The right preparation can turn an interview into an opportunity to showcase your expertise. This guide to Rigging and Lashing Cargo interview questions is your ultimate resource, providing key insights and tips to help you ace your responses and stand out as a top candidate.

Questions Asked in Rigging and Lashing Cargo Interview

Q 1. Explain the different types of rigging hardware and their applications.

Rigging hardware encompasses a wide array of components crucial for safely lifting, moving, and securing loads. Choosing the right hardware is paramount to preventing accidents. Here are some key types:

- Shackles: These are U-shaped metal fasteners with a pin or screw to connect rigging components. They’re used for connecting slings, chains, or wire ropes to other parts of the rigging system. There are bow shackles (easier to attach) and Dee shackles (better for side loading).

- Slings: These are flexible load-bearing elements, commonly made of wire rope, synthetic webbing, or chain. Wire rope slings are strong but can be damaged by abrasion, while synthetic webbing slings are lighter and less prone to damage but have lower SWLs. Chain slings are durable and resistant to abrasion but can stretch over time.

- Hooks: These are used to attach slings to loads or other rigging components. They come in various shapes and sizes, and their strength and design must match the load. Always inspect hooks for cracks or deformation.

- Rings and Eyes: These provide connection points within a rigging system. They can be made of various metals and are crucial for load distribution and connecting multiple parts.

- Turnbuckles: These allow for adjusting the tension in a rigging assembly. They’re used to fine-tune the positioning of a load or to take up slack in a system.

- Clevis Pins: These pins secure shackles and other components in place. Their design ensures secure fastening.

The application of each type depends on the specific load, its weight, shape, and the environment. For instance, a heavy steel beam might require a chain sling and heavy-duty shackles, whereas a delicate piece of machinery might necessitate a soft synthetic webbing sling.

Q 2. Describe the process of calculating the safe working load (SWL) of a rigging assembly.

Calculating the Safe Working Load (SWL) of a rigging assembly is critical for safety. It’s not just about the SWL of individual components; it’s about the entire system’s capacity. This requires careful consideration of several factors:

- Individual Component SWLs: Obtain the SWL of each component (sling, shackle, hook, etc.) from the manufacturer’s markings or data sheets. This is the maximum load the component can safely handle.

- Angle of Load: Loads applied at angles reduce the effective SWL. Rigging charts or online calculators can determine the reduction factor based on the angle. A load suspended at a 30-degree angle to the sling, for example, will significantly reduce the effective SWL.

- Number of Legs: Using multiple slings to support a load distributes the weight. For example, two slings share the load, each carrying half the total weight. However, ensure the slings are properly spaced and balanced to avoid uneven loading.

- Type of Sling: Different sling materials (wire rope, chain, webbing) and configurations (straight, choker, basket hitch) have different SWLs.

- Safety Factor: Always apply a safety factor (typically 5:1 or higher) to the calculated SWL. This accounts for unforeseen circumstances, wear and tear, and potential variations in loading conditions.

For example, if a load weighs 10,000 lbs and you’re using two synthetic webbing slings with an individual SWL of 6,000 lbs each, applying a 5:1 safety factor, the safe working load of each leg (considering it’s a two-leg lift) would be 1,200 lbs (6000 lbs / 5). Therefore, the total safe working load of your assembly is 2,400 lbs. This is considerably less than the initial 10,000 lb load, demonstrating the importance of the angle and safety factor in this calculation.

Q 3. What are the critical factors to consider when selecting appropriate rigging equipment for a specific load?

Selecting appropriate rigging equipment requires a thorough assessment of several factors. Ignoring even one factor can result in an unsafe situation. Key considerations include:

- Load Weight and Dimensions: The equipment’s SWL must exceed the load’s weight, and its size and configuration must accommodate the load’s shape and dimensions.

- Load Characteristics: Is the load fragile, heavy, sharp-edged, or oddly shaped? This impacts the choice of sling material (e.g., soft webbing for fragile objects).

- Environmental Conditions: High temperatures, corrosive chemicals, or wet conditions may degrade certain materials. Choose corrosion-resistant or weather-resistant materials as needed.

- Lifting Height and Distance: Longer lifts require stronger and more durable equipment to compensate for increased stress on the components.

