The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Reading and interpreting electrical schematics and blueprints interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Reading and interpreting electrical schematics and blueprints Interview

Q 1. Explain the difference between a single-line diagram and a three-line diagram.

Single-line and three-line diagrams are both simplified representations of electrical systems, but they differ in their level of detail. A single-line diagram (SLD) shows the main power flow paths using only one line to represent each phase, regardless of the number of conductors. Think of it as a high-level overview, perfect for understanding the overall system architecture. It’s ideal for initial design planning or system studies, focusing on major components and connections.

In contrast, a three-line diagram (3LD) provides a more detailed representation, explicitly showing all three phases (or more, depending on the system) and their individual connections. This means you’ll see separate lines for each phase, making it much clearer how each phase is routed and connected. 3LDs are crucial during detailed design and construction phases where precise wiring configurations are essential. Imagine it as a zoomed-in view of the system, useful for installers and technicians.

Example: An SLD might show a transformer feeding a motor, while a 3LD would show each phase of the transformer connected to the respective phase of the motor, including neutral and grounding connections if applicable.

Q 2. How do you identify different types of wires and their gauges on a schematic?

Identifying wires and gauges on a schematic relies on understanding the standard conventions used. Wire types are often indicated by color codes (e.g., black for hot, white for neutral, green for ground) or alphanumeric designations. The legend or key of the schematic will define these. Gauge, referring to the wire’s diameter, is typically represented numerically (e.g., AWG 12, meaning American Wire Gauge size 12). A smaller number indicates a thicker, higher-current-carrying wire. Sometimes the gauge is written directly next to a wire segment, or it might be listed in the components table or the wire schedule provided with the schematic.

Example: A schematic might show a black wire labeled ‘AWG 14’ connected to a switch, indicating a 14-gauge hot wire. Another might use color-coded wires with a legend explicitly detailing their type and gauge.

Q 3. What are the standard symbols used for resistors, capacitors, and inductors?

Standard symbols for common components are essential for understanding schematics. These symbols are usually standardized by organizations like IEEE (Institute of Electrical and Electronics Engineers).

- Resistor: Typically represented by a zig-zag line, sometimes with a value indicated next to it (e.g.,

1kΩ). - Capacitor: Often shown as two parallel lines, sometimes with a curved line indicating polarity for polarized capacitors. The value is usually also indicated (e.g.,

10µF). - Inductor: Usually represented by a coil shape, sometimes with a value indicated (e.g.,

10mH).

Example: A resistor might be drawn as ~~~ with 100Ω next to it, a capacitor as |-| with 22µF, and an inductor as lllllll with 10mH.

Q 4. How do you interpret a ladder logic diagram?

Ladder logic diagrams are used primarily in Programmable Logic Controllers (PLCs) to represent control logic. They use a ladder-like structure with two vertical rails representing power supply and ground. Horizontal rungs represent logical statements, which, when true, allow current (or signals) to flow between the rails. Each rung contains various elements such as contacts (representing inputs), coils (representing outputs), timers, counters, and other logic gates. The sequence from left to right determines the order of operation.

Interpreting a ladder logic diagram involves tracing the current flow through each rung based on the input conditions. If all contacts on a rung are closed (representing a true condition), the coil on that rung is energized (output is activated). This activation can trigger subsequent actions in the circuit.

Example: A simple rung might show a normally open (NO) contact representing a pressure switch. If the pressure switch is activated, the contact closes, allowing current to flow, energizing a coil connected to an output device like a motor or valve.

Q 5. Explain the process of tracing a circuit on a schematic.

Tracing a circuit on a schematic involves systematically following the path of the current or signal flow. Start at a designated point (usually a power source) and follow the wires, noting each component and connection. It’s like following a map. Use a pencil or highlighter to track the paths, ensuring that you note each connection point and component value. Pay close attention to junctions, splits, and branches in the circuit. The schematic’s legend will clarify the symbols and meanings.

Example: To trace a signal through an amplifier, start at the input terminal, follow the signal path through the transistors, resistors, and capacitors, and finally reach the output terminal. Note any feedback loops or signal splitting points along the way.

