Cracking a skill-specific interview, like one for Raw Stock Handling, requires understanding the nuances of the role. In this blog, we present the questions you’re most likely to encounter, along with insights into how to answer them effectively. Let’s ensure you’re ready to make a strong impression.

Questions Asked in Raw Stock Handling Interview

Q 1. Describe your experience with different types of raw materials.

My experience encompasses a wide range of raw materials, from agricultural products like grains and cotton to industrial materials such as metals, polymers, and chemicals. I’ve worked with both homogenous materials, where the properties are consistent throughout a batch, and heterogeneous materials, requiring careful sorting and segregation. For instance, in one role, I managed the receiving, inspection, and storage of various cotton grades, each with different fiber lengths and strengths, impacting their subsequent processing. In another, I oversaw the handling of steel coils with varying thicknesses and alloy compositions, demanding precise handling to prevent damage. This diverse experience has given me a deep understanding of the unique handling requirements of different materials.

- Agricultural Products: Grains (wheat, corn, soybeans), cotton, coffee beans.

- Industrial Materials: Steel coils, aluminum sheets, polymers (pellets, powder), chemicals (liquids, powders).

- Perishable Goods: While not my primary focus, I’ve also supported projects involving perishable raw materials, requiring specialized handling and cold storage.

Q 2. Explain your understanding of FIFO and LIFO inventory management methods.

FIFO (First-In, First-Out) and LIFO (Last-In, First-Out) are two common inventory management methods. FIFO assumes that the oldest items are used or sold first. This is particularly crucial for perishable goods or items with expiration dates to minimize waste and maintain quality. Think of it like a queue – the first item in line gets served first. LIFO, conversely, assumes the newest items are used or sold first. This method is more suitable for non-perishable items where the risk of obsolescence is low. Imagine a stack of plates – you’d likely take the top one (newest) first.

The choice between FIFO and LIFO impacts financial reporting; FIFO generally leads to lower cost of goods sold during inflation, resulting in higher reported profits (but higher taxes), while LIFO can lead to a lower tax burden during inflation. The best method depends entirely on the nature of the raw materials and the company’s financial goals. For example, in a food processing plant, FIFO is vital to prevent spoilage; while in a steel mill handling consistent materials, LIFO might be more efficient.

Q 3. How do you ensure the accuracy of inventory records?

Ensuring inventory accuracy is paramount. My approach is multi-faceted, relying on a combination of physical inventory counts, cycle counting, and robust inventory management systems. Regular physical counts, while time-consuming, provide a benchmark of accuracy. Cycle counting involves regularly counting smaller sections of the inventory instead of doing a complete count all at once; this reduces disruption and improves accuracy over time. I strongly advocate for the use of barcode scanning or RFID tagging for efficient tracking, minimizing human error during both receiving and dispatch. Regular reconciliation of physical counts against the system records helps to identify discrepancies and investigate potential issues, such as theft or data entry errors.

For instance, at one company, we implemented a system of daily cycle counting, assigning different areas to team members, resulting in a significant improvement in inventory accuracy and reduced stock-out situations. We also integrated our inventory management system with our accounting software for real-time updates.

Q 4. What are the common challenges in raw stock handling and how have you overcome them?

Common challenges in raw stock handling include inventory shrinkage (loss or damage), inaccurate records, inefficient storage practices, and damage during handling. I’ve overcome these challenges by implementing several strategies. For example, to address inventory shrinkage, we implemented stricter security measures, including improved access control, CCTV monitoring, and regular audits. To tackle inaccurate records, we streamlined data entry procedures, invested in barcode scanners, and trained staff on proper inventory management techniques. Inefficient storage was solved by optimizing warehouse layout, implementing proper stock rotation procedures (FIFO), and using appropriate storage equipment. Damage during handling was reduced by providing staff with training on safe lifting techniques and using protective packaging where necessary.

One memorable instance involved a significant increase in damaged goods. By analyzing damage patterns, we realized that improper stacking and insufficient protection during transport were the root causes. We implemented new stacking procedures, procured better packaging materials, and updated our handling instructions, which dramatically reduced damage rates.

Q 5. Explain your experience with warehouse management systems (WMS).

My experience with Warehouse Management Systems (WMS) is extensive. I’ve worked with various systems, including SAP WM, Oracle WMS, and several industry-specific solutions. I am proficient in configuring, implementing, and optimizing these systems. My responsibilities have ranged from data entry and maintenance to designing custom reports and workflows to enhance efficiency. I’m adept at integrating WMS with other enterprise resource planning (ERP) systems for seamless data flow and real-time visibility into inventory levels, locations, and movement. For example, at a previous company, I helped implement a new WMS that automated the picking process, reducing order fulfillment time by 20% and minimizing errors.

A key aspect is understanding the capabilities of each system and tailoring its use to the specific needs of the warehouse and the types of materials being handled. Proper training for staff is also vital for effective WMS utilization.

Q 6. How do you prioritize tasks in a fast-paced warehouse environment?

