Every successful interview starts with knowing what to expect. In this blog, we’ll take you through the top Read and Interpret Shipping Labels interview questions, breaking them down with expert tips to help you deliver impactful answers. Step into your next interview fully prepared and ready to succeed.

Questions Asked in Read and Interpret Shipping Labels Interview

Q 1. What are the key components of a standard shipping label?

A standard shipping label is like a package’s passport, containing all the essential information for its journey. Key components include the shipper’s and consignee’s addresses (who’s sending and receiving), the tracking number (allowing you to monitor its location), the shipping carrier’s information (e.g., UPS, FedEx, USPS), the weight and dimensions of the package, and any special handling instructions (e.g., ‘fragile,’ ‘handle with care’). Often, you’ll also see a barcode that’s automatically scanned at various points during transit.

- Shipper Address: The sender’s complete address, including street address, city, state, zip code, and country.

- Consignee Address: The recipient’s complete address, mirroring the shipper’s address format.

- Tracking Number: A unique alphanumeric code assigned to each package for tracking its progress.

- Service Type: Indicates the type of shipping service used (e.g., Ground, Express, Overnight).

- Special Handling: Instructions for handling the package based on its contents (e.g., ‘Fragile,’ ‘Perishable,’ ‘Keep Dry’).

Q 2. How do you identify the shipper and consignee on a shipping label?

Identifying the shipper and consignee is straightforward. The shipper’s address is usually at the top of the label, often labeled ‘From’ or ‘Sender.’ It provides the full address of the person or company sending the package. Similarly, the consignee’s address is typically below it, clearly marked as ‘To’ or ‘Recipient,’ giving the complete address of the intended recipient. Think of it like a letter – the return address and delivery address are prominent for clear identification.

Example: A label might show ‘From: Acme Corp, 123 Main St, Anytown, CA 91234’ and ‘To: John Doe, 456 Oak Ave, Somewhere, NY 10001’.

Q 3. Explain the significance of tracking numbers on shipping labels.

Tracking numbers are crucial for monitoring the shipment’s status and location throughout its journey. Each tracking number is unique and linked to specific package data within the carrier’s system. By entering the tracking number on the carrier’s website or app, you can see updates such as when the package was picked up, where it is currently located, and when it’s estimated to be delivered. This provides peace of mind and allows for proactive problem-solving if delays or issues occur. Imagine trying to find a needle in a haystack without a tracking number – that’s how critical it is.

Q 4. How do you interpret different shipping label classifications (e.g., fragile, perishable)?

Shipping label classifications, such as ‘fragile,’ ‘perishable,’ or ‘handle with care,’ provide critical instructions to handlers regarding the package’s contents and how it should be treated. ‘Fragile’ means the package contains easily breakable items and requires extra caution. ‘Perishable’ indicates temperature-sensitive goods requiring specific storage and handling. These labels help ensure the package arrives safely and in good condition. Ignoring these labels can lead to damage or spoilage.

For example, a package labeled ‘Perishable’ with a temperature range might need to be stored in a refrigerated truck, while one marked ‘Fragile’ might require additional padding during transit.

Q 5. What are the different types of shipping labels you have encountered?

Over the years, I’ve encountered various shipping label types, including standard labels printed directly by shippers, pre-printed labels from carriers (like those you buy at the post office), and labels generated electronically through integrated shipping systems. There are also labels with specific markings for hazardous materials, oversized packages, and international shipments. Each type serves a unique purpose and often contains specific information tailored to its use case.

- Standard Labels: Common for everyday packages.

- Hazardous Materials Labels: For dangerous goods requiring specific handling and documentation.

- International Shipping Labels: Contain customs information for international shipments.

- Pre-printed Labels: Purchased from carriers and filled in by the shipper.

Q 6. How do you handle damaged or illegible shipping labels?

Damaged or illegible labels present a significant challenge. First, I assess the damage. If minor, I try to piece together the information. If it’s completely illegible, I carefully document the package condition, including photos, and try to identify any remaining markings, even partially visible ones. I would then contact the shipping carrier to report the issue, providing all available information and the package’s details. The carrier’s expertise might help identify the sender and recipient using their systems, and may determine the best course of action based on the specifics of the situation.

Q 7. What are the implications of incorrect shipping label information?

