Are you ready to stand out in your next interview? Understanding and preparing for Pumps and Valves interview questions is a game-changer. In this blog, we’ve compiled key questions and expert advice to help you showcase your skills with confidence and precision. Let’s get started on your journey to acing the interview.

Questions Asked in Pumps and Valves Interview

Q 1. Explain the difference between centrifugal and positive displacement pumps.

Centrifugal and positive displacement pumps are the two primary categories of pumps, distinguished by how they move fluids. Think of it like this: a centrifugal pump uses centrifugal force to increase fluid velocity, while a positive displacement pump traps a fixed volume of fluid and forces it through the system.

- Centrifugal Pumps: These pumps use a rotating impeller to accelerate the fluid outward, increasing its velocity and pressure. They’re best suited for high-flow, low-pressure applications. Imagine a spinning fan; it creates a low-pressure area in the center, drawing in air and pushing it outwards. A centrifugal pump works similarly with liquids.

- Positive Displacement Pumps: These pumps displace a specific volume of fluid with each rotation of the pump. They achieve high pressure and are ideal for viscous fluids or applications requiring precise fluid delivery. Examples include gear pumps, piston pumps, and diaphragm pumps. Think of a syringe: you create pressure to push out a fixed amount of fluid.

In short, centrifugal pumps are high-volume, low-pressure machines, while positive displacement pumps excel in high-pressure, low-volume applications. The choice depends on the specific requirements of the system.

Q 2. Describe the various types of valves and their applications.

Valves are control devices that regulate the flow of fluids or gases. There are many types, each suited for specific applications:

- Gate Valves: These valves offer full flow when open, ideal for on/off control of large pipelines. They’re simple and reliable, but not suitable for throttling (controlling flow rate).

- Globe Valves: These valves use a disc to regulate flow, allowing for precise throttling. They are more resistant to cavitation than gate valves, but offer higher pressure drop across the valve.

- Ball Valves: These valves feature a rotating ball with a hole that opens or closes the flow path. They’re simple, compact, and good for quick on/off service. They are not ideal for throttling.

- Butterfly Valves: These use a rotating disc to control flow, offering a balance between cost and performance. They are common in large diameter pipelines and provide acceptable throttling capabilities.

- Check Valves: These valves automatically prevent reverse flow. Examples include swing check valves and ball check valves, essential for preventing backflow in pump systems.

- Control Valves: These are sophisticated valves designed to precisely control flow rate based on signals from process control systems. They are used in automated industrial processes.

The selection of valve type depends on factors such as the fluid being handled, pressure, flow rate, required control, and cost considerations.

Q 3. How do you select the appropriate pump for a given application?

Selecting the right pump requires a thorough understanding of the application. A systematic approach is crucial:

- Fluid Properties: Viscosity, density, temperature, and corrosiveness influence pump selection. A highly viscous fluid might necessitate a positive displacement pump, while a corrosive fluid demands a pump made of corrosion-resistant materials.

- Flow Rate and Head: The required flow rate (volume per unit time) and head (pressure required to lift and move the fluid) are paramount. A centrifugal pump’s performance curve needs to meet these parameters.

- System Requirements: The entire system, including piping, fittings, and valves, affects pressure losses and pump requirements. Accurate system modeling is key.

- Budget and Maintenance: Some pumps are more expensive to purchase and maintain than others. The total cost of ownership must be considered.

- Environmental Considerations: Noise levels, energy efficiency, and potential environmental impact should also be evaluated.

Software and pump selection guides are essential tools in this process. It’s often advisable to consult with pump specialists to ensure optimal selection.

Q 4. What are the key factors to consider when sizing a pump?

Pump sizing is critical for efficient and reliable operation. The following factors are essential:

- Flow Rate (Q): The volume of fluid to be pumped per unit time (e.g., gallons per minute or liters per second).

- Total Dynamic Head (TDH): The total pressure the pump needs to overcome, including friction losses in the piping system and the vertical lift of the fluid.

- Fluid Properties: Viscosity, density, and specific gravity directly influence pump sizing. Higher viscosity requires higher power.

- Suction Conditions: NPSH available must be greater than NPSH required to avoid cavitation.

- Pump Efficiency: Choosing a pump with high efficiency minimizes energy consumption and operating costs. Efficiency curves should be carefully examined.

- Future Needs: Oversizing can be cost-effective in the long run by allowing for future increases in flow demand.