Prioritization in a fast-paced warehouse is crucial. I utilize a combination of methods, including urgency, importance, and deadline. I typically use a Kanban system or a similar visual task management tool to track progress and identify bottlenecks. Tasks are prioritized based on factors such as order deadlines, material criticality, and potential impact on production. For example, urgent orders for critical materials always take precedence over less urgent tasks. This requires excellent communication and collaboration among team members to ensure everyone is aligned on the priorities and working towards common goals. Regularly reviewing the task list and adjusting priorities based on real-time changes is essential for maintaining efficiency and meeting deadlines.

Q 7. What safety procedures do you follow when handling raw materials?

Safety is always my top priority. I strictly adhere to all company safety regulations and industry best practices when handling raw materials. This includes using appropriate personal protective equipment (PPE), such as gloves, safety glasses, and steel-toed boots, depending on the material being handled. I ensure proper training for all staff on safe handling procedures, including lifting techniques, equipment operation, and emergency response protocols. I regularly inspect the warehouse to identify and address any potential hazards, such as spills, obstructions, and damaged equipment. Proper storage practices, including appropriate racking and segregation of incompatible materials, are crucial. I also maintain detailed records of all safety incidents and near misses to identify patterns and implement preventative measures. Regular safety meetings and drills are also conducted to reinforce safety awareness and preparedness.

Q 8. Describe your experience with using material handling equipment (forklifts, pallet jacks, etc.).

Throughout my career, I’ve extensively utilized various material handling equipment, including forklifts, pallet jacks, and reach trucks. My experience encompasses safe operation, preventative maintenance awareness, and understanding of their limitations. For instance, I’ve been certified to operate sit-down forklifts, and I’m proficient in using pallet jacks for maneuvering heavier loads within confined spaces. My experience isn’t just limited to operation; it includes understanding the appropriate equipment for specific tasks. For example, using a reach truck for high-bay storage is much safer and more efficient than using a standard forklift. I understand the importance of regular inspections and adhering to all safety protocols, including pre-operational checks and load capacity limits. I’ve also participated in training programs focusing on hazard identification and accident prevention related to equipment operation.

In a previous role, we were optimizing warehouse layout. The implementation of a narrow-aisle racking system required extensive training on reach trucks to maximize space utilization and improve order picking efficiency. This experience highlighted the importance of selecting the right equipment for the task and the subsequent training required for safe operation.

Q 9. How do you identify and report damaged or defective raw materials?

Identifying and reporting damaged or defective raw materials is crucial for maintaining product quality and preventing production delays. My process involves a thorough visual inspection at every stage, from receiving to storage. I look for physical damage like cracks, dents, discoloration, or signs of infestation. For materials with specific quality parameters, I use measuring instruments like calipers or scales to verify specifications. Any discrepancies are immediately documented with clear photographs and detailed descriptions, noting the location, quantity, and nature of the damage. This information is then reported to the appropriate supervisor or quality control department using our company’s designated reporting system, usually a digital form or database.

For example, in my previous role, we received a shipment of lumber with noticeable warping and insect damage. I documented the affected pieces with photos, noting the pallet number and quantity affected. This report immediately initiated a return process with the supplier and prevented those damaged materials from being used in production.

Q 10. Explain your experience with receiving and inspecting incoming raw materials.

Receiving and inspecting incoming raw materials is a critical quality control step. My process begins with verifying the delivery against the purchase order, ensuring the correct quantity and type of materials have arrived. Next, a thorough visual inspection is conducted for any signs of damage during transit. This includes checking for packaging integrity, obvious physical defects, and verifying labels for accurate identification and traceability. I then sample the materials for further quality checks based on specific requirements; this might involve testing for moisture content, weight, or other relevant parameters depending on the raw material type. The inspection results are meticulously documented, and any discrepancies are immediately reported. If the materials don’t meet specifications, they are quarantined and documented pending resolution with the supplier.

Once, we received a batch of chemical compounds where the label’s expiration date was approaching. Through my stringent inspection process, we flagged this discrepancy, avoided usage past the expiration, and prevented potential production issues.

Q 11. How do you manage inventory discrepancies?

Inventory discrepancies, the difference between recorded inventory and physical inventory, are addressed systematically. My approach begins with identifying the discrepancy through cycle counting or a full inventory audit. Once identified, I investigate potential causes, including data entry errors, theft, damage, or process inefficiencies. I then reconcile the discrepancies by comparing physical counts with inventory records. In cases of minor discrepancies due to data entry errors, corrections are made directly in the system. More significant discrepancies usually require a thorough investigation to determine the root cause, involving reviewing all related documentation and potentially implementing improved tracking methods. In cases of theft or damage, appropriate action is taken to improve security or address the damage.

For example, a significant discrepancy in a previous role led us to discover a flaw in our scanning procedure. Addressing this process gap significantly reduced future discrepancies and improved overall inventory accuracy.

Q 12. What methods do you use to track raw material usage?

Tracking raw material usage is essential for production planning, cost control, and waste reduction. We utilize a combination of methods including barcoding or RFID tagging at the receiving stage, integrated with our inventory management system. As materials are issued for production, they are scanned at the point of use, recording the quantity and time. This data is automatically fed into our system, providing a real-time view of raw material consumption. Regular reports are generated to monitor usage patterns, identify potential shortages, and optimize inventory levels. We also conduct periodic physical inventory checks to reconcile the system data with actual stock levels.