- Accessibility and Work Area: The equipment must be easily maneuvered and used in the available space.

- Regulatory Requirements: Adhere to all relevant safety standards and regulations for rigging and lifting in your specific industry and location.

For example, lifting a large, heavy engine would require a strong chain sling and heavy-duty shackles due to the weight and potential for damage. Conversely, lifting a delicate antique would need a soft webbing sling to prevent scratching or damage.

Q 4. How do you ensure the proper use and inspection of rigging equipment?

Proper use and inspection of rigging equipment are paramount for safety. A pre-use inspection is essential before every lift:

- Visual Inspection: Check for any signs of damage, including fraying, cuts, kinks, bends, corrosion, or deformation on all components (slings, shackles, hooks, etc.).

- Load Test: Conduct a test lift with a smaller weight (if possible) to verify proper operation and detect any hidden damage.

- Documentation: Record inspection results and any issues found, indicating the date, time, inspector’s name, and any corrective actions taken.

- Proper Use: Use the equipment according to manufacturer’s instructions. This includes correct hitching techniques, load distribution, and avoidance of overloading.

- Regular Maintenance: Rigging equipment needs regular maintenance, including cleaning, lubrication, and repairs as needed. Follow the manufacturer’s recommendations for maintenance intervals.

- Retirement Policy: Establish a policy for retiring damaged or worn-out equipment. Never use equipment beyond its specified lifespan or after significant damage.

Imagine a scenario where a worn-out sling fails during a lift; the consequences could be catastrophic. Regular inspections and proper maintenance are the only way to prevent such disasters.

Q 5. What are the different types of lashing methods and when would you use each?

Lashing methods secure cargo during transport to prevent shifting or damage. The choice of method depends on the cargo’s shape, size, and weight, as well as the mode of transport:

- Diagonal Lashing: This method uses straps or chains diagonally across the load, providing excellent stability. It’s suitable for most types of cargo.

- Vertical Lashing: Vertical straps or chains secure the load from top to bottom, providing extra support against vertical movement. This is good for tall and unstable cargo.

- Combination Lashing: This combines diagonal and vertical lashing for maximum security, ideal for heavy or unusually shaped cargo.

- Basket Lashing: Straps are looped around the load and secured with tensioners, forming a ‘basket’. This is useful for securing smaller, irregularly shaped items.

- Chain Lashing: Using chains offers superior strength for exceptionally heavy or dense loads. It requires specialized chain binders for securing.

Consider a scenario involving transporting heavy machinery on a flatbed truck. A combination lashing method using both diagonal and vertical straps would be the most effective to prevent shifting during transit.

Q 6. Explain the importance of proper documentation in rigging and lashing operations.

Proper documentation is essential in rigging and lashing for several reasons:

- Safety Records: Detailed records of inspections, SWL calculations, and rigging configurations provide crucial evidence in case of accidents or near misses.

- Compliance and Auditing: Documentation ensures compliance with industry regulations and standards, making audits easier and less stressful.

- Training and Improvement: Records can be used to track trends in incidents, identify areas for improvement, and enhance training programs.

- Liability and Insurance: Complete documentation protects your company’s liability in case of claims or legal disputes.

- Continuity and Consistency: Detailed procedures and records ensure consistency in work practices, helping maintain safety across projects and personnel.

Imagine an accident occurs. Without proper documentation, tracing the cause, assigning responsibility, and determining the extent of liability become incredibly difficult. Maintaining detailed records is not just a safety measure but also a critical business practice.

Q 7. Describe your experience with different types of knots used in rigging and lashing.

My experience encompasses a wide range of knots, each suited for specific applications in rigging and lashing. Here are some examples:

- Bowline: A fundamental knot that forms a closed loop that won’t slip, ideal for creating a secure loop at the end of a rope. It’s strong and easy to untie, even after being under load.

- Clove Hitch: A simple and quick knot, perfect for temporarily attaching a rope to a post or ring. It’s not as strong as other knots, but it’s extremely useful for quick lashings.

- Figure Eight Knot: Used to create a stopper knot at the end of a rope to prevent it from running through a pulley system. It’s secure and easily untied.

- Sheet Bend: Used to join two ropes of different diameters. It’s essential when working with various rope sizes in a rigging scenario.

