Interviews are opportunities to demonstrate your expertise, and this guide is here to help you shine. Explore the essential Replace or repair lamp fixtures and components interview questions that employers frequently ask, paired with strategies for crafting responses that set you apart from the competition.

Questions Asked in Replace or repair lamp fixtures and components Interview

Q 1. What are the common types of lamp fixtures you’ve worked with?

Over the years, I’ve worked with a wide variety of lamp fixtures, encompassing various technologies and designs. Some of the most common include:

- Fluorescent Fixtures: These are ubiquitous in offices and commercial spaces, ranging from simple troffer fixtures to more complex linear systems. I’ve handled both T8 and T5 fluorescent tubes, as well as integrated LED replacements.

- High-Intensity Discharge (HID) Fixtures: These are often found in high-bay applications, such as warehouses or sports arenas. I’ve worked with metal halide, high-pressure sodium, and mercury vapor lamps – each requiring specialized handling due to their high power and potential hazards.

- LED Fixtures: The prevalence of LED lighting is rapidly increasing. I’ve installed and repaired various LED fixtures, from simple bulb replacements to complex integrated systems with dimming capabilities and smart controls. The variety in form factors (recessed, surface-mounted, track lighting) is enormous.

- Incandescent Fixtures: While less common now due to energy efficiency concerns, I’ve still encountered and repaired incandescent fixtures, particularly in older buildings or specialized applications where the warm light is desired.

- Compact Fluorescent Lamps (CFLs): These are a less common sight now thanks to LEDs, but I’ve replaced many CFLs in residential and commercial settings. Their smaller size and often twist-lock bases presented unique installation challenges compared to traditional fluorescents.

My experience spans both the repair of existing fixtures and the installation of new ones, ensuring I can address a broad spectrum of lighting needs.

Q 2. Describe the process of replacing a fluorescent lamp.

Replacing a fluorescent lamp is a straightforward process, but safety is paramount. First, always turn off the power at the breaker box. Then, depending on the fixture type:

- Access the Lamp: Carefully remove any protective covers or diffusers to access the lamp. Some fixtures require specific tools or techniques for this.

- Remove the Lamp: Fluorescent lamps are typically held in place by spring clips or twist-locks. Gently release the lamp from its holders, taking care not to touch the glass.

- Install the New Lamp: Carefully insert the new lamp, ensuring it’s properly seated in the sockets. Match the pins to the sockets carefully.

- Reassemble the Fixture: Replace the diffusers or covers, ensuring they’re securely fastened.

- Restore Power: Turn the power back on at the breaker box and check for proper operation.

Remember to always handle fluorescent lamps with care, as they contain mercury. If broken, follow appropriate cleanup procedures.

Q 3. How do you troubleshoot a malfunctioning ballast?

Troubleshooting a malfunctioning ballast involves systematically checking several components. A ballast is the device that regulates the power supply to a fluorescent or HID lamp. Here’s a common approach:

- Visual Inspection: Start by visually inspecting the ballast for any obvious signs of damage, such as burns, cracks, or loose connections.

- Check the Wiring: Carefully examine the wiring connections to and from the ballast. Look for loose wires, frayed insulation, or any signs of overheating.

- Measure Voltage: Use a multimeter to check the voltage at the ballast’s input and output terminals. Compare the readings to the ballast’s specifications.

- Listen for Unusual Noises: A buzzing or humming sound from the ballast might indicate a problem. An unusual clicking might be a sign of a failing capacitor.

- Lamp Testing: Try replacing the fluorescent lamp with a known-good one. If the problem persists, the ballast is likely the culprit.

If you’re not comfortable working with electrical components, it’s always best to call a qualified electrician. Incorrectly handling a ballast can lead to electric shock.

Q 4. What safety precautions do you take when working with electrical fixtures?

Safety is my top priority when working with electrical fixtures. My procedures always include:

- Turning off the power: Always turn off the power at the breaker box before working on any electrical fixture. Never rely solely on a light switch.

- Using appropriate PPE: This includes safety glasses or goggles, insulated gloves, and non-conductive footwear.

- Using insulated tools: I always use tools with insulated handles to prevent electric shock.

- Double-checking power: After turning off the power, I always double-check with a non-contact voltage tester to ensure the circuit is truly de-energized.

- Working with a partner: For more complex jobs or high-voltage situations, I always work with a partner for safety and efficiency.

- Proper disposal of hazardous materials: I carefully dispose of any hazardous materials, such as broken fluorescent lamps or ballasts, according to local regulations.

Safety isn’t just about following procedures; it’s about having a mindset that prioritizes safety above all else.

Q 5. Explain the differences between HID, LED, and fluorescent lighting.

These three lighting technologies have distinct characteristics:

- Fluorescent Lighting: Uses electricity to excite mercury vapor, producing ultraviolet (UV) light that then excites a phosphor coating inside the tube, producing visible light. They are relatively energy-efficient compared to incandescent bulbs but less so than LEDs. They contain mercury.

- High-Intensity Discharge (HID) Lighting: Similar to fluorescents, but uses a much higher voltage and produces a much more intense light. Different types (metal halide, high-pressure sodium) have different color temperatures and efficiencies. They have a longer lifespan than fluorescents but require more specialized ballasts.

- LED Lighting: Light Emitting Diodes convert electricity directly into light, with very high energy efficiency and a long lifespan. They offer a wide range of color temperatures and are available in many form factors. They’re more expensive upfront, but the lower operating costs and long lifespan often offset the initial investment.

The best choice depends on the application’s needs. LEDs are increasingly becoming the preferred choice for new installations due to their efficiency and longevity, while HID remains prevalent in high-bay applications where high light output is needed.

Q 6. How do you determine the appropriate replacement lamp for a fixture?

Determining the appropriate replacement lamp involves careful consideration of several factors:

- Socket Type: The lamp’s base must match the fixture’s socket. Look for markings on the old lamp or the fixture.

- Wattage: The replacement lamp’s wattage should generally match or be close to the original lamp’s wattage. Overpowering a fixture can damage it.