In one instance, using detailed tracking of usage revealed a previously unnoticed pattern of higher-than-expected consumption of a particular raw material during certain production runs. This prompted an investigation that led to optimization of the manufacturing process, reducing waste and improving overall efficiency.

Q 13. Describe your experience with cycle counting and inventory audits.

Cycle counting and inventory audits are crucial for maintaining accurate inventory records. Cycle counting involves counting a small subset of inventory items on a regular basis, rather than a full count. This allows for continuous monitoring of inventory accuracy, minimizing the disruption of a full audit. Inventory audits, on the other hand, involve a complete physical count of all inventory items at a specific point in time. This provides a more comprehensive assessment of inventory accuracy and helps identify larger-scale discrepancies. Both methods involve careful planning, accurate counting procedures, and thorough documentation. The results are compared to system records, and any discrepancies are investigated and reconciled.

In a past role, we implemented a regular cycle counting schedule targeting high-value or high-demand raw materials. This proactive approach improved inventory accuracy, reduced the risk of stockouts, and minimized the time required for the annual inventory audit.

Q 14. How do you maintain a clean and organized warehouse environment?

Maintaining a clean and organized warehouse is vital for safety, efficiency, and product quality. Our approach involves implementing a 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain). This includes regular cleaning schedules, designated storage locations for all materials, proper labeling of aisles and storage areas, and clear pathways to facilitate efficient movement of goods. Regular inspections ensure that the workplace remains organized and that any potential hazards are identified and mitigated promptly. Employee training is conducted to reinforce good housekeeping practices, emphasizing the importance of safety and efficiency. This also includes proper disposal procedures for waste materials and regular preventative maintenance of warehouse equipment.

For instance, implementing a color-coded system for storage locations improved the speed and accuracy of order picking, as well as reducing the risk of errors. The improvements in efficiency contributed to a safer work environment.

Q 15. What is your experience with different storage methods for raw materials?

My experience encompasses a wide range of raw material storage methods, tailored to the specific characteristics of the material. For example, temperature-sensitive materials like certain chemicals or pharmaceuticals require refrigerated or climate-controlled warehousing, often with specialized racking systems to ensure even temperature distribution. Bulk materials, such as grains or powders, are typically stored in silos or large bins, sometimes with automated conveying systems for efficient movement. Smaller, packaged goods might be stored on pallets in standard warehouse racking, organized by SKU and lot number for easy traceability. Finally, hazardous materials need dedicated storage areas with specific safety measures, including proper labeling, spill containment, and ventilation.

- Refrigerated Storage: Ideal for perishable goods or temperature-sensitive chemicals.

- Silo Storage: Efficient for storing large quantities of bulk materials.

- Pallet Racking: A versatile system for storing packaged goods, enabling efficient space utilization and access.

- Hazardous Material Storage: Requires specialized facilities complying with all safety regulations.

The choice of storage method always depends on factors like material properties, volume, handling requirements, and budget constraints. I’ve successfully implemented and managed all these methods throughout my career.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prevent stock loss or damage?

Preventing stock loss and damage requires a multi-pronged approach. It begins with proper handling during receiving, employing techniques like careful unloading, inspection for damage, and appropriate storage placement. Regular inventory checks are crucial to detect discrepancies early. Maintaining optimal storage conditions—temperature, humidity, and cleanliness—is essential to preserve product quality and prevent spoilage or degradation. Proper labeling and organization make locating items easy and prevent mix-ups. Furthermore, implementing robust security measures, such as access control and surveillance, minimizes theft or unauthorized access. Finally, the use of appropriate packaging materials further protects the goods during storage and transportation.

For instance, in a previous role, we implemented a FIFO (First-In, First-Out) system for perishable goods, minimizing waste due to spoilage. We also invested in better pallet racking and forklift training to reduce accidental damage during handling. These proactive measures led to a significant reduction in both stock loss and damage claims.

Q 17. How familiar are you with inventory control software?

I’m highly familiar with various inventory control software solutions. My experience includes working with systems like SAP, Oracle, and Fishbowl Inventory. I understand how to configure these systems to track raw materials from procurement to production, managing data like lot numbers, expiration dates, and storage locations. I’m proficient in using these systems to generate reports on stock levels, usage trends, and potential shortages, enabling proactive planning and purchasing. I also understand the importance of integrating inventory management systems with other enterprise systems like ERP and MRP for seamless data flow.

For example, I once used SAP to optimize our inventory levels of a particular chemical, reducing our storage costs while still ensuring we had enough on hand to meet production demands. This involved analyzing historical usage data, forecasting future needs, and adjusting reorder points accordingly. The result was significant cost savings without compromising production.

Q 18. Describe a time you had to troubleshoot a problem with raw material handling.