- Rolling Hitch: This knot is helpful for securing a rope to a cylindrical object, ensuring a strong grip. It’s often used in lashing operations.

For example, I’ve used Bowline knots extensively when creating loops for slings, while Clove hitches have been invaluable for quickly attaching ropes to various points in makeshift lashing setups.

It’s crucial to understand the strength limitations of each knot and to select the appropriate knot based on the load, material, and the task at hand. Improper knot tying can have serious consequences.

Q 8. How do you handle unexpected challenges or emergencies during a rigging or lashing operation?

Unexpected challenges during rigging and lashing are common. My approach involves a systematic response. First, I assess the situation calmly, identifying the specific problem and potential hazards. This might involve a sudden shift in the cargo, equipment malfunction, or even adverse weather conditions. Then, I communicate clearly with my team and any other relevant personnel, ensuring everyone understands the situation and our plan of action. Depending on the severity, this might involve implementing emergency procedures, securing the load temporarily, requesting additional equipment or personnel, or even halting the operation until the issue is resolved safely. For instance, if a lashing strap breaks unexpectedly, my immediate priority would be to stabilize the load, preventing further movement, before replacing the damaged strap. Thorough documentation of the incident and corrective actions is crucial for future prevention.

Q 9. What safety precautions do you take when working with heavy loads and rigging equipment?

Safety is paramount in rigging and lashing. We utilize a comprehensive approach:

- Pre-operation Inspection: Rigging equipment (chains, slings, wire ropes, shackles, etc.) is meticulously inspected for damage, wear, and proper certification before each use.

- Load Capacity Calculation: We carefully calculate the load’s weight and center of gravity, ensuring the rigging equipment and lashing system have adequate capacity. We never overload equipment.

- Proper Lifting Techniques: We utilize proper lifting techniques, avoiding sudden movements or sharp angles which could place undue stress on equipment or cause the load to shift.

- Personal Protective Equipment (PPE): This includes hard hats, safety glasses, gloves, steel-toe boots, and high-visibility clothing. We also implement fall protection measures as needed.

- Safe Work Procedures: Strict adherence to established work procedures, including signal communication between crane operator and rigging crew, is essential.

- Environmental Awareness: We consider environmental factors like wind, weather, ground conditions which might impact stability.

Q 10. Explain your understanding of relevant safety regulations and standards (e.g., OSHA, ASME).

My understanding of safety regulations is comprehensive. I’m well-versed in OSHA (Occupational Safety and Health Administration) standards relevant to rigging and lashing, including those related to crane operation, load securing, and personal protective equipment. I also understand ASME (American Society of Mechanical Engineers) standards for rigging hardware and its safe working load limits. These regulations are not just guidelines; they are legally binding requirements designed to prevent accidents and protect workers. For example, OSHA regulations mandate regular inspections of rigging equipment and the proper documentation of these inspections. A deep understanding of these standards allows for proactive risk mitigation and ensures all work is compliant.

Q 11. Describe your experience with different types of cargo and their unique securing requirements.

My experience encompasses a wide range of cargo types, each presenting unique securing challenges. I’ve worked with everything from standard shipping containers and heavy machinery to oversized, oddly shaped components and delicate instruments. Securing a container is relatively straightforward, relying on standardized lashing points and procedures. In contrast, securing a large transformer demands specialized knowledge of its center of gravity, potential stress points, and the appropriate use of padding and specialized rigging equipment. Delicate cargo, such as fine art or scientific equipment, requires custom-designed cradles and lashing systems to prevent damage during transit. Each situation necessitates a customized approach informed by the cargo’s physical characteristics, weight, and susceptibility to damage.

Q 12. How do you determine the appropriate number and placement of lashing points for a given load?

Determining the number and placement of lashing points is a critical step, directly affecting load stability and safety. This involves considering several factors:

- Cargo weight and dimensions: Heavier and larger cargo requires more lashing points.

- Cargo’s center of gravity: Lashing points must be strategically placed to counteract the load’s center of gravity, preventing shifting.

- Cargo type and fragility: Delicate cargo might necessitate more lashing points and padding to avoid damage.

- Transport conditions: Rough terrain or sea voyages require more robust lashing than smooth road transport.

