, gypsum, and various ores require different pulverizing techniques due to variations in hardness, abrasiveness, and moisture content. For example, hard ores necessitate more robust mills and potentially higher energy input.

Coal: Coal pulverization is crucial for power generation. Its moisture content and tendency to form agglomerates require careful control of feed rate and mill design.

Agricultural Products: Grains, seeds, and other agricultural products often require gentler pulverizing to avoid damaging the material or generating excessive heat. Low-speed impact mills might be preferred here.

Chemicals and Pharmaceuticals: These often require very fine particle sizes and stringent quality control measures. Specialized mills with advanced dust collection systems are essential.

Adapting techniques and equipment to the specific properties of each material is critical for optimal pulverization and maintaining product quality.

Q 19. How do you manage waste and by-products from pulverizing?

Waste and by-product management in pulverizing operations is crucial for environmental compliance and operational efficiency. Strategies include:

Recycling: Oversized particles returned to the mill for further processing minimize waste.

Proper Disposal: Waste materials are disposed of according to environmental regulations. This might involve landfill disposal or specialized treatment depending on the material’s composition.

Dust Collection and Treatment: Efficient dust collection systems capture fine particles, minimizing airborne emissions. Collected dust may be recycled or disposed of according to regulations.

Process Optimization: Improving the efficiency of the pulverizing process reduces the generation of by-products and waste.

A well-managed waste management program is vital for sustainability and compliance.

Q 20. What are the environmental considerations related to pulverizing?

Environmental considerations are paramount in pulverizing operations. Key concerns include:

Air Emissions: Dust generation is a major environmental concern, leading to air pollution and potential respiratory problems. Strict regulations govern airborne emissions, mandating the use of effective dust collection and control systems.

Noise Pollution: Pulverizers can generate significant noise, potentially impacting nearby communities. Noise reduction measures, such as enclosures and sound dampening materials, are often necessary.

Water Usage: Some pulverizing processes use water for cooling or material handling. Minimizing water usage and implementing water recycling techniques are essential for water conservation.

Waste Management: Proper disposal of waste materials and by-products is vital to prevent environmental contamination.

Adherence to environmental regulations and the implementation of best practices are crucial for minimizing the environmental impact of pulverizing operations.

Q 21. Explain the importance of proper ventilation and dust collection systems.

Proper ventilation and dust collection systems are essential for safety and environmental compliance in pulverizing operations. These systems prevent the accumulation of dust, which can be a fire hazard, and minimize airborne emissions of potentially harmful materials.

Ventilation systems remove dust and other airborne particles from the pulverizer area, creating a safe working environment. Dust collection systems, employing methods like baghouses or cyclones, capture dust particles for further processing or disposal. These systems are often equipped with monitoring devices to track dust levels and ensure efficient operation. Failure to adequately address dust control can lead to serious health risks (silicosis, for example) for workers and environmental damage.

Regular maintenance and inspection of ventilation and dust collection systems are vital to maintain their effectiveness and prevent operational issues. Think of them as the lungs and kidneys of the pulverizing process – crucial for its healthy functioning and long-term viability.

Q 22. Describe your experience with different types of motors and drives for pulverizers.

My experience encompasses a wide range of motors and drives used in pulverizers, primarily focusing on their suitability for the specific application and material being processed. For example, high-torque, low-speed motors like synchronous motors are often preferred for large-scale pulverizers handling tough materials due to their consistent speed and high starting torque. These are frequently coupled with variable frequency drives (VFDs) to provide precise control over the pulverizer’s speed, optimizing energy consumption and minimizing wear and tear. In contrast, smaller pulverizers might utilize induction motors with simpler controls for less demanding applications. I’ve also worked with specialized motors designed for explosive atmospheres in certain industries where safety is paramount. The selection process always involves a careful consideration of factors such as power requirements, operational characteristics, maintenance needs, and overall cost-effectiveness.

For instance, in a cement plant, we opted for high-efficiency synchronous motors with VFDs to precisely control the pulverizer speed according to the varying demands of the kiln, leading to significant energy savings and improved efficiency. Conversely, in a smaller food processing facility, we installed standard induction motors coupled with simpler, less expensive starters, tailored to the less strenuous pulverization requirements.

Q 23. How do you monitor and control the temperature during pulverizing?

Temperature monitoring and control are crucial in pulverizing to prevent overheating, which can lead to material degradation, equipment damage, or even fire hazards. We typically employ a multi-pronged approach. This includes strategically placed thermocouples within the pulverizer chamber itself to directly measure the material temperature. We also monitor the motor temperature using thermal sensors to prevent motor burnout. The data from these sensors is fed into a Programmable Logic Controller (PLC) which continuously monitors the temperature. If the temperature exceeds a predefined setpoint, the PLC triggers pre-programmed responses – this could involve reducing the pulverizer speed, increasing the cooling airflow, or even automatically shutting down the system. Visual inspections and regular maintenance, checking for blockages and ensuring proper airflow, also play a key role in temperature management. The entire process is documented extensively for traceability and analysis.

For example, in a recent project involving coal pulverization for a power plant, we implemented a sophisticated temperature control system incorporating multiple thermocouples, infrared sensors, and a PLC with advanced algorithms for predictive control to prevent any thermal runaway. This prevented potential operational disruptions and ensured the longevity of the equipment.