Pump manufacturers’ performance curves are critical tools in the pump sizing process. These curves illustrate the relationship between flow rate, head, and efficiency at various operating points.

Q 5. Explain the concept of Net Positive Suction Head (NPSH).

Net Positive Suction Head (NPSH) is the difference between the absolute pressure at the pump inlet and the vapor pressure of the fluid. It’s a crucial parameter for avoiding cavitation. Cavitation occurs when the liquid pressure drops below the vapor pressure, causing the formation of vapor bubbles that implode, leading to pump damage and reduced efficiency. Imagine trying to suck water up a straw that’s too long – the water pressure drops, and you can’t suck the water to the top. NPSH is all about making sure there’s enough pressure to keep the fluid liquid.

- NPSHa (Available): The actual NPSH available at the pump inlet, considering suction line pressure, fluid properties, and elevation.

- NPSHr (Required): The minimum NPSH the pump needs to operate without cavitation. This is a characteristic of the pump itself and is specified by the manufacturer.

To avoid cavitation, NPSHa must always be greater than NPSHr. This means the pressure at the pump inlet must be high enough.

Q 6. How do you troubleshoot a pump that is not performing optimally?

Troubleshooting a pump that’s not performing optimally requires a systematic approach. Here’s a step-by-step process:

- Check for obvious issues: Inspect the pump for leaks, loose connections, obstructions in the suction or discharge lines, and motor problems.

- Measure performance: Check the flow rate, pressure, and power consumption. Compare the measured values to the pump’s performance curve.

- Analyze pressure drops: Identify the location of high pressure drops in the piping system. Check for blockages or valves partially closed.

- Investigate suction conditions: Ensure adequate NPSHa. Check for leaks or blockages in the suction line, and ensure the suction lift is within the pump’s capabilities.

- Examine the bearings: Check the condition of pump bearings for wear or damage. Excessive vibration can indicate bearing issues.

- Check the seals: Inspect the seals for leaks that could lead to reduced performance or damage to the pump.

- Inspect the impeller: Check the impeller for damage, erosion, or wear. A damaged impeller can significantly reduce pump efficiency.

Proper maintenance and regular inspections can minimize the risk of pump malfunctions. Maintaining pump logs and documentation is crucial for troubleshooting.

Q 7. What are common causes of valve failure?

Valve failure can stem from several factors:

- Erosion and Corrosion: Fluid erosion and corrosion damage valve components, particularly in aggressive environments. Material selection is critical.

- Cavitation: The implosion of vapor bubbles due to low pressure can damage valve internal parts.

- Improper Operation: Frequent cycling, slamming, or throttling beyond design limits can damage valves.

- Sediment and Debris: Solid particles in the fluid can abrade and damage valve internals.

- Overpressure: Exceeding the valve’s pressure rating can lead to structural failure.

- Improper Sizing: Choosing a valve too small for the application can cause excessive wear and failure.

- Lack of Maintenance: Regular inspection, lubrication (where applicable), and cleaning can greatly extend valve life.

Choosing the right valve material, proper sizing, and regular maintenance programs are essential to extend valve lifespan and reliability.

Q 8. How do you perform a valve inspection and maintenance?

Valve inspection and maintenance are crucial for ensuring safety, efficiency, and longevity of your system. A thorough inspection involves a visual check for leaks, corrosion, damage, and proper operation. This includes checking the valve body, stem, packing gland, and actuator (if applicable). Maintenance depends on the valve type and service conditions but generally includes:

- Lubrication: Applying lubrication to moving parts reduces friction and wear, extending the valve’s lifespan. Think of it like oiling a bicycle chain – it keeps things running smoothly.

- Packing Gland Adjustment: Adjusting the packing gland helps prevent leaks around the valve stem. Too tight, and you risk damage; too loose, and you get leaks.

- Seat Repair/Replacement: Over time, the valve seat can wear down, leading to leaks. Repair or replacement might be necessary.

- Actuator Maintenance: If the valve is automated, the actuator (pneumatic, hydraulic, or electric) also requires regular checks and maintenance, including lubrication and calibration.

- Testing: After maintenance, always test the valve’s functionality to ensure it opens and closes properly and holds its position.

For instance, in a chemical processing plant, a failing valve could lead to a hazardous chemical spill. Regular maintenance prevents such scenarios and ensures consistent operational performance.

Q 9. Explain the importance of proper valve alignment.