- Load distribution: Points should evenly distribute the load’s weight.

Q 13. Explain the process of inspecting cargo securing points before, during, and after transport.

Inspecting cargo securing points is a multi-stage process.

- Before transport: A thorough inspection verifies the integrity of the lashing points on the vehicle or container, checking for damage or corrosion. The condition of the cargo itself is also assessed, noting any potential issues.

- During transport: Regular checks, especially during long hauls or challenging conditions, ensure that the lashing remains secure and that the cargo hasn’t shifted. This might involve visual inspections or even using tension gauges.

- After transport: A final inspection upon arrival identifies any damage to the lashing system or the cargo that may have occurred during transit. This helps to determine the effectiveness of the securing methods and potentially highlights areas for improvement in future operations.

Q 14. What are the potential hazards associated with improper rigging and lashing techniques?

Improper rigging and lashing techniques pose significant hazards.

- Cargo shifting or falling: This is the most obvious risk, leading to damage to the cargo, the transport vehicle, and potentially injury or death to nearby personnel.

- Equipment failure: Overloading or mishandling rigging equipment can cause it to fail, resulting in dropped loads or injuries.

- Injury to personnel: Improper handling or securing can lead to crushing injuries, lacerations, or falls.

- Damage to cargo: Improper techniques may damage the cargo itself, causing financial loss.

- Vehicle damage: A shifting load can damage the vehicle’s structure or cause a traffic accident.

Q 15. How do you communicate effectively with your team and other stakeholders during rigging and lashing operations?

Effective communication is paramount in rigging and lashing, where safety is the top priority. I employ a multi-pronged approach. Before any operation, I hold a pre-job briefing, clearly outlining the plan, including the specific tasks, equipment to be used, safety protocols, and potential hazards. This briefing involves all team members and relevant stakeholders like crane operators, supervisors, and even representatives from the cargo owner if necessary. I use visual aids like diagrams or sketches to ensure everyone is on the same page. During the operation, I use clear and concise language, avoiding jargon. I encourage open communication – team members are empowered to voice concerns or suggest safer alternatives. After the operation, a post-job debrief is held to review the process, identify areas for improvement, and celebrate successes. This feedback loop ensures continuous learning and refinement of our processes.

For example, during a recent project involving the rigging of an oversized transformer, I used a combination of 3D models and a detailed checklist to communicate the complex lifting procedure to the crane operator and ground crew. This prevented misunderstandings and ensured a smooth, safe operation.

Career Expert Tips:

- Ace those interviews! Prepare effectively by reviewing the Top 50 Most Common Interview Questions on ResumeGemini.

- Navigate your job search with confidence! Explore a wide range of Career Tips on ResumeGemini. Learn about common challenges and recommendations to overcome them.

- Craft the perfect resume! Master the Art of Resume Writing with ResumeGemini’s guide. Showcase your unique qualifications and achievements effectively.

- Don’t miss out on holiday savings! Build your dream resume with ResumeGemini’s ATS optimized templates.

Q 16. Describe your experience with using different types of lifting equipment (e.g., cranes, forklifts).

I have extensive experience operating and overseeing the use of various lifting equipment. My experience with cranes encompasses a range of types, including mobile, tower, and overhead cranes. I’m proficient in understanding load charts, performing pre-operational checks, and communicating effectively with crane operators to ensure safe and efficient lifts. With forklifts, my expertise involves safe load handling, proper weight distribution, and understanding the limitations of the equipment in relation to ground conditions and load characteristics. I am familiar with the different types of forklift attachments and their applications. I always prioritize pre-shift inspections to check for any mechanical issues or damage before operating any equipment.

For instance, during a project involving the movement of heavy steel beams, I coordinated the use of a mobile crane to lift and position them accurately. I ensured the crane operator had a clear understanding of the weight and center of gravity of each beam, and we used tag lines to control the swing and prevent any potential accidents.

Q 17. Explain your understanding of load distribution and its importance in preventing accidents.