Q 6. Describe different types of electrical drawings (e.g., wiring diagrams, P&ID diagrams).

Several types of electrical drawings serve different purposes:

- Wiring Diagrams: Show the physical layout and connections of wires, cables, and components in a system. They are detailed and crucial for installation and maintenance.

- Schematic Diagrams: Symbolic representation of circuits, showing the components and their relationships without focusing on physical layout. Used for design, troubleshooting, and understanding circuit operation.

- Piping and Instrumentation Diagrams (P&IDs): Primarily used in process industries; they show the flow of fluids (liquids, gases) and the instrumentation used to monitor and control these processes. They often include electrical aspects related to instrumentation and control.

- Block Diagrams: Show the major components of a system and their interactions, but without detailed circuitry.

- Layout Drawings: Depict the physical arrangement of equipment in a room or building, showing locations of panels, motors, and other devices. This is vital for installation and maintenance.

Each type provides specific information for different stages of the project lifecycle, from initial design to final installation and maintenance.

Q 7. How do you identify power sources and loads on an electrical schematic?

Identifying power sources and loads is fundamental in interpreting electrical schematics. Power sources are usually depicted with standard symbols and often labeled explicitly. Common symbols include:

- Batteries: Two parallel lines of differing lengths (+ and – terminals).

- AC power sources: A circle with a sine wave symbol or other similar representation.

- DC power sources: A circle with a plus and minus sign.

Loads consume power and are usually components like motors, lamps, resistors, etc. They are clearly indicated on the schematic, and their power ratings may be specified. Sometimes the load is indicated by its function, such as a ‘Motor’ label next to the motor symbol. Following the path of the wires from the power source to the component will help identify the load.

Example: A schematic may show an AC source symbol (circle with sine wave) connected to a light bulb symbol, identifying the source and load clearly.

Q 8. What are the safety precautions you take when working with electrical schematics and blueprints?

Safety is paramount when working with electrical schematics and blueprints. Before even beginning, I always ensure I’m in a well-lit, organized workspace free from clutter. This prevents accidental trips or falls, especially important when concentrating on intricate details. I always keep my work area clean and free from any conductive materials that could create a short circuit.

Next, I familiarize myself with the specific document I’m working with. I carefully review the legend to understand the symbols used. This prevents misinterpretations that could lead to dangerous assumptions during design or troubleshooting. I also check the date and revision number to ensure I’m using the most up-to-date version. Using outdated documents is a significant safety hazard.

Finally, I never work on live electrical systems while reviewing schematics. I always verify the power is completely disconnected before undertaking any hands-on work related to the schematics. If working with high-voltage systems, I follow strict lockout/tagout procedures to ensure the system is fully isolated and secured.

Q 9. Explain the purpose of a grounding symbol on a schematic.

The grounding symbol, often depicted as a triangle with a vertical line, represents a connection to earth ground. Its purpose is to provide a safe path for fault currents to flow, preventing dangerous voltage buildup and protecting equipment and personnel from electrical shocks. Think of it as a safety valve for electricity; if something goes wrong, the current is safely diverted into the ground instead of causing harm.

For instance, in a household electrical system, the grounding wire ensures that if a fault occurs (like a short circuit in an appliance), the current will flow to ground through the grounding wire instead of through the metal casing of the appliance, preventing electric shock. The grounding symbol on a schematic highlights this crucial safety connection, reminding designers and technicians of its importance in maintaining a safe electrical system.

Q 10. How do you interpret relay logic symbols?

Relay logic symbols represent the logical operations performed by relays – electromechanical switches that open or close circuits based on input signals. Common symbols include normally open (NO) and normally closed (NC) contacts, depicted by differently oriented lines within a relay coil symbol. Understanding these symbols is essential for tracing the flow of control signals and understanding the overall system’s behavior.

For example, a relay with NO contacts will close and complete the circuit when the relay coil is energized. Conversely, a relay with NC contacts will open the circuit when energized. Multiple relays can be combined to create complex logic, such as AND, OR, and NOT gates, depicted through the interconnection of contacts.