Proper valve alignment is paramount for preventing premature wear and tear, ensuring smooth operation, and preventing leaks. Misalignment puts undue stress on the valve body, stem, and seals, potentially leading to damage and failure. Imagine trying to force a square peg into a round hole – it won’t work and will likely cause damage. Similarly, a misaligned valve will struggle to operate correctly.

Correct alignment ensures that the valve stem moves freely within the valve body and that the sealing surfaces mate correctly. This minimizes friction, reduces stress on the components, and extends the service life of the valve. For example, in high-pressure systems, misalignment can be catastrophic, leading to leaks and potential safety hazards. Always refer to the manufacturer’s instructions for specific alignment procedures.

Q 10. What are the different types of pump seals and their applications?

Pump seals prevent fluid leakage from the pump casing. The choice of seal depends heavily on the pumped fluid’s characteristics (temperature, pressure, chemical compatibility), and the operating conditions. Common types include:

- Packing Seals: These are relatively simple and inexpensive, consisting of compressible materials packed around the shaft. They require regular adjustment and maintenance to prevent leaks. Think of them as a tightly packed rope around a pipe.

- Mechanical Seals: These are more sophisticated and generally more reliable than packing seals. They consist of stationary and rotating faces that create a leak-tight seal. They are often preferred for higher pressure and temperature applications. Imagine two perfectly flat, polished surfaces pressing together.

- Magnetic Couplings (Sealless Pumps): These completely eliminate the need for shaft seals. The pump shaft is coupled to the impeller via a magnetic drive, allowing the fluid to be completely contained within the pump casing. Ideal for applications involving toxic or hazardous fluids. No physical contact between the rotating and stationary parts mean no possibility of leakage through seals.

For example, a centrifugal pump handling corrosive chemicals would likely use a mechanical seal made from materials compatible with the chemical. A sealless pump might be selected for handling highly toxic substances where even minimal leakage is unacceptable.

Q 11. Describe the principles of cavitation in pumps.

Cavitation in pumps is a phenomenon caused by the formation and collapse of vapor bubbles in the pump’s impeller. This happens when the liquid pressure drops below its vapor pressure. The collapsing bubbles create shock waves that erode the pump components, leading to reduced efficiency, noise, and even damage.

Imagine throwing a rock into a calm pond; the impact creates ripples. Similarly, the collapsing bubbles in cavitation create shockwaves that damage the pump’s surfaces. These shockwaves are extremely localized, but repeated cavitation events can lead to significant pitting and erosion over time. Factors that contribute to cavitation include excessive suction lift, high pump speeds, and low NPSH (Net Positive Suction Head). Ensuring sufficient NPSH is critical to preventing cavitation.

Q 12. How do you calculate the required pump power?

Pump power calculation involves determining the energy required to move a specific volume of fluid at a given pressure and flow rate. The most common formula is:

Power (kW) = (Q x H x ρ x g) / (η x 1000)

Where:

Q= Flow rate (m³/s)H= Total head (m)ρ= Fluid density (kg/m³)g= Acceleration due to gravity (9.81 m/s²)η= Pump efficiency (decimal)

This formula calculates the hydraulic power. You’ll need to add a safety factor to account for losses and ensure the motor selected has sufficient capacity. For example, a pump with 90% efficiency moving 1 m³/s of water against a 10-meter head would require approximately 9.81 kW of power. Remember to always use consistent units.

Q 13. What are the different types of valve actuators?

Valve actuators are mechanisms that provide the force to open or close a valve. Common types include:

- Manual Actuators: These are hand-operated, such as a handwheel or lever. Simple and inexpensive but require manual intervention.

- Pneumatic Actuators: These use compressed air to provide the actuating force. Relatively inexpensive, readily available, and offer quick response times.

- Hydraulic Actuators: These use hydraulic fluid to generate considerable force. Ideal for large valves or high-pressure applications. Provide very high force at a lower pressure than pneumatic actuators.

- Electric Actuators: These use electric motors to provide the actuating force. Precise control and often integrated with automated control systems, though generally more expensive than pneumatic actuators.

The selection of an actuator depends on factors such as the size of the valve, the required force, the speed of operation, and the level of automation required. For example, a large pipeline valve would require a hydraulic actuator because of its ability to provide high forces.

Q 14. Explain the concept of control valves and their role in process control.

Control valves are used to regulate the flow of fluids within a process. They are key components in process control systems, allowing for precise adjustments to maintain desired process parameters such as temperature, pressure, and flow rate. These valves are often automated, responding to signals from a control system.