Load distribution is crucial for preventing accidents in rigging and lashing. It involves strategically distributing the weight of the cargo to ensure that no single point or area experiences excessive stress. Uneven load distribution can lead to structural failure of the lifting equipment, cargo damage, or even serious injuries. The principle is simple: the more evenly the weight is spread, the lower the stress on any single point. This involves carefully considering the center of gravity of the cargo and using appropriate lashing techniques to secure it firmly in place. I always use appropriate calculations and consider the load limits of the lifting equipment and the lashing materials.

Consider an example of lashing a container onto a flatbed truck. If the container is not centered, it could shift during transit, potentially causing an accident. By using multiple lashing points and ensuring the load is evenly distributed, we significantly reduce the risk.

Q 18. How do you address the challenges of working in confined or difficult-to-access spaces?

Working in confined spaces or difficult-to-access areas requires meticulous planning and specialized techniques. I always begin with a thorough risk assessment, identifying potential hazards specific to the location, like limited visibility, restricted movement, and the presence of obstacles. This assessment dictates the choice of equipment and methodology. Smaller, more maneuverable equipment may be necessary, such as smaller cranes or specialized rigging gear. The use of appropriate personal protective equipment (PPE) is paramount. Team communication becomes even more vital in these situations, using clear hand signals and radios to avoid misunderstandings. Employing experienced personnel, and sometimes specialist riggers, who are accustomed to such challenges, enhances safety.

For example, rigging equipment inside a ship’s hold necessitates specialized techniques and equipment due to limited space and often poor visibility. Employing experienced riggers accustomed to these challenges is crucial for success and safety.

Q 19. How do you adapt your rigging and lashing techniques to different weather conditions?

Weather conditions significantly impact rigging and lashing operations. High winds, heavy rain, and extreme temperatures all pose risks. My approach is adaptable and safety-centric. I consult weather forecasts before any operation and adjust the plan accordingly. In high winds, we may postpone the lift, use additional securing measures, or choose a more sheltered location. Heavy rain can compromise the strength of lashing materials; in such cases, we might utilize waterproof materials or delay the operation. Extreme temperatures can affect the integrity of equipment and materials, necessitating careful consideration of material properties and potential for failure. In all scenarios, rigorous safety checks are performed throughout the process.

For instance, during a project involving the offloading of cargo in a coastal area prone to strong winds, we employed additional securing measures, including extra lashing straps and heavy-duty dunnage, to mitigate the risk of cargo shifting during the operation.

Q 20. What are the best practices for maintaining rigging and lashing equipment?

Rigging and lashing equipment maintenance is critical for safety. Regular inspections are key. Before each use, I conduct a thorough visual inspection of all equipment, looking for signs of wear and tear, damage, or corrosion. Detailed records are kept to track these inspections. Regular servicing is scheduled according to manufacturer recommendations. This includes lubrication of moving parts and replacement of worn-out components. Equipment is stored properly to prevent damage from the elements or accidental misuse. Any damaged or questionable equipment is immediately taken out of service and replaced or repaired.

For example, we have a detailed checklist for inspecting slings, ensuring that there are no cuts, fraying, or other damage that might compromise their strength. This rigorous maintenance ensures the longevity and safety of our equipment.

Q 21. Describe your experience with risk assessment and mitigation in rigging and lashing operations.

Risk assessment is an integral part of every rigging and lashing operation. I use a systematic approach, starting with identifying potential hazards, such as equipment failure, environmental factors, human error, and the characteristics of the load itself. Each hazard is then assessed for its likelihood and severity. Based on this assessment, appropriate control measures are implemented. These could include using redundant safety equipment, employing stricter working procedures, providing additional training, or selecting alternative rigging techniques. The goal is to minimize the risk to an acceptable level. The process is documented and reviewed regularly to ensure its effectiveness.

For example, during a complex lift involving a heavy piece of machinery, the risk assessment identified the potential for the crane to be overloaded. To mitigate this, we used two cranes to share the load, reducing the stress on each crane and enhancing overall safety.

Q 22. How do you ensure compliance with relevant environmental regulations during cargo handling?

Ensuring compliance with environmental regulations during cargo handling is paramount. It involves preventing pollution from spills, leaks, or emissions associated with the cargo itself or the handling process. This requires a multi-pronged approach.

- Pre-handling assessment: Before any operation, we identify potential environmental risks associated with the cargo – hazardous materials, oil, chemicals etc. This informs the choice of handling techniques and safety precautions.