Incorrect shipping label information can lead to serious consequences, including delays, misdelivery, or even the package being lost entirely. An incorrect address will prevent the package from reaching its intended recipient. Missing or inaccurate information can lead to confusion for handlers, causing delays or the package to be held until the discrepancies are resolved. In the worst-case scenario, incorrect information for hazardous materials can pose safety risks. Accuracy is paramount – it’s the foundation of successful shipping.

Q 8. Explain the process of verifying shipping label accuracy.

Verifying shipping label accuracy is crucial for ensuring timely and accurate delivery. It’s like proofreading a crucial document before sending it – a small error can have significant consequences. My process involves a multi-step verification procedure:

Data Matching: I meticulously compare the information on the label against the order details, including the recipient’s and sender’s addresses, contact information, package weight and dimensions, and the number of packages. Any discrepancy here is a red flag.

Barcode Verification: I scan the barcode (if applicable) to confirm it matches the tracking number and other label data. This automated check quickly identifies inconsistencies.

Carrier-Specific Rules: I check for compliance with the specific carrier’s requirements. For example, USPS labels may have different formatting requirements than FedEx or UPS labels. This often involves checking for correct labeling of hazardous materials or special handling instructions if needed.

Visual Inspection: I visually inspect the label for clarity, legibility, and damage. A smudged or torn label could lead to delays or misdelivery.

By following these steps, I ensure accuracy and minimize the risk of shipping errors.

Q 9. How do you identify potential shipping label discrepancies?

Identifying shipping label discrepancies requires a keen eye for detail. Think of it as detective work – you need to find the clues that indicate something isn’t right. Common discrepancies include:

Address Mismatches: Incorrect street numbers, zip codes, or missing apartment numbers are frequent errors.

Weight and Dimension Discrepancies: The weight or dimensions stated on the label may not match the actual package, leading to incorrect pricing and potential delivery issues.

Incorrect Carrier Information: The carrier’s logo or tracking information might be incorrect or missing.

Missing or Incorrect Service Type: The label may not clearly indicate the required shipping speed (e.g., express, ground).

Damaged or Illegible Labels: Smudged ink, tears, or incorrect font sizes can make the label difficult to read, causing delays.

I often use a checklist during my review to ensure I catch all potential discrepancies.

Q 10. How do you use shipping labels to track shipments?

Shipping labels are the key to tracking shipments. The tracking number, usually a barcode and alphanumeric string, is the heart of this process. I use the tracking number in conjunction with the carrier’s website or tracking software to monitor the shipment’s progress. For example, a tracking number like 1Z999AA10123456789 (a hypothetical example) can be entered into the respective carrier’s website (FedEx, UPS, USPS, etc.).

This allows me to see the current location of the shipment, its estimated delivery date, and any significant events, such as when it was picked up, sorted at a facility, or delivered. This real-time information provides visibility into the shipment’s journey and helps manage expectations and resolve any potential delays.

Q 11. What are some common mistakes made when creating or interpreting shipping labels?

Common mistakes in creating or interpreting shipping labels often stem from human error or a lack of attention to detail. These include:

Incorrect Address Information: A misspelled address or a missing apartment number is a frequent cause of delays or misdelivery. It’s like trying to send a letter with an incomplete address – it’s unlikely to reach its destination.

Incorrect Weight and Dimensions: Underestimating the package weight leads to increased shipping costs or delayed delivery; overestimating leads to unnecessary expenses.

Failure to Declare Hazardous Materials: This is a safety hazard and can lead to significant fines and penalties. This is particularly important for international shipping.

Insufficient Postage: This is a classic mistake – the package won’t be delivered until additional postage is added.

Unclear or Damaged Labels: A faded or damaged label makes it hard for the carrier to read the information and often results in delays.

Careful attention to detail and using label-creation software with verification features can prevent these errors.

Q 12. How do you handle international shipping labels?

International shipping labels require significantly more attention to detail than domestic shipments. Think of it as navigating a complex international airport – you need the right paperwork and you need it to be correct. Key differences include:

Customs Declarations: International labels require detailed customs declarations, including the contents, value, and origin of the goods. Incorrect declarations can result in delays, fees, or even seizure of the goods.

Harmonized System (HS) Codes: Accurate HS codes (a standardized system of names and numbers used to classify traded products) are crucial for customs processing. Incorrect HS codes can cause delays or penalties.

Prohibited and Restricted Items: Certain items are prohibited or restricted for import into specific countries. It’s vital to understand these regulations before creating the label.