They are very different to on/off valves. Control valves continuously modulate the flow, achieving fine adjustments and maintaining stability. They can be thought of as automated throttles, responding to changes in demand. For instance, in a chemical reactor, a control valve might regulate the flow of reactants to maintain the desired reaction temperature. A change in the temperature reading would result in the control system adjusting the valve’s position to achieve the set point. The type of valve is selected based on the specific requirements of the application, including flow characteristics, pressure drop, and fluid properties.

Q 15. Describe different types of pump curves and their significance.

Pump curves are graphical representations of a pump’s performance characteristics. They typically plot flow rate (on the x-axis) against head (the vertical distance the pump can lift the fluid, on the y-axis), and often include efficiency curves. Different types exist, each providing valuable insights:

- Performance Curve: This shows the relationship between flow rate and head at a constant speed. It illustrates the pump’s maximum head, best efficiency point (BEP), and shut-off head (head at zero flow).

- System Curve: This represents the resistance of the piping system to fluid flow. It shows the head required to overcome friction and elevation changes at various flow rates. The intersection of the performance and system curves determines the operating point of the pump in a specific system.

- Efficiency Curve: This shows the pump’s efficiency at different flow rates. The highest point on this curve indicates the BEP, where the pump operates most efficiently. Operating far from the BEP can lead to decreased efficiency and increased energy consumption.

Significance: Pump curves are crucial for pump selection, system design, and troubleshooting. They help engineers determine the right pump for a given application, predict operating conditions, and identify potential problems like cavitation or insufficient flow. For example, if the system curve intersects the performance curve at a point significantly below the BEP, it suggests the pump is oversized and running inefficiently. Conversely, if the intersection is close to the shut-off head, the pump may be undersized.

Career Expert Tips:

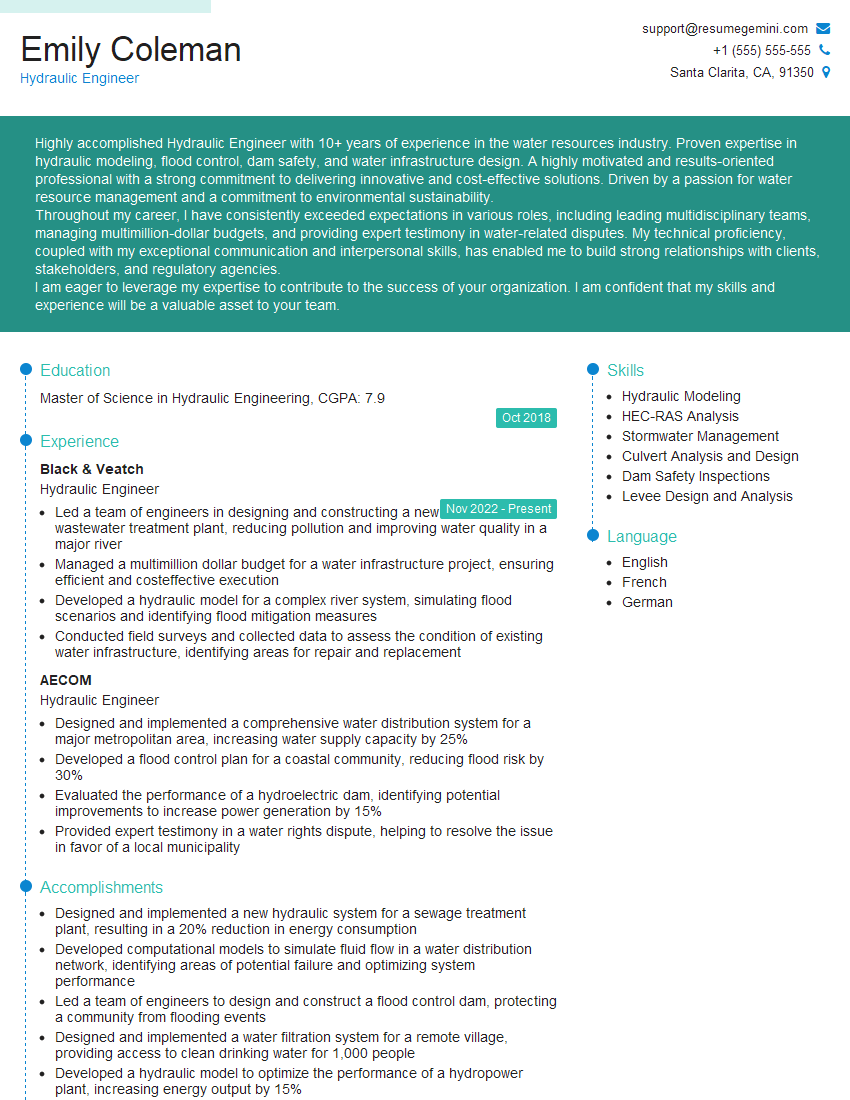

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you handle pump vibration issues?