- Lamp Type: Ensure you replace a fluorescent lamp with a fluorescent lamp, an LED with an LED, etc. Don’t mix technologies without careful consideration and often modifications to the fixture’s wiring and ballast.

- Dimensions: The physical dimensions of the replacement lamp should also match the space in the fixture.

- Color Temperature: The color temperature (measured in Kelvin) affects the look of the light. Higher Kelvin values indicate cooler, bluer light while lower values indicate warmer, yellower light. Consider maintaining consistency.

Always refer to the manufacturer’s specifications for both the fixture and the lamp to ensure compatibility. If unsure, consult a qualified electrician.

Q 7. What are the common causes of lamp failure?

Several factors contribute to lamp failure. Some of the most common include:

- End-of-Life: Lamps have a finite lifespan, and eventually, they will fail due to normal wear and tear.

- Overheating: Overheating can significantly shorten a lamp’s lifespan. This might be due to poor ventilation, dust accumulation, or a faulty ballast.

- Power Surges: Sudden voltage spikes can damage lamps, especially LEDs and fluorescents.

- Physical Damage: Dropping or otherwise physically damaging a lamp will often lead to failure.

- Faulty Ballast (for Fluorescent and HID lamps): A malfunctioning ballast can cause premature lamp failure by supplying incorrect voltage or current.

- Improper Installation: Incorrectly installing a lamp can also lead to premature failure. This includes poor wiring connections or incorrectly seating the lamp.

Understanding the potential causes can help in both preventative maintenance and efficient troubleshooting.

Q 8. How do you identify and address wiring issues in lamp fixtures?

Identifying and addressing wiring issues in lamp fixtures requires a systematic approach, prioritizing safety. First, always disconnect the power to the fixture at the breaker box before beginning any work. This is crucial to prevent electrical shock.

Next, I visually inspect the wiring for any obvious problems like loose connections, frayed wires, or burn marks. I use a voltage tester to confirm the power is off before touching any wires. If there are loose connections, I carefully tighten them using the appropriate tools. Frayed or damaged wires must be replaced; I would cut out the damaged section, stripping back the insulation on the remaining wire, and joining it with wire nuts and electrical tape, ensuring a secure connection. It’s critical to follow the proper color-coding for wiring (typically black for hot, white for neutral, and green or bare copper for ground). Incorrect wiring can lead to malfunction or even fire.

For more complex issues, such as a short circuit, I might use a multimeter to trace the problem. A multimeter can measure voltage, current, and resistance, helping to pinpoint the exact location of the fault. In cases of significant wiring damage or if I’m uncertain about a repair, I always recommend contacting a qualified electrician.

For instance, I once encountered a fixture with a short circuit in a ceiling fan light. By using a multimeter, I identified a faulty wire within the fan motor’s wiring harness. Replacing that segment resolved the issue. Always remember safety first!

Q 9. Describe your experience with different types of lighting controls.

My experience encompasses a broad range of lighting controls, from simple on/off switches to sophisticated systems. I’m familiar with dimmer switches, which allow for adjustable light levels, creating different moods and saving energy. These can be rotary, slider, or digital types. I’ve also worked with occupancy sensors, which automatically turn lights on when motion is detected and off when the area is unoccupied. This is particularly efficient in areas like hallways or bathrooms.

Furthermore, I’ve installed and repaired timer switches, which turn lights on and off at predetermined times. These are useful for security purposes or for automating lighting schedules. More advanced systems include smart lighting controls, which can be integrated with home automation systems, enabling control through smartphones or voice commands. These typically use technologies like Zigbee or Z-Wave for wireless communication. My experience also extends to three-way switches, allowing lights to be controlled from two different locations, commonly seen in hallways or stairwells.

Each type presents its own challenges and requires a thorough understanding of its wiring and functionality. For instance, installing a dimmer switch requires careful consideration of the lamp’s compatibility, as some lamps aren’t dimmable.

Q 10. What are the advantages and disadvantages of LED lighting?

LED lighting has revolutionized the industry, offering numerous advantages over traditional incandescent and fluorescent lighting. The primary advantage is energy efficiency; LEDs consume significantly less power to produce the same amount of light, leading to lower electricity bills and a reduced carbon footprint. They also boast a much longer lifespan, often lasting many years before needing replacement, reducing maintenance costs and waste.

However, LEDs also have some disadvantages. The initial cost of LED fixtures can be higher compared to incandescent bulbs. While the long-term savings outweigh the initial investment, it’s a factor to consider. Also, the color temperature of LEDs can be a concern for some; while many options exist, finding the right color rendering index (CRI) and color temperature (measured in Kelvin) to suit the application is important. Finally, improper disposal of LEDs is crucial, due to the presence of small amounts of heavy metals in some models.

Q 11. How do you handle a situation where a fixture is beyond repair?

When a fixture is beyond repair, due to extensive damage or obsolete parts, my approach is to recommend replacement. Safety is paramount; using a damaged fixture poses a fire or shock hazard. I begin by identifying the type and style of fixture needed. This involves considering factors such as the room’s purpose, desired aesthetic, and required light output. I then source a replacement fixture, ensuring it is compatible with the existing wiring and electrical system.

Before installation, I confirm the new fixture’s specifications match the circuit’s capacity. I carefully disconnect the old fixture, following proper safety procedures, then install the new fixture, making sure all connections are secure and properly grounded. After installation, I thoroughly test the fixture to verify its functionality and safety. In cases involving more complex installations or if I’m dealing with high-voltage systems, I may consult with a qualified electrician. For example, I once had to replace a severely corroded outdoor fixture. After sourcing a suitable replacement, I had to consult an electrician to ensure the proper grounding and installation were handled efficiently and safely given its location.

Q 12. What tools and equipment are essential for lamp fixture repair?