Additional Documentation: International shipments often require additional documentation, such as commercial invoices or certificates of origin.

I utilize specialized software and resources to ensure compliance with all international shipping regulations.

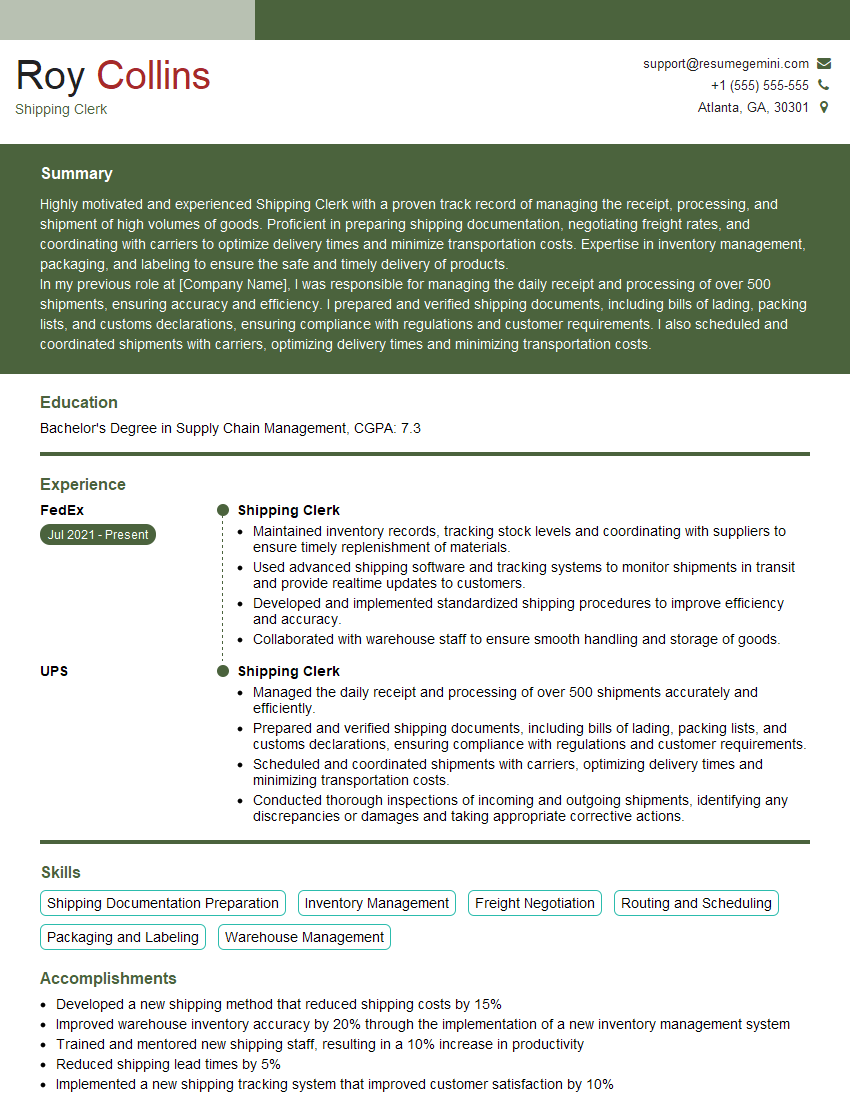

Q 13. Describe your experience with different carrier labels (e.g., FedEx, UPS, USPS).

My experience encompasses a wide range of carriers, including FedEx, UPS, and USPS. Each carrier has its own specific label formats, tracking systems, and regulations. For example:

FedEx: FedEx labels often feature a unique tracking number format and a focus on speed and efficiency.

UPS: UPS labels are known for their clear layout and comprehensive tracking capabilities.

USPS: USPS labels are often simpler in design, reflecting the carrier’s focus on cost-effective solutions. They might require different formats and labeling requirements depending on the service type.

Understanding the nuances of each carrier’s system is key to accurate label creation and efficient shipment tracking.

Q 14. How do you ensure compliance with shipping regulations when reviewing labels?

Ensuring compliance with shipping regulations is paramount – it’s about following the rules and preventing legal issues. My approach involves:

Staying Updated: I regularly review the latest regulations from relevant agencies (e.g., DOT, IATA for hazardous materials). Shipping laws frequently change.

Carrier-Specific Compliance: I confirm that each label adheres to the specific carrier’s rules regarding prohibited items, packaging standards, and labeling requirements.