Pump vibration is a serious issue, potentially leading to equipment failure and safety hazards. Addressing it requires a systematic approach:

- Identify the Source: Vibration analysis using instruments like accelerometers can pinpoint the source (e.g., imbalance, misalignment, cavitation, wear, resonance). Visual inspection for loose components is also critical.

- Diagnose the Cause: Once the source is identified, determine the underlying cause. Imbalance is commonly addressed by balancing the pump’s rotating elements. Misalignment is corrected through precise shaft alignment. Cavitation necessitates reviewing the system’s Net Positive Suction Head (NPSH) and potentially modifying the piping.

- Implement Corrective Actions: Solutions range from simple adjustments (like tightening bolts) to more involved repairs (e.g., replacing worn bearings or seals). If resonance is the cause, structural modifications or vibration dampeners might be necessary.

- Monitor and Prevent Recurrence: After implementing solutions, monitor vibration levels regularly. Implement a preventive maintenance schedule including regular inspections and lubrication to reduce the likelihood of future problems.

For example, I once worked on a centrifugal pump exhibiting excessive vibration. Analysis revealed misalignment between the pump and motor. Correcting the alignment significantly reduced the vibration and prevented potential damage.

Q 17. Explain the concept of pump efficiency and how to improve it.

Pump efficiency refers to how effectively a pump converts input power into hydraulic power (the power used to move the fluid). It is typically expressed as a percentage. High efficiency means less energy waste and lower operating costs.

Improving Pump Efficiency:

- Select the Right Pump: Choosing a pump sized appropriately for the application and operating conditions is crucial. Using a pump that’s too large or too small leads to inefficiency.

- Optimize System Design: Reducing friction losses in the piping system through proper pipe sizing, smooth bends, and minimizing valves significantly improves overall efficiency. Regular cleaning of the system to prevent blockages also plays a vital role.

- Regular Maintenance: Routine maintenance, including bearing lubrication, seal replacement, and impeller inspection, keeps the pump running smoothly and prevents energy losses due to friction and wear.

- Control System Optimization: Implementing a variable frequency drive (VFD) allows for precise control of the pump speed, enabling efficient operation at varying flow demands. This is particularly effective when the flow is frequently changing.

- Use of High-Efficiency Pumps: Newer pump designs incorporate features to minimize energy losses, enhancing overall efficiency. These may include improved impeller designs or more effective sealing mechanisms.

For instance, replacing an old inefficient pump with a high-efficiency model coupled with a VFD can drastically reduce energy consumption and operating costs in a large industrial system.

Q 18. What are the safety considerations when working with pumps and valves?

Safety considerations when working with pumps and valves are paramount due to the potential hazards involving high pressure, moving parts, hazardous fluids, and electricity. Key safety precautions include:

- Lockout/Tagout Procedures: Before any maintenance or repair, always follow strict lockout/tagout procedures to prevent accidental start-up.

- Personal Protective Equipment (PPE): Wear appropriate PPE, including safety glasses, gloves, hearing protection, and safety shoes, based on the specific hazards involved.

- Pressure Relief Devices: Ensure pressure relief valves are functional and properly sized to prevent over-pressurization and potential ruptures.

- Confined Space Entry Procedures: Follow appropriate confined space entry protocols if working inside pump housings or tanks.

- Emergency Shutdown Procedures: Understand and practice emergency shutdown procedures in case of unexpected events like leaks or equipment malfunctions.

- Regular Inspections: Conduct regular inspections of pumps and valves to identify potential problems early and prevent accidents.

- Training: Provide thorough training to personnel on safe operating procedures, maintenance techniques, and hazard identification.

Failure to adhere to these safety measures can lead to serious injuries or fatalities. A strong safety culture and adherence to established procedures are crucial for preventing accidents.

Q 19. Describe your experience with different pump materials and their selection criteria.

Pump material selection is critical for ensuring the pump’s longevity, performance, and compatibility with the pumped fluid. Factors to consider include:

- Fluid Compatibility: The material must be resistant to corrosion or degradation by the pumped fluid. For instance, stainless steel is often used for aggressive chemicals, while cast iron may suffice for less corrosive fluids.