- Spill containment: We utilize absorbent materials, containment booms, and designated spill areas to minimize the impact of any accidental spills. Regular inspections of these areas are crucial.

- Waste management: Proper disposal of any waste generated during the process, following all local and international regulations. This includes packaging materials, used absorbent pads, etc.

- Documentation: Meticulous record-keeping is essential. This includes documenting the cargo type, handling procedures, any incidents, and waste disposal methods. This ensures traceability and aids in demonstrating compliance during audits.

- Training and awareness: All personnel involved are thoroughly trained on environmental regulations and best practices. Regular refresher courses reinforce safe and compliant procedures.

For example, when handling chemicals, we’d use specialized containers, secondary containment systems, and personal protective equipment (PPE) to prevent leaks and exposure. We also ensure proper labeling and documentation to trace the cargo’s movement and handling.

Q 23. Explain your understanding of different types of cargo securing devices (e.g., chains, straps, wire rope).

Various cargo securing devices are used depending on the cargo’s nature, weight, and the transport method. Each has its strengths and weaknesses.

- Chains: Durable and strong, ideal for heavy loads. However, they can be susceptible to rust and require regular inspection for wear and tear. Proper lubrication is key to extending their lifespan.

- Straps: Lightweight, relatively easy to use, and offer flexibility in securing various cargo shapes. They are available in different materials (e.g., polyester, nylon) with varying strengths. Proper tensioning is crucial to prevent slippage.

- Wire rope: Strong and versatile, often used for heavy lifting and securing. Regular inspection for fraying, kinking, and corrosion is necessary. Correct usage of wire rope clips is vital to prevent slippage and catastrophic failure.

The choice of device depends heavily on the specific application. For instance, delicate cargo might require soft straps to avoid damage, while heavy machinery demands robust chains or wire ropes.

Q 24. How do you handle damaged or defective rigging equipment?

Damaged or defective rigging equipment is immediately taken out of service. This is non-negotiable for safety reasons.

- Immediate removal: The damaged equipment is clearly marked and removed from the work area to prevent accidental use.

- Inspection and assessment: A thorough inspection is conducted to determine the extent of the damage and its cause. This may involve visual inspection or more rigorous testing depending on the device and severity.

- Repair or replacement: Minor damage might be repairable by qualified personnel following manufacturer’s guidelines. However, severely damaged equipment is generally replaced to ensure safety and reliability. Documentation of repairs or replacements is essential.

- Root cause analysis: Investigating the cause of the damage helps prevent future occurrences. This might involve reviewing work procedures, training practices, or equipment maintenance schedules.

Imagine a chain with a broken link – using it would be incredibly dangerous. Removing it immediately and investigating the cause (was it overloaded, corroded, or improperly used?) prevents accidents and improves safety practices.

Q 25. Describe your experience with using software or technology to aid in rigging and lashing calculations or planning.

Software and technology play a significant role in modern rigging and lashing. Specialized software allows for precise calculations of load distribution, tension, and stability. This is particularly crucial for complex rigging setups.

I have experience using software that allows for:

- 3D modeling of the cargo and rigging system: This visual representation helps visualize load distribution and potential points of failure.

- Automated calculations of required securing forces: The software considers factors like cargo weight, dimensions, center of gravity, and the type of securing devices used to determine the necessary forces.

- Simulation of different scenarios: This allows for testing various rigging configurations before implementation, identifying potential weaknesses.

- Documentation and reporting: Software generates detailed reports documenting the calculations and design parameters, aiding in compliance and auditing.

For instance, when securing a large container on a vessel, the software helps determine the optimal placement of lashing points, the required tension on the straps, and ensures the whole system can withstand the stresses during the journey.

Q 26. What are the key differences between static and dynamic loading in rigging?

The key difference between static and dynamic loading lies in the nature of the forces applied to the rigging system.

- Static loading: This involves a constant, unchanging load. Think of a container sitting stationary on a truck. The forces on the rigging are relatively predictable and remain consistent.

- Dynamic loading: This involves fluctuating or impact forces. Imagine the same container on a truck going over a bumpy road or during ocean waves. The forces on the rigging are constantly changing, potentially leading to much higher stresses than under static conditions. Sudden jolts or impacts significantly increase the risk of failure.

