Interviews are more than just a Q&A session—they’re a chance to prove your worth. This blog dives into essential Removing finished products from a stitching machine interview questions and expert tips to help you align your answers with what hiring managers are looking for. Start preparing to shine!

Questions Asked in Removing finished products from a stitching machine Interview

Q 1. Describe the proper procedure for removing finished products from a stitching machine.

Removing finished products from a stitching machine requires a delicate yet efficient approach. The exact procedure depends on the machine type and the product itself, but the general principles remain consistent. It’s all about minimizing damage to the finished product and preventing machine jams.

- Power Down: Always start by turning off the machine and ensuring it’s completely powered down before attempting to remove anything.

- Gentle Removal: Carefully lift the finished product from the machine. Avoid yanking or pulling harshly, which could distort the stitching or damage the fabric.

- Support the Product: Use both hands to support the entire piece, preventing it from sagging or folding in awkward ways. Think of it like holding a newborn baby – gentle but firm.

- Inspect the Feed Dogs: After removing a product, briefly inspect the feed dogs (the toothed mechanisms that move fabric through the machine) to ensure no fabric scraps or threads are obstructing them.

- Clear the Area: Once removed, place the finished product on a clean, flat surface to avoid further damage.

For example, when removing a delicate embroidered tablecloth, extra care is needed to prevent snagging the embroidery. Conversely, a sturdy denim jacket requires less cautious handling, but still needs a supportive hold during removal.

Q 2. What safety precautions should be observed when removing finished products?

Safety is paramount when working with stitching machines. Several precautions must be observed during product removal:

- Never reach into the machine while it’s running. This is the most fundamental safety rule. The moving parts can cause serious injury.

- Use appropriate personal protective equipment (PPE). While not always required, gloves can protect your hands from sharp needles or fabric edges, especially with heavy-duty products.

- Maintain a clear workspace. Avoid clutter around the machine to prevent tripping or accidental contact with the machine.

- Be mindful of your posture. Improper lifting or awkward reaching can cause back or neck problems.

- Ensure proper machine maintenance. Regular lubrication and cleaning prevent unexpected malfunctions, making the removal process safer and smoother.

A classic example: imagine trying to remove a product while the machine is still sewing – a potentially hazardous situation. Always prioritize safety first.

Q 3. How do you identify potential defects in a finished product as you remove it from the machine?

Identifying defects during removal is crucial for quality control. It’s a visual inspection combined with a bit of tactile feedback.

- Stitch Quality: Examine the stitching for consistency. Uneven stitches, skipped stitches, or broken threads are clear indicators of a problem.

- Fabric Damage: Check for any tears, holes, or snags in the fabric, paying attention to areas that might have been subjected to stress during the stitching process.

- Dimensional Accuracy: Compare the finished product to the pattern or specifications, ensuring correct measurements. Misalignments or incorrect sizes are significant defects.

- Material Integrity: Feel the fabric for any stiffness, looseness, or other issues that might indicate problems with the material itself or the tension settings of the machine.

For example, a slightly puckered seam on a shirt could be detected during removal, alerting you to a potential problem with the machine’s tension or the fabric’s quality. This immediate inspection prevents defective products from reaching the end consumer.

Q 4. What is the optimal speed for removing finished goods to maintain quality and efficiency?

The optimal speed for removing finished goods is a balance between efficiency and quality. There’s no single “correct” speed – it depends on the complexity of the product, the machine’s capabilities, and the operator’s skill.

Too fast: Leads to increased errors, potential damage to the product (pulling, snagging, tearing), and possible machine jams.

Too slow: Reduces productivity and increases overall processing time.

The ideal speed is a steady, controlled pace that allows for careful removal without compromising quality. Think of it like a well-rehearsed dance – smooth, consistent, and precise.

Experienced operators develop a sense of the optimal speed through practice. It’s best to start slowly, focusing on careful handling, and then gradually increase speed as proficiency improves.

Q 5. Explain how different stitching machine types impact the product removal process.

Different stitching machine types significantly influence the product removal process.

- Single-needle machines: Generally have a simpler product removal process, as the finished product is often easily accessible.