- Temperature: The operating temperature of the fluid influences material selection. Some materials have limited temperature ranges.

- Pressure: Higher pressures require materials with greater strength and resistance to stress.

- Abrasion Resistance: For fluids containing abrasive particles, materials like high-chromium stainless steel or special alloys are needed.

- Cost: Material cost is an important factor, balancing the need for longevity and performance against economic considerations.

Examples: Cast iron is a common choice for general-purpose water pumps due to its cost-effectiveness. Stainless steel (various grades) is preferred for corrosive fluids and high-purity applications. Ductile iron provides better strength and ductility than cast iron. Specialized polymers are suitable for certain applications where chemical resistance is paramount. In my experience, selecting the right material is a balancing act involving a thorough understanding of the fluid properties and operating conditions.

Q 20. How do you maintain and troubleshoot a control valve?

Control valve maintenance and troubleshooting involve a systematic process:

- Regular Inspections: Regularly inspect for leaks, corrosion, damage, and proper operation. Check valve position indicators and verify responsiveness.

- Cleaning: Clean the valve body and components as needed to remove debris that can affect performance. For some valves, a simple wipe-down may suffice; others may require more thorough cleaning.

- Calibration: Periodic calibration ensures the valve operates within its specified parameters. This often involves using specialized test equipment.

- Lubrication: Lubricate moving parts as recommended by the manufacturer to reduce friction and extend the valve’s life.

- Troubleshooting: If a problem is identified (e.g., sticking, leaking), diagnose the cause. This may require checking for pressure differentials, examining the valve internals, and potentially testing actuators and positioners.

- Repair/Replacement: Repair or replace damaged components as necessary. This may involve repairing seals, replacing internal parts, or replacing the entire valve.

Example: I once dealt with a control valve that was exhibiting inconsistent performance. Initial inspection revealed a buildup of debris affecting proper operation. After cleaning and lubrication, the valve returned to normal operation.

Q 21. Explain the difference between globe, ball, and gate valves.

Globe, ball, and gate valves are common types, each suited for different applications:

- Globe Valves: These valves use a disc-shaped element to regulate flow. They offer excellent throttling capabilities (precise flow control) but have higher pressure drop than other types. Suitable for applications requiring precise flow regulation and on-off control, they are less ideal for high-velocity applications due to the pressure drop.

- Ball Valves: These valves use a spherical ball with a central hole to control flow. They are primarily on-off valves, providing quick and easy shut-off. They offer low pressure drop when fully open. They are generally not suitable for precise flow regulation. The simplicity of design makes them relatively low maintenance.

- Gate Valves: These valves use a sliding gate to control flow. They are primarily on-off valves, offering minimal pressure drop when fully open. They are not suitable for throttling as the gate’s motion does not provide sufficient control of the flow. They are best suited for large diameter lines where quick on/off action is needed.

In summary: Choose globe valves for applications requiring precise flow control, ball valves for quick on/off action, and gate valves for high-flow applications needing minimal pressure drop when fully open. The choice depends on the specific needs of the system.

Q 22. What are the different types of pump impellers?

Pump impellers are the heart of centrifugal pumps, responsible for converting rotational energy into fluid energy. Different impeller designs cater to specific fluid characteristics and application requirements. Here are some key types:

- Radial Impellers: These are the most common type, with vanes that impart energy to the fluid in a radial direction. They’re efficient for high-flow, low-pressure applications. Think of a fan; it moves a large volume of air with relatively low pressure.

- Axial Impellers: Also known as propeller impellers, these push the fluid axially (parallel to the shaft). They excel in high-flow, low-head applications like large drainage systems or irrigation.

- Mixed-Flow Impellers: These combine features of both radial and axial impellers, providing a balance between flow rate and pressure head. They’re versatile and suitable for a wider range of applications.

- Francis Impellers (Turbine Pumps): Used in turbine pumps, these impellers operate at higher pressures and lower flow rates compared to radial impellers. They’re commonly found in applications requiring significant pressure increase, like boosting water to higher elevations.

The choice of impeller depends on factors like the required flow rate (volume per unit time), head (pressure difference), fluid viscosity, and the presence of solids in the fluid. Selecting the wrong impeller can lead to inefficient operation, cavitation (formation of vapor bubbles), or even pump failure.

Q 23. How do you determine the appropriate valve trim for a given application?