A well-equipped toolbox is crucial for efficient and safe lamp fixture repair. Essential tools include various screwdrivers (Phillips and flathead, in different sizes), pliers (needle-nose and lineman’s), wire strippers/cutters, a voltage tester, a multimeter (for more complex troubleshooting), wire nuts, electrical tape, and a ladder (for ceiling fixtures). Safety glasses and gloves are non-negotiable for protection. Depending on the type of fixture, other specialized tools might be necessary, such as a fish tape for running wires through walls or ceilings, or a special bit for removing specific types of screws.

For instance, when working with recessed lighting, I would use a specialized tool to secure the fixture into the ceiling. The appropriate tools for the job ensure efficiency and prevent damage to components.

Q 13. How do you ensure the proper disposal of old lamps and components?

Proper disposal of old lamps and components is essential for environmental and safety reasons. Different components require different disposal methods. For example, fluorescent tubes contain mercury, so these must be disposed of at designated recycling centers or through municipal hazardous waste programs. LEDs, while less hazardous, often contain small amounts of heavy metals and should be recycled responsibly.

Broken glass from incandescent bulbs should be handled carefully to prevent cuts and disposed of in a manner that avoids environmental contamination. Metal parts of fixtures can often be recycled at scrap yards. Always check local regulations and recycling programs for guidance on proper disposal procedures. Many municipalities offer convenient drop-off locations or pick-up services for e-waste and hazardous materials.

Q 14. Explain your experience with high-bay or low-bay lighting systems.

High-bay and low-bay lighting systems are commonly used in industrial and commercial settings. High-bay lighting illuminates high ceilings, typically found in warehouses, factories, or gymnasiums. These often use high-intensity discharge (HID) lamps, such as metal halide or high-pressure sodium, or increasingly, high-power LEDs. Low-bay lighting, on the other hand, is suitable for spaces with lower ceilings, such as retail stores or offices.

My experience with these systems involves installation, maintenance, and repair. This includes troubleshooting issues such as ballast failures (common in HID systems), lamp replacements, and wiring problems. I’m familiar with the different types of fixtures used in these systems, including various mounting options and light distributions. Safety is paramount when working with high-bay lighting, as the fixtures are often located at significant heights. Proper safety equipment and procedures are essential to prevent falls and electrical hazards. For instance, I once worked on a high-bay system in a warehouse where some of the HID lamps had failed. I had to use a lift to access them safely and replace the faulty lamps and ballasts.

Q 15. What is your experience with emergency lighting systems?

Emergency lighting systems are crucial for safety during power outages. My experience encompasses installation, maintenance, and troubleshooting of various types, including battery-powered units and central emergency power systems. I’m familiar with testing procedures, ensuring compliance with relevant codes, and replacing components like batteries and lamps. For example, I recently worked on a project where we upgraded an outdated emergency lighting system in a hospital, ensuring continuous illumination in crucial areas like hallways and operating rooms during power failures. This involved careful planning, adherence to strict safety protocols, and rigorous testing to guarantee the system’s reliability.

I understand the importance of regular testing and maintenance to ensure the system’s readiness in case of an emergency. This includes checking battery voltage, lamp function, and the overall system’s response to a simulated power outage.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. How do you maintain and inspect lighting systems to prevent failures?

Preventing lighting system failures involves a proactive maintenance strategy. This includes regular inspections, cleaning, and testing. Inspections should check for loose connections, damaged wiring, flickering or dim lights, and any signs of overheating. Cleaning involves removing dust and debris that can impact performance and lifespan. Testing includes verifying voltage levels, checking for continuity in the circuit, and testing the functionality of each component. Think of it like a car – regular oil changes and checkups prevent major breakdowns. Similarly, regular maintenance of lighting systems prevents costly repairs and ensures optimal performance.

For example, in a recent office building project, we implemented a preventative maintenance program that included monthly inspections and quarterly testing of all lighting fixtures. This proactive approach reduced the number of reported failures significantly.

Q 17. Describe your experience with troubleshooting dimming systems.

Troubleshooting dimming systems requires a systematic approach. I start by visually inspecting the system for loose connections, faulty dimmer switches, or burned-out bulbs. Then, I check the wiring using a multimeter to ensure continuity and proper voltage levels. I also check the dimmer switch itself for any signs of damage or malfunction. Dimming systems can be complex, often incorporating multiple components including the dimmer switch, the wiring, and the ballasts (for fluorescent or LED lamps). Issues can range from simple bulb replacement to more complex problems with the dimmer circuit or even the control system.

For instance, I once encountered a dimming system where the lights would flicker uncontrollably. After thorough investigation, I discovered a loose connection within the dimmer itself, which was easily repaired. In other cases, a malfunctioning ballast might need replacement.

Q 18. What is your experience with different types of lamp sockets?

I have experience with a wide range of lamp sockets, including Edison screw (E26/E27), bayonet (B22), GU10, MR16, and various types used for fluorescent and LED lamps. Understanding the different types is crucial for safe and effective installation and repair. Each socket type has specific electrical and mechanical characteristics that need to be considered to ensure proper fitting and operation. Incorrectly installing a lamp into the wrong socket can lead to electrical hazards or damage to the fixture.

For example, a GU10 lamp, commonly used for halogen spotlights, is quite different from an E26 socket for incandescent or LED bulbs. Trying to force the wrong lamp into the socket is dangerous and could damage both.

Q 19. How do you test the continuity of wiring in a lamp fixture?

Testing the continuity of wiring in a lamp fixture involves using a multimeter set to the continuity test mode. This typically involves a visual inspection first, to identify the wires and their connections. Then, one lead of the multimeter is placed on one end of the wire, and the other lead on the other end. A continuous beep indicates a closed circuit, showing that the wire is intact. Lack of a beep indicates a break in the wire, which needs to be investigated and repaired. Safety precautions such as switching off the power supply are paramount before testing any electrical wiring.

It is vital to always ensure the power is switched off at the breaker before testing. Failure to do so could lead to electrical shock.

Q 20. Explain your understanding of electrical codes and safety standards related to lighting.

My understanding of electrical codes and safety standards related to lighting is comprehensive. I’m familiar with the National Electrical Code (NEC) and other relevant local regulations. These codes define safety requirements for wiring, installation, and maintenance of lighting systems, including aspects like grounding, proper circuit protection, and the use of appropriate materials. Adhering to these standards is crucial for preventing electrical hazards, fires, and injuries. This knowledge is crucial for my work and ensures all my projects comply with the highest safety standards.