Hazardous Materials Handling: I have extensive knowledge of handling and labeling hazardous materials, adhering to strict regulations to ensure safe transport. This involves verifying correct classification, packaging, and documentation.

International Regulations: For international shipments, I ensure compliance with the regulations of both the origin and destination countries. This often involves using specialized software or consulting with customs brokers.

By proactively ensuring compliance, I avoid potential delays, penalties, and legal issues.

Q 15. What software or systems have you used to generate or manage shipping labels?

Throughout my career, I’ve utilized a variety of software and systems for generating and managing shipping labels. This includes widely used platforms like ShipStation, Shippo, and EasyPost, which offer streamlined label creation, tracking, and management capabilities. I’m also proficient with integrating these systems with enterprise resource planning (ERP) software such as SAP and Oracle, allowing for seamless order fulfillment and label generation directly from the order management system. For smaller-scale operations, I’ve utilized the built-in label printing features within e-commerce platforms like Shopify and WooCommerce. My experience spans both cloud-based and on-premise solutions, giving me a broad understanding of the various approaches to shipping label management.

For example, in a previous role, we migrated from a manual, spreadsheet-based system to ShipStation. This significantly improved efficiency, reducing label creation time by over 50% and eliminating manual errors associated with data entry. The integration with our ERP system allowed for automated label generation upon order confirmation, further streamlining the process.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you prioritize shipments based on shipping label information?

Prioritizing shipments hinges on several factors gleaned directly from the shipping label. The most common include:

- Delivery Deadline/Service Level: Labels clearly indicate the selected shipping service (e.g., Next Day Air, 2-Day Shipping, Standard Ground). Shipments with tighter deadlines are naturally prioritized.

- Customer Priority: Some labels may include internal flags indicating high-value customers or urgent orders requiring expedited handling.

- Freight Charges: For larger or more expensive shipments, prioritization may be necessary to ensure timely delivery and minimize potential losses due to delays.

- Destination: Certain geographic locations might require priority handling due to logistical complexities or potential delivery challenges.

In practice, I often use a combination of these factors, employing a system that may involve color-coding labels or using specialized software that prioritizes shipments based on configurable rules. Think of it like an air traffic controller managing numerous flights, each with its own urgency and destination.

Q 17. How do you resolve discrepancies between shipping label information and received goods?

Discrepancies between shipping labels and received goods are addressed through a methodical process. The first step is a thorough verification of the label information against the physical contents. This includes checking the:

- Number of items: Compare the quantity indicated on the label with the actual number of items received.

- Item descriptions: Verify that the product names and SKUs match those on the label and packing slip.

- Weight and dimensions: Compare the dimensional weight (or actual weight) with the information on the label to identify potential discrepancies.

If discrepancies exist, I investigate potential causes such as picking or packing errors, mislabeling during transit, or potential theft. Documentation of the discrepancies, including photos and detailed descriptions, is crucial. Depending on the severity, contact with the carrier and/or the customer may be necessary to initiate a claim or return/replacement process. Thorough record-keeping ensures accountability and helps prevent future issues.

Q 18. Explain your experience using barcode scanners to read shipping labels.

I’m highly proficient in using barcode scanners to read shipping labels. This is a fundamental aspect of efficient warehouse and logistics operations. My experience ranges from handheld scanners to integrated conveyor systems with embedded scanners. I understand the importance of proper scanning techniques to ensure accurate data capture, minimizing misreadings and associated errors. I’m also familiar with various barcode symbologies (e.g., EAN, UPC, Code 128) commonly used on shipping labels and can troubleshoot issues related to scanner malfunctions or poor label quality.

For example, I once identified a pattern of misread barcodes due to label damage occurring during the packaging process. By implementing better packaging procedures and using higher quality labels, we significantly reduced the error rate.

Q 19. How familiar are you with different types of shipping label formats?

My familiarity with shipping label formats is extensive. I’m adept at interpreting labels from various carriers (e.g., FedEx, UPS, USPS) and understand the standard information included on each, such as tracking numbers, recipient and sender addresses, weight, dimensions, and service type. Beyond the common formats, I also possess knowledge of specialized label formats used in specific industries or for particular services (e.g., hazardous materials labels, international shipping labels). This includes understanding the regulations and compliance requirements associated with these different label types. The ability to quickly parse information from various label designs is key to my efficiency and accuracy.