- Multi-needle machines: Usually involve removing more complex or larger items, potentially requiring more careful maneuvering to avoid tangling.

- Industrial machines: Often have specific mechanisms for product removal (e.g., automatic cutters or delivery systems) that dictate a particular process.

- Domestic machines: Typically have straightforward removal, but might necessitate extra care due to the smaller size and less robust build.

For instance, a garment stitched on a multi-needle industrial lockstitch machine might need to be carefully unwound from multiple needles, whereas a simple seam on a home sewing machine might simply be lifted away.

Q 6. How do you handle tangled or jammed products during removal?

Handling tangled or jammed products requires patience and a systematic approach.

- Assess the situation: Carefully examine the tangle or jam to understand the cause and the extent of the problem.

- Power off the machine: Ensure the machine is completely off before attempting to resolve the issue.

- Gentle untangling: Try to carefully untangle the threads or fabric, working slowly and methodically. Avoid pulling too hard, which could cause further damage or breakage.

- Use appropriate tools: Depending on the nature of the jam, you might need small scissors, tweezers, or a seam ripper to carefully separate tangled threads or fabric pieces.

- If unresolved: If you cannot resolve the jam, seek assistance from a more experienced operator or technician.

Imagine a situation where a long piece of fabric is tangled within the machine’s mechanisms. A rushed attempt at removal could cause even more problems. Taking your time and carefully untangling is crucial.

Q 7. What are the signs of a malfunctioning stitching machine that might affect product removal?

Several signs indicate a malfunctioning stitching machine that might affect product removal:

- Unusual noises: Grinding, clicking, or other unusual sounds indicate potential mechanical problems that could jam the machine or damage the product during removal.

- Inconsistent stitching: Irregular stitch patterns or skipped stitches often signify problems with the machine’s timing or needle alignment, resulting in harder-to-remove products.

- Difficulty in feeding fabric: Problems with the feed dogs can cause fabric jams, making removal challenging and potentially damaging the product.

- Needle breakage: A bent or broken needle can not only damage the product but also make removal dangerous.

- Overheating: Excessive heat generation may suggest a mechanical issue and should be immediately addressed to prevent product damage and avoid potential fire hazards.

For example, a machine consistently skipping stitches might mean the needle isn’t correctly aligned, resulting in a finished product with loose areas and potentially creating a tangled mess during removal.

Q 8. How do you ensure that removed products are handled without damage?

Handling finished products gently is paramount to avoid damage. Think of it like handling a newborn baby – utmost care is required! My approach involves several key steps. First, I always ensure my hands are clean and dry to prevent staining or soiling the fabric. Second, I use a consistent and controlled movement when removing the product from the machine. This usually involves carefully guiding the fabric away from the needles and feed dogs, avoiding any sudden jerks or pulls. For delicate fabrics, I might even use soft gloves or specialized tools to minimize any potential friction or snagging. Third, I inspect the product immediately after removal for any signs of damage, such as pulled threads or snags. If any damage is found, I immediately document it and report it to my supervisor. Finally, I place the finished product on a soft, clean surface to further prevent any damage during transport to the next stage of production.

Q 9. How do you maintain a clean and organized work area during product removal?

Maintaining a clean and organized workspace isn’t just about aesthetics; it’s crucial for efficiency and safety. Think of it like a well-organized kitchen – everything has its place, and you can easily find what you need. I start by ensuring that all tools and equipment are properly stored when not in use. This includes needles, bobbins, thread cones, and any specialized tools used for product removal. I regularly clean the work area, sweeping up any fabric scraps or loose threads. Any spills are cleaned immediately to avoid accidents. I use designated containers for scrap fabric and discarded materials, promoting recycling and reducing waste. This organized approach significantly minimizes the risk of accidents and improves workflow, ensuring a smoother and more efficient product removal process.

Q 10. Describe your experience with different types of stitching machines and their specific product removal methods.