For example, I always ensure that all fixtures are properly grounded, circuits are protected by appropriate circuit breakers, and wiring is correctly installed and protected from damage. Ignoring these standards can have serious consequences.

Q 21. What are the common types of ballasts and their functions?

Ballasts are essential components in fluorescent and some LED lighting systems. They provide the necessary voltage and current to start and operate the lamps. Common types include magnetic ballasts (older technology, often noisy and inefficient), electronic ballasts (more efficient and quieter than magnetic ballasts), and LED drivers (specifically for LED lamps). Magnetic ballasts use a transformer to step up the voltage, whereas electronic ballasts use electronic circuitry to regulate voltage and current more precisely. LED drivers regulate the current to the LEDs. The choice of ballast depends on the type of lamp and desired energy efficiency.

For instance, in older buildings you often find magnetic ballasts, which often need replacing due to their inefficiency and potential for failure. Modern installations utilize electronic ballasts or LED drivers for higher efficiency and longer lifespan.

Q 22. How do you diagnose and repair problems with lighting control circuits?

Diagnosing problems with lighting control circuits involves a systematic approach. First, I’d visually inspect the circuit for any obvious issues like loose wires, burnt components, or damaged insulation. Then, I’d use a multimeter to check voltage, current, and continuity at various points within the circuit. This helps pinpoint the faulty component—be it a switch, dimmer, ballast, or sensor. For example, if a light switch doesn’t work, I might test for voltage at the switch terminals to see if power is even reaching it. If voltage is present but the light doesn’t turn on, the problem lies further down the line, potentially in the wiring or the fixture itself. I might also check the circuit breaker to ensure it hasn’t tripped. More complex systems, like those incorporating smart home technology, might require specialized diagnostic tools and software to access system logs and identify software-related issues. Repair typically involves replacing the faulty component, ensuring proper connections, and testing the repaired circuit before restoring power.

Q 23. Describe your experience working with different types of lighting fixtures (e.g., recessed, surface mount, pendant).

I have extensive experience with various lighting fixture types. Recessed lighting, for instance, requires careful attention to proper installation to ensure secure mounting and adequate heat dissipation. I’m comfortable working with both new construction and retrofit applications. Surface mount fixtures are relatively straightforward to install but require attention to detail regarding proper wiring and mounting to ensure stability and aesthetic appeal. Pendant lighting often presents unique challenges related to cable management and ensuring the fixture is properly secured to avoid potential hazards. My experience spans different ballast types, including magnetic and electronic ballasts, and I’m proficient in troubleshooting issues related to each. For example, I recently replaced a faulty ballast in a series of pendant lights in a restaurant, restoring their functionality and maintaining the ambiance of the space.

Q 24. How do you assess the energy efficiency of a lighting system?

Assessing the energy efficiency of a lighting system involves a multi-faceted approach. I would start by identifying the type of lamps used – LEDs are far more energy-efficient than incandescent or fluorescent lamps. I would then measure the wattage of each fixture and calculate the total power consumption. The system’s lighting schedule also plays a significant role; utilizing occupancy sensors, daylight harvesting, and timers reduces energy consumption significantly. Furthermore, I would consider the lighting design itself; proper placement and aiming of fixtures can minimize energy waste. For instance, replacing outdated fluorescent tubes with LED equivalents can drastically reduce energy consumption and operating costs while extending the lifespan of the fixtures. I often use energy auditing software to simulate different scenarios and model the potential energy savings of proposed upgrades.

Q 25. What are the steps involved in replacing a high-pressure sodium (HPS) lamp?

Replacing a high-pressure sodium (HPS) lamp requires careful attention to safety, as these lamps operate at high temperatures and contain hazardous materials. First, I’d ensure the power to the fixture is completely disconnected. Then, I would allow the lamp to cool down completely to prevent burns. Next, I’d carefully remove the lamp from its fixture, following the manufacturer’s instructions. It’s crucial to avoid touching the lamp’s glass envelope to prevent contamination. The new HPS lamp should be handled with clean gloves, and it’s essential to check for any damage before installation. Once installed, I’d restore power carefully and verify the lamp is functioning correctly. Remember to always dispose of the old lamp properly, according to local regulations, as it contains mercury.

Q 26. Describe your experience with working at heights and using safety equipment.

Safety is my paramount concern when working at heights. I always use appropriate fall protection equipment, such as harnesses and lanyards, whenever working above ground level. I ensure the equipment is properly inspected and secured before commencing any work. Proper ladder usage is essential, employing the three-point contact rule and ensuring the ladder is stable on level ground. I regularly undergo safety training to update my knowledge of best practices and equipment usage. I always adhere to all relevant safety regulations and company policies. For example, on a recent project involving high-bay lighting, I used a properly secured harness and safety line to replace faulty lamps, preventing potential falls and injuries.

Q 27. How do you handle situations where special tools or equipment are required?

When specialized tools or equipment are needed, I begin by identifying the specific tools required to complete the job safely and efficiently. I then check the availability of these tools within my own toolkit and, if necessary, arrange for rental or purchase from a reputable supplier. Before using any unfamiliar equipment, I carefully review the manufacturer’s instructions and ensure I understand how to operate it safely and correctly. For example, for certain types of lighting fixtures, I may need specialized tools like a crimping tool for wire connections or a high-voltage tester for ensuring safety before working with high-power components. Safety training and appropriate certification are key aspects of handling such specialized equipment.

Q 28. What is your approach to problem-solving when confronted with an unfamiliar lighting issue?