Q 20. Describe your process for identifying and addressing potential shipping delays based on label information.

Identifying and addressing potential shipping delays involves close monitoring of tracking information. By regularly checking the status updates provided by carriers, I can proactively identify potential issues such as:

- Late pickup: If a shipment hasn’t been picked up as scheduled, immediate action is needed to contact the carrier and investigate the cause.

- Unforeseen delays: Weather events, unforeseen transportation issues, or carrier-related problems can all cause delays. The label information helps pinpoint the location and stage of the shipment, facilitating better communication with the carrier and customer.

- Incorrect address information: Verification of the address on the label is critical. Errors in the address can lead to significant delays or lost shipments.

My approach involves implementing a system for tracking shipments and promptly notifying relevant parties when delays are anticipated, providing proactive updates to customers to manage expectations. This approach minimizes negative impact and promotes trust.

Q 21. How would you handle a situation where a shipment arrives with an incorrect label?

A shipment arriving with an incorrect label is a serious issue requiring immediate attention. My first step would be to carefully document the situation, including photos of the label, packaging, and contents. Then, I would compare the contents with the information on the incorrect label and any accompanying documentation (packing slip). This helps determine if the contents match a different shipment altogether. I’d then investigate possible causes, like mislabeling at the warehouse or during transit. Based on my findings, I would:

- Contact the carrier: Report the issue and initiate an investigation into how the mislabeling occurred.

- Contact the sender and/or receiver: Explain the situation, provide updates, and coordinate the correct delivery or return process.

- Initiate a claim if necessary: If the mislabeling results in damage or loss, filing a claim with the carrier is important.

The goal is to resolve the issue efficiently and minimize inconvenience to all involved parties. Preventing future occurrences requires analyzing the root cause and implementing corrective actions to ensure accurate labeling processes.

Q 22. Explain your experience with hazardous materials labels and regulations.

My experience with hazardous materials labels and regulations is extensive. I’ve worked for over eight years handling and interpreting labels for a wide range of dangerous goods, from flammable liquids to corrosive substances and radioactive materials. I’m deeply familiar with the intricacies of regulations like the International Air Transport Association (IATA) Dangerous Goods Regulations and the US Department of Transportation (DOT) Hazardous Materials Regulations. This includes understanding the proper classification of hazardous materials, the required label markings, and the specific packaging and handling requirements for safe transportation.

For instance, I once had to identify a mislabeled shipment of Class 3 flammable liquids. By carefully examining the discrepancies between the label and the shipping documents, I was able to prevent a potential accident. I immediately initiated a protocol to re-label the shipment correctly, ensuring compliance with all regulations before its transportation could resume.

- Understanding the different hazard classes and their associated labels

- Knowing the specific requirements for packaging, handling, and documentation

- Proficiently using the various regulatory documents and databases

- Experience with emergency response procedures for hazardous material incidents

Q 23. How familiar are you with different classes of hazardous materials?

My familiarity with the different classes of hazardous materials is comprehensive. I understand the nine main classes defined by the UN and how they are further divided into subclasses. This knowledge enables me to correctly identify the hazards associated with each class and the appropriate handling procedures. Think of it like a color-coded system for danger – each color (class) represents a different type of hazard, and each shade (subclass) represents a specific level of risk within that category. I’m proficient in interpreting the pictograms and warning labels associated with each class, allowing me to quickly assess the potential risks involved.

For example, Class 1 (Explosives) has many subcategories, ranging from extremely insensitive explosives (1.1) to extremely sensitive ones (1.5), demanding vastly different handling. Similarly, Class 9 (Miscellaneous Dangerous Goods) encompasses a diverse range of items requiring detailed understanding of their specific hazards.

Q 24. How do you ensure the safety and security of shipments based on label information?

Ensuring the safety and security of shipments relies heavily on accurately interpreting label information. My approach is multi-faceted. First, I meticulously examine each label for compliance with relevant regulations. This includes verifying the accuracy of the hazard class, UN number, proper shipping name, and any additional warnings. Then, I cross-reference this information with the shipping documents to ensure consistency. Any discrepancies immediately trigger a further investigation to resolve potential issues before shipment.