Rigging systems must be designed to handle both static and dynamic loads, often with a significant safety factor to accommodate for the unpredictable nature of dynamic forces. The design and selection of securing devices must consider these varying stress levels.

Q 27. Explain your understanding of center of gravity and its impact on load stability.

The center of gravity (CG) is the point where the entire weight of an object is considered to be concentrated. Understanding its location is crucial for stability in rigging.

A load’s stability is directly impacted by its CG. If the CG is too high or outside the support base, the load becomes unstable and prone to tipping. Conversely, a lower CG contributes to better stability.

Imagine stacking boxes. If you stack them unevenly, the CG shifts and increases the risk of the stack toppling over. Properly positioning the CG within the support base, in this case, the base of the stack, ensures stability.

In rigging, proper weight distribution and secure lashing ensure the CG remains within the supporting structure’s footprint. This prevents load shifting, preventing accidents and potential damage.

Q 28. Describe a time you had to troubleshoot a rigging or lashing problem. What was the solution?

During the transport of a large, oddly shaped piece of machinery, we encountered a problem with uneven load distribution. The initial lashing plan resulted in excessive stress on one corner of the load, leading to a noticeable tilt during transit.

Troubleshooting steps:

- Assessment: We carefully examined the load, identified the point of excessive stress, and reassessed the CG.

- Re-evaluation of lashing points: We adjusted the lashing points to redistribute the weight more evenly, ensuring the CG remained within the support base.

- Additional securing measures: We added supplemental support to the stressed corner using additional straps and padding to cushion the load and prevent shifting.

- Testing: We simulated the transit conditions with a limited test movement to confirm the effectiveness of the modifications.

The solution involved a combination of strategic repositioning of lashing points, additional securing measures, and careful attention to the CG. The revised setup successfully ensured the safe transport of the machinery without incident.

Key Topics to Learn for Rigging and Lashing Cargo Interview

- Understanding Cargo Types and Characteristics: Learn to identify different cargo types (e.g., bulk, breakbulk, containerized) and their specific handling requirements, including weight, dimensions, and stability considerations.

- Rigging Principles and Techniques: Master the theoretical principles of rigging, including load distribution, center of gravity, and safe working loads. Understand various rigging hardware (e.g., slings, shackles, wire rope) and their proper application.

- Lashing Methods and Securement: Familiarize yourself with different lashing techniques (e.g., tensioning, securing, blocking) and the appropriate lashing materials for various cargo types and sea conditions. Understand relevant regulations and standards.

- Risk Assessment and Safety Procedures: Develop a strong understanding of hazard identification, risk assessment, and the implementation of safety protocols for rigging and lashing operations. This includes personal protective equipment (PPE) and emergency procedures.

- Practical Application: Be prepared to discuss real-world scenarios involving cargo securing, problem-solving during lashing operations, and adapting techniques to different vessel types and cargo configurations.

- Regulations and Compliance: Demonstrate knowledge of relevant international maritime regulations (e.g., SOLAS, IMDG Code) related to cargo securing and safe practices.

- Troubleshooting and Problem Solving: Be ready to discuss how you would handle unexpected challenges during rigging and lashing, such as damaged cargo, adverse weather conditions, or equipment malfunction.