My approach to unfamiliar lighting issues is systematic and methodical. First, I thoroughly document the problem, taking notes, photos, and even videos to understand the situation completely. Then, I consult various resources, such as wiring diagrams, manufacturer specifications, and online forums, to gather information. If I’m still stuck, I don’t hesitate to reach out to colleagues with more experience or seek advice from industry experts. I consider the problem from multiple perspectives, systematically testing different components and systematically eliminating potential causes. I often use a ‘divide and conquer’ approach to isolate the problem to a specific area of the circuit or system. For example, recently, I encountered a flickering LED fixture that didn’t respond to standard troubleshooting. After careful observation and research, I discovered the issue was caused by a faulty dimmer switch incompatible with LED technology. This systematic approach and willingness to seek assistance ensures successful resolution.

Key Topics to Learn for Replace or Repair Lamp Fixtures and Components Interview

- Electrical Safety: Understanding and applying safe work practices around electricity, including lockout/tagout procedures and proper use of personal protective equipment (PPE).

- Fixture Types and Components: Familiarity with various lamp fixture types (e.g., fluorescent, incandescent, LED), their components (ballasts, sockets, wiring), and their functionalities.

- Troubleshooting Faulty Fixtures: Diagnosing common problems such as flickering lights, non-functional fixtures, and identifying the root cause through systematic testing and observation.

- Wiring and Connections: Understanding different wiring methods and ensuring correct connections to maintain safety and functionality. This includes knowledge of wire gauges and color coding.

- Code Compliance: Awareness of relevant electrical codes and regulations to ensure installations meet safety standards.

- Repair Techniques: Practical knowledge of repairing or replacing damaged components, including ballast replacement, socket repair, and wire splicing.

- Installation Procedures: Understanding the steps involved in installing new fixtures, including mounting, wiring, and testing.

- Tools and Equipment: Familiarity with the tools and equipment commonly used in lamp fixture repair and installation (e.g., voltage testers, wire strippers, screwdrivers).

- Energy Efficiency: Knowledge of different lighting technologies and their energy efficiency ratings, enabling informed recommendations for replacements.

- Customer Service: Understanding the importance of professional communication and courteous interaction with clients or supervisors.