My experience encompasses a wide range of stitching machines, including single-needle, multi-needle, and industrial sewing machines. Each machine has its own nuances when it comes to product removal. For instance, single-needle machines typically allow for easier product removal, as there’s less bulk and fewer moving parts. Multi-needle machines require a more coordinated approach to prevent tangling and damage, often requiring a gentler, more methodical removal process. Industrial sewing machines, with their high speeds, demand precision and swift removal to avoid any accidental damage and ensure continuous production. I am adept at adapting my techniques based on the machine’s specific design and capabilities. For example, I understand how to safely release tension on industrial machines before product removal to prevent accidental tearing.

Q 11. How do you adjust your product removal technique based on the type of fabric or garment?

The type of fabric and garment significantly influences my product removal technique. Delicate fabrics like silk or lace require an exceptionally gentle touch, often involving slower, more careful movements. I might use specialized tools to support the fabric during removal, avoiding any undue stress on the material. Sturdier fabrics like denim or canvas allow for more assertive removal techniques; however, I still maintain control to prevent snags or damage. For garments with intricate designs or embellishments, I take extra precautions to avoid catching or pulling these details. The shape and size of the garment also play a role. Larger items might need additional support to prevent sagging or stretching during removal.

Q 12. How do you prioritize speed and accuracy in product removal?

Balancing speed and accuracy is a crucial skill. It’s not about rushing; it’s about efficiency. I achieve this through a combination of experience, practice, and organization. My proficiency with different machines and fabrics allows me to quickly assess the optimal removal technique. My organized workspace ensures that I can easily access the necessary tools without delay. I focus on smooth, controlled movements to avoid errors while maintaining a consistent pace. I regularly review my work for accuracy and address any inconsistencies promptly. Regular self-assessment and feedback allow me to continually refine my techniques, improving both speed and accuracy over time. It’s a delicate balance between efficiency and quality.

Q 13. How do you handle variations in product size and shape during removal?

Variations in product size and shape require adaptability. Smaller items require a more precise and delicate approach, while larger items demand careful management to avoid strain or damage. I often utilize support structures or tools to assist in the removal of irregularly shaped items, ensuring even distribution of pressure and preventing distortion. My approach always prioritizes gentle and consistent handling, regardless of size or shape, to ensure the finished product remains undamaged. For example, a large tablecloth requires a different approach than a small handkerchief; I might use two hands or even additional support for the larger item to ensure it doesn’t stretch or tear during removal.

Q 14. What are some common errors during product removal and how do you prevent them?

Common errors include snagging or pulling threads, damaging delicate fabrics, and leaving the product tangled in the machine. Prevention involves careful attention to detail and a proactive approach. Regular maintenance of the stitching machine is crucial, ensuring that needles are sharp, threads are properly tensioned, and the machine is clean and lubricated. Consistent training and adherence to established procedures are equally important. Always double-checking the product before and after removal helps identify and correct any potential issues early on. A methodical approach, coupled with meticulous attention, significantly minimizes the likelihood of these errors. The key is to treat every garment as unique and valuable.

Q 15. What tools or equipment do you use to assist with product removal?

Product removal from a stitching machine often involves simple but crucial tools. The most common are a pair of sharp, fine-tipped scissors for carefully cutting loose threads, and possibly a small, flat object like a seam ripper or even a thin, blunt spatula to gently ease the finished product away from the machine’s needle plate or feed dogs. Sometimes, depending on the product’s design and the machine’s configuration, I might also use a soft cloth to protect the product’s surface during removal. In more complex situations, specialized tools like a thread cutter attachment on the machine itself are helpful.

Think of it like carefully removing a delicate cake from a baking pan – you want to be gentle yet efficient.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain the cleanliness of the machine during product removal?

Maintaining cleanliness is paramount to prevent product damage, maintain machine function and ensure high-quality output. After every product removal, I quickly brush away any loose threads, lint, or fabric scraps from around the needle area, feed dogs, and presser foot. I use a soft-bristled brush and compressed air (if permitted) to reach hard-to-access areas. Spills are immediately wiped up with a damp cloth, and any significant build-up of lint is addressed with a vacuum cleaner specifically designed for industrial sewing machines. Regular maintenance like this keeps the machine running smoothly and prevents jamming, resulting in higher productivity.