Selecting the appropriate valve trim is critical for optimizing valve performance and longevity. The trim—the internal parts of the valve that come into direct contact with the fluid—influences flow characteristics, pressure drop, and cavitation resistance. The process involves considering several factors:

- Fluid Properties: Viscosity, temperature, corrosiveness, and the presence of solids significantly impact trim material selection. Highly corrosive fluids necessitate materials like stainless steel or special alloys. Abrasive fluids might require hard-faced or ceramic trims.

- Flow Characteristics: Do you need linear flow control, quick opening, or a specific flow coefficient (Cv)? Different trim designs achieve various flow characteristics. For instance, a globe valve with a conventional plug might offer linear flow control, while a ball valve provides rapid on/off switching.

- Pressure Drop: The desired pressure drop across the valve needs to be considered. A poorly chosen trim might create excessive pressure drop, leading to energy loss and increased wear.

- Erosion and Cavitation: If the application involves high velocities or pressure fluctuations, cavitation-resistant trims are essential. Materials like stellite or tungsten carbide offer superior resistance.

In practice, this often involves consulting valve manufacturer data sheets and utilizing selection software. For critical applications, engineers often conduct computational fluid dynamics (CFD) simulations to predict valve performance with different trim options.

Q 24. Explain the concept of pressure relief valves and their function.

Pressure relief valves (PRVs), also called safety relief valves (SRVs), are crucial safety devices designed to automatically release excess pressure from a system to prevent catastrophic failures. They act as a pressure-limiting safeguard.

Function: A PRV remains closed under normal operating pressure. When the system pressure exceeds a predetermined set point, the valve opens, allowing fluid to escape to a safe location. Once the pressure falls below the set point, the valve closes automatically.

Types: PRVs come in various types depending on the fluid, pressure, and flow requirements, including spring-loaded, pilot-operated, and weight-loaded valves.

Real-world example: Consider a large boiler system. If the boiler pressure surpasses a safe limit, the PRV will open, discharging steam to prevent an explosion. This is a critical safety mechanism. Regular testing and maintenance are vital for ensuring the proper functioning of PRVs.

Q 25. Describe your experience with Programmable Logic Controllers (PLCs) in relation to pump and valve control.

I have extensive experience integrating PLCs into pump and valve control systems. PLCs provide automated control, monitoring, and data acquisition capabilities.

Applications: I’ve used PLCs to implement:

- Automated pump sequencing: Coordinating multiple pumps to meet varying demands while optimizing energy efficiency. For example, starting and stopping pumps based on tank levels or pressure requirements.

- Valve control: Precisely controlling valve positions using analog or digital signals from the PLC to achieve accurate flow regulation and pressure maintenance. This could involve controlling flow through a pipeline or managing pressure in a process vessel.

- Data logging and alarm systems: Monitoring key parameters like pressure, flow, temperature, and vibration and generating alarms when deviations from set points occur. This is crucial for preventative maintenance and ensuring safe operation.

- Supervisory Control and Data Acquisition (SCADA) integration: Connecting the PLC to a SCADA system for remote monitoring and control of the entire pumping and valve system. This allows operators to oversee the system from a central location, improving efficiency and safety.

Example: In a water treatment plant, I implemented a PLC-based system that controlled the flow of water through various filters and pumps based on real-time turbidity and water level readings. The PLC also monitored pressure and flow rates, generating alarms if any deviation from the set points occurred, preventing system disruptions.

Q 26. How do you assess the condition of a pump using vibration analysis?

Vibration analysis is a powerful non-invasive technique for assessing the condition of pumps. Excessive vibration often indicates developing problems.

Assessment Process:

- Data Acquisition: Using accelerometers, we measure vibration levels at various points on the pump, including the bearings, motor, and casing.

- Frequency Analysis: The vibration data is then analyzed using Fast Fourier Transform (FFT) to identify the dominant frequencies of vibration. Specific frequencies are associated with different mechanical issues, such as imbalance, misalignment, bearing wear, and cavitation.

- Trend Analysis: Tracking vibration levels over time allows us to identify developing trends. Gradual increases in vibration amplitude are indicative of worsening problems.

- Comparison with Baseline Data: Comparing current vibration levels with established baseline data (from when the pump was in good condition) enables us to identify significant changes and potential issues.

Interpretation: High vibration levels at specific frequencies, along with characteristic changes in the vibration waveform, can indicate bearing wear, shaft misalignment, impeller imbalance, or cavitation. The analysis helps us predict potential failures and schedule timely maintenance, preventing costly repairs or downtime.