I find using truth tables and Boolean algebra to systematically analyze relay logic extremely helpful. This allows me to predict the circuit’s output for various input combinations, ensuring the logic correctly implements the intended function. For complex systems, simulation software aids in verification and troubleshooting.

Q 11. How do you determine voltage and current ratings from a schematic?

Voltage and current ratings are usually indicated directly on the components’ symbols within the schematic, often accompanied by specifications such as power (Watts) and resistance (Ohms). For example, a resistor might be labeled “1kΩ, 1/4W,” indicating its resistance and power rating. Similarly, a capacitor might show its capacitance and voltage rating. These values are crucial for selecting appropriate components and preventing damage from exceeding the electrical limits.

If the ratings aren’t directly on the component symbol, I would refer to the component’s datasheet referenced in the schematic or bill of materials. The schematic will often indicate the specific part number which can then be used to look up the specifications in the manufacturer’s documentation. Failing to correctly identify the ratings could lead to component failure, system malfunction, and potentially dangerous situations.

Q 12. Describe your experience using AutoCAD or similar CAD software for electrical design.

I have extensive experience using AutoCAD Electrical and similar CAD software for electrical design, from creating single-line diagrams to developing detailed panel layouts. I’m proficient in creating and modifying electrical schematics, generating reports, and managing project revisions using version control. I’ve used AutoCAD Electrical to design everything from small control circuits to large industrial power distribution systems.

My experience includes creating libraries of standard components, generating reports for bill of materials and wiring schedules, and collaborating with other engineers on large-scale projects using shared design files. I’m comfortable utilizing the software’s advanced features like schematic symbol creation, automated wire numbering, and error checking. For complex designs, I use the software’s simulation capabilities to verify the functionality of the circuit before physical construction.

Q 13. How do you identify potential hazards or errors in an electrical drawing?

Identifying potential hazards and errors in electrical drawings involves a systematic review process. I start with a visual inspection, checking for any inconsistencies or obvious errors like missing components, incorrect wiring, or improperly labeled components. I then check for compliance with relevant electrical codes and standards. This is often an iterative process, checking against a checklist.

Next, I verify the circuit’s logic by tracing signal flow paths. This helps identify potential short circuits, open circuits, or incorrect logic operations. For more complex systems, I might use simulation tools to verify the circuit’s behavior and identify any unexpected outcomes. Furthermore, I look for discrepancies between the schematic and the physical layout of the system, if available, to catch any errors before construction begins. Finally, a thorough review helps identify potential hazards like insufficient grounding, improper fuse sizing, or inadequate protection from overcurrent or overvoltage.

Q 14. How do you interpret control system schematics?

Interpreting control system schematics involves understanding the interaction between different components, such as sensors, actuators, Programmable Logic Controllers (PLCs), and Human Machine Interfaces (HMIs). These schematics illustrate the flow of information and control signals within the system, showing how the various components interact to achieve a specific task. Understanding the logic involved in control processes (e.g., sequential logic, feedback loops) is crucial.

For example, a control system for a manufacturing process might show sensors monitoring temperature and pressure, sending signals to a PLC that adjusts actuators (valves, motors) to maintain the desired conditions. The HMI displays the system status and allows operators to adjust set points. I use these schematics to understand the system architecture, troubleshoot malfunctions, and propose improvements. A methodical approach, tracing the signal paths and understanding the role of each component, is vital for effectively interpreting these complex systems.

Q 15. What is the significance of a bill of materials (BOM) in electrical design?

A Bill of Materials (BOM) in electrical design is an essential document listing every single component required for a project. Think of it as a shopping list for your electrical system, ensuring nothing is missed during procurement and construction. It’s crucial for accurate budgeting, efficient ordering, and smooth project execution. A comprehensive BOM typically includes the component’s description, part number, quantity, manufacturer, and possibly even a cost. For example, a BOM might list ’10 x 12 AWG copper wire, 50ft rolls,’ specifying exactly what’s needed. Without a detailed BOM, projects can easily face delays and cost overruns due to missing parts or inaccurate ordering.

A well-structured BOM contributes to better inventory management, simplifies assembly, and facilitates future maintenance and repairs. It’s a cornerstone of effective project management in electrical engineering.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience working with electrical codes (e.g., NEC).