In one instance, we experienced a significant drop in the quality of our processed product. After a thorough investigation, we discovered that a batch of raw material had been contaminated during storage. The contamination was traced to a leak in a storage container. To troubleshoot this, we first isolated the affected batch and immediately stopped using it. We then meticulously reviewed our storage procedures, identified the faulty container, and implemented enhanced leak detection measures, including regular inspections and the use of improved sealant materials. We also reviewed our supplier’s handling procedures to ascertain if there were issues at their facility as well. Finally, we instituted a more stringent quality control process for incoming raw materials, including enhanced testing for contamination before storage. This systematic approach allowed us to resolve the issue quickly, prevent further contamination, and regain product quality.

Q 19. How do you ensure the security of raw materials?

Ensuring the security of raw materials requires a layered security approach. This starts with physical security measures such as secured storage areas, access control systems (e.g., key card access, surveillance cameras), and regular security patrols. For particularly valuable or sensitive materials, additional security measures like alarm systems and specialized storage containers might be necessary. Beyond physical security, robust inventory control procedures are crucial to track material movement and identify discrepancies. Regular audits and reconciliation of inventory records with physical stock help detect any unauthorized access or loss. Thorough employee background checks and strict security protocols for personnel also play a significant role. Finally, proper documentation and chain of custody records help track material throughout its lifecycle.

Q 20. How do you comply with regulations regarding hazardous materials?

Compliance with regulations regarding hazardous materials is paramount. This necessitates strict adherence to OSHA (Occupational Safety and Health Administration), EPA (Environmental Protection Agency), and other relevant regulations. This includes proper labeling and storage of hazardous materials in designated areas, comprehensive safety data sheets (SDS) readily available, employee training on safe handling procedures, and emergency response plans in place for spills or accidents. Regular inspections ensure compliance with all applicable regulations and help identify potential hazards. Accurate record-keeping of material usage, disposal, and any incidents related to hazardous materials is essential for audit purposes. We must always maintain up-to-date knowledge of the evolving regulations and implement appropriate changes to our processes to remain compliant.

Q 21. Describe your experience with managing raw material rotation.

Effective raw material rotation, typically using the FIFO (First-In, First-Out) method, is crucial to minimize waste and maintain product quality. This involves using the oldest materials first, preventing spoilage or degradation of older stock. Implementing a clear labeling system, including lot numbers and expiration dates, is essential for tracking and rotating stock efficiently. Regular inventory checks and adjustments to storage organization help ensure FIFO practices are followed consistently. In some cases, specialized software can assist in tracking lot numbers and expiration dates to automate the rotation process. For example, in a food manufacturing setting, using FIFO for ingredients ensures that the freshest ingredients are used, minimizing the risk of spoilage and maintaining the quality of the finished product.

Q 22. How do you communicate effectively with warehouse staff and other departments?

Effective communication in raw stock handling is crucial for smooth operations. I believe in a multi-faceted approach. With warehouse staff, I prioritize clear, concise instructions, using both verbal and visual aids like diagrams or checklists for complex tasks. Regular team meetings allow for open dialogue, addressing concerns and celebrating successes. For interdepartmental communication, I rely heavily on email and project management software for documenting tasks, deadlines, and progress updates. For instance, when coordinating with procurement, I use detailed purchase orders and regularly confirm delivery schedules to avoid delays. I also participate actively in cross-functional meetings to ensure seamless flow of information.

Consider this: Imagine a miscommunication about the temperature requirements for a batch of perishable goods. Clear communication prevents spoilage and financial losses. I actively foster a culture of open communication where everyone feels comfortable raising questions or concerns.

Q 23. What is your experience with reporting and analyzing inventory data?

My experience with inventory data reporting and analysis is extensive. I’m proficient in using various software (such as ERP systems and dedicated inventory management tools) to track stock levels, analyze consumption rates, and identify trends. I can generate reports on various metrics, including stock turnover, obsolete inventory, and storage capacity utilization. For example, I’ve used this data to identify slow-moving items and propose strategies to liquidate them, preventing unnecessary storage costs. I also utilize data analysis to forecast future demand, allowing us to optimize stock levels and prevent stockouts. I can create visual dashboards that present key inventory metrics in an easily understandable format for different stakeholders. This allows management to make data-driven decisions.

In one instance, by analyzing inventory data, I identified a consistent overstocking of a particular raw material. By adjusting ordering quantities and implementing a just-in-time inventory strategy, we were able to reduce storage costs by 15%.

Q 24. How do you manage peak seasons or periods of high demand?

Managing peak seasons requires proactive planning and flexible resource allocation. Before peak periods, I conduct thorough assessments of expected demand, reviewing historical data and considering any market trends or anticipated promotional activities. Based on these projections, we adjust staffing levels, potentially by utilizing temporary workers or overtime. We also optimize our warehouse layout to maximize efficiency and ensure sufficient storage space. This might involve pre-positioning frequently used items or rearranging stock for better accessibility. Furthermore, we refine our internal processes, implementing more streamlined procedures and improving communication to ensure that we meet the increased demand without compromising quality. We may also explore options like third-party logistics providers to handle excess volume if needed.

For instance, during a previous holiday season, we implemented a color-coded system for prioritizing orders and allocating resources efficiently, leading to a 20% increase in order fulfillment rate.

Q 25. How do you adapt to changing priorities and work demands?