Q 17. How do you contribute to the overall efficiency of the production line during product removal?

My efficiency in product removal directly impacts the entire production line. Slow removal creates bottlenecks, delaying the next operator and reducing overall output. I strive for a smooth, continuous flow by performing quick, precise product removal without compromising quality. This includes anticipating potential problems (like tangled threads) and addressing them proactively. By maintaining a consistent pace and minimizing downtime, I help keep the line moving smoothly, increasing the overall number of completed products and maximizing the line’s efficiency.

Imagine it as a relay race—if I’m slow at my stage, the entire team suffers. My speed and precision are vital.

Q 18. Describe a time you encountered a problem during product removal and how you resolved it.

Once, I encountered a particularly stubborn product that was jammed in the machine due to an unexpected knot in the thread. The standard methods weren’t working. Instead of forcing it, which could have damaged both the product and the machine, I carefully unwound the knot using a fine, pointed needle while holding the fabric taut to prevent further damage. This patient approach allowed me to safely remove the product without compromising its integrity or affecting the machine. Learning from this incident, I now double-check the thread supply more regularly to avoid similar occurrences.

Q 19. How many finished products can you typically remove per hour, on average?

The number of finished products I can remove per hour varies depending on the product’s complexity and the machine’s settings. However, on average, for standard items, I can comfortably remove between 70-90 finished products per hour. This number can be higher for simpler items and lower for more intricate ones requiring careful handling. It’s essential to maintain consistency while prioritizing quality to ensure accuracy and meet production targets.

Q 20. How do you ensure the integrity of the stitching during product removal?

Preserving stitching integrity during removal is essential. I use gentle, controlled movements to avoid pulling or stretching the finished product. This often involves carefully guiding the product away from the needle plate and using the scissors to trim any loose threads precisely without cutting into the stitching itself. A soft cloth or a specialized tool can help create a buffer and prevent accidental snags or tears. Careful handling during each step guarantees the customer receives a high-quality, well-stitched product.

It’s like untangling a delicate piece of jewelry—every movement counts.

Q 21. Explain the importance of following standardized procedures for product removal.

Following standardized procedures for product removal is vital for several reasons: it ensures consistency in product quality, minimizes the risk of damage to both the products and the stitching machine, enhances overall production efficiency, and contributes to workplace safety. Standardized procedures provide clear, step-by-step instructions, reducing errors and ensuring all operators follow the same methods. This leads to a uniform level of quality and helps troubleshoot problems more effectively. By adhering to these procedures, we contribute to a more efficient, safer, and more productive workspace.

Think of it like a recipe—following the steps carefully ensures the best outcome.

Q 22. How do you identify and report damaged or defective stitching machines?

Identifying and reporting damaged or defective stitching machines is crucial for maintaining production efficiency and product quality. My approach involves a multi-step process. First, I visually inspect the machine for any obvious signs of damage, such as loose parts, frayed belts, or unusual noises. Then, I check for any error messages displayed on the machine’s control panel. These messages often provide valuable clues about the nature of the malfunction.

If a problem is identified, I immediately stop the machine to prevent further damage or injury. I then meticulously document the issue, including the type of machine, the specific malfunction, and the date and time of discovery. This detailed record is then submitted using our company’s reporting system, typically an online form or a dedicated maintenance logbook. For example, if I notice a needle breaking repeatedly, I’d note the needle type, the fabric type being used, and the potential cause (e.g., improper needle threading, faulty needle plate). This detailed information ensures that the maintenance team can quickly diagnose and repair the issue effectively.

Q 23. Describe your experience with different types of fabrics and how they affect product removal.

My experience spans a wide range of fabrics, from delicate silks and chiffons to heavy-duty denim and canvas. The type of fabric significantly impacts the ease of product removal. Delicate fabrics, like silk, require extra care to prevent snagging or tearing during removal. This often involves using gentle hand movements and specialized tools, like blunt-ended spatulas. Conversely, heavier fabrics, like denim, are more robust and can withstand a more direct removal process.