Next Steps

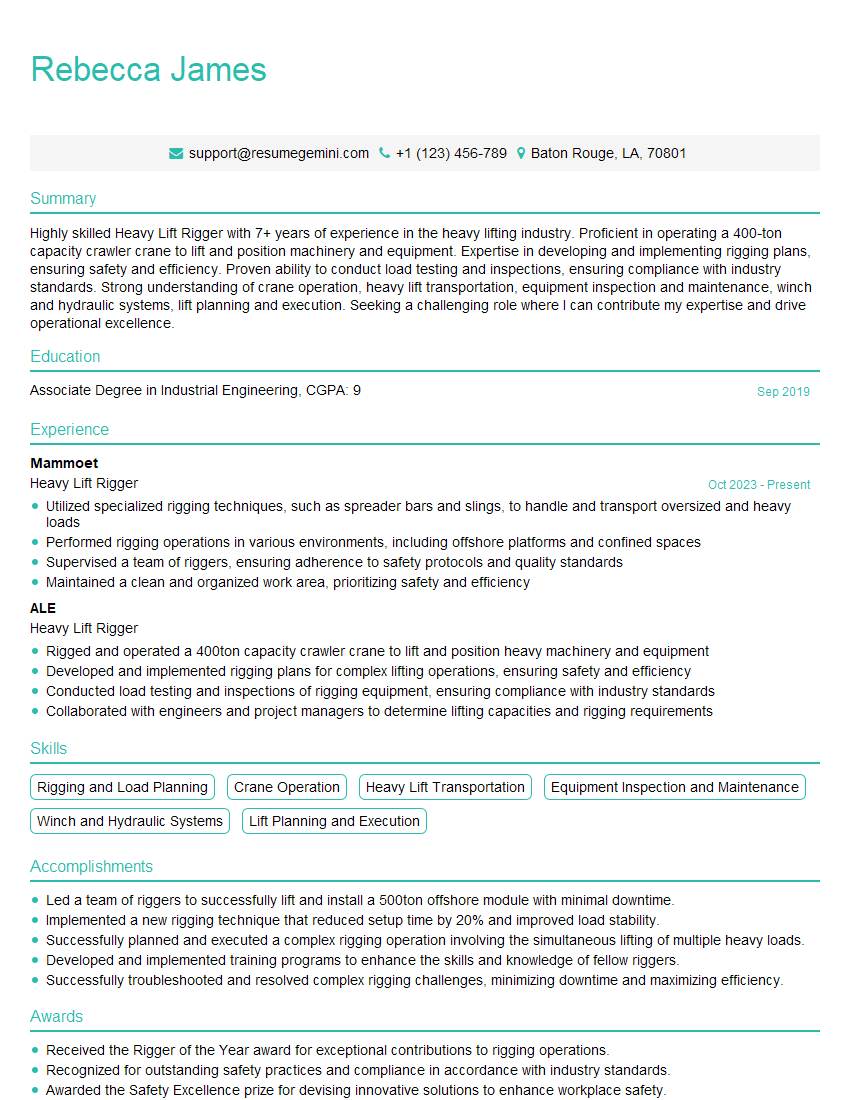

Mastering Rigging and Lashing Cargo is crucial for career advancement in the maritime industry, opening doors to higher-paying roles and increased responsibility. A well-crafted resume is your key to unlocking these opportunities. An ATS-friendly resume, optimized for applicant tracking systems, significantly improves your chances of getting your application noticed by recruiters. ResumeGemini is a trusted resource for creating professional and effective resumes. They provide examples of resumes tailored specifically to the Rigging and Lashing Cargo field, ensuring your application stands out from the competition. Take the next step in your career journey – create a powerful resume with ResumeGemini today.

Explore more articles

Users Rating of Our Blogs

Share Your Experience

We value your feedback! Please rate our content and share your thoughts (optional).

What Readers Say About Our Blog

Hello,

We found issues with your domain’s email setup that may be sending your messages to spam or blocking them completely. InboxShield Mini shows you how to fix it in minutes — no tech skills required.

Scan your domain now for details: https://inboxshield-mini.com/

— Adam @ InboxShield Mini

Reply STOP to unsubscribe

Hi, are you owner of interviewgemini.com? What if I told you I could help you find extra time in your schedule, reconnect with leads you didn’t even realize you missed, and bring in more “I want to work with you” conversations, without increasing your ad spend or hiring a full-time employee?

All with a flexible, budget-friendly service that could easily pay for itself. Sounds good?

Would it be nice to jump on a quick 10-minute call so I can show you exactly how we make this work?

Best,

Hapei

Marketing Director

Hey, I know you’re the owner of interviewgemini.com. I’ll be quick.

Fundraising for your business is tough and time-consuming. We make it easier by guaranteeing two private investor meetings each month, for six months. No demos, no pitch events – just direct introductions to active investors matched to your startup.

If youR17;re raising, this could help you build real momentum. Want me to send more info?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

Hi, I represent an SEO company that specialises in getting you AI citations and higher rankings on Google. I’d like to offer you a 100% free SEO audit for your website. Would you be interested?

good