Adaptability is paramount in raw stock handling. I approach changing priorities by focusing on prioritization and clear communication. Using project management tools, I ensure that tasks are re-evaluated and adjusted based on the new demands. I communicate the changes to the team clearly and transparently, providing necessary training or support. This includes maintaining flexibility within the team by encouraging cross-training so that individuals can handle various tasks as priorities shift. I also ensure regular feedback sessions to address any challenges and make necessary adjustments in our workflow. I believe in using a flexible approach and prioritize tasks based on their urgency and impact, which allows me to effectively manage any shifting demands while maintaining efficiency.

Imagine a sudden supplier delay – I’d immediately inform relevant stakeholders, explore alternative sources, and adjust our production schedule accordingly, preventing disruption of the entire operation.

Q 26. Explain your experience with barcode scanning and other inventory tracking technologies.

My experience with inventory tracking technologies is extensive. I’m proficient in using barcode scanners, RFID (Radio-Frequency Identification) systems, and warehouse management systems (WMS). I understand the importance of data accuracy and the efficiency gains achieved through automation. Barcodes allow for quick and accurate identification of raw materials, aiding in efficient receiving, put-away, and picking processes. RFID offers enhanced tracking capabilities, allowing for real-time monitoring of inventory location and movement. WMS integration provides a holistic view of our inventory, enabling better stock control and forecasting. I am also adept at troubleshooting any technical issues that might arise with these systems, ensuring continuous operation.

For example, we implemented an RFID system for tracking high-value raw materials, which significantly reduced inventory discrepancies and improved the accuracy of our stock reporting. It allowed us to instantly locate and manage items across our warehouse.

Q 27. What steps do you take to prevent contamination of raw materials?

Preventing contamination of raw materials is crucial for maintaining product quality and safety. We employ a multi-layered approach. First, we ensure appropriate storage conditions: proper temperature control, humidity control, and protection from pests are implemented based on the specific requirements of each material. We also maintain strict cleanliness protocols within the warehouse, including regular cleaning and sanitation of storage areas and equipment. Raw materials are stored in designated areas according to their sensitivity to contamination, preventing cross-contamination. Our receiving process involves thorough inspections of incoming materials for any signs of damage or contamination. We also implement FIFO (First-In, First-Out) methods to minimize the risk of spoilage and maintain optimal product rotation.

For instance, we use specialized containers and pallets for storing temperature-sensitive raw materials, and we conduct regular pest control inspections to prevent infestations.

Q 28. Describe your understanding of quality control procedures in raw stock handling.

Quality control in raw stock handling is fundamental to our operations. Our procedures begin with the incoming inspection of raw materials, which includes verifying their quality against specifications, checking for damage or defects, and ensuring they meet our quality standards. We use various tools, including visual inspections, tests, and sometimes specialized equipment. This allows us to identify and reject any substandard materials before they enter our production process. Sampling methods are employed for large quantities, to ensure representative quality assessment. Throughout the storage process, we adhere to strict protocols to maintain the quality and integrity of the materials, including regular checks of storage conditions and monitoring for any signs of degradation. Documentation is key, and we maintain detailed records of each inspection, ensuring traceability for any quality-related issues.

For example, we may conduct regular moisture content tests on grains to ensure they meet specific parameters. This ensures consistent quality for final products and prevents issues like spoilage or mold growth.

Key Topics to Learn for Raw Stock Handling Interview

- Inventory Management: Understanding FIFO/LIFO methods, cycle counting, and stock rotation techniques. Practical application: Explain how you’d optimize stock levels to minimize waste and maximize efficiency.

- Receiving and Inspection: Processes for verifying incoming raw materials against purchase orders, identifying discrepancies, and documenting quality checks. Practical application: Describe your experience handling damaged or substandard materials and the steps you took to resolve the issue.

- Storage and Organization: Best practices for storing raw materials to prevent damage, spoilage, and contamination. Practical application: Explain how you would design a storage system for a specific type of raw material, considering factors like space constraints and material properties.

- Warehouse Safety and Compliance: Adherence to safety regulations, proper handling procedures, and understanding of relevant legislation. Practical application: Describe a time you had to address a safety concern related to raw material handling.

- Record Keeping and Documentation: Accurate and timely recording of all raw material transactions, including receipts, transfers, and disposals. Practical application: Explain your experience with inventory management software and data entry procedures.

- Technology and Equipment: Familiarity with common warehouse equipment (forklifts, pallet jacks, etc.) and inventory management systems. Practical application: Discuss your proficiency with specific technologies used in raw stock handling.

- Problem-Solving and Troubleshooting: Identifying and resolving issues related to stock discrepancies, damaged goods, or inefficiencies in the handling process. Practical application: Detail a situation where you identified a problem and implemented a solution to improve the efficiency of raw stock handling.