I have extensive experience working with the National Electrical Code (NEC), the standard for electrical safety in the United States. My experience encompasses both residential and commercial projects, and I’m thoroughly familiar with its various articles and sections. This includes understanding requirements for grounding, wiring methods, overcurrent protection, and more. For instance, I’ve routinely applied NEC Article 210 (Branch Circuits) to design and calculate proper branch circuit protection for various loads, and Article 250 (Grounding) for implementing effective grounding systems. My familiarity extends to interpreting local amendments and regulations to ensure complete compliance with all applicable codes. I’m adept at identifying potential code violations and proposing solutions to ensure safety and adherence to standards. In fact, I once identified a potential fire hazard in a building’s electrical system during a review, preventing a potentially dangerous situation.

Q 17. How do you determine the proper sizing of conductors and fuses?

Conductor and fuse sizing are crucial for safety and efficient system operation. It’s not just about picking the biggest wire; it’s about balancing current-carrying capacity with voltage drop and safety considerations. To determine proper conductor size, I calculate the expected load current and refer to NEC tables to find the appropriate ampacity for the chosen conductor type (copper or aluminum) and installation method. Voltage drop calculations ensure the voltage at the load remains within acceptable limits, preventing performance issues. For example, a long run of thin wire can lead to excessive voltage drop, making appliances work inefficiently. Fuses and circuit breakers are sized to protect the circuit from overcurrents caused by short circuits or overloads. They are typically chosen to be slightly larger than the maximum expected load current, providing a safety margin. The calculations are based on the NEC’s requirements and load calculations. For instance, a 15-amp circuit would typically use a 15-amp breaker, but the wiring would be sized to handle a slightly higher current to account for momentary overloads.

Q 18. Explain your understanding of different types of protective devices (e.g., circuit breakers, fuses).

Protective devices like circuit breakers and fuses are critical for preventing damage and ensuring safety within electrical systems. They act as the first line of defense against overcurrents, which can lead to overheating, fires, or equipment damage. Circuit breakers are resettable devices that automatically interrupt the current flow when an overload or short circuit occurs. They are typically preferred for their convenience and ease of reset. Fuses, on the other hand, are one-time use devices that melt and break the circuit when subjected to excessive current. They require replacement after tripping. Both devices are selected based on the ampacity of the circuit they protect, ensuring that they trip at a current level that is high enough to protect equipment from minor overloads but low enough to prevent fires or other catastrophic events. The choice between a circuit breaker and a fuse depends on factors like cost, convenience, and specific application requirements. In some high-voltage applications, fuses are preferred due to their faster response time in case of a fault.

Q 19. How do you interpret symbols related to motor control circuits?

Motor control circuits use a variety of symbols to represent different components and their functions. Understanding these symbols is crucial for interpreting the schematic and troubleshooting any issues. Common symbols include those for motors (often depicted as a circle with internal lines suggesting rotation), contactors (represented by a stylized switch), overload relays (often shown as a coil with a contact), and various types of switches and push buttons. The schematic usually uses lines to indicate the interconnections between these elements. For example, a start button is commonly shown as a normally open (NO) contact, while a stop button is a normally closed (NC) contact. The arrangement of these contacts and other components defines the logic of how the motor is controlled, such as the start-stop sequence or any safety interlocks. A thorough understanding of these symbols and their interactions is essential for analyzing and modifying motor control systems. Being able to read these symbols allows for easy troubleshooting and modification of industrial control systems.

Q 20. How do you identify different types of transformers on a schematic?

Transformers are depicted on schematics with specific symbols that indicate their type and characteristics. The basic symbol usually shows two coils, representing the primary and secondary windings. Different transformer types are distinguished by added details in the symbol. For instance, a step-up transformer might show a taller secondary coil than the primary. A step-down transformer shows the opposite. Autotransformers are often shown with a single continuous winding with multiple taps. Three-phase transformers have three primary and three secondary windings represented, often depicted in a delta or wye configuration. Other details, like tap changers, may be shown directly on the symbol or with additional notations. Understanding these variations in the symbol allows an engineer to quickly identify the function and type of transformer within a larger electrical system. It’s essential for analyzing voltage levels, power distribution, and isolation aspects of the electrical design.