Next Steps

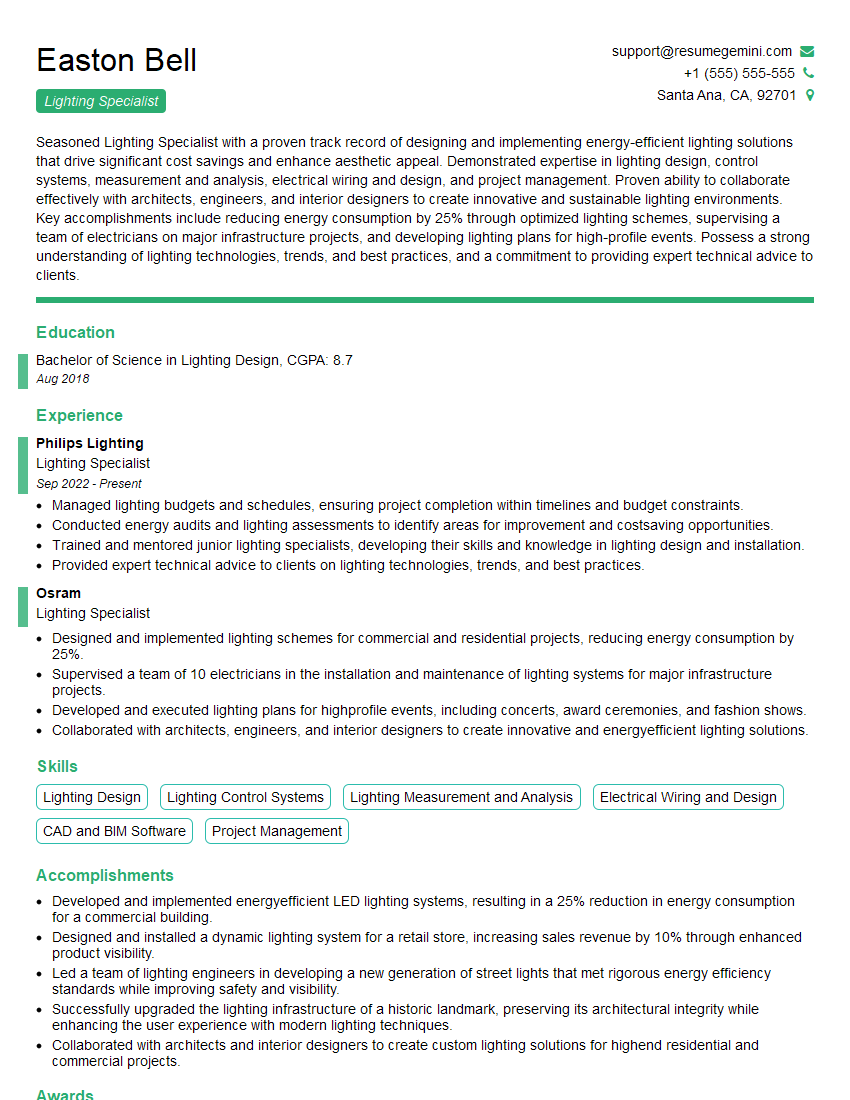

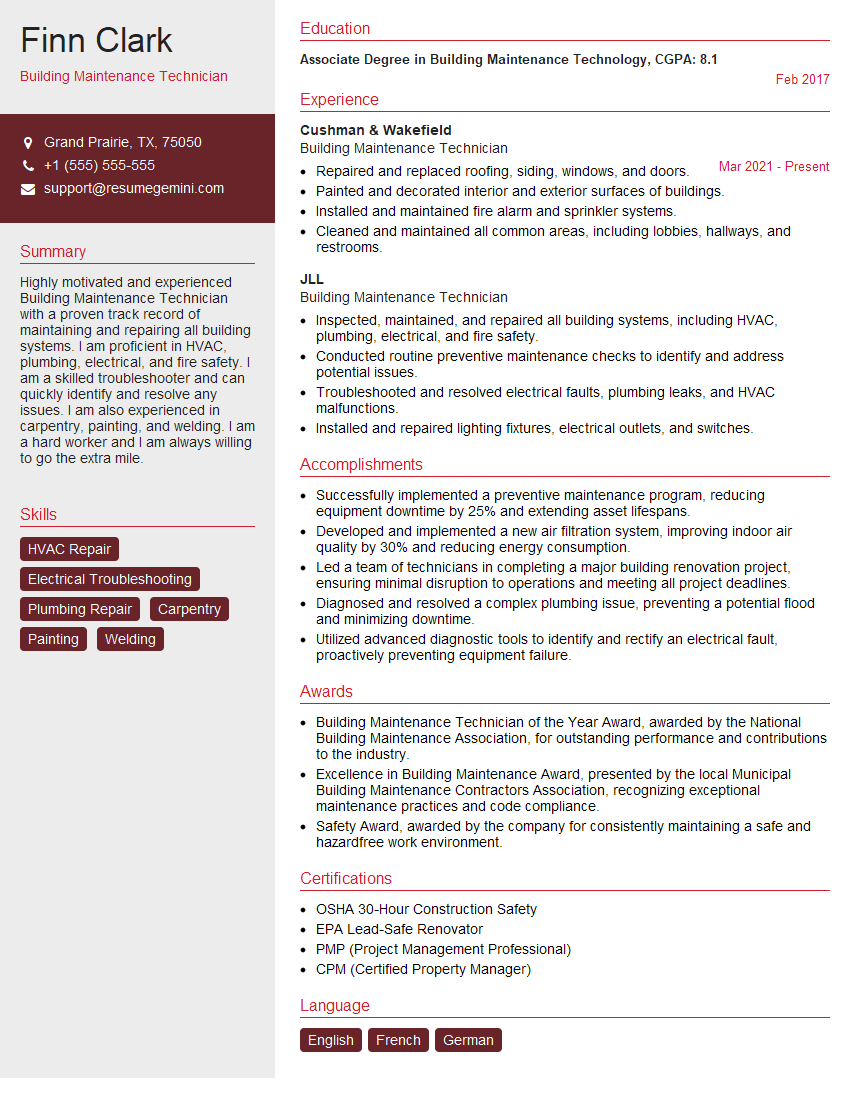

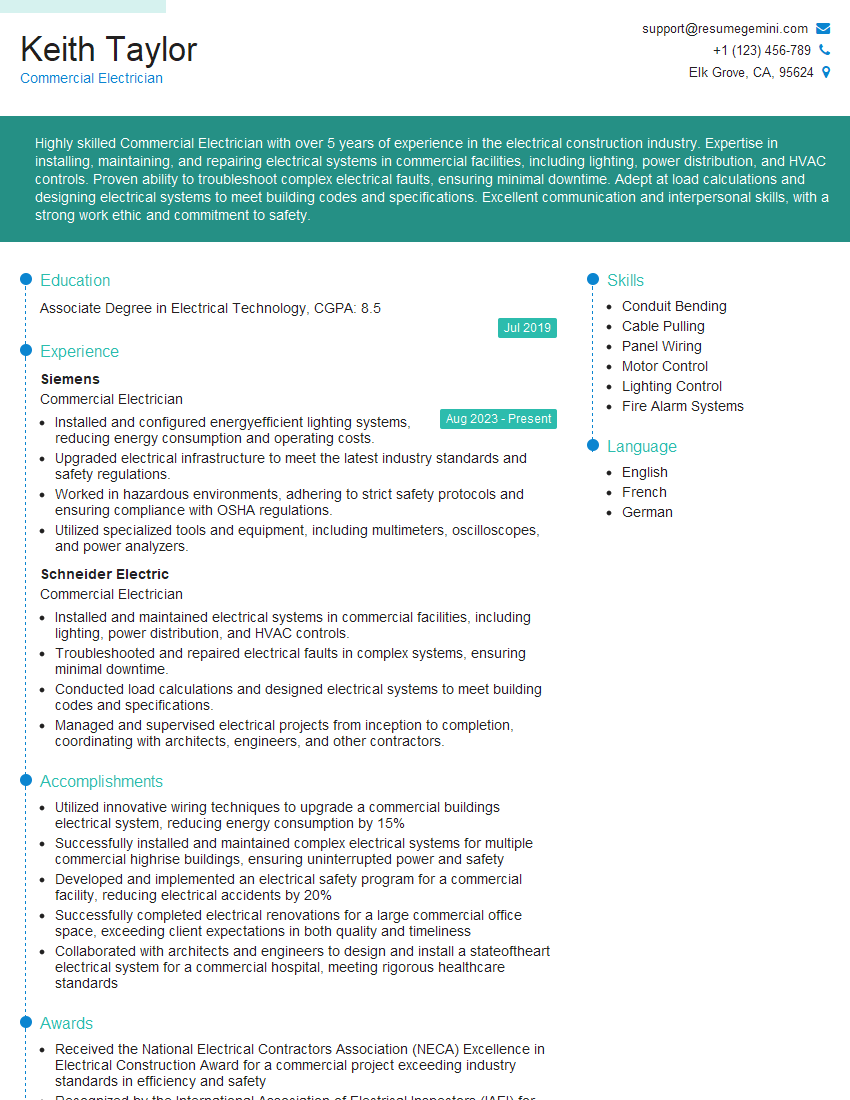

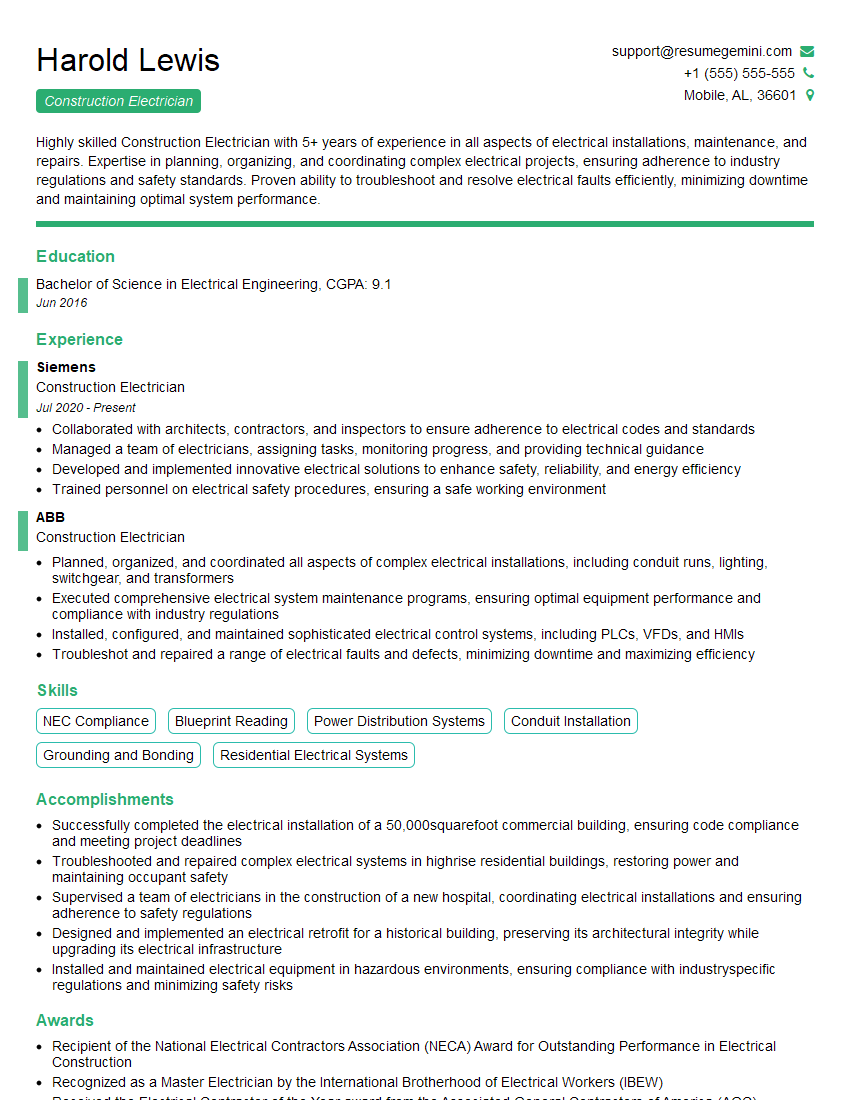

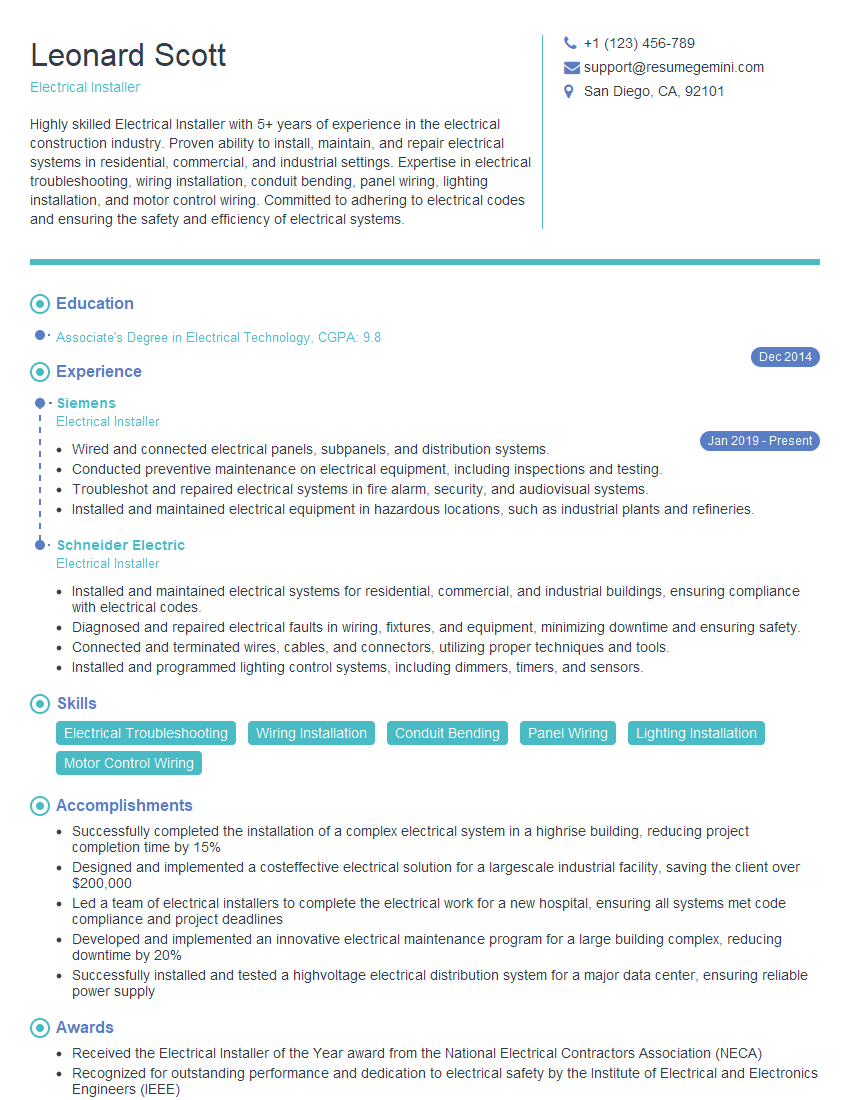

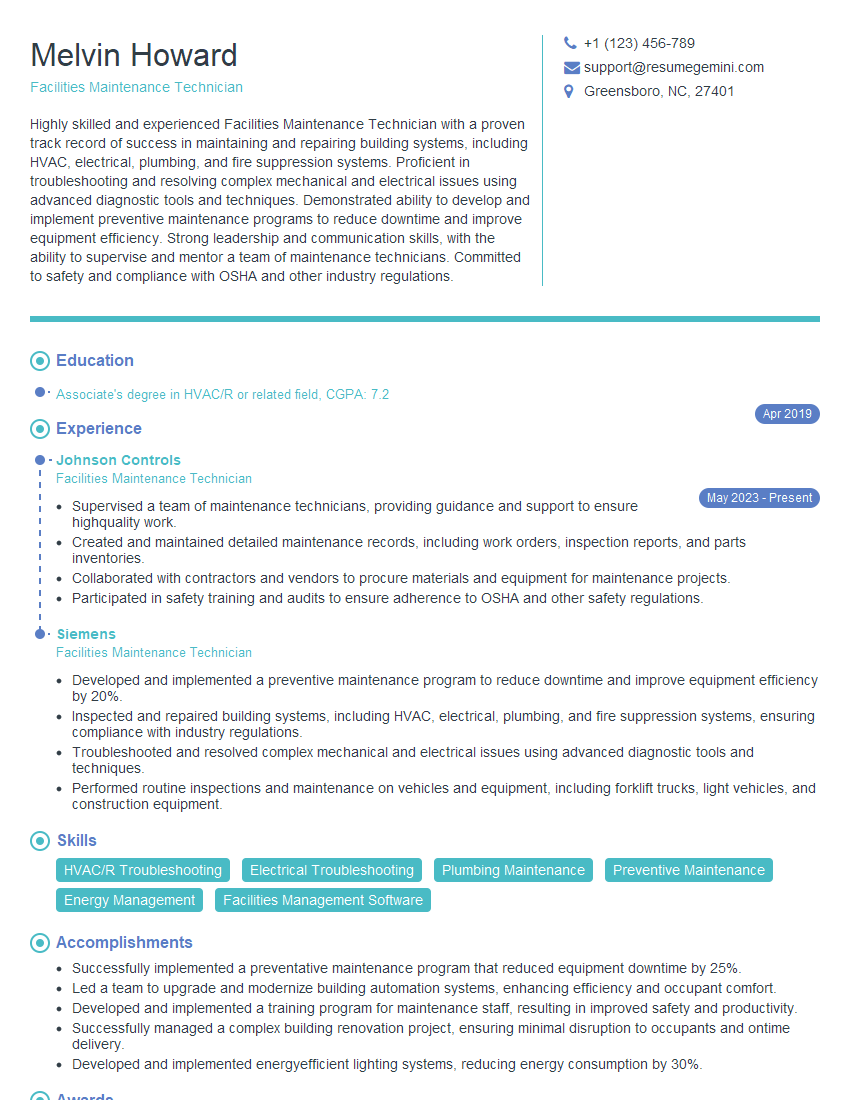

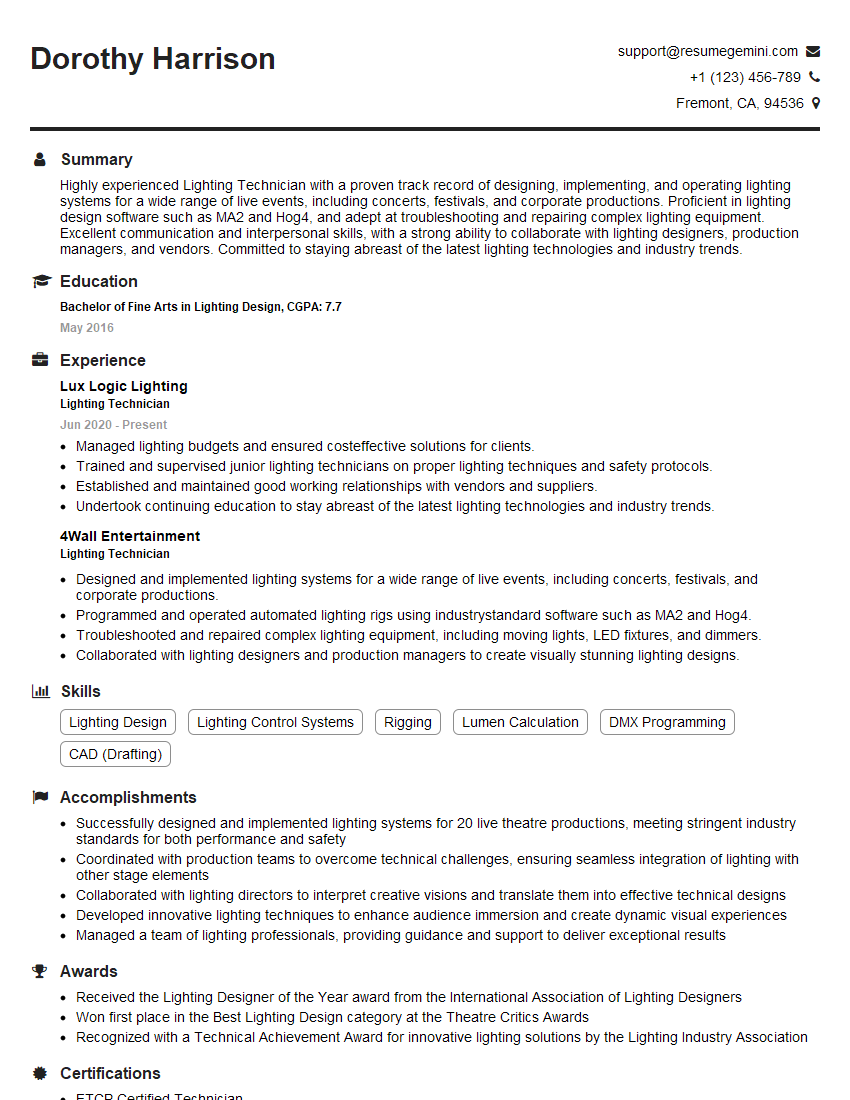

Mastering the skills of replacing and repairing lamp fixtures and components is crucial for career advancement in the electrical and maintenance fields. A strong understanding of these topics demonstrates competency and professionalism, opening doors to more challenging and rewarding opportunities. To maximize your job prospects, create an ATS-friendly resume that highlights your relevant skills and experience. ResumeGemini is a trusted resource to help you build a professional and impactful resume. We provide examples of resumes tailored to the Replace or Repair Lamp Fixtures and Components field to guide you through the process.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good