Next Steps

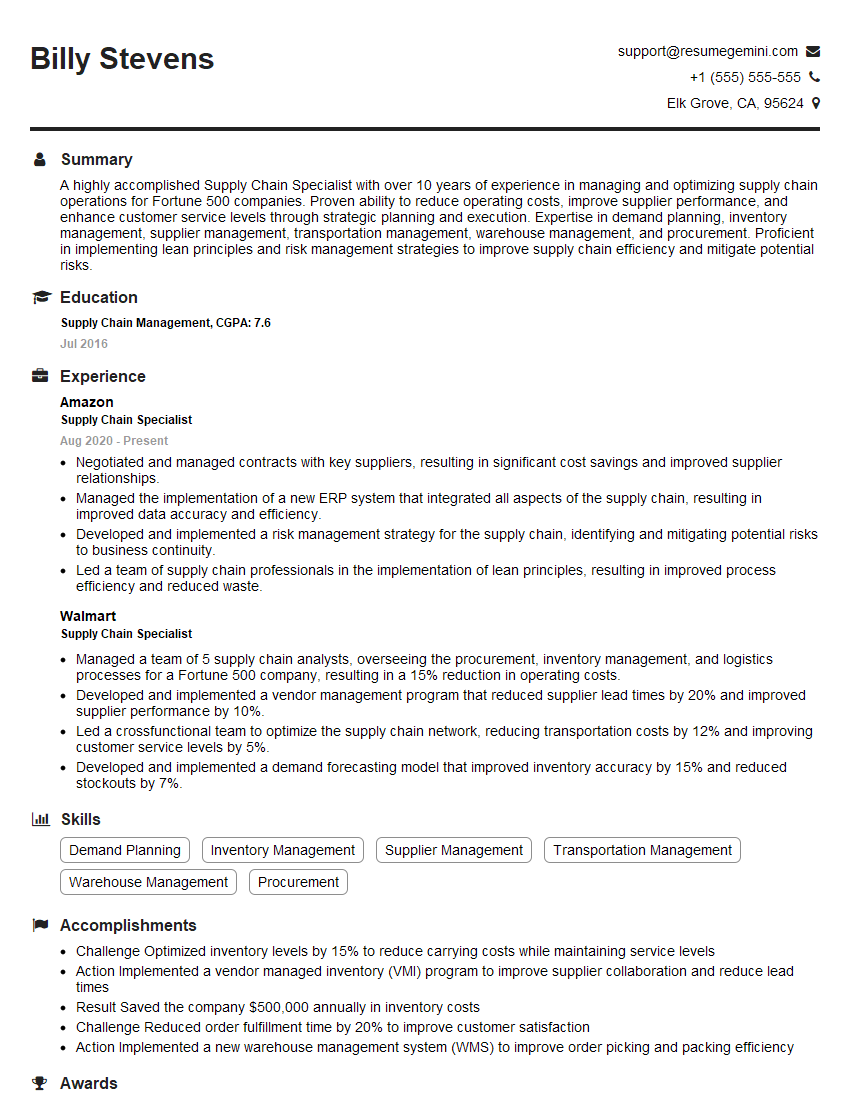

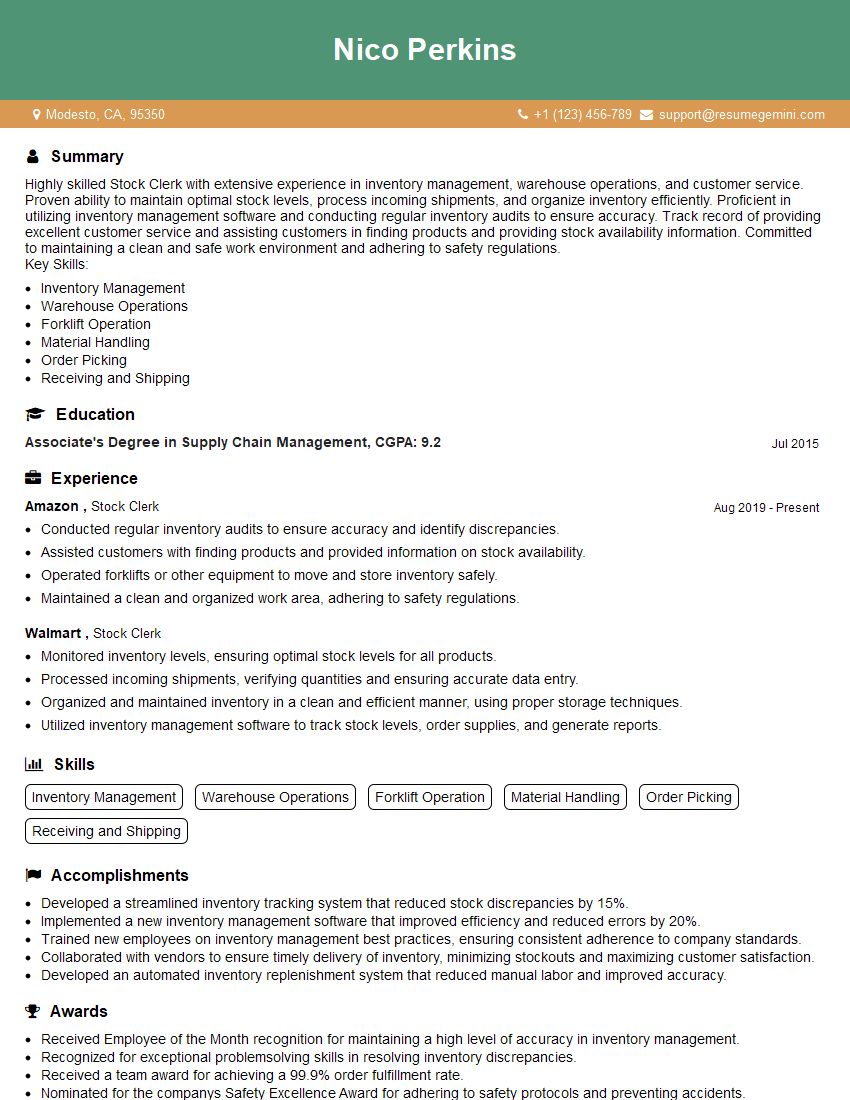

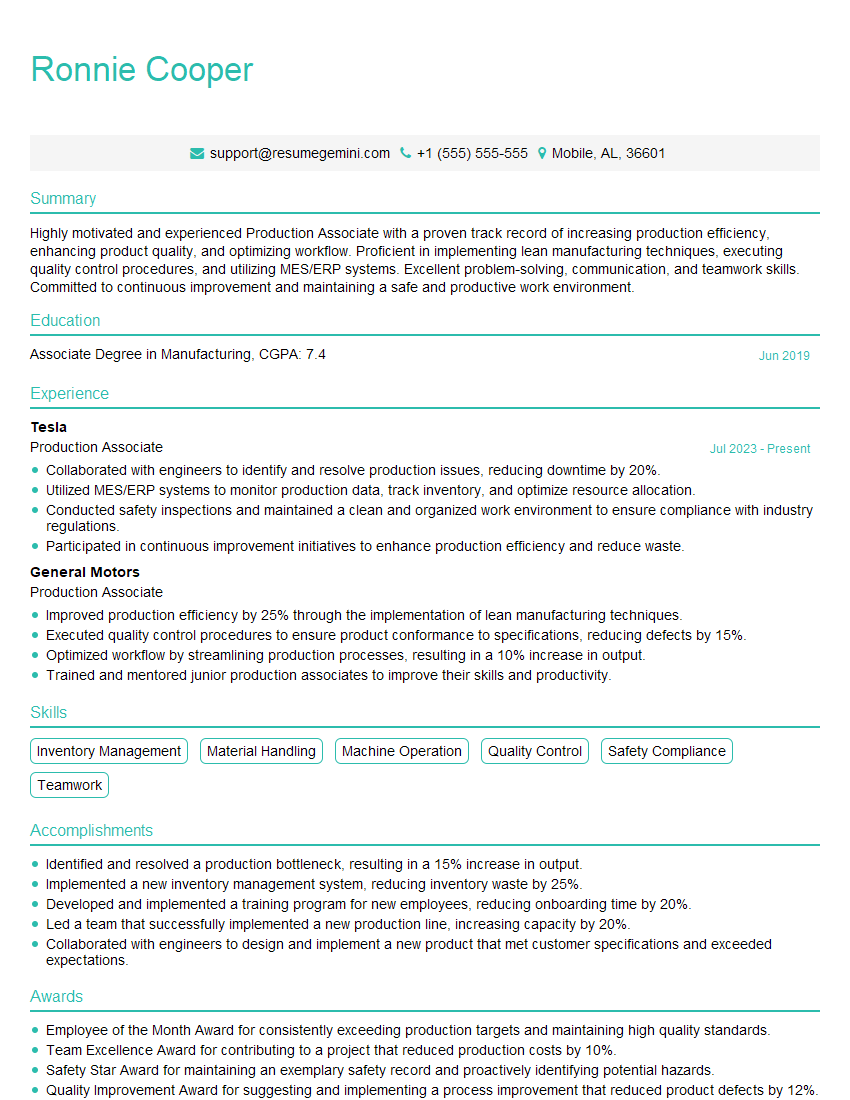

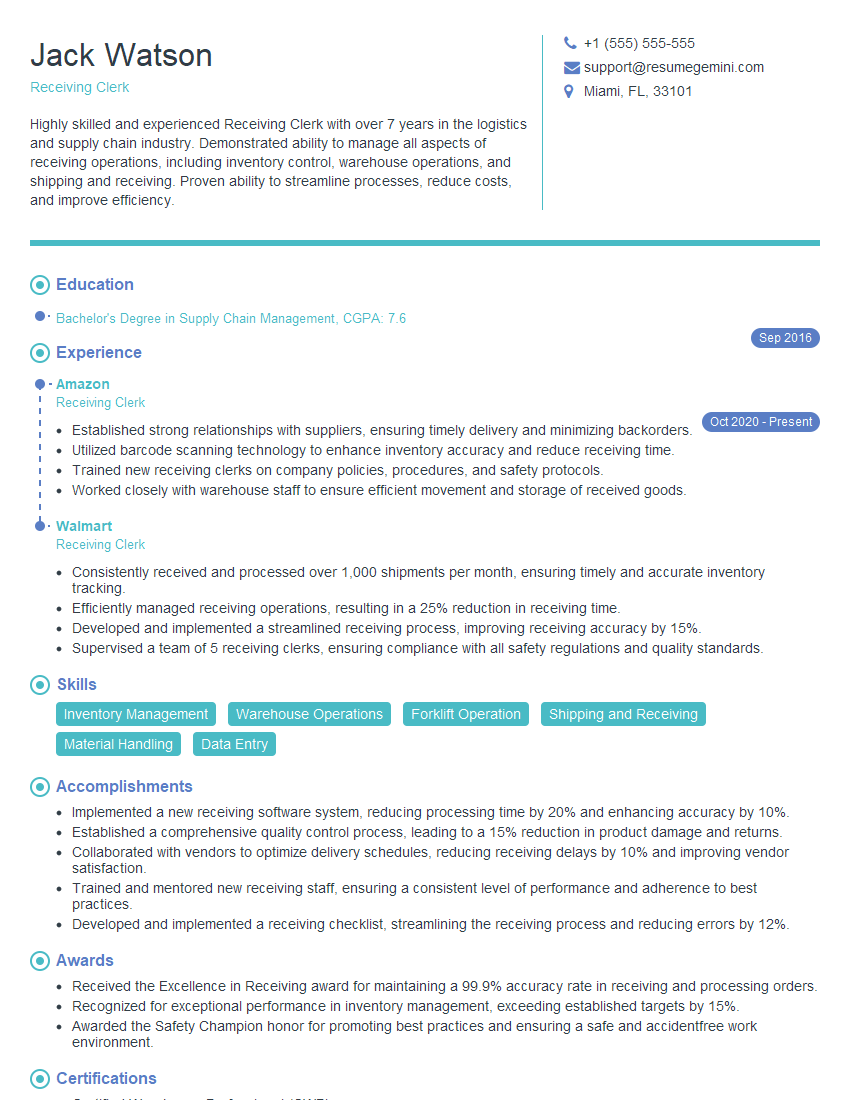

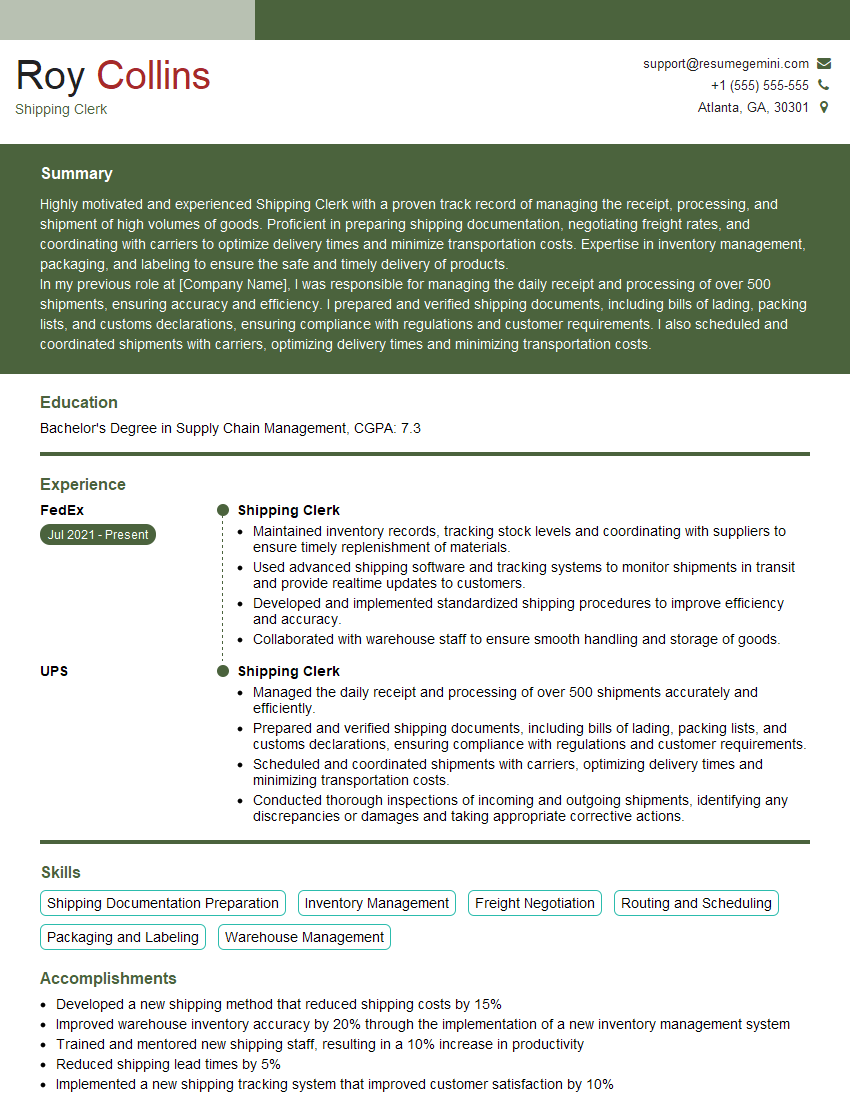

Mastering raw stock handling is crucial for career advancement in logistics, manufacturing, and supply chain management, opening doors to higher-paying roles and increased responsibility. To boost your job prospects, creating an ATS-friendly resume is essential. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your skills and experience effectively. Examples of resumes tailored to Raw Stock Handling are available to help guide you.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good