Q 21. What is your experience with using electrical simulation software?

I have significant experience utilizing electrical simulation software, including [mention specific software, e.g., ETAP, PSCAD, or similar]. This software allows for comprehensive analysis of electrical systems, including things like power flow studies, short-circuit calculations, and protective device coordination. For instance, I’ve used these tools to model complex power distribution systems for large commercial buildings, verifying that the design would meet all requirements under various operating conditions. The software also allows for detailed simulations of motor starting and transient behavior, crucial for ensuring proper design and preventing equipment damage. Simulation provides a virtual test bed, allowing me to identify and resolve potential issues before actual construction begins, saving time and resources. It’s essential for optimizing designs, enhancing safety, and mitigating potential problems before they arise in the real-world implementation of electrical systems.

Q 22. Describe your process for troubleshooting an electrical circuit based on a schematic.

Troubleshooting an electrical circuit using a schematic is a systematic process that involves careful observation, logical deduction, and the application of electrical principles. My approach begins with a thorough understanding of the schematic itself, identifying the power source, load components, and the pathways of current flow. I then carefully inspect the physical circuit, comparing it point-by-point with the schematic.

- Visual Inspection: I start with a visual inspection of the circuit for any obvious problems such as loose wires, burnt components, or damaged insulation. This often helps identify the problem area quickly.

- Continuity Testing: Using a multimeter, I check the continuity of wires and components to confirm connections. This is particularly useful in tracing broken wires or faulty components.

- Voltage Measurement: I measure the voltage at various points in the circuit to identify where voltage drops occur, indicating a potential fault. A significant voltage drop across a component suggests a possible malfunction.

- Current Measurement: Measuring current helps determine if a component is drawing excessive current, which might indicate a short circuit or an overloaded component.

- Signal Tracing (if applicable): For more complex circuits, I may use an oscilloscope or logic analyzer to trace signals and identify problems in their timing or amplitude.

For example, if the schematic shows a light not illuminating, I’d first check the bulb, then the switch, followed by the wiring connecting them to the power source. Each step involves a visual check and the appropriate multimeter test (continuity or voltage). This methodical process ensures efficient and safe troubleshooting.

Q 23. How do you interpret symbols for sensors and actuators?

Interpreting symbols for sensors and actuators on electrical schematics is crucial for understanding the system’s functionality. These symbols are standardized to represent specific components and their behavior. I’m familiar with a wide variety of sensor and actuator symbols, and I always refer to the relevant standards and documentation to ensure accurate interpretation.

- Sensors: Sensor symbols usually indicate the type of physical quantity being measured (temperature, pressure, light, etc.) and often include a visual cue such as a thermometer for temperature sensors or an arrow for flow sensors. For example, a temperature sensor might be represented by a circle with a thermometer inside.

- Actuators: Actuator symbols generally depict the type of motion or action they perform (e.g., a motor, solenoid, valve). A motor might be shown with a circular symbol indicating rotation, while a valve might be shown with a circular symbol with a line indicating the flow control.

Understanding these symbols is paramount because they directly relate to the system’s functionality. Misinterpreting a symbol can lead to incorrect troubleshooting or design choices. I always cross-reference the symbol with the component’s datasheet to ensure a complete understanding of its specifications and operation.

Q 24. Explain your experience with reading and interpreting PLC ladder logic programs.

I have extensive experience reading and interpreting PLC ladder logic programs. Ladder logic provides a visual representation of the logic controlling a Programmable Logic Controller (PLC), making it relatively easy to understand the sequence of operations and interdependencies within an automated system. I am proficient in various PLC programming software such as Rockwell Automation RSLogix 5000, Siemens TIA Portal, and Allen-Bradley Studio 5000.

My experience includes:

- Troubleshooting PLC programs: Identifying and resolving faults in existing ladder logic code based on error messages, diagnostics, or observed malfunctions.

- Developing new PLC programs: Designing and implementing ladder logic programs from scratch based on project requirements and specifications.