Q 27. What are your experiences with different types of valve positioners?

I’ve worked with several types of valve positioners, each with its strengths and weaknesses:

- Pneumatic Positioners: These are the most common type, using compressed air to drive a piston or diaphragm that adjusts the valve stem position. They are robust and reliable, but require a clean, dry compressed air supply. They offer good accuracy and responsiveness.

- Electro-pneumatic Positioners: These combine an electronic controller with a pneumatic actuator. They allow for precise control via electronic signals and are readily integrated with PLCs and other control systems.

- Hydraulic Positioners: These use hydraulic pressure to position the valve. They are used for larger valves or in high-pressure applications where pneumatic positioners might not be sufficient.

- Electric Positioners: These use an electric motor to directly position the valve stem. They offer precise control and are energy-efficient, but may require more sophisticated electronics for reliable operation and are more vulnerable to electrical disturbances.

The selection of a positioner depends on factors such as valve size, required accuracy, environmental conditions, power availability, and the overall control system architecture. For example, a large, high-pressure control valve in an offshore platform might require a robust hydraulic positioner for reliable operation in harsh conditions, whereas smaller valves in a controlled indoor setting might be adequately served by an electro-pneumatic or even an electric positioner.

Q 28. Describe your experience with pump and valve maintenance scheduling and preventative maintenance programs.

Effective pump and valve maintenance scheduling is crucial for maximizing equipment lifespan, minimizing downtime, and ensuring safety. My experience involves developing and implementing preventative maintenance (PM) programs based on:

- Manufacturer’s Recommendations: Starting with the manufacturer’s recommended maintenance schedules, which often outline specific inspection and service intervals.

- Operating Conditions: Adjusting the PM schedule based on the actual operating conditions. For example, pumps operating in harsh environments or handling aggressive fluids might require more frequent maintenance than those in ideal conditions.

- Predictive Maintenance Techniques: Integrating predictive maintenance techniques such as vibration analysis, oil analysis, and thermal imaging to identify potential problems before they escalate into major failures. This allows for proactive maintenance and reduces unexpected downtime.

- Historical Data Analysis: Analyzing historical maintenance records to identify recurring problems and adjust the PM schedule accordingly. This data-driven approach helps focus maintenance efforts on critical areas.

Example: In a refinery, I implemented a PM program that incorporated vibration analysis for pumps and regular inspections for valves. This approach identified a potential bearing failure in a critical pump well in advance, allowing for a planned repair that minimized production disruptions. The program reduced unplanned downtime and extended equipment life.

Key Topics to Learn for Pumps and Valves Interview

- Pump Fundamentals: Centrifugal pumps, positive displacement pumps (reciprocating, rotary), pump curves, operating characteristics, NPSH, cavitation.

- Valve Fundamentals: Globe valves, gate valves, ball valves, check valves, butterfly valves, control valves; their applications and limitations.

- Fluid Mechanics Principles: Pressure, flow rate, viscosity, Bernoulli’s equation, head loss calculations – understanding how these principles apply to pump and valve selection and operation.

- Practical Applications: Discuss real-world scenarios where specific pump and valve types are used (e.g., water treatment, oil & gas, chemical processing). Be prepared to explain the rationale behind the choices made.

- Troubleshooting and Maintenance: Common pump and valve failures, preventative maintenance strategies, and basic troubleshooting techniques. Be ready to discuss practical solutions to common problems.

- Materials Selection: Understand the importance of material selection based on the fluid being handled and the operating conditions (pressure, temperature, corrosiveness).

- Instrumentation and Control: Familiarity with flow meters, pressure sensors, and control systems used in conjunction with pumps and valves.

- Safety Considerations: Discuss safety protocols related to the operation and maintenance of pumps and valves, including lockout/tagout procedures.

- Industry Standards and Codes: Awareness of relevant industry standards and codes (e.g., API, ASME) relating to pump and valve design, selection, and operation.

Next Steps

Mastering pumps and valves is crucial for advancement in many engineering and technical fields. A strong understanding of these systems demonstrates valuable problem-solving skills and practical knowledge, significantly enhancing your career prospects. To maximize your chances of landing your dream role, creating a strong, ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience. We offer examples of resumes tailored specifically to the Pumps and Valves industry to give you a head start. Invest the time to craft a compelling resume – it’s your first impression on potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good