Beyond label verification, I consider environmental factors. For example, a shipment of temperature-sensitive goods might require special handling based on the expected transit conditions. Finally, I ensure that appropriate handling and storage procedures are followed, including proper segregation of incompatible materials. Imagine it as being a detective – you need to gather all the evidence (label information, shipping documents, etc.) to understand the nature of the shipment and take the right steps to secure it. Ignoring even the smallest detail could lead to a significant incident.

Q 25. How do you manage large volumes of shipping labels efficiently?

Managing large volumes of shipping labels efficiently requires a systematic approach. I utilize digital tools like label scanning software and database management systems to organize and track shipments. This allows for quick retrieval of information and automated checks for compliance. Think of it as a well-organized library – each label is a ‘book’ with crucial information, and the software acts as the cataloguing and search engine, helping you quickly find what you need. Data-driven analytics allows identification of potential issues or patterns that might not be obvious through manual review. For example, identifying a particular carrier who consistently has labeling issues allows for proactive communication and potential training or compliance action.

Implementing barcode or RFID systems allows for automated tracking and processing, greatly reducing manual labor and improving overall accuracy. This also makes it easier to identify and resolve problems swiftly.

Q 26. Describe a situation where you had to interpret a complex or ambiguous shipping label.

In one instance, I encountered a shipment with a partially damaged label. The UN number was illegible, and some of the hazard pictograms were smudged. This ambiguity made proper classification difficult. My approach was methodical. I first examined the remaining legible parts of the label, focusing on the shipping name and any partially visible pictograms. This gave me some clues about the potential hazard class. Then, I cross-referenced the partially legible shipping name with regulatory databases to try and find a match.

Next, I investigated the accompanying shipping documents to look for any further clues, such as the contents description. Through this painstaking process of cross-referencing and investigation, I was able to deduce the correct hazard class and UN number. I immediately initiated contact with the shipper to clarify the discrepancies and prevent potential risks. This situation reinforced the importance of thoroughness and the need to utilize all available resources when dealing with ambiguous shipping labels.

Q 27. How do you stay updated on changes in shipping label regulations and best practices?

Staying updated on changes in shipping label regulations is crucial for maintaining compliance and ensuring safety. I subscribe to industry newsletters, attend professional conferences and workshops, and regularly consult regulatory bodies’ websites for updates. It’s like staying abreast of the latest software updates – you need to constantly adapt and upgrade your knowledge to maintain peak performance. Organizations like IATA and DOT publish regular updates, and staying informed allows me to apply these changes to my work practices promptly.

Further, I actively participate in online forums and professional networks to exchange information with other experts and learn about emerging best practices. This continuous learning ensures my skills and knowledge remain current and aligned with the ever-evolving landscape of shipping regulations.

Key Topics to Learn for Read and Interpret Shipping Labels Interview

- Understanding Label Structure: Learn to identify key components like shipper and receiver information, addresses, tracking numbers, weight, dimensions, and handling instructions. Practice recognizing variations in label formats across different carriers.

- Interpreting Shipping Codes and Abbreviations: Familiarize yourself with common shipping codes, abbreviations, and special handling instructions (e.g., fragile, perishable, hazardous materials). Understand the implications of these markings for handling and logistics.

- Identifying Potential Issues: Learn to spot discrepancies or inconsistencies on shipping labels that might indicate potential problems, such as incorrect addresses, missing information, or damaged goods. Develop skills in recognizing potential delays or delivery issues based on label information.

- Applying Knowledge to Practical Scenarios: Practice interpreting labels in various contexts, including inbound and outbound shipments, different types of goods, and various carrier requirements. Consider how label information impacts inventory management and customer service.

- Regulatory Compliance: Understand relevant regulations and standards related to shipping labels, such as hazardous materials regulations (e.g., IATA, DOT) and international shipping standards. This demonstrates a commitment to safety and legal compliance.

- Technology Integration: Explore how shipping labels interact with warehouse management systems (WMS) and other logistics technologies. Understanding data flow and integration points is crucial in many roles.

Next Steps

Mastering the ability to read and interpret shipping labels is crucial for success in numerous logistics and supply chain roles. It demonstrates attention to detail, problem-solving skills, and a commitment to efficient operations. To maximize your job prospects, it’s essential to present your skills effectively. Creating an ATS-friendly resume is key to getting noticed by potential employers. ResumeGemini is a trusted resource to help you build a professional and impactful resume that highlights your expertise. Examples of resumes tailored to Read and Interpret Shipping Labels are available to help guide you. Invest time in building a strong resume – it’s your first impression on a potential employer!

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good