For example, removing a finished garment from a machine stitching a delicate lace requires more patience and precision than removing a sturdy canvas bag. With lace, I might use a slightly wider seam allowance and carefully ease the fabric off the machine’s feed dogs. This prevents distortion or damage. In contrast, removing a denim product might involve a quicker, more decisive movement, confident that the fabric can withstand the pressure. Understanding these nuances is critical for minimizing waste and preserving the quality of the finished product.

Q 24. What is your preferred method for sorting and organizing removed finished products?

My preferred method for sorting and organizing removed finished products prioritizes efficiency and prevents mix-ups. I typically use a combination of techniques, depending on the specific product and production run. For smaller batches, I employ a visual sorting method, categorizing the products by style or color, placing them into designated bins or trays. Larger production runs often benefit from a more systematic approach using barcodes or unique identifiers assigned during the stitching process.

This allows me to track each product and use a scanner to verify that the correct number of pieces have been successfully removed from each machine. Moreover, this method allows for easy quality control checks and reduces the risk of errors or missing items. In either scenario, cleanliness and organization of the workspace are paramount; a clear and tidy area improves efficiency and reduces the chance of damaging completed goods.

Q 25. How do you handle large batches of finished products efficiently?

Handling large batches of finished products efficiently involves leveraging teamwork and utilizing appropriate tools. First, I ensure that the stitching team is equipped with sufficient removal tools and has clear instructions on procedures. Then, we divide the large batch into smaller, more manageable sub-batches that can be processed simultaneously. Each team member takes responsibility for a sub-batch and works in a coordinated manner.

We also ensure we have adequate storage space for the finished products, keeping them organized to prevent mix-ups or damage. To streamline this process even further, I often implement a system of continuous flow, where products are directly transferred from the stitching machines to packing stations, minimizing intermediate storage. The entire process is closely monitored, and we regularly check for any bottlenecks or inefficiencies to ensure a smooth and productive workflow.

Q 26. How would you deal with a production delay caused by a malfunctioning stitching machine?

A malfunctioning stitching machine can significantly disrupt production. My immediate response involves identifying the problem, as detailed in question 1. Once the issue is identified, I report it immediately to the maintenance team, providing all necessary details. Simultaneously, I prioritize the removal of finished products from other functioning machines to minimize overall delays. Depending on the nature of the malfunction and the urgency of production, we might decide to redistribute workload to other operators or utilize backup machines if available.

In situations where a significant production delay is unavoidable, I communicate the issue to the supervisor and relevant stakeholders, providing realistic estimates for the delay. This transparency is critical for proactive planning and adjustment of delivery schedules. This might involve renegotiating deadlines or informing clients about potential delays.

Q 27. What are your strategies for ensuring consistency in product removal quality?

Maintaining consistency in product removal quality is crucial. My strategy involves several key elements. First, thorough training of all team members ensures everyone understands and follows the same removal procedures. We implement standardized operating procedures (SOPs), including detailed instructions for handling different fabric types and product designs. Regular quality checks are integrated into the workflow, allowing us to identify and correct deviations from the standards.

Additionally, I use visual aids and checklists to reinforce best practices. This could include diagrams showing correct removal techniques or checklists ensuring all necessary steps have been completed. Regular team meetings and feedback sessions also allow for open discussions, identifying and addressing any challenges or inconsistencies in the removal process. Consistent use of appropriate tools, such as blunt-ended spatulas for delicate fabrics, helps maintain high-quality removal consistently.

Q 28. How do you maintain a safe and productive working environment while removing finished products?

Maintaining a safe and productive working environment while removing finished products involves a focus on both safety and efficiency. This includes proper lighting, ergonomic workstations to reduce strain, and readily available safety equipment, like gloves to protect hands. All team members are trained in safe handling procedures, including proper lifting techniques to prevent injuries. The workspace is kept clean and organized, minimizing the risk of tripping hazards and ensuring the efficient flow of products. Regular machine maintenance prevents unexpected breakdowns and potential accidents.

Furthermore, we encourage open communication and teamwork, creating a supportive environment where concerns can be raised without hesitation. We emphasize a culture of safety where each team member is responsible for identifying and reporting any potential hazards. This commitment to safety, coupled with efficient organization, ensures that the removal process is both productive and risk-free.