Q 24. What are the energy efficiency measures you employ while operating pulverizers?

Energy efficiency is a top priority in pulverizer operation. We implement several measures to minimize energy consumption. Firstly, optimizing the pulverizer’s speed and feed rate is crucial. Using VFDs allows us to adjust the speed precisely to match the demands of the process, avoiding unnecessary energy expenditure. Regular maintenance, including ensuring the proper alignment of components, reduces friction and increases efficiency. We also focus on improving air flow management within the pulverizer chamber, ensuring optimal air-to-material ratio for efficient pulverization and minimizing energy losses due to air leakage. Selecting high-efficiency motors and employing energy-efficient drive systems are also critical factors. Finally, we periodically conduct energy audits to identify areas for further improvement.

One successful implementation involved switching to higher efficiency motors and employing optimized control strategies. This resulted in a noticeable decrease in energy consumption, leading to substantial cost savings. This was followed up with a detailed report and presentation to the clients, highlighting the positive results of the upgrade.

Q 25. How do you handle emergency situations related to pulverizer malfunctions?

Handling emergency situations requires a swift and well-coordinated response. Our procedures involve immediately shutting down the pulverizer using emergency stop buttons and isolating the power supply. The next step is to assess the situation to identify the cause of the malfunction – this might involve checking for blockages, examining the motor for overheating, or inspecting for damaged components. Based on the assessment, appropriate corrective actions are taken. We have established detailed emergency response plans that include procedures for contacting maintenance personnel, notifying relevant authorities, and ensuring the safety of personnel. Regular safety drills and training programs are vital to familiarize the operators with these procedures.

For example, during a recent incident involving a sudden power failure, our immediate actions were according to the established procedure. This ensured the safe shutdown of the pulverizer, minimizing damage and preventing any accidents. A post-incident investigation identified the root cause and improvements were implemented to avoid future occurrences.

Q 26. What are your experiences with different types of safety interlocks and sensors?

Safety interlocks and sensors are paramount for the safe operation of pulverizers. We utilize a variety of these, including proximity sensors to detect the presence of personnel near moving parts, pressure sensors to monitor the pressure within the pulverizer chamber, and temperature sensors to prevent overheating, as previously discussed. Interlocks prevent the operation of the pulverizer unless all safety conditions are met. For example, the system might refuse to start if the safety guards are open or if the emergency stop button is activated. Furthermore, we utilize overload protection devices on the motor to prevent damage due to excessive current draw. Regular testing and calibration of these sensors and interlocks are crucial to maintain their effectiveness and reliability.

In one instance, a proximity sensor malfunction was identified during routine testing. Replacing the faulty sensor prevented a potential safety hazard.

Q 27. How do you document and report operational data and maintenance activities?

We maintain meticulous records of operational data and maintenance activities. This involves using a computerized maintenance management system (CMMS) to track all aspects of pulverizer operation, including operating parameters (speed, temperature, pressure, power consumption), maintenance schedules, repair history, and any incidents. This data is used for performance monitoring, predictive maintenance, and compliance reporting. Daily logs are maintained, noting any unusual events or operational issues. Maintenance reports detail the work performed, parts replaced, and any observations made. All this information is stored securely and readily accessible for analysis and reporting. Regular reports summarizing key performance indicators (KPIs) are generated to track efficiency and identify areas for improvement.

This system has proven invaluable in identifying recurring issues, optimizing maintenance schedules, and demonstrating compliance with regulatory requirements.

Key Topics to Learn for Pulverizing Equipment Operation Interview

- Equipment Types and Principles: Understanding the mechanics of various pulverizing equipment (e.g., hammer mills, ball mills, roller mills) and their operational principles, including size reduction mechanisms and energy efficiency.

- Safety Procedures and Regulations: Deep knowledge of lockout/tagout procedures, personal protective equipment (PPE) requirements, and relevant safety regulations for operating pulverizing equipment in a safe and compliant manner. Practical experience demonstrating adherence to these procedures is highly valued.

- Material Handling and Processing: Understanding the properties of different materials processed and their impact on equipment selection and operation. This includes material flow control, feed rate adjustments, and product quality control. Experience troubleshooting material-related issues is crucial.

- Maintenance and Troubleshooting: Familiarity with routine maintenance tasks, predictive maintenance techniques, and troubleshooting common equipment malfunctions. The ability to diagnose problems, perform repairs, and minimize downtime is essential.

- Quality Control and Optimization: Understanding the parameters that influence product quality (particle size distribution, uniformity, etc.) and methods for optimizing equipment performance to meet specifications. Data analysis skills and process improvement methodologies are highly beneficial.

- Automation and Controls: Knowledge of automated control systems used in pulverizing operations, including programmable logic controllers (PLCs) and supervisory control and data acquisition (SCADA) systems. Experience with process monitoring and data interpretation is a significant advantage.

Next Steps

Mastering Pulverizing Equipment Operation opens doors to exciting career opportunities in various industries, offering excellent growth potential and competitive salaries. To maximize your chances of landing your dream job, a well-crafted, ATS-friendly resume is crucial. ResumeGemini can significantly enhance your resume-building experience, helping you present your skills and experience effectively. ResumeGemini provides examples of resumes tailored to Pulverizing Equipment Operation, allowing you to create a compelling document that showcases your expertise and gets you noticed.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good