- Modifying existing PLC programs: Adapting and updating existing ladder logic programs to meet changing operational needs or integrate new equipment.

For instance, I once worked on a project where a bottling line had intermittent production stoppages. By analyzing the ladder logic program, I identified a timing issue within the control sequence causing the machine to halt prematurely. I corrected the timing parameters in the ladder logic, effectively resolving the issue and restoring the line’s efficient operation.

Q 25. How familiar are you with various types of electrical connectors and their symbols?

I possess a strong understanding of various types of electrical connectors and their associated symbols. Accurate interpretation of these symbols is critical for proper wiring and connection of devices. My familiarity encompasses various types including terminal blocks, screw connectors, crimp connectors, quick-disconnect connectors, and various industrial connectors.

I’m comfortable identifying and using symbols for different connector types in schematics and blueprints. This includes understanding the number of poles, wire gauge, and any specific features like grounding connections or shielding. For example, I can readily distinguish between a standard terminal block symbol and a DIN rail connector symbol based on their respective graphical representation.

My experience involves selecting appropriate connectors based on voltage, current, and environmental factors such as temperature and humidity, ensuring the reliability and safety of the electrical connections.

Q 26. Describe your experience with interpreting architectural blueprints as they relate to electrical systems.

Interpreting architectural blueprints in relation to electrical systems is a crucial aspect of my work. Architectural blueprints provide the spatial context for the electrical design and installation. I use them to identify locations for power outlets, lighting fixtures, and other electrical components. They provide vital information about the layout of walls, ceilings, and floors, which helps determine cable routing and conduit placement.

I analyze the blueprints to understand the overall building layout and identify potential challenges such as obstructions, structural limitations, or specific requirements for different areas. This involves coordinating the electrical design with other building systems, like HVAC or plumbing, to avoid conflicts and ensure efficient installation.

For example, a blueprint will show the location of rooms, doors, and windows. I use this information to plan the placement of light switches and outlets, ensuring they are conveniently located and adhere to building codes. I also use the blueprint to identify where conduits need to be run and to ensure that the electrical system is installed according to building regulations.

Q 27. How do you use schematics to plan and execute electrical installations or repairs?

Schematics are the cornerstone of planning and executing electrical installations or repairs. They serve as a roadmap, detailing the components, connections, and power flow within the system. I utilize schematics throughout the entire process, from initial design to final testing and commissioning.

- Planning: I use schematics to determine the necessary materials and components, and to plan the wiring routes and locations for devices.

- Installation: During installation, I follow the schematic to connect components accurately, ensuring proper polarity and grounding. I frequently cross-reference the physical layout with the schematic to avoid errors.

- Testing: After installation, I test the system thoroughly against the schematic to ensure everything is functioning as designed. I use multimeters and other test equipment to verify voltages, currents, and continuity, comparing my readings with the values specified on the schematic.

- Troubleshooting: If problems arise, I use the schematic to trace the circuits, identify potential fault points, and implement appropriate corrective actions.

For a recent project involving a motor control system, I used the schematic to determine the appropriate motor protection devices, calculate wire sizes, and plan the installation of the motor starter and associated controls. The schematic ensured that the installation was safe, efficient, and met all regulatory requirements.

Key Topics to Learn for Reading and Interpreting Electrical Schematics and Blueprints Interview

- Basic Electrical Symbols and Notation: Understanding common symbols for components like resistors, capacitors, transistors, and integrated circuits. Practice recognizing and interpreting these symbols within the context of a schematic.

- Circuit Analysis Techniques: Applying Ohm’s Law, Kirchhoff’s Laws, and other fundamental circuit analysis methods to understand voltage, current, and power relationships within electrical circuits depicted in schematics.

- Schematic Interpretation: Tracing signal flow, identifying power supplies, understanding component interconnections, and analyzing circuit functionality based on the schematic diagram.

- Blueprint Reading Fundamentals: Interpreting architectural blueprints to understand the building layout and identify locations of electrical components, conduits, and junction boxes.

- Electrical Code Compliance: Familiarizing yourself with relevant electrical codes and regulations (e.g., NEC) and how they are reflected in schematics and blueprints.