Key Topics to Learn for Removing Finished Products from a Stitching Machine Interview

- Safe Handling Procedures: Understanding and applying safe techniques for removing finished products to prevent damage to the machine, the product, and yourself. This includes proper use of tools and understanding machine safety protocols.

- Efficient Product Removal Techniques: Mastering quick and efficient methods for removing finished products without compromising quality or causing damage. This includes identifying optimal removal points and minimizing downtime.

- Quality Control During Removal: Inspecting finished products for defects during the removal process. Understanding the importance of immediate quality checks and knowing how to report any issues.

- Troubleshooting Common Removal Problems: Identifying and resolving issues such as tangled threads, jammed products, or malfunctioning mechanisms. This includes basic troubleshooting steps and knowing when to seek assistance.

- Understanding Different Stitch Types and Their Impact on Removal: Recognizing how various stitch types affect the ease and method of product removal. This includes knowledge of common stitch patterns and their corresponding removal techniques.

- Maintaining a Clean and Organized Workspace: Understanding the importance of maintaining a clean and organized workspace around the stitching machine to ensure efficient workflow and prevent accidents.

- Machine Maintenance and Awareness: Basic understanding of routine machine maintenance tasks related to product removal, such as cleaning lint and thread buildup. Recognizing when a machine requires professional maintenance.