- Troubleshooting and Problem-Solving: Developing skills in using schematics and blueprints to diagnose faults, identify potential problems, and propose solutions in electrical systems.

- Practical Applications: Understanding how schematics and blueprints are used in various applications, such as residential wiring, industrial control systems, and automation systems.

- Advanced Concepts (Optional): Explore topics like PLC programming, motor control circuits, or power distribution systems, depending on the specific job requirements.

Next Steps

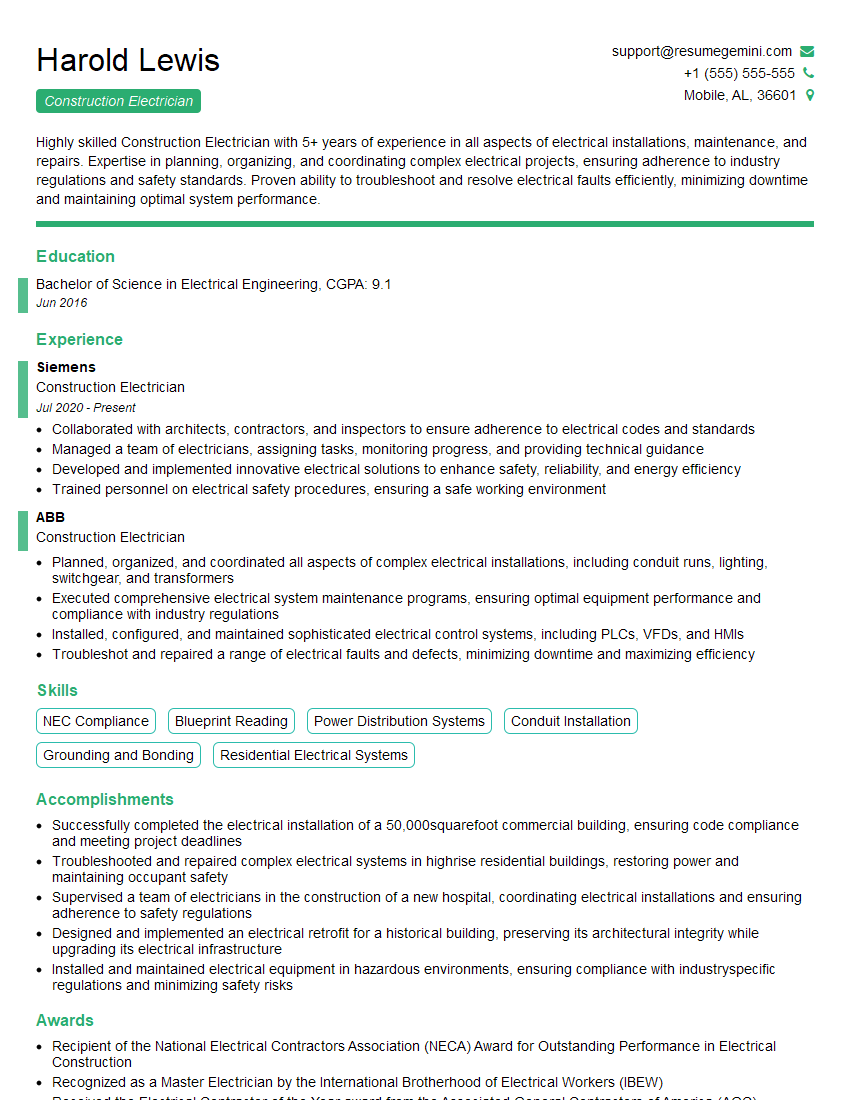

Mastering the ability to read and interpret electrical schematics and blueprints is crucial for career advancement in the electrical engineering and related fields. It demonstrates a strong foundation in electrical theory and practical application, opening doors to more challenging and rewarding roles. To significantly boost your job prospects, crafting an ATS-friendly resume is essential. ResumeGemini is a trusted resource that can help you build a professional and impactful resume tailored to highlight your skills and experience. Examples of resumes specifically designed for candidates with expertise in reading and interpreting electrical schematics and blueprints are available to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good