Next Steps

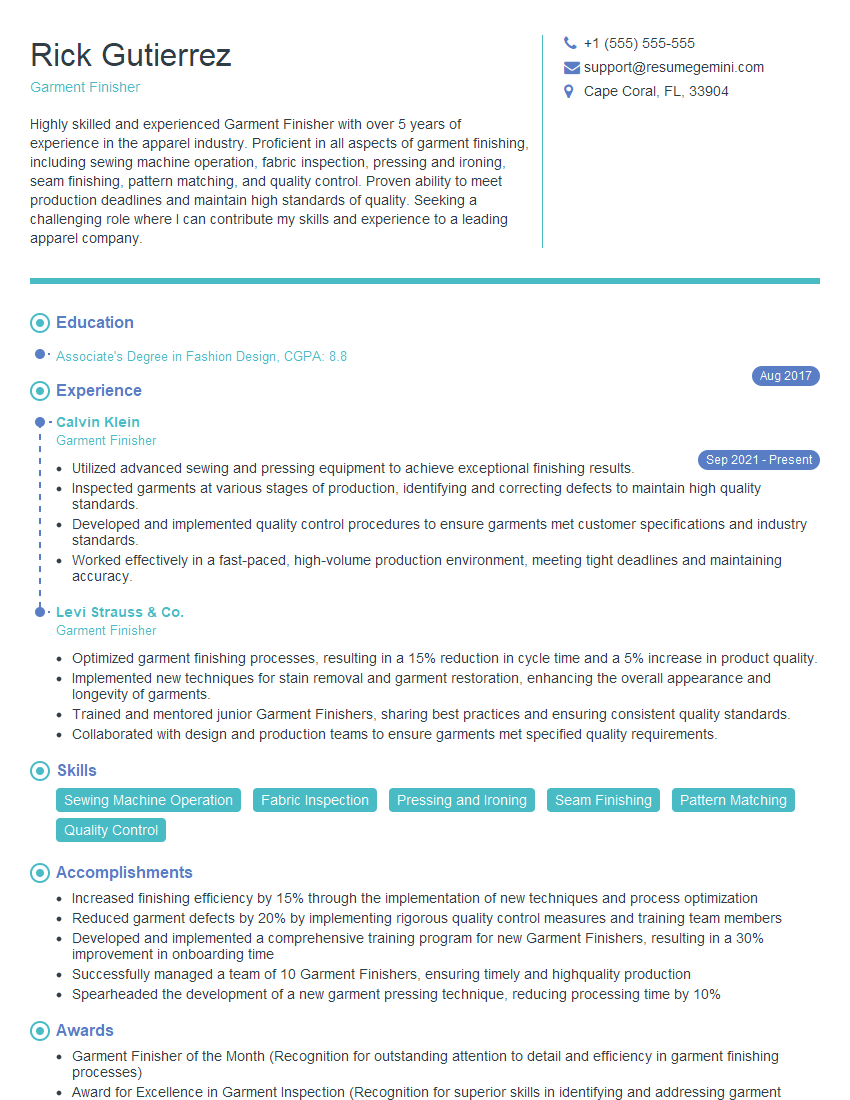

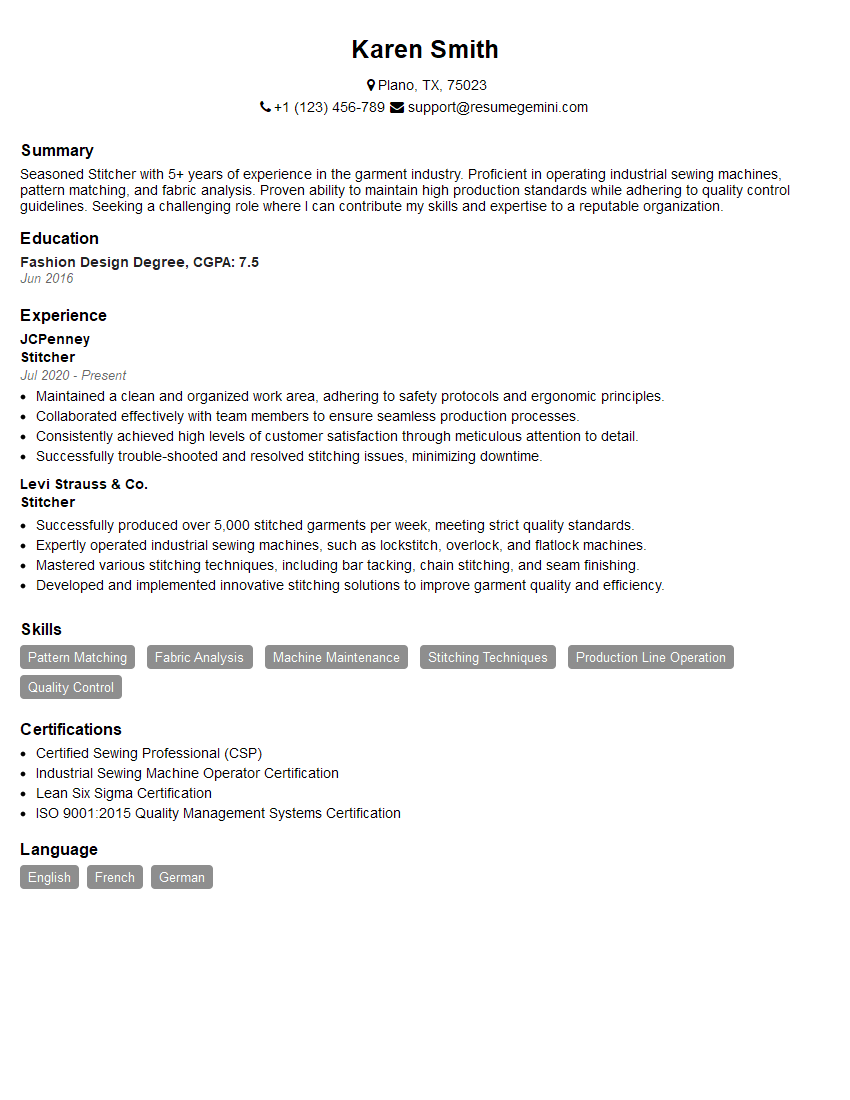

Mastering the skills of removing finished products from a stitching machine is crucial for career advancement in the manufacturing and textile industries. It demonstrates efficiency, attention to detail, and a commitment to quality—highly valued attributes by employers. To maximize your job prospects, it’s essential to create a professional and ATS-friendly resume that highlights your skills and experience. ResumeGemini is a trusted resource that can help you build a compelling resume showcasing your abilities effectively. Examples of resumes tailored to this specific skill set are available through ResumeGemini, allowing you to see how to best present your qualifications to